Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Avoid deformation defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

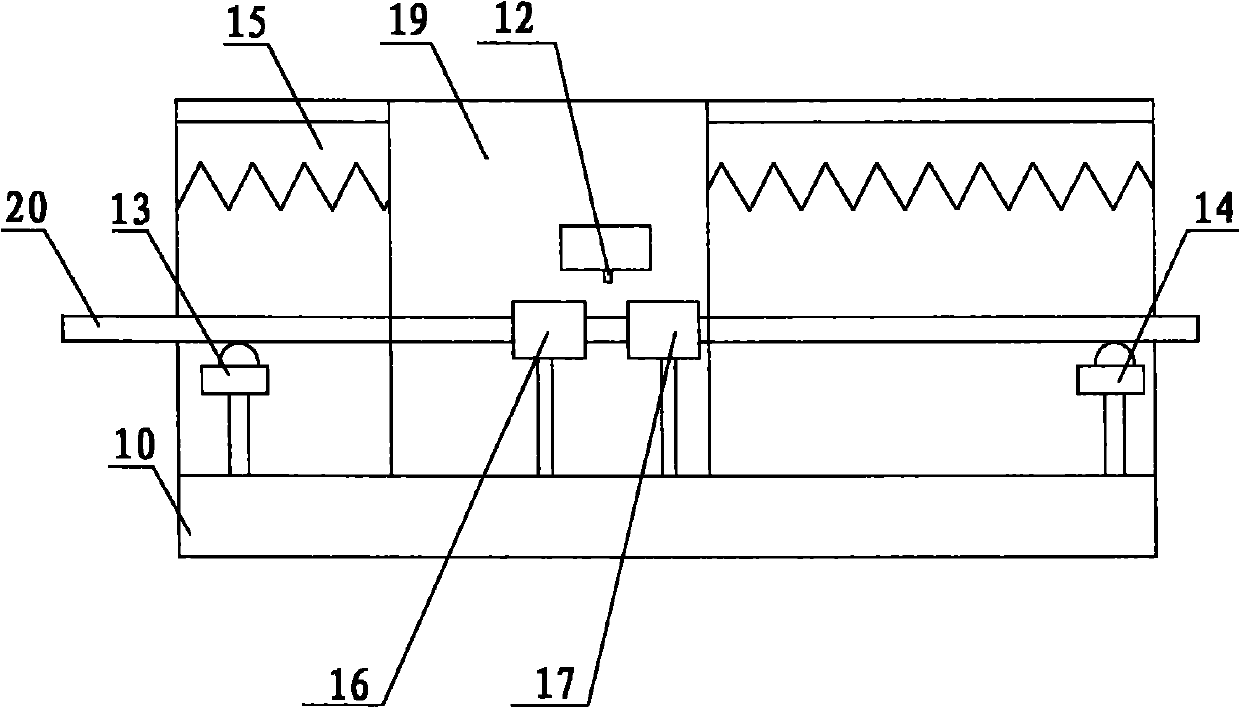

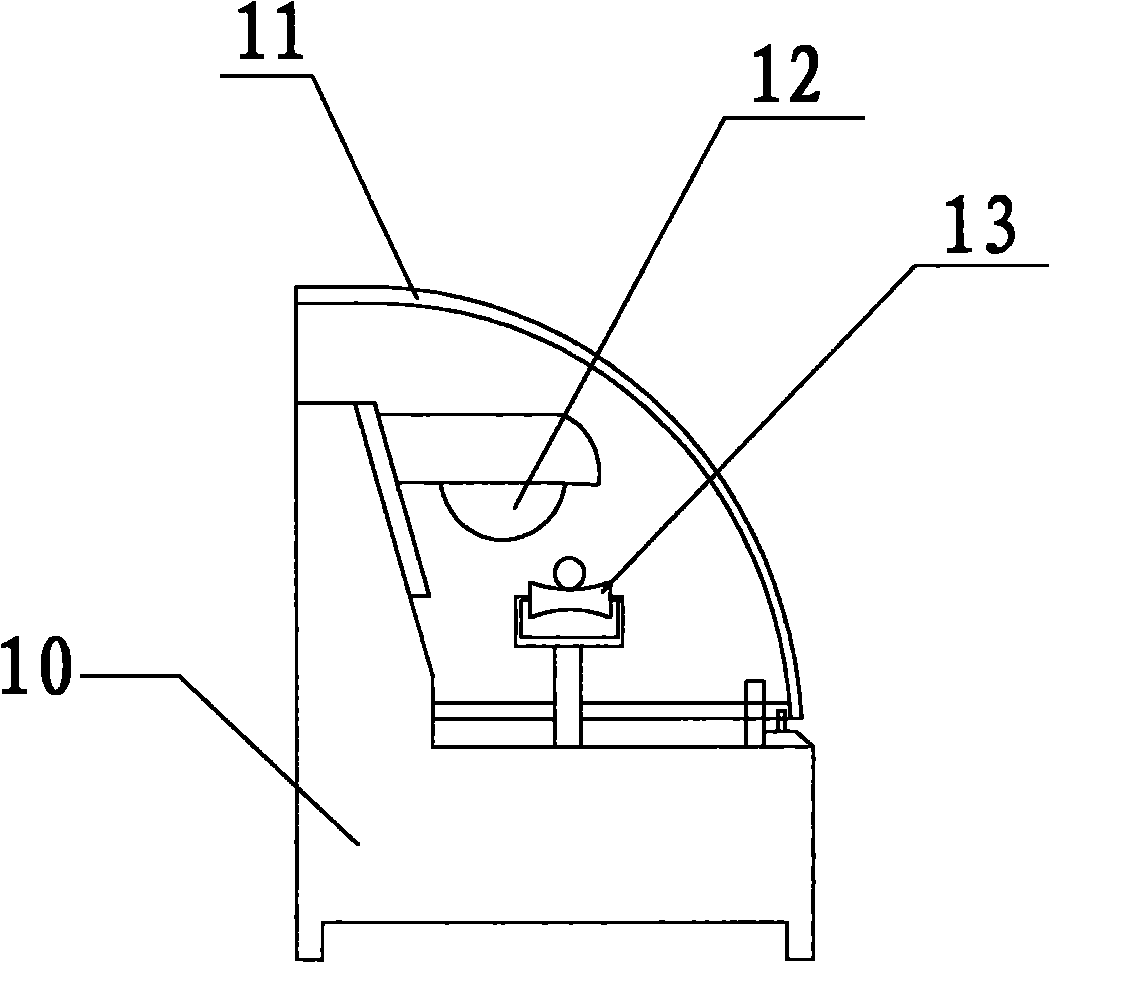

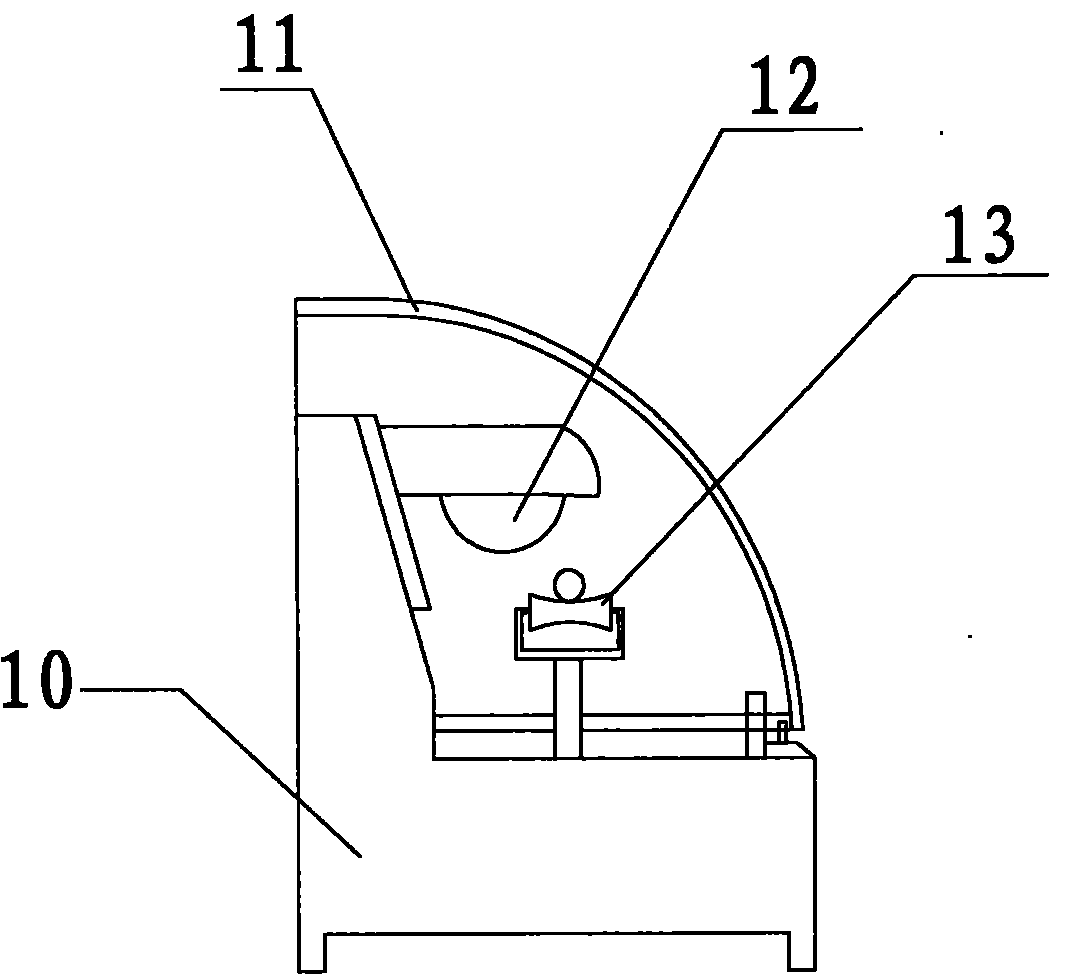

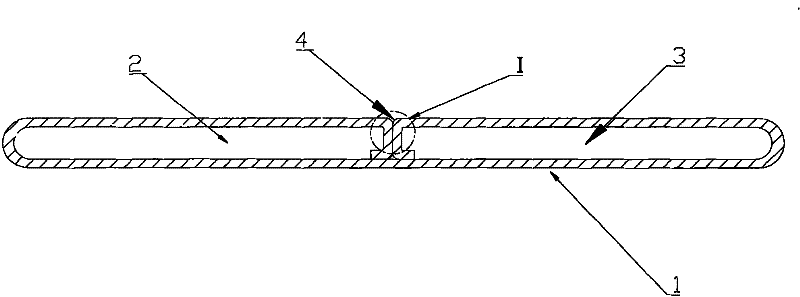

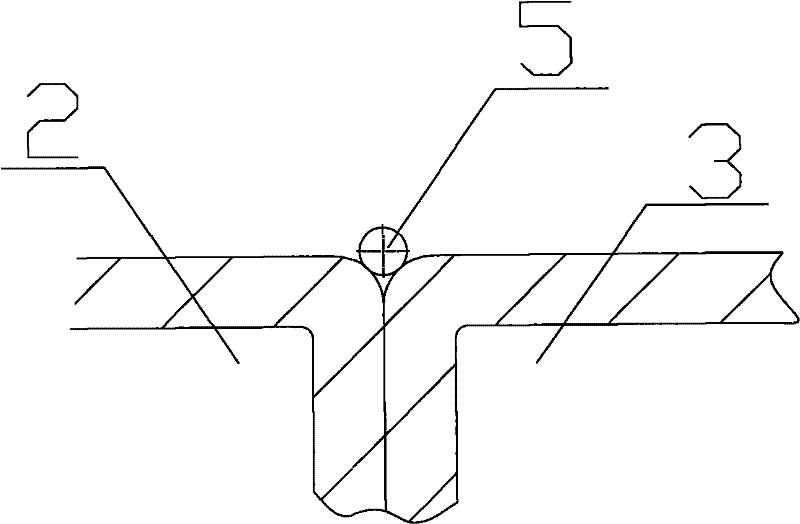

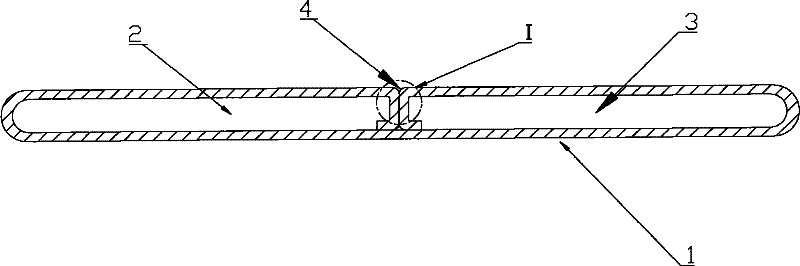

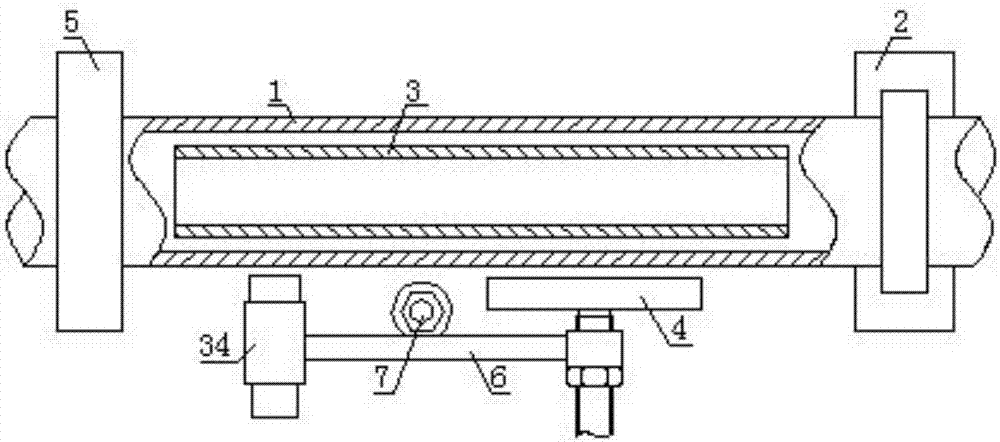

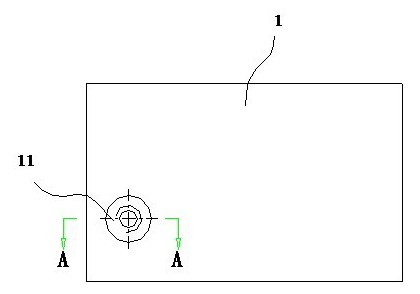

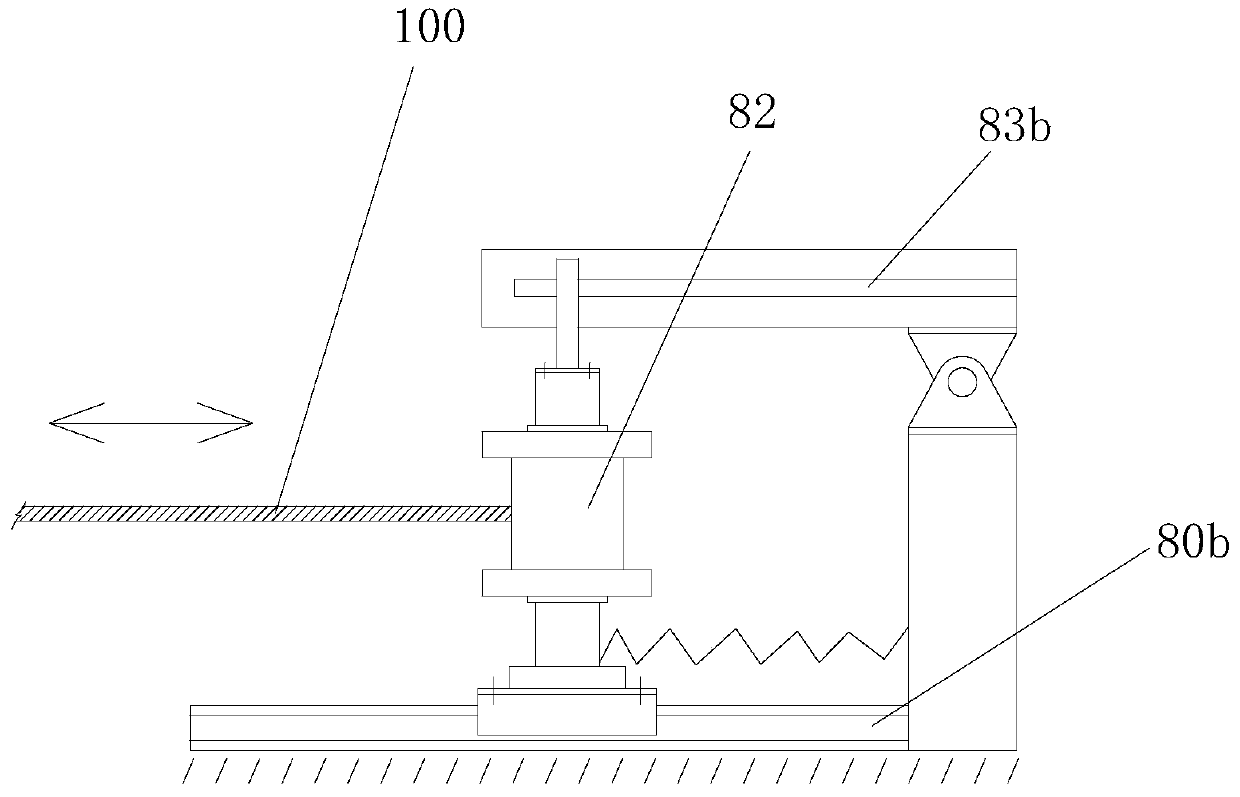

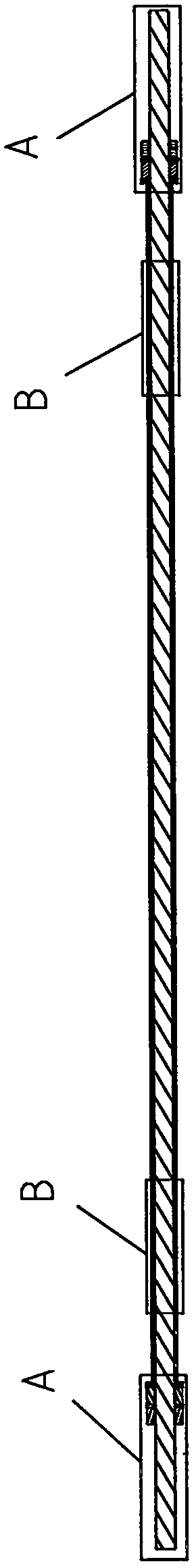

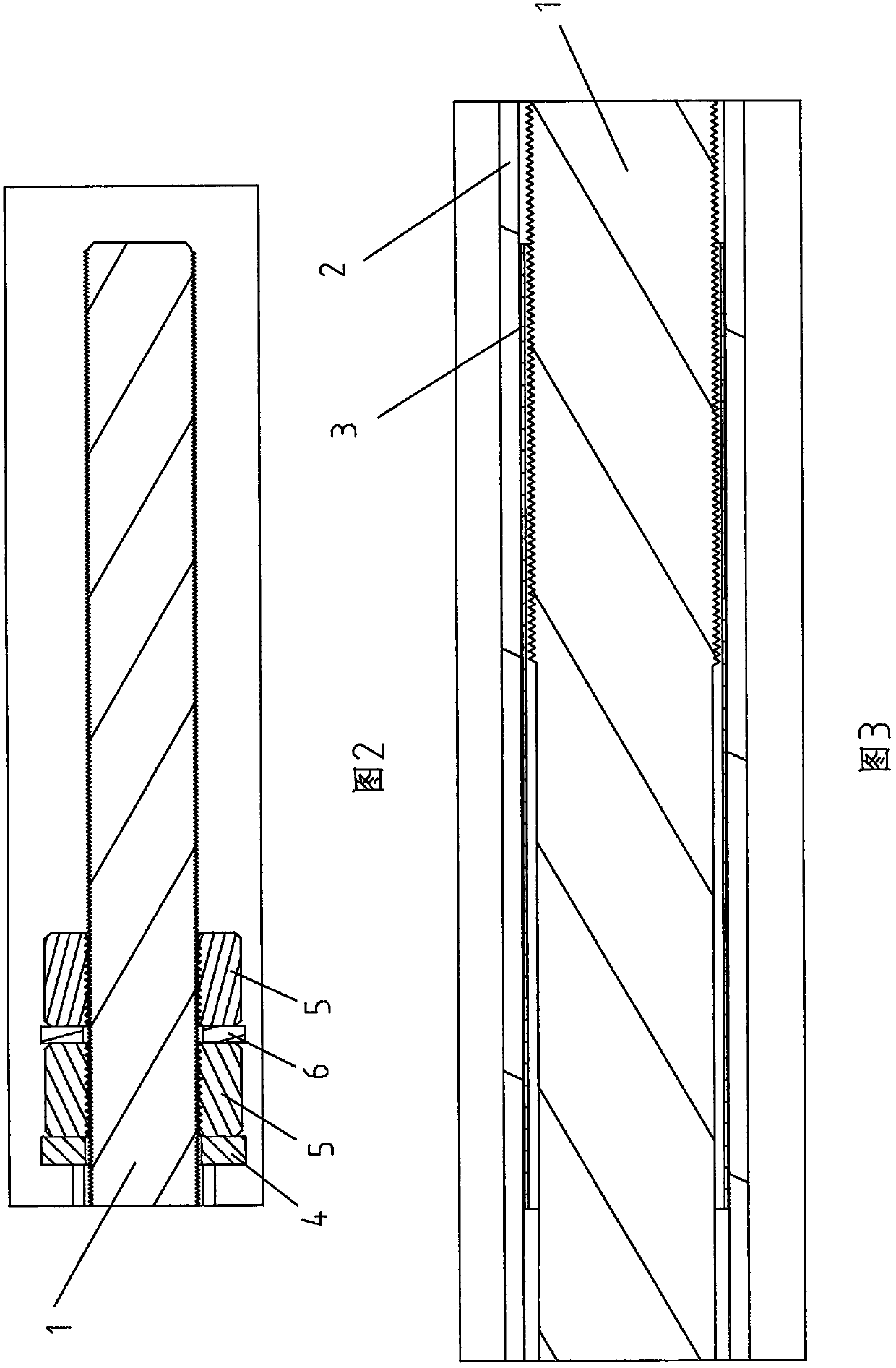

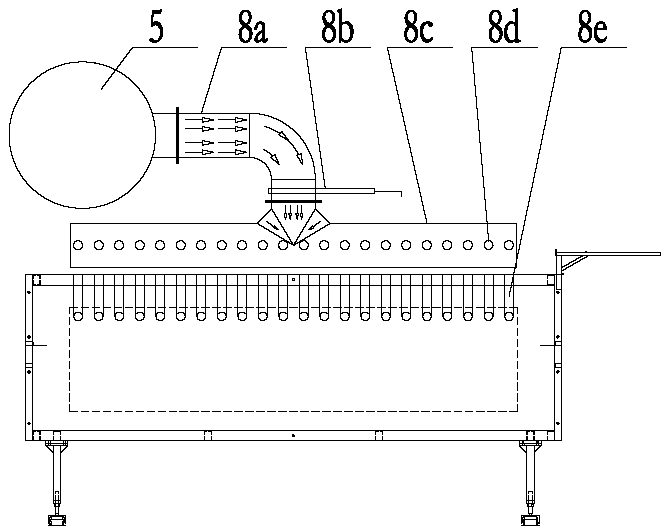

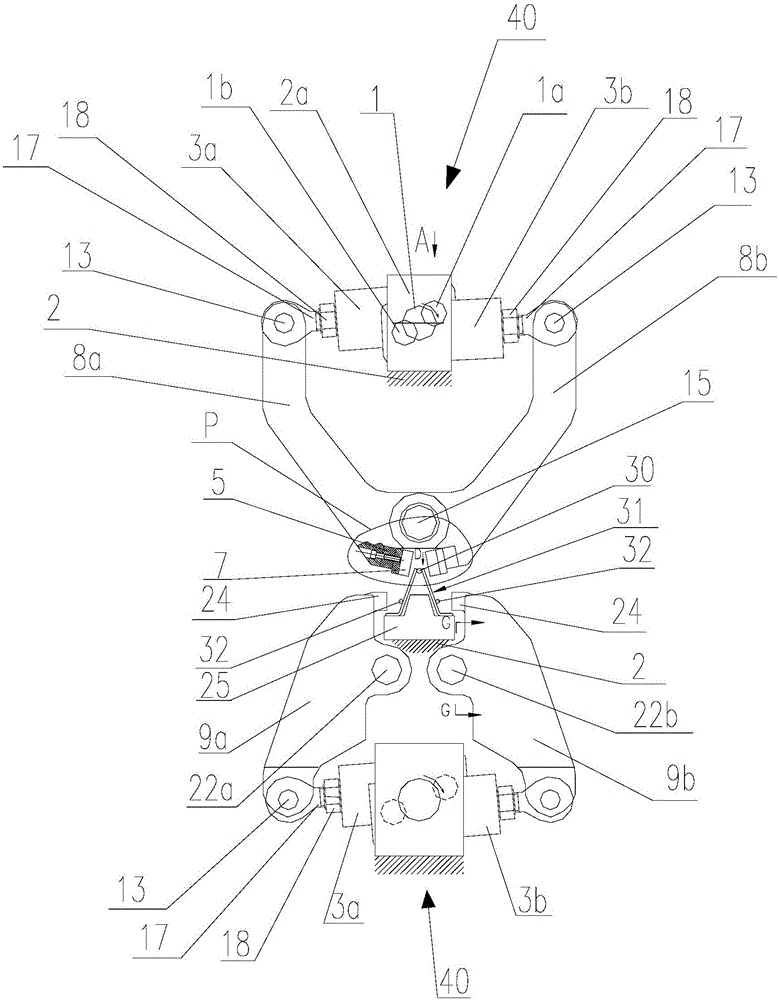

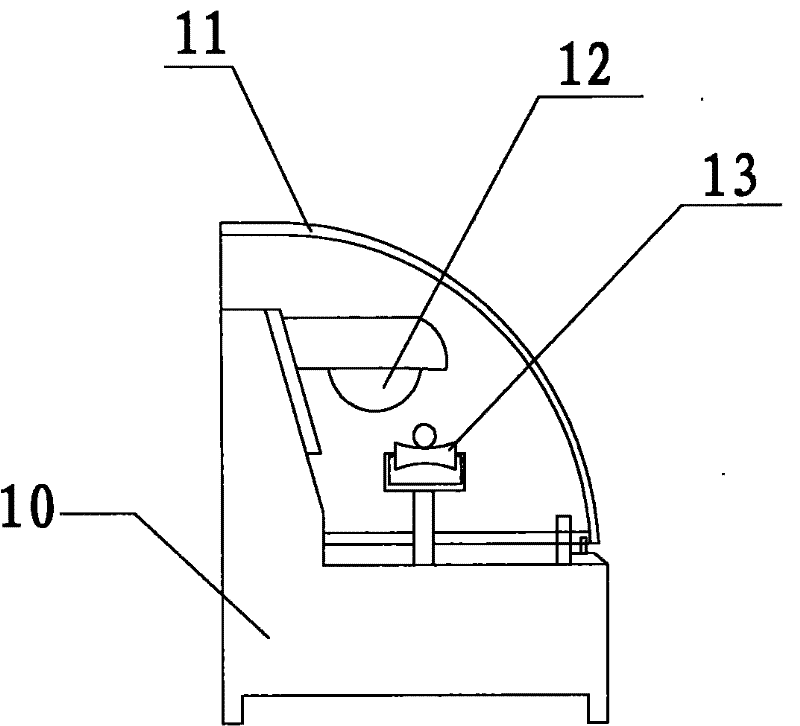

Cutting machine for metal tube

ActiveCN101920359AAvoid chamfersAvoid deformation defectsMetal sawing devicesStructural engineeringMechanical engineering

The invention discloses a cutting machine for a metal tube, which comprises a lengthwise base, wherein, a first support and a second support for supporting the metal tube are oppositely and horizontally arranged on two ends of the base. The cutting machine is characterized in that a box is movably arranged on the base and positioned between the first support and the second support; the metal tube can penetrate into the box from one side thereof and penetrate out of the box from the other side thereof; the box is internally equipped with a first fixture and a second fixture at an interval for clamping the metal tube; and a cutting device is arranged in a spacing area between the first fixture and the second fixture. When the cutting machine using the structure is used for cutting the metal tube, the cutting device can horizontally move with the metal tube synchronously and complete cutting the metal tube during the movement process of the metal tube so as to effectively prevent the metal tube from being bevelled and deformed.

Owner:BAOLAI STAINLESS STEEL TECH (KUNSHAN) CO LTD

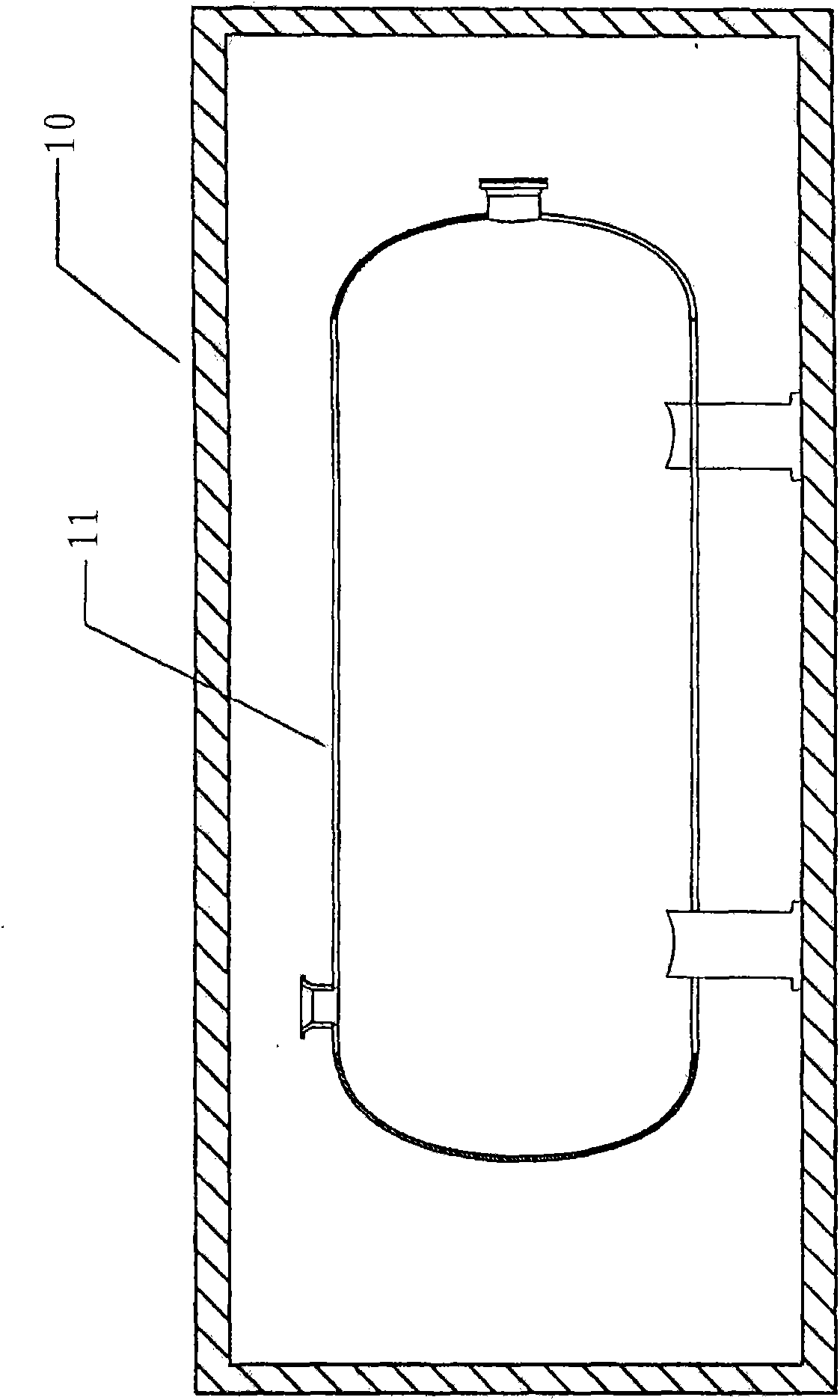

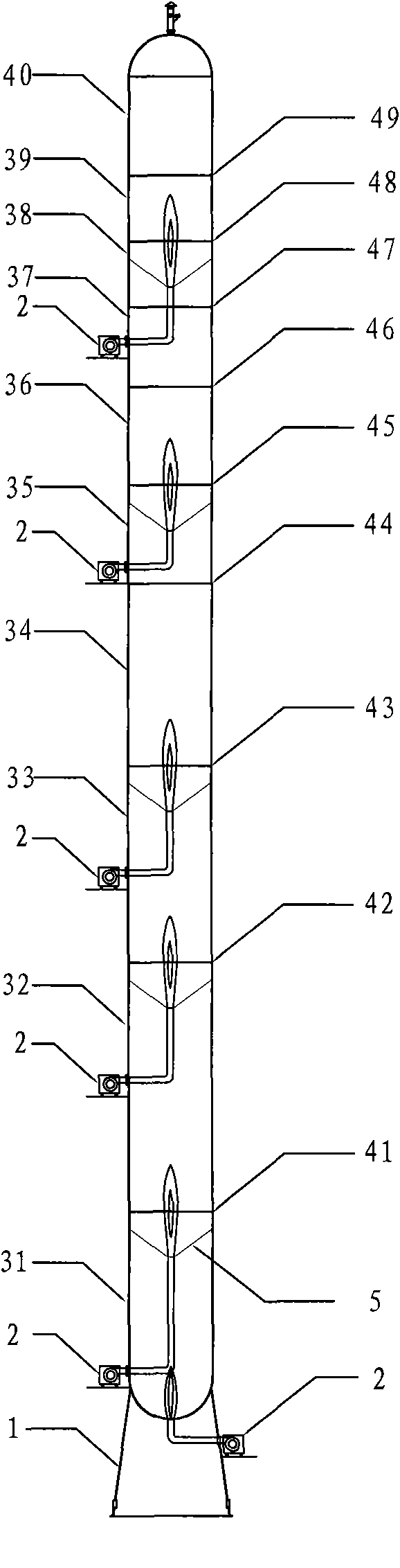

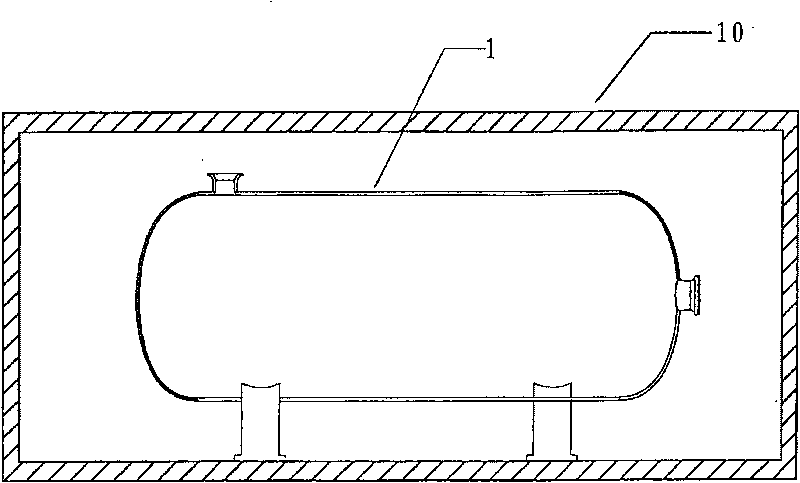

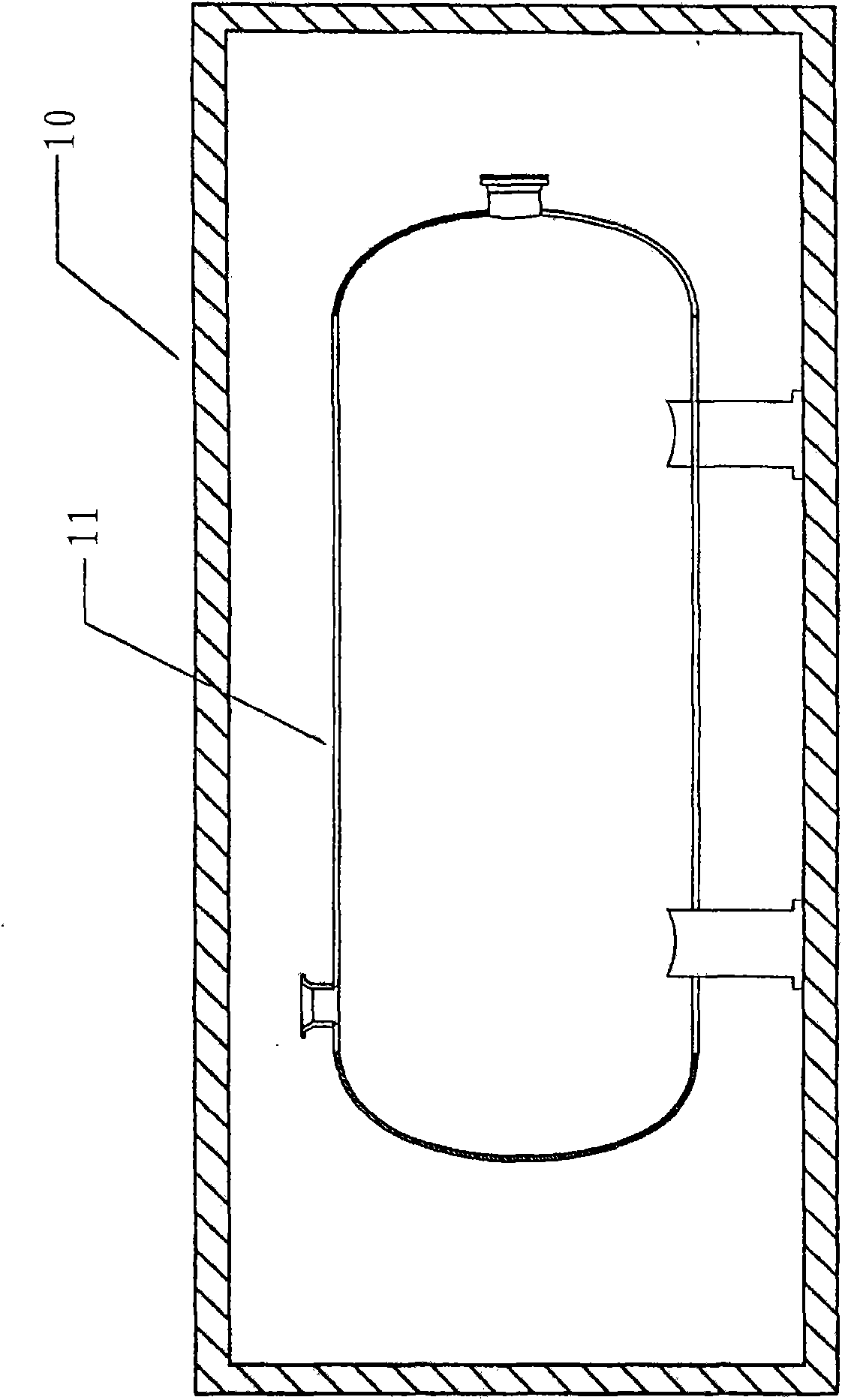

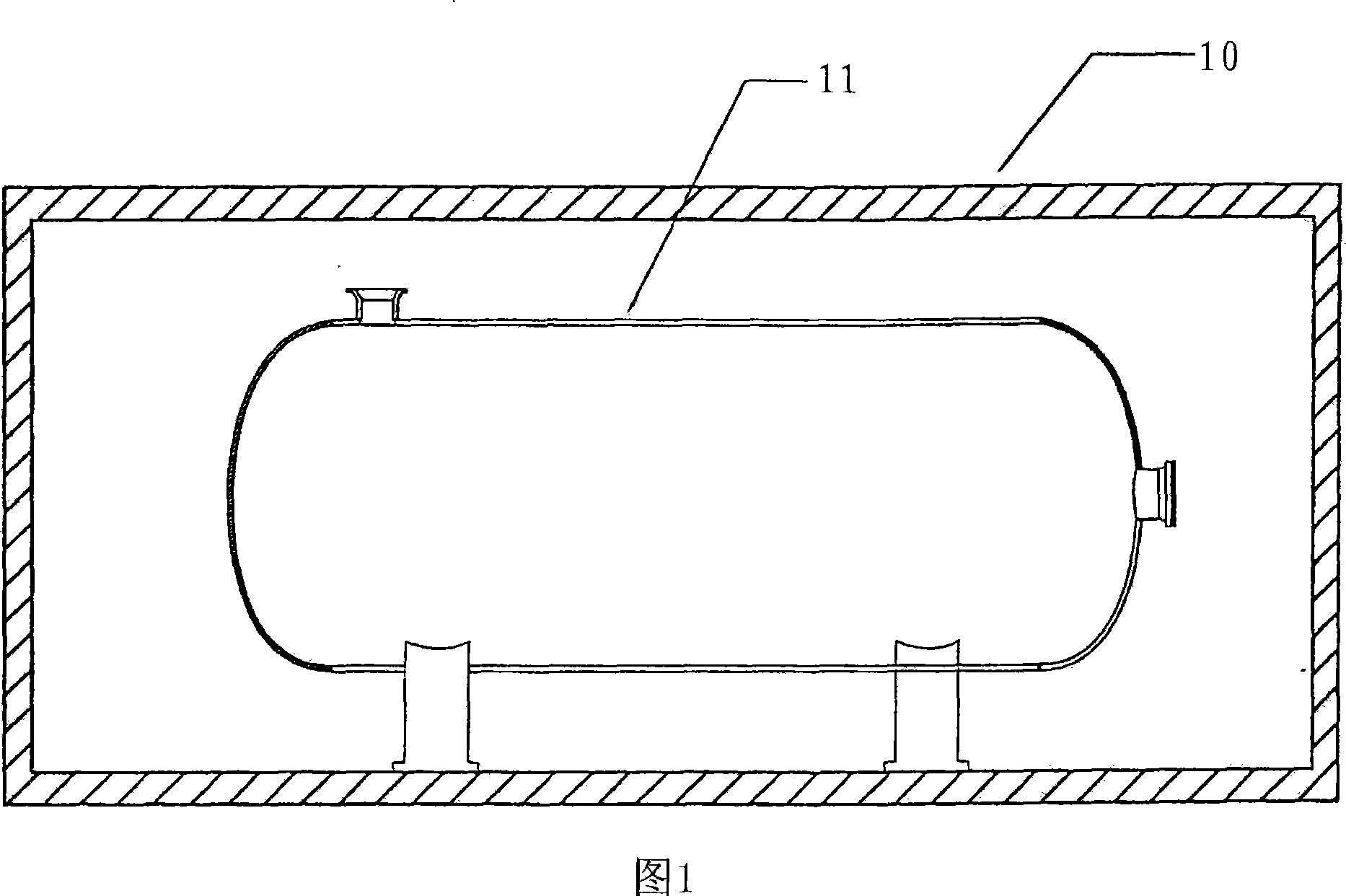

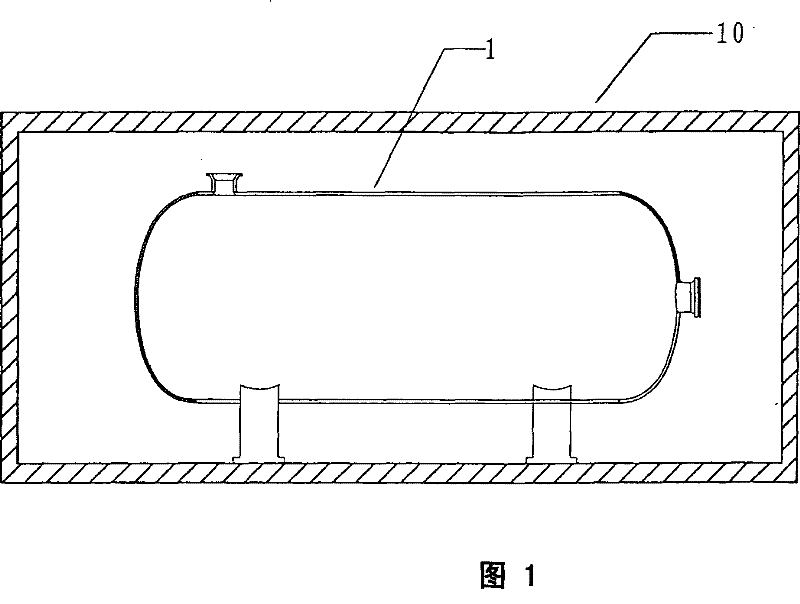

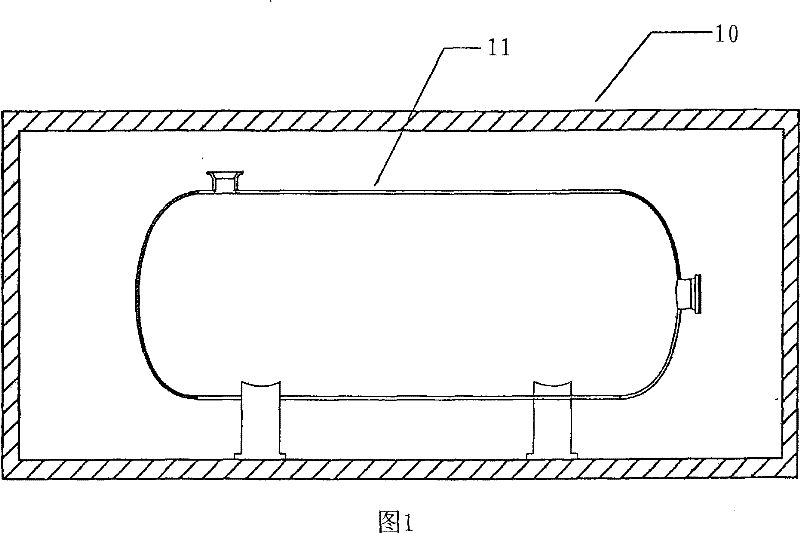

In-situ piecewise heat treatment method of large pressure container

InactiveCN101684515AAvoid deformation defectsSmall amount of deformationFurnace typesHeat treatment furnacesHearthEngineering

The invention discloses an in-situ piecewise heat treatment method of a large pressure container, which comprises the following steps: respectively setting an inner cavity of each section of pressurecontainer cylinder body of the large pressure container being installed and constructed into a hearth; starting from the bottom section, performing the heat treatment on one section of pressure container cylinder body when installing and constructing the section of pressure container cylinder body; and installing and constructing one section of pressure container cylinder body on the heat-treatedsection of pressure container, and performing the heat treatment on the former section of pressure container cylinder body until the heat treatment is performed on the installed and constructed highest section of pressure cylinder body. The invention can save the step of heat treatment on a welding circular seam by using an electric heater.

Owner:傅家仁 +1

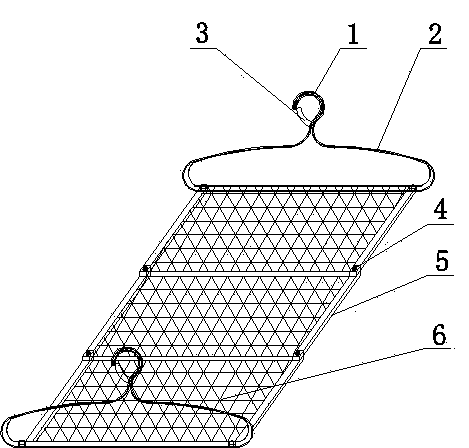

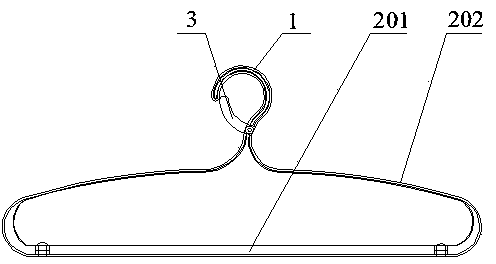

Telescopic clothes rack

The invention relates to a telescopic clothes rack. The telescopic clothes rack comprises two clothes rack bodies, wherein each clothes rack body comprises a pothook and a clothes rack body part connected to one end of the pothook, the other end of the pothook is a free end, a connecting sheet which can be in sealing connection with the free end of the pothook is articulated at a connecting end between the pothook and the clothes rack body part, two expansion links arranged in parallel are fixedly connected between the two clothes rack bodies, each expansion link comprises multiple fixed links which are sequentially arranged from top to bottom in a lap joint manner, a sliding chute matched with the fixed link at the upper part is formed in the fixed link at the lower part, the two adjacent fixed links are fixed together through elastic positioning screws arranged at the lap joint ends of the fixed links, and a flexible supporting net is formed between the two expansion links. When the telescopic clothes rack is used, clothes can be spread out on the supporting net so as to avoid the defect that when the clothes are vertically hung, the clothes deform; when the telescopic clothes rack is not in use, the extension links can be folded, and the telescopic clothes rack is easy to store and place; and when the telescopic clothes rack is hung on a clothesline or a clothesline pole, the telescopic clothes rack does not fall off, so that the clothes is prevented from being polluted.

Owner:LUOYANG INST OF SCI & TECH

B-shaped aluminum tube belt type heat radiator for water tank

InactiveCN102331195AReduce investmentReduce manufacturing costStationary conduit assembliesTubular elementsEngineeringHigh intensity

The invention relates to a B-shaped aluminum tube belt type heat radiator for a water tank. The heat radiator comprises a heat radiating tube, a heat radiating belt, a side plate and a main fin, wherein the heat radiating tube is a B-shaped tube; the heat radiating tube is divided into two cavities by using the folding part in the middle of the B-shaped tube, so that liquid separately flows in two separate cavities; and a coating layer of the B-shaped tube is connected with the heat radiating belt at the outer side; and the inner side of the B-shaped tube is a shiny surface. Compared with the prior art, the B-shaped aluminum tube belt type heat radiator has the advantages of low cost, favorable heat transfer performance, high intensity and the like.

Owner:SHANGHAI DELANG AUTO PARTS MFG

Wind guide swinging blade assembly structure and air conditioner

ActiveCN105509150AAvoid forceAvoid deformation defectsLighting and heating apparatusAir conditioning systemsEngineeringAssembly structure

The invention discloses a wind guide swinging blade assembly structure and an air conditioner. The wind guide swinging blade assembly structure comprises a volute tongue, and wind guide swinging blades assembled at the volute tongue, wherein the volute tongue is provided with mounting columns; buckling grooves are formed in the mounting columns; a locking holding piece is formed at one end of one wind guide swinging blade correspondingly; buckling parts are formed at the locking holding pieces; the locking holding pieces are arranged at the mounting columns in a sleeving manner; and the buckling parts are buckled in the buckling grooves. With the adoption of the wind guide swinging blade assembly structure, the wind guide swinging blades can be mounted at or dismounted from the volute tongue more conveniently and quickly, and damage to the wind guide swinging blades is avoided.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

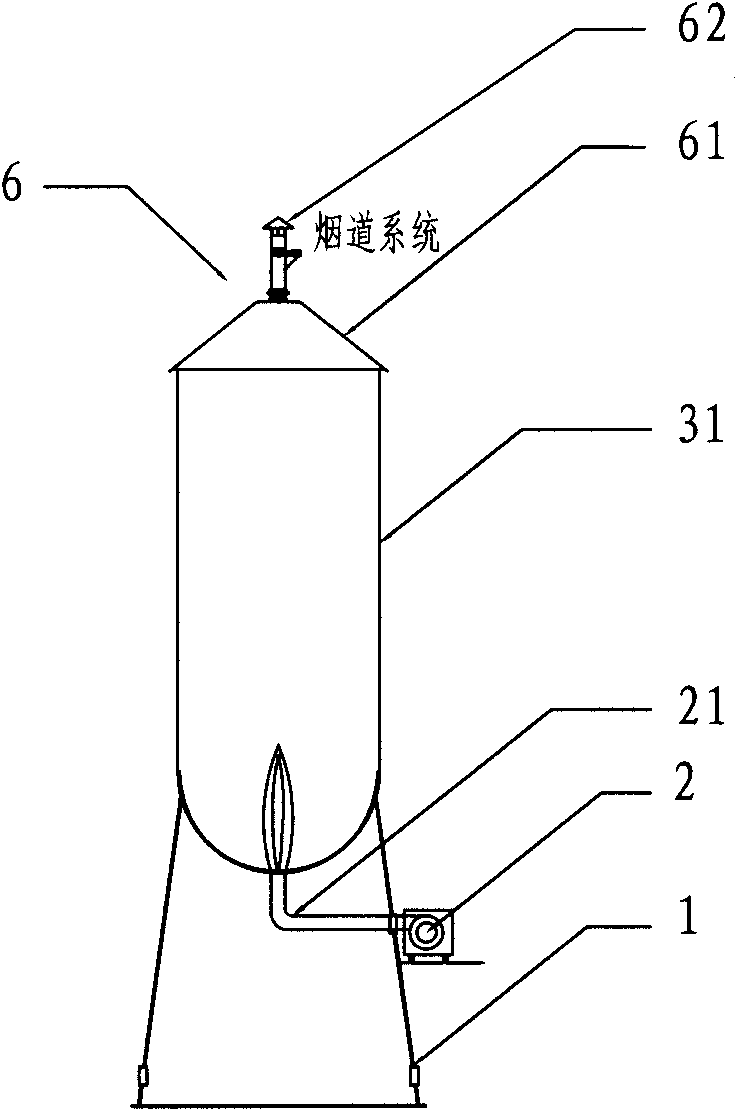

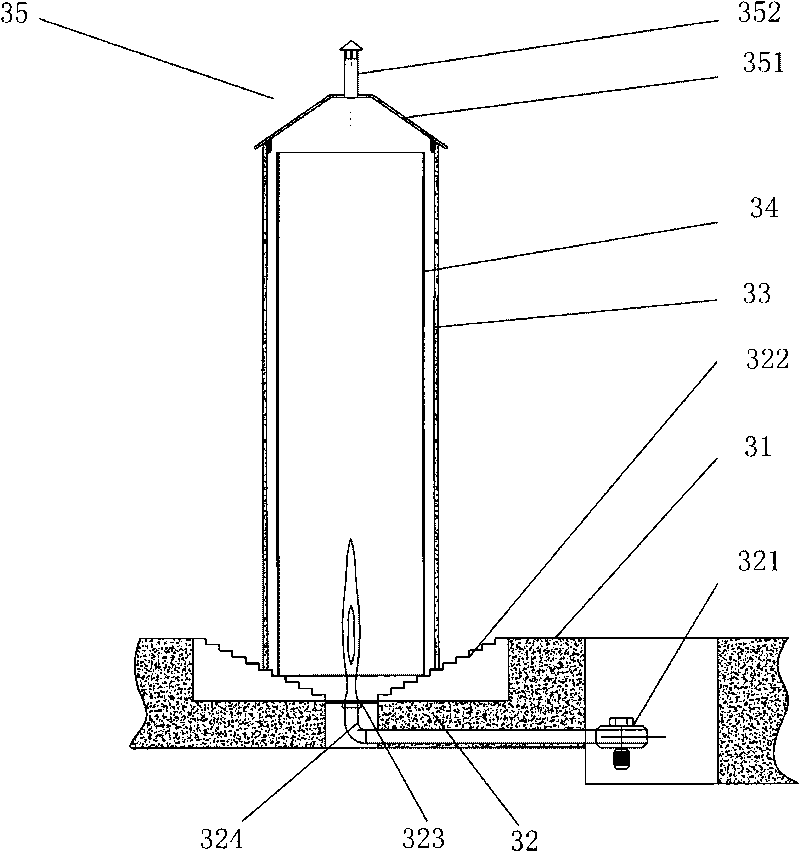

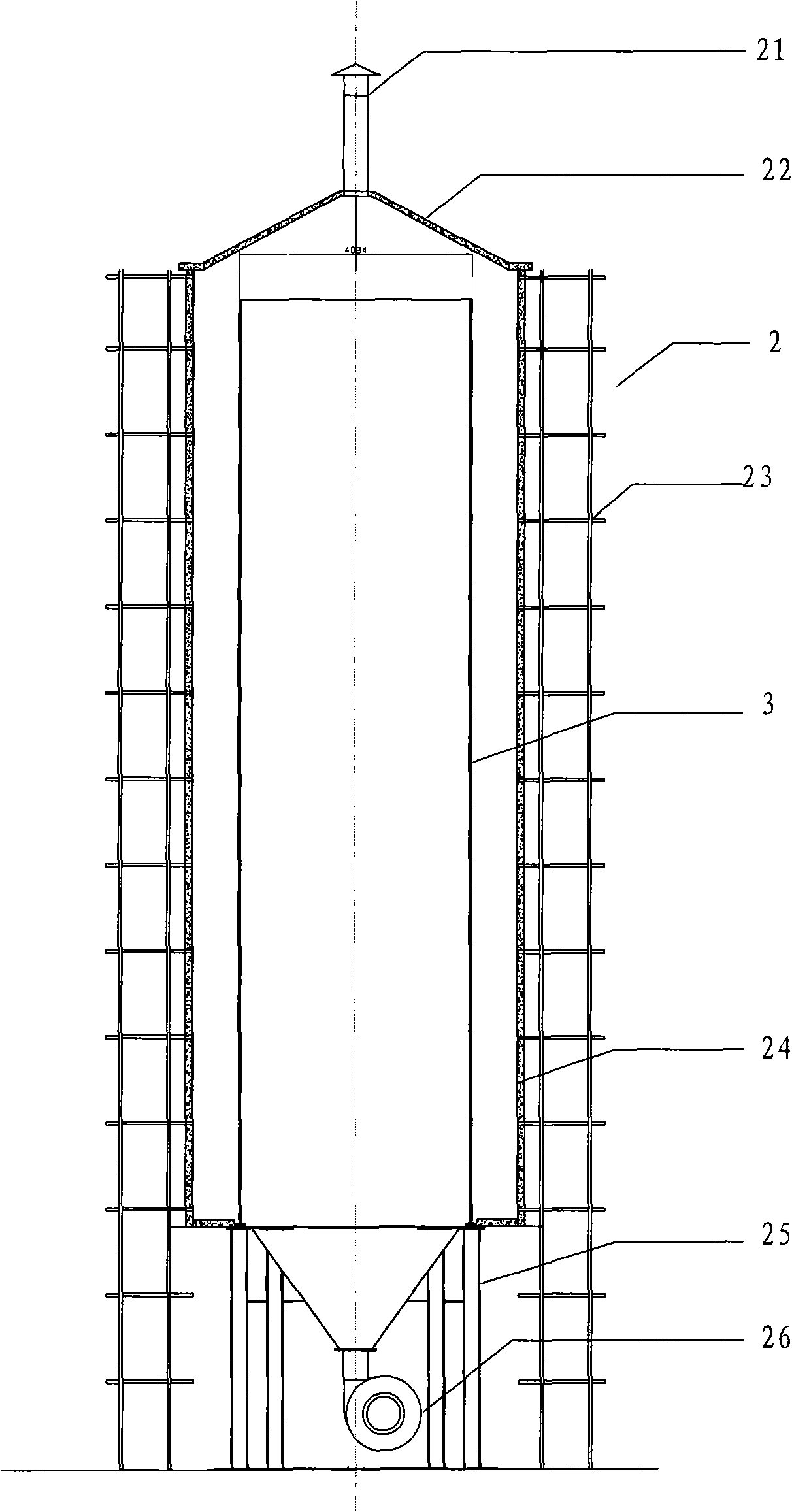

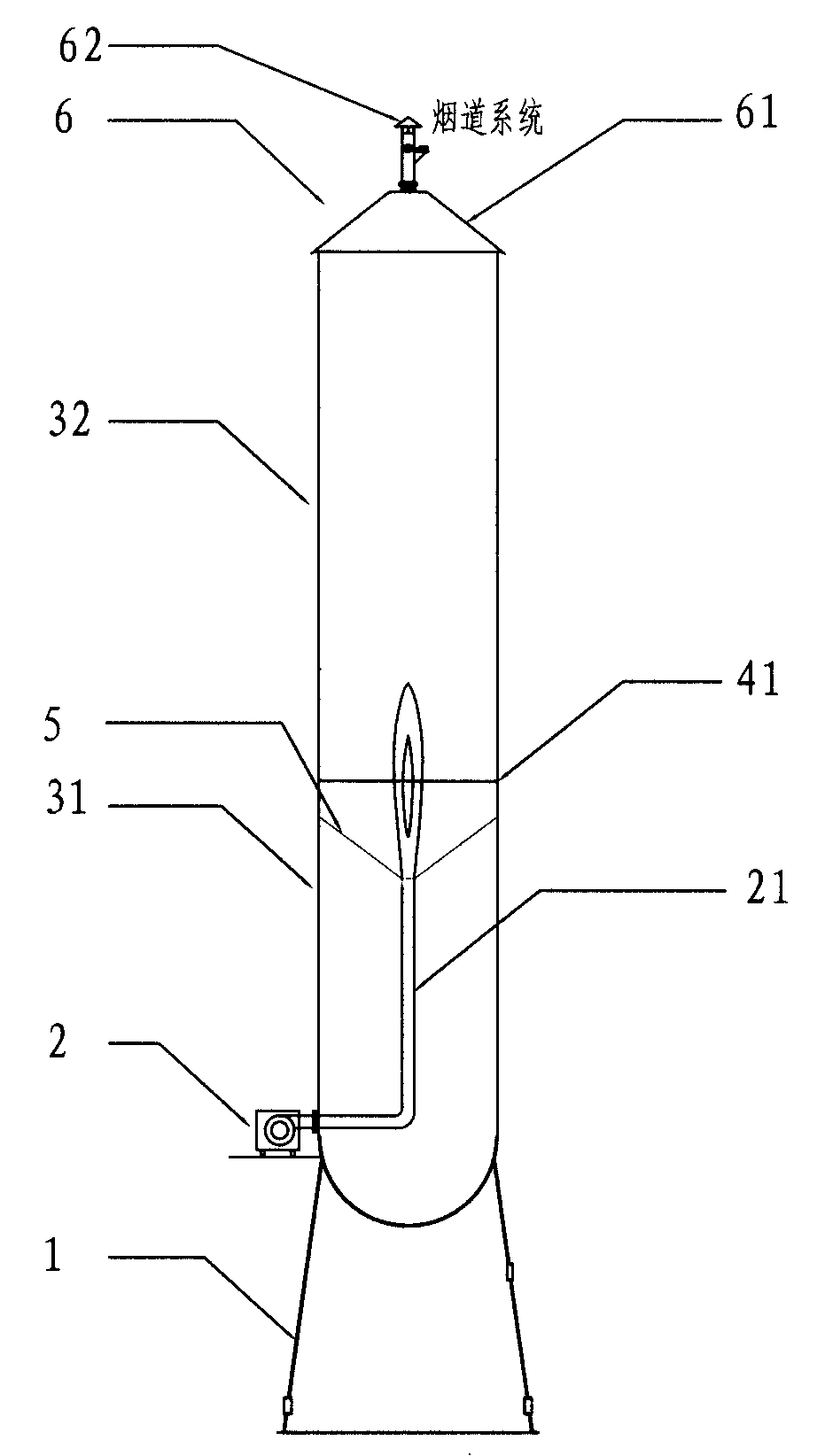

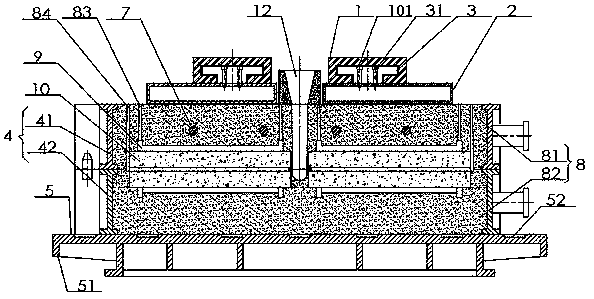

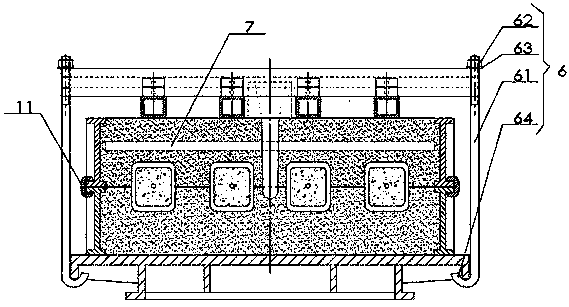

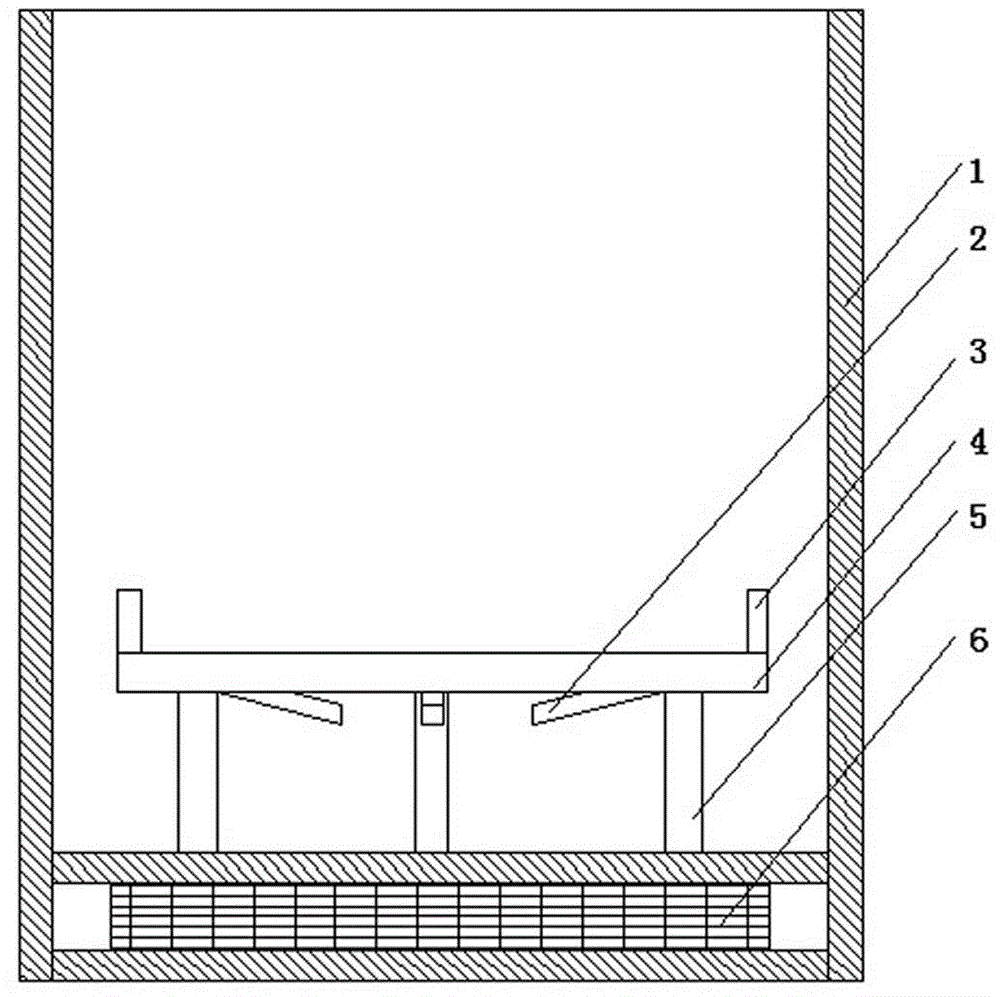

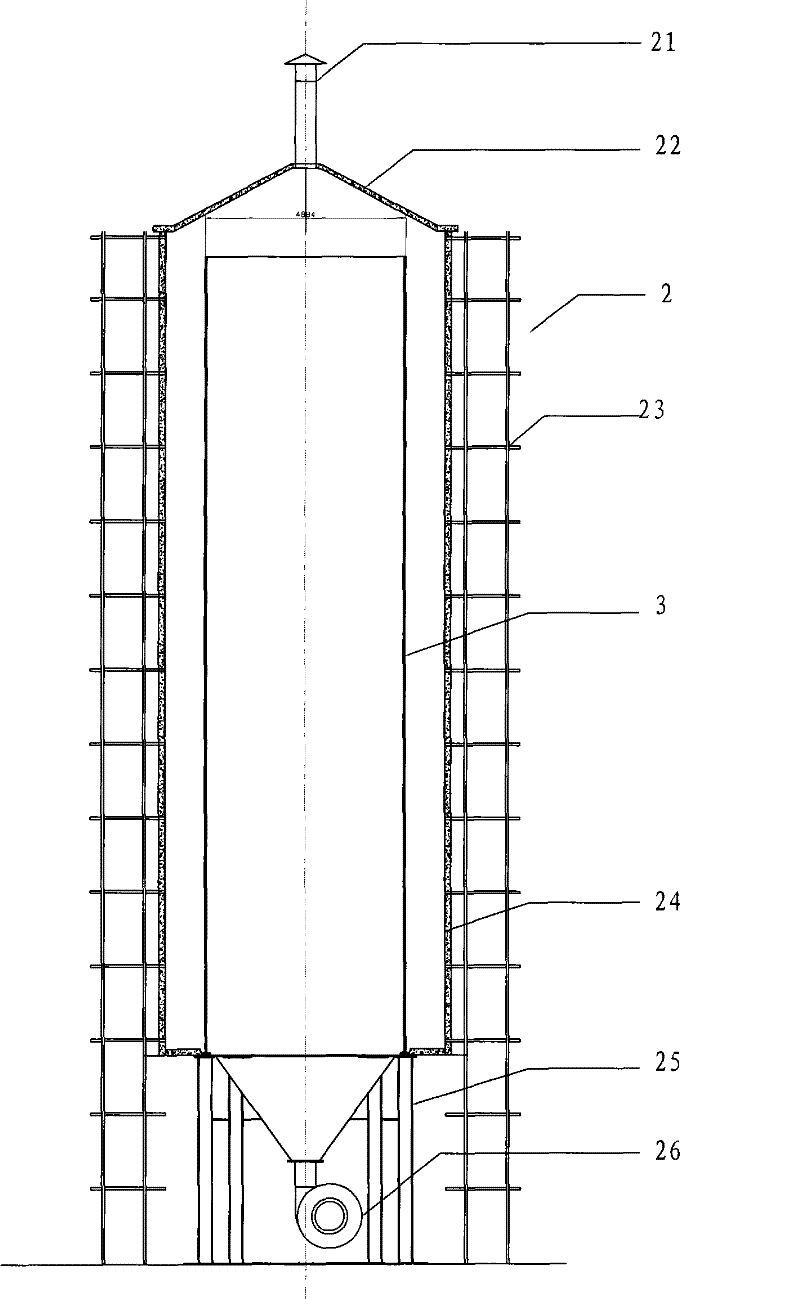

Upright thermal treatment furnace for pressure container factory

PendingCN101724738AAvoid deformation defectsSmall amount of deformationFurnace typesHeat treatment furnacesEngineeringHearth

The invention discloses an upright thermal treatment furnace for a pressure container factory, which comprises a heat insulation furnace shell and a thermal treatment facility positioned in the pressure container factory, wherein a traveling crane of the pressure container factory shifts a large pressure container section to be thermally treated to the thermal treatment facility, the large pressure container section is upright on the thermal treatment facility and is enclosed by the heat insulation furnace shell so that the thermal treatment facility directly sets the upright large pressure container section to be thermally treated as a hearth, and the large pressure container section is heated through thermal radiation, convection and conduction so as to carry out the thermal treatment on the large pressure container section. Through the thermal treatment for the large pressure container section, the technical problem that a large pressure container is easy to deform in the thermal treatment is solved.

Owner:寿比南 +3

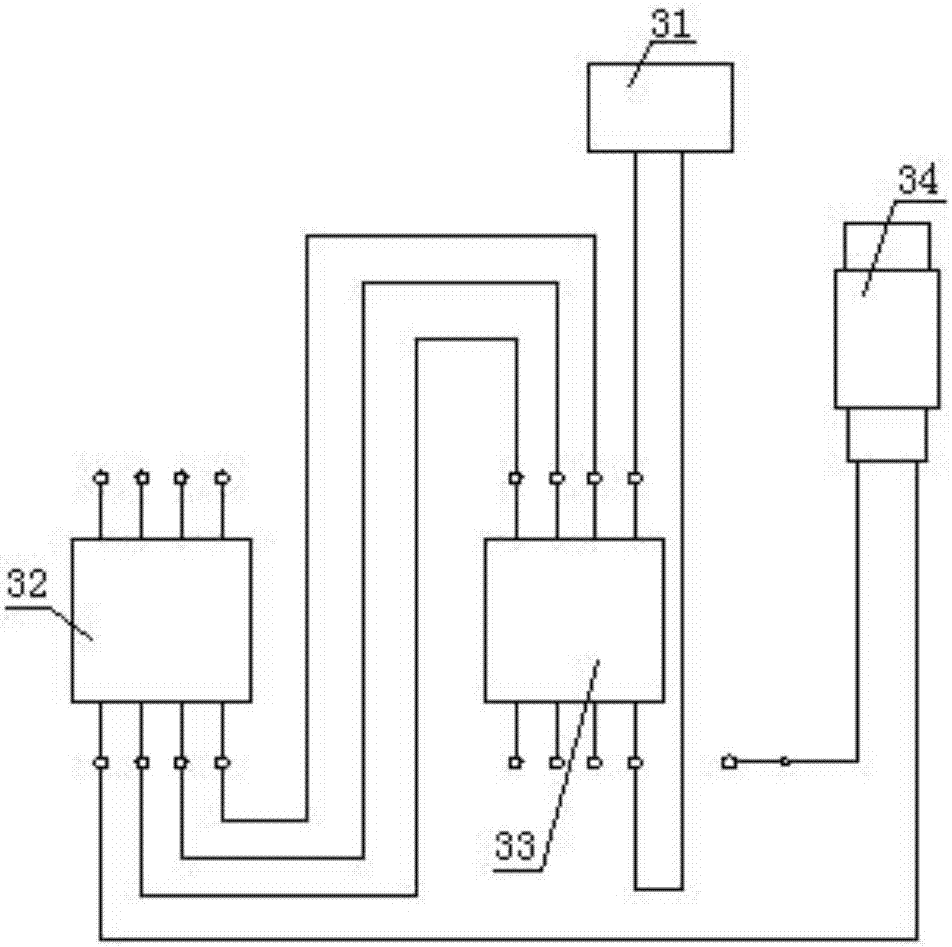

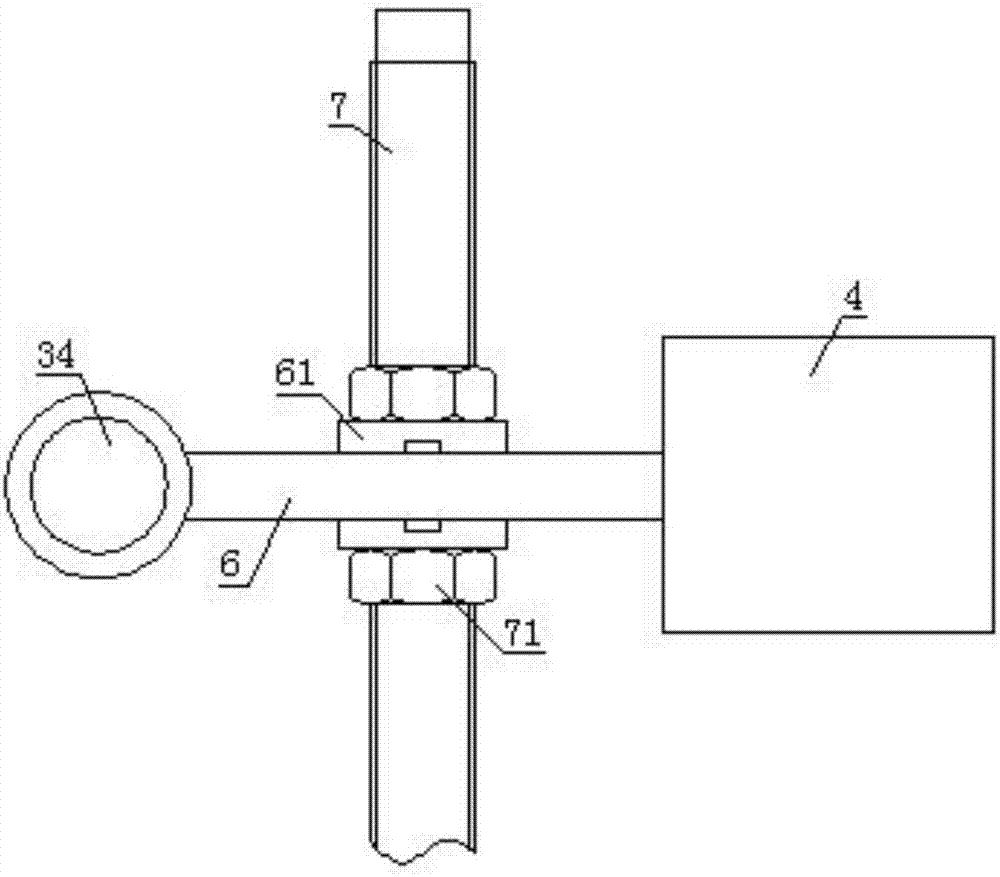

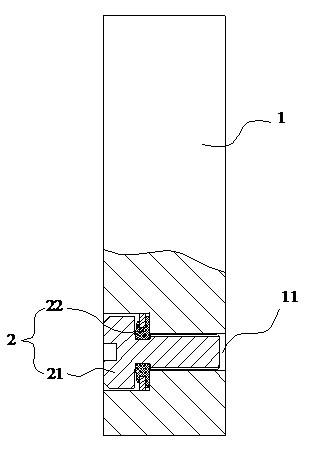

Detection alarm system for automatically checking deformation of inner wall of pipeline

InactiveCN107101574ASimple structureFar from simpleElectrical/magnetic solid deformation measurementEngineeringElectromagnetic induction

The invention relates to the field of pipeline detection, and particularly relates to a detection alarm system for automatically checking deformation of an inner wall of a pipeline. The technical scheme is the detection alarm system for automatically checking deformation of the inner wall of the pipeline comprises a pipeline; the pipeline is connected with a conveying device for conveying a pipeline; a metal piece is placed in the pipeline, and the pipeline is externally provided with an electromagnetic induction system and a magnet for sucking the metal piece respectively; the electromagnetic induction system comprises an alarm. The invention provides the detection alarm system for automatically checking if the inner wall of the pipeline is deformed; the detection alarm system solves the problems that the existed pipe wall detection device cannot detect the deformation of the inner wall of the pipeline, and the detection result is unreliable.

Owner:郑州天魁实业有限公司

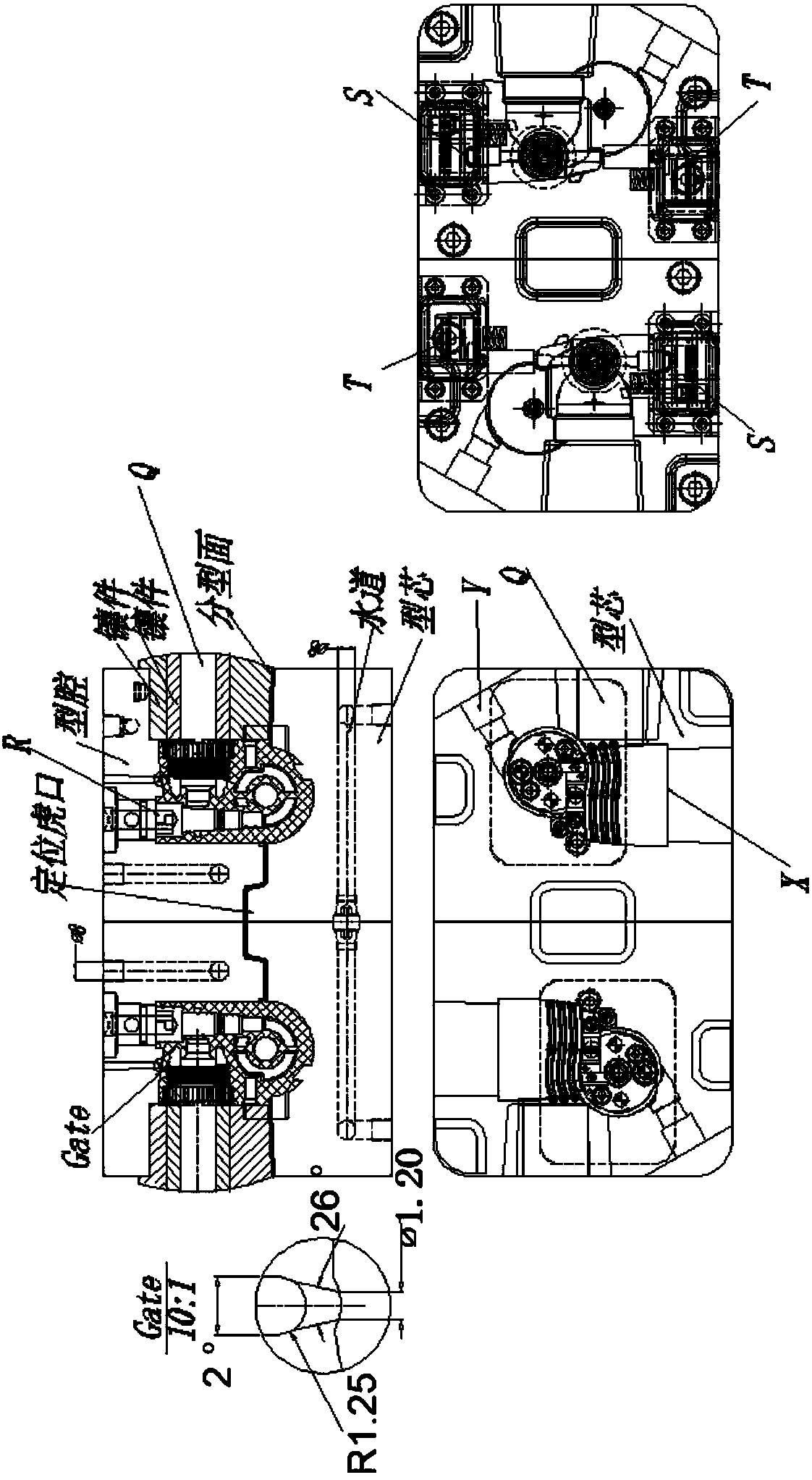

Medical waste treatment device and manufacturing method thereof

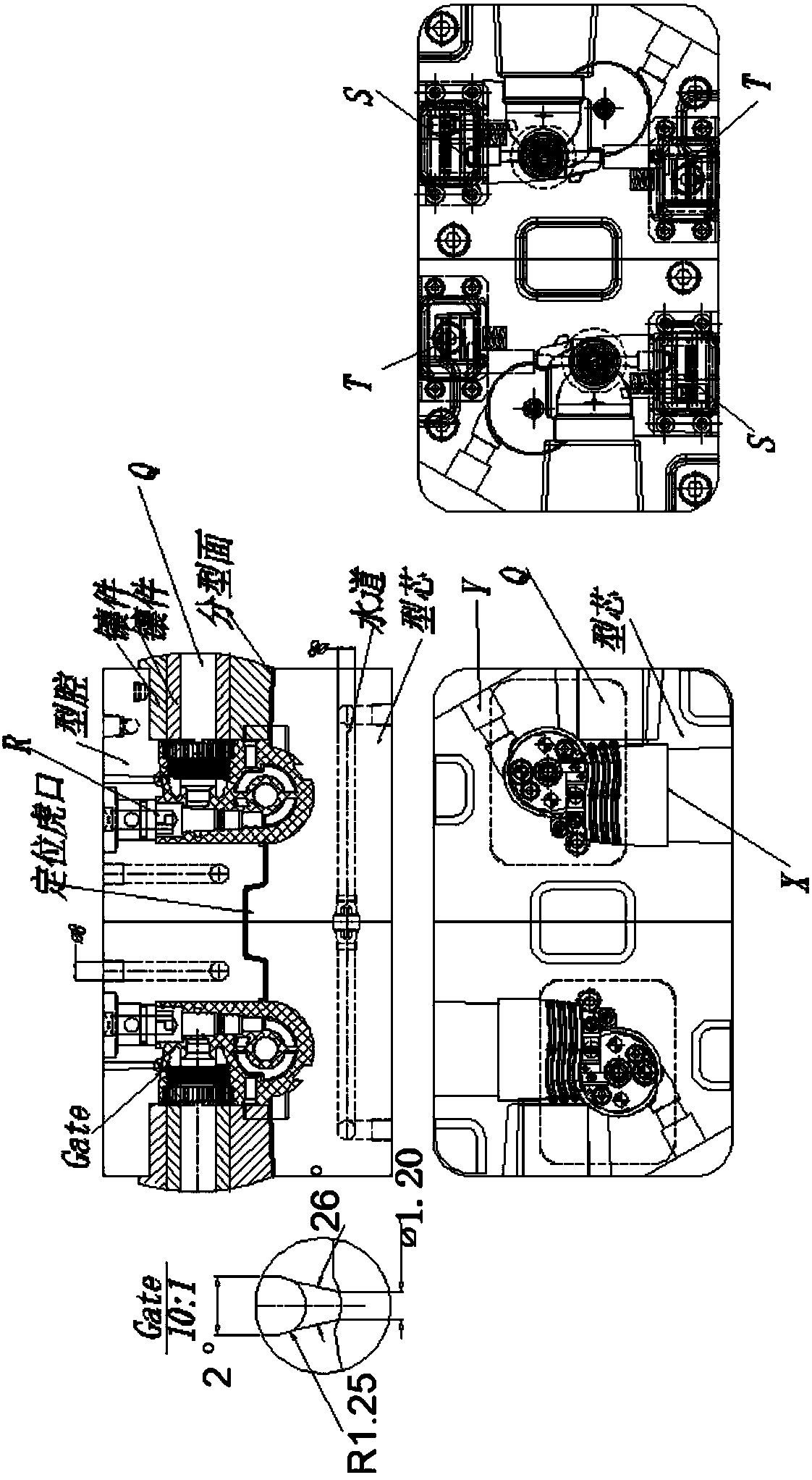

The invention provides a medical waste treatment device and a manufacturing method thereof. A gating system is a cold runner point pointed gate pouring manner, single-point feeding is achieved, in order to shorten the length of the runner and ensure the injection molding liquidity of a material flow, a flange type positioning ring flange sleeve is adopted in a gate sleeve, a phi8mm round runner isadopted in a horizontal runner on a flowing plate in the runner system, a pointed gate sleeve independent embedding manner is adopted in a vertical runner penetrating a fixed mold plate, and the gatewater inlet diameter is phi1.2mm.

Owner:乌鲁木齐九品芝麻信息科技有限公司

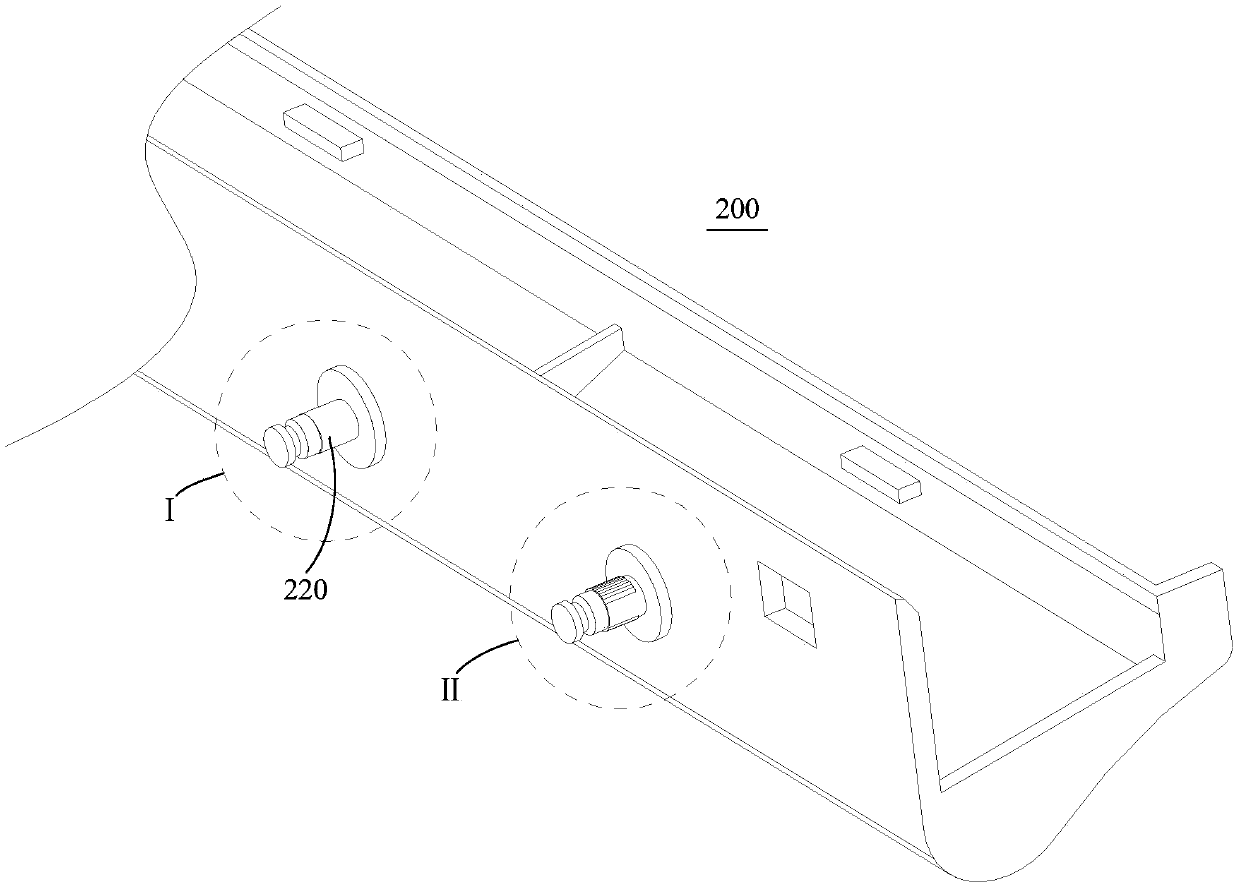

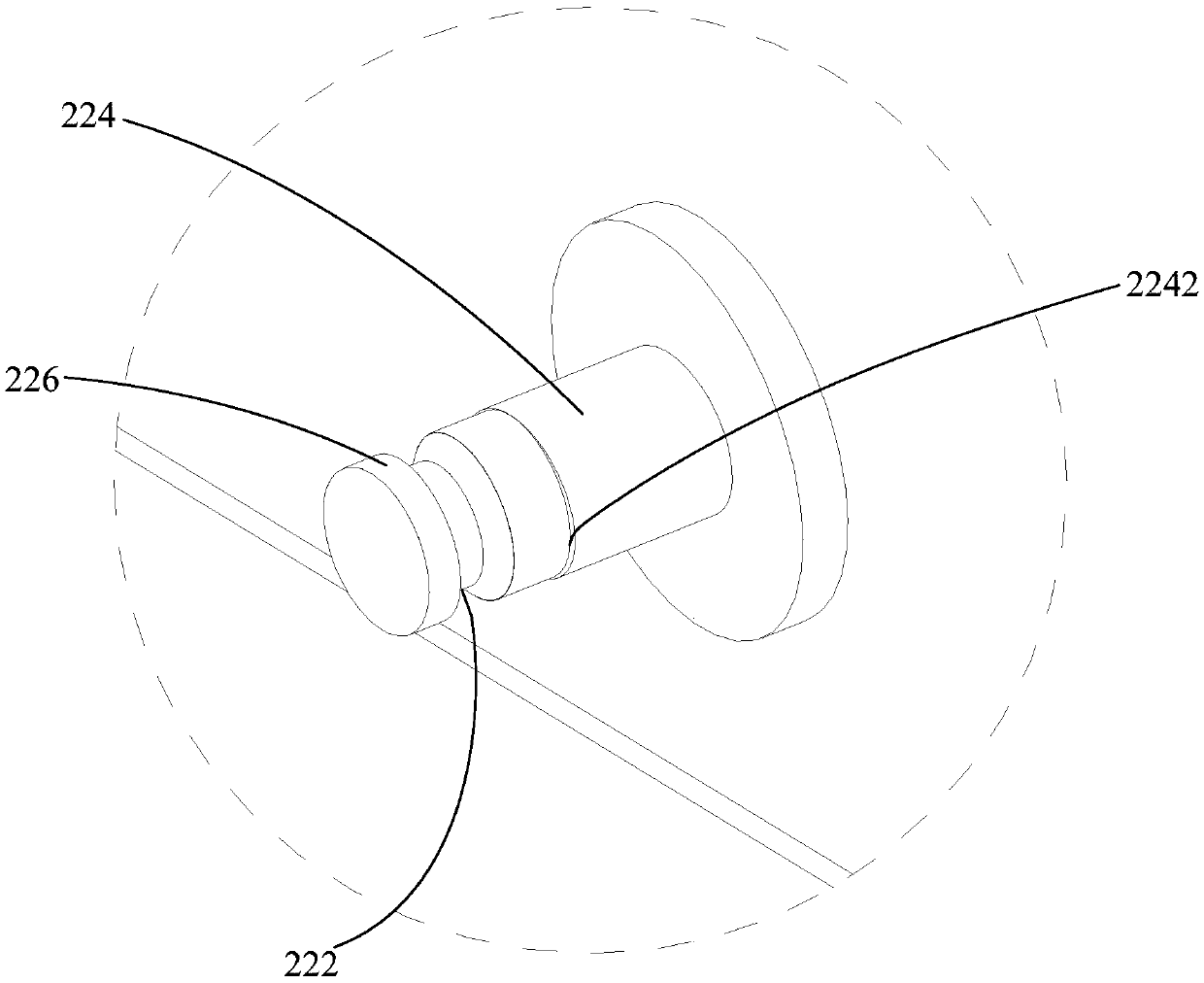

Cover plate structure of battery

The invention relates to a cover plate structure of a battery, comprising a base plate and a sealing device, wherein the base plate is provided with a threaded through hole; the sealing device is hermetically assembled and connected with the threaded through hole of the base plate. The cover plate structure has the advantages of good closing effect in a formation process, simple process, easy operation, good sealing effect, resource reusability and enhanced production efficiency; in addition, a screw and the threaded through hole are separated from each other or generate a gap due to overhigh internal air pressure in the using process of the battery so that the internal air pressure of the battery is released and the phenomena, i.e. shell bulge, valve bulge, and the like of the battery are prevented, and thereby the service life of the battery is prolonged.

Owner:WUXI FUHONG TECH

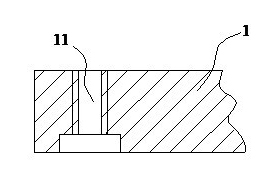

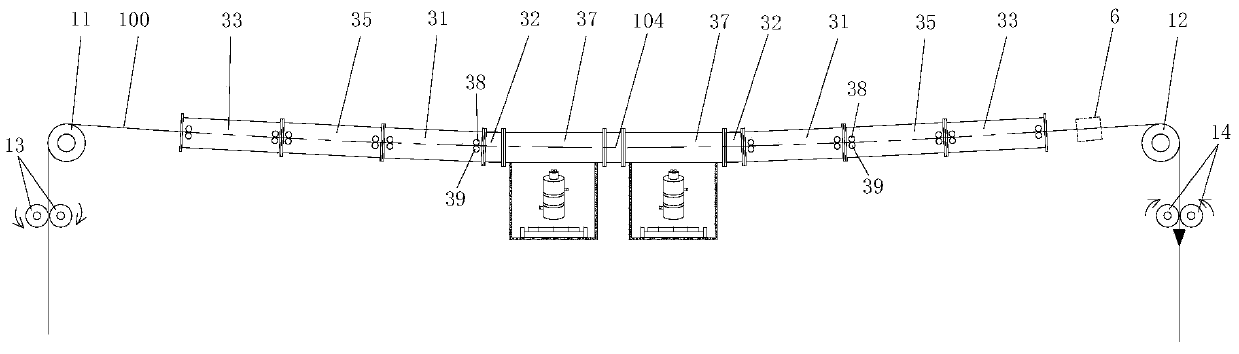

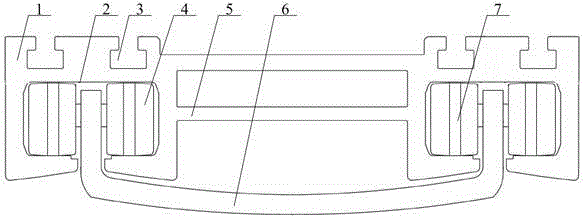

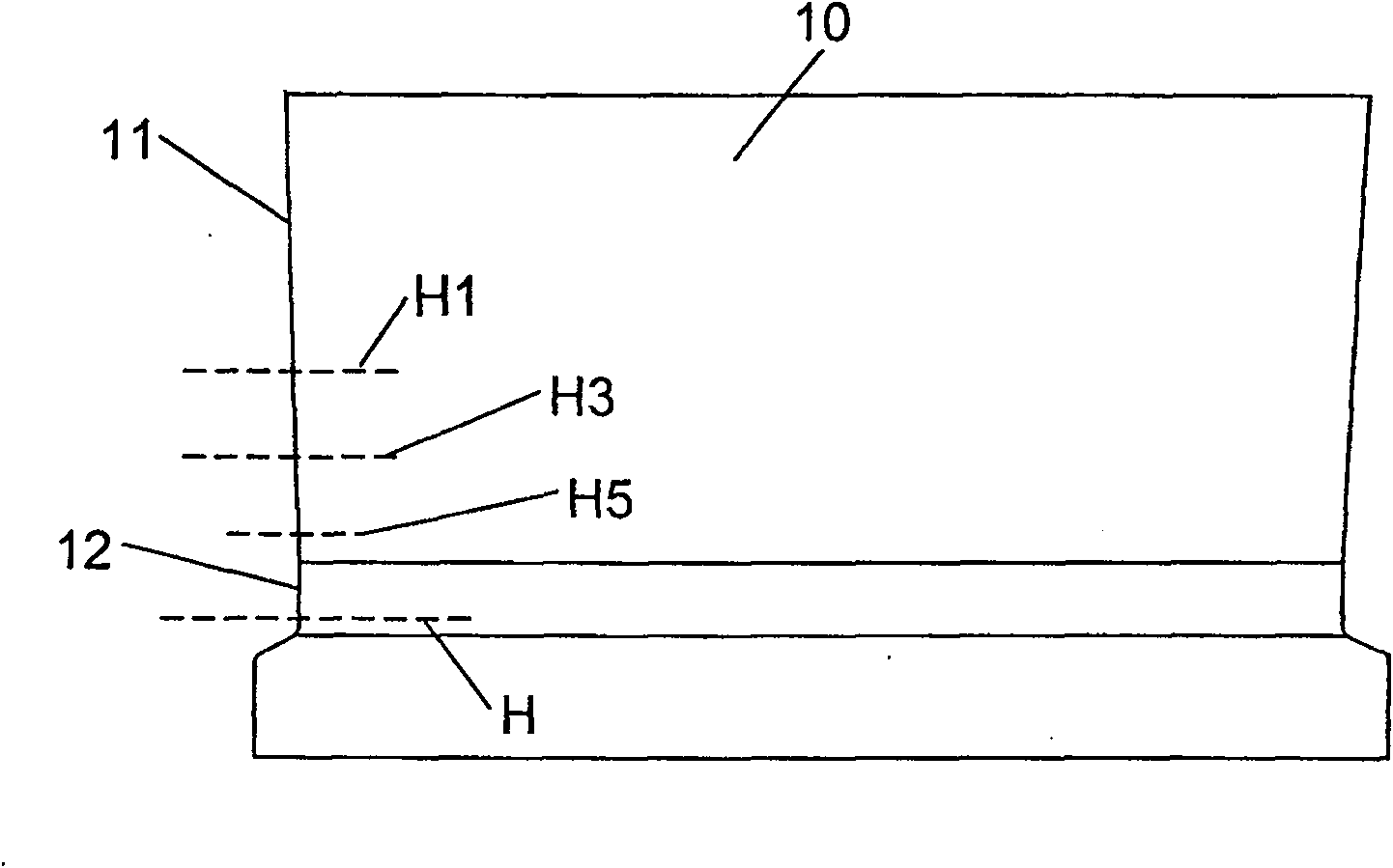

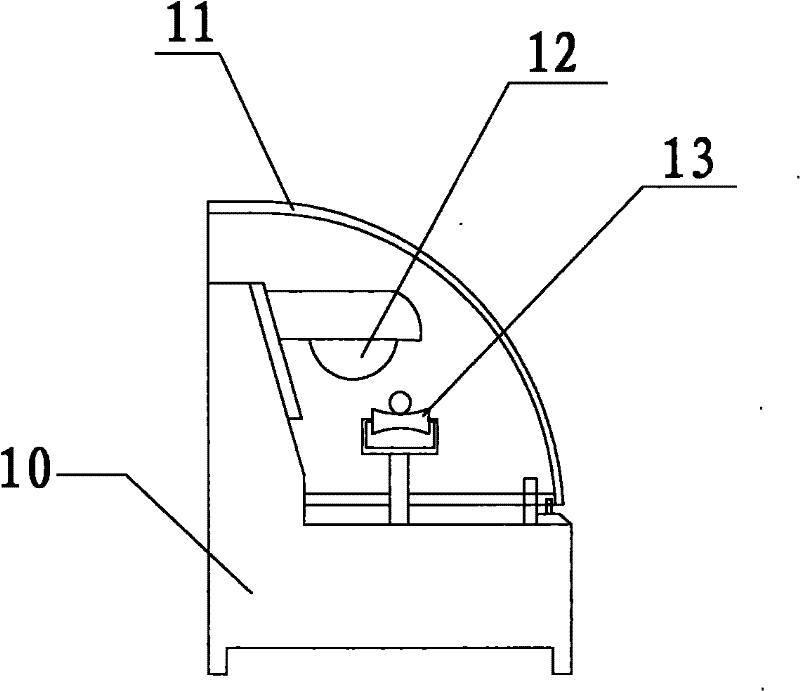

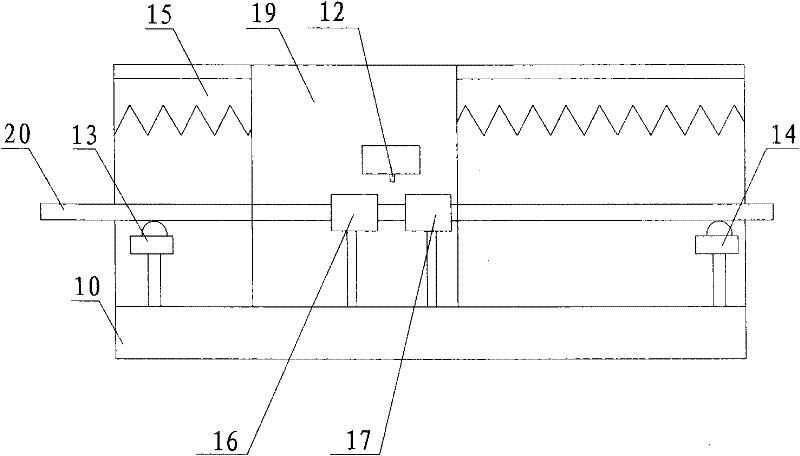

Vacuum coating device, vacuum double-sided coating device and position regulating method for belts

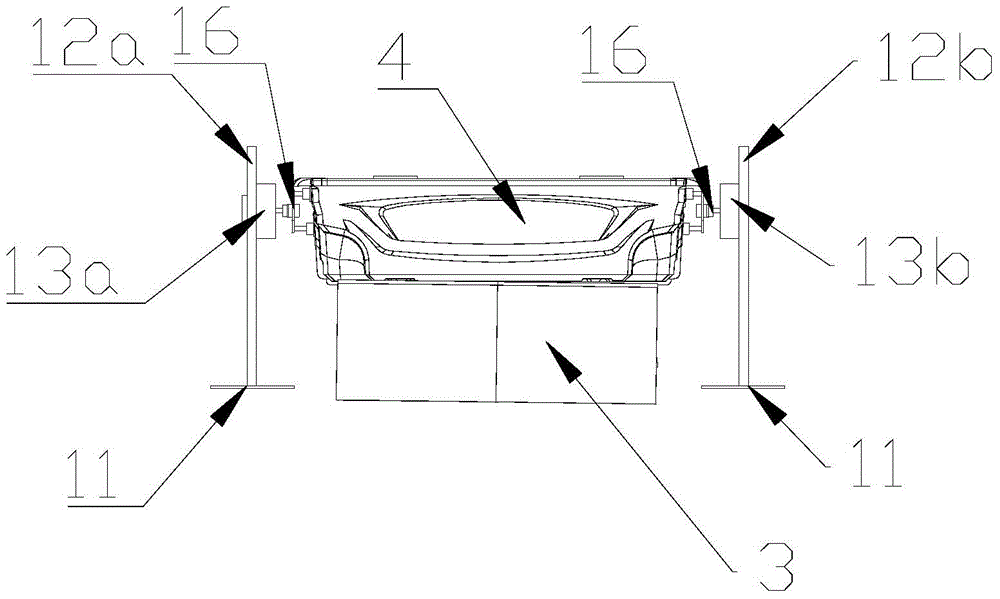

ActiveCN105506553AAvoid deformation defectsAdjust the overhang heightVacuum evaporation coatingSputtering coatingPulp and paper industryVacuum coating

The invention discloses a vacuum coating device for metal belts, a vacuum double-sided coating device for metal belts, and a position regulating method for metal belts in the vacuum coating device. The vacuum coating device comprises a vacuum coating chamber, wherein the input end of the vacuum coating chamber is provided with an input end roller (11) and an input clamping roller set (13); the output end of the vacuum coating chamber is provided with an output end roller (12) and an output clamping roller set (14); the metal belts are clamped by the input clamping roller set (13) for being conveyed forwards, pass through the input end roller and the output end roller, and are clamped by the output clamping roller set for being pulled forwards; the metal belts between the input end roller and the output end roller are partly in a hanging chain state or are partly in a similar hanging chain state. The vacuum coating device disclosed by the invention can prevent the metal belts from deformation and defects in a coating process while carrying out coating operation.

Owner:蒯一希

Positioning system for laser printer

ActiveCN102514403AAvoid partial printing, frequent alarms, affecting production efficiency and other issuesImprove general performanceOther printing apparatusEngineeringBlock match

The invention relates to a printer, in particular to a positioning system for a laser printer, which comprises a positioning plate, a cylinder clamp and a positioning device, wherein the cylinder clamp is arranged on the positioning plate and connected with the printer through a cylinder clamp connector, and the positioning device is arranged below the positioning plate. The positioning device comprises an upper pressing block component and a lower pressing block, the upper pressing block component is slidably connected with the positioning plate, and the lower pressing block matched with the upper pressing block component is fixed below the upper pressing block component. The positioning system for the laser printer has the advantages of accuracy in positioning, difficulty in damaging positioned products, high universality, high compatibility and low cost.

Owner:NANTONG FUJITSU MICROELECTRONICS

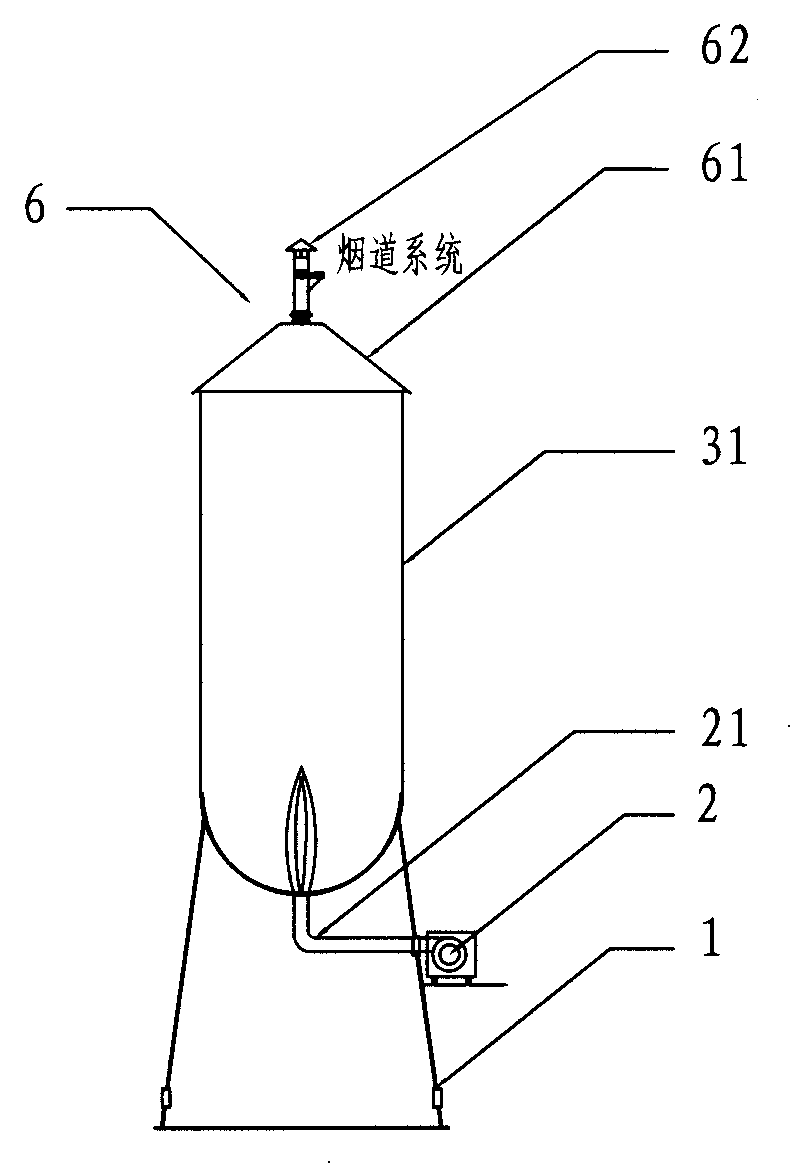

Piecewise heat treatment method of large pressure container

InactiveCN101684516AAvoid deformation defectsIncrease heat treatment speedFurnace typesHeat treatment furnacesHearthIndustrial furnace

The invention discloses a piecewise heat treatment method of a large pressure container, which comprises the following steps: building a temporary combustion heating furnace near an installation siteof the large pressure container; vertically installing the pressure container section into the combustion heating furnace, setting an inner cavity of the pressure container section into a hearth; butting a combustor with the bottom of the pressure container section; and combusting and heating the pressure container section by using the combustor. Compared with the traditional method for heat treatment by using an industrial furnace, the invention can improve the heat treatment speed to the pressure container section by building the temporary combustion heating furnace to perform the piecewiseheat treatment on the pressure container section.

Owner:傅家仁 +1

In-situ piecewise heat treatment method of large pressure container

InactiveCN101684515BAvoid deformation defectsSmall amount of deformationFurnace typesHeat treatment furnacesEngineeringHeat treated

Owner:傅家仁 +1

Metal hot processing solid-state lubricant

InactiveCN108410545AImprove the lubrication effectGood release effectAdditivesWater bathsParaffin wax

The invention discloses a metal hot processing solid-state lubricant, and relates to a solid-state lubricant. The metal hot processing solid-state lubricant comprises lubricants, heat-resistant components, stabilizers and preservatives. The metal hot processing solid-state lubricant particularly comprises, by weight, 25-40% of molybdenum disulfide, 20-30% of stearic acid, 10-20% of paraffin wax, 10-20% of oleic acid, 0.5-2% of sodium phosphate, 2-8% of silicone oil, and 0.5-2% of sodium benzoate. A method for preparing the metal hot processing solid-state lubricant includes placing the silicone oil, the paraffin wax and the stearic acid into a water bath kettle, and mixing and heating the silicone oil, the paraffin wax and the stearic acid with one another until the temperatures reach 80 DEG C so as to obtain first mixtures; stirring the first mixtures by an electric stirring machine, and slowly adding the molybdenum disulfide into the first mixtures after the first mixtures are uniformly stirred; sufficiently stirring the molybdenum disulfide and the first mixtures to obtain second mixtures and simultaneously adding the oleic acid, the sodium benzoate and the sodium phosphate intothe second mixtures; uniformly stirring the oleic acid, the sodium benzoate, the sodium phosphate and the second mixtures to obtain third mixtures, then pouring the third mixtures into molds and cooling the third mixtures to obtain the metal hot processing solid-state lubricant. The metal hot processing solid-state lubricant has the advantages of good mold release effect and stability, high-temperature resistance and environmental protection. Besides, the metal hot processing solid-state lubricant can be used for lubricating large complicated aluminum alloy die castings and forged pieces in the field of metal hot processing industry.

Owner:SHENYANG UNIV

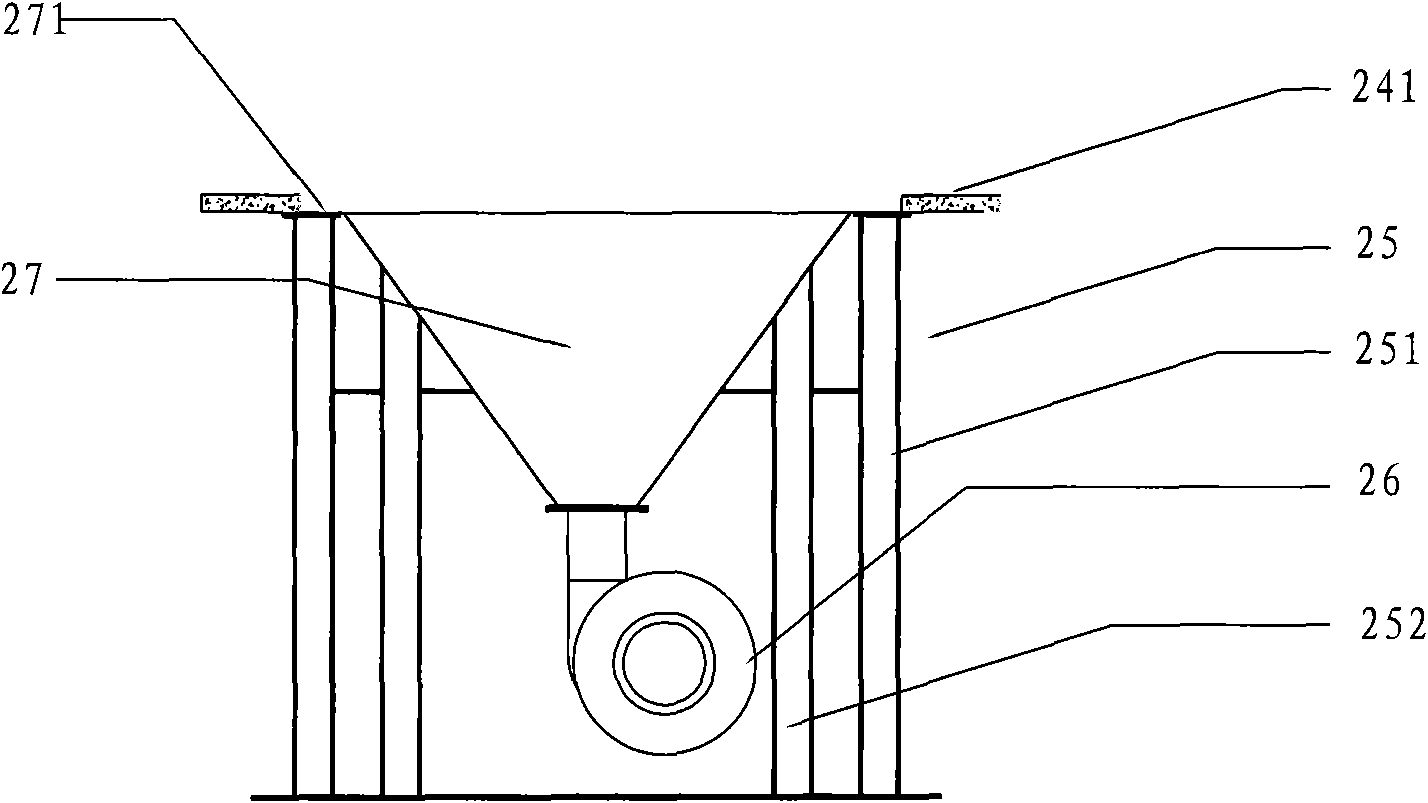

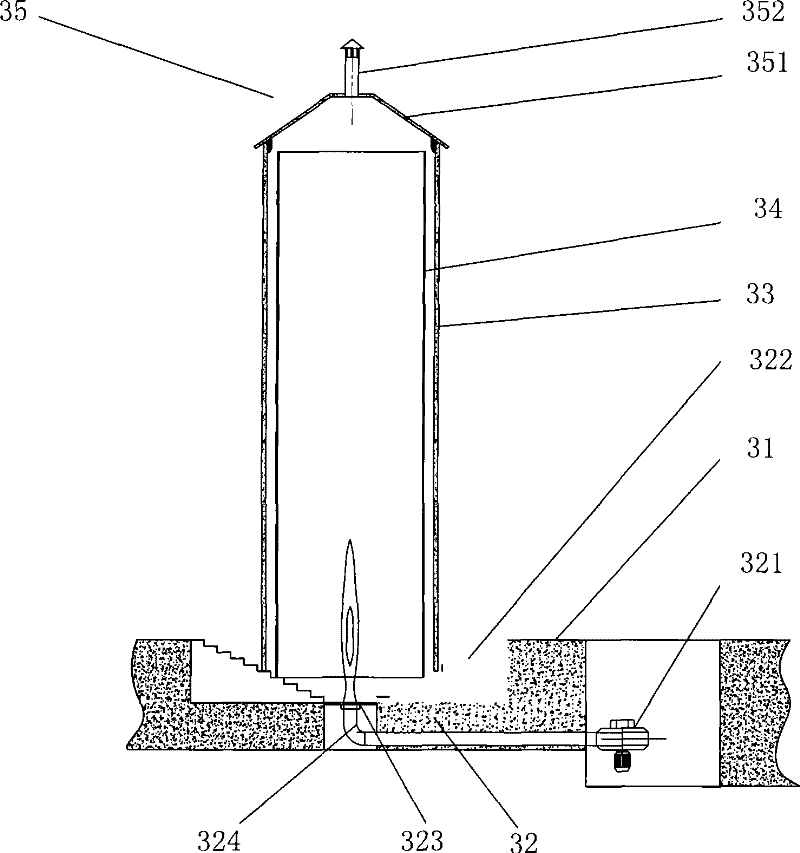

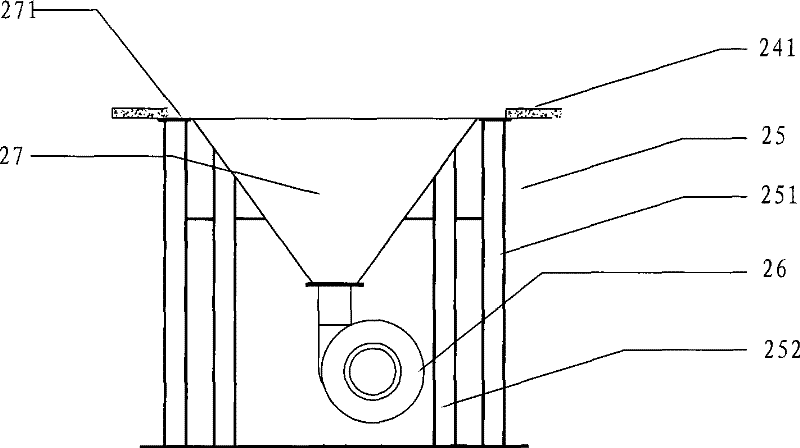

Internal combustion segmental heat treatment method for pressure container

InactiveCN101713020BAvoid deformation defectsSmall amount of deformationFurnace typesHeat treatment furnacesCombustorEngineering

The invention discloses a segmental heat treatment method for a large-scale pressure container in the manufacturing and mounting field. The method comprises the following steps of: building a heat-treatment underground facility which is lower than the ground in a manufacturing shop for the large-scale pressure container, and mounting a burner used for heating in the heat-treatment underground facility; translating the large-scale pressure container segment to be subjected to heat treatment by a travelling crane in the manufacturing shop so as to vertically mount the large-scale pressure container segment on the heat-treatment underground facility; mounting a heat-insulating furnace shell for heat preservation on the periphery of the large-scale pressure container segment; mounting a temperature-uniformizing device at the top of the heat-insulating furnace shell; and heating the large-scale pressure container segment by the burner so as to realize heat treatment. The segmental heat treatment method solves the technical problem that the large-scale pressure container is susceptible to deformation during the heat treatment through the heat treatment of the vertical large-scale pressure container.

Owner:寿比南 +3

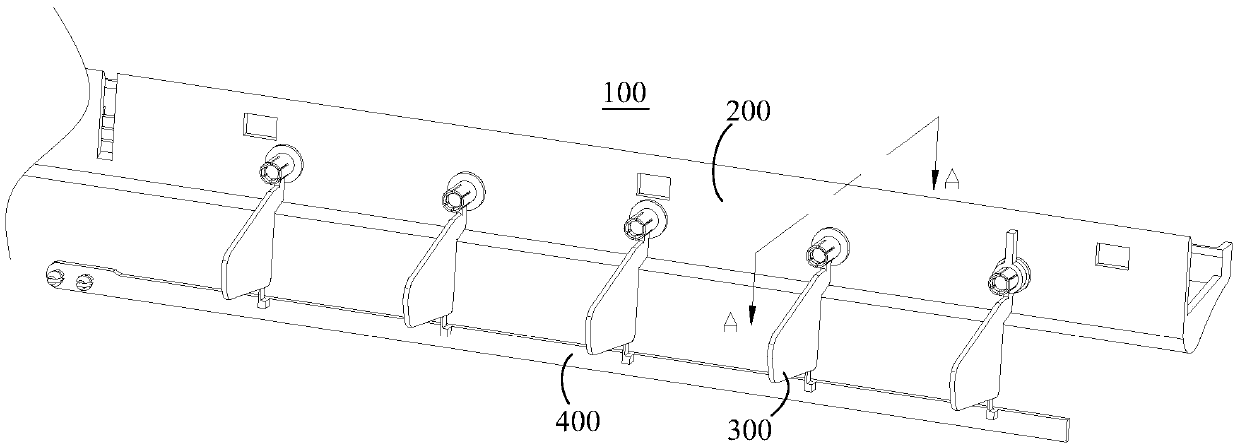

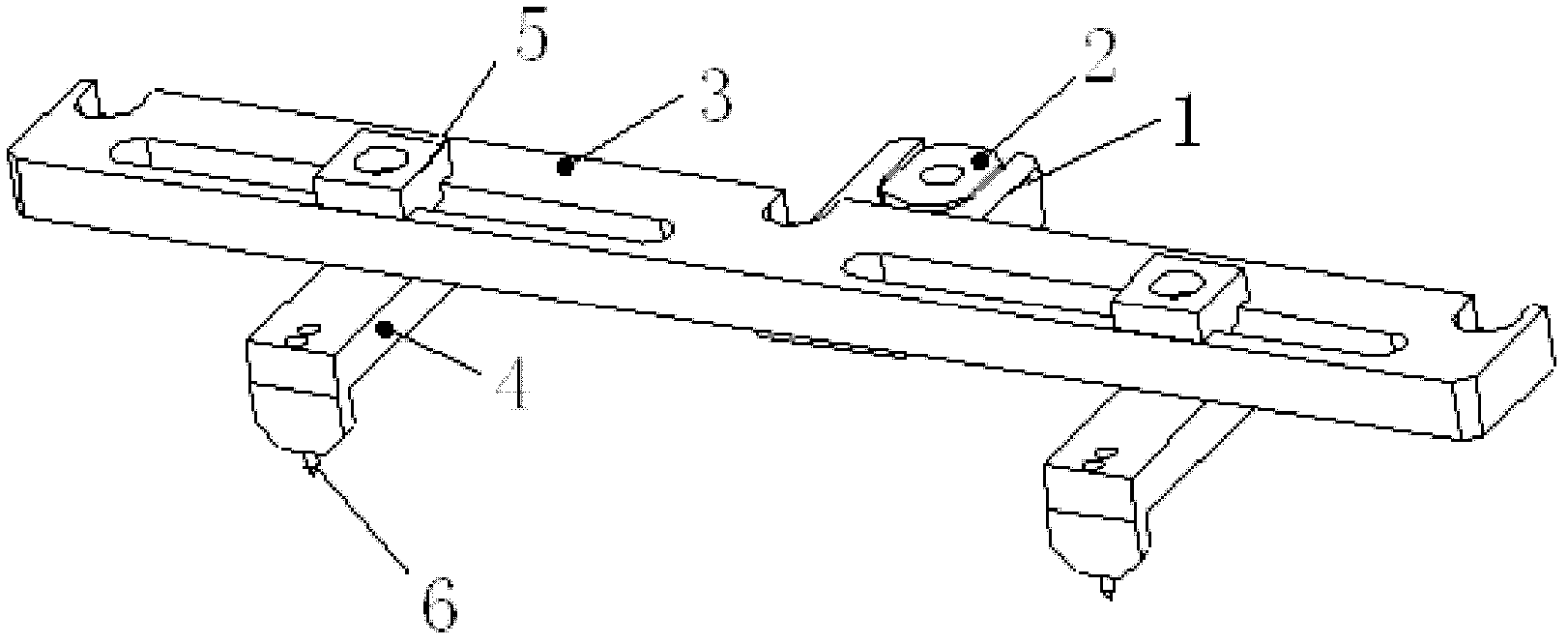

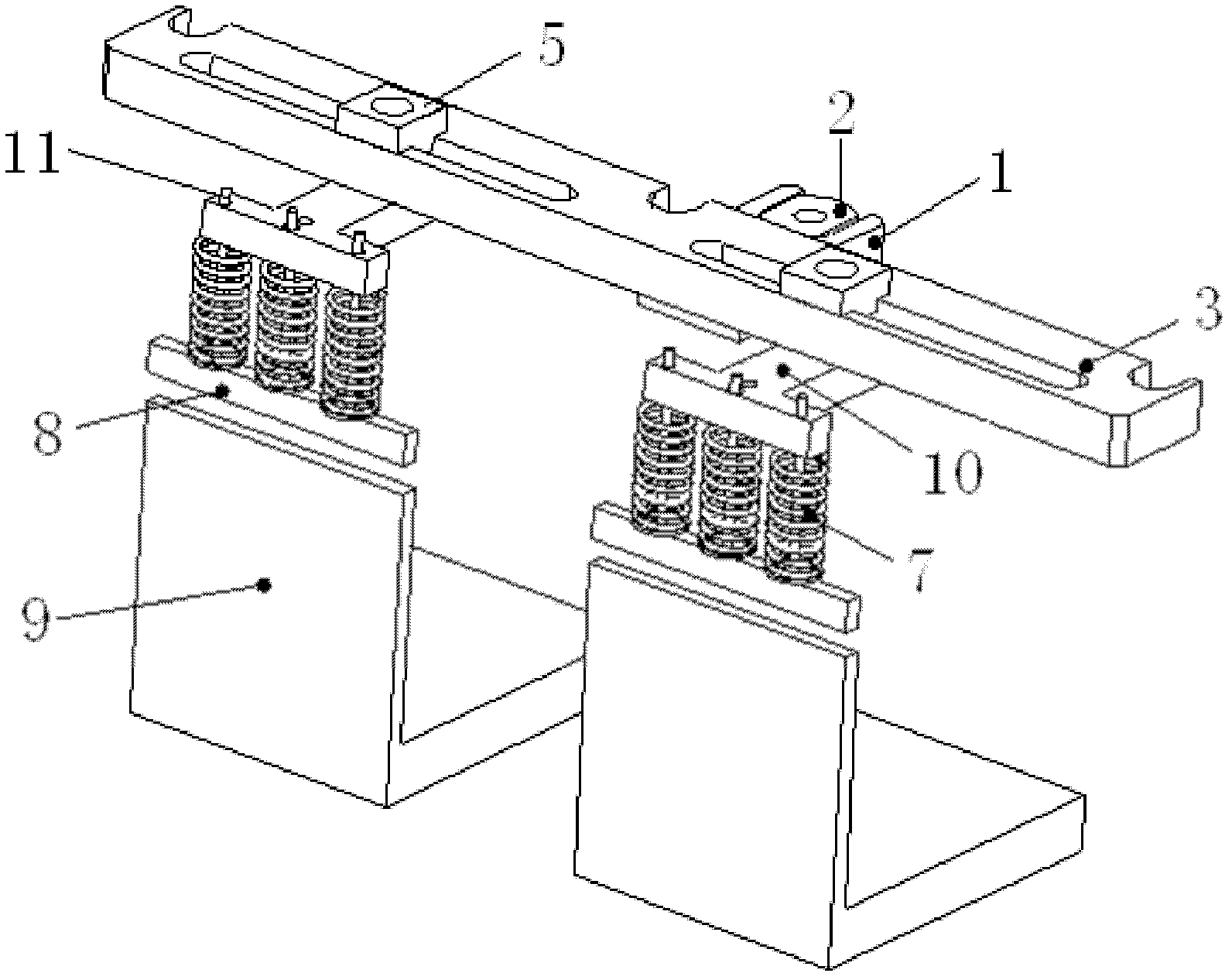

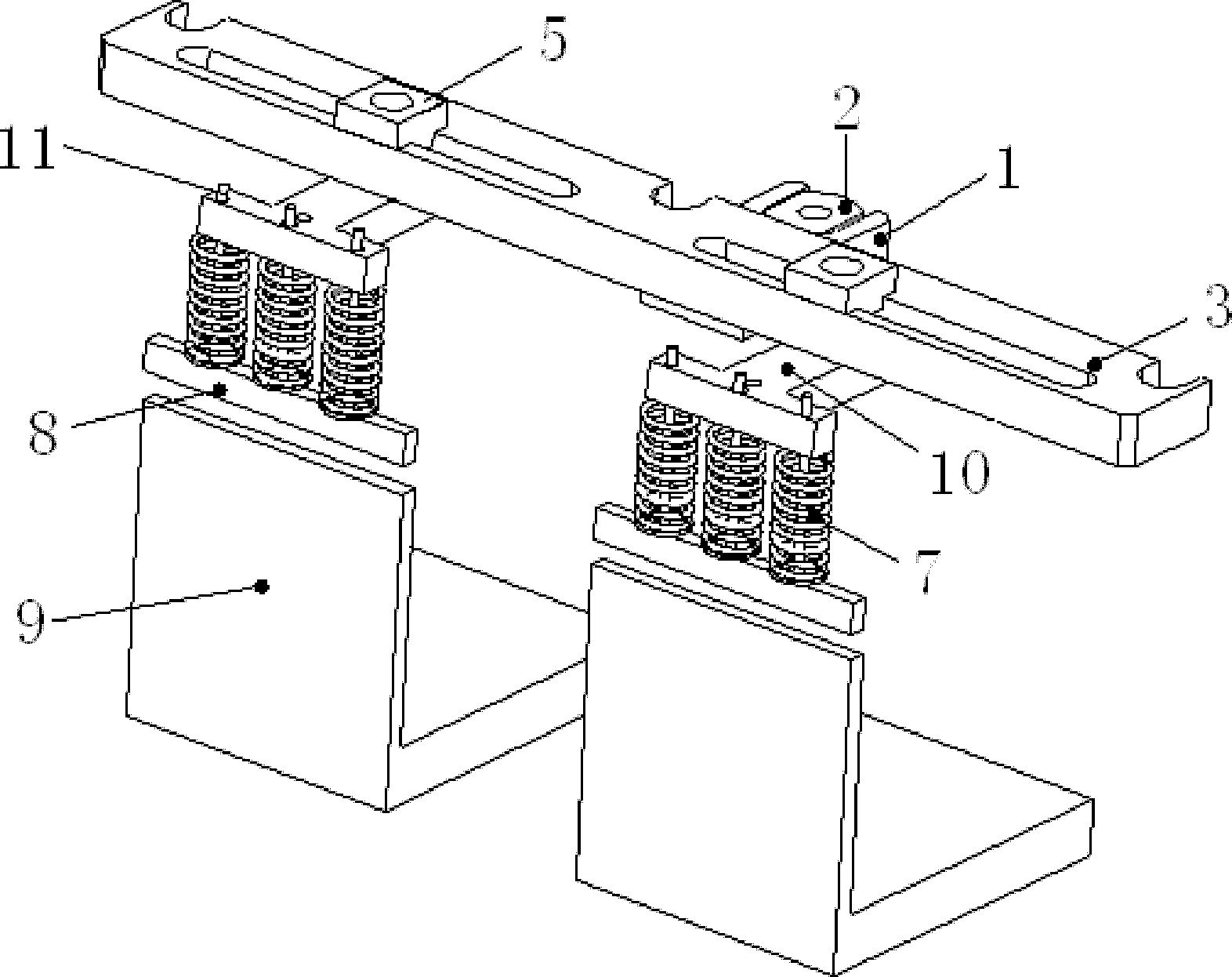

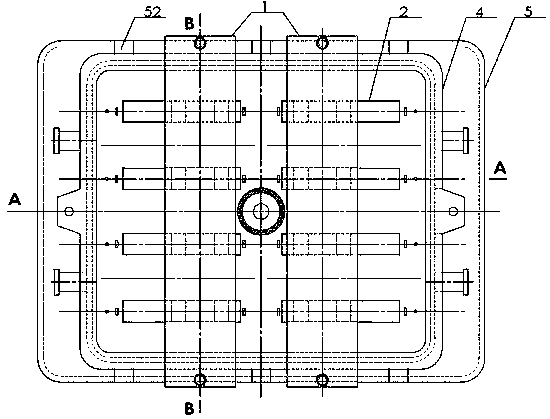

Mould weight fastening device and method for casting assembly line resin sand

PendingCN110293218AAvoid deformation defectsSimple structureMould handling equipmentsMoulding flasksEngineeringAssembly line

The invention discloses a mould weight fastening device and method for casting assembly line resin sand. The mould weight fastening device comprises cross beams, pressing plates, fixed blocks, sand boxes, casting bottom plates, movable box stops and bolt-stud fastening structures, wherein at least two groups of bolt-stud fastening structures are arranged on one side of each of the cross beams, thesand boxes and the casting bottom plates; the pressing plates can move along T-shaped grooves of the cross beams through the fixed blocks; the fixed blocks are fixedly connected with the pressing plates through fastening bolts; the pressing plates are directly pressed on casting cavities; air outlet sheets or risers of castings are avoided; and one end of each of studs takes the shape of a bent hook, and is tightly hung on a concave stop of the corresponding casting bottom plate. Through the cooperation of the cross beams with the movable pressing plates, the sand boxes and the casting bottomplates, the castings with the sand boxes are pressed by the bolt-stud fastening structures, the requirements of mould weights of different casting cavities of the assembly line are met, box lifting and deformation defects of the castings are effectively prevented, the quality and the production efficiency of the castings are improved, and the mould weight fastening device is simple in structure and convenient to operate, and has a satisfactory using effect.

Owner:溧阳市联华机械制造有限公司

Machining method for wind-power ground anchor bolt

The invention discloses a machining method for a wind-power ground anchor bolt. The machining method comprises the following steps that a, hardening and tempering heat treatment is conducted on an alloy steel bar according to technical requirements; b, threads are prepared at the two ends of the alloy steel bar after being subjected to heat treatment according to size requirements; c, anticorrosion treatment is conducted on the alloy steel bar with the threads; and d, a corresponding nut and a gasket which are matched according to requirements are assembled, and the required wind-power groundanchor bolt (1) is obtained. According to the machining method for the wind-power ground anchor bolt, possible deformation caused in the machining process is avoided, thermal stress in the bar is reduced, the service life of the bolt is improved, and finally, further protective measures to the bolt are taken.

Owner:宁波埃索伦能源有限公司

Chain crater detection method

ActiveCN109883834AJudge eligibilityAvoid deformation defectsMaterial strength using tensile/compressive forcesManufacturing technologyComputer science

The invention relates to the technical field of manufacturing of protection chains, and in particular relates to a chain crater detection method comprising the steps of S1, stamping a crater of a detection object; and S2, detecting the position of the crater of the detection object, and if the position of the crater of the detection object is cracked, it indicates that the crater is detected to beunqualified. In the technical scheme, the position of the crater of the detection object is stamped, if the crater of the detection object is welded by one or more of cold solder joint and dry joint,the position of the crater is wholly cracked. Therefore, whether the crater is qualified can be easily judged. The defect that when the tensile test mode is used, the detection object needs to be prevented from being deformed under the effect of the tensile force is avoided, and the condition that the detection object flies out and causes a safety accident during a detection process is avoided.

Owner:DEQING GENERAL IND CO LTD

Dual-pulley pathway mechanism for medical suspension bridge

InactiveCN105167859AImprove bearing capacityImprove balanceDiagnosticsSurgeryEngineeringMedical device

The invention discloses a dual-pulley pathway mechanism for a medical suspension bridge, and belongs to the field of medical equipment. The pathway mechanism comprises a guide rail and a sliding base which is arranged on the guide rail, wherein the cross section of the sliding base is of a U-shaped structure; two pulleys are respectively arranged on the inner and outer edges of two sides of the sliding base; chutes, which correspond to the pulleys, are respectively formed in two sides of the guide rail; and the pulleys are matched with the chutes and are capable of sliding along the chutes. The pulleys, which are arranged on the inner and outer edges of two sides of the sliding base, are operated in a mode of being matched with the chutes, and two sides of the sliding base are simultaneously exerted uniformly, so that the overall bearing capacity and balancing capacity of the sliding base are improved; therefore, the pathway mechanism can overcome the defect that the chute of the guide rail becomes deformed with the sliding of a single pulley, so as to improve the operating stability and reliability of the pathway mechanism.

Owner:NANJING PERFCARE MEDICAL EQUIP

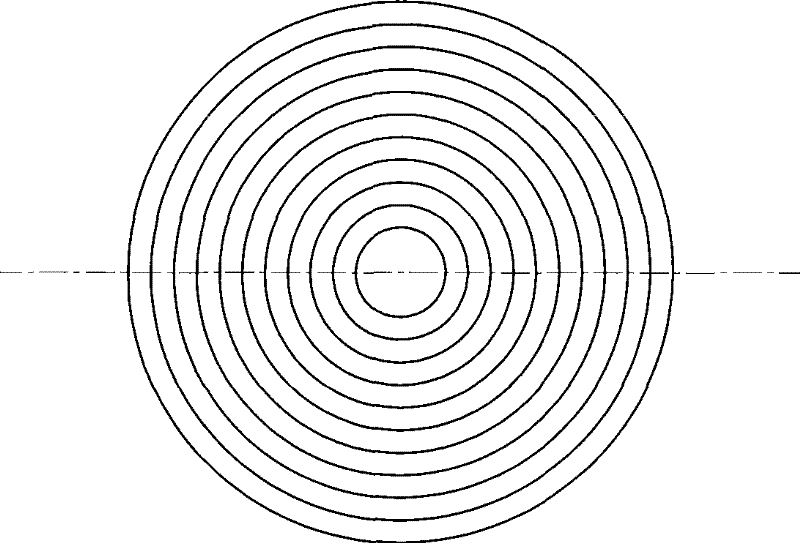

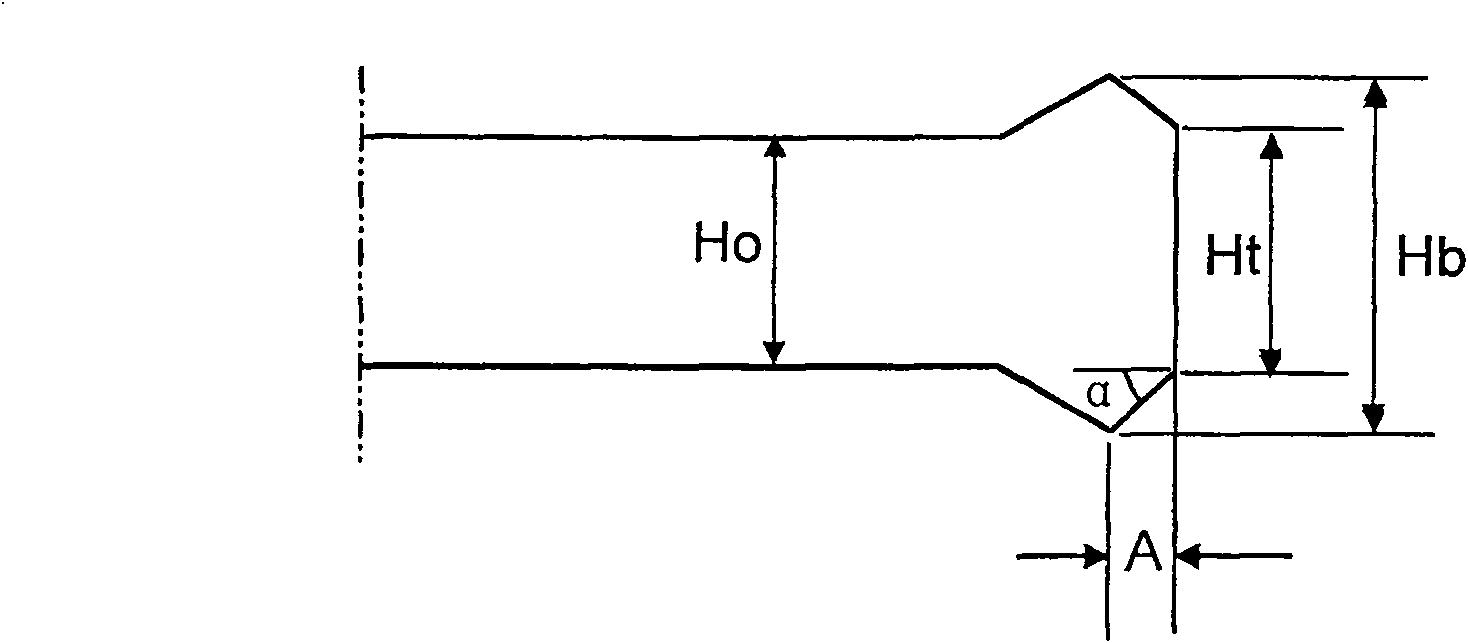

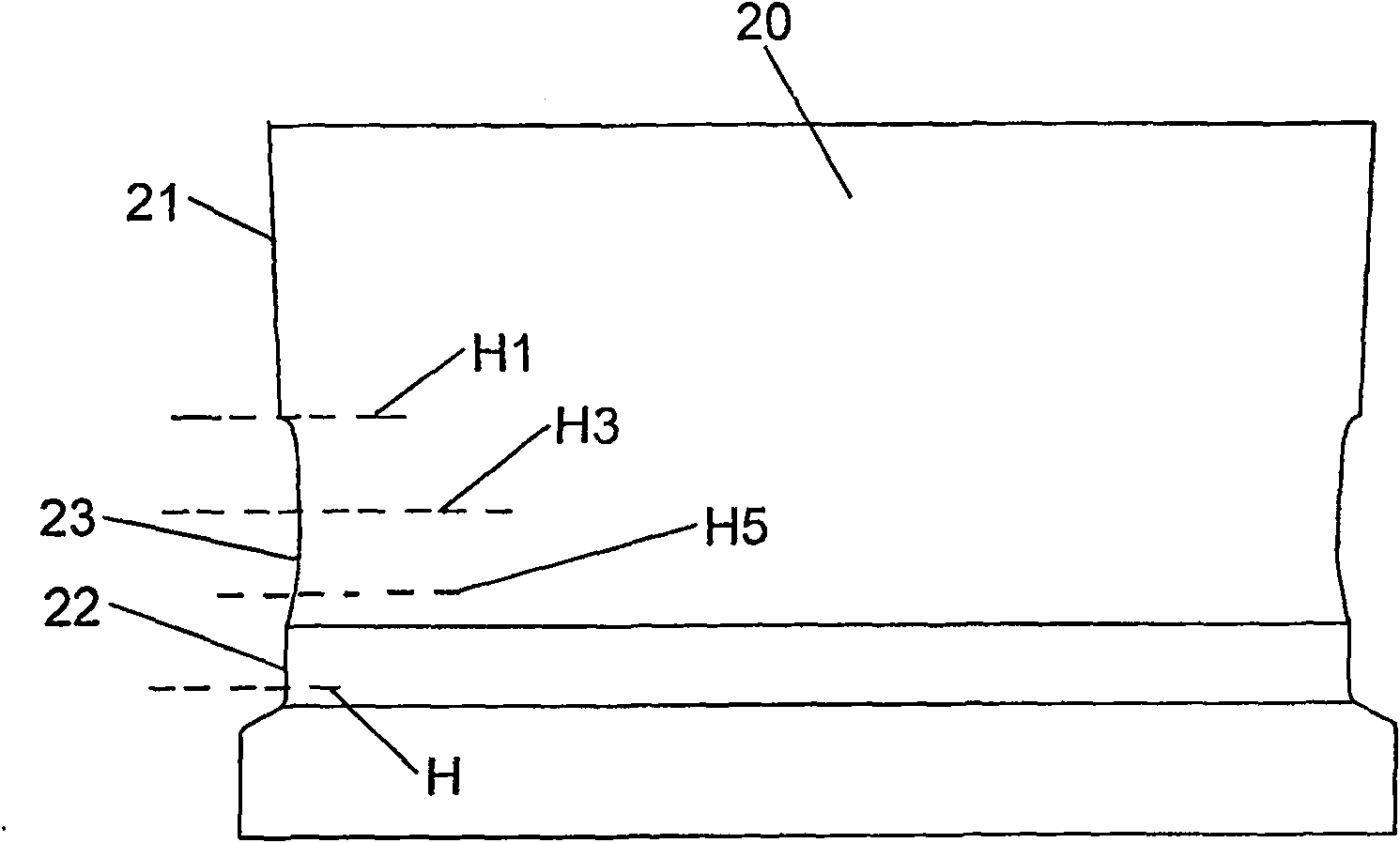

Vertical roll of vertical edger and design method thereof

InactiveCN100593442CReduced Peak Height RequirementsMaintain lateral pressureRollsMetal rolling arrangementsPeak valueEngineering

The invention discloses a vertical roller used for a vertical edger; roller edges at the two sides of the vertical roller are symmetric correspondingly to a central vertical shaft of the vertical roller; the roller edges at the two sides comprise three sections: an upper section, a middle section and a lower section; wherein, the upper section is an inclined line, the lower section is a vertical line and the middle section is an arc which is concave towards the internal side of the roller; the upper end and the lower end of the arc are respectively connected with the inclined line and the vertical line. The invention also discloses a design method used for the vertical roller of the vertical edger. By changing the shape of the roller edges at the two sides of the vertical roller, the widthside pressure quantity can be reduced and the requirement of peak value height of dog bone can be reduced; furthermore, in the horizontal direction, the dog bone on the upper surface of the blank wholly generates displacement towards external side so as to cause the width reduction quantity of the upper surface and the lower surface of the blank to be consistent, thus effectively controlling a slot and causing the slot to comply with the standard; furthermore, a side pressure angle is still formed, thus keeping the side pressure capability on the blank and preventing the warping of the blank.The parabola at the middle section of the roller edge is connected with the joint of the inclined line of the upper section and the vertical line of the lower section smoothly, thus preventing the defect that the blank generates the deformation during the rolling process.

Owner:BAOSHAN IRON & STEEL CO LTD

A ceramic energy-saving kiln with high-efficiency relay recovery of cooling waste heat

ActiveCN106440836BReduce pollutionReduce fuel consumptionEnergy industryIncreasing energy efficiencyAir blowerSlow cooling

The invention discloses a ceramic energy-saving kiln for recovering cooling waste heat in high-efficiency relay. Hot air blower; the slow cooling area is equipped with a slow cooling area outlet pipe, multiple slow cooling area air supply pipe groups, multiple slow cooling area outlet pipe groups, slow cooling area exhaust pipes and heat exchange fans; the rapid cooling area is equipped with Combustion-supporting fan, air supply supervisor and burner, the air supply supervisor is equipped with air supply pipe group in quenching area and air outlet pipe group in quenching area. By adopting the present invention, a pipeline structure for recovering hot air is formed in an efficient continuous and relay manner, and all the cooling heat when cooling ceramics at each stage is recycled and utilized, which significantly reduces the fuel consumption in the drying and firing process, and can also effectively reduce the impact of heat sources on Environmental pollution can also improve product quality.

Owner:DLT TECH CO LTD

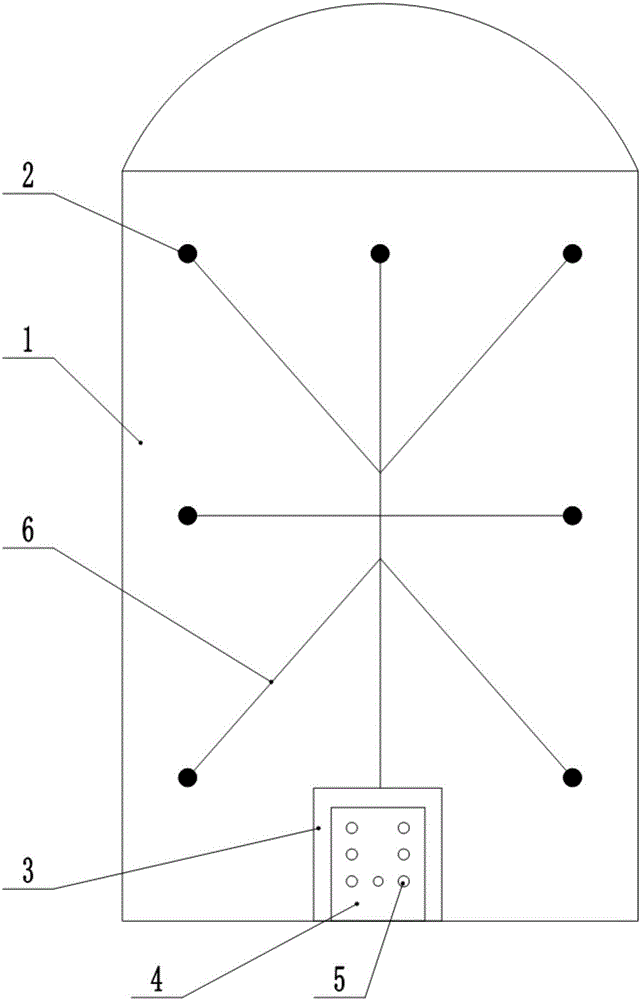

Method for cleaning powder plate of sweet potato vermicelli extruding device and device for cooking powder plate

ActiveCN103433253BAvoid deformation defectsAvoid corrosion and rust defectsCleaning processes and apparatusPotato starchProcess engineering

The invention discloses a method for cleaning a vermicelli plate of a sweet potato vermicelli extrusion device. The method comprises the following steps and conditions: a. cooking the vermicelli plate: placing the vermicelli plate, to which sweet potato starch is adhered, on a bracket in a vermicelli plate cooking barrel, adding edible oil into the vermicelli plate cooking barrel until the vermicelli plate can be covered by the edible oil completely, heating and cooking at the oil temperature of 180 to 220 DEG C for 20 to 40 minutes; b. roasting the vermicelli plate: taking out of the vermicelli plate which is treated in step a, placing the vermicelli plate on an electric furnace, roasting for 10 to 15 minutes, and then cooling; c. washing and brushing the vermicelli plate: washing and brushing the vermicelli plate which is treated in step b in water for 5 to 10 minutes, so that ashed sweet potato powder in vermicelli plate holes are completely separated from the vermicelli plate; d. cleaning the vermicelli plate: cleaning the vermicelli plate which is treated in step c with clean water for 1 to 2 minutes; e. air-drying the vermicelli plate: naturally air-drying the vermicelli plat which is treated in step d for later use. The invention also discloses a vermicelli plate cooking device for implementing the method.

Owner:HUNAN YUXIANG FOODS

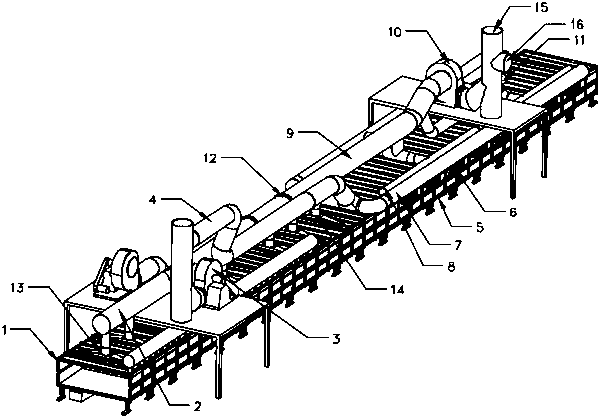

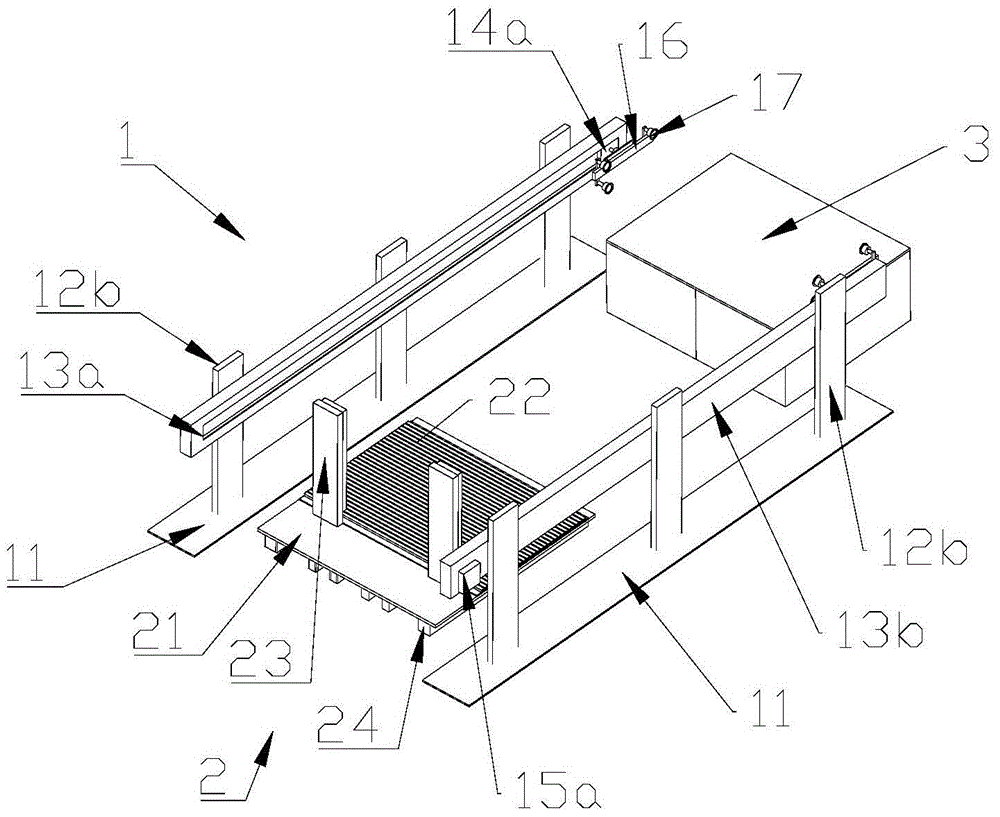

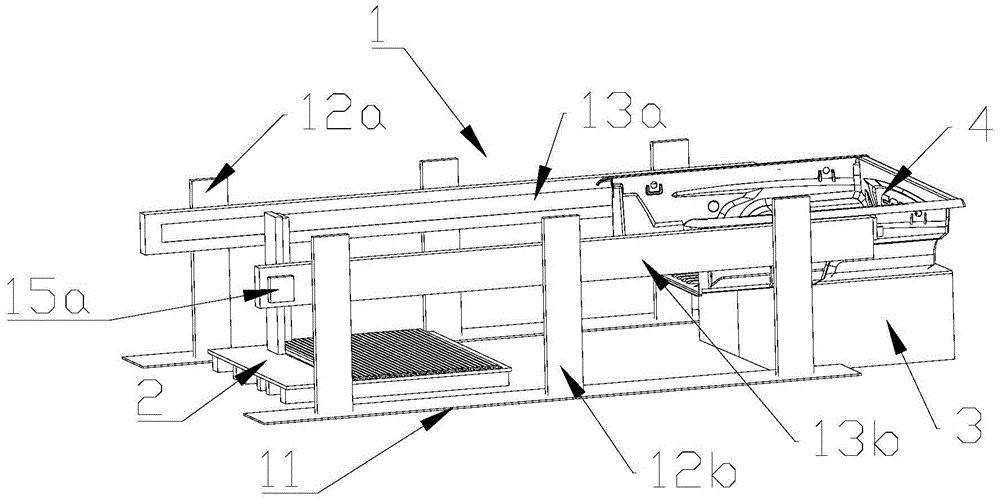

Palletizing equipment for stacking cargo boxes

ActiveCN104843493BImprove work efficiencyAvoid deformation defectsStacking articlesMechanical engineering

The invention discloses a stacking device for stacking cargo box covers. The stacking device comprises a flat conveying device, a turning conveying device and a storage device. The flat conveying device is used for keeping the cargo box covers in the original state and conveying the cargo box covers to the turning conveying device. The turning conveying device comprises a clamping piece capable of clamping the cargo box covers in a releasable mode, the clamping piece can move to the storage device from the flat conveying device in the direction parallel to the conveying direction of the flat conveying device and can rotate the cargo box covers into the vertical state in which the cargo box covers are perpendicular to the conveying direction of the flat conveying device from the original state so that the tails of the cargo box covers can face downwards. The storage device can move relative to the flat conveying device and the turning conveying device and is provided with a plurality of slots used for storing the cargo box covers in the vertical state in an insertion mode. By means of the stacking device, the loading efficiency of the cargo box covers is improved, and the damage and deformation of the cargo box covers in the process from production finishing to loading are avoided to the maximum degree.

Owner:BEIQI FOTON MOTOR CO LTD

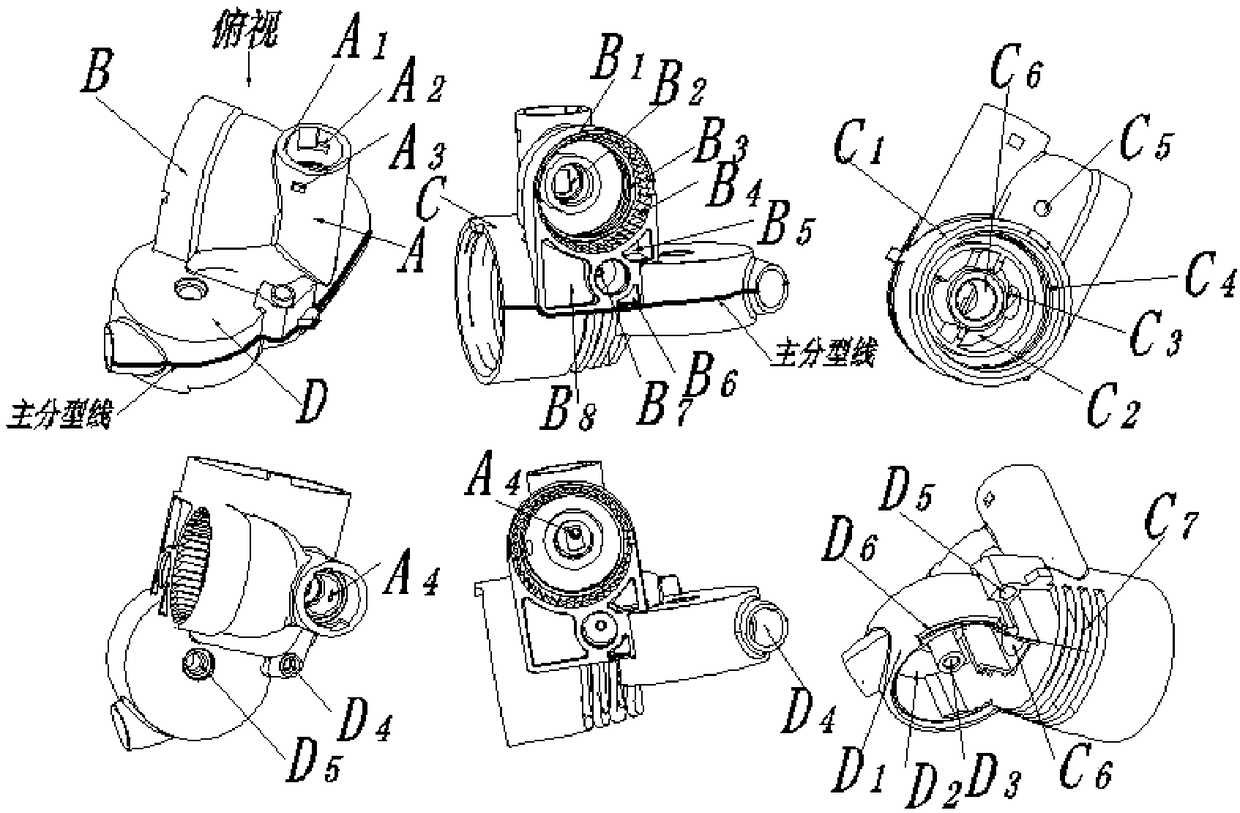

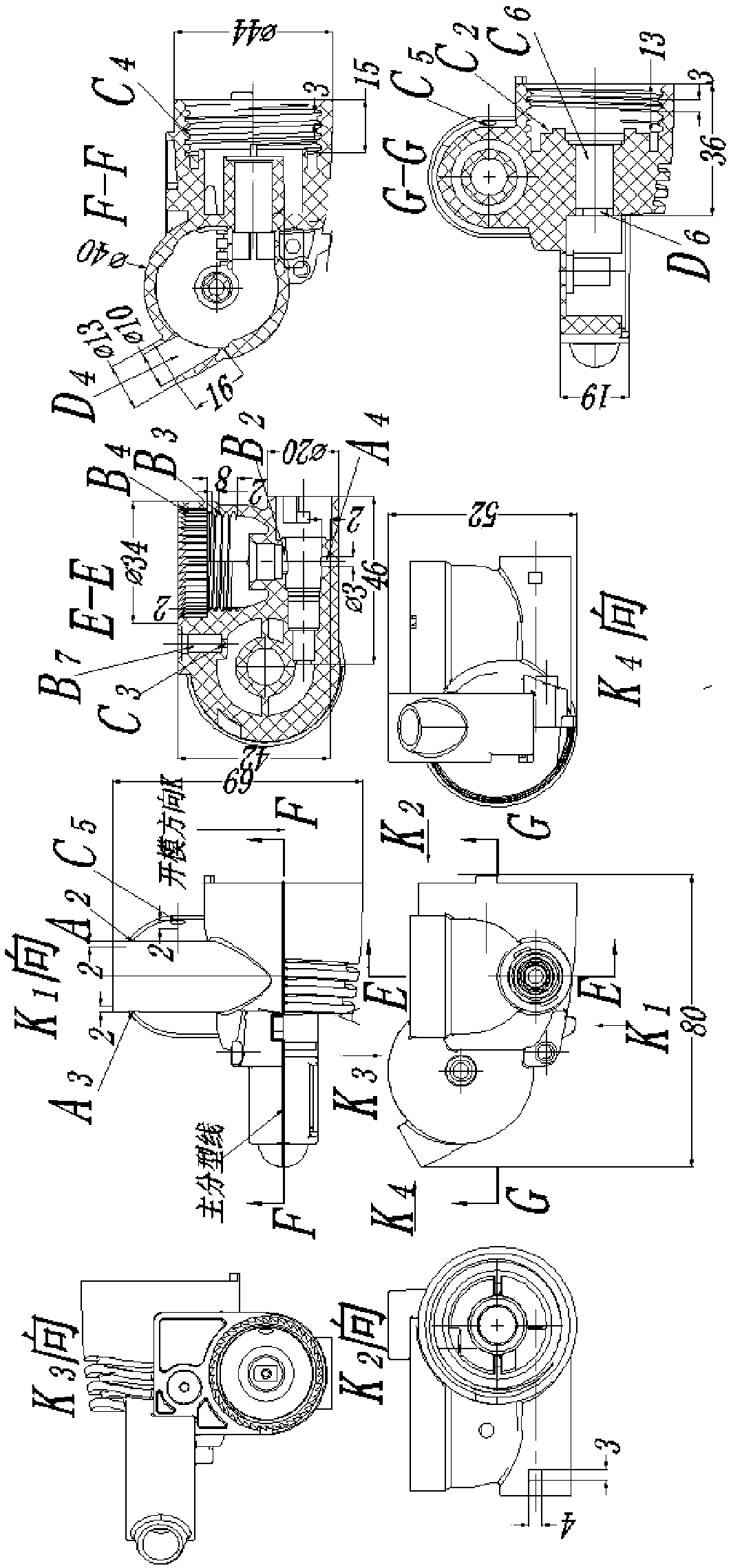

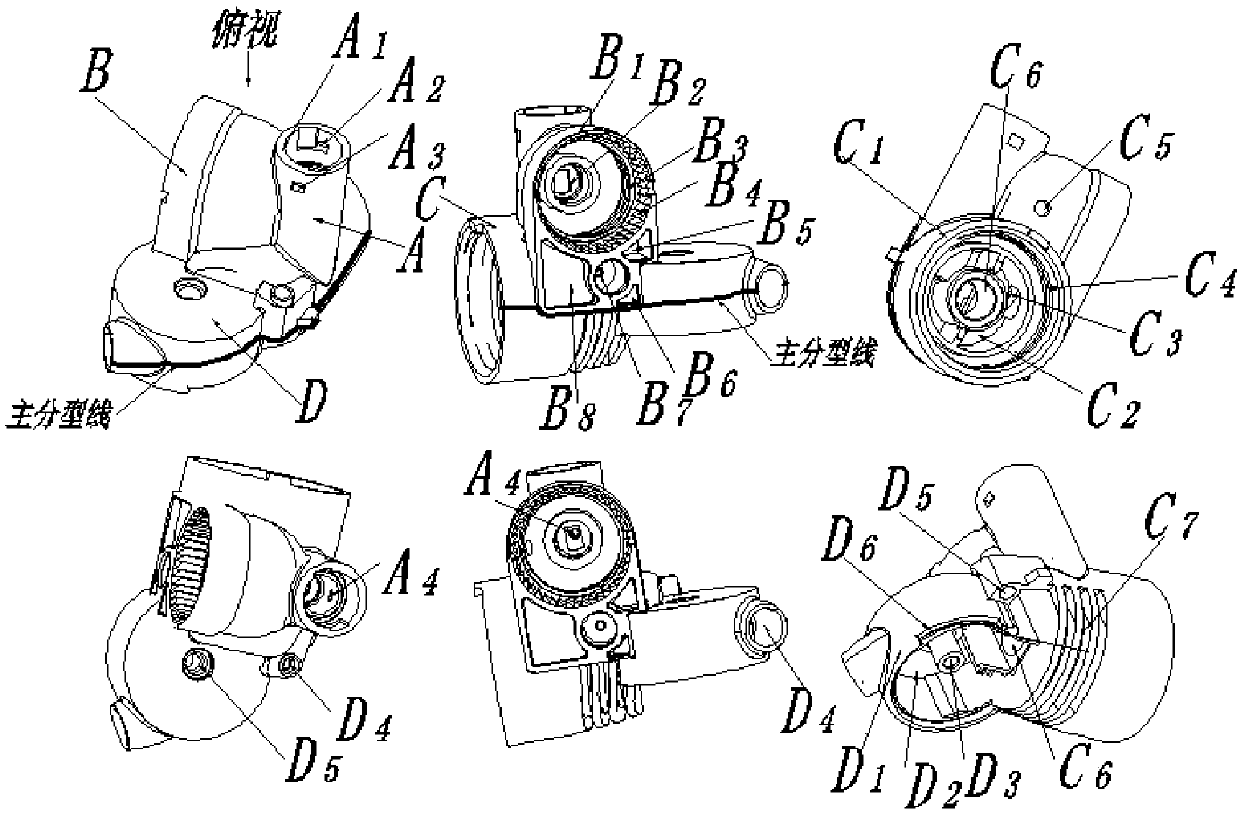

Medical infusion pump body and manufacturing method thereof

The invention provides a medical infusion pump body and a manufacturing method thereof. The medical infusion pump body is characterized in that an X thread mold core sleeves an X middle layer mold core, a driving gear is machined on the X thread mold core, X rack oil cylinder drives the X thread mold core to rotate through an X first transmission gear and an X second transmission gear, a thread lead of the X thread mold core is controlled by an X thread sleeve, when an X mechanism performs core pulling aiming at each feature of the feature C, firstly, the X rack oil cylinder drives the X thread mold core for thread de-molding, and then an X inclined guide column drives an X sliding block for lateral core pulling.

Owner:刘云梦

Temperature-measuring furnace door for thermal treatment furnace

InactiveCN106435095AAvoid deformation defectsSimple operation of temperature measurementFurnace typesHeat treatment process controlEngineeringThermal treatment

The invention relates to a temperature-measuring furnace door for a thermal treatment furnace. The temperature-measuring furnace door comprises a door body. A plurality of temperature measuring points are arranged on the door body. An opening is formed in the bottom of the door body. A temperature measuring plate is mounted at the opening. The temperature measuring plate is provided with detecting points corresponding to the temperature measuring points. The detecting points and the temperature measuring points are connected through temperature conductive wires. The temperature-measuring furnace door has the advantages that the temperature measuring plate is arranged at the lower opening, only the detecting points on the measuring plate need to be measured during detection, the furnace door needs not to be opened, temperature measuring operation is simple, and the defect of furnace door deformation can be avoided.

Owner:无锡市智锋金属科技有限公司

Piecewise heat treatment method of large pressure container

InactiveCN101684516BAvoid deformation defectsSmall amount of deformationFurnace typesHeat treatment furnacesCombustorEngineering

The invention discloses a piecewise heat treatment method of a large pressure container, which comprises the following steps: building a temporary combustion heating furnace near an installation site of the large pressure container; vertically installing the pressure container section into the combustion heating furnace, setting an inner cavity of the pressure container section into a hearth; butting a combustor with the bottom of the pressure container section; and combusting and heating the pressure container section by using the combustor. Compared with the traditional method for heat treatment by using an industrial furnace, the invention can improve the heat treatment speed to the pressure container section by building the temporary combustion heating furnace to perform the piecewiseheat treatment on the pressure container section.

Owner:傅家仁 +1

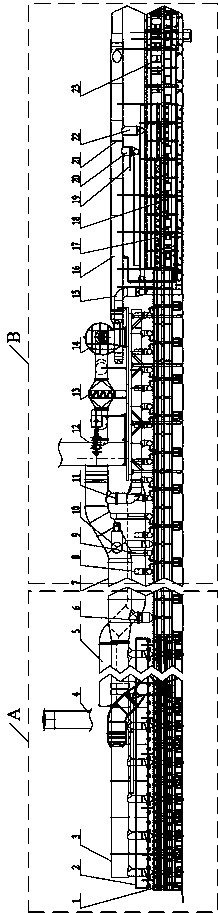

Truss Shearing Mechanism of Triangular Truss Production Line

The invention discloses a truss shearing mechanism of a triangular truss production line. The truss shearing mechanism of the triangular truss production line structurally comprises an upper shearing device and a lower shearing device. According to the upper shearing device, two upper shearing arms are hinged to an upper hinged shaft, upper scissors are installed at the corresponding ends of the upper shearing arms, the other end of each upper shearing arm is hinged to a crankshaft driving mechanism, and the crankshaft driving mechanism drives the two upper shearing arms to shear an upper spiral rib. The lower shearing device comprises two lower shearing arms, wherein the lower shearing arms are hinged to a first lower hinged shaft and a second lower hinged shaft respectively, lower scissors are installed at the corresponding ends of the lower shearing arms, the other ends of the lower shearing arms are hinged to the two sides of the crankshaft driving mechanism, and the crankshaft driving mechanism drives the two lower shearing arms to shear a lower spiral rib. The truss shearing mechanism of the triangular truss production line has the advantages that power is low, impact on a power grid is low, the structure is simple, and the cost is low; the phenomenon that the two pairs of scissors collide with each other is avoided, the service life is long, and the quality of a sheared truss is improved; a cut of the lower spiral rib is flat after the lower spiral rib is sheared, and the phenomenon that due to the fact that the width of the inner side of the triangular truss becomes narrower, the defect of deformation of the triangular truss is avoided.

Owner:TJK MACHINERY TIANJIN

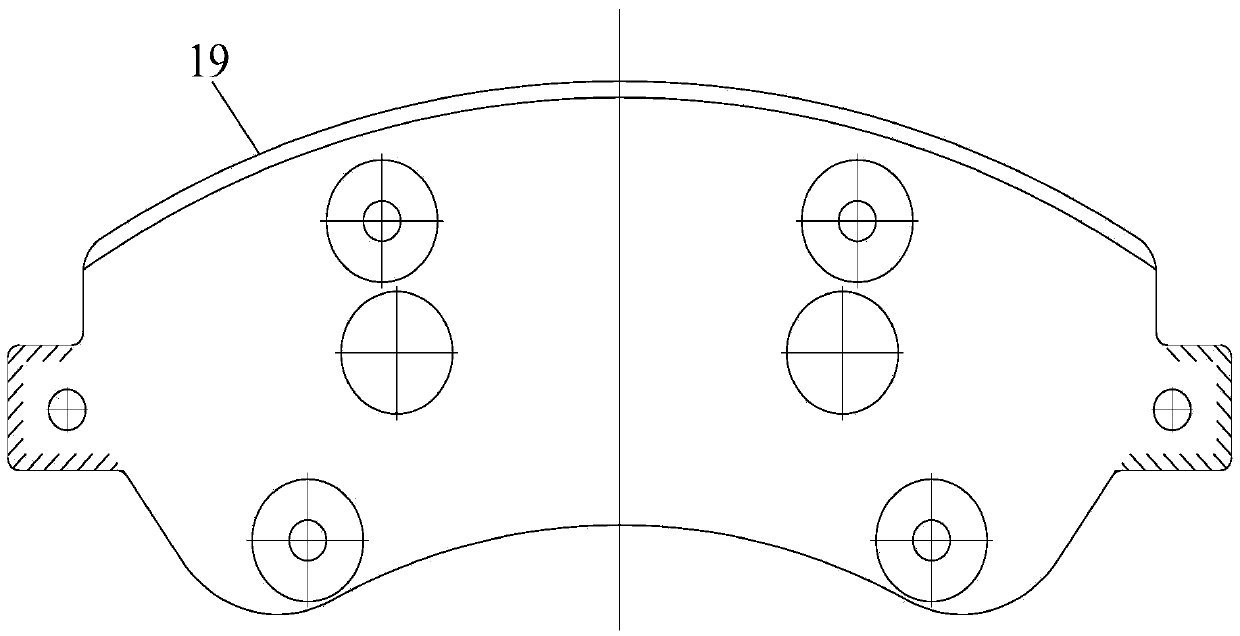

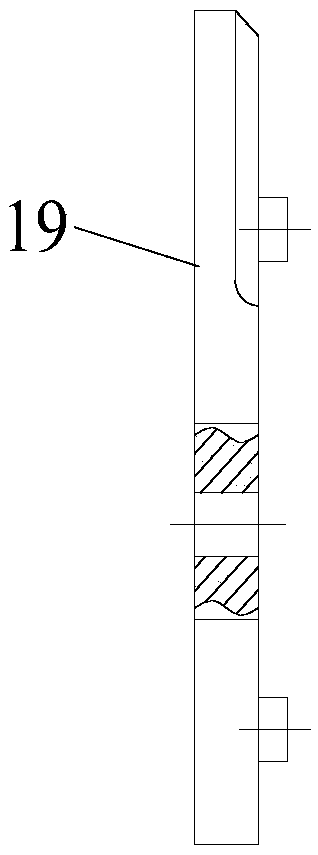

Steel back pressure hypotenuse fine blanking continuous die and steel back production method

Owner:韶关德嘉汽车零部件有限公司

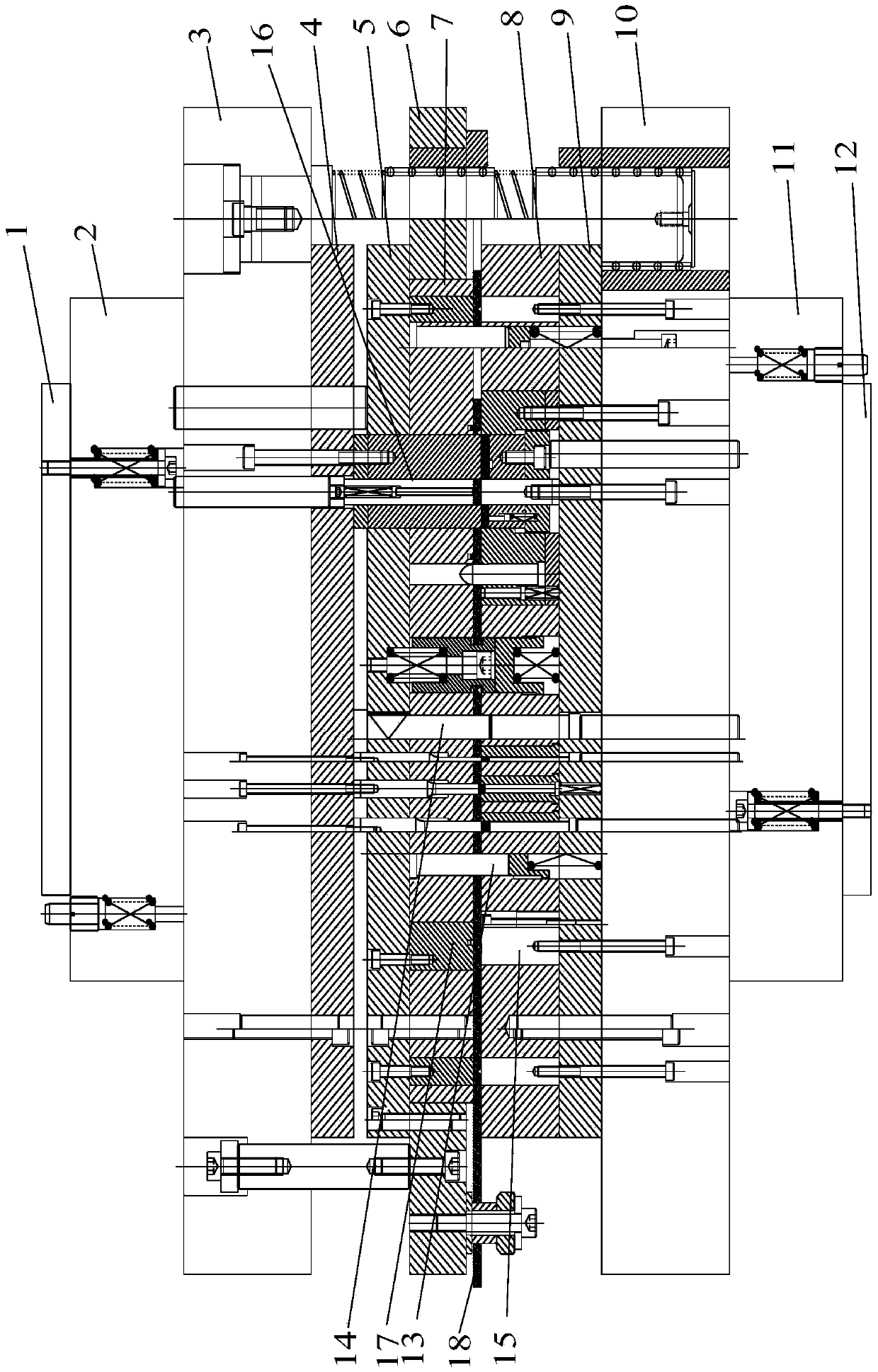

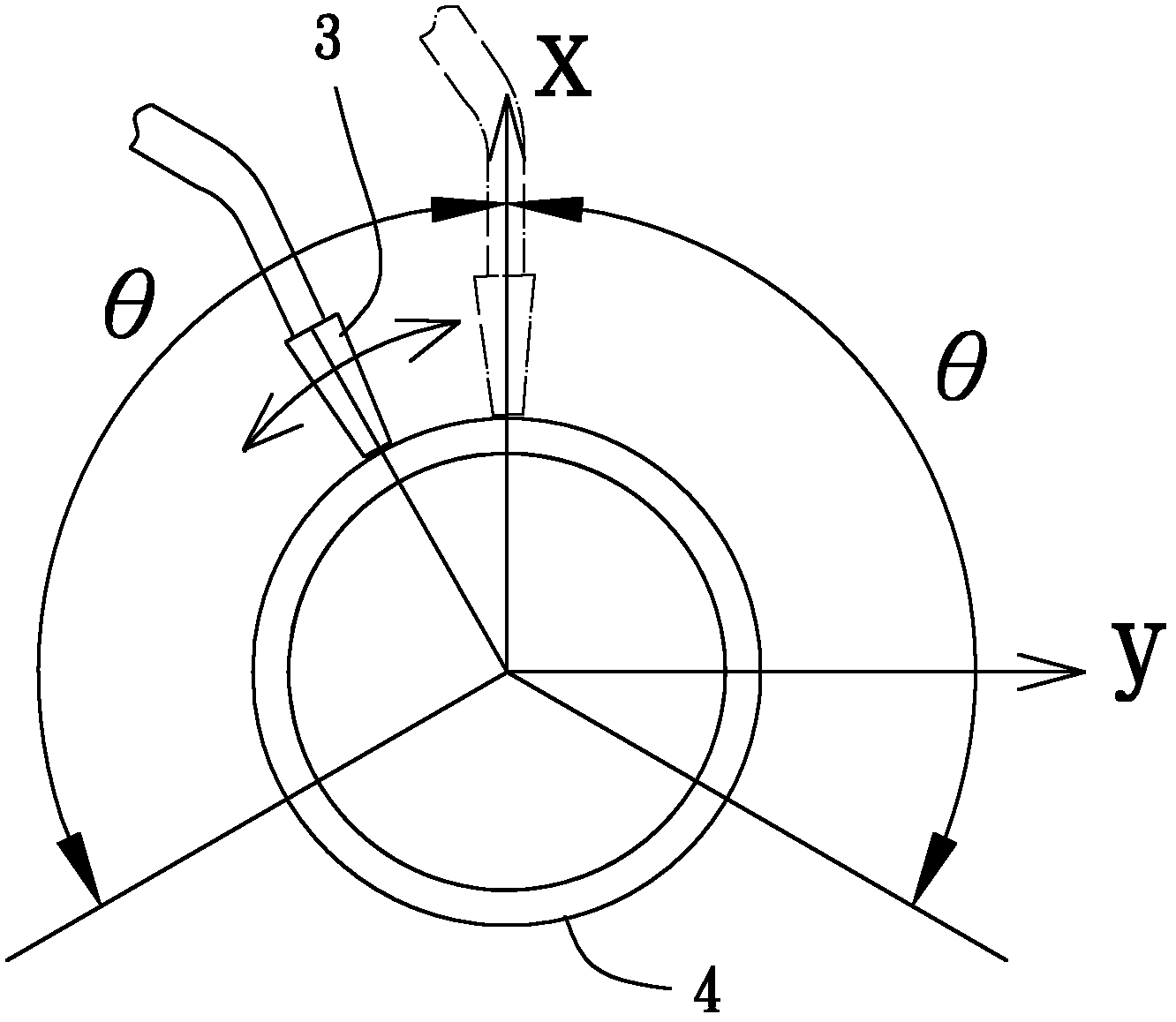

Automatic welding method

Owner:METAL INDS RES & DEV CENT

Cutting machine for metal tube

ActiveCN101920359BAvoid chamfersAvoid deformation defectsMetal sawing devicesEngineeringMechanical engineering

The invention discloses a cutting machine for a metal tube, which comprises a lengthwise base, wherein, a first support and a second support for supporting the metal tube are oppositely and horizontally arranged on two ends of the base. The cutting machine is characterized in that a box is movably arranged on the base and positioned between the first support and the second support; the metal tubecan penetrate into the box from one side thereof and penetrate out of the box from the other side thereof; the box is internally equipped with a first fixture and a second fixture at an interval for clamping the metal tube; and a cutting device is arranged in a spacing area between the first fixture and the second fixture. When the cutting machine using the structure is used for cutting the metaltube, the cutting device can horizontally move with the metal tube synchronously and complete cutting the metal tube during the movement process of the metal tube so as to effectively prevent the metal tube from being bevelled and deformed.

Owner:BAOLAI STAINLESS STEEL TECH (KUNSHAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com