Piston type medium-frequency air pressure sensor detection device

An air pressure sensor and detection device technology, which is applied to measurement devices, vibration measurement in fluids, instruments, etc., can solve problems such as low efficiency and accuracy, low frequency bandwidth to be measured, and difficulty in rapid delivery detection, so as to avoid safety problems, Improved handling comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

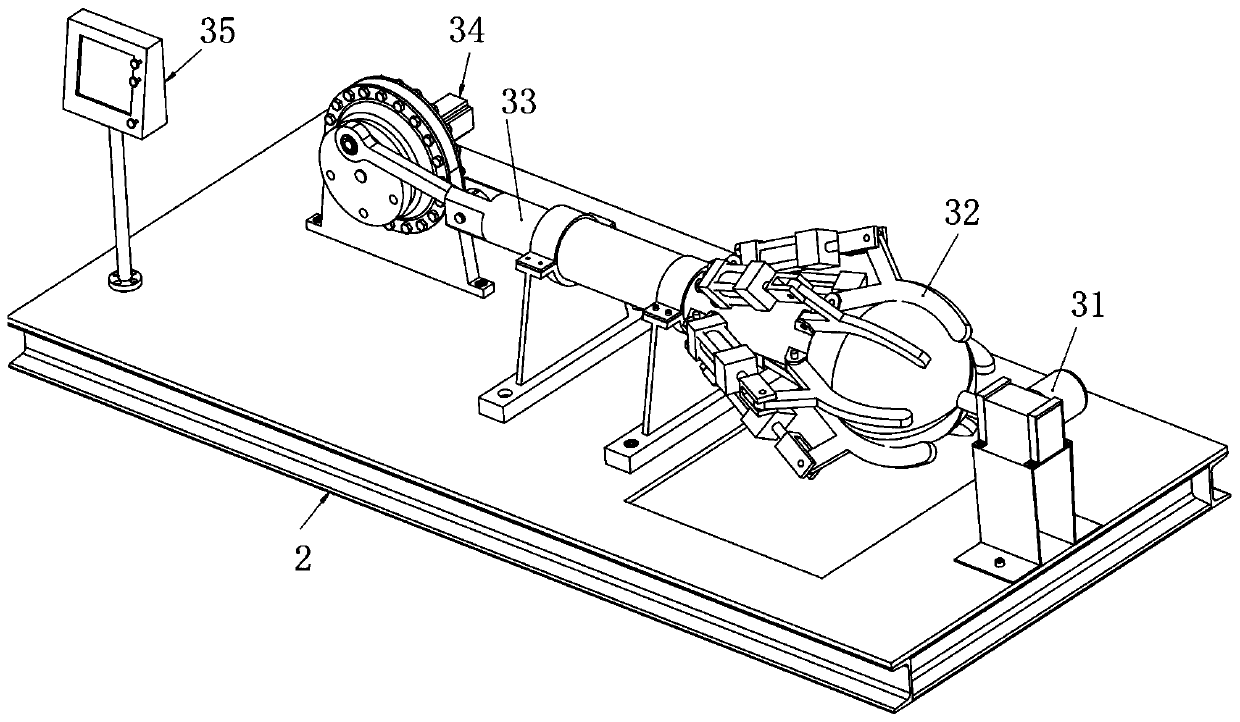

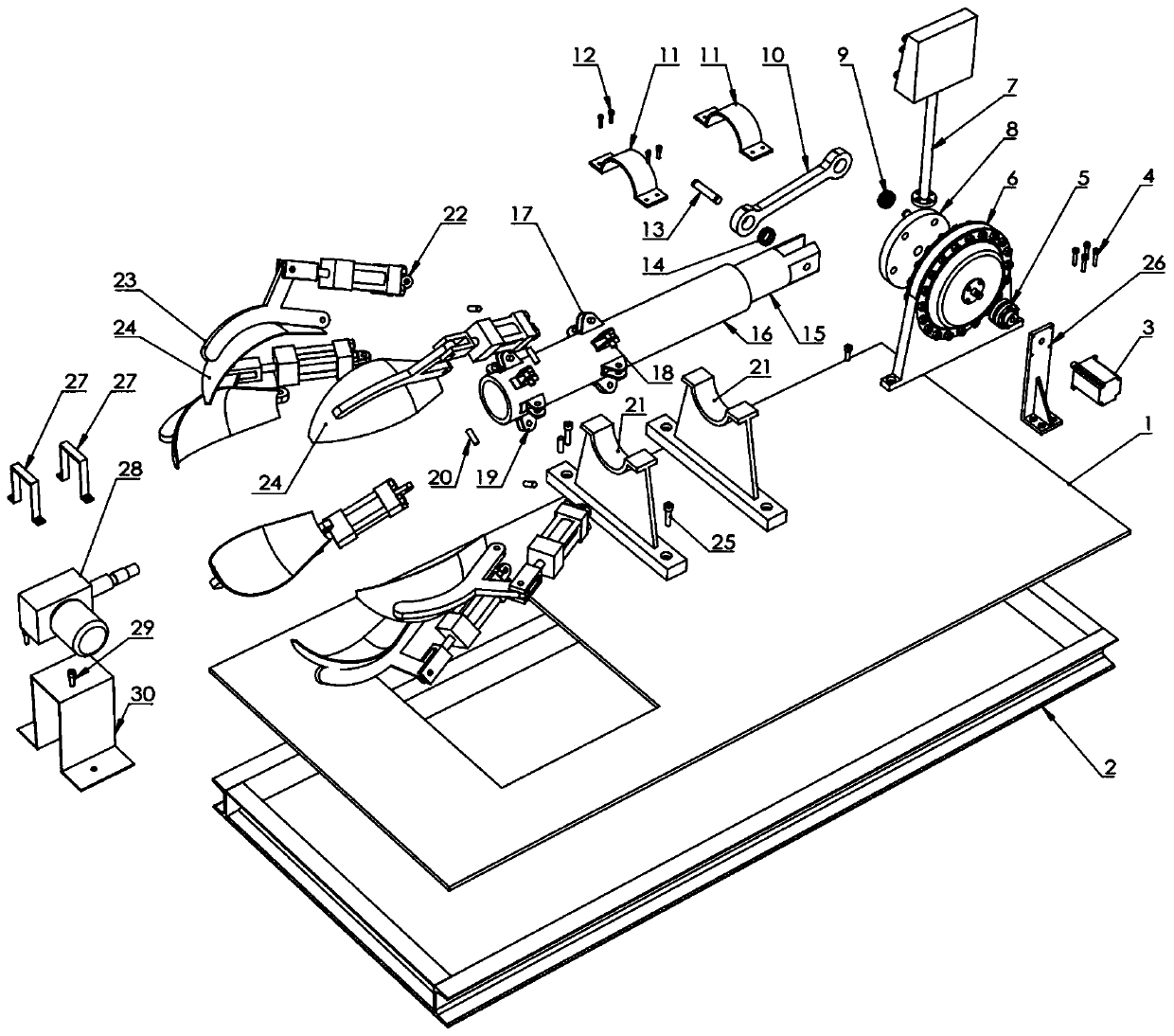

[0021] figure 1 It is an assembly diagram of the piston-type high-frequency air pressure sensor detection system. It can be seen from the figure that the system is mainly composed of the base 2, the numerical control display system 35, the motor-speed increaser assembly 34, the piston-connecting rod-cylinder assembly 33, the opening width The control assembly 32 and the sensor assembly 31 are composed of parts.

[0022] The numerical control display system is used to display various parameter information such as the current system operating status and pressure frequency, and is responsible for the overall control of the system. The motor-gearbox assembly is used to adjust the movement speed of the piston, which is the power source for generating the test air pressure frequency, and different test frequency requirements can be realized by adjusting the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com