Device and method for detecting N-type silicon on edge of polysilicon wafer

A detection device, polysilicon technology, applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of large instrument operation test errors, inability to ensure PN removal at the edge of silicon wafers, uneconomical test operations, etc. Achieve the effect of simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

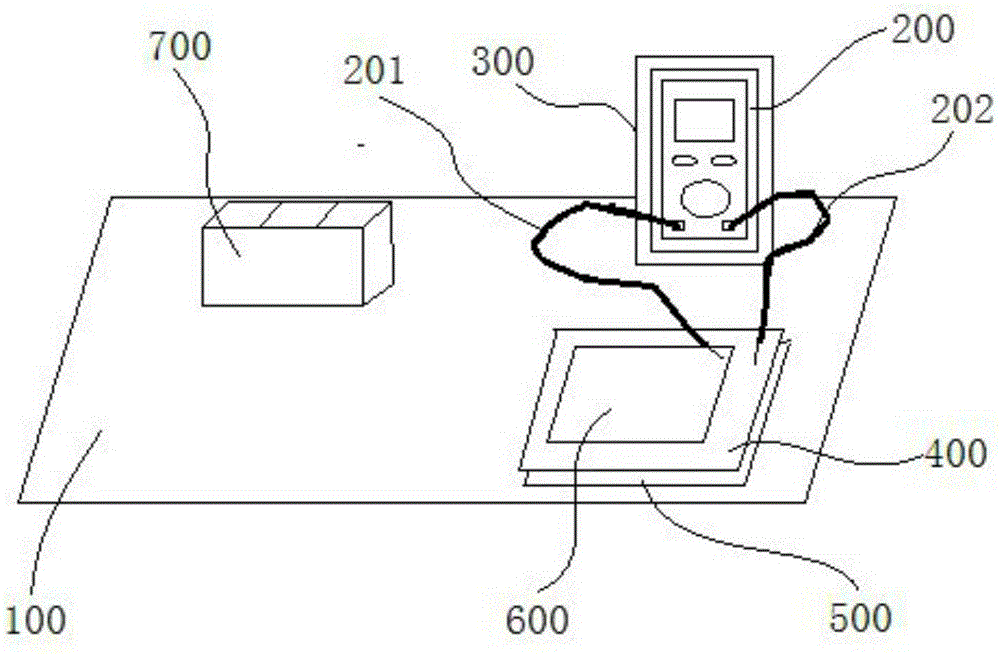

[0014] Such as figure 1 The N-type silicon detection device at the edge of the polycrystalline silicon wafer of the present invention includes an operating platform 100, a multimeter 200, a multimeter fixed bracket 300, a red copper sheet 400 and a red copper sheet support frame 500; the multimeter fixed bracket 300 and the red copper sheet support frame 500 are set On the operating platform 100, the multimeter 200 is fixed on the multimeter fixing bracket 300, the copper sheet 400 is placed flat on the copper sheet support frame 500, and the silicon wafer 600 to be tested is placed flat on the copper sheet 400; the operating platform 100 is also provided with a A silicon wafer storage box 700 for placing the silicon wafer to be tested.

[0015] The method for detecting N-type silicon o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com