Method for sensing stability of acid tank and reaction tank

A technology of stability and reaction tank, applied in the field of detection, can solve problems such as uneven thickness, and achieve the effect of avoiding poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

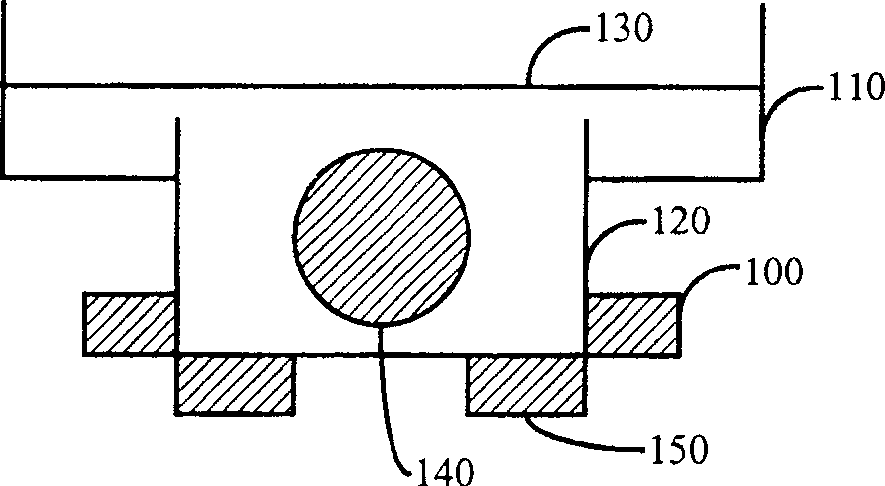

Image

Examples

no. 1 example

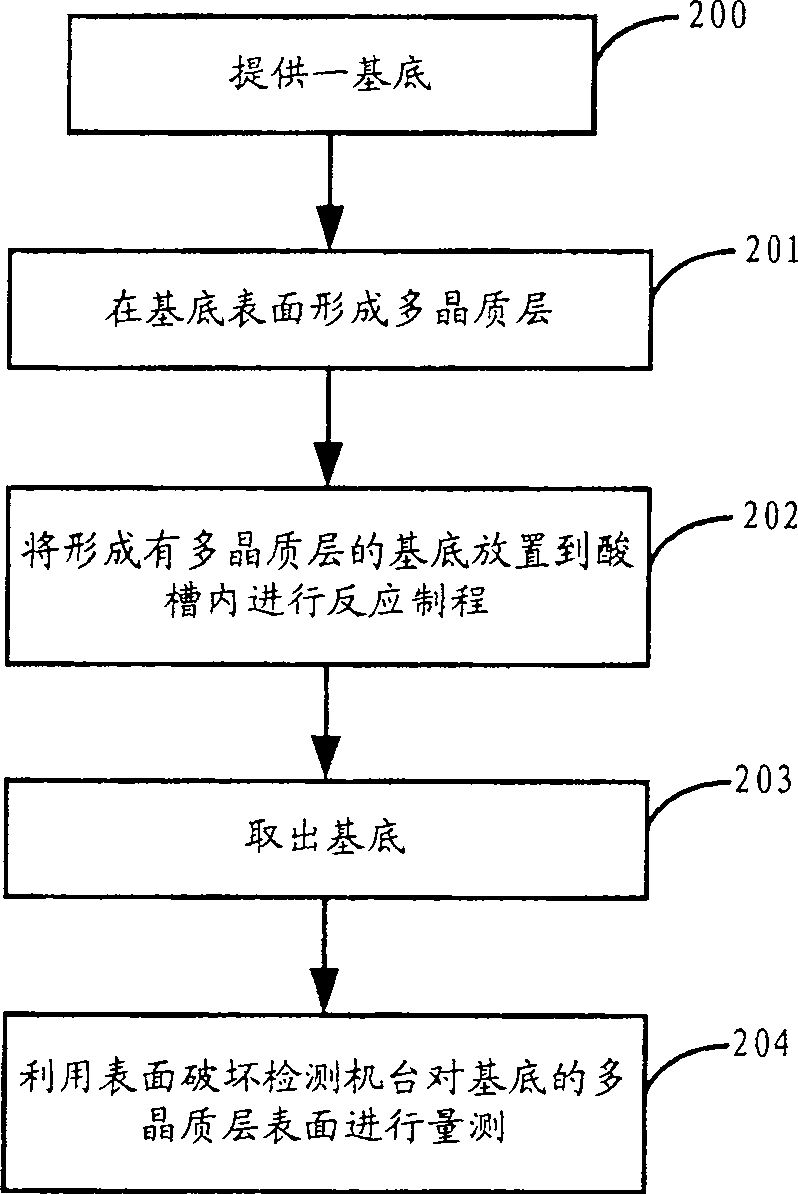

[0024] Such as figure 2 Shown is a diagram of the acid tank stability detection steps according to the first embodiment of the present invention. Please refer to figure 2 , first in step 200, a substrate is provided. Next, in step 201 , a polycrystalline layer is formed on the surface of the substrate, wherein the polycrystalline layer includes, for example, a polysilicon layer and a metal layer. Then in step 202, the substrate formed with the polycrystalline layer is placed in an acid tank to perform the reaction process, wherein the acid tank includes, for example, a phosphoric acid reaction tank. Then in step 203, the substrate is taken out. Then in step 204, the surface of the polycrystalline layer of the substrate is measured by using a surface damage detection machine, such as E500 manufactured by Thermo Wave Company, to determine the stability of the acid tank. The surface damage detection machine uses a light source to shine on the surface of the polycrystalline ...

no. 2 example

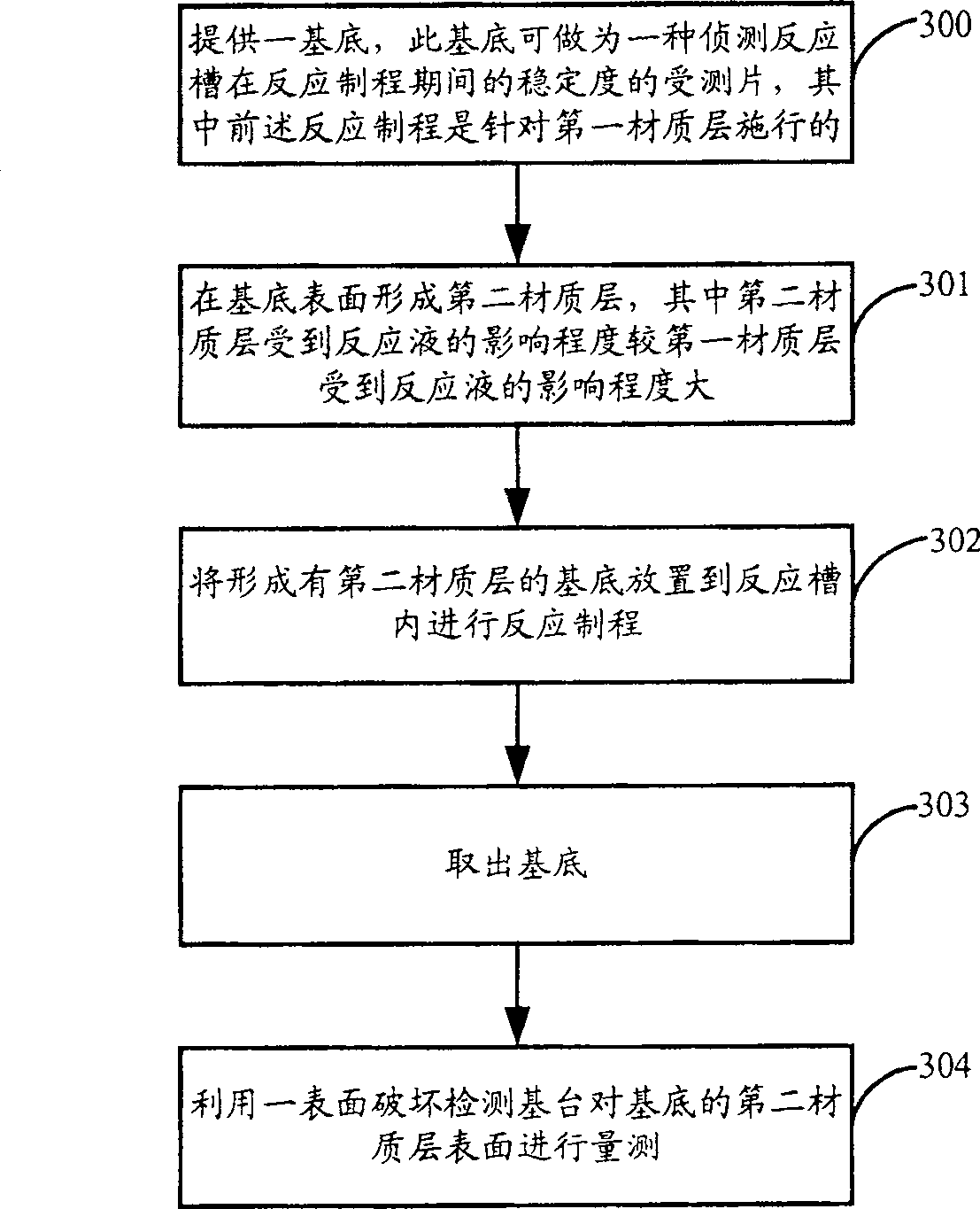

[0026] Such as image 3 Shown is a step diagram of detecting the stability of the reaction tank according to the second embodiment of the present invention. This embodiment is suitable for detecting the stability of a reaction tank with a reaction solution during a reaction process, wherein the reaction process is assumed to be performed on a first material layer, and the first material layer includes, for example, a silicon nitride layer. Please refer to image 3 Firstly, in step 300, a substrate is provided, and the substrate can be used as a test piece for detecting the stability of the reaction tank during the reaction process. Then in step 301, a second material layer is formed on the surface of the substrate, wherein the second material layer includes, for example, a polysilicon layer or a metal layer, and the degree of influence of the second material layer by the reaction solution is greater than that of the first material layer by the reaction solution. Big. Then i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com