Workpiece clamping and detecting tool

A technology for detecting tooling and workpieces, applied in measuring devices, instruments, using wave/particle radiation, etc., can solve problems such as complex detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

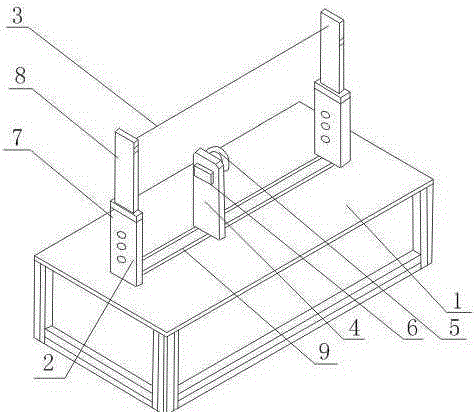

[0016] Such as figure 1 As shown, a workpiece clamping and testing tooling includes a workbench 1, an adjustment seat 2 arranged on the left and right sides of the workbench 1, a detection wire harness 3 connected to the adjustment seats 2 on both sides, and a detection wire harness 3 arranged on the adjustment seat 2 and the detection wire harness 3 The fluctuation sensor at the joint; also includes the splint 4 arranged between the left and right sides adjustment seat 2, the suction cup 5 that is arranged on the splint 4 and the motor 6 connected with the suction cup 5; the adjustment seat 2 includes an upper end opening and is empty The base 7 of the cavity structure, the connecting rod 8 that runs through the opening of the upper end of the base 7 is slidably arranged in the base 7; the base 7 and the connecting rod 8 are respectively provided with uniform holes, and the base 7 and the connecting rod 8 pass through the holes on the base 7 and the connecting rod 8 at the sam...

Embodiment 2

[0019] On the basis of Embodiment 1, this embodiment further includes two moving grooves 9 arranged in parallel on the worktable 1 , and the splint 4 is slidably arranged on the moving grooves 9 .

[0020] The splint 4 can slide on the moving groove 9, so that the splint 4 can select a suitable position according to the thickness of the workpiece to be tested, so as to achieve the best test effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com