Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Increase discharge temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

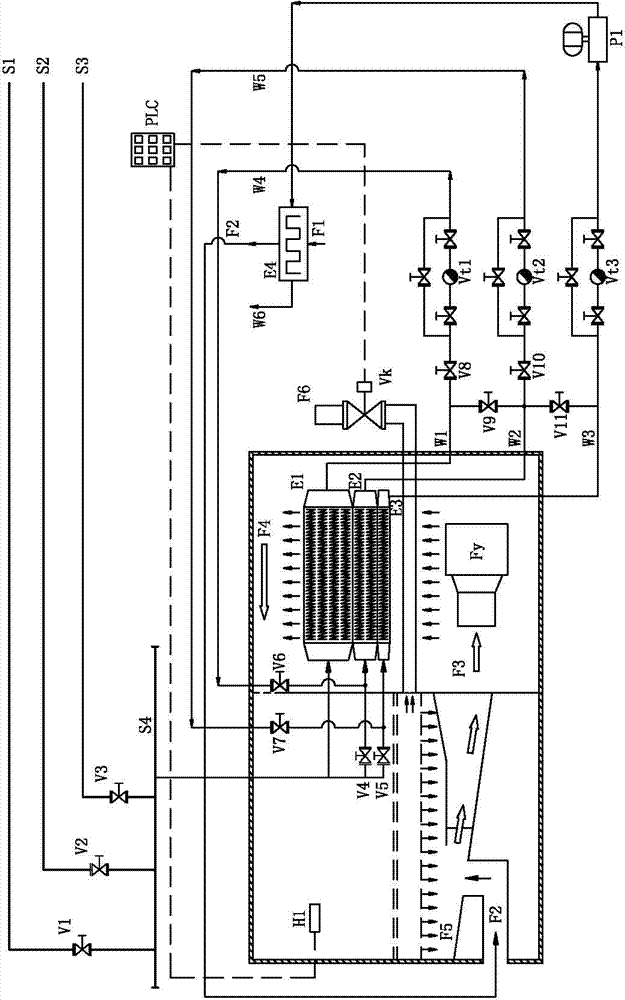

Smoke washing device

InactiveCN102716656AReduce the temperatureSmall volume flowUsing liquid separation agentFlue gasMiniaturization

The invention relates to a smoke washing device. A washing tower of the smoke washing device comprises a cooling adsorption washing area and an adverse current adsorption washing area. When smoke passes through the cooling adsorption washing area, partial pollutant such as smoke dust in the smoke can be removed, volume flow rate of the smoke is reduced simultaneously, and sectional area of the adverse current adsorption washing area is favorably reduced. In the adverse current adsorption washing area, the smoke dust in the smoke can be absorbed through sufficient contact between the smoke dust and a liquid film, and simultaneously pollutant such as sulfur dioxide can be sufficiently reacted. By means of the smoke washing device, high-efficient smoke dedusting desulfuration is achieved. In addition, washed smoke and heated air are mixed and then discharged out, smoke humidity is reduced, and rime fog at an air outlet of the smoke washing device is avoided. The smoke washing device is small in size, light in weight and applicable to flue gas treatment of a host machine and a boiler of an offshore platform or a traveling ship, and meets miniaturization requirements of on-land fume treatment equipment.

Owner:BEIJING DONGZHAN KEBO ELECTRONICS

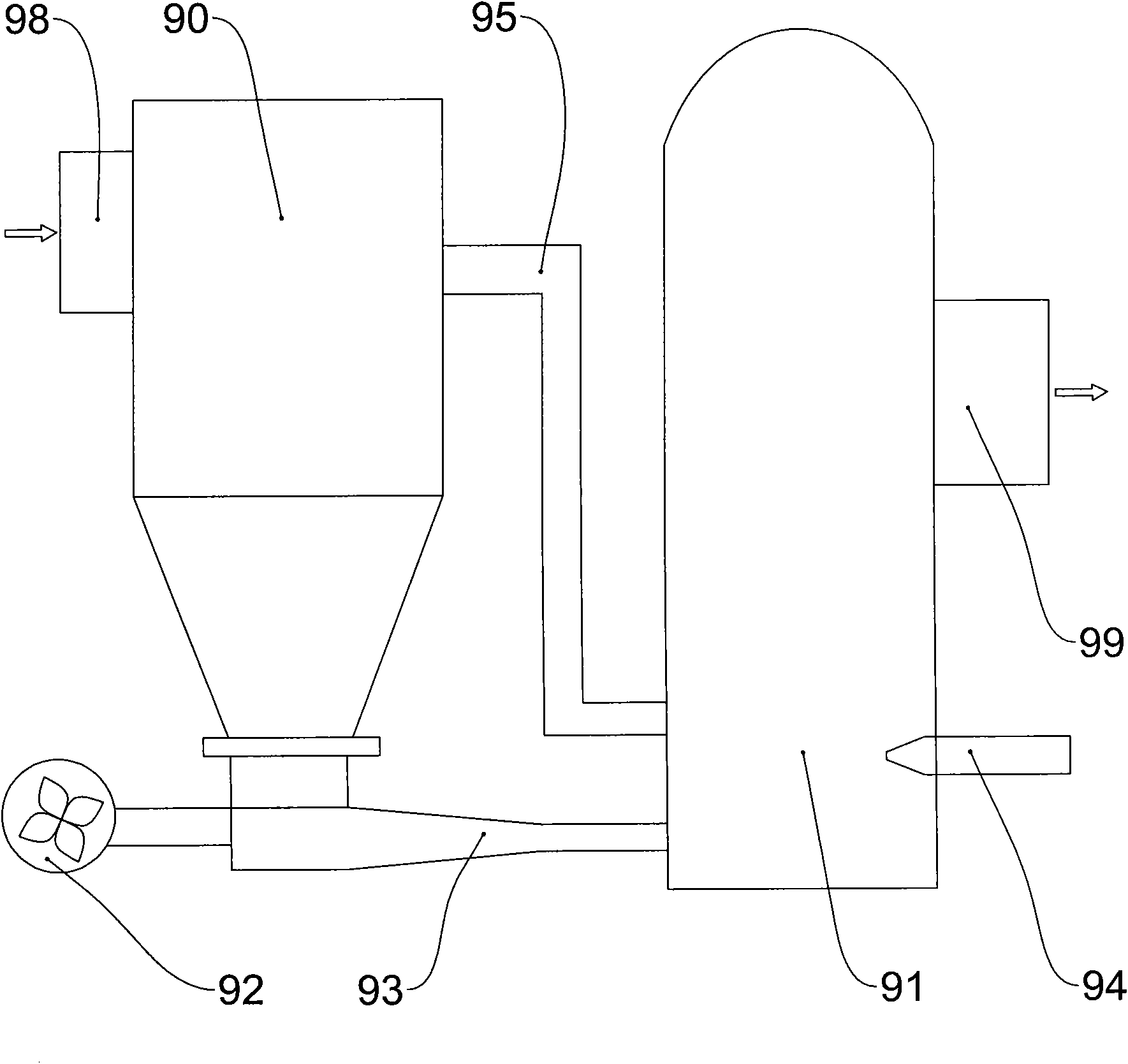

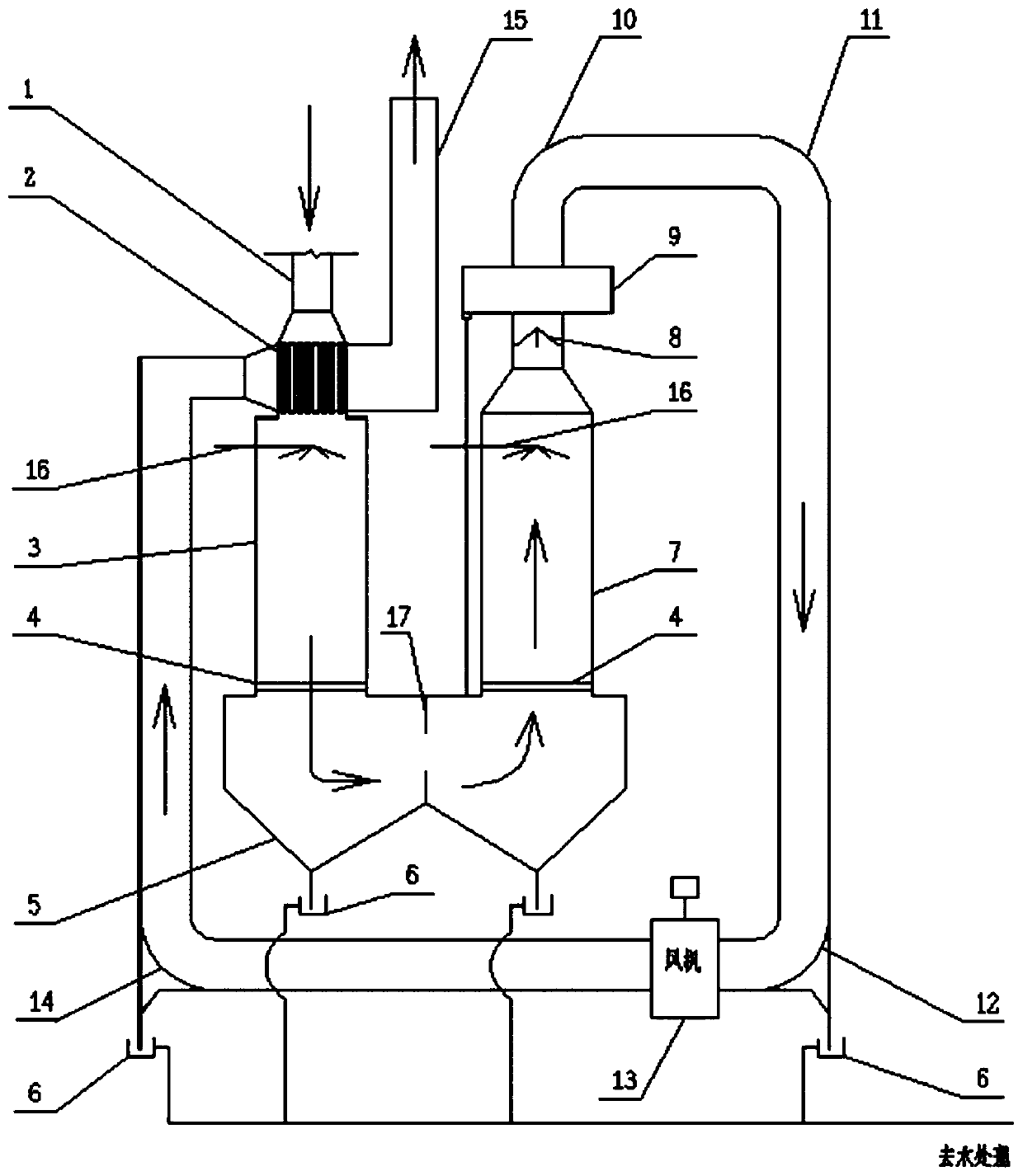

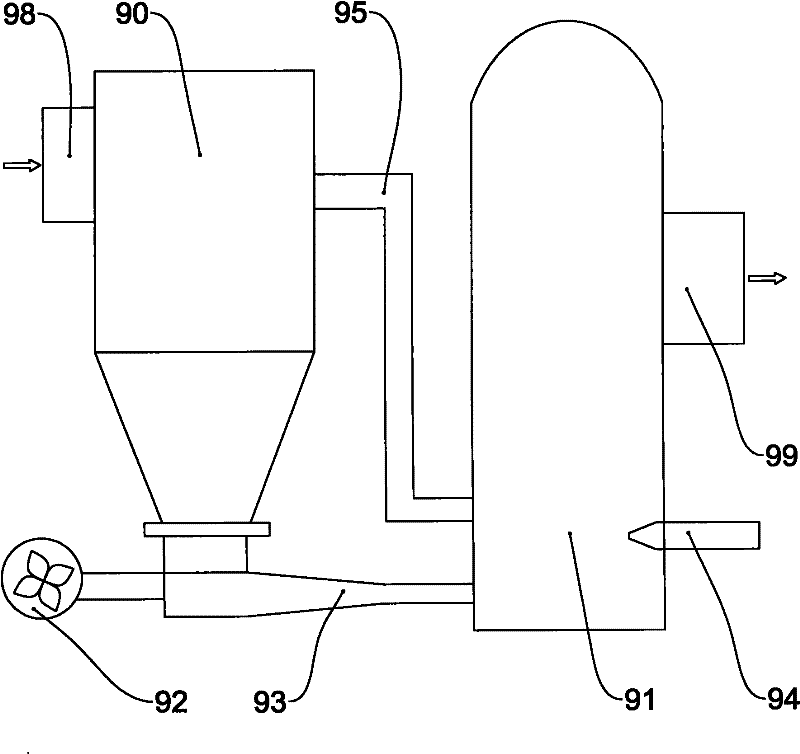

Drying production method and device thereof for polyaluminium chloride water purifying agent

InactiveCN103193305AImprove economyLess investmentAluminium chloridesWater/sewage treatment by flocculation/precipitationCoalChemistry

The invention discloses a drying production method and a device thereof for a polyaluminium chloride water purifying agent. The drying production method comprises the steps of: adopting a fluidized bed roaster as a hot blast stove to supply heat, and dividing high temperature flue gas at the temperature of 800-1000 DEG C into first-part flue gas and second-part flue gas, wherein the first-part flue gas and the second-part flue gas can be suitable for drying polyaluminium chloride liquid prepared by taking aluminum hydroxide, bauxite, calcium aluminate, hydrochloric acid and the like as raw materials through utilizing a one-step method or a two-step method, the content of liquid aluminum oxide can be 9-19%, and the basicity of products can be adapted to 40-98%; after liquid materials are dried, the quality of the drum-dried products meet a national standard GB / T22627-2008, and the quality of the spray-dried products meet the national standard GB15892-2009; and after the liquid is subjected to energy-saving drying, compared with the conventional drying process, 50-90 kg of the coals are saved during the production of each ton of solid products. The drying production method and the drying production device are more suitable for production devices in which the annual output of the single set of the drying device is 20000-50000 tons.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

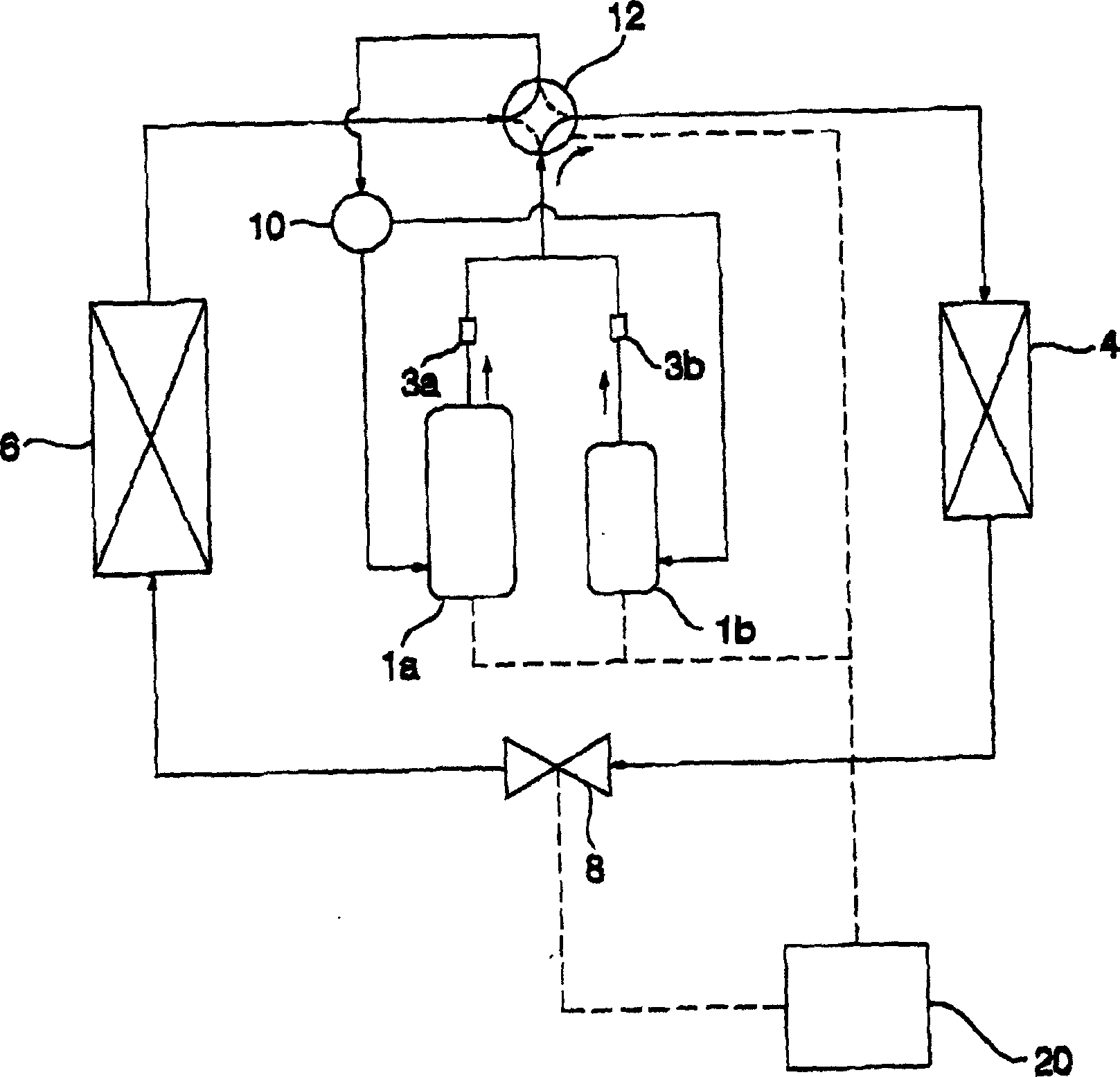

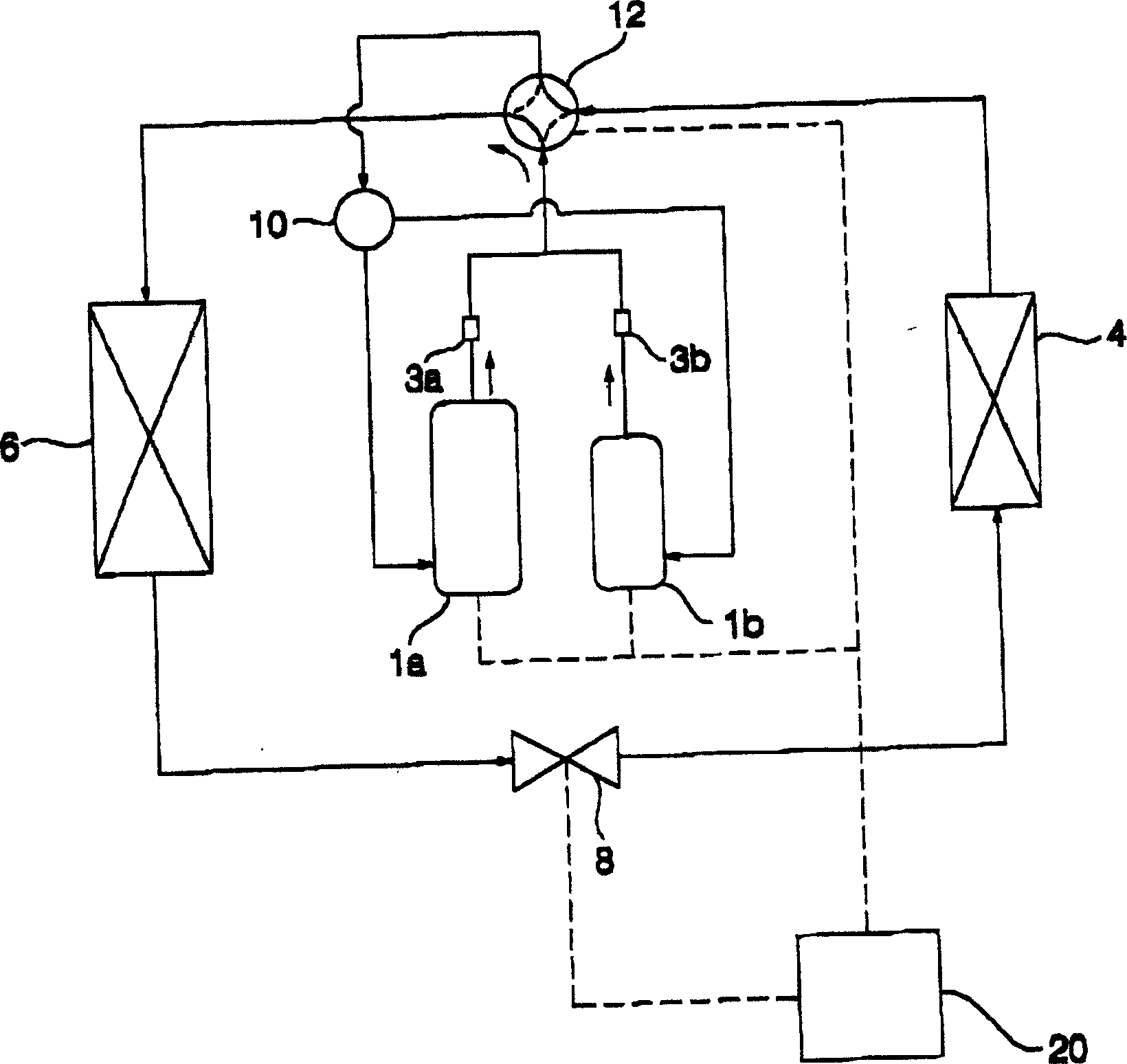

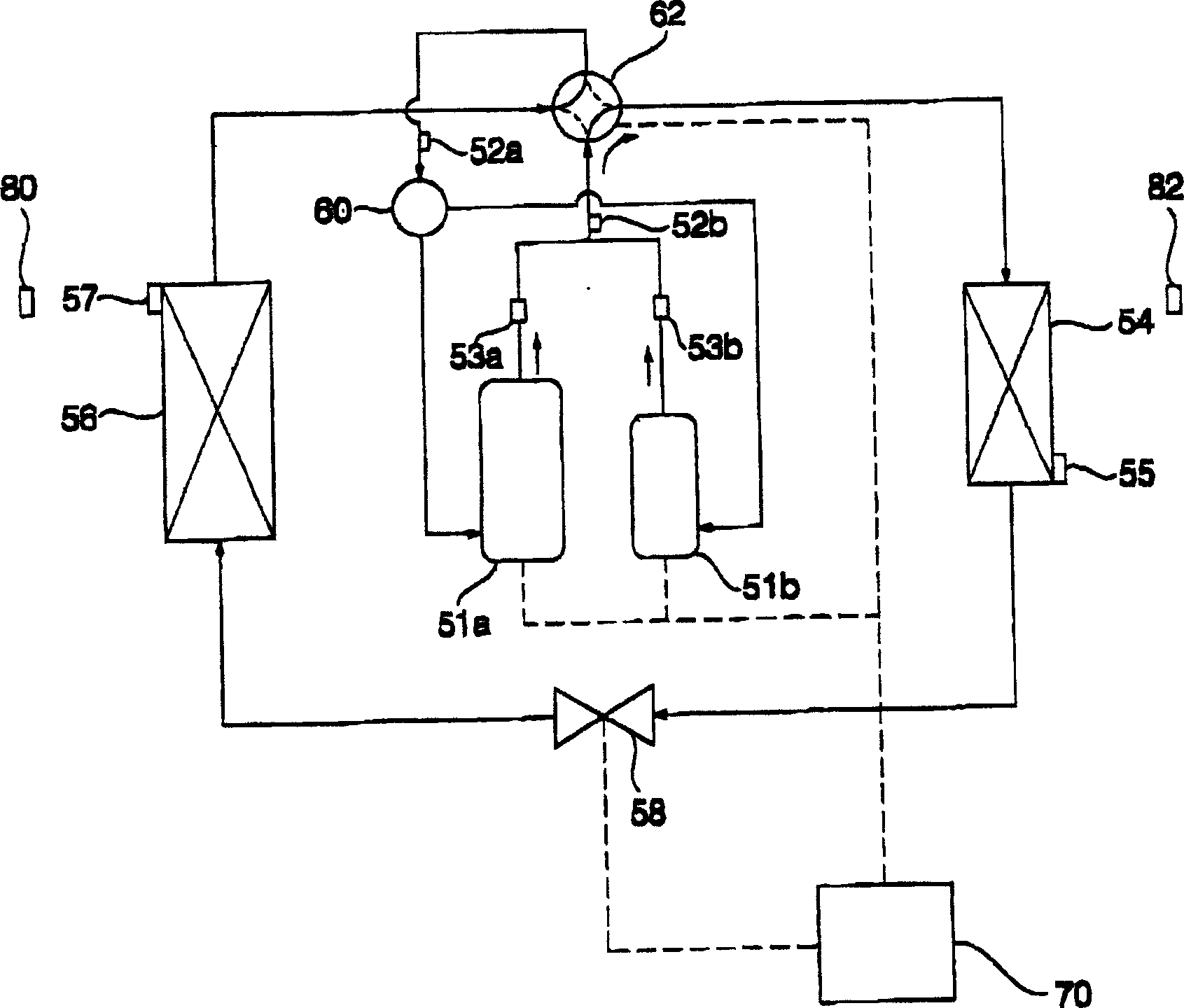

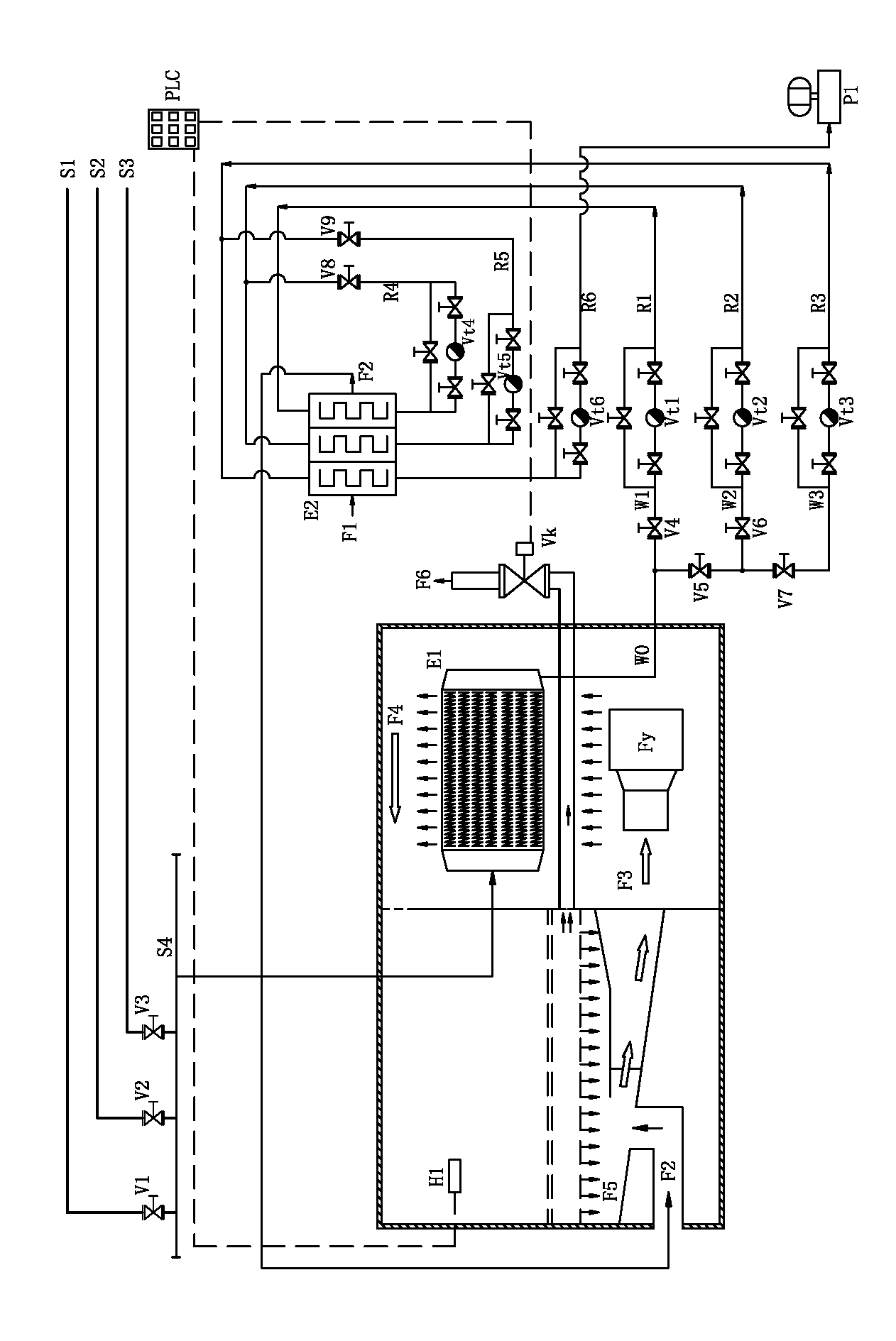

Cooling cycle apparatus and method of controlling linear expansion valve of the same

InactiveCN1683848AImprove reliabilityEasy to handleMechanical apparatusFluid circulation arrangementControl theoryThermal expansion valve

Disclosed herein is a method of controlling a linear expansion valve of a cooling cycle apparatus. The method comprises a first step of calculating a target opening level value according to suction overheat level of compressors to control a linear expansion valve based on the calculated target opening level value, and a second step of calculating a new target opening level value according to the suction overheat level of the compressors and discharge temperature of the compressors to control the linear expansion valve based on the calculated new target opening level value. Consequently, the discharge temperature of the compressors is prevented from being excessively increased, and therefore, the compressors are prevented from being overheated and damaged, and reliability of the cooling cycle apparatus is improved.

Owner:LG ELECTRONICS INC

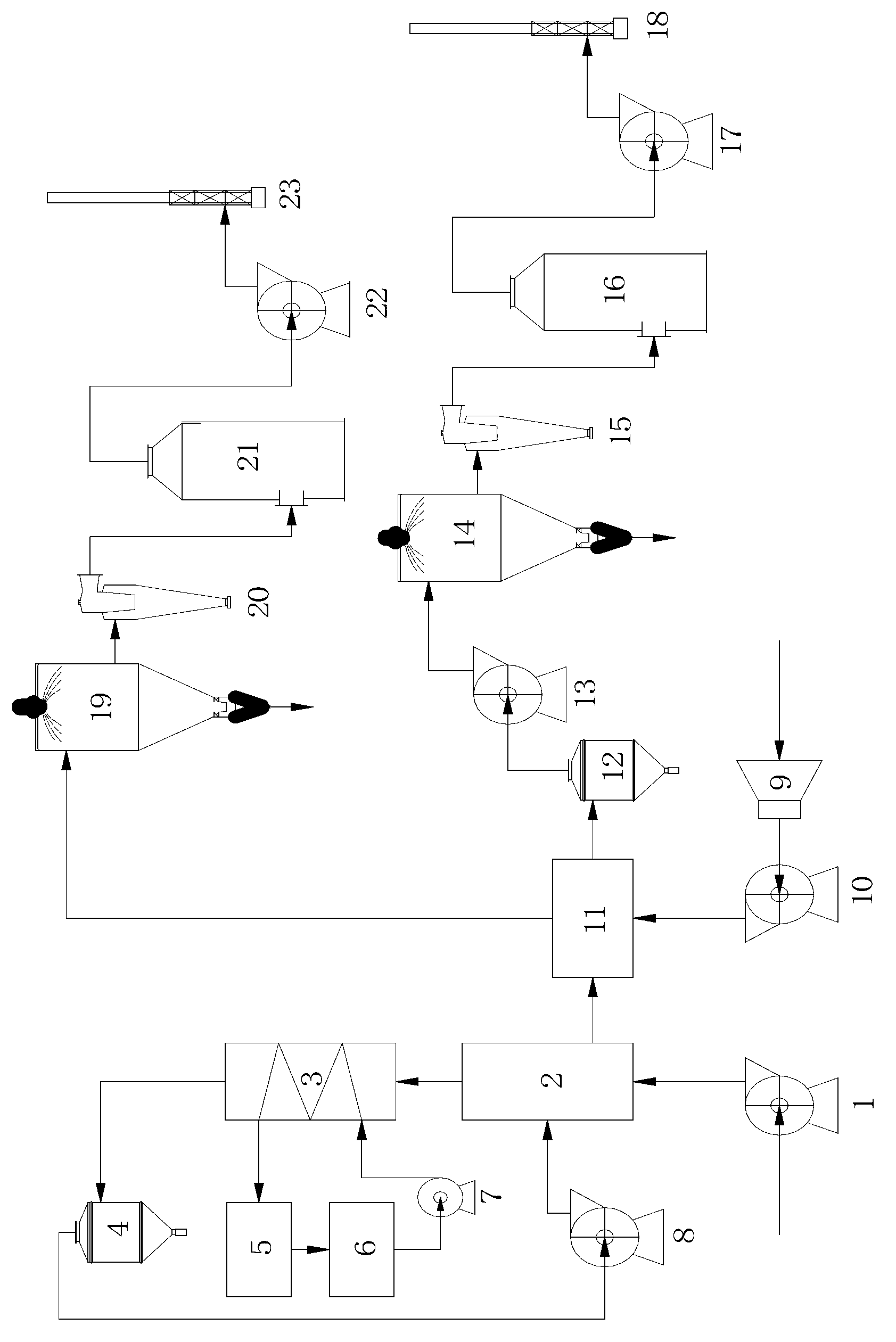

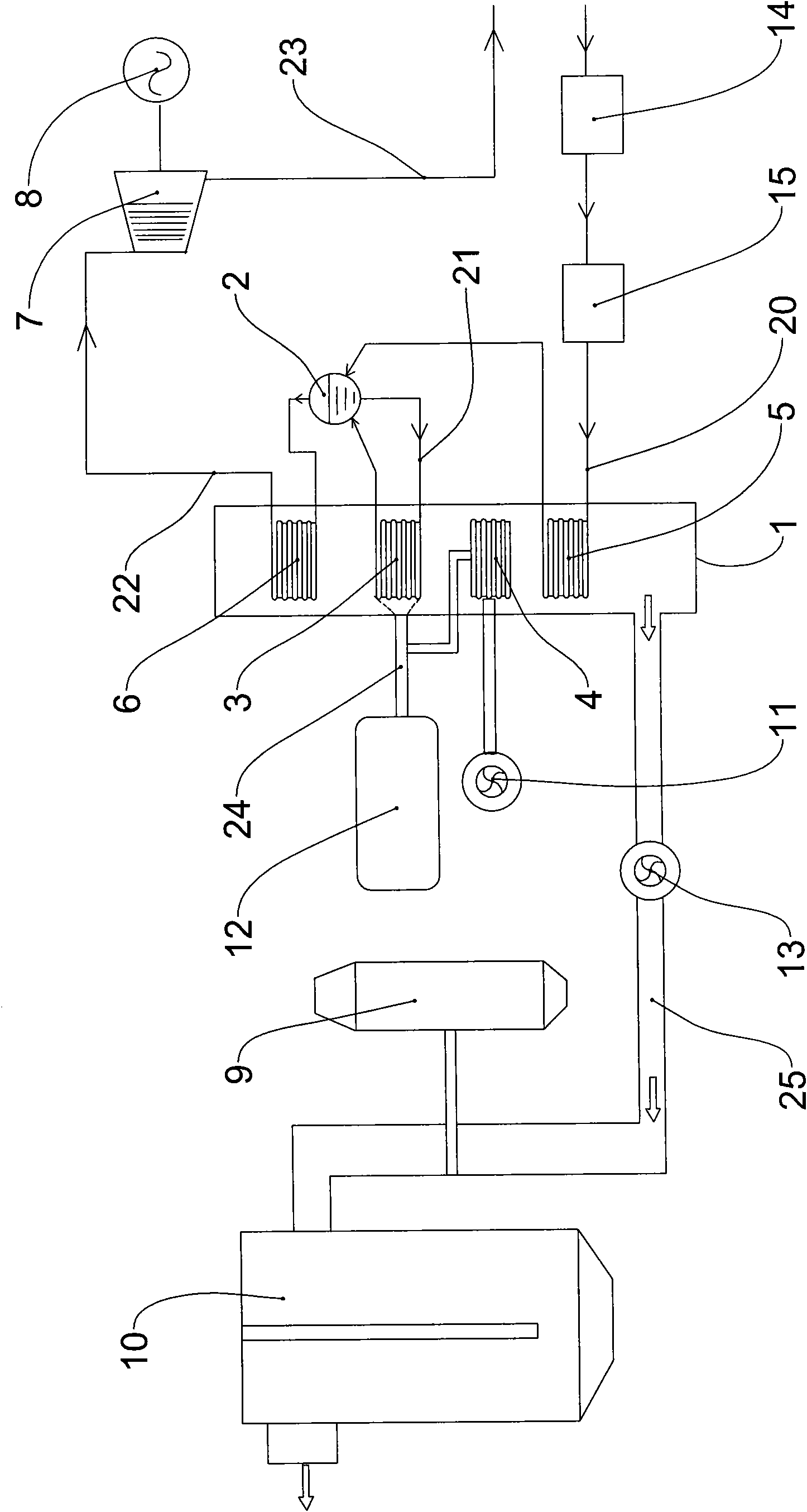

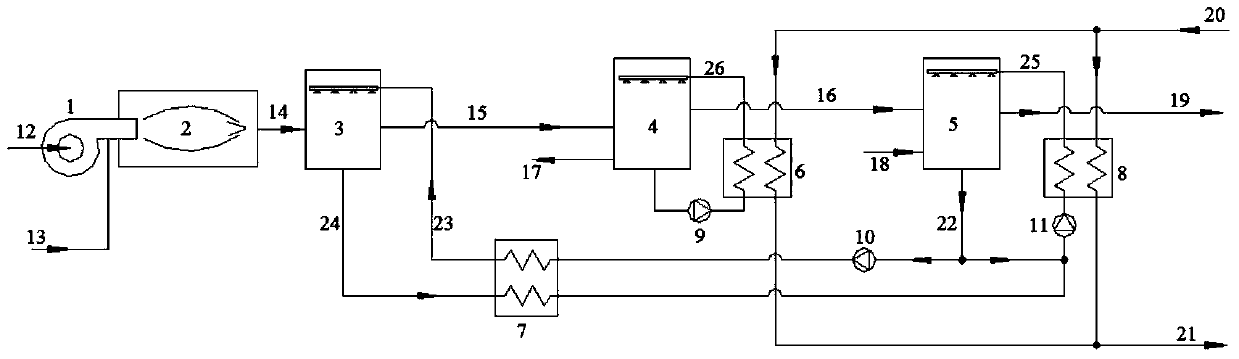

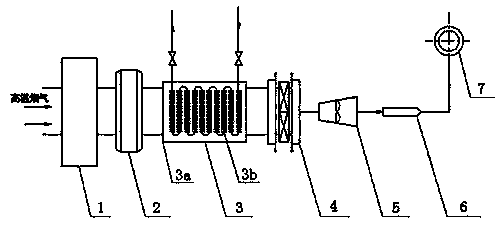

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025AObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and a smoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

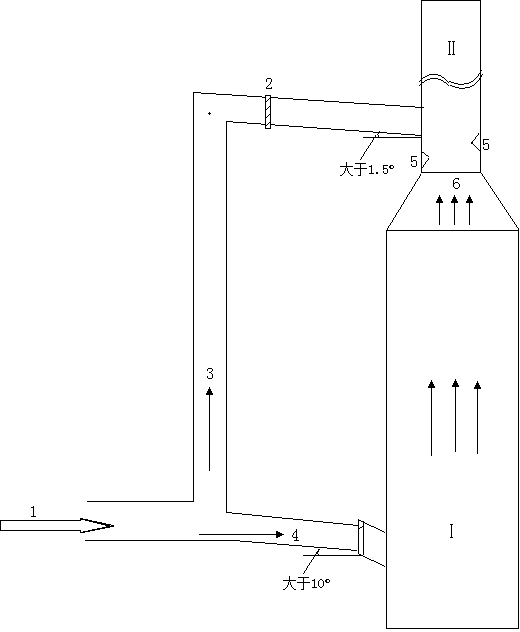

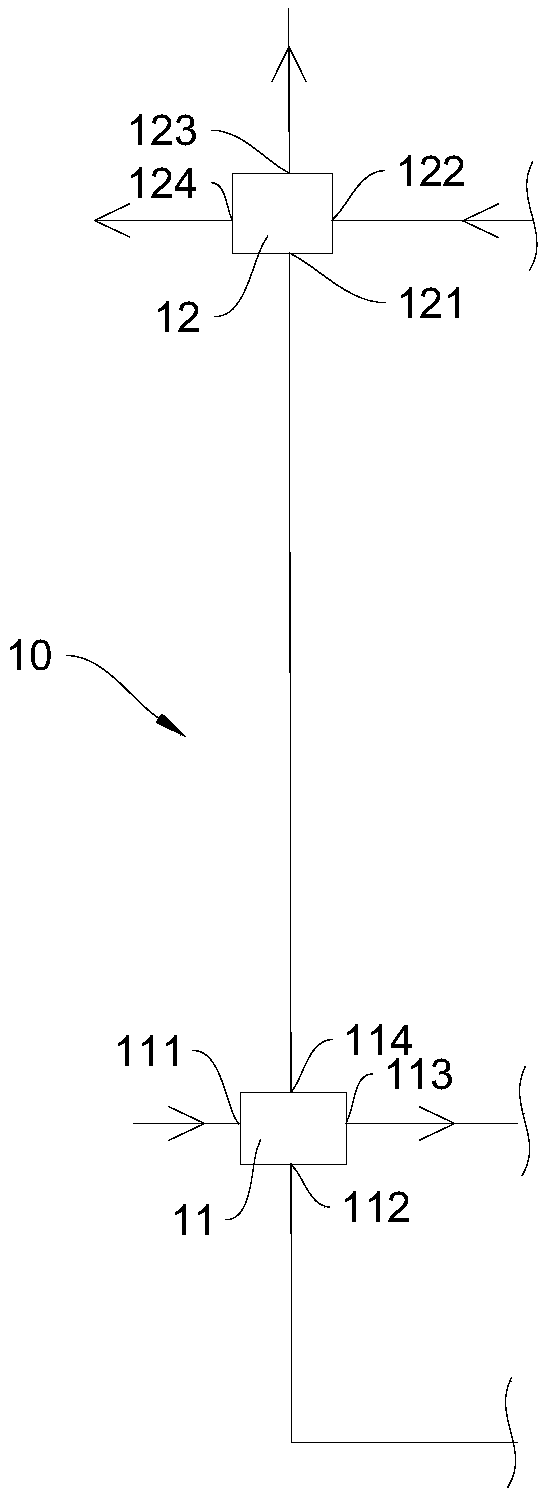

Discharged flue gas self-heating technology of wet flue gas desulfurization and desulfuration purified flue gas self-heating device

InactiveCN103591599AIncrease discharge temperatureReduce corrosionLighting and heating apparatusPhysicsFlue gas

The invention discloses a discharged flue gas self-heating technology of wet flue gas desulfurization. Original flue gas is divided into the thionizer entering flue gas and the bypass flue gas. After the thionizer entering flue gas is washed by spraying a doctor solution in a thionizer, purified flue gas is formed and enters a straight discharging chimney. The bypass flue gas is conveyed into the straight discharging chimney. In the straight discharging chimney, the purified flue gas and the bypass flue gas are fully mixed and then discharged into the atmosphere. Mixed flue gas meets the requirement for environment-protection discharging, meanwhile, the bypass flue gas exchanges heat with the purified flue gas, so that the temperature of the mixed flue gas is raised, and the discharging temperature of the mixed flue gas is controlled to reach more than 70 DEG C. The invention further discloses a desulfuration purified flue gas self-heating device. In order to overcome the defects of a GGH, heat flue gas is used for directly heating the purified flue gas, and the heat flue gas and the purified flue gas are mixed and then discharged. The technology is simple, resistance is small, the GGH does not need to be arranged, the maintenance workload of the device is small, and therefore the wet flue gas desulfurization device is more simple and more practical in technology and meets the requirement for long-time efficient operation.

Owner:SHANGHAI UNIV

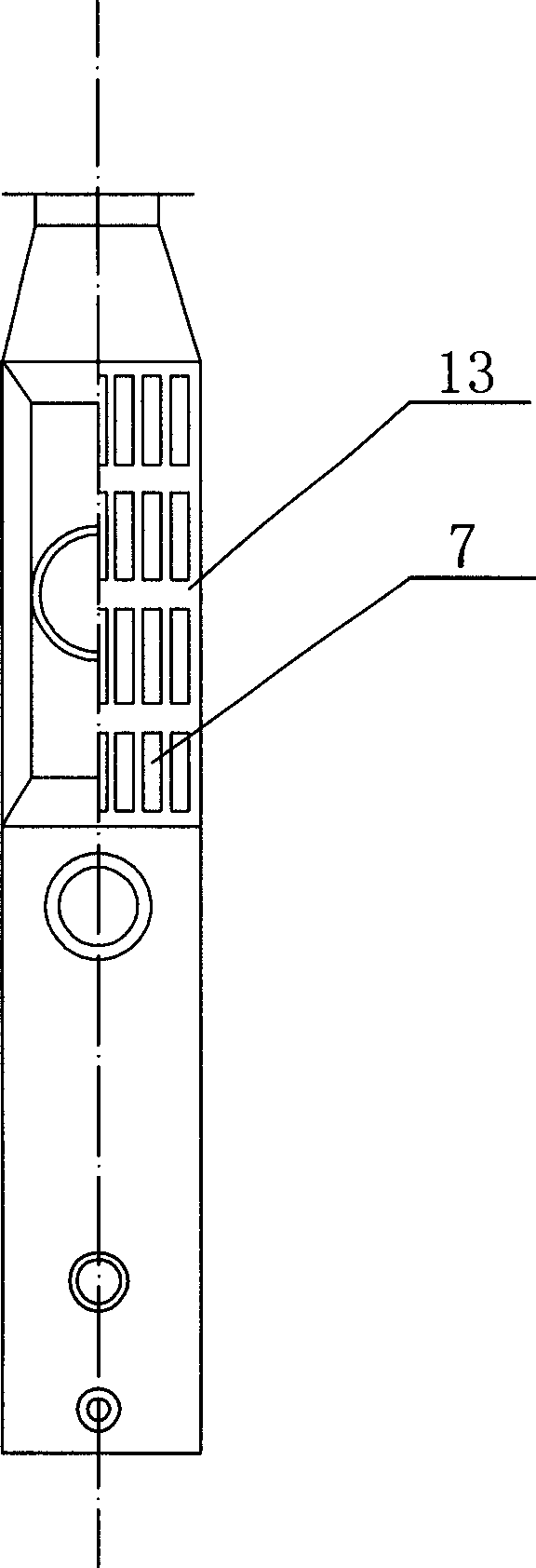

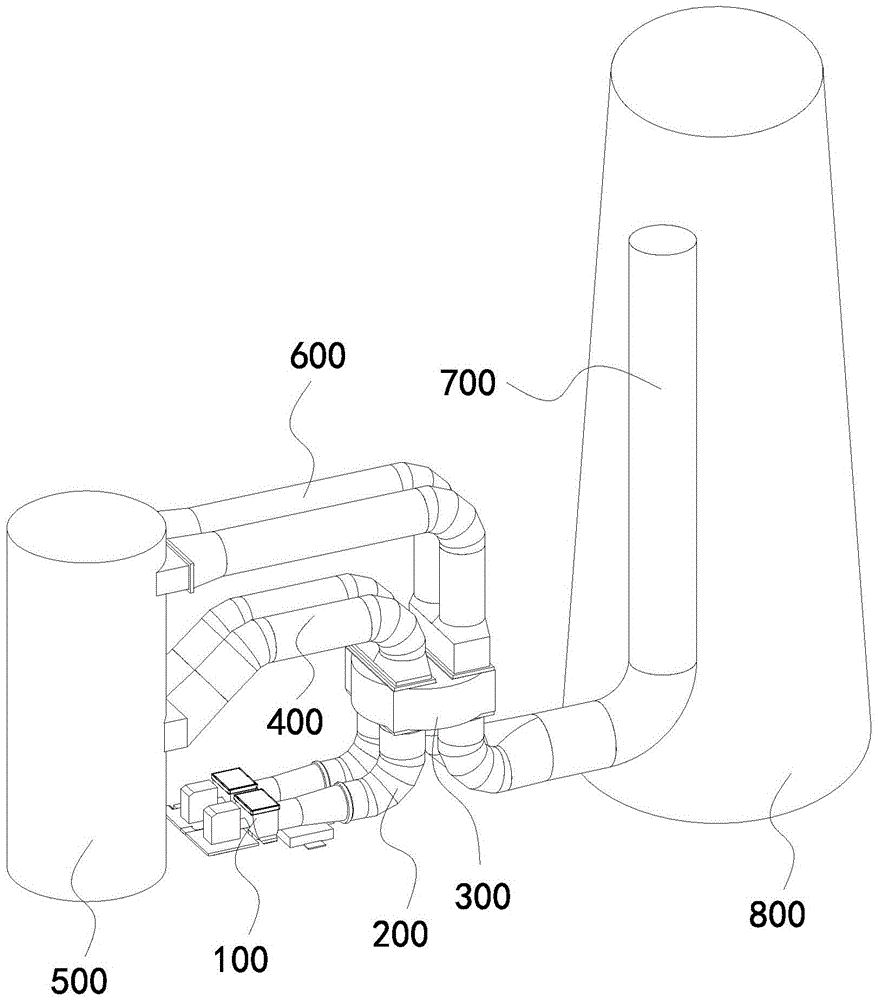

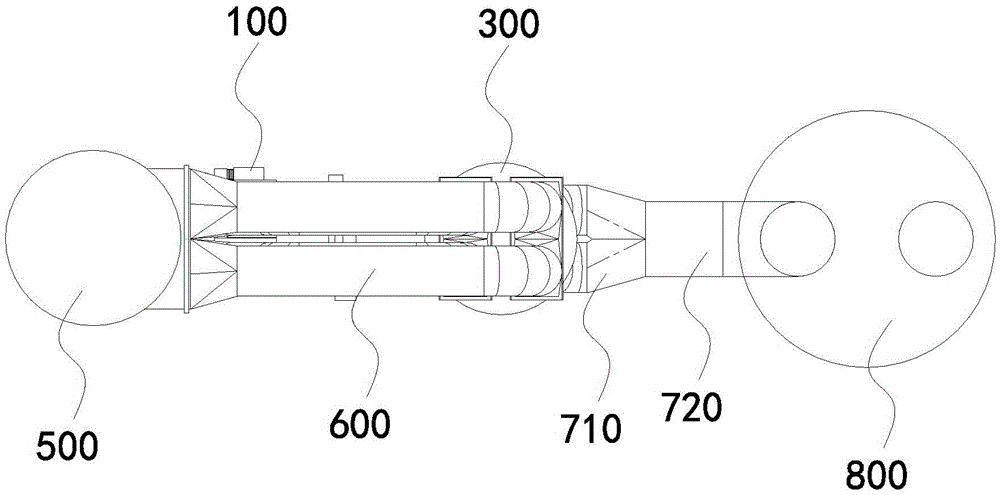

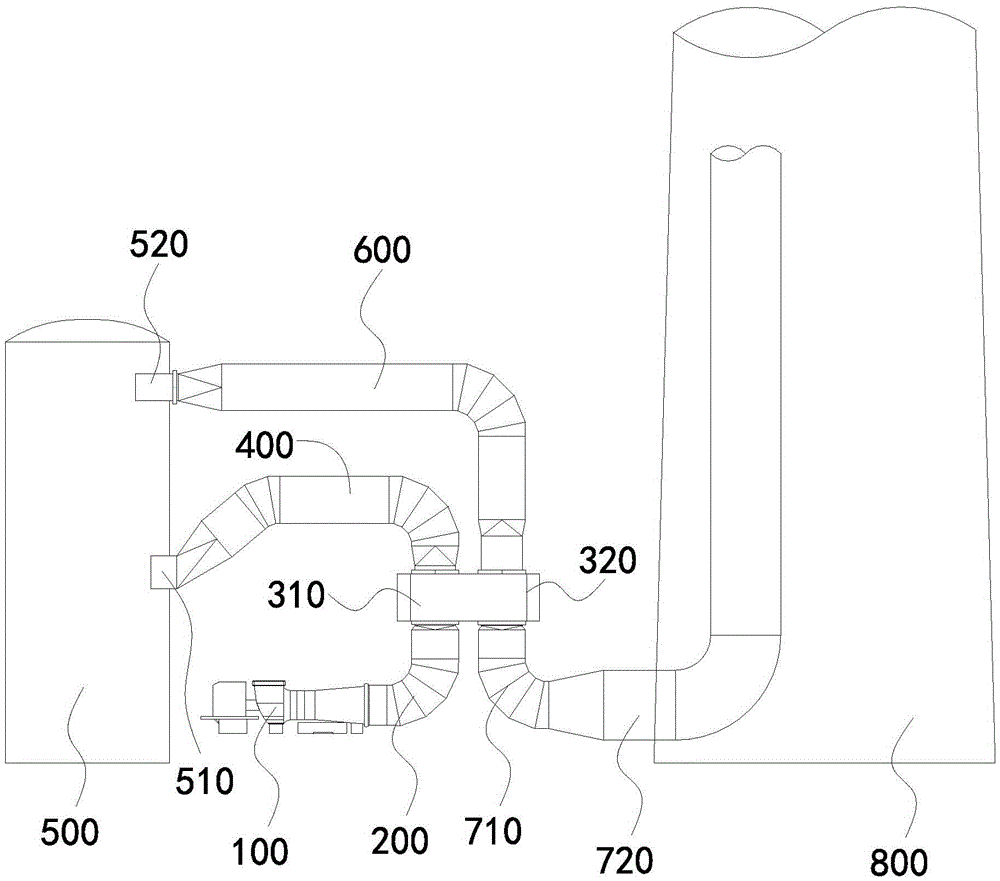

White smoke eliminating and purification integrated device

InactiveCN110448976AIncrease discharge temperatureReduce the temperatureCombination devicesGas treatmentFlue gasProcess engineering

The invention relates to a white smoke eliminating and purification integrated device. The white smoke eliminating and purification integrated device comprises a gas inlet pipeline, the gas inlet pipeline is communicated with a flue gas warming device, the flue gas warming device is communicated with a purification device, and the purification device is communicated with a flue gas discharge pipe.The flue gas warming device comprises a shell, an inner cavity of the shell is provided with multiple heat exchange pipes, one ends of the heat exchange pipes are communicated with the gas inlet pipeline, the other ends of the heat exchange pipes are communicated with the purification device, and a heat exchange space is formed between the inner wall of the shell and the outer walls of the heat exchange pipes and communicated with the flue gas discharge pipe. By means of the flue gas warming device, high-temperature flue gas in the gas inlet pipeline and low-temperature flue gas in the flue gas discharge pipe can conduct heat exchange to increase the discharge temperature of the flue gas and decrease the temperature of the flue gas entering the purification device. By means of the white smoke eliminating and purification integrated device, the defect that existing flue gas cannot be subjected to purification and white smoke eliminating in one system can be overcome, and the efficiencyof purification and dewatering the flue gas is improved.

Owner:BERIS ENG & RES CORP

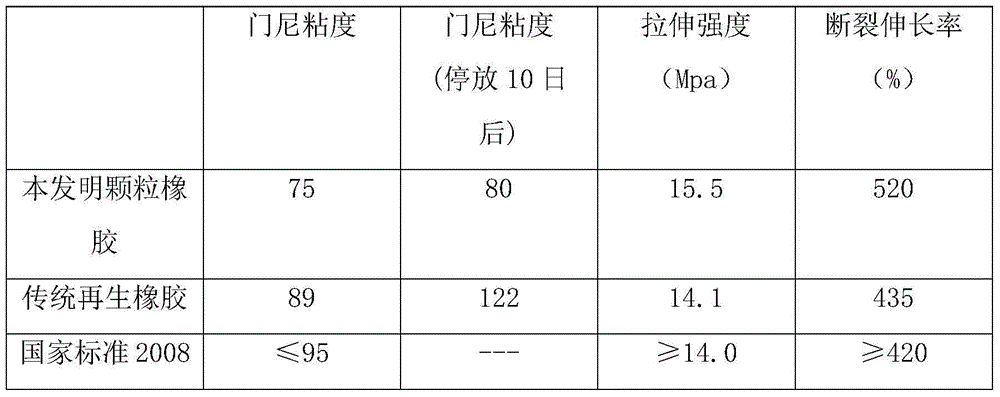

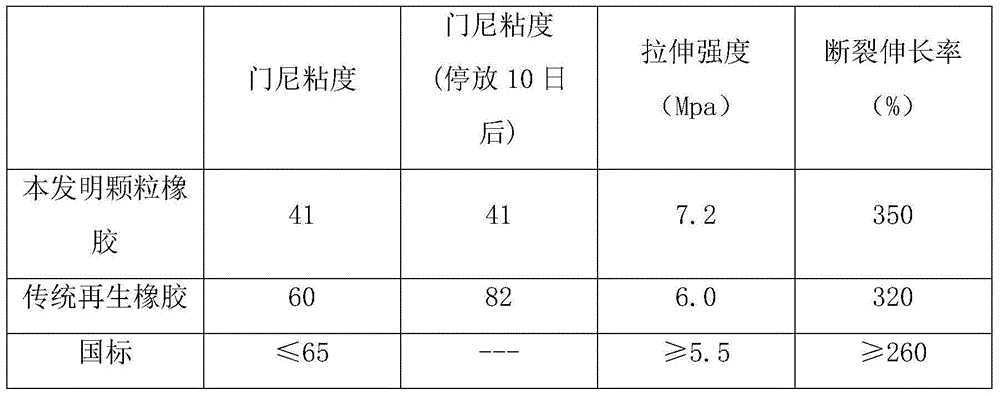

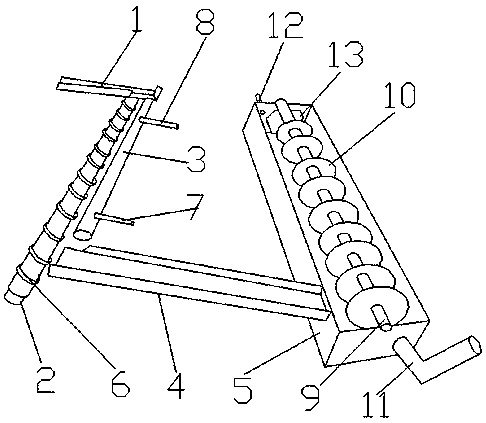

Method for preparing granular rubber by adopting three screw rods to continuously extrude devulcanized rubber powder

ActiveCN104690844AImprove safe continuous productionImprove working environmentCross-linkEnvironmental resistance

The invention discloses a method for preparing granular rubber by adopting three screw rods to continuously extrude devulcanized rubber powder, and belongs to the field of waste rubber cyclic regeneration. Devulcanized rubber powder which is preliminarily and thoroughly cooled is added into a three-screw-rod extruder through a metering feeding device, high shearing, stretching and compression effects are applied on the devulcanized rubber powder on the lower temperature condition by means of the strong material conveying capability, the shearing and mixing capability and the high productivity ratio of the three-screw-rod extruder, a cross-linked network in the devulcanized rubber powder is damaged further, the Mooney viscosity of the devulcanized rubber powder is lowered on the premise of not lowering the mechanical property, a granular rubber product is obtained, and a traditional refiner is replaced. Operation is continuously completed by the adoption of the three-screw-rod extruder on the closed, low temperature and high shearing conditions. The devulcanized rubber powder Mooney viscosity lowering effect which is originally achieved by the traditional refiner is achieved, the production process is environmentally friendly and continuous and saves energy, the stability of the mechanical property and the Mooney viscosity of the obtained granular rubber product is better than that of a product obtained by the traditional refiner.

Owner:NANJING L J R RUBBE & PLASTIC CO LTD +1

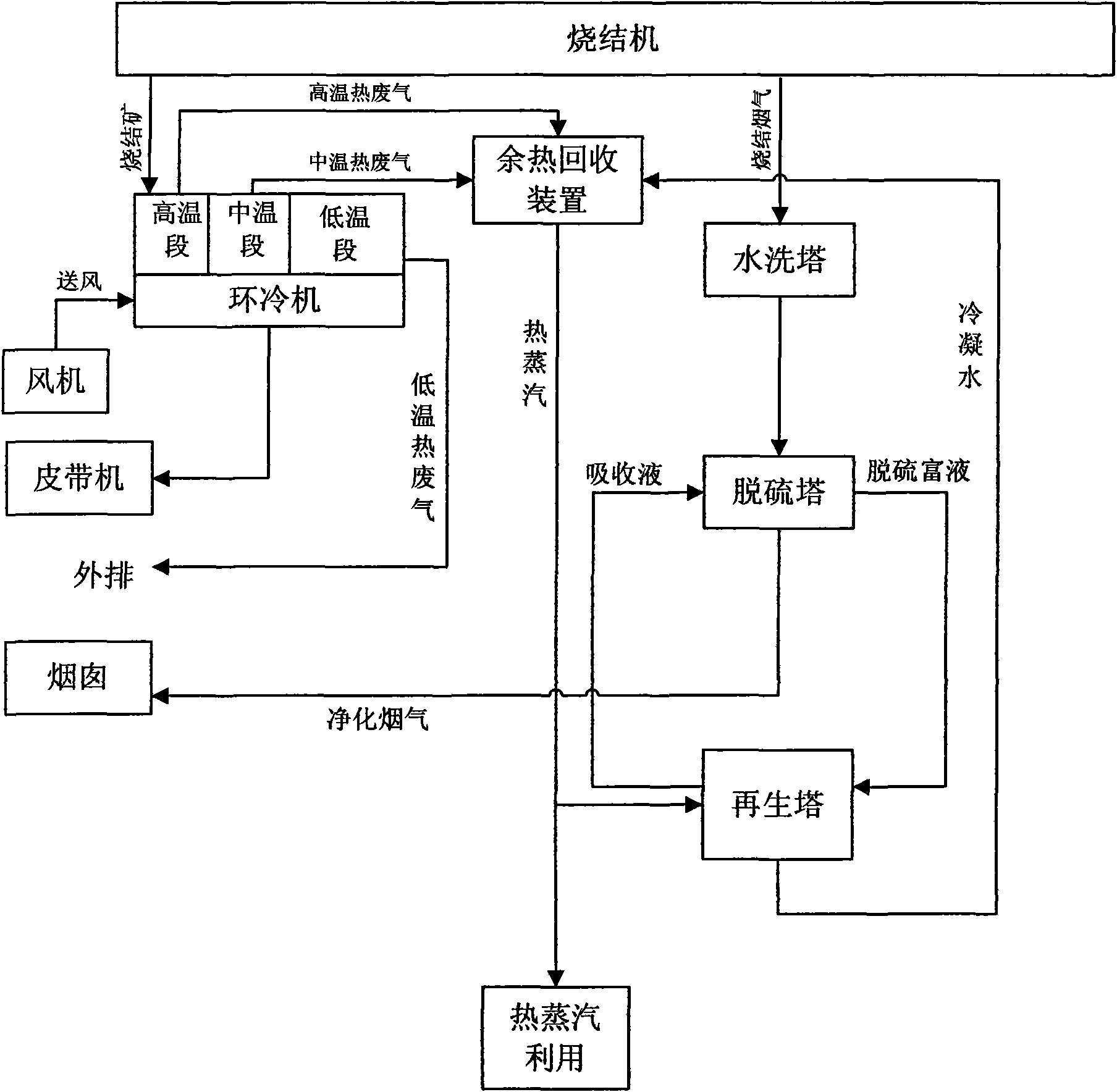

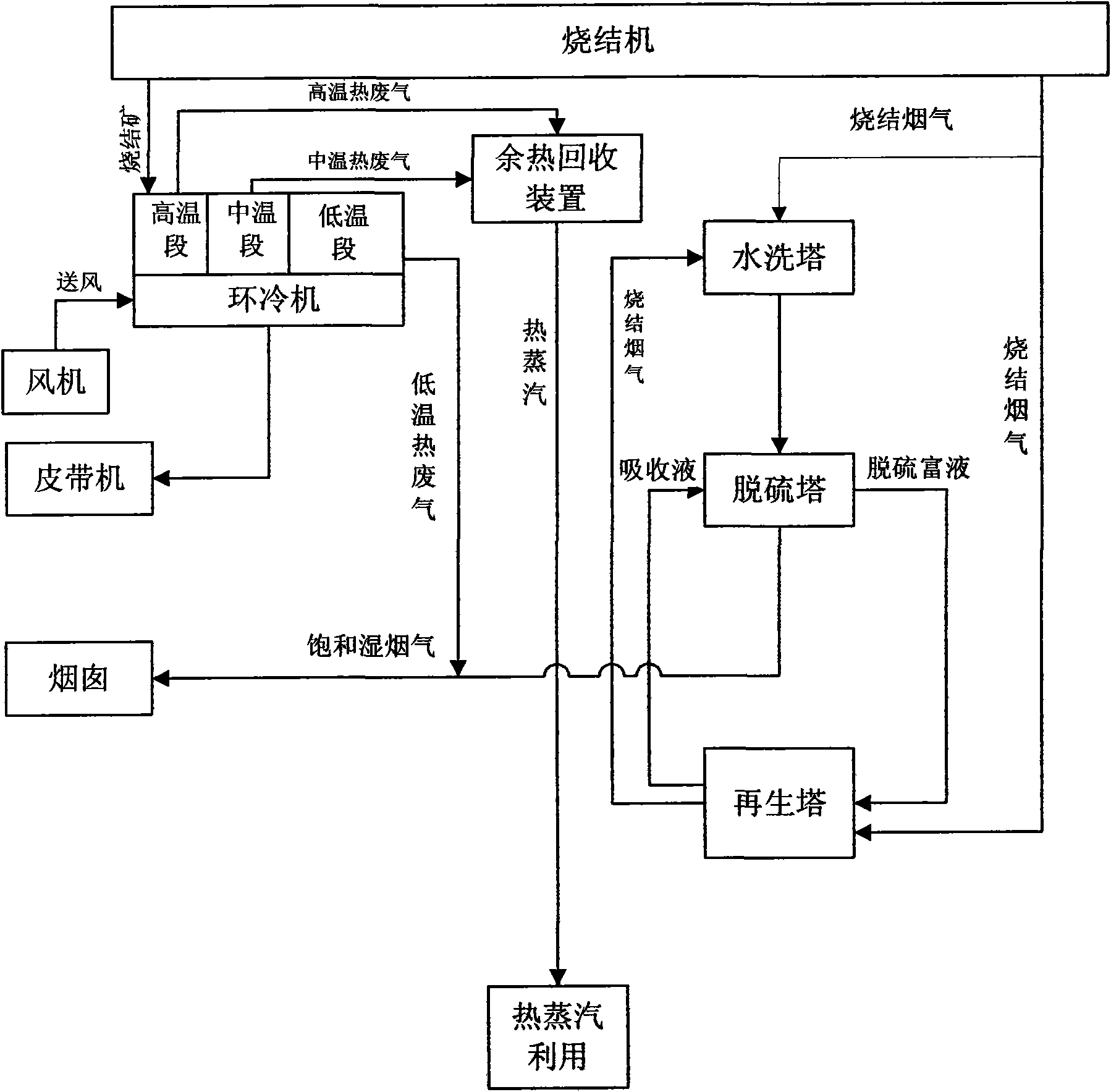

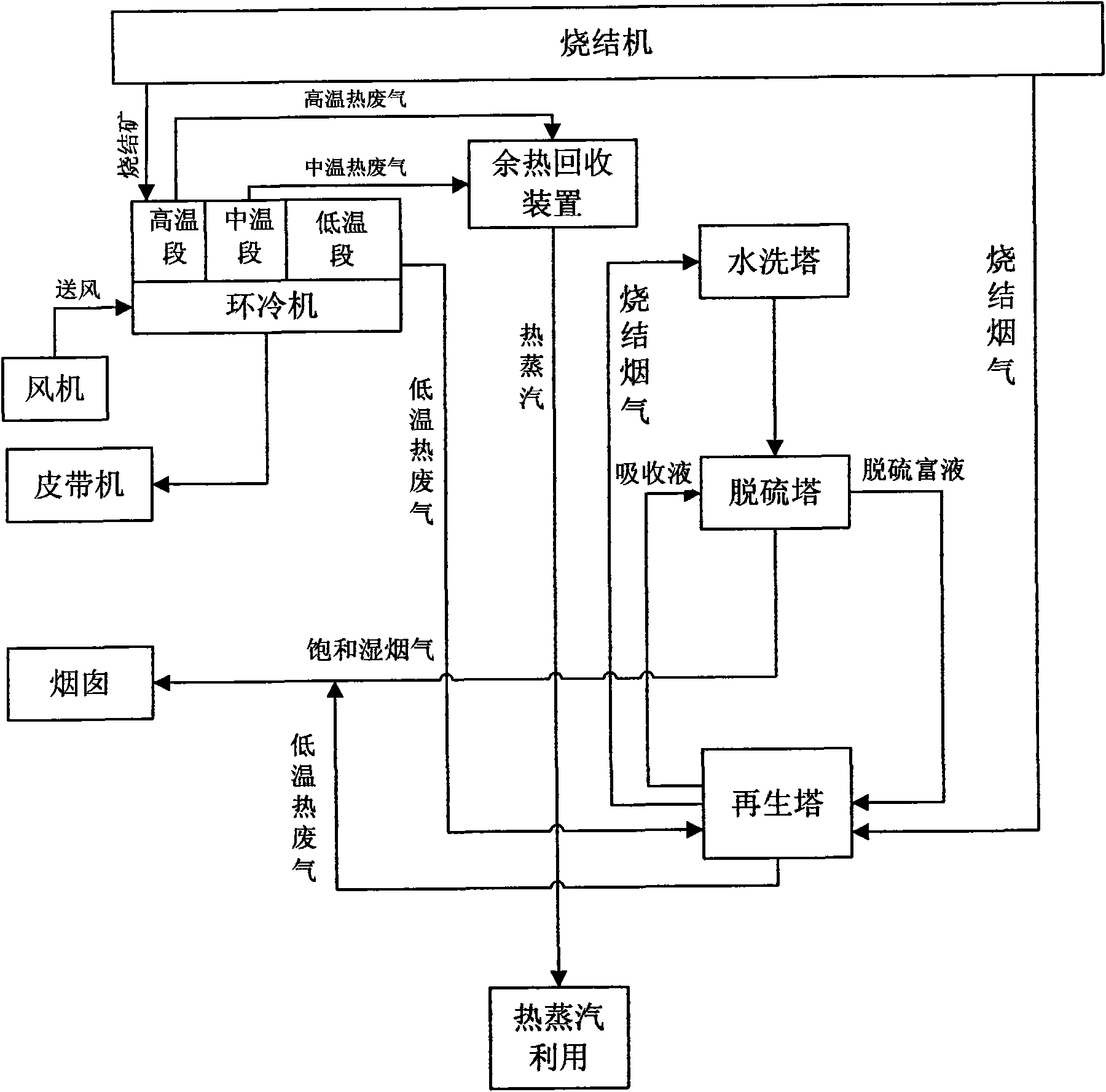

Flue gas desulfurization process for comprehensively utilizing sintering flue gas

ActiveCN101569819AReduce consumptionIncrease discharge temperatureDispersed particle separationFurnace typesFlue gasTower

The invention discloses a flue gas desulfurization process for comprehensively utilizing sintering flue gas. In the flue gas desulfurization process, a desulfurizing tower for absorbing sulfur dioxide and a regeneration tower for reclaiming desulphurization rich solution discharged by the desulfurizing tower are arranged; the sintering flue gas discharged by a sintering machine is conveyed to the regeneration tower, the sintering flue gas taken as a heat source indirectly heats the desulphurization rich solution in the regeneration tower to decompose the sulfur dioxide in the desulphurization rich solution, and an absorption liquid obtained after the desulphurization rich solution is regenerated is conveyed to the desulfurizing tower; and the discharged sintering flue gas in the regeneration tower is subjected to washing, dedusting and temperature reduction and then is sent into the desulfurizing tower, the sintering flue gas is subjected to cyclical absorption and desulphurization by the absorption liquid to obtain purified gas, and the purified gas is exhausted into atmosphere. The flue gas desulfurization process fully makes use of abandon resources, has less energy consumption, and low cost and can effectively reduce the occurrence of the phenomenon of flue gas condensation.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Device and method for condensing, drying and heating flue gas

InactiveCN102058994AHelp flowHeating effectDispersed particle separationVapor condensationFlue gasWater vapor

The invention discloses a device and method for condensing, drying and heating flue gas, in particular to a device and method for recovering and recycling condensed water in the flue gas and meeting the temperature requirement for diffusing pollutants in the flue gas to the upper air. A heat fluid outlet of a high-temperature heat tube heat exchanger of the device is connected with a heat fluid inlet of a low-temperature heat tube heat exchanger; a heat fluid outlet of the low-temperature heat tube heat exchanger is connected with a cold fluid inlet of the high-temperature heat tube heat exchanger. The method comprises the following steps of: introducing wet flue gas into an evaporation section of the high-temperature heat tube heat exchanger; heating a high-temperature heat tube; feedingthe wet flue gas subjected to temperature drop into an evaporation section of the low-temperature heat tube heat exchanger; feeding a coolant medium into the evaporation section of the low-temperature heat tube heat exchanger; reducing the temperature of the wet flue gas to below a dew point of water vapor under the action of the low-temperature heat tube; condensing the water vapor in the wet flue gas into water and discharging the water from a flue gas condensed water outlet; discharging the coolant medium absorbing the heat from a cold fluid outlet of the low-temperature heat tube heat exchanger; and heating the condensed dried flue gas by a high-temperature heat tube and discharging the heated flue gas by a chimney.

Owner:SOUTHEAST UNIV

Flue gas waste heat recovery unit

ActiveCN104180523AIncrease discharge temperatureReduce consumptionStorage heatersAir heatersWaste heat recovery unitFlue gas

The invention relates to a flue gas waste heat recovery unit which comprises a flue gas unit, a generator unit, a condenser unit, an absorber unit, a water return pipe and a water supply pipe. The flue gas unit is sequentially connected with the generator unit, the condenser unit and the absorber unit to form a flue gas heat exchanging path; the outlet of the generator unit is connected with the inlet of a solution-to-solution heat exchanger, the outlet of the absorber unit is divided into two paths: one path is merged with the outlet of the solution-to-solution heat exchanger to be connected with the inlet of a solution-to-water heat exchanger through a solution spray pump, the outlet of the solution-to-water heat exchanger is connected with a solution spray mechanism in the absorber unit, the other path is connected with the inlet of a solution-to-solution heat exchanger through a solution circulating pump, and the outlet of the solution-to-solution heat exchanger is connected with a dilute solution spray mechanism through the generator unit so as to form a solution heat exchanging and circulating loop; the outlet of the condenser unit is connected with the inlet of a water-to-water heat exchanger through a condense water spray pump, the outlet of the water-to-water heat exchanger is connected with a condense water spray mechanism through the condenser unit to form a condense water heat exchanging and circulating loop; the water return pipe is connected with a water-to-water heat exchanger unit and the inlet of a solution-to-water heat exchanger, and the water supply pipe is connected with the water-to-water heat exchanger and the inlet of the solution-to-water heat exchanger.

Owner:TSINGHUA UNIV +1

Constant humidity type classification heat exchange dewatering and water sensible heat multistage utilization relaxation heat setting machine

InactiveCN103088509AReduce consumptionFull exchangeDrying gas arrangementsTextiles and paperTyping ClassificationEngineering

The invention relates to a constant humidity type classification heat exchange dewatering and water sensible heat multistage utilization relaxation heat setting machine. A return air inlet and an exhaust outlet are formed in the lower portion of a drying chamber, the exhaust outlet is communicated to the outside of a box body through an exhaust tube, the return air inlet and an air compensation port in the box body are both communicated with a suction outlet of a fan, an air outlet of the fan is aligned to heat exchangers above the fan, the air outlet above the heat exchangers enters into the drying chamber, an inlet of a high pressure heat exchanger is connected with a steam supply main tube, an outlet of the high pressure heat exchanger is connected with an inlet of a middle pressure heat exchanger through a high pressure drain valve, an outlet of the middle pressure heat exchanger is connected into an inlet of a lower pressure heat exchanger through a middle pressure drain valve, an outlet of the low pressure heat exchanger is connected into a condensate pump through a low pressure drain valve, an outlet of the condensate pump is connected into a new wind preheater, a preheating air outlet of the new wind preheater is connected into the air compensation port of the relaxation setting machine, and low pressure condensate water of the relaxation setting machine is connected into the new wind preheater to achieve indirect heat exchange with new wind. The setting machine can achieve sufficient utilization of waste heat of the exhaust and the condensate water, and is high in heat efficiency.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

Box-type waste heat recovering device of sintered ores

PendingCN106969639AContinuous stable operationImprove air tightnessEnergy industryIncreasing energy efficiencyChinese charactersEngineering

The invention relates to a box-type waste heat recovering device of sintered ores. The box-type waste heat recovering device comprises a vertical-type box body, a tapered hoper, heat exchanging flowing plates and an air supply unit. A feeding port is formed in the top of the vertical-type box body, the tapper hopper is arranged at the bottom of the vertical-type box body, and a discharging port is formed in the bottom of the tapered hopper. The air supply unit is arranged in the tapered hopper, a circulating air inlet is formed in the bottom of the air supply unit, and an annular air outlet is formed in the top of the air supply unit. A circulating air outlet is formed in one side of the upper portion of the vertical-type box body, and the multiple layers of heat exchanging flowing plates arranged in a staggered mode are arranged on the vertical-type box body in the height direction to form a sintered ore flowing channel which is shaped like the Chinese character 'zhi'. The box-type waste heat recovering device of the sintered ores has the advantages of being continuous and stable in operating, good in airtightness, high in heat exchanging efficiency, small in system resistance and high in waste heat recovering quality.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Solar high-efficient spraying and cooling system

ActiveCN103411342AIncrease discharge temperatureIncrease the compression ratioMachines using refrigerant evaporationEvaporationCollector device

The invention discloses a solar high-efficient spraying and cooling system, which comprises a solar heat collector and a vapor generator. A heat exchanger is arranged in the cavity, filled with a coolant, of the vapor generator, the heat exchanger and the solar heat collector form a closed circuit, and after the coolant absorbs energy of circulated hot water of the solar heat collector, high-temperature and high-pressure coolant vapor is formed. The system further comprises a secondary spraying device, an evaporation device and a gas condenser, wherein the secondary spraying device is respectively communicated with the evaporation device and the gas condenser, the high-temperature and high-pressure coolant vapor and low-temperature and low-pressure coolant vapor coming from the evaporation device pass through the secondary spraying device to enter the gas condenser, the low-temperature and low-pressure coolant vapor is formed in the evaporation device, and the temperature of the coolant in the evaporation device is enabled to be lowered to a designed temperature. By utilizing solar energy, the system has the characteristics of reliable working performance, low cost, stable operation and high efficiency.

Owner:西安前沿重型工业工程技术有限公司

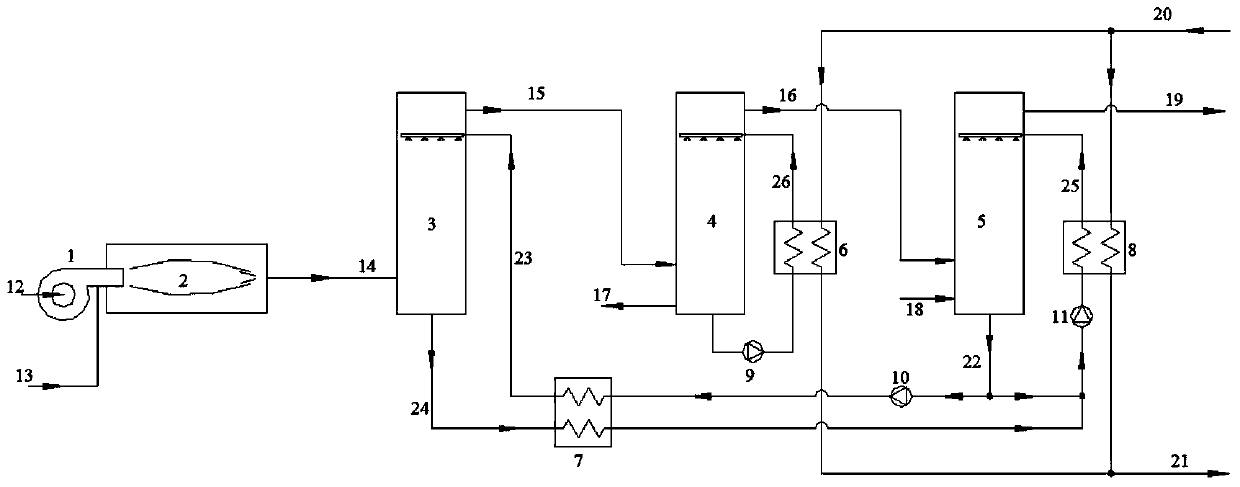

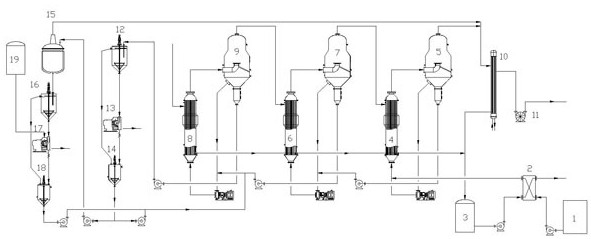

Three-stage countercurrent evaporation salt separating system for high-salt wastewater and salt separating method thereof

PendingCN112321048ASolve the problem of coprecipitationHigh purityWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentWastewaterProcess engineering

The invention discloses a three-stage countercurrent evaporation salt separating system for high-salt wastewater and a salt separating method thereof. The system comprises a storage tank, a preheater,a condensed water tank, a first heater, a first evaporation chamber, a second heater, a second evaporation chamber, a third heater, a third evaporation chamber, a steam condenser, a vacuum pump, a first concentrator, a first centrifugal machine, a first mother liquor tank, a flash chamber, a second concentrator, a second centrifugal machine and a second mother liquor tank, by adopting a process of combining three-stage countercurrent evaporation sodium salt separating and flash evaporation cooling potassium salt separating with opposite flow directions of steam and materials, the discharge temperature is high, the problem that the low discharge temperature is not beneficial to sodium-potassium separating is solved, and the problem of coprecipitation of potassium chloride and sodium chloride is solved by controlling the concentration of discharged potassium chloride.

Owner:JIANGSU TIANYING PLASMA TECH CO LTD +1

Graded drain and condensed water sensible heat cascade use relaxation heat setting machine

InactiveCN103074719AIncrease temperatureReduce consumptionDrying gas arrangementsTextiles and paperEngineeringHeat setting

The invention relates to a graded drain and condensed water sensible heat cascade use relaxation heat setting machine. In a fresh air preheater, fresh air flows through a low-pressure condensed water preheating section, an intermediate-pressure condensed water preheating section and a high-pressure condensed water preheating section in sequence, and then the fresh air enters an air-supplement port of the relaxation heat setting machine; a main drain pipe of a heat exchanger is connected with a high-pressure drain pipe, an intermediate-pressure drain pipe and a low-pressure drain pipe in parallel, and the high-pressure drain pipe, the intermediate-pressure drain pipe and the low-pressure drain pipe can be switched; an outlet of a high-pressure drain valve is connected to the high-pressure condensed water preheating section through a first condensed water recycling pipe; an outlet of an intermediate-pressure drain valve is connected to the intermediate-pressure condensed water preheating section through a second condensed water recycling pipe; an outlet of a low-pressure drain valve is connected to the low-pressure condensed water preheating section through a third condensed water recycling pipe; drain water of the high-pressure condensed water preheating section is also connected into an inlet of the intermediate-pressure condensed water preheating section; and drain water of the intermediate-pressure condensed water preheating section is also connected into an inlet of the low-pressure condensed water preheating section. The setting machine has the advantage of high heat efficiency, and residual heat of condensed water can be fully utilized.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

Annealing and cooling device for hot-rolled steel balls

ActiveCN109082518BIncrease discharge temperatureReduce CooldownFurnace typesHeat treatment furnacesSpiral bladeSteel ball

Owner:TONGLING MINGCHENG FOUNDRY

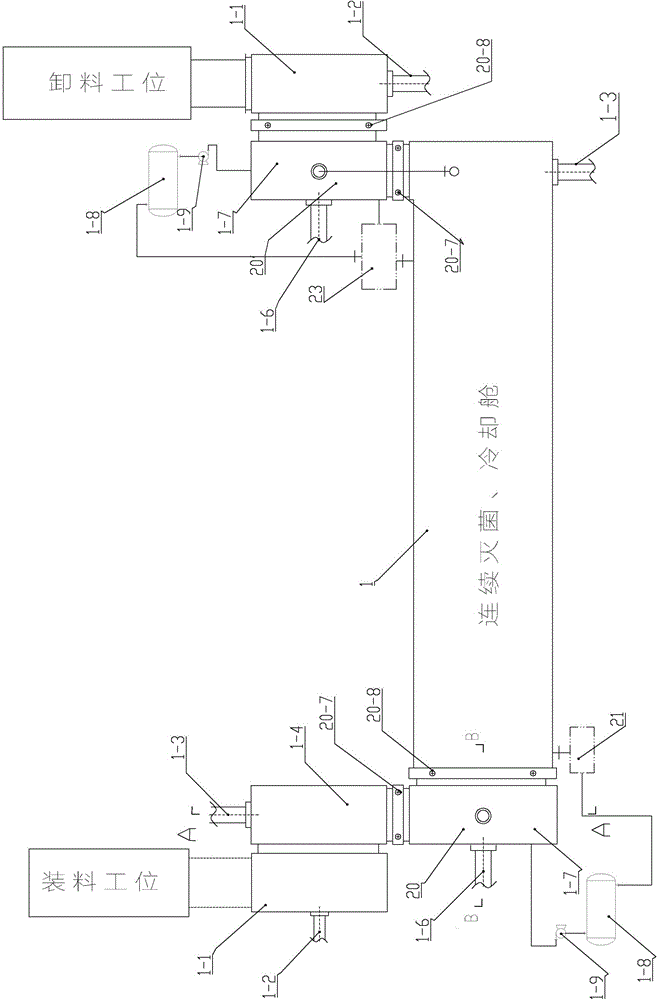

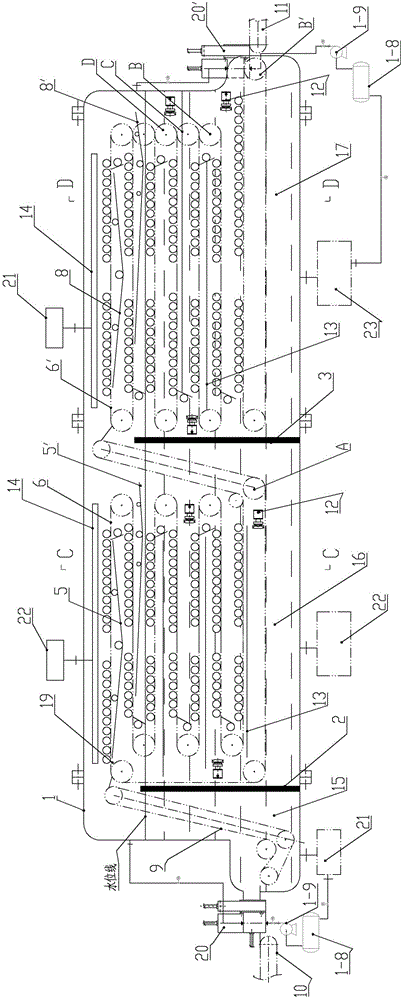

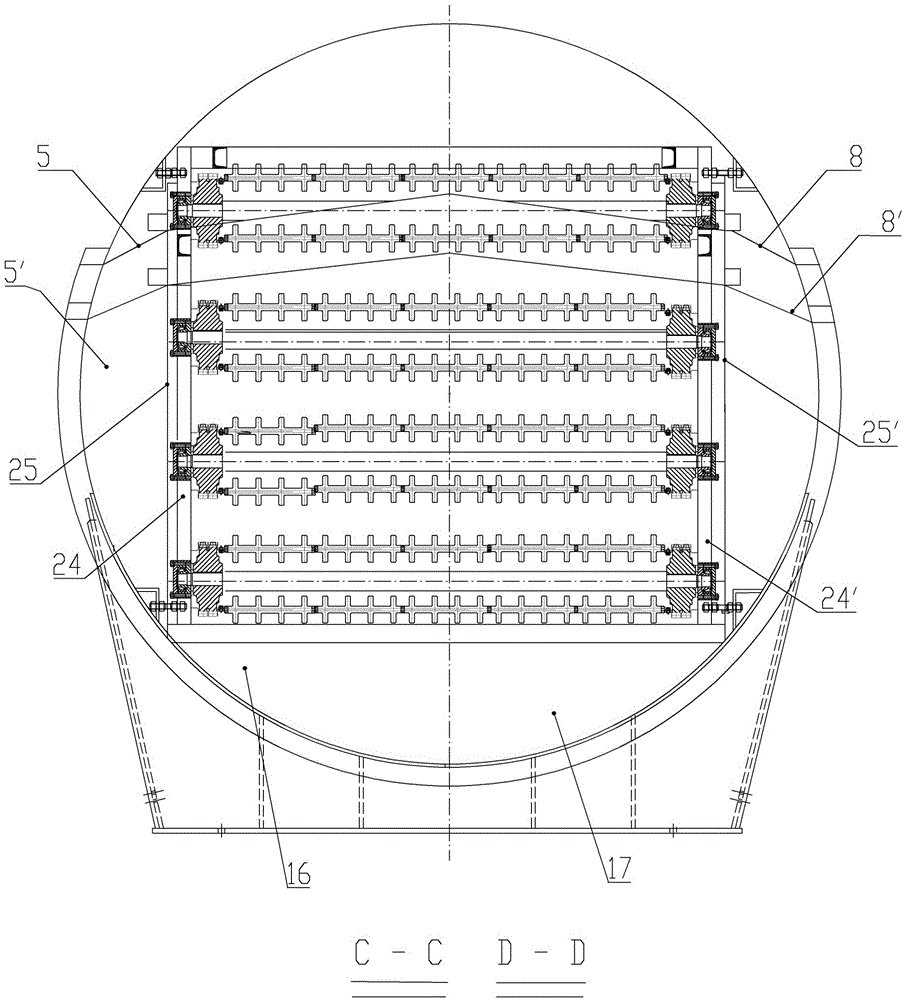

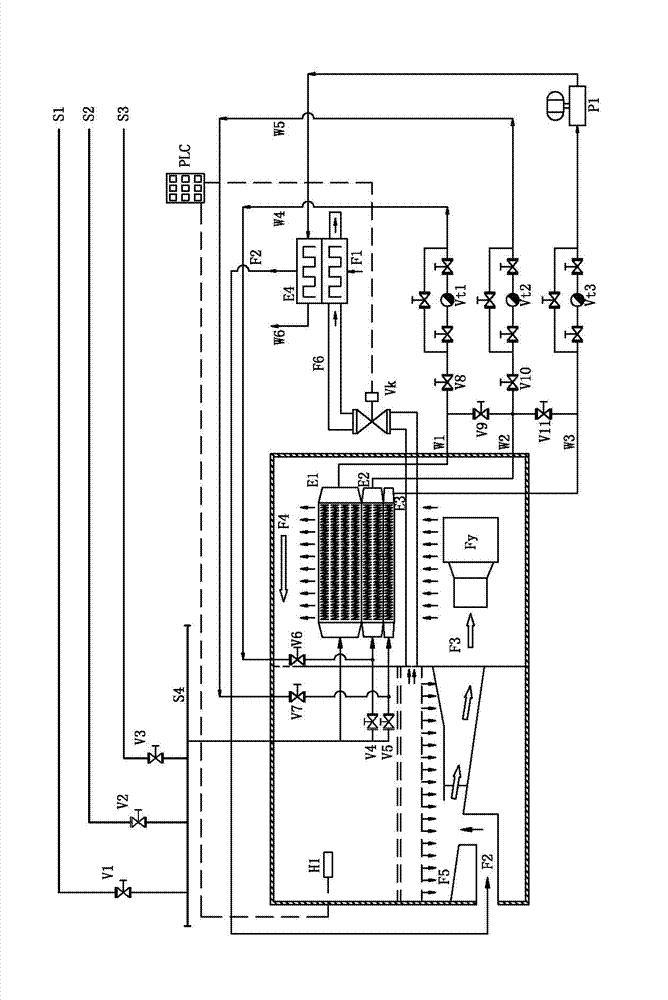

Continuous water bath sterilization pot

PendingCN106178009AGuaranteed qualitySimple structureFood preservationHeatThermodynamicsPlastic packaging

The invention relates to a continuous water bath sterilization pot. Horizontal sliding gate type feeding and discharging sealing devices adopt the principle of back pressure sealing of gate type U-shaped seal rings and adopt the mode of parallel feeding and discharging. The continuous water bath sterilization pot is suitable for sterilization processing of articles, such as flexibly packaged drinks, flexibly packaged medicaments, ham sausages, flexibly packaged food, pop-top cans, plastic packages and plastic cans, and is mainly formed by combining a material conveying chain, the horizontal sliding gate type feeding sealing device, a sterilization cabin, double layers of load conveying devices, a high-temperature water supply and recovery system, a cooling water supply and recovery system, the discharging sealing device, and the like. The continuous water bath sterilization pot has the advantages that the used sterile water is repeatedly heated by a boiler and then is reused after being filtered and the used cooling water can undergo circulating cooling in a cooling water tower and then can be used, so that the heat energy and plenty of water resources can be saved and the floor area can be reduced; the horizontal sliding gate type feeding and discharging sealing devices can enter 1-3 frames once; the continuous water bath sterilization pot can achieve the effect of increasing the degree of automation and has high application performance and reliability.

Owner:陈长清

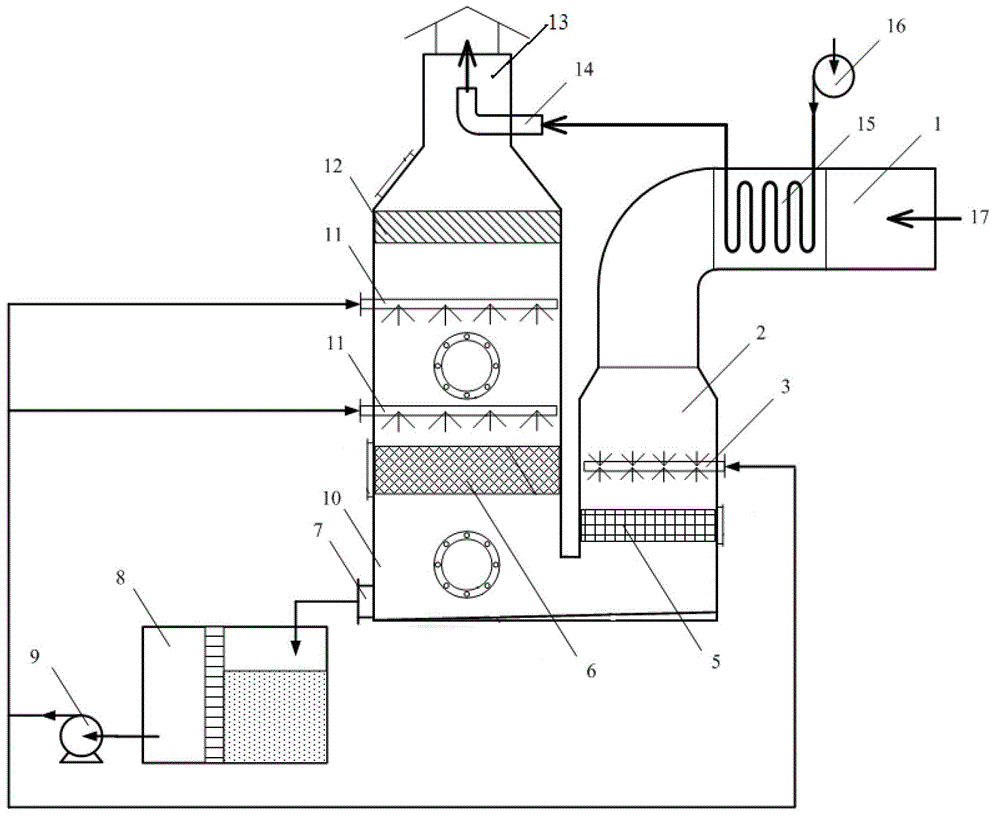

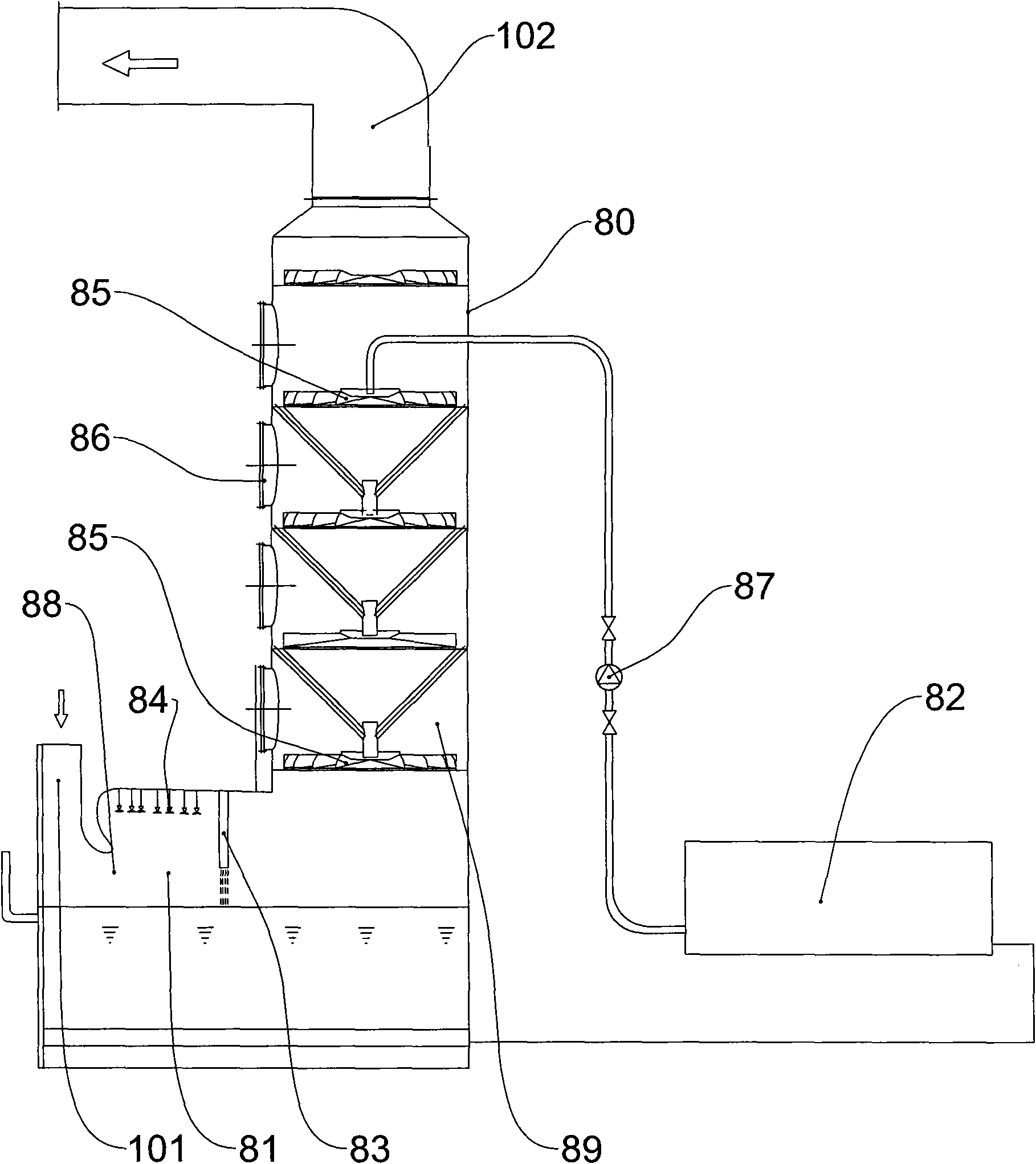

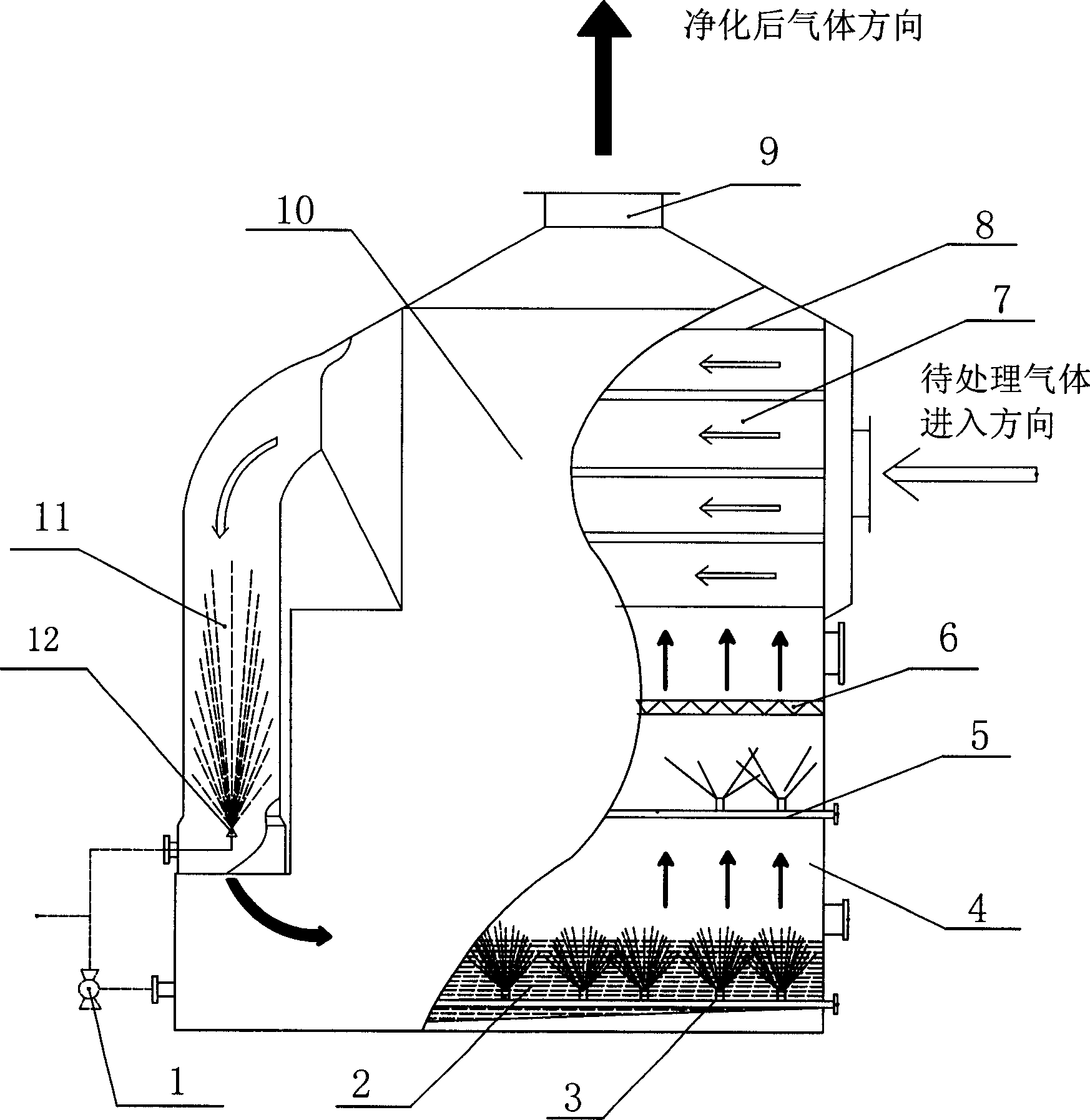

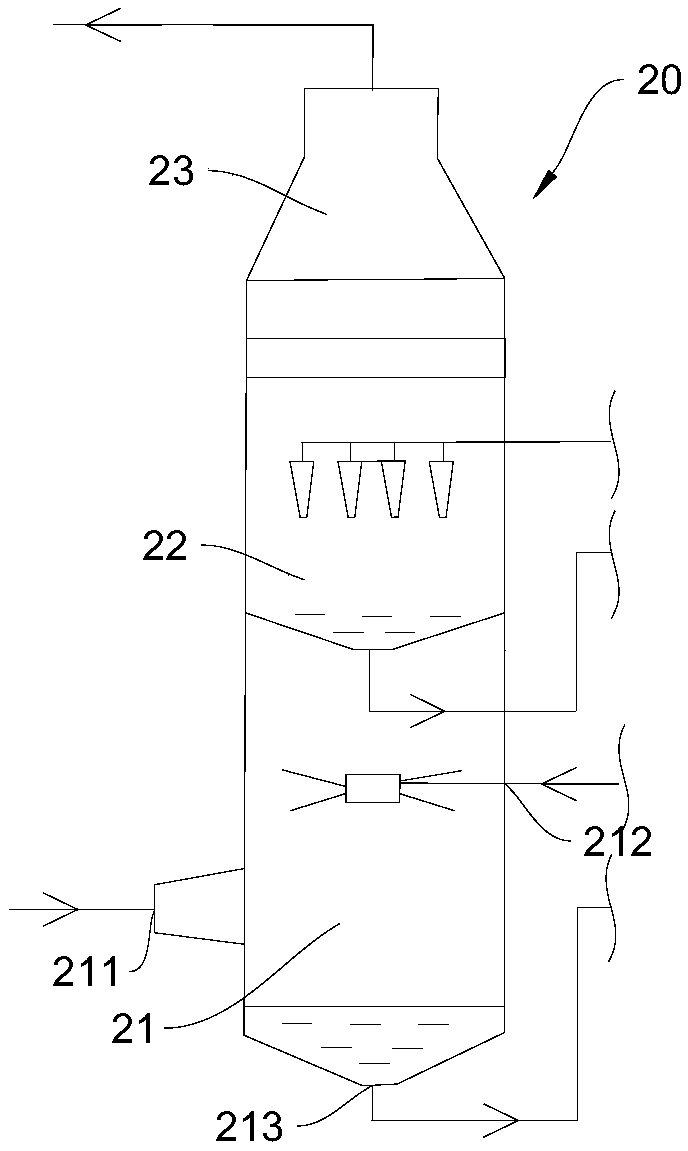

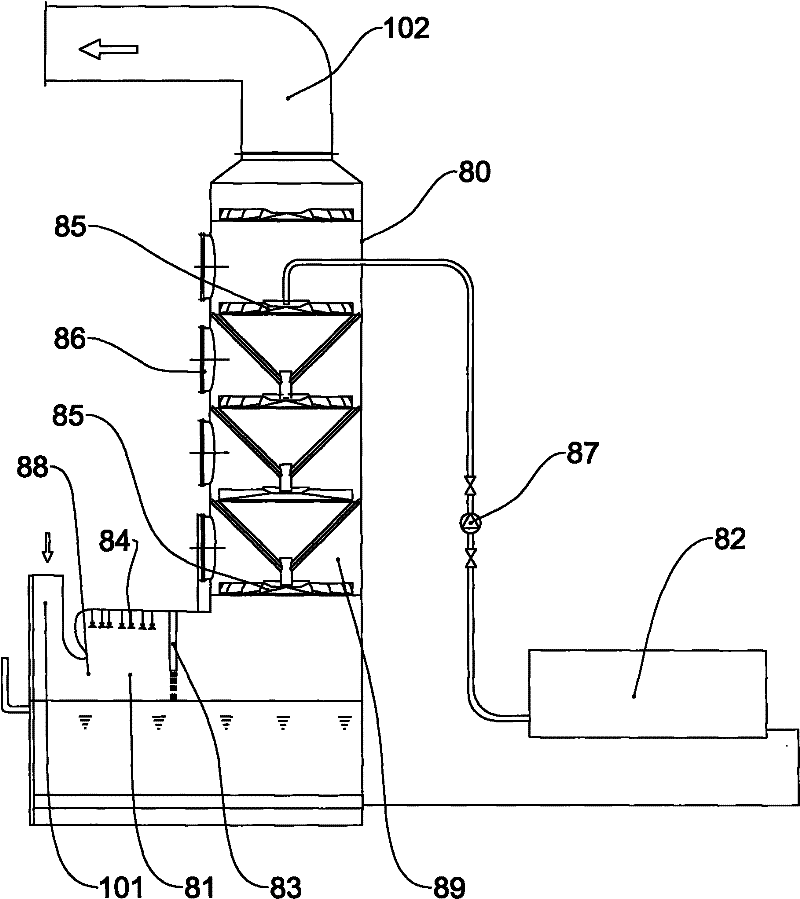

Wet fume purifier

ActiveCN1772350AReduce the temperatureIncrease discharge temperatureDispersed particle separationPower stationEngineering

The present invention relates to fume desulfurizing technology, and is especially a wet fume purifier for dedusting and desulfurizing fume in coal (oil) burning boiler in large power generating plant. The present invention features the heat exchanger for heat exchange with the high temperature fume to be treated, and aims at providing wet fume purifier capable of raising the temperature of treated fume. Compared with available technology, the present invention has the advantages of high dedusting and desulfurizing efficiency, obvious energy saving effect, compact structure, convenient operation, etc. and can eliminate the corrosion problem of downstream apparatus.

Owner:ZHEJIANG SHUANGYU IND +1

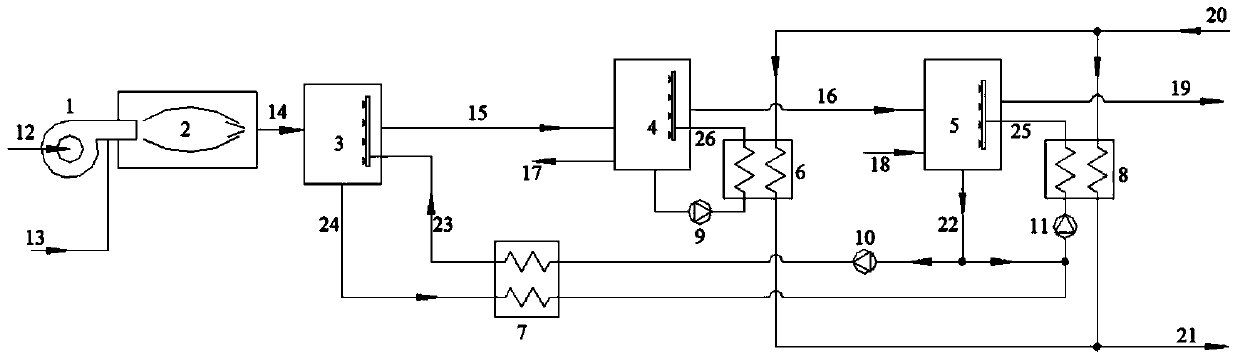

System for deeply eliminating white smoke of wet desulfurization flue gas

ActiveCN109432935AReduce fine particle contentReduce moisture contentGas treatmentHeat pumpsWater vaporFlue gas

The invention provides a system for deeply eliminating white smoke of a wet desulfurization flue gas, and belongs to the technical field of the flue gas desulfurization application. The system comprises a flue gas heat exchanging system, a desulfurization system and a heat pump circulating system. The flue gas heat exchanging system comprises a first heat exchanger and a second heat exchanger. Thedesulfurization system comprises a desulfurization tower. The desulfurization tower comprises a cooling absorbing section, an outlet section and a washing demisting section which are communicated. The heat pump circulating system comprises a generator, a condenser, an evaporator and an absorber. The system does not need an additional high-temperature heat source, and is capable of cooling desulfurization tower circulating liquid by using a heat pump technology, reducing moisture content of the purified flue gas, and through using circulating slurry heat and high-temperature inlet flue gas heat, improving a discharging temperature of the purified flue gas, greatly improving an unsaturation degree of the purified flue gas, thereby achieving a purpose of deeply eliminating the white smoke, and further reducing content of fine particulate matters in the flue gas through using condensation of water vapor.

Owner:SINOPEC ENG GRP CO LTD

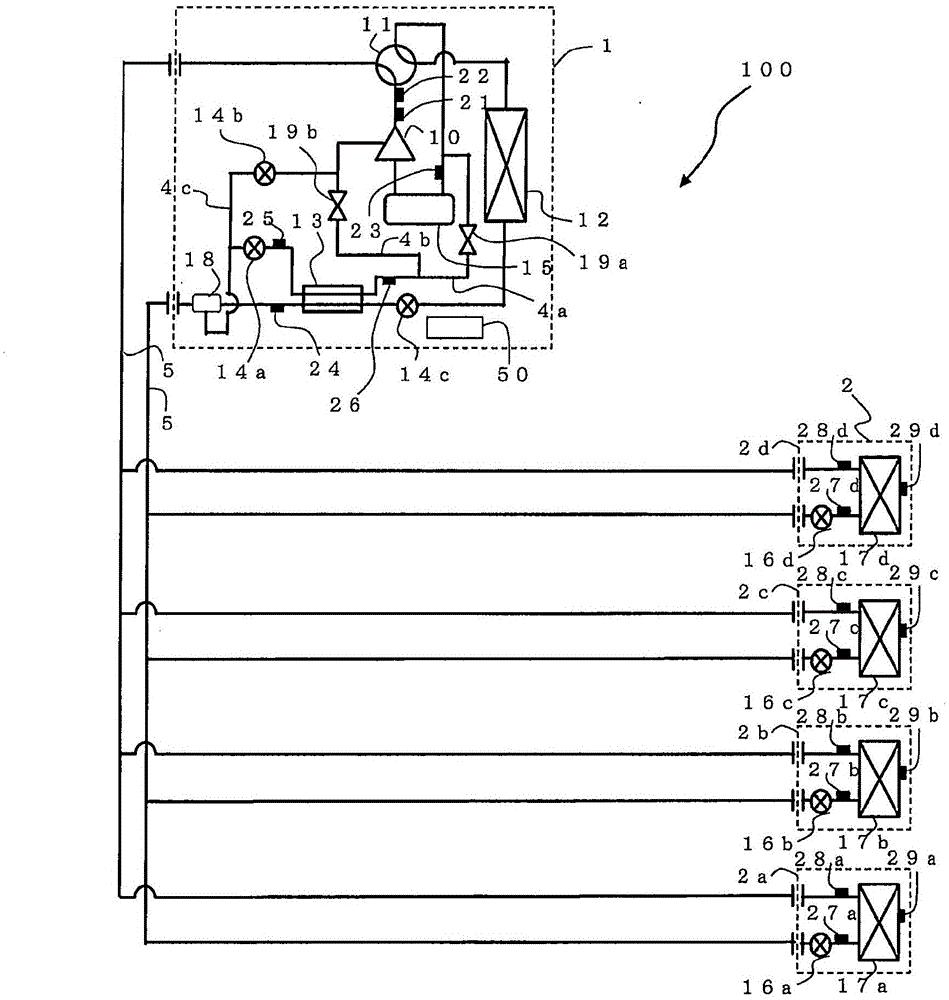

Air conditioner

ActiveCN105074351AAvoid damageIncrease discharge temperatureCompressorMechanical apparatusInjection portEngineering

An air conditioner (100) is provided with first bypass piping (4a) connected to an input-side flow passage of an accumulator (15) via a second throttling device (14a), a second flow passage of a supercooling heat exchanger (13) that exchanges heat with a refrigerant that flows through a first flow passage of the supercooling heat exchanger (13), and a first switching device (19a); second bypass piping (4b) that branches from the first bypass piping (4a) between the supercooling heat exchanger (13) and the first switching device (19a), and is connected to an injection port of a compressor (10) via a second switching device (19b); and third bypass piping (4c) that branches from refrigerant piping between a heat source-side heat exchanger (12) and utilization-side heat exchangers (17), and is connected to the second bypass piping (4b) between the second switching device (19b) and the injection port of the compressor (10), via a third throttling device (14b).

Owner:MITSUBISHI ELECTRIC CORP

Treatment method for low-temperature methanol washing exhaust gas

InactiveCN107626184AIncrease discharge temperatureReduce dosageDispersed particle separationStationary tubular conduit assembliesLower gradeSalt water

The invention discloses a treatment method for low-temperature methanol washing exhaust gas. The treatment method comprises the following steps: washing the low-temperature methanol washing exhaust gas with water by using a water washing tower, and carrying out heat exchange on the washed low-temperature methanol washing exhaust gas used as a cold source and condensate water and / or a low-grade heat source. The low-temperature methanol wash exhaust gas is utilized as the low-temperature cold source to exchange heat with the condensate water or the low-grade heat source, so the discharge temperature of the low-temperature methanol wash exhaust gas is increased, and recovery of the low-grade heat source and condensate water in enterprises and saving of the use amount of desalinated water arerealized in order to achieve the purposes of energy saving and environmental protection.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Dust remover rear flue gas system provided with flue gas heat exchanger

ActiveCN105627341AShorten the lengthReduce the amount of materialEmission preventionCombustion technology mitigationPlate heat exchangerFlue gas

The invention discloses a dust remover rear flue gas system provided with a flue gas heat exchanger. The system comprises two columns of induced draft fans communicated with a dust remover outlet, the flue gas heat exchanger communicated with the two columns of induced draft fans, a desulfurization absorption tower communicated with the flue gas heat exchanger, and a chimney communicated with the flue gas heat exchanger. The two columns of induced draft fans, the flue gas heat exchanger, the desulfurization absorption tower and the chimney are all arranged on the same straight line. The desulfurization absorption tower and the chimney are vertically arranged side by side. The two columns of induced draft fans and the flue gas heat exchanger are arranged between the chimney and the desulfurization absorption tower. The flue gas heat exchanger is arranged above the two columns of induced draft fans and comprises a gas inlet heat exchanger part communicated with one end of the desulfurization absorption tower, and a gas outlet heat exchanger part communicated with the other end of the desulfurization absorption tower. The gas inlet heat exchanger part and the gas outlet heat exchanger part are arranged into a whole. The dust remover rear flue gas system provided with the flue gas heat exchanger effectively utilizes space, the occupied land is saved, flue resistance and flue material consumption are reduced, and operating economy of a power plant is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025BObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionSuperheater

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and asmoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

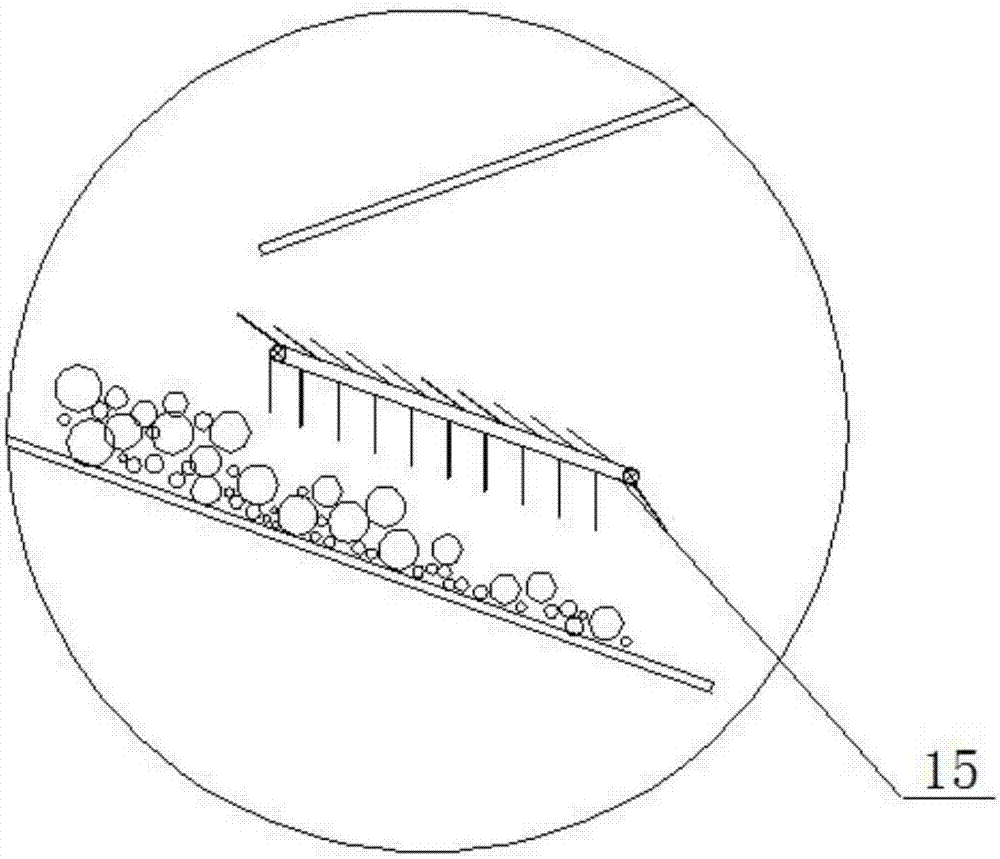

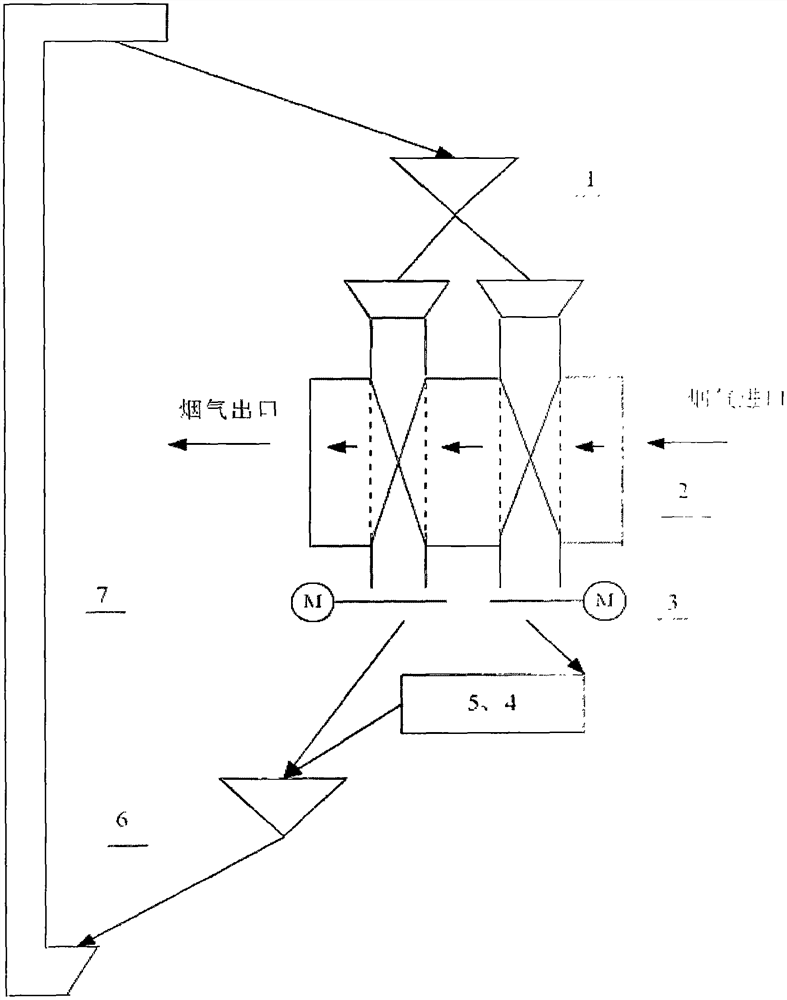

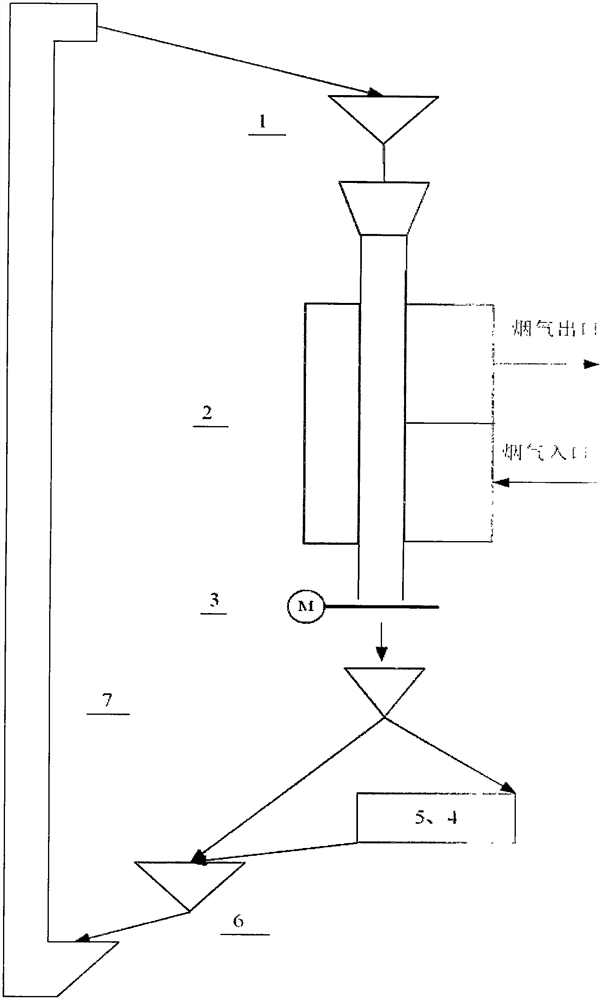

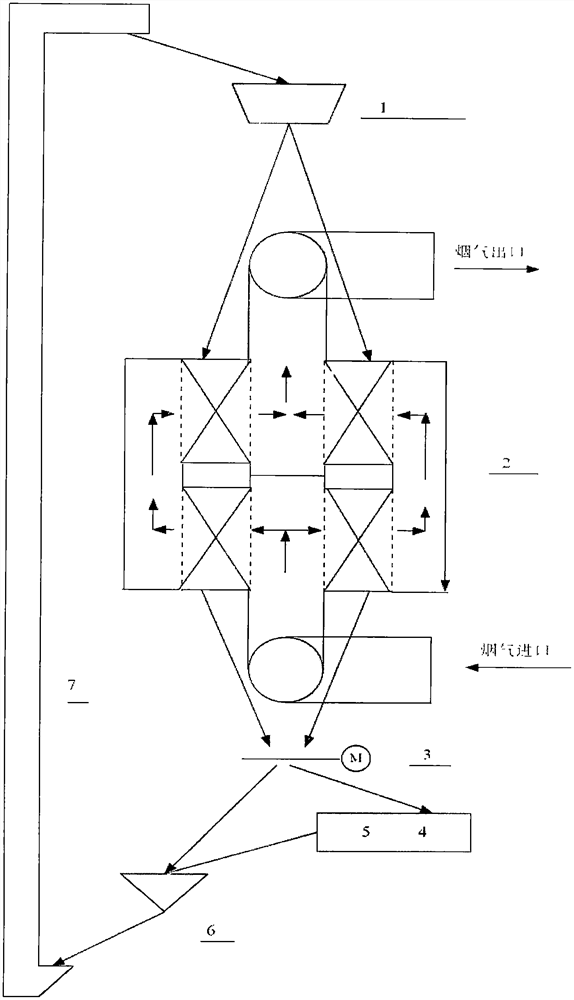

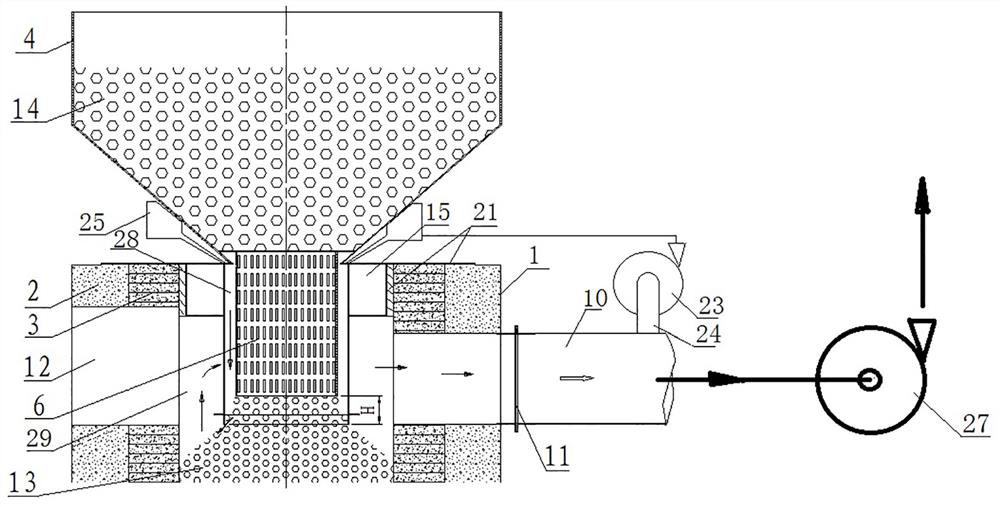

Moving bed dry flue gas desulfurization method

ActiveCN113332851AIncrease profitEasy to moveGas treatmentDispersed particle separationCalcium hydroxideCombustion

The invention discloses a process method for removing sulfur dioxide from boiler flue gas, coke oven flue gas, oil refining FCC regeneration flue gas and the like in hydrocarbon oxidative combustion, and a system for implementing the method. Therefore, the desulfurization process method disclosed by the invention has the advantages that the desulfurization efficiency and the emission suspended matter index can reach the special emission limit standard of atmospheric pollution of the Ministry of Environmental Protection; and in addition, the method also has the characteristics of low water content of the discharged flue gas and high flue gas emission temperature, and effective support is provided for reducing the generation of atmospheric haze and high-altitude heat emission of the flue gas. The typical implementation scheme is as follows: a carrier ball loaded with calcium hydroxide particles is in full contact with flue gas flowing transversely, radially and vertically through a moving bed reactor and is subjected to desulfurization reaction. The carrier ball can vertically move from top to bottom and also can obliquely move and flow according to a certain angle, so that a concentration difference is formed between a desulfurizing agent and sulfur dioxide in flue gas, and the desulfurizing effect is ensured to meet the environment-friendly emission requirement.

Owner:薛援

Waste heat recovery system for improving efficiency of electric dust collector

ActiveCN102645112BAvoid corrosionImprove ESP EfficiencyStationary tubular conduit assembliesTubular elementsAir preheaterPower station

The invention discloses a waste heat recovery system for improving the efficiency of an electric dust collector, belonging to the technical field of a flue gas waste heat recovery system of a thermal power plant and the like. The system comprises a high-temperature flue gas pretreatment device, an air preheater, an electric dust collector, a desulfurization system and a chimney which are connected sequentially, wherein a waste heat recovery device is cooperatively arranged between the air preheater and the electric dust collector; the waste heat recovery device comprises a shell and a heat exchange tube bundle cooperatively arranged in the shell; the heat exchange tube bundle is a spiral finned tube; and a liquid inlet I is arranged at one end of the heat exchange tube bundle, and a liquid outlet I is arranged at the other end. The waste heat recovery system disclosed by the invention has a simple overall structure, a self-dust cleaning function and a good heat exchange effect, and prevents dust accumulation; the temperature of the flue gas is reduced from 130-180 DEG C to 90-110 DEG C, and the water temperature is increased from 40-70 DEG C to 70-100 DEG C; and moreover, the volume of the flue gas entering the electric dust collector is reduced, the flow velocity of the flue gas is reduced, the efficiency of the electric dust collector can be effectively improved, and the discharge requirement of the new standard is met.

Owner:武汉蓝宁能源科技有限公司

Method for cleaning and purifying sulfur-containing tail gases

ActiveCN110052111AExhaust fastDiffusion fastGas treatmentLighting and heating apparatusSulfur containingChemistry

The invention belongs to the technical field of waste gas treatment, and discloses a method for cleaning and purifying sulfur-containing tail gases. The method includes the following steps: subjectingthe acidic sulfur-containing tail gases to a second-stage Claus reaction, feeding the reacted Claus tail gases to the bottom of a spraying tower, enabling the gases to run upwardly, discharging the gases from the top of the spraying tower after the gases contact with clear water downwardly sprayed from a spray nozzle at the top of the spraying tower, injecting the gases into a primary adsorptiontower provided with CuO activated carbon adsorbents to conduct adsorption treatment, cooling the gases by a heat exchanger, injecting the gases into a secondary adsorption tower provided with boron-nitrogen double-doped iron oxide activated carbon composite adsorbents to conduct adsorption treatment, and discharging out the treated gases. The method for cleaning and purifying the sulfur-containingtail gases has the advantages that efficient and stable desulfurization can be realized, the operational stability of the process is high, the treated gases can be directly discharged into the atmosphere, the diffusion speed is high, and formation of haze can be effectively prevented.

Owner:安徽皖华环保设备科技有限公司

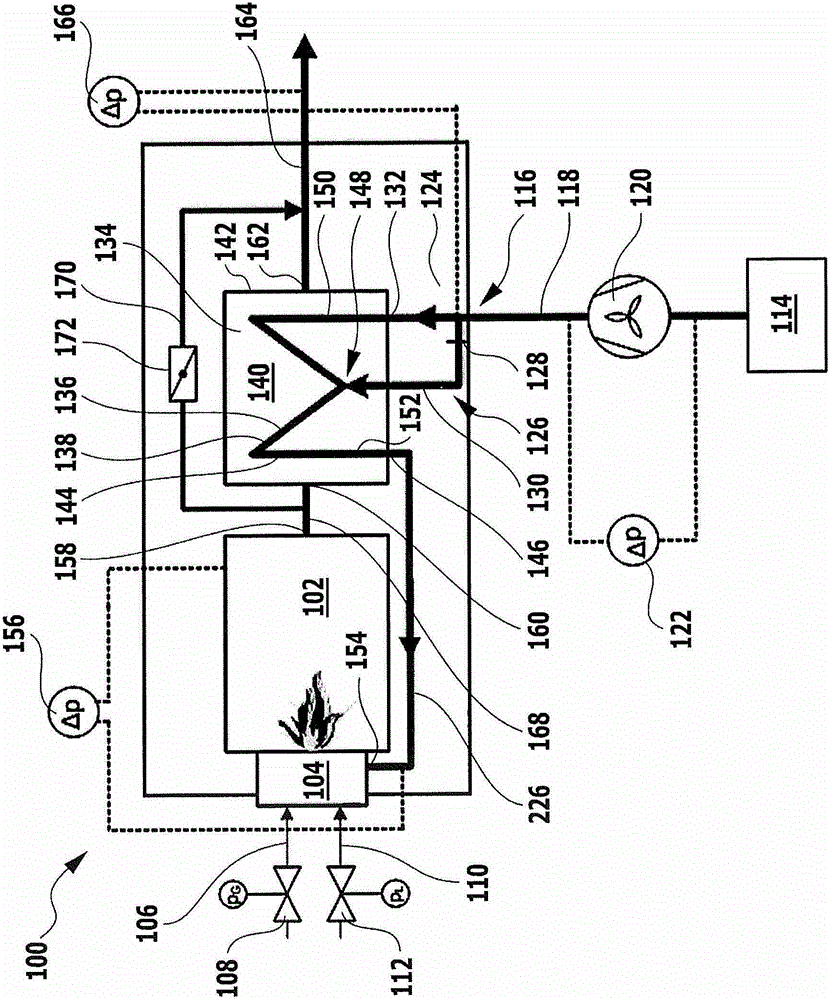

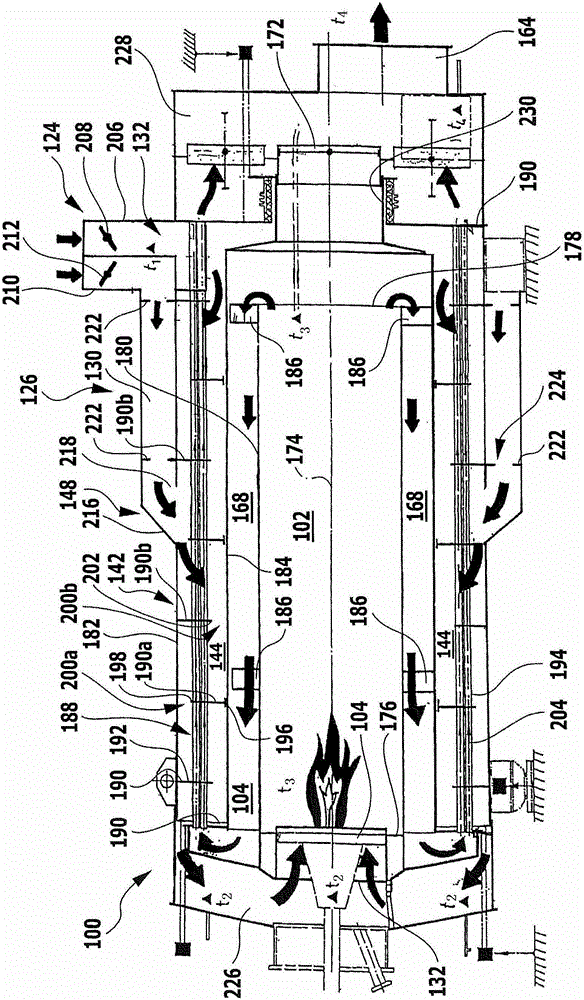

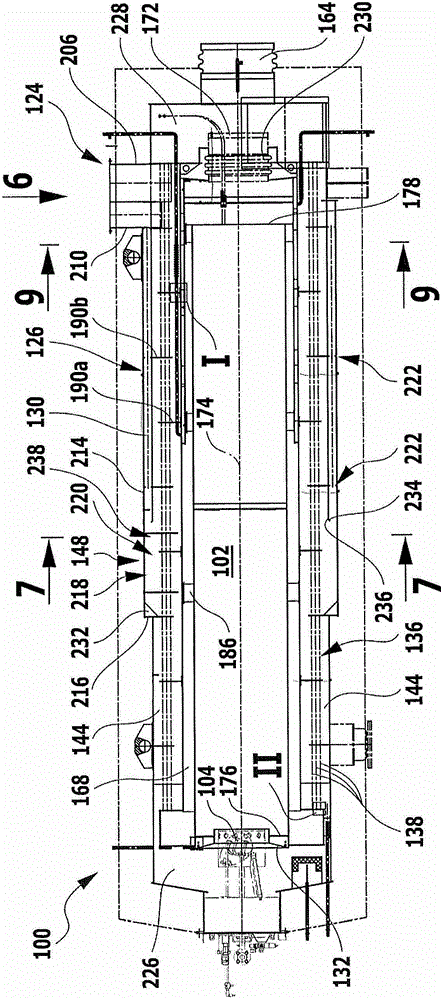

Thermal exhaust air treatment plant

ActiveCN102803853AEvenly mixedImprove distributionIncinerator apparatusCombustion chamberPlate heat exchanger

To provide a thermal exhaust air treatment plant, comprising a combustion chamber and a heat exchanger for transferring heat from a cleaned gas produced in the combustion chamber to an untreated gas to be supplied to the combustion chamber, wherein the heat exchanger comprises an inner heat exchanger chamber through which an inner fluid medium can flow and comprises an outer heat exchanger chamber through which an outer fluid medium can flow, which thermal exhaust air treatment plant permits regulation of the cleaned gas outlet temperature without a reduction in the cleaned gas quality, it is proposed that the thermal exhaust air treatment plant comprises a bypass device with a separating device by means of which a part of the outer fluid flow can be separated, as a bypass fluid flow, from an outer residual fluid flow, and with an admixing device by means of which the bypass fluid flow can be admixed to the residual fluid flow again after the residual fluid flow has passed through a section of the outer heat exchanger chamber.

Owner:杜尔涂装系统工程(上海)有限公司

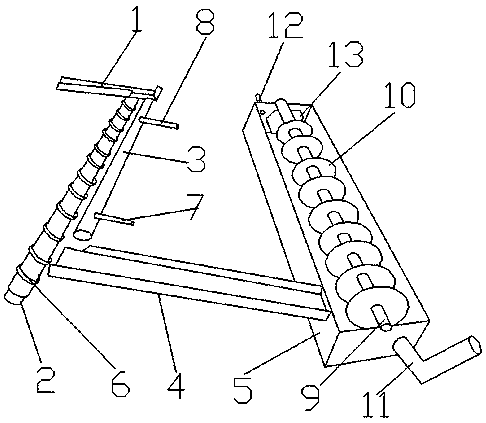

Annealing cooling device for hot-rolled steel balls

ActiveCN109082518AIncrease discharge temperatureReduce CooldownFurnace typesHeat treatment furnacesSpiral bladeSteel ball

The invention discloses an annealing cooling device for hot-rolled steel balls. The annealing cooling device for hot-rolled steel balls comprises a first chute, a horizontal transportation shaft, a heat exchange iron tube, a second chute and a water cooling tank. A spiral reinforcing steel bar is connected to the outer shaft wall of the horizontal transportation shaft in a sleeving mode, and the heat exchange iron tube and the horizontal transportation shaft are arranged in parallel; the top end of the first chute is connected to an annealing furnace, a notch in the bottom end of the first chute is located right above one end of the heat exchange iron tube, the other end of the heat exchange iron tube is located right above the top end of the second chute, and the heat exchange iron tube is provided with a circulating water inlet pipe and a circulating water outlet pipe; the bottom end of the second chute is connected to the side wall of the water cooling tank, a rotary shaft with feeding spiral blades is arranged on the water cooling tank, and the water cooling tank is also provided with a cold water inlet pipe, a water outlet pipe and a steel ball outlet. By cooing the annealed steel balls by way of sectional cooling, the steel ball cooling time is relatively short, the annealing effect is good and the work efficiency is high. The annealing cooling device has a function of identifying the internal stress of the steel balls, so that the product quality of the steel balls is guaranteed.

Owner:TONGLING MINGCHENG FOUNDRY

Constant humidity type classification heat exchange dewatering and water-wind sensible heat multistage utilization relaxation heat setting machine

InactiveCN103088508AReduce consumptionReduce heat pollutionDrying gas arrangementsTextiles and paperEngineeringRecuperator

The invention relates to a constant humidity type classification heat exchange dewatering and water-wind sensible heat multistage utilization relaxation heat setting machine. A return air inlet and an exhaust outlet are formed in the lower portion of a drying chamber, the exhaust outlet is communicated to the outside of a box body through an exhaust tube, the return air inlet and an air compensation port in the box body are both communicated with a suction outlet of a fan, an air outlet of the fan is aligned to heat exchangers above the fan, the air outlet above the heat exchangers enters into the drying chamber, an inlet of a high pressure heat exchanger is connected with a steam supply main tube, an outlet of the high pressure heat exchanger is connected into an inlet of a middle pressure heat exchanger through a high pressure drain valve, an outlet of the middle pressure heat exchanger is connected into an inlet of a lower pressure heat exchanger through a middle pressure drain valve, an outlet of the low pressure heat exchanger is connected into a condensate pump through a low pressure drain valve, an outlet of the condensate pump is connected into a new wind preheater, a preheating air outlet of the new wind preheater is connected into the air compensation port of the relaxation setting machine, and exhaust and low pressure condensate water of the relaxation setting machine are respectively connected into the new wind preheater to achieve indirect heat exchange with new wind. The setting machine can achieve sufficient utilization of waste heat of the exhaust and the condensate water, and is high in heat efficiency.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

A method for energy-saving, environment-friendly and efficient operation of a high-temperature shaft kiln for high-purity magnesia calcination

ActiveCN109824282BReduce energy consumptionThe absolute value of negative pressure increasesThermodynamicsFlue gas

The invention belongs to the technical field of high-purity magnesia high-temperature shaft kiln production, and specifically relates to a method for energy-saving, environment-friendly and efficient operation of a high-purity magnesia high-temperature shaft kiln for calcining high-purity magnesia. And the three aspects of raising the discharge flue gas temperature; wherein the method of maintaining the negative pressure in the kiln is to use the kiln cover plate of the welded structure; the method of forming the high-speed air flow at the kiln mouth feeding position is to use the air flow to form a sleeve; the lifting discharge The structure of flue gas temperature includes return air fan, return air pipeline and hot air circulation inlet pipeline. Compared with the prior art, the beneficial effects of the present invention are: 1) The absolute value of the negative pressure inside the kiln is increased by 500pa, which can reduce the energy consumption of the smoke exhaust fan by 40% compared with the past. 2) The bonding in the high temperature area is not obvious, and the operating life of the kiln (cleaning cycle) is more than doubled. 3) Raise the temperature of flue gas discharged from the kiln by more than 50°C, realizing the energy-saving, environment-friendly, efficient and safe operation of the high-temperature shaft kiln.

Owner:亨特利(海城)镁矿有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com