Wet fume purifier

A wet purification and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of induced draft fan impeller, flue and chimney corrosion, downstream equipment corrosion, etc., to save consumption and solve problems. Corrosion problem, effect of increasing discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

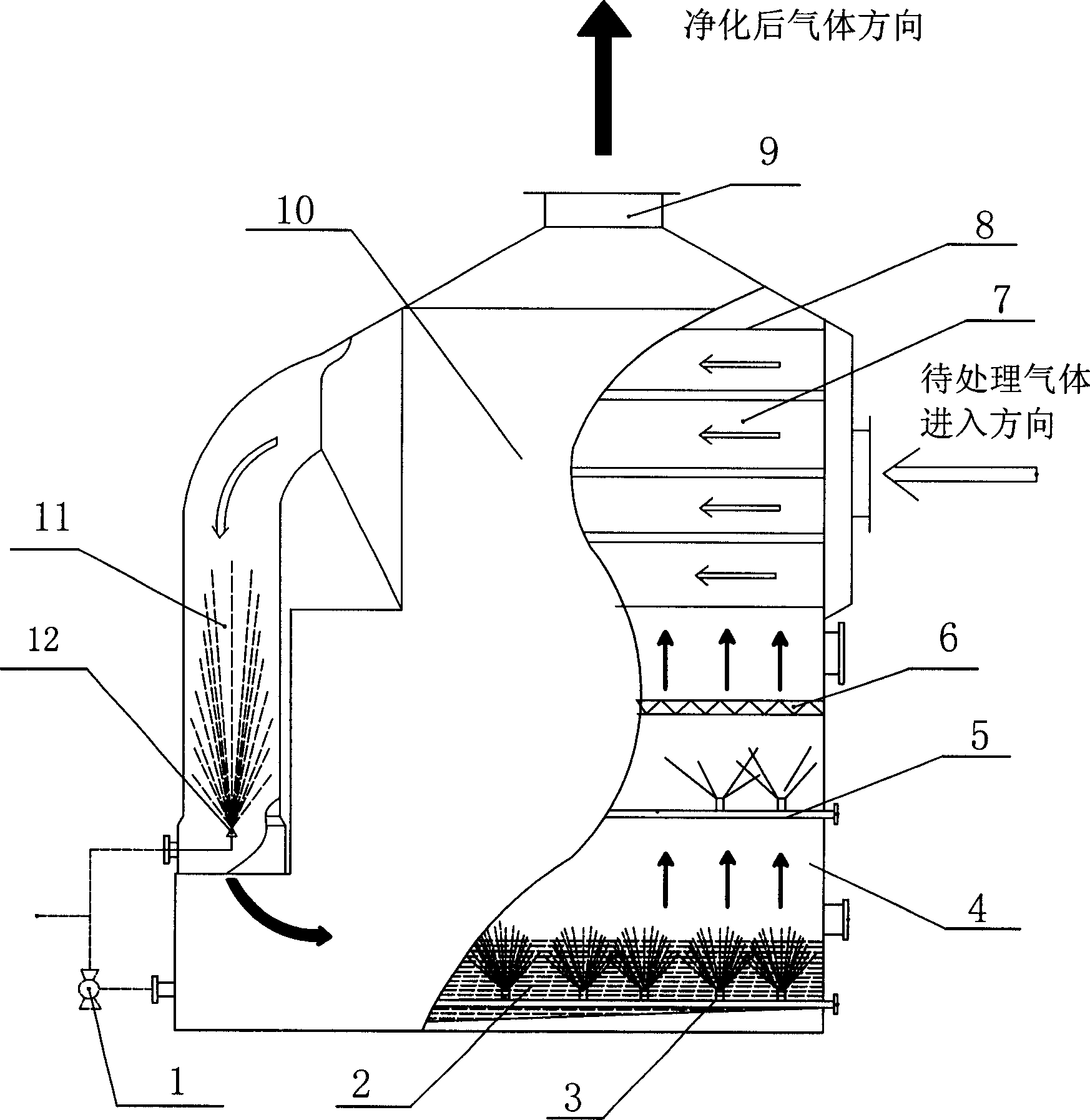

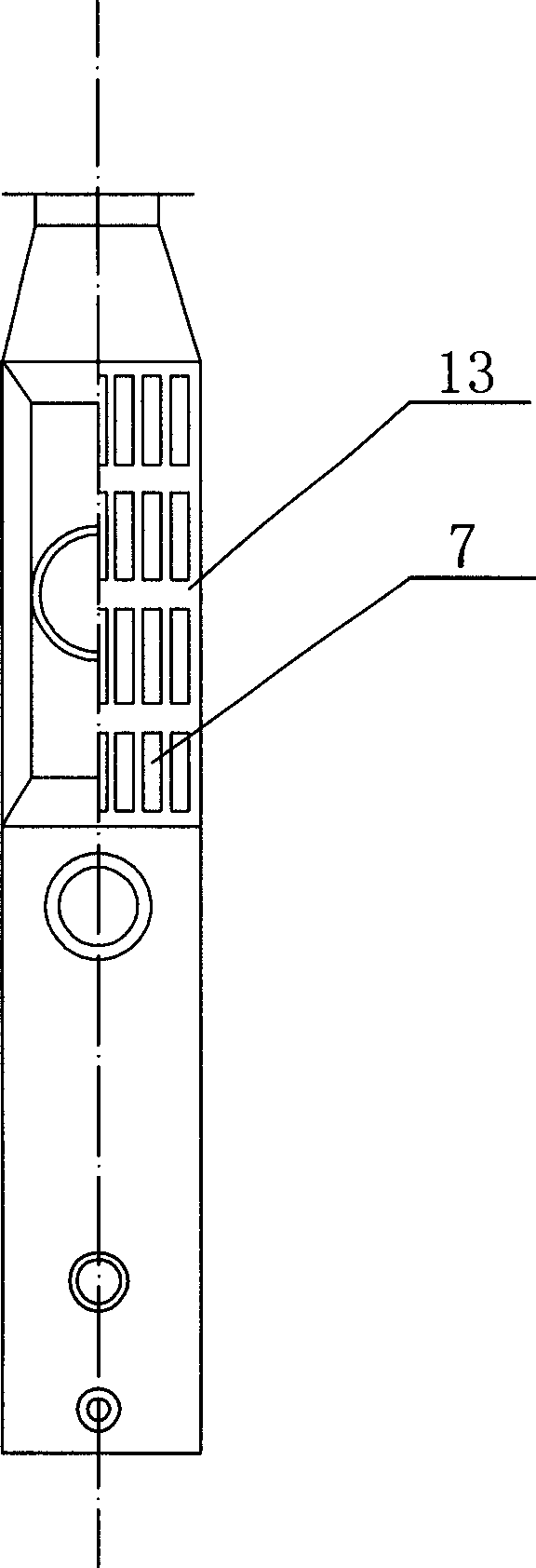

[0010] Such as figure 1 , figure 2 Shown, the present embodiment comprises absorption reactor (11), purification comprehensive tower (10), wherein absorption reactor (11) comprises nozzle (12), circulating pump (1), and concentrates in purification comprehensive tower (10) There are liquid collecting tank (2), gas micro-explosive device (3), demister (6), cleaning device (5) and graphite heat exchanger (8), and demuerating device (6) is located in liquid collecting tank (4 ), there is a gas-liquid separation belt (4) between them, the washer (5) is set under the demister (6), and the graphite heat exchanger (8) is set above the demister (6) in contact with the smoke Between the gas discharge outlets (9), the two ends of the shell side (13) of the graphite heat exchanger are connected to the flue gas discharge main channel, and the two ends of the tube side (7) of the graphite heat exchanger (8) are connected to the flue gas to be purified. Between the gas inlet and the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com