Drying production method and device thereof for polyaluminium chloride water purifying agent

A technology of polyaluminum chloride and production method, which is applied in the fields of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as not being successfully promoted, and achieve a clean, more environmentally friendly production process and full of market competition The effect of high utilization rate of force and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

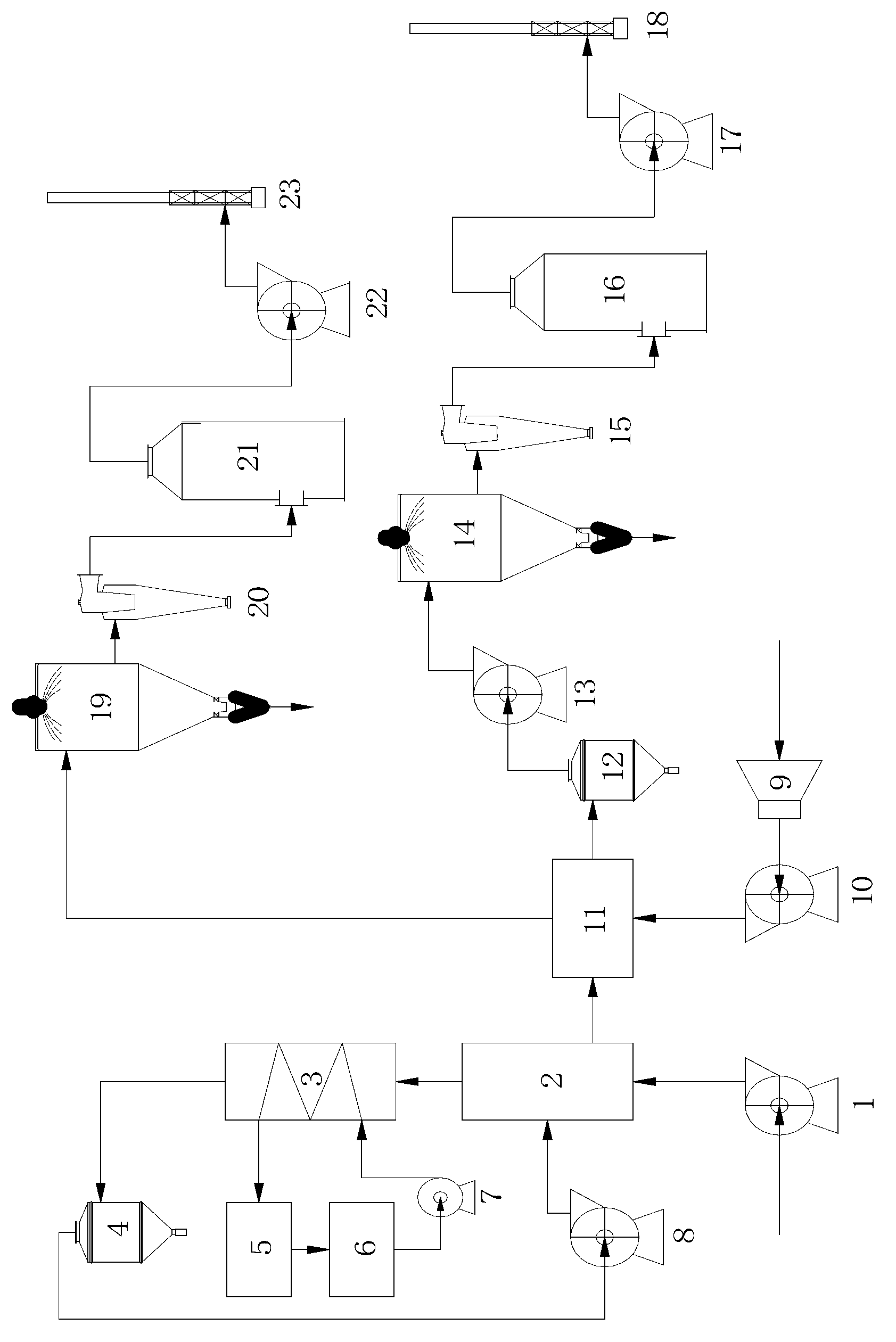

[0027] Using aluminum hydroxide, calcium aluminate, bauxite and hydrochloric acid as raw materials, use 10m 3 Enamel Reactor and 100m 3 The reaction tank prepares liquid polyaluminum chloride, and obtains high-purity polyaluminum chloride liquid with an alumina content of 17%, drinking water-grade polyaluminum chloride liquid with an alumina content of 13%, and ordinary non-filtered polyaluminum chloride liquid with an alumina content of 9%. Polyaluminum chloride liquid, using the above three liquid polyaluminum chlorides as raw materials, adopts the water purifying agent drying production method of the present invention to carry out drying production, and the temperature of the first part of the flue gas at the outlet of the fluidized furnace and the temperature of the second part of the flue gas are both 950 ° C ~ 1000°C, the flue gas temperature of the first part of the flue gas is reduced by 450°C to 500°C after heat exchange, and the heat transfer oil is heated to 280°C t...

Embodiment 2

[0029] Using aluminum hydroxide, calcium aluminate, bauxite and hydrochloric acid as raw materials, use 10m 3 Enamel Reactor and 100m 3 The reaction tank prepares liquid polyaluminum chloride, and produces high-purity polyaluminum chloride liquid with an alumina content of 19%, drinking water grade polyaluminum chloride liquid with an alumina content of 13.5%, and ordinary non-filtered polyaluminum chloride liquid with an alumina content of 10%. Polyaluminum chloride liquid, using the above three liquid polyaluminum chlorides as raw materials, adopts the water purifying agent drying production method of the present invention to carry out drying production, and the temperature of the first part of the flue gas at the outlet of the fluidized furnace and the temperature of the second part of the flue gas are both 900 ° C ~ 950°C, the flue gas temperature of the first part of the flue gas is reduced by 400°C to 450°C after heat exchange, and the heat transfer oil is heated to 280°...

Embodiment 3

[0031] Using aluminum hydroxide, calcium aluminate, bauxite and hydrochloric acid as raw materials, use 10m 3 Enamel Reactor and 100m 3 The reaction tank prepares liquid polyaluminum chloride, and obtains high-purity polyaluminum chloride liquid with an alumina content of 19.5%, drinking water-grade polyaluminum chloride liquid with an alumina content of 14%, and ordinary non-filtered polyaluminum chloride liquid with an alumina content of 11%. Polyaluminum chloride liquid, using the above three liquid polyaluminum chlorides as raw materials, adopts the water purifying agent drying production method of the present invention to carry out drying production, and the temperature of the first part of the flue gas at the outlet of the fluidized furnace and the temperature of the second part of the flue gas are both 800 ° C ~ 850°C, the flue gas temperature of the first part of the flue gas is reduced by 350°C to 400°C after heat exchange, and the heat transfer oil is heated to 280°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com