Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improved turning performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic Tire

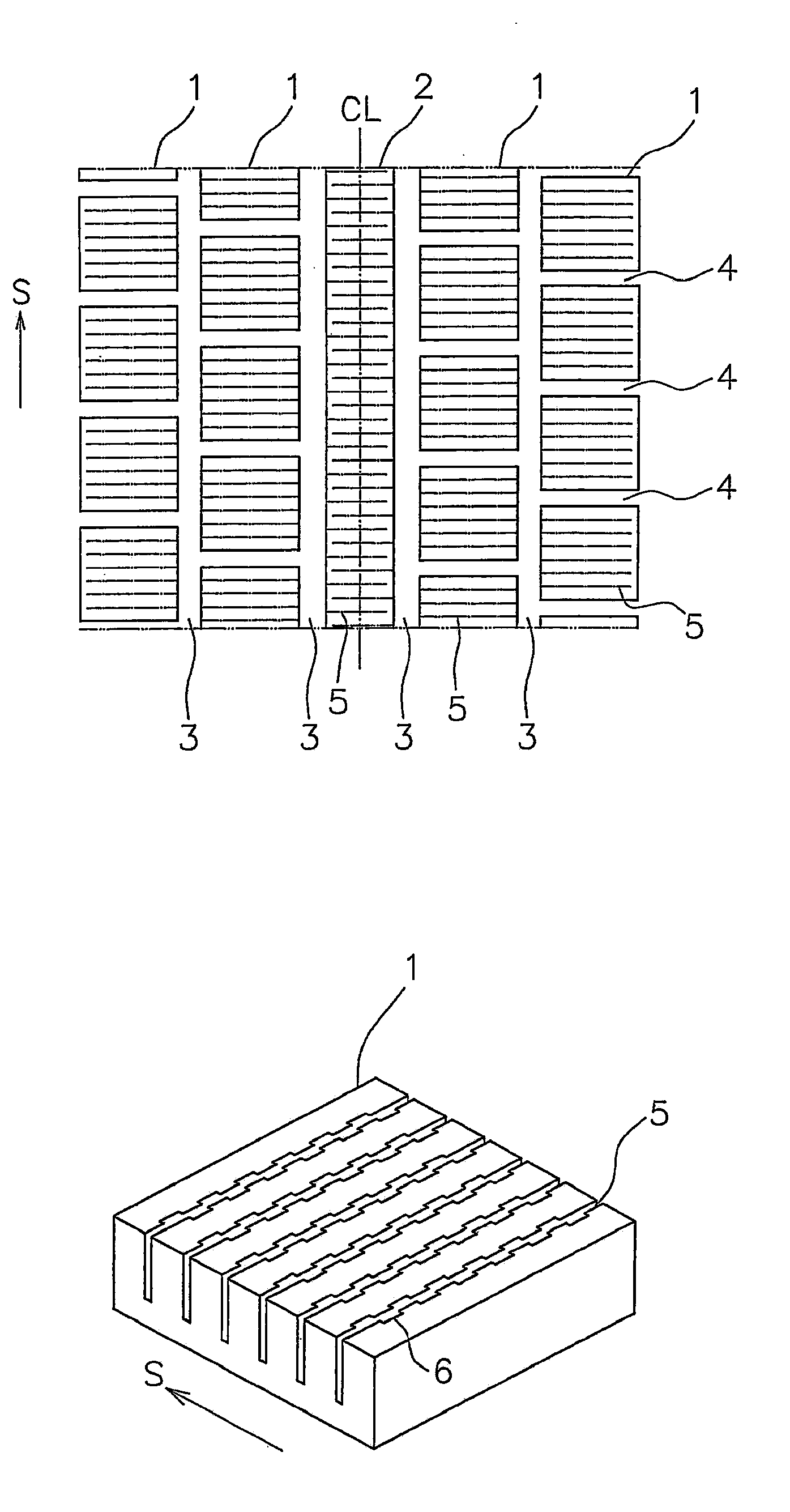

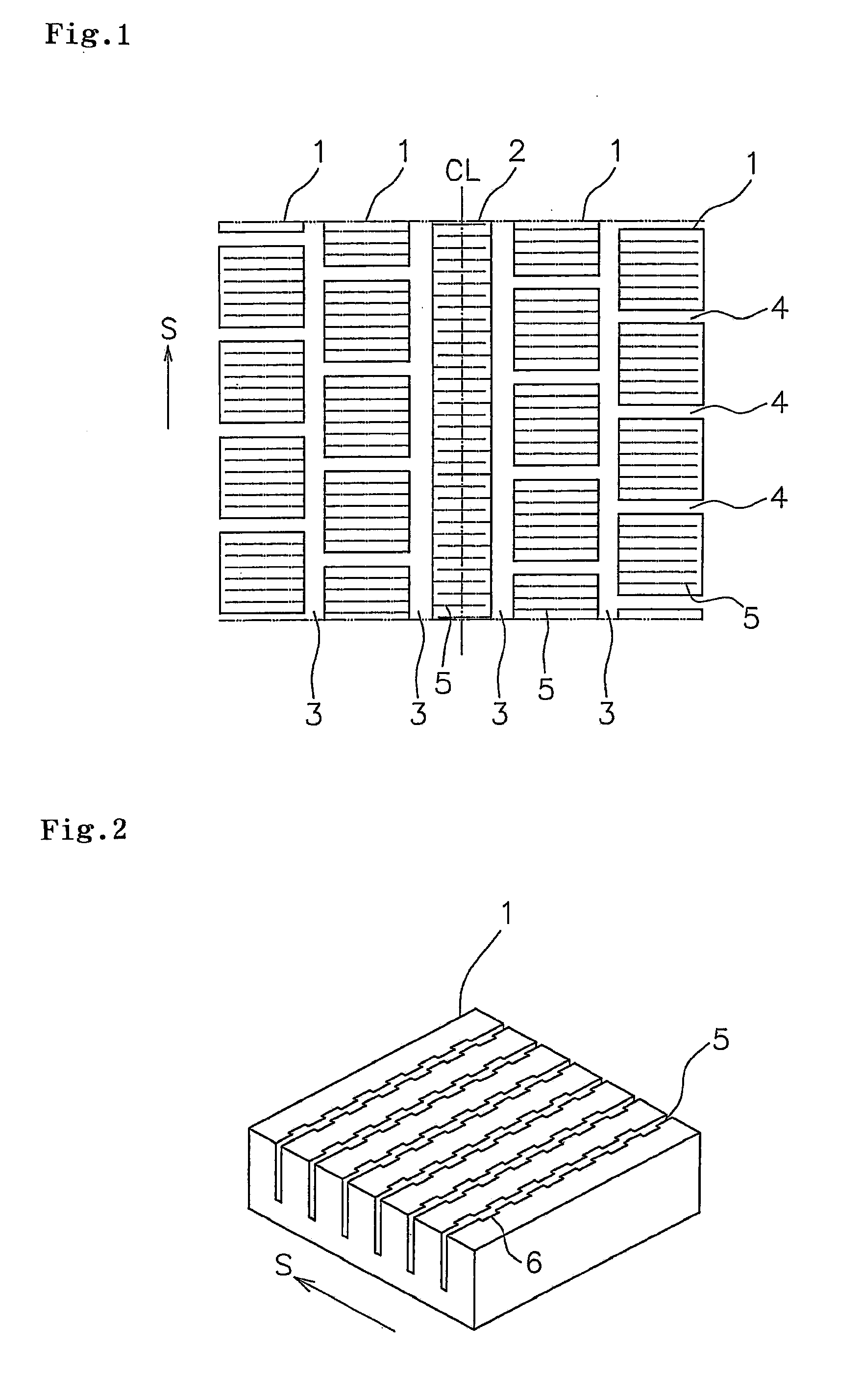

InactiveUS20100084062A1Increasing dry steering stability performanceImprove rigidityTyre tread bands/patternsNon-skid devicesRoad surfaceEngineering

An object of the present invention is to provide a pneumatic tire capable of ensuring both of the ice braking performance and the ice turning performance while increasing the dry steering stability performance. To achieve the above object, a sipe extending in a width direction of the tire is formed a land portion, the sipe having: pluralities of wide portions each having an inclined plane that begins from the tread surface of a road surface, and terminates in the half way of a sipe wall while inclining so that a sipe width decreases toward the groove bottom of the sipe, and a pair of side faces connecting the inclined plane and the sipe wall therebetween, wherein the pluralities of wide portions are located alternately on both sipe walls along a longitudinal direction of the sipe.

Owner:TOYO TIRE & RUBBER CO LTD

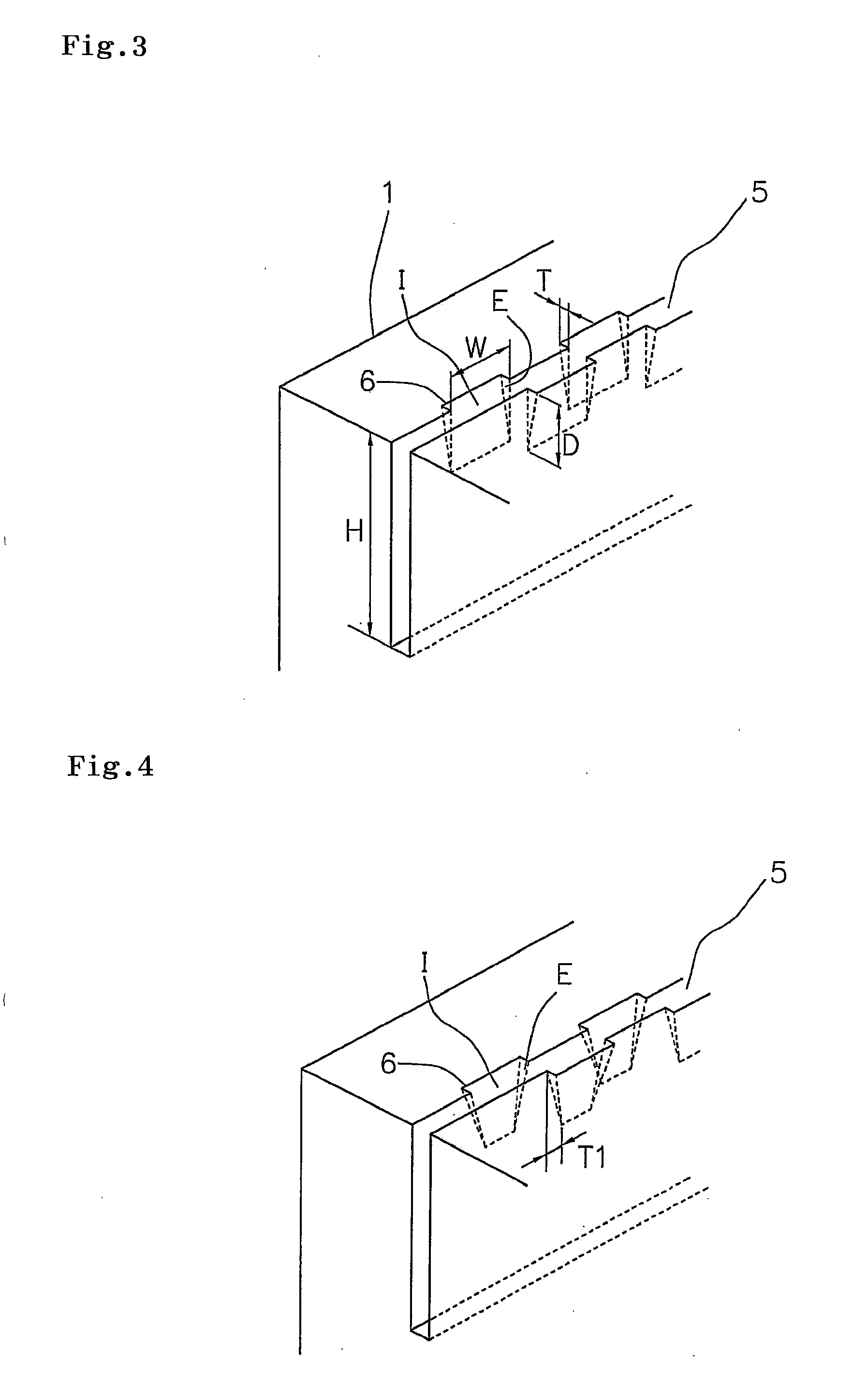

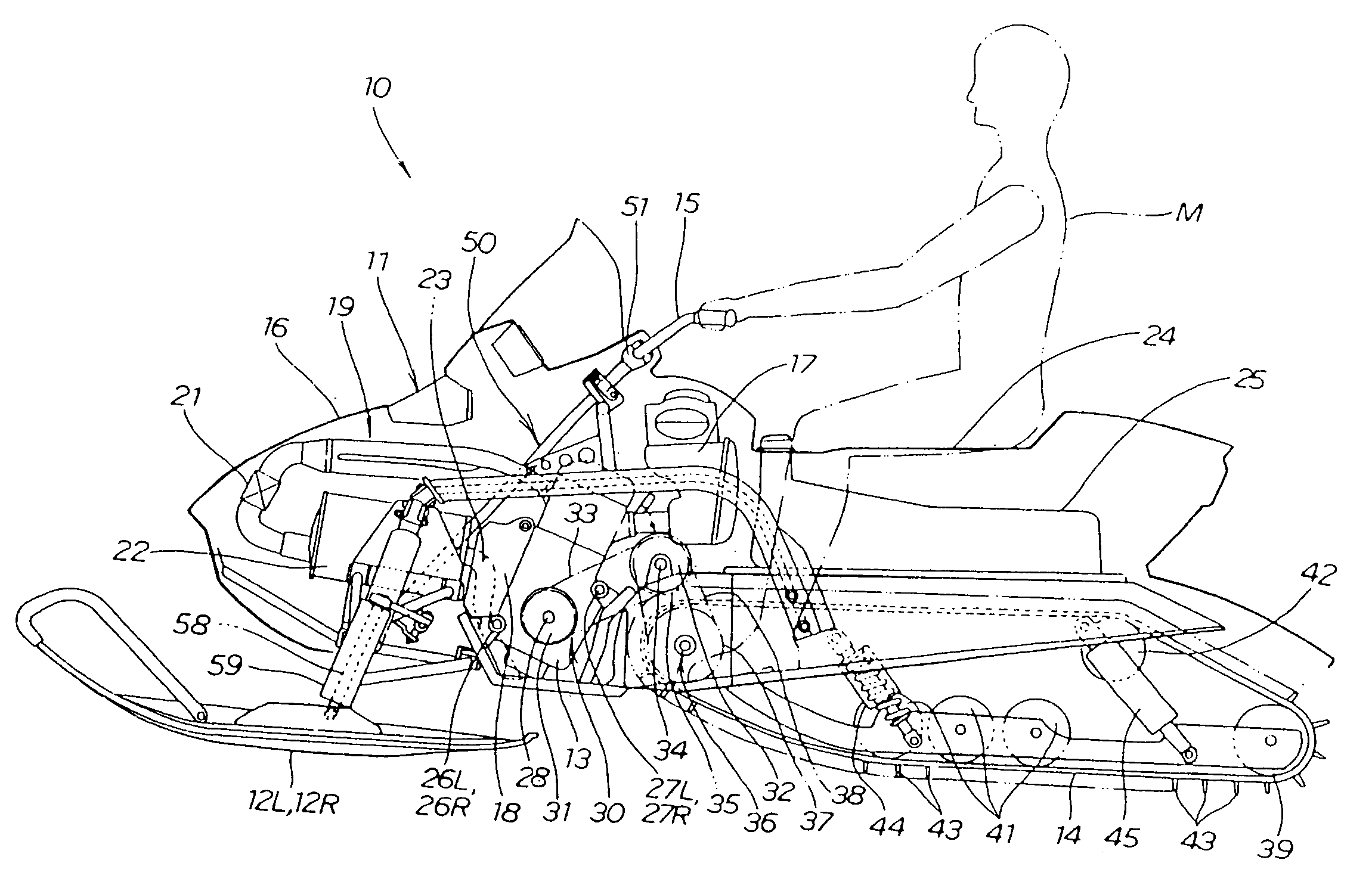

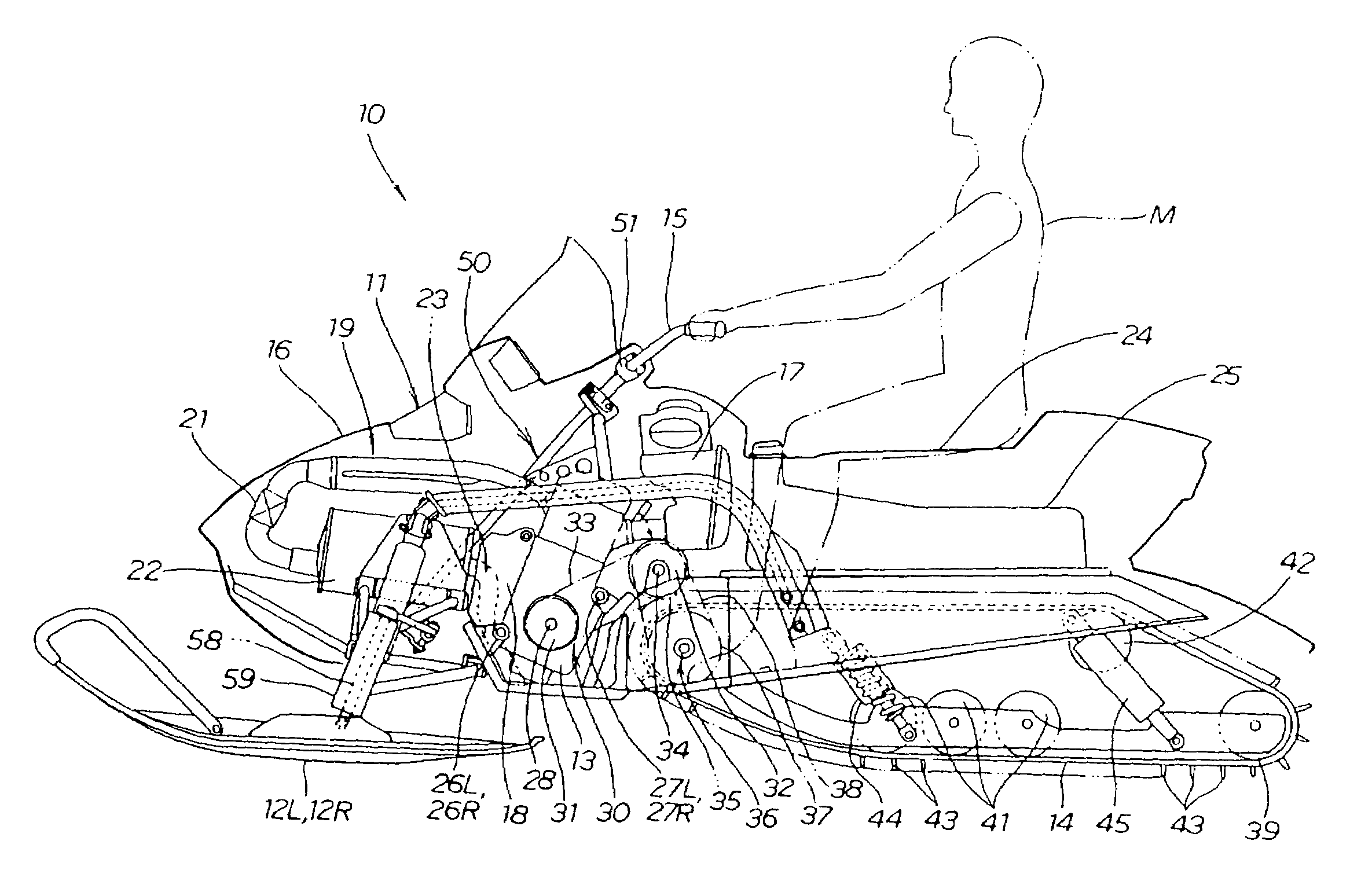

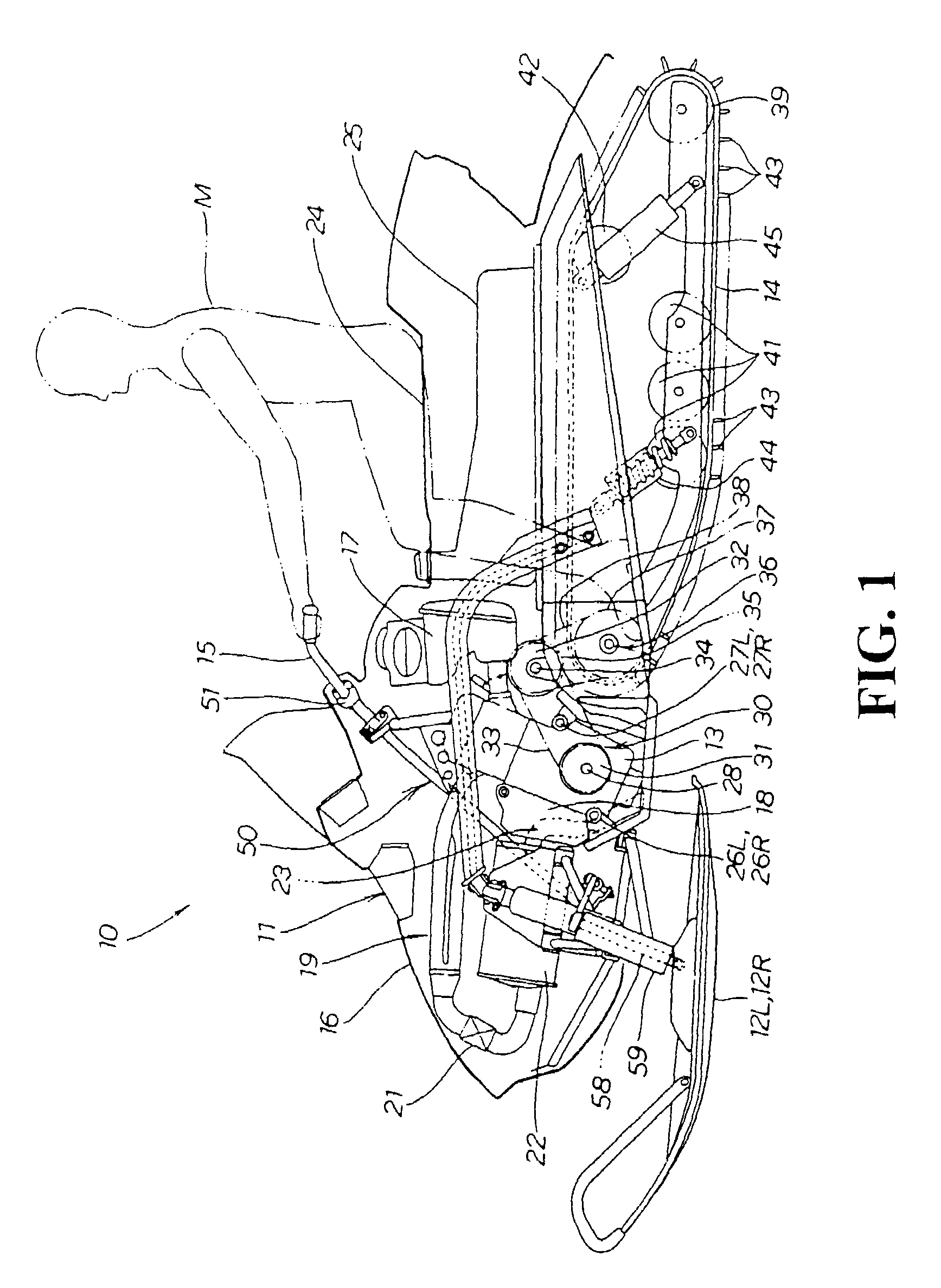

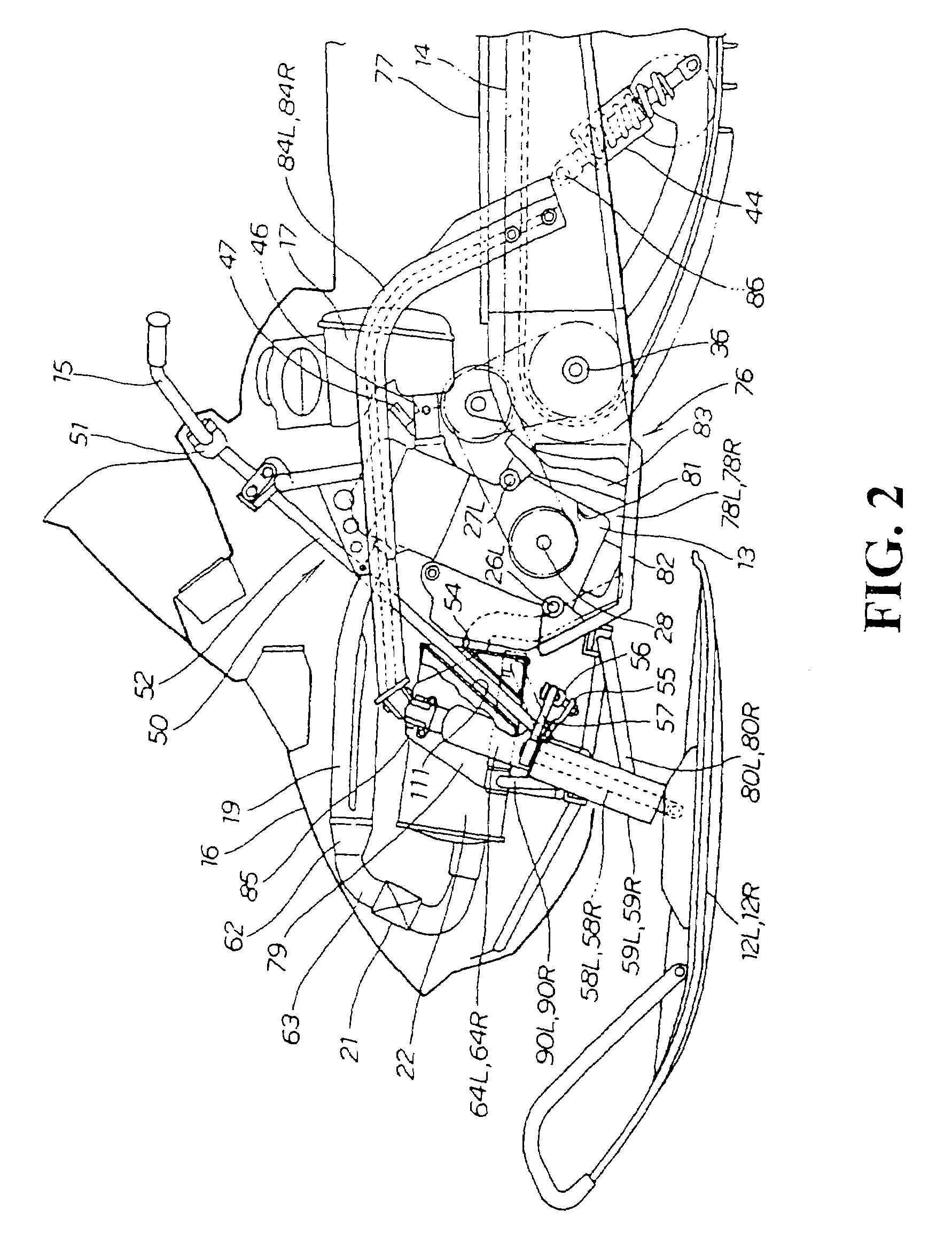

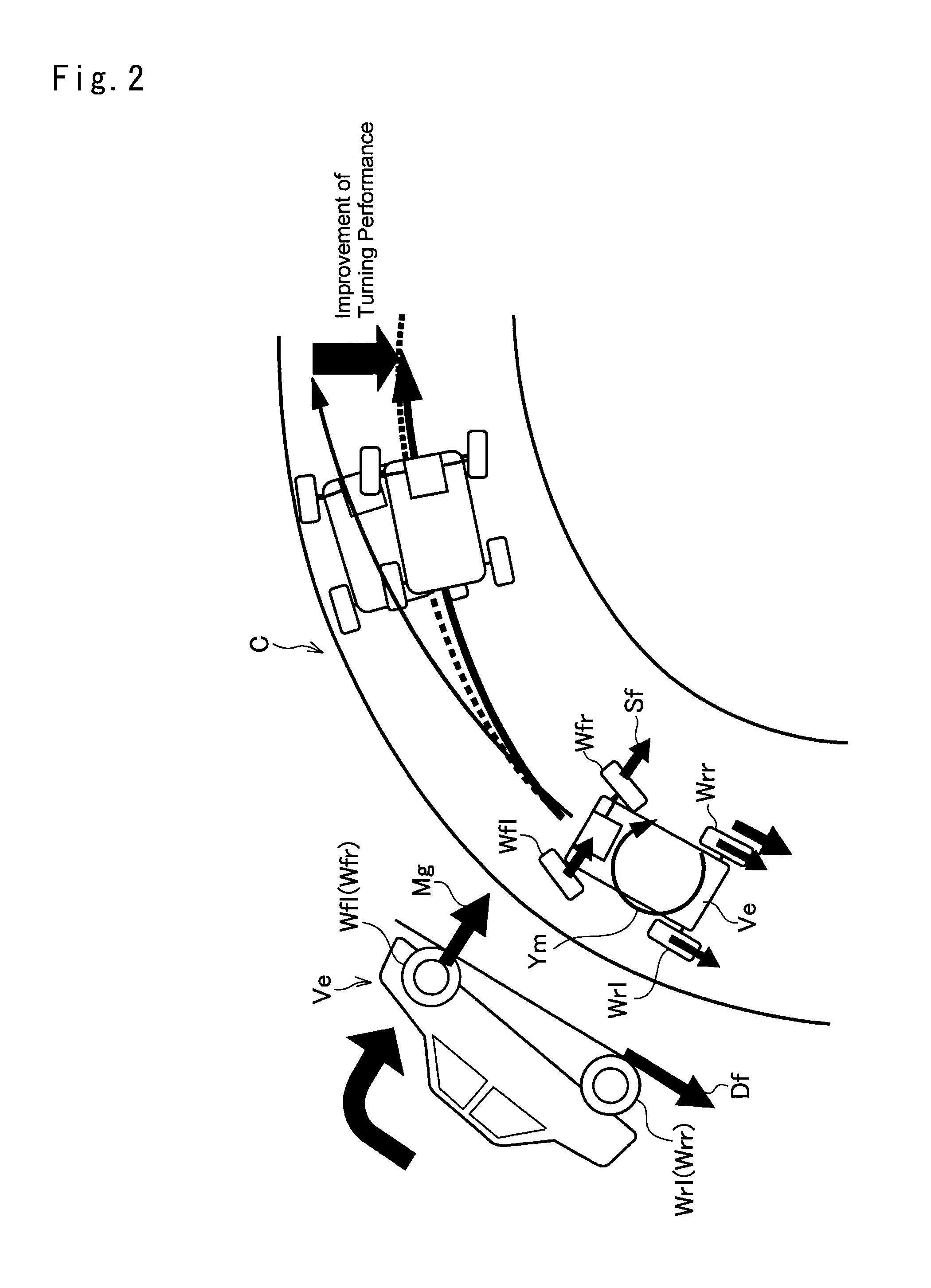

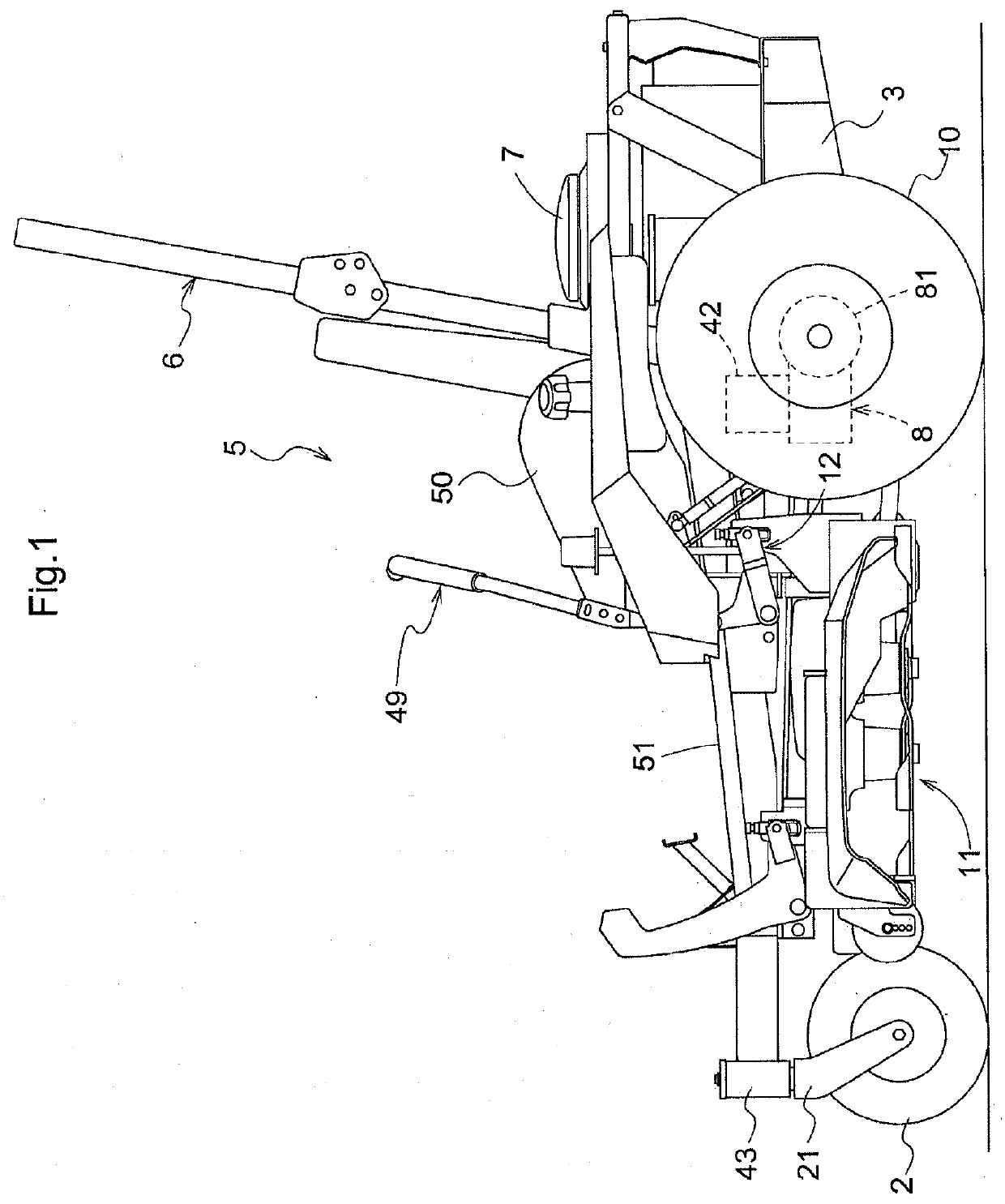

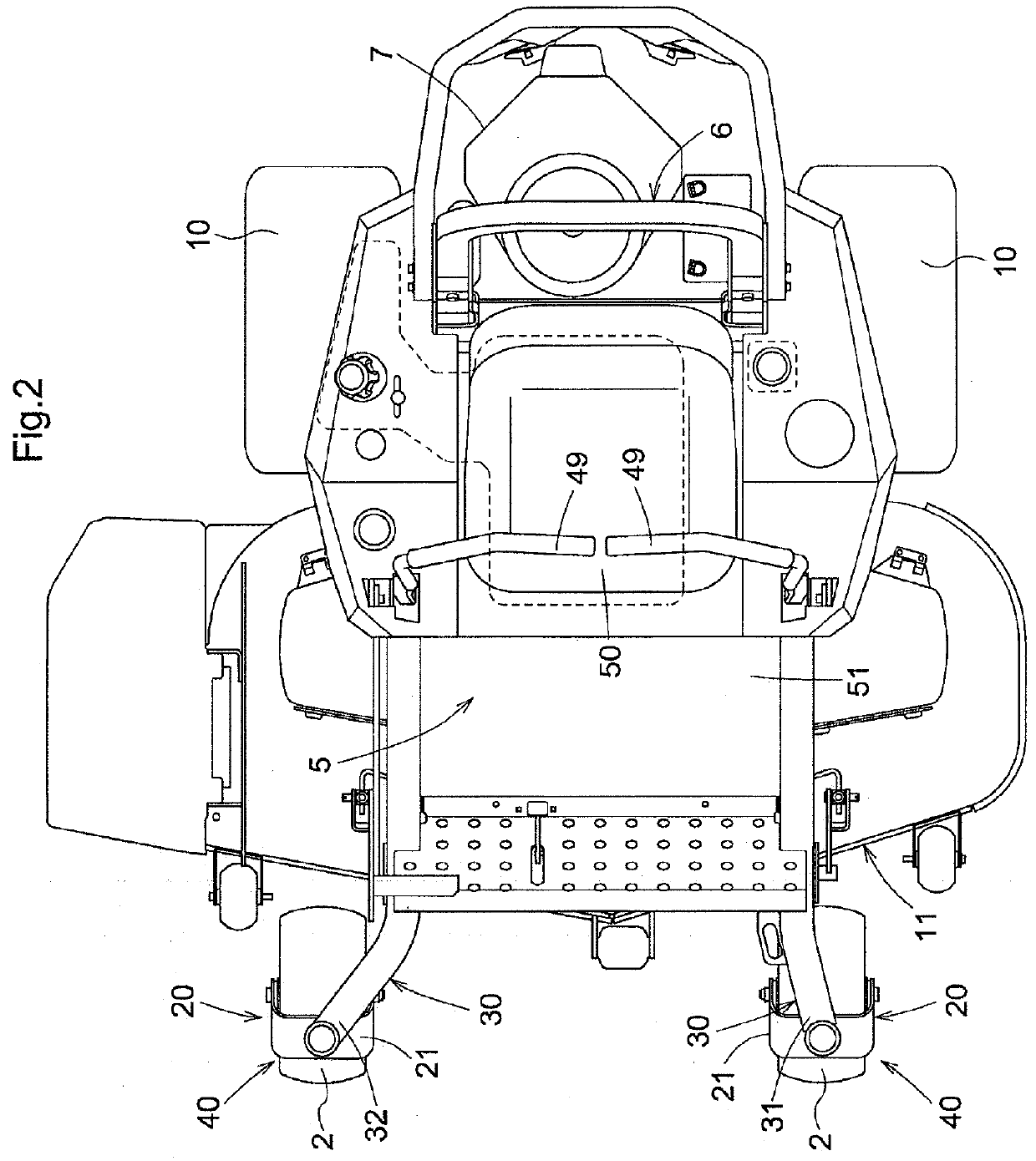

Snowmobile

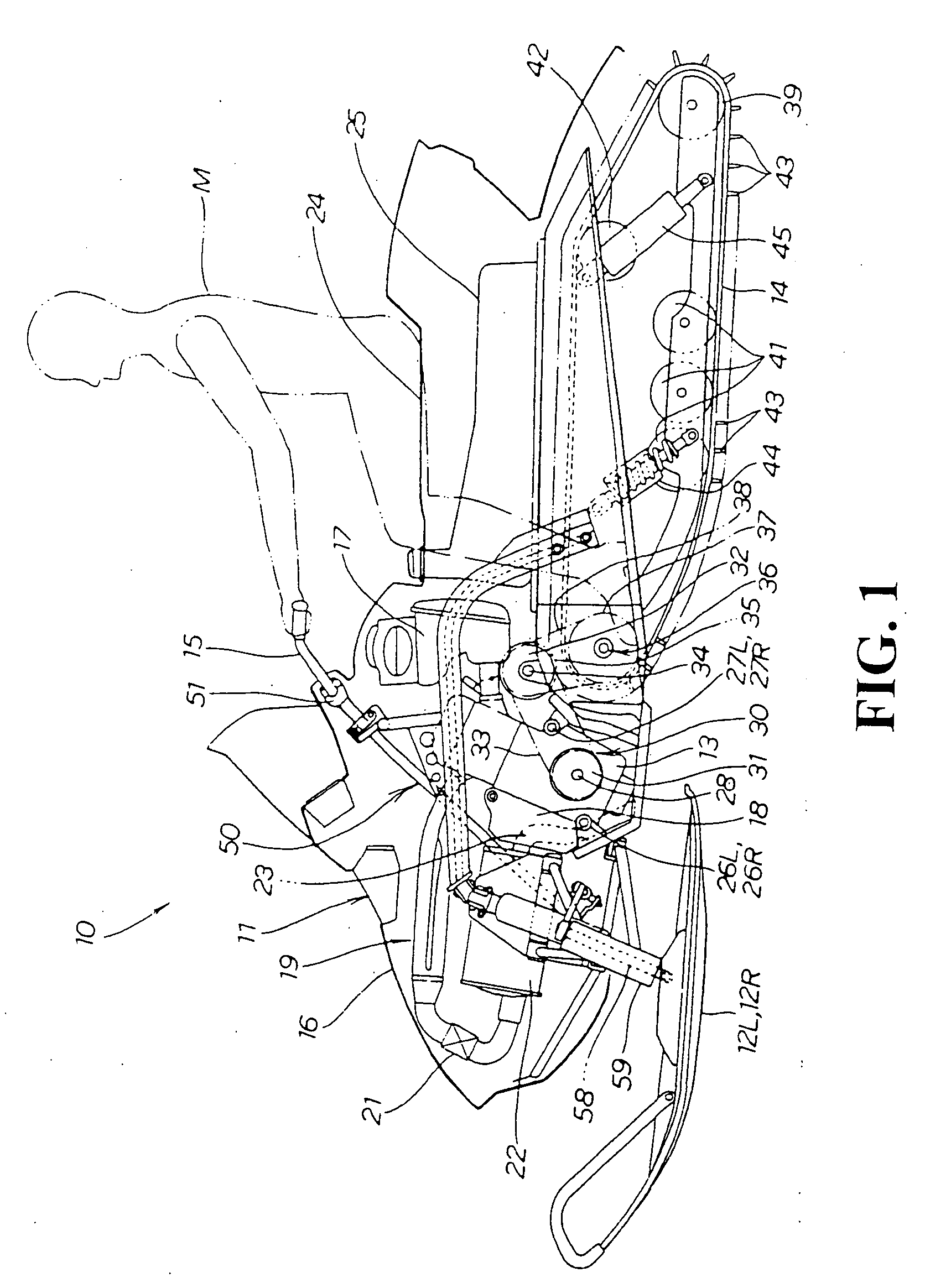

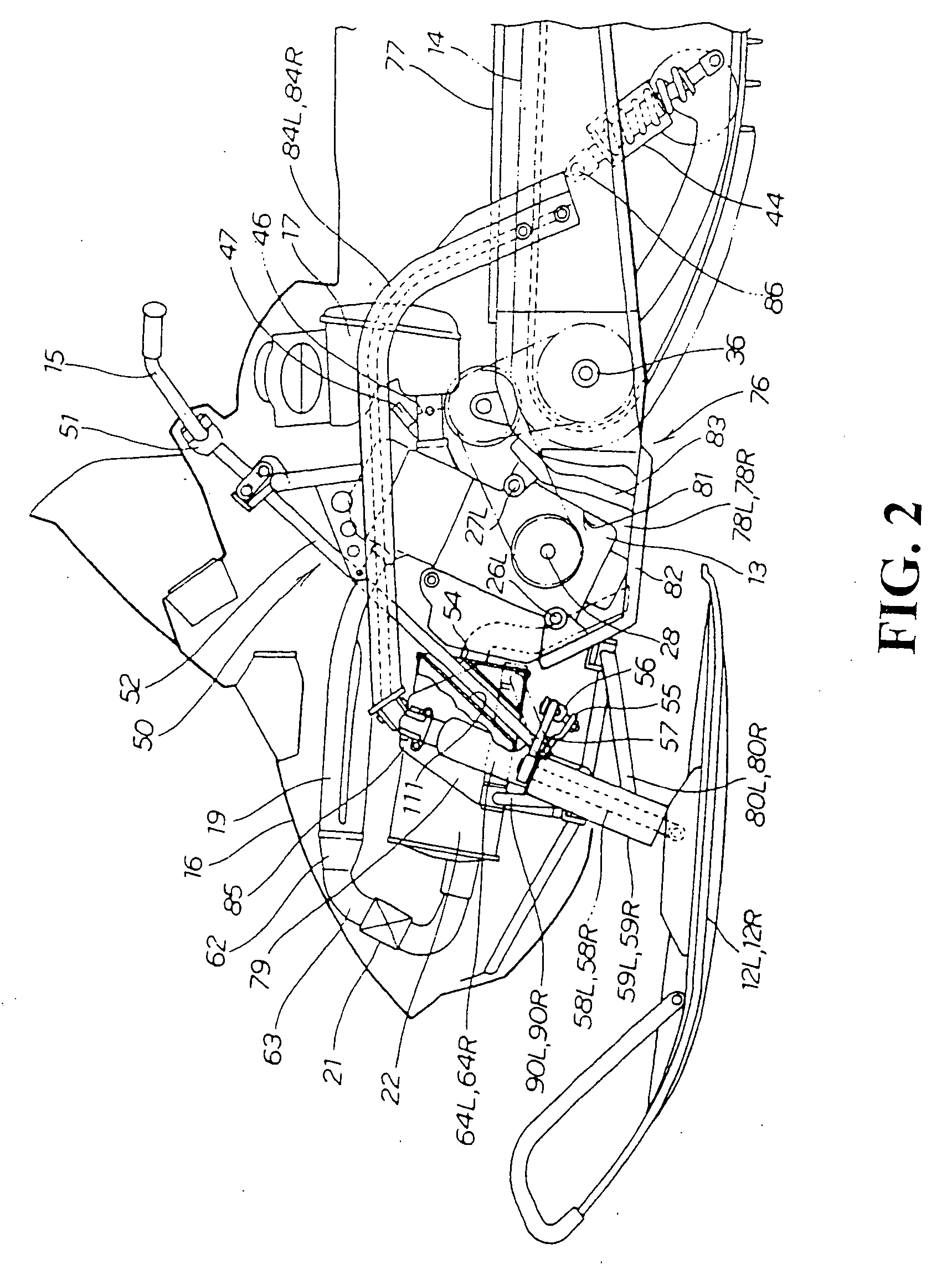

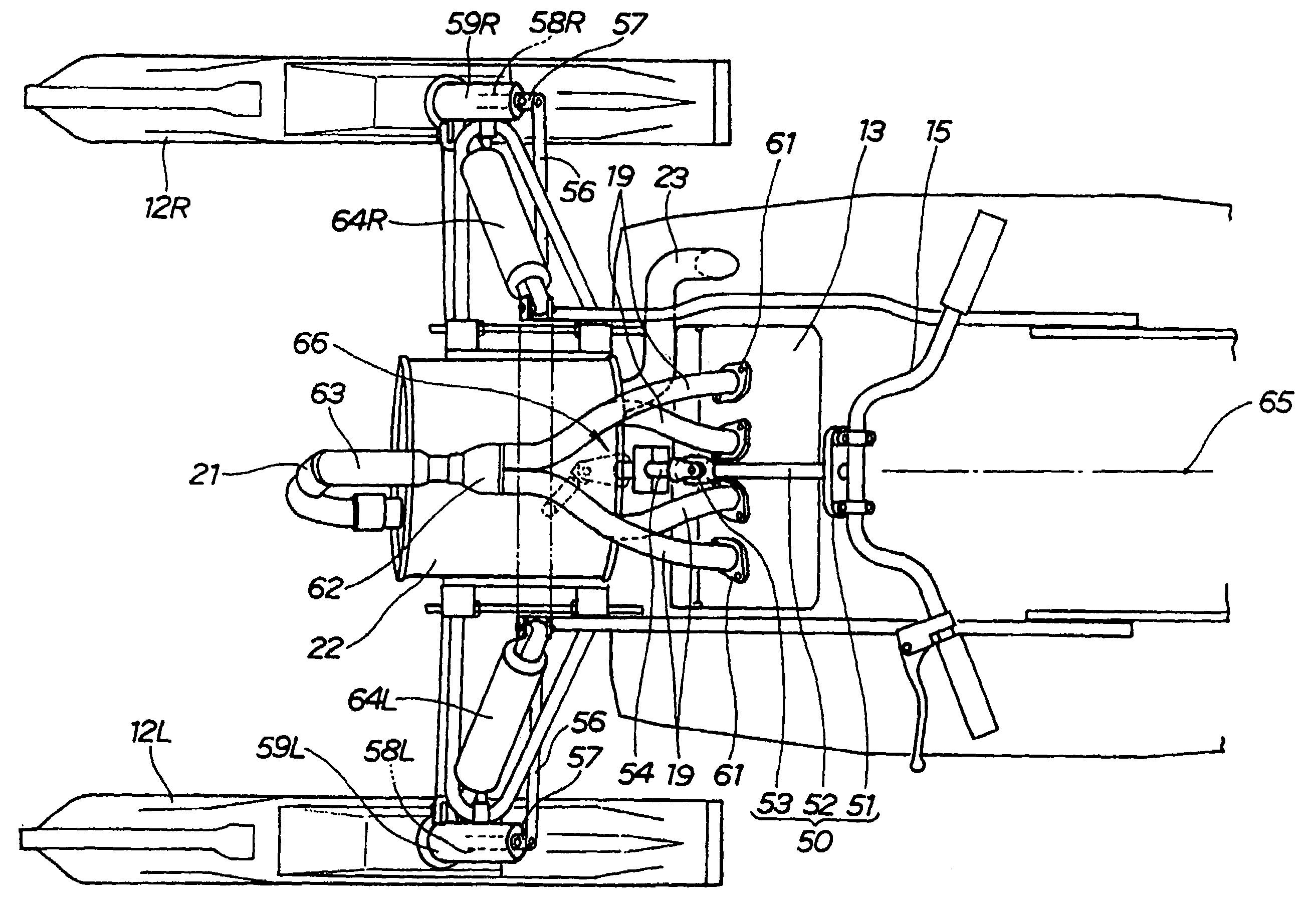

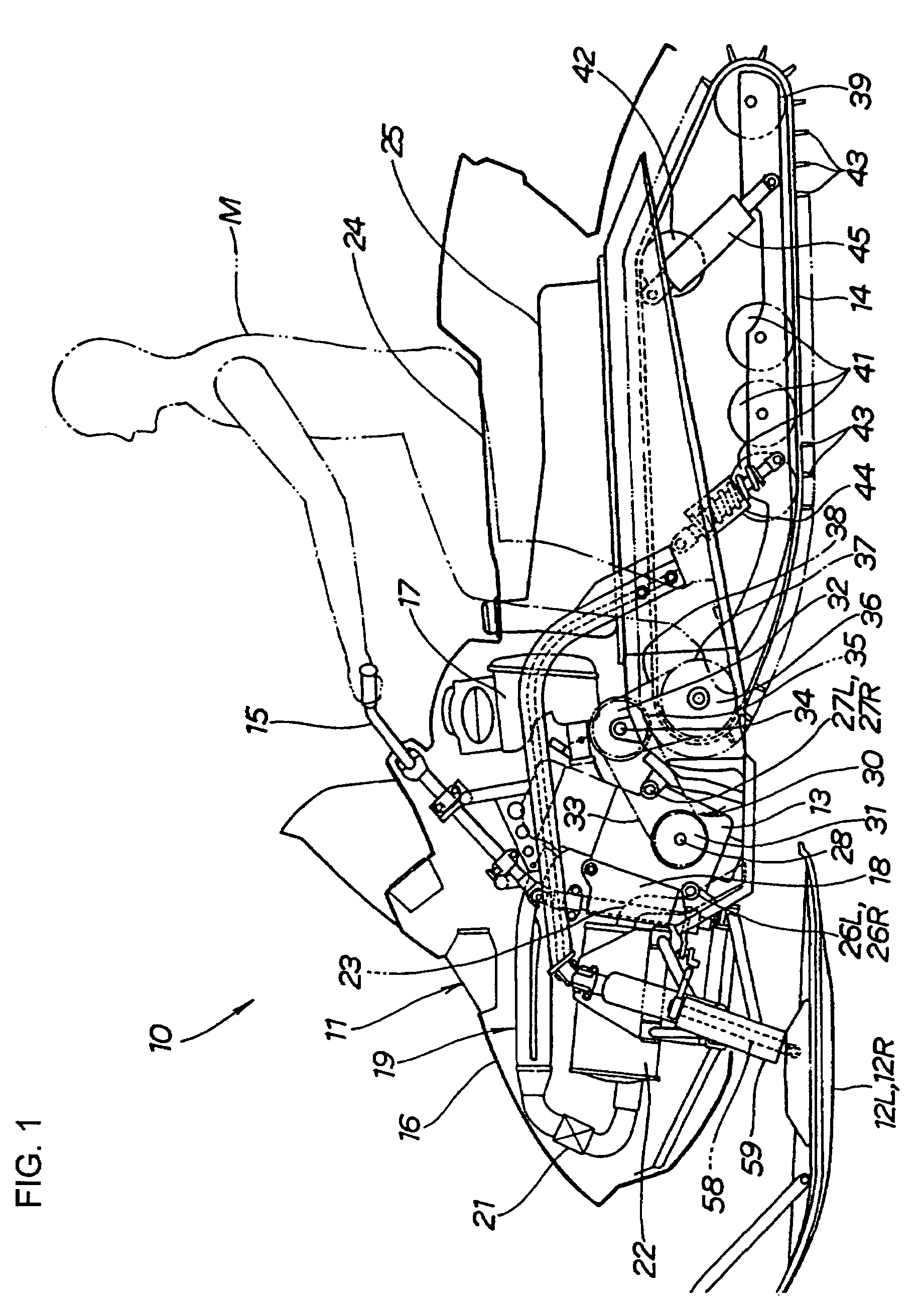

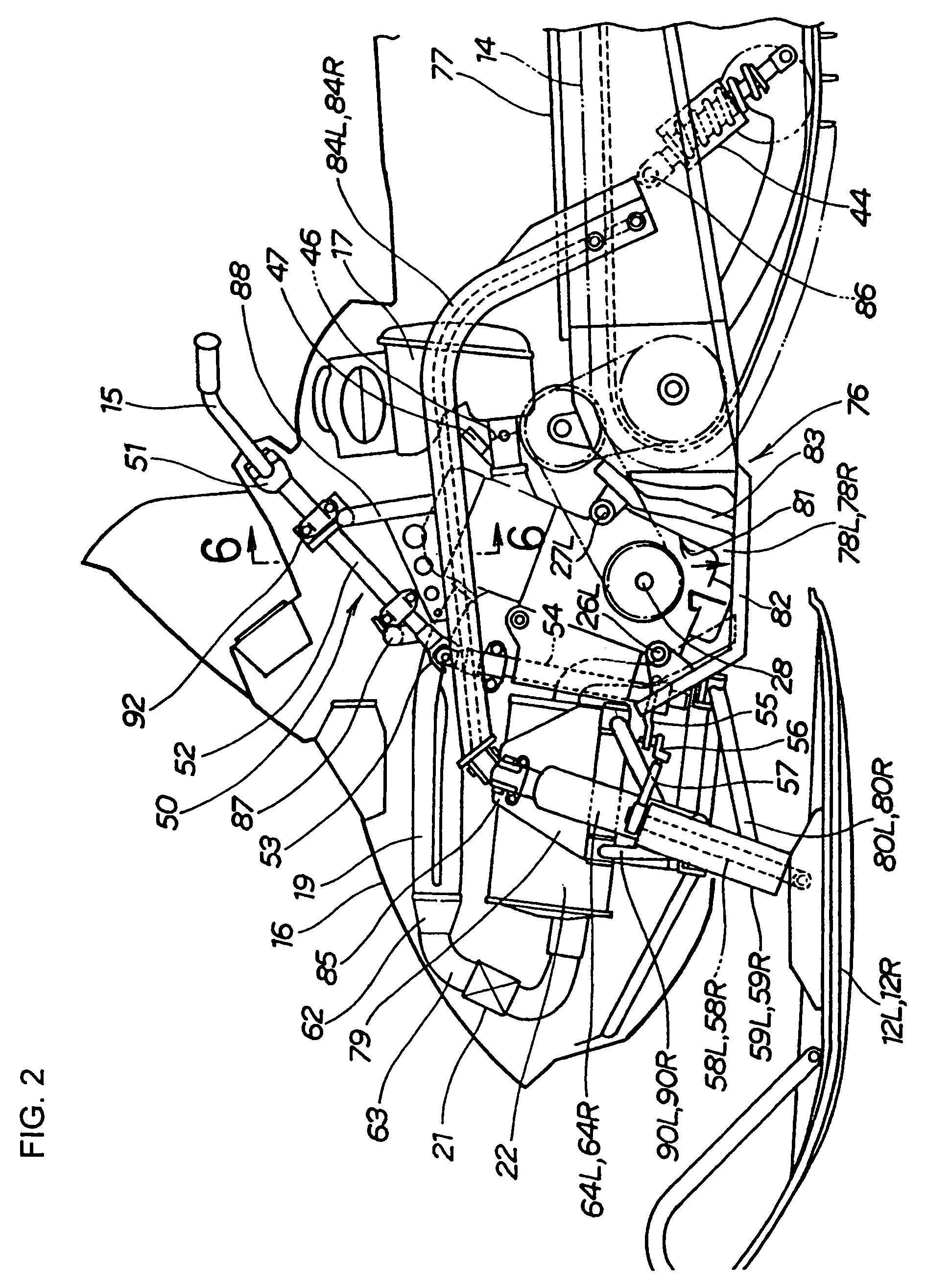

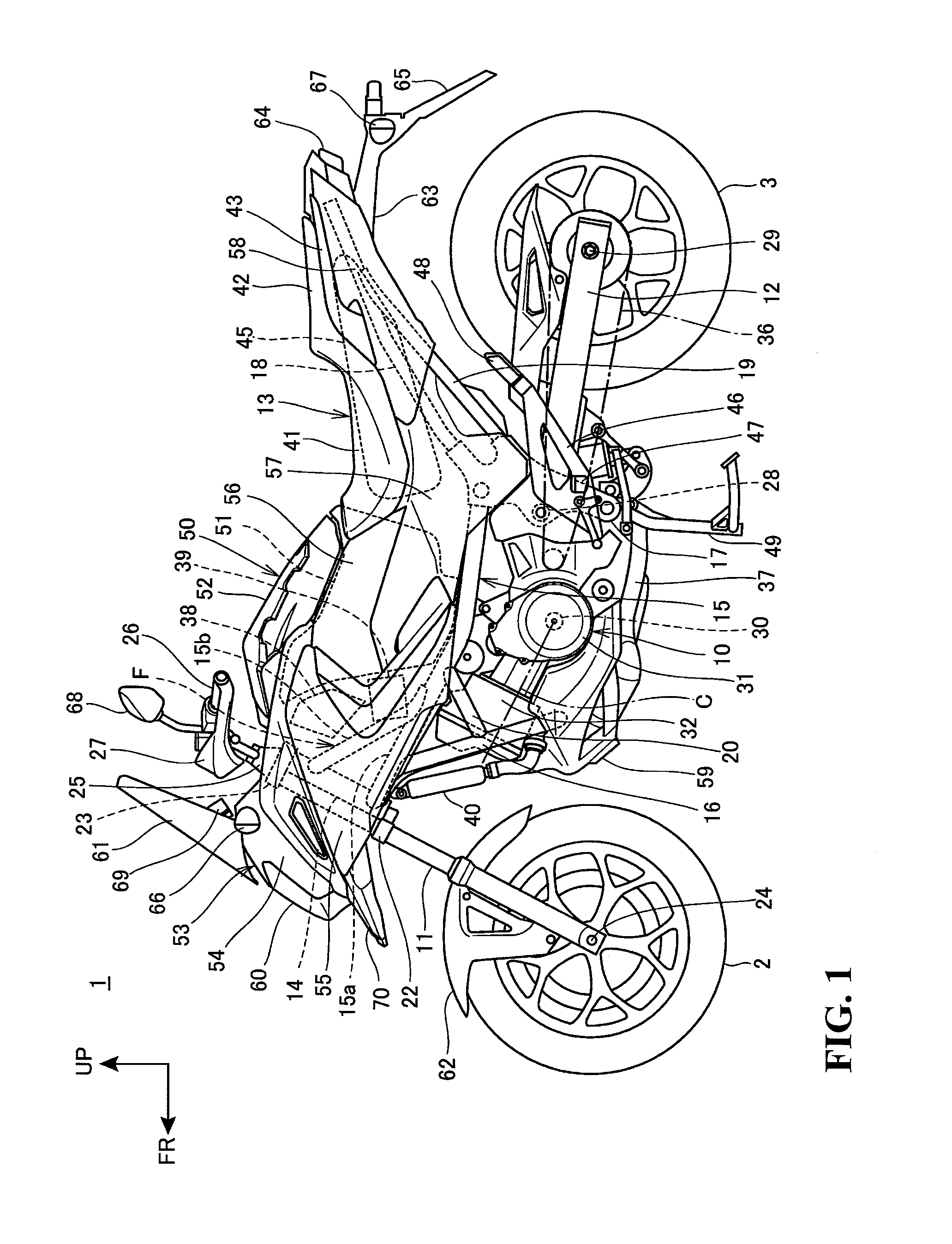

InactiveUS20050252705A1Improved turning performanceStable supportExhaust apparatusSilencing apparatusEngineeringMechanical engineering

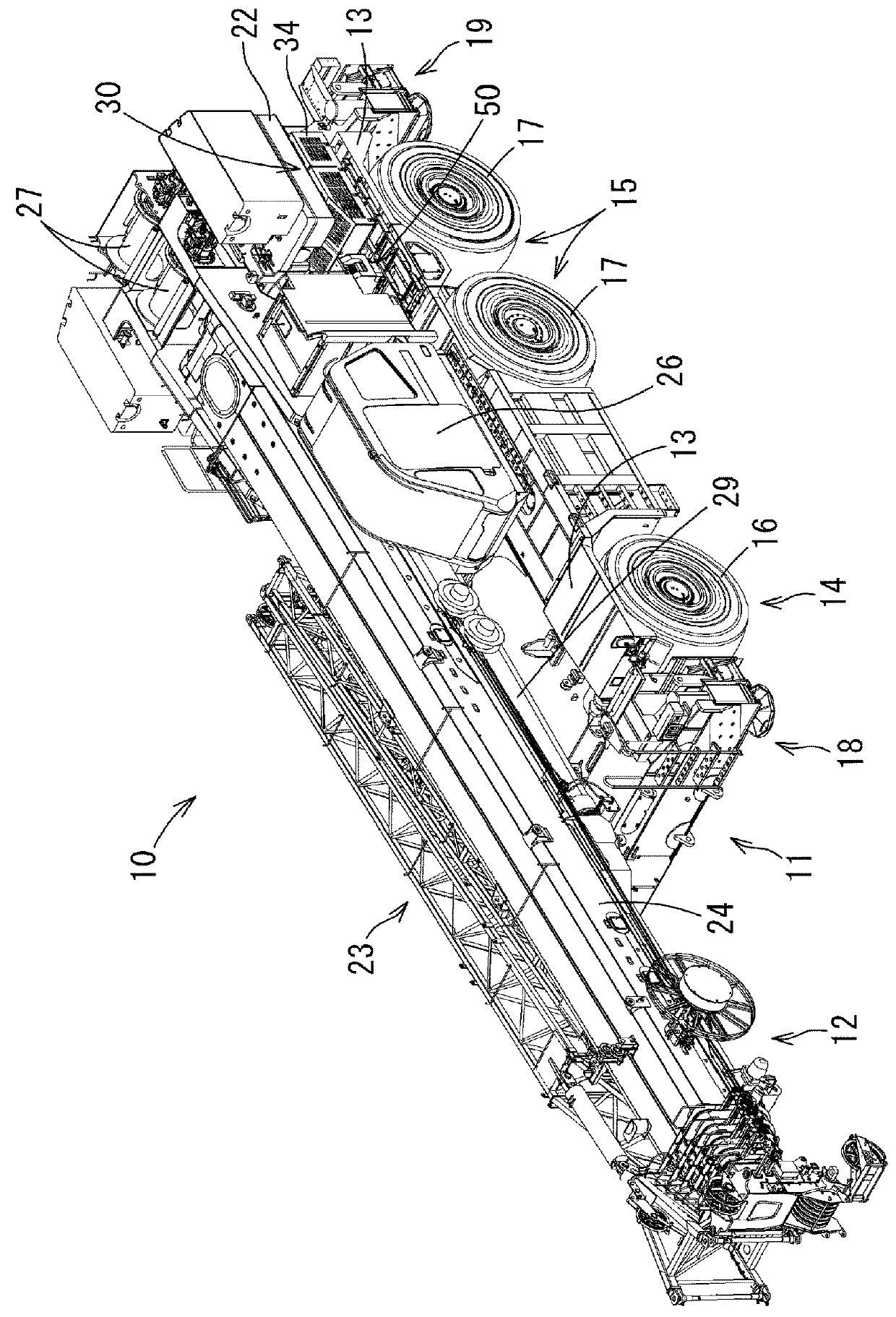

A snowmobile provided with skis and being steerable by a steering shaft, and being provided with a silencer on the front side of an engine. The steering shaft passes between the engine and the silencer and overlaps the silencer in side view. Flat step floors for a rider's feet are provided on lateral sides of a lower portion of a seat. Step bars for enabling positioning of the rider's feet are provided at front portions of the step floors. The step bars are each provided on the rear side relative to the step floor tip end and within 350 mm from a track belt drive shaft which is provided on the rear side of the engine. The resulting configuration of the snowmobile makes it possible to lay out the silencer close to the engine, affords excellent turning performance, and provides step floors for good foot holding properties.

Owner:HONDA MOTOR CO LTD

Pneumatic tire

ActiveUS20110073230A1Sufficient hydroplaning prevention performanceReduce the amount of waterTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A pneumatic tire having a designated rotational direction is disclosed, wherein an entire area having a width 85% of a total tire width and a center area having a width 30% of the total tire width are defined in a tread portion. A center main groove is positioned on a tire equatorial line and extends in a tire circumferential direction. Subsidiary main grooves are positioned on two sides of the center main groove and extend in the tire circumferential direction. Angled and lateral grooves extend at an angle, in a direction opposite the rotational direction towards an outside in the tire width direction. Lateral grooves extend from each subsidiary main groove. Sub grooves extend from the lateral grooves towards the rotational direction. A total length of a block edge in the center area is from 40% to 60% of a total length of a block edge in the entire area.

Owner:YOKOHAMA RUBBER CO LTD

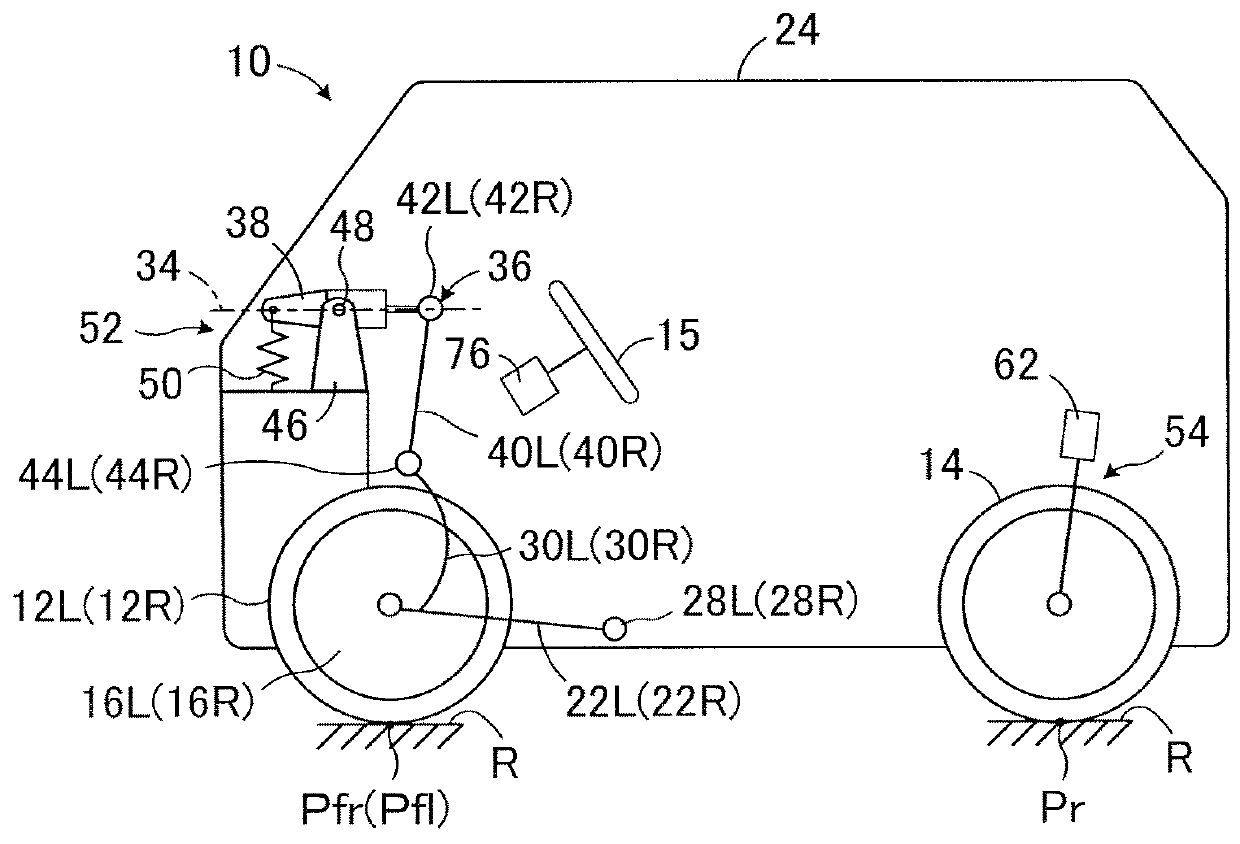

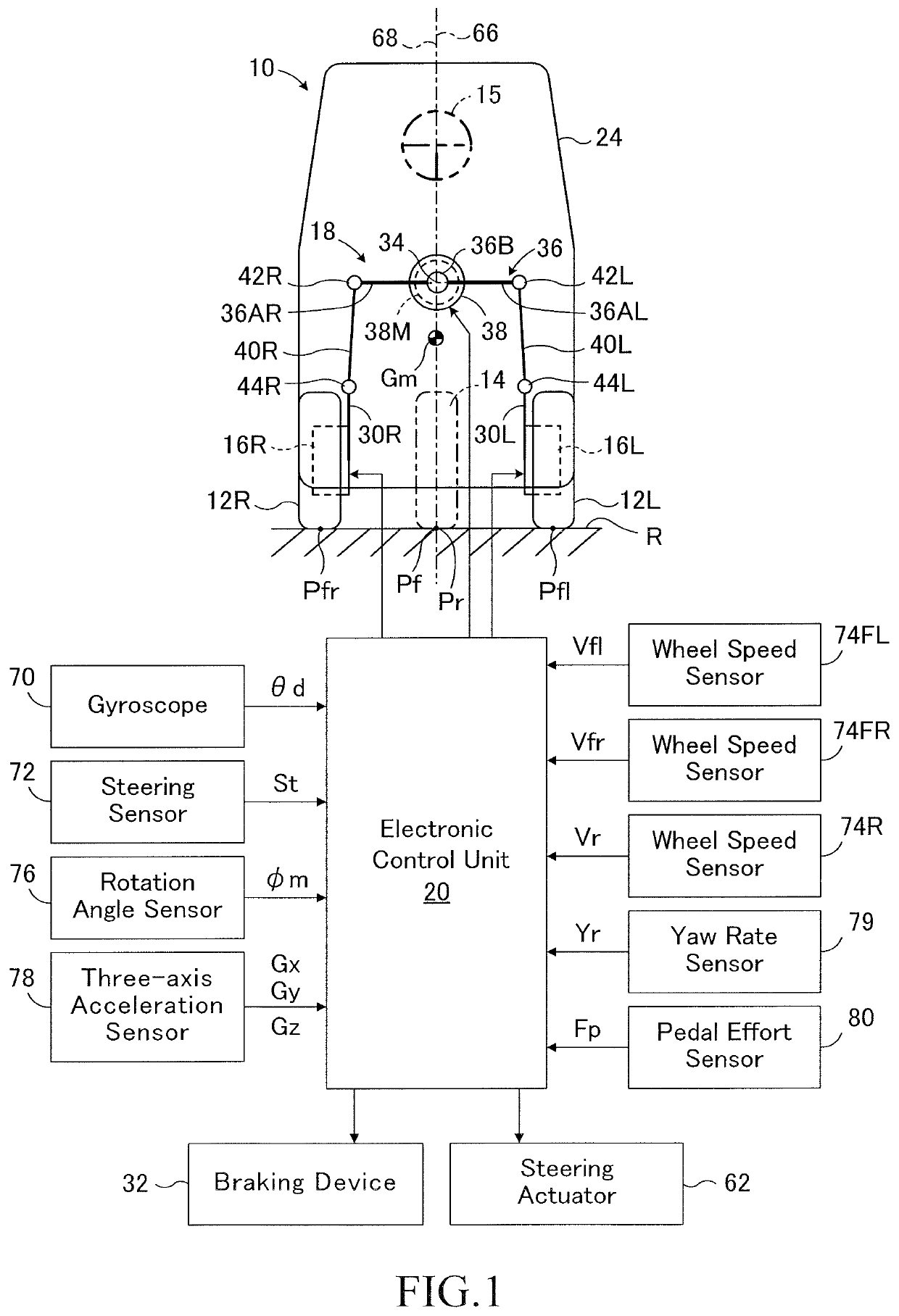

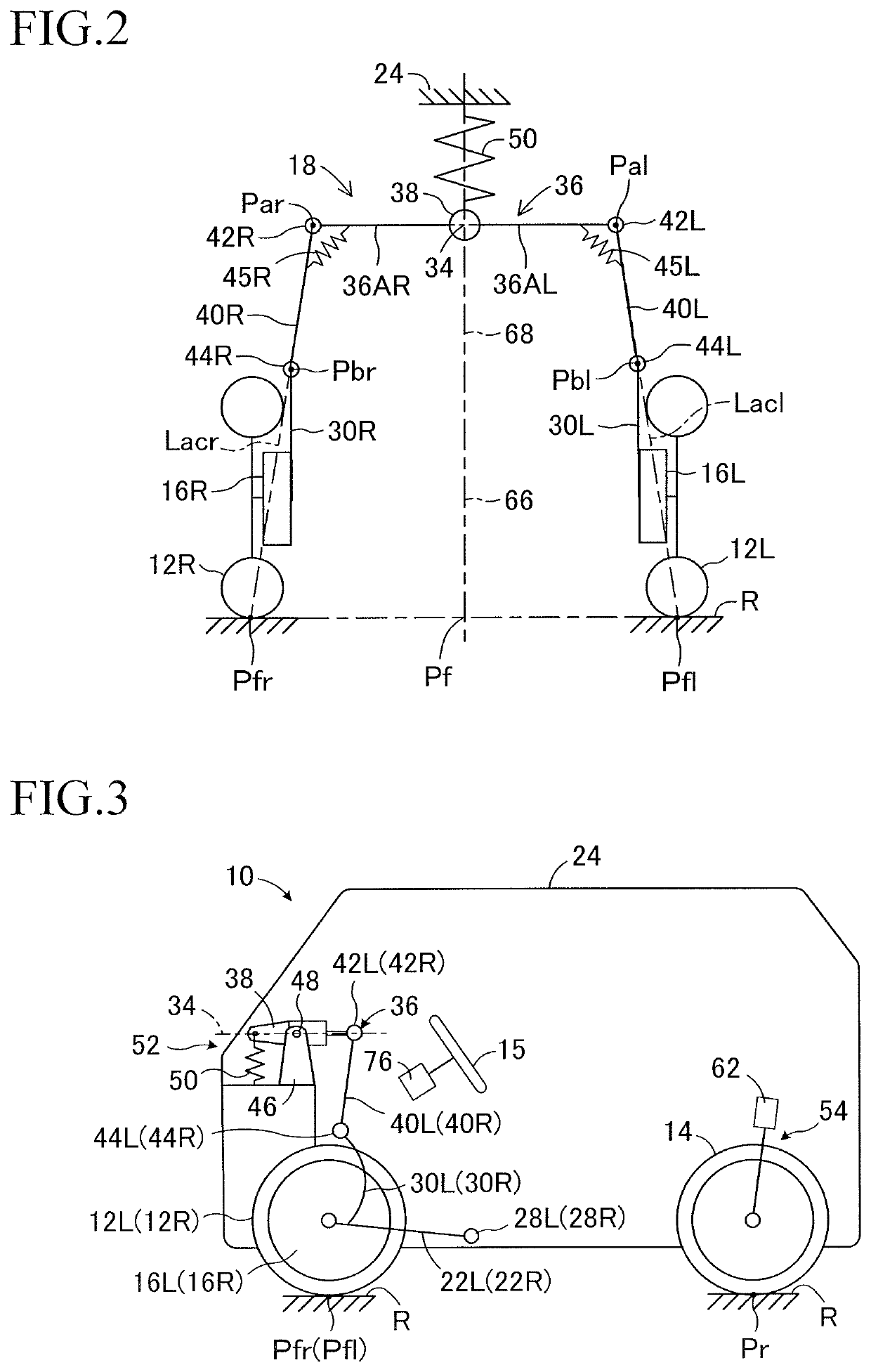

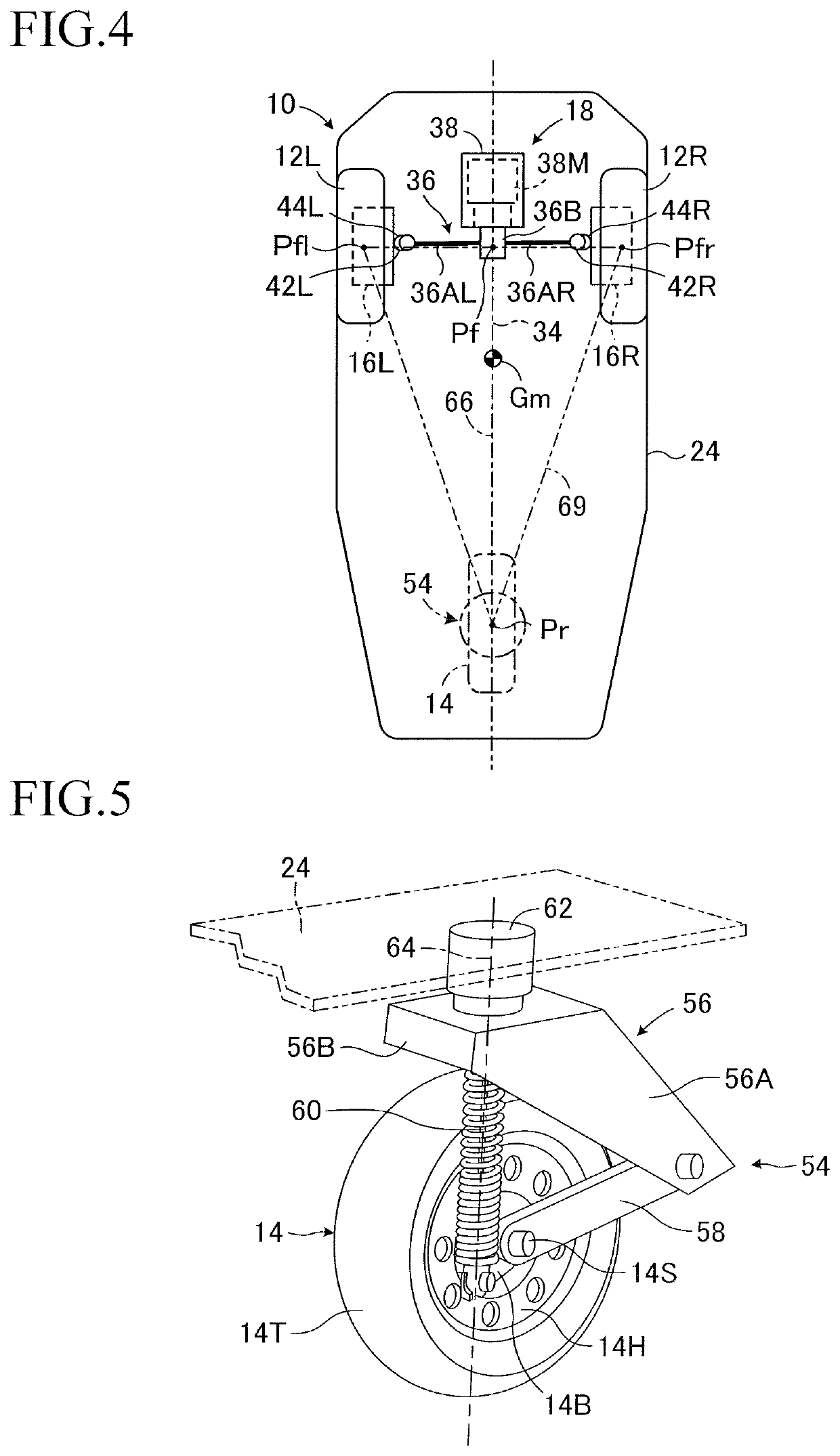

Automatic tilting vehicle

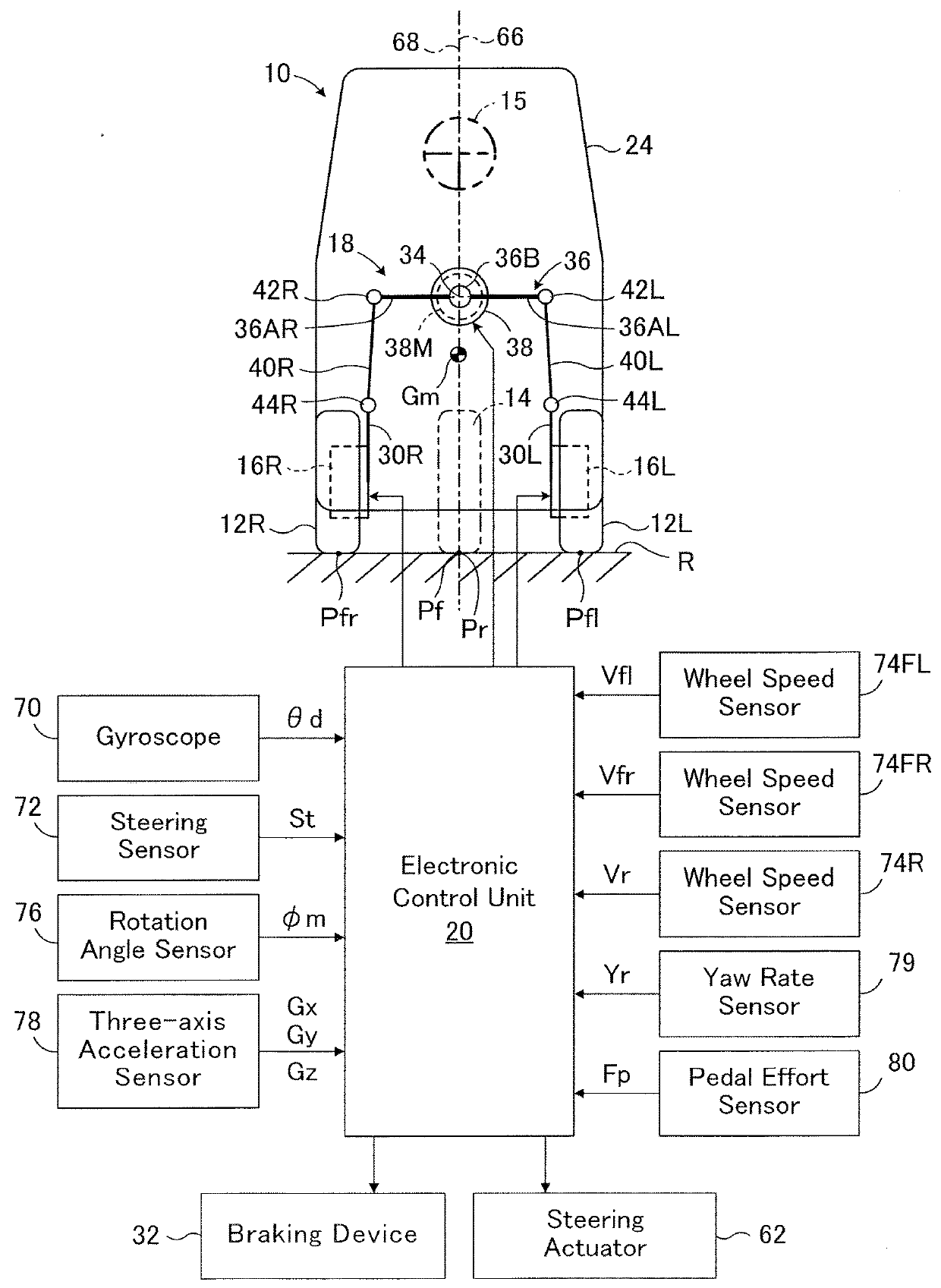

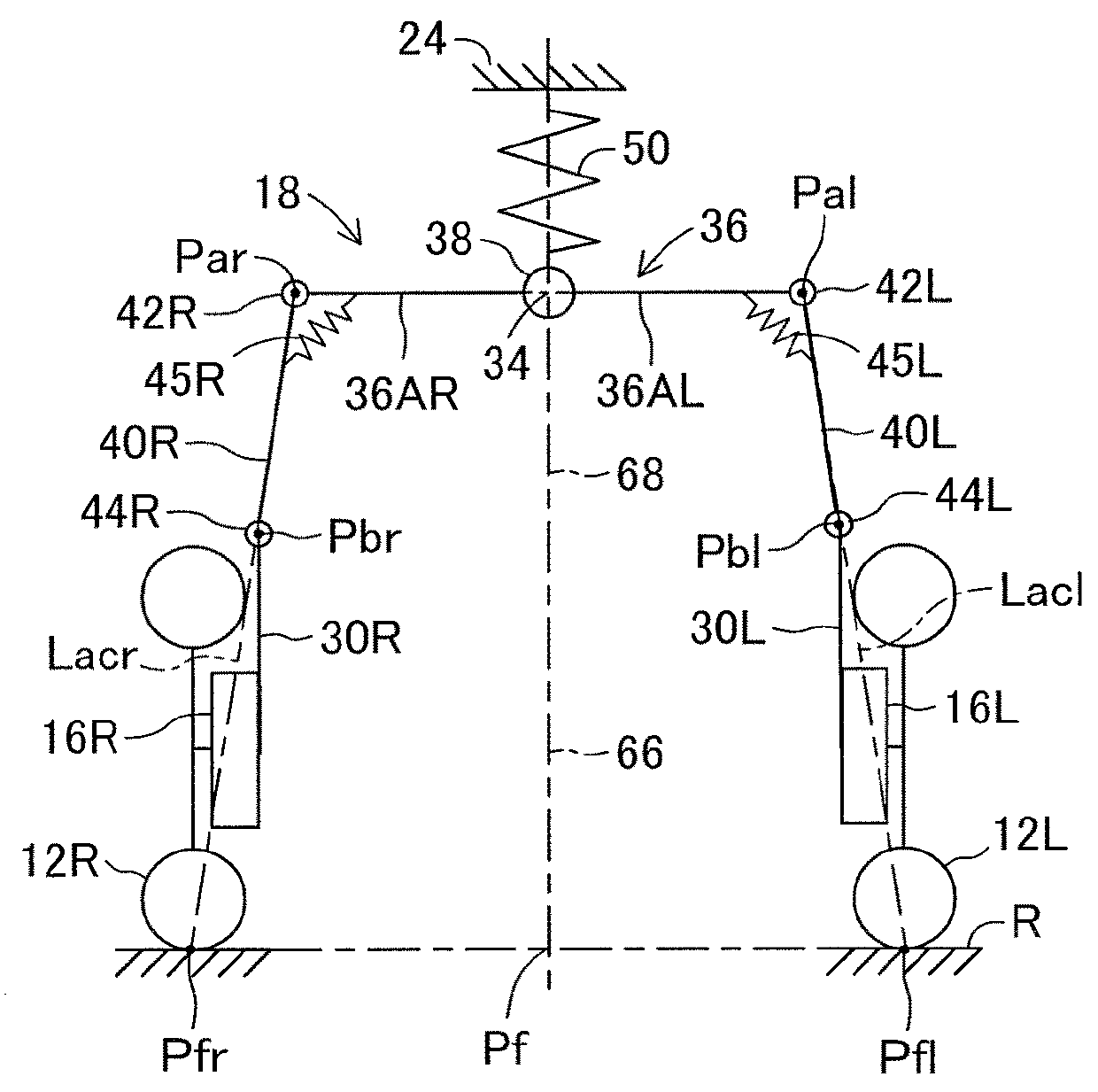

ActiveUS20180264905A1Reduce effectGood performanceCyclesSteering linkagesAutomotive engineeringKnuckle

An automatic tilting vehicle is provided that includes left and right front wheels supported by knuckles, a steerable rear wheel, a vehicle tilting device, and a control unit. The vehicle tilting device includes a swing member, a tilt actuator for swing the swing member, and a pair of tie rods pivotally attached to the swing member and the knuckles. The control unit calculates a target lateral acceleration of the vehicle, estimates a lateral acceleration of the vehicle caused by the gyro moments of the wheels and calculates a target tilt angle of the vehicle based on a sum of the target lateral acceleration and the lateral acceleration caused by the gyro moments.

Owner:TOYOTA JIDOSHA KK

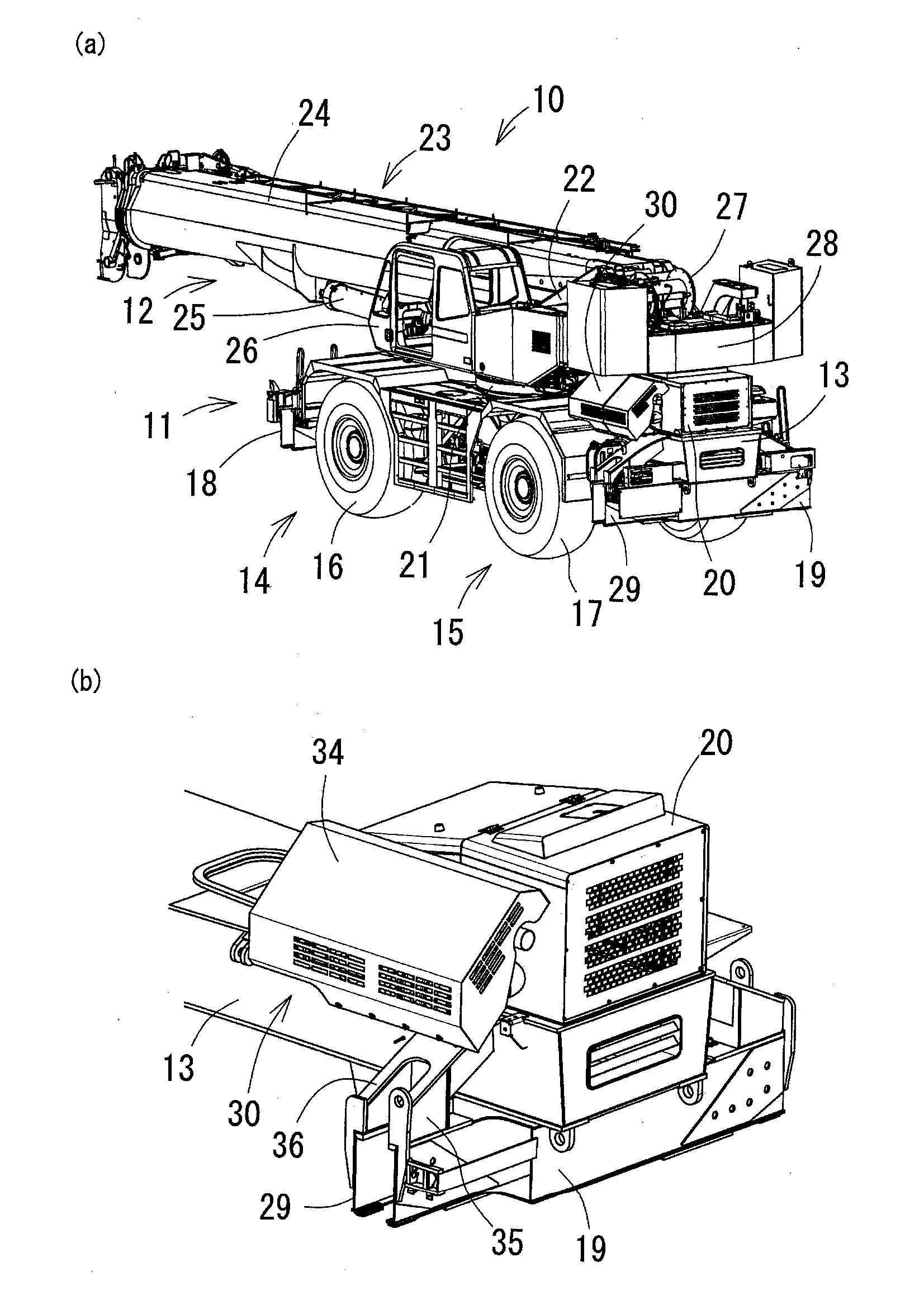

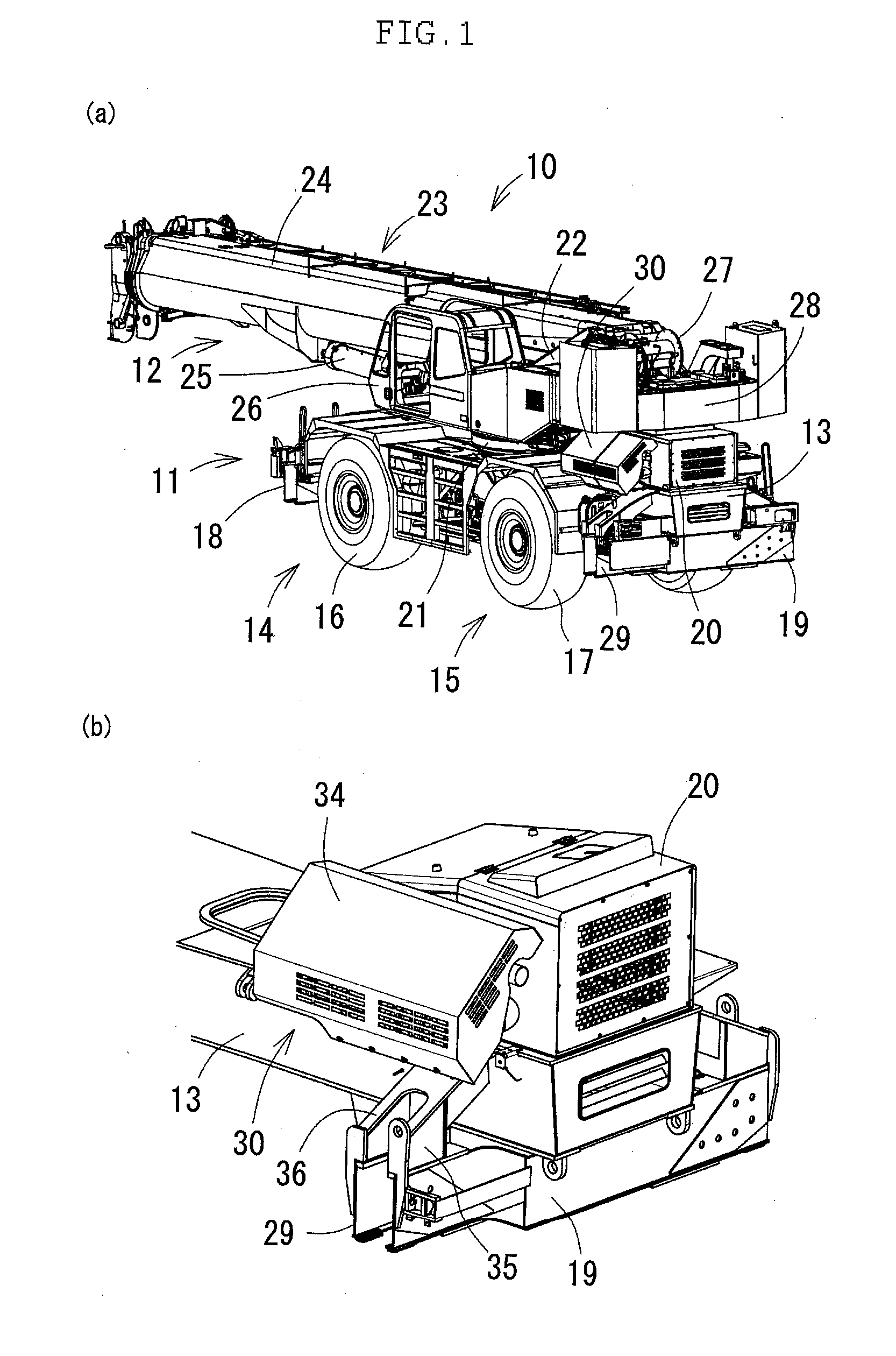

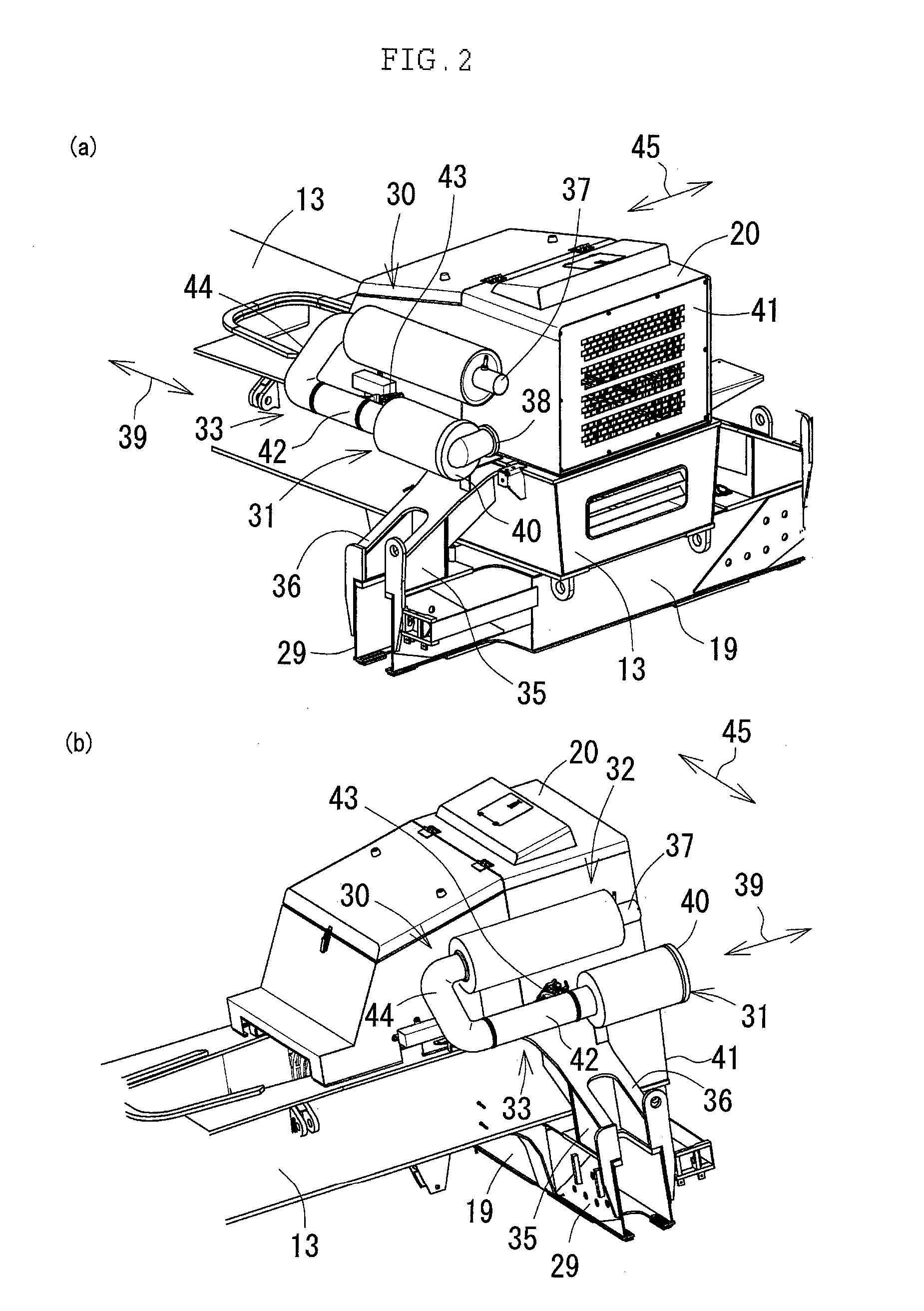

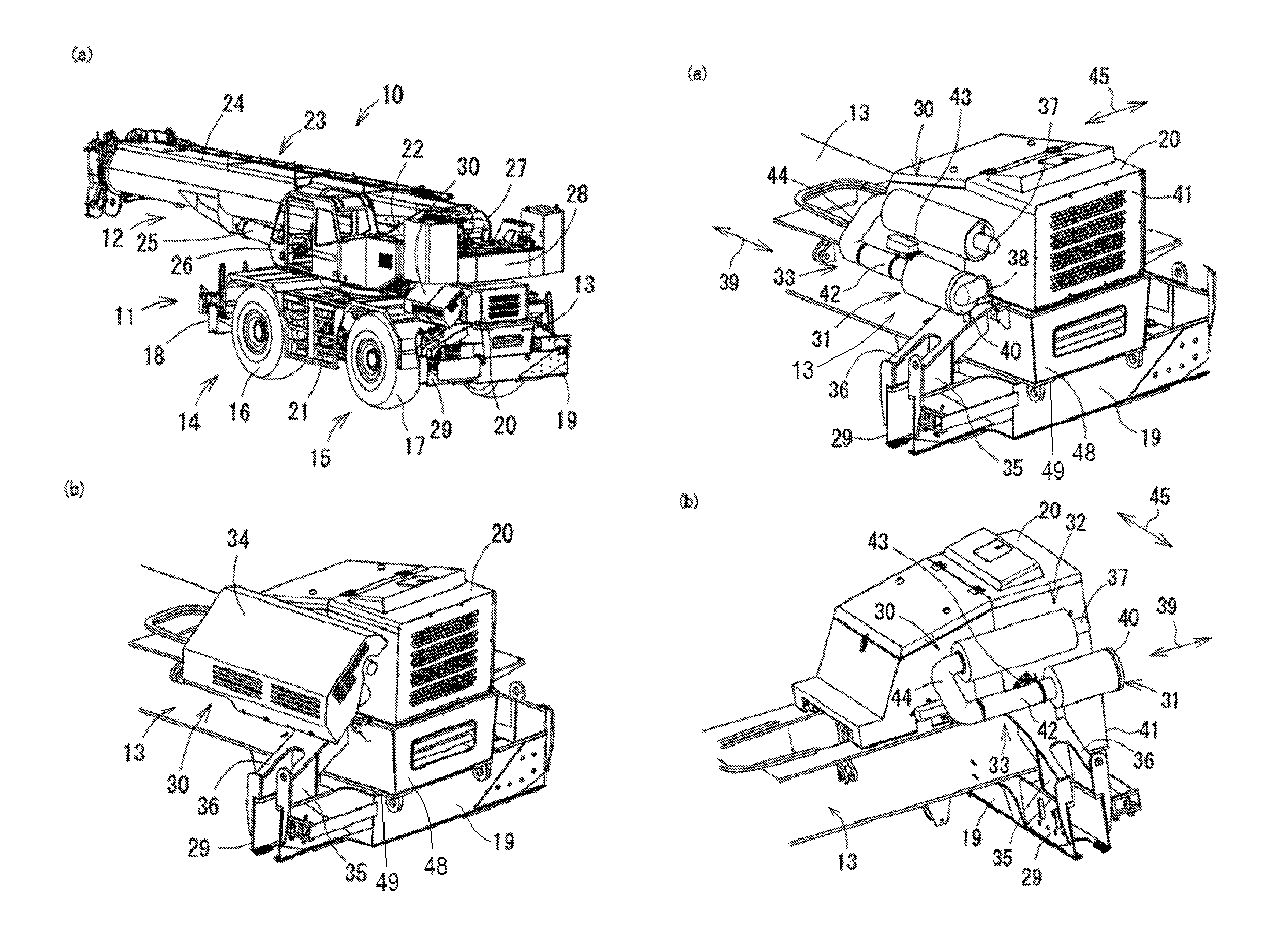

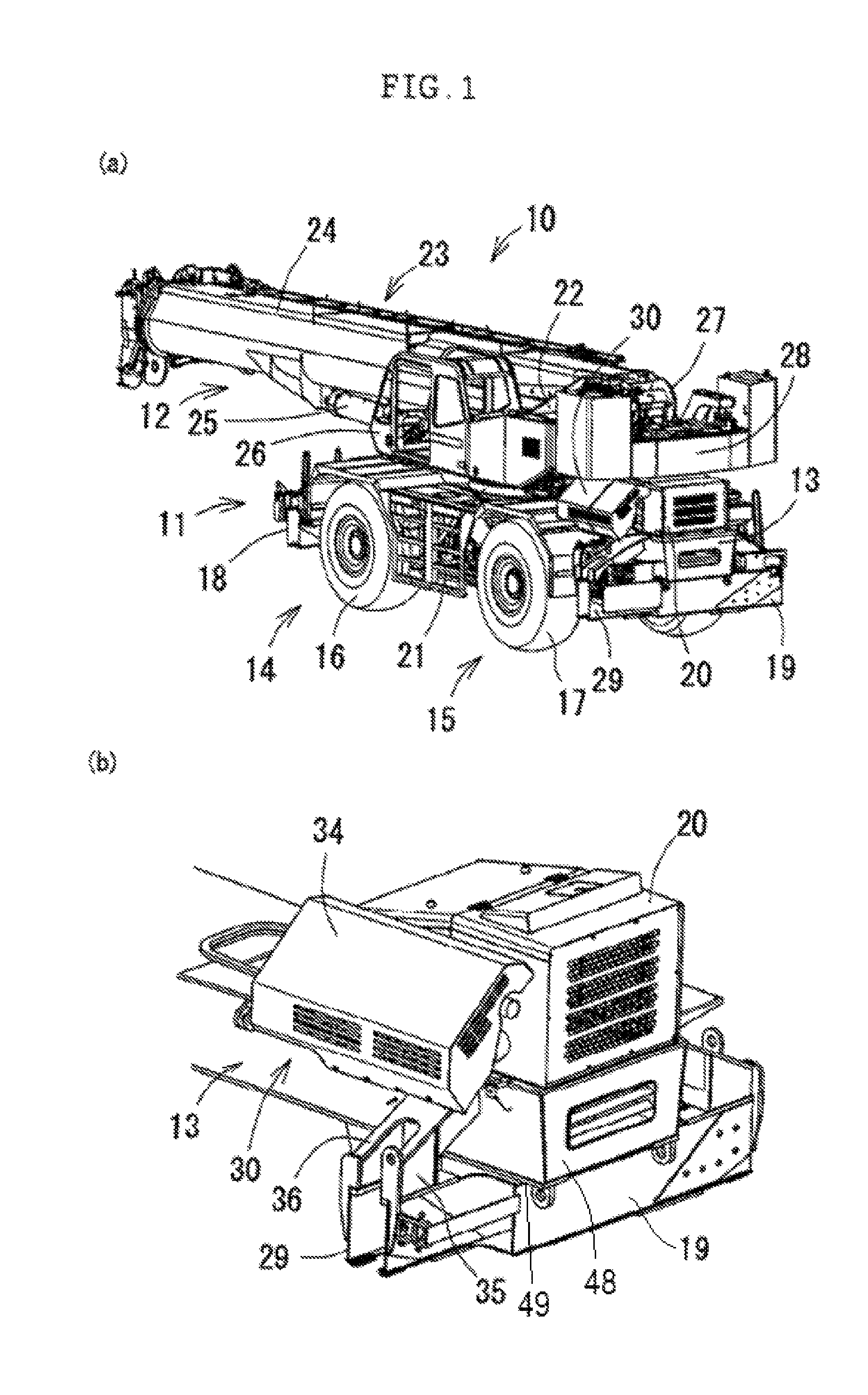

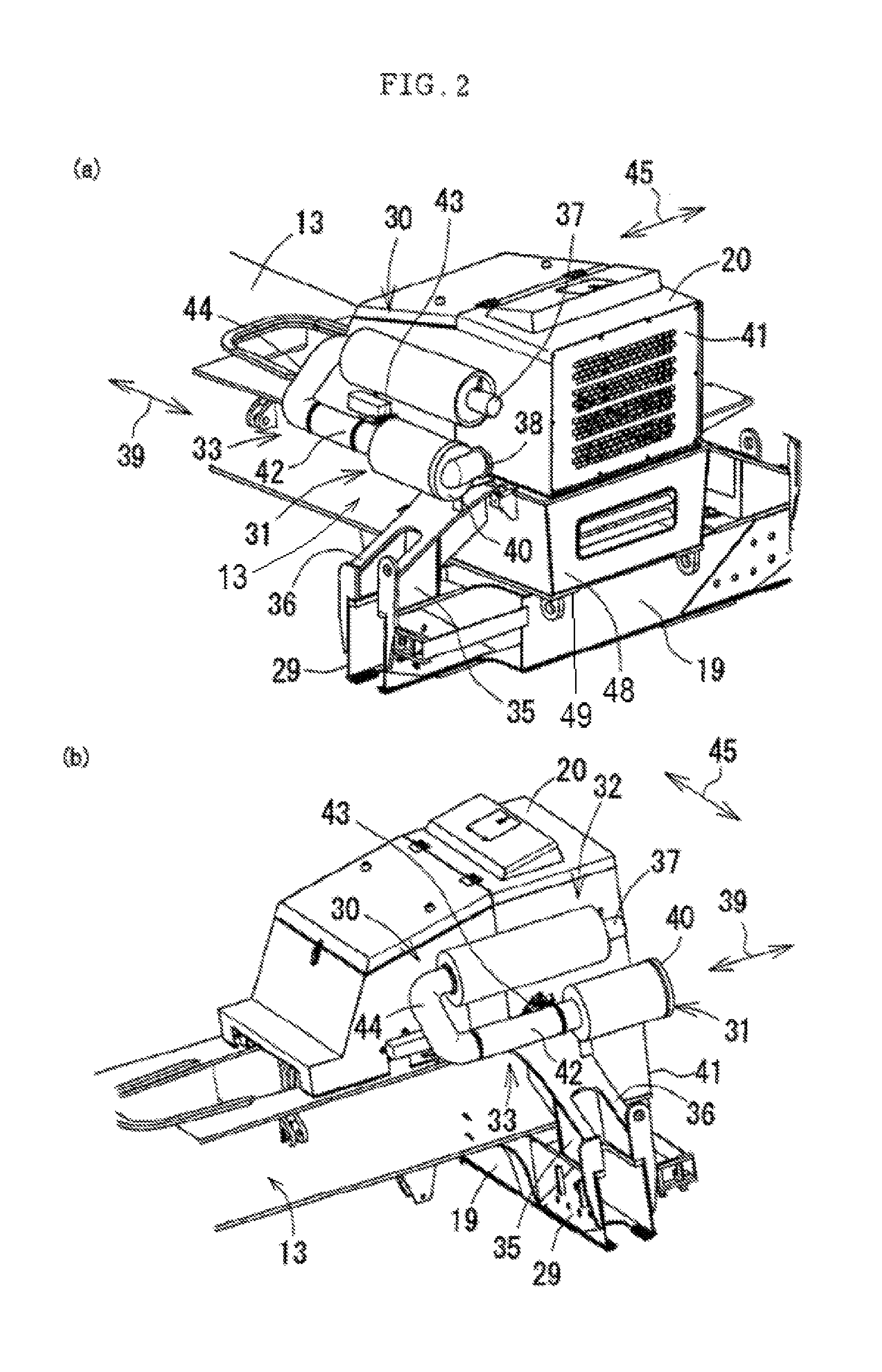

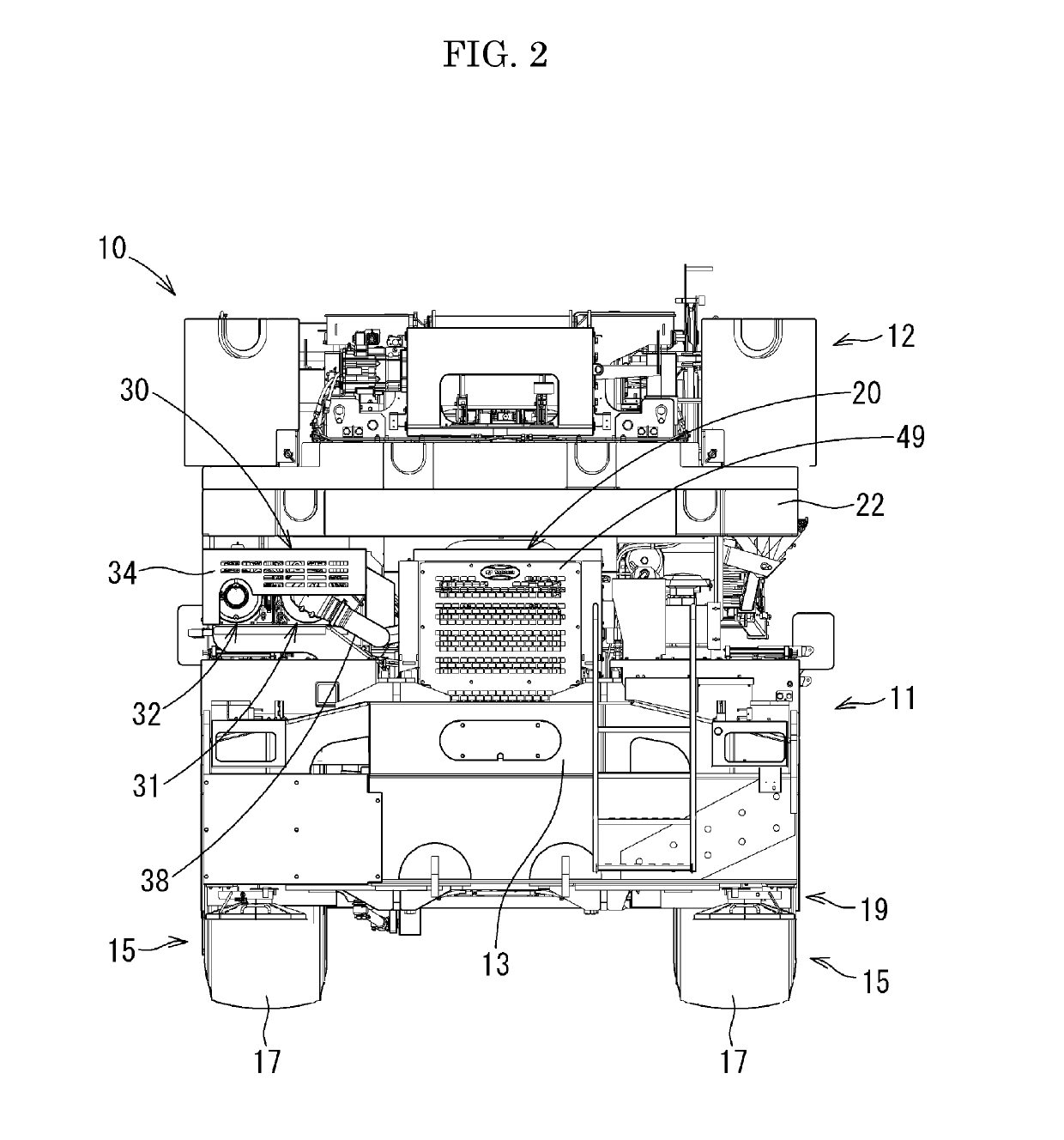

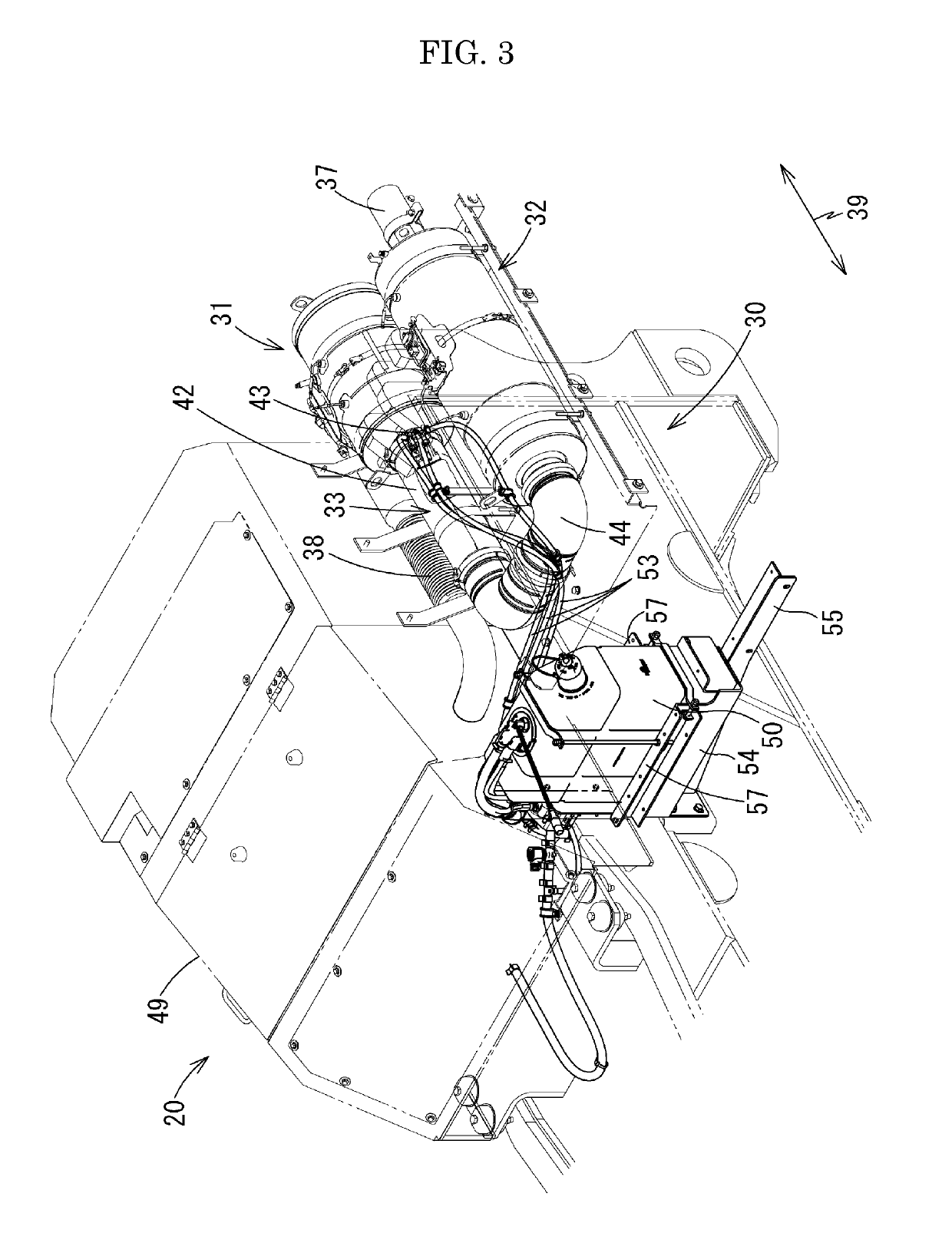

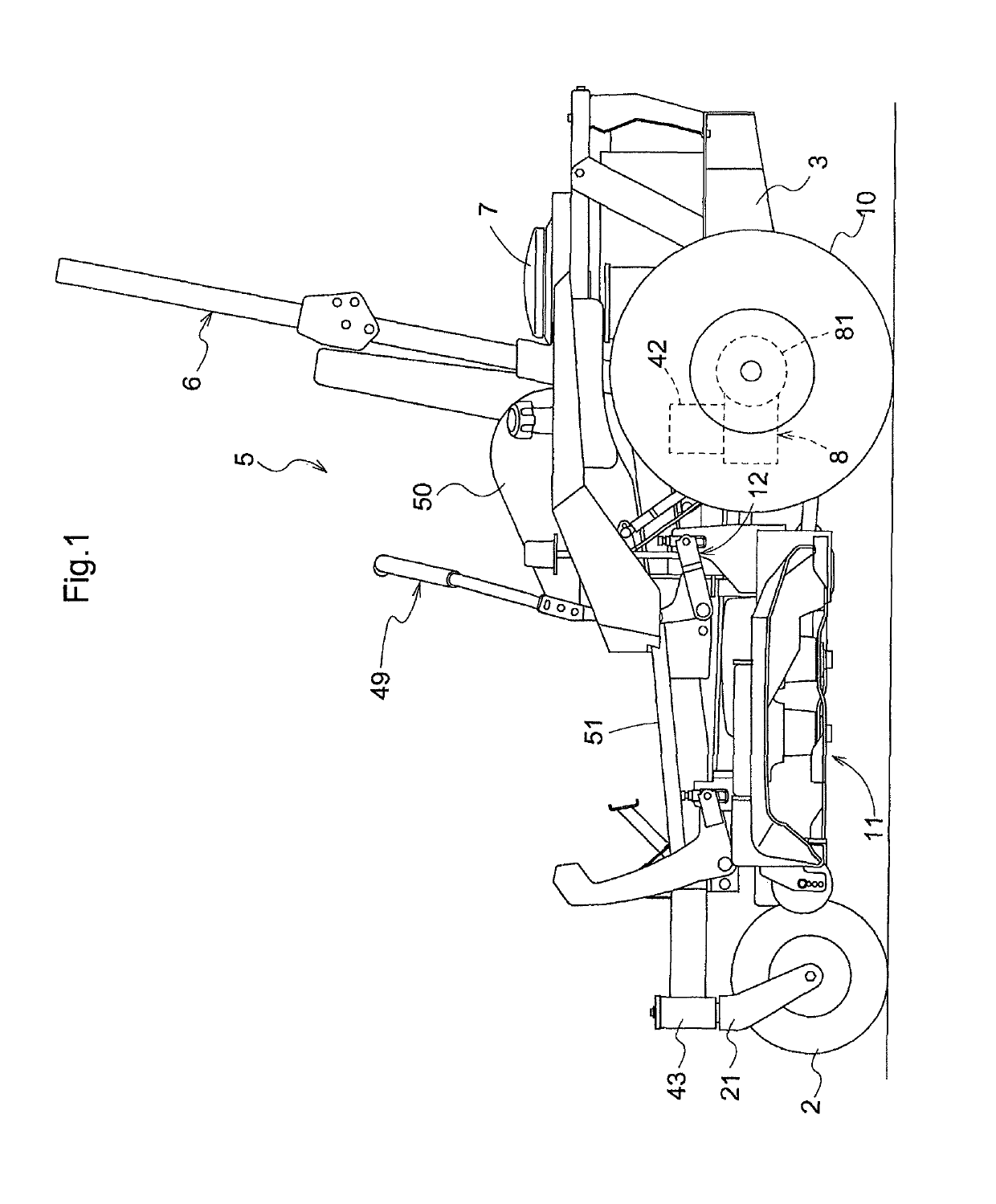

Exhaust emission control device for rough terrain crane

ActiveUS20150001170A1Improve visibilityEasy to viewInternal combustion piston enginesExhaust apparatusTerrainEngineering

A new rough terrain crane has an exhaust emission control device that has a DOC, a DRT, and a SCR. The DOC and the DRT are connected in series and disposed along a longitudinal direction of a vehicle. A rear end of the DOC is positioned at the front side relative to a rear end of an engine. The SCR is disposed in parallel to the DOC and both devices are disposed above a support member of a rear outrigger. The SCR is disposed on the upper side relative to the DOC at a position close to the engine.

Owner:TADANO LTD

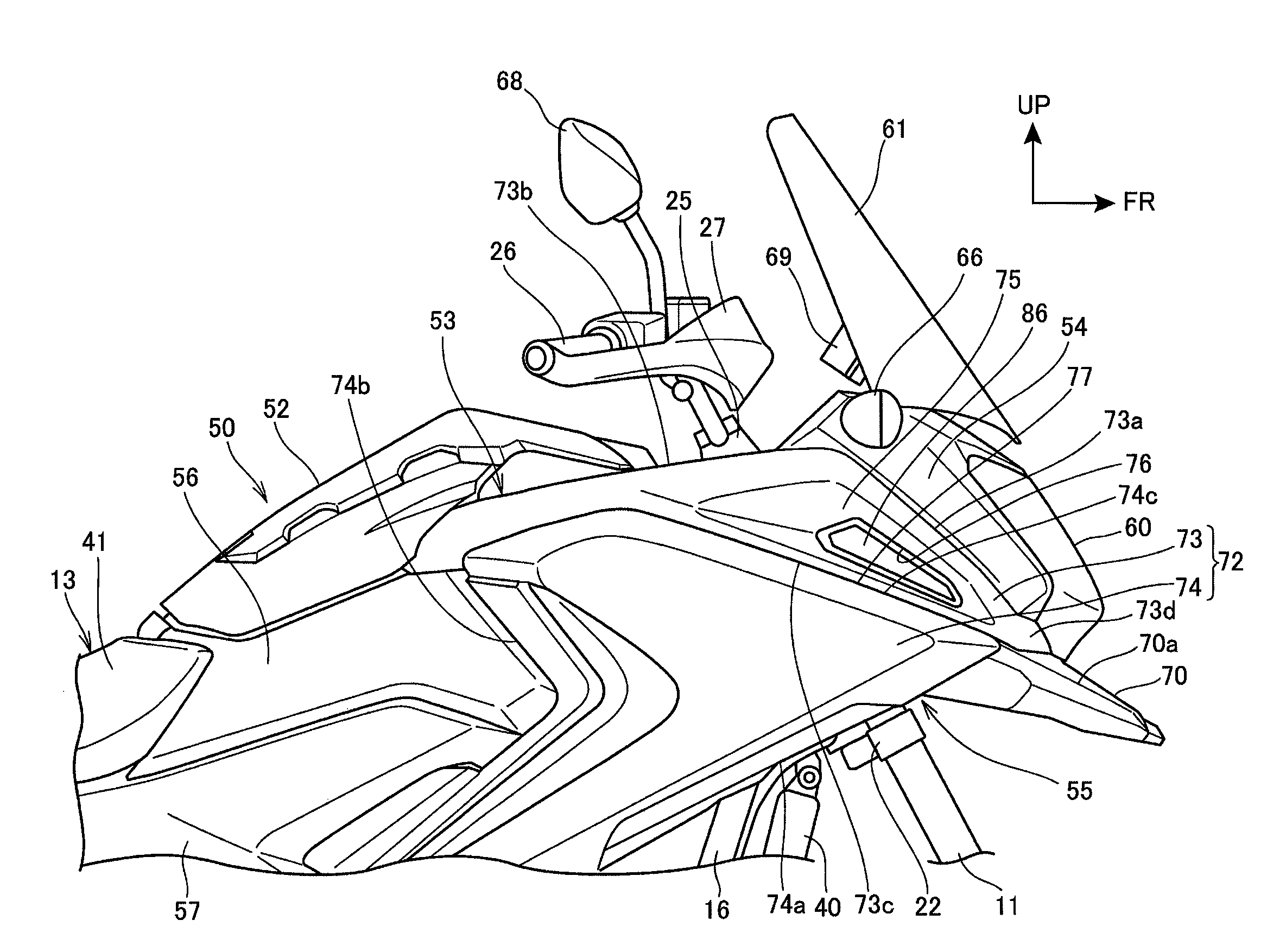

Snowmobile with improved component layout

An improved component layout in a snowmobile includes a muffler is disposed on the front side of an engine, and a lower portion of a steering shaft extends between the muffler and the engine. The engine is disposed rearwardly of the lower portion of the steering shaft. In other words, the steering shaft lower portion is disposed on the front side of the engine, whereby the engine is easily relocated rearwards with respect to the vehicle body so as to concentrate the center of mass at a central location of the vehicle body.

Owner:HONDA MOTOR CO LTD

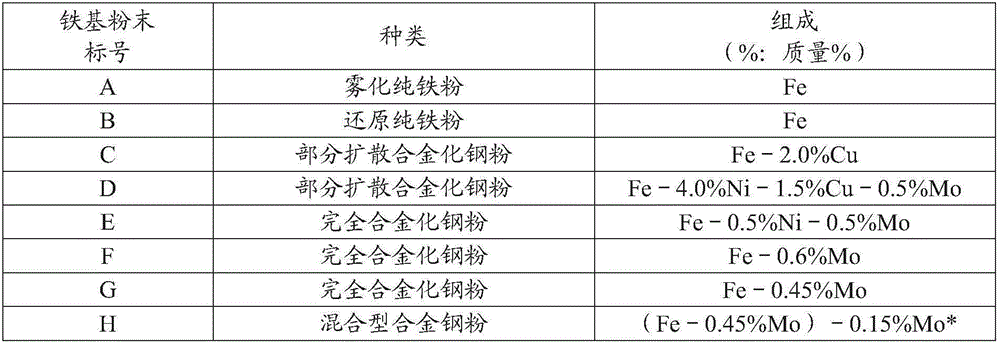

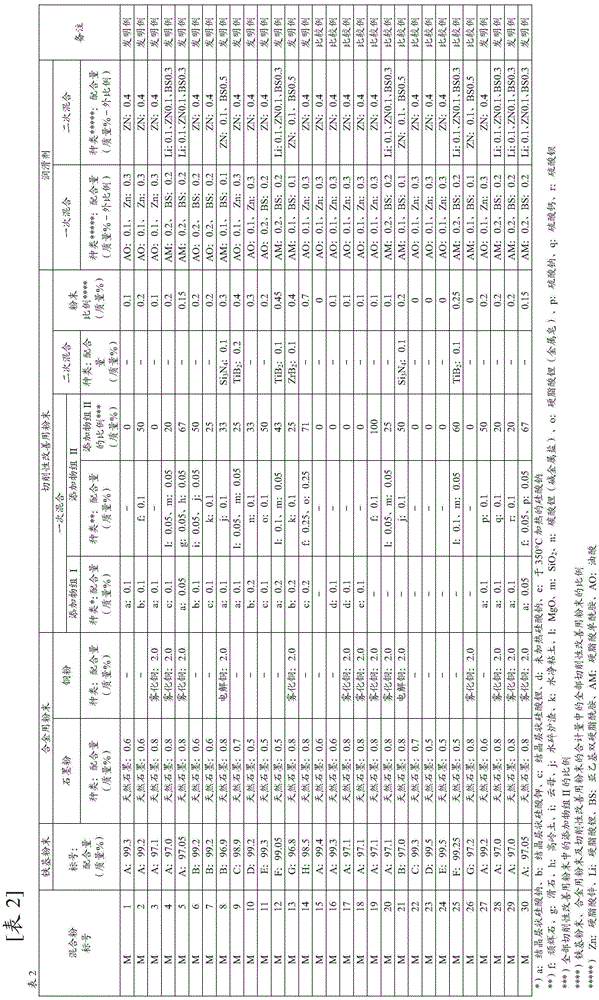

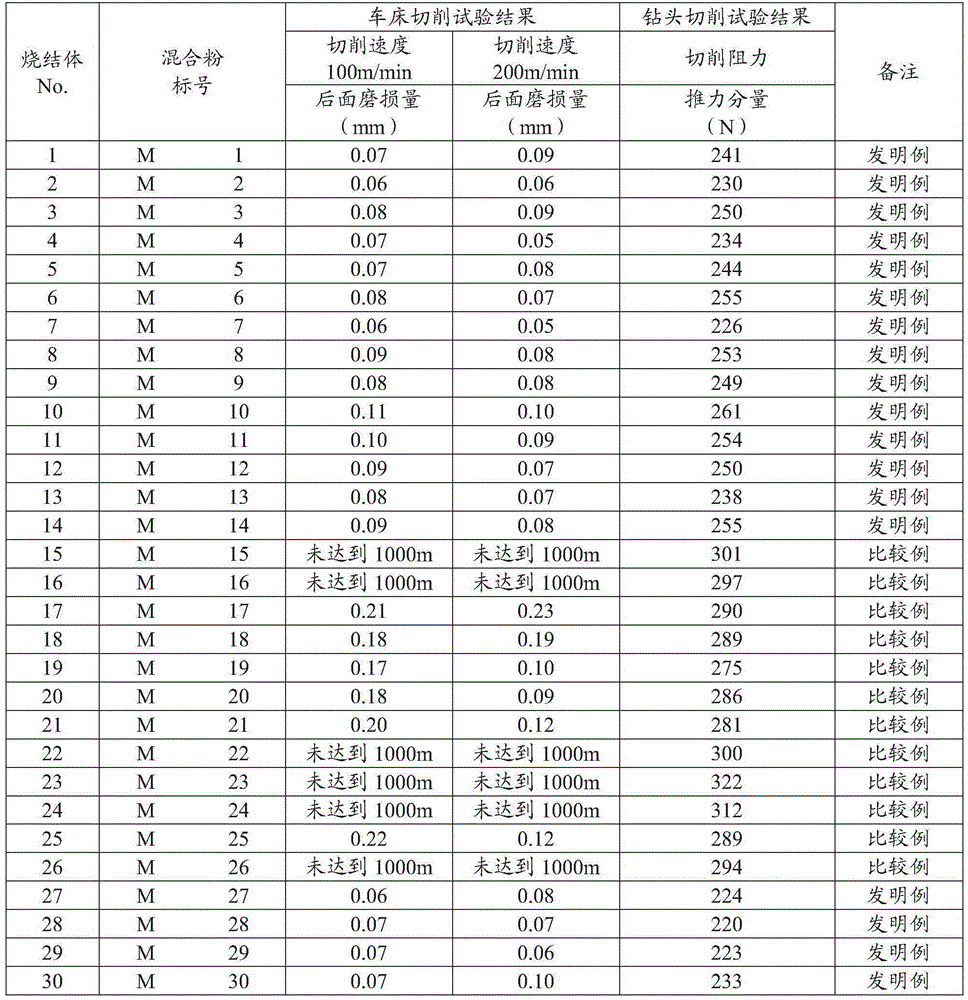

Mixed powder for powder metallurgy, method of manufacturing same, and method of manufacturing iron-based powder sintered body

ActiveCN105377477AFunctionalFunction increaseTransportation and packagingMetal-working apparatusAlloyMachining

According to the present invention, a machining-improving powder is a crystalline layered alkali silicate heat-treated at a temperature range of 400-1100 DEG C, and the mixture constituting the machining-improving powder is set such that an iron-based powder takes up 0.01-1.0 mass% in relation to the total amount of alloy powder and machining-improving powder. As a result, not only can sintering of a compact be performed in a sintering furnace without having any negative effects on the environment inside the furnace, but it is also possible to attain a mixed powder for powder metallurgy by which it is possible to obtain a sintered body having both exceptional lathing properties and exceptional drilling properties.

Owner:JFE STEEL CORP

Snowmobile

InactiveUS7478694B2Improved turning performanceStable supportExhaust apparatusSilencing apparatusEngineeringFootplate

Owner:HONDA MOTOR CO LTD

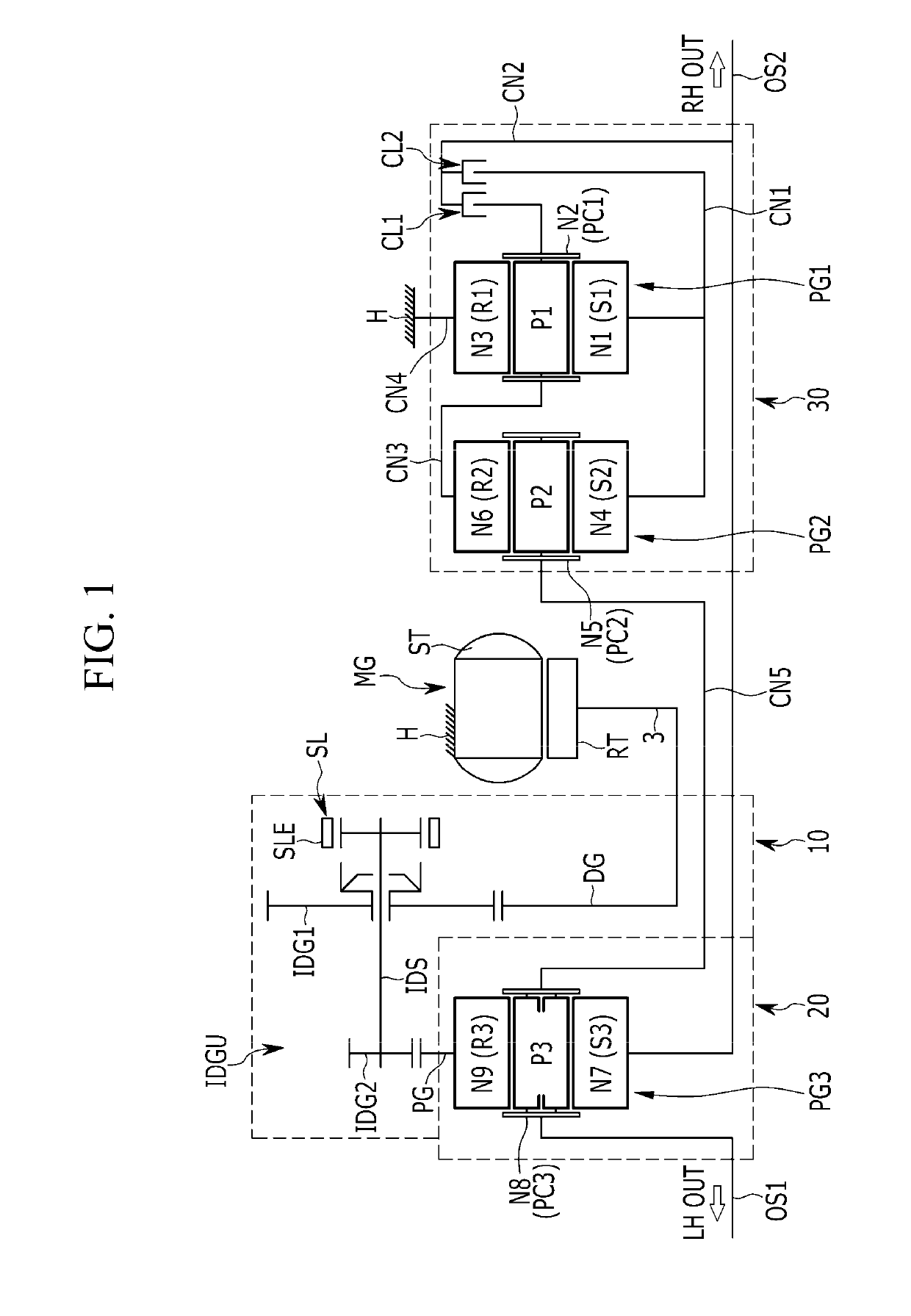

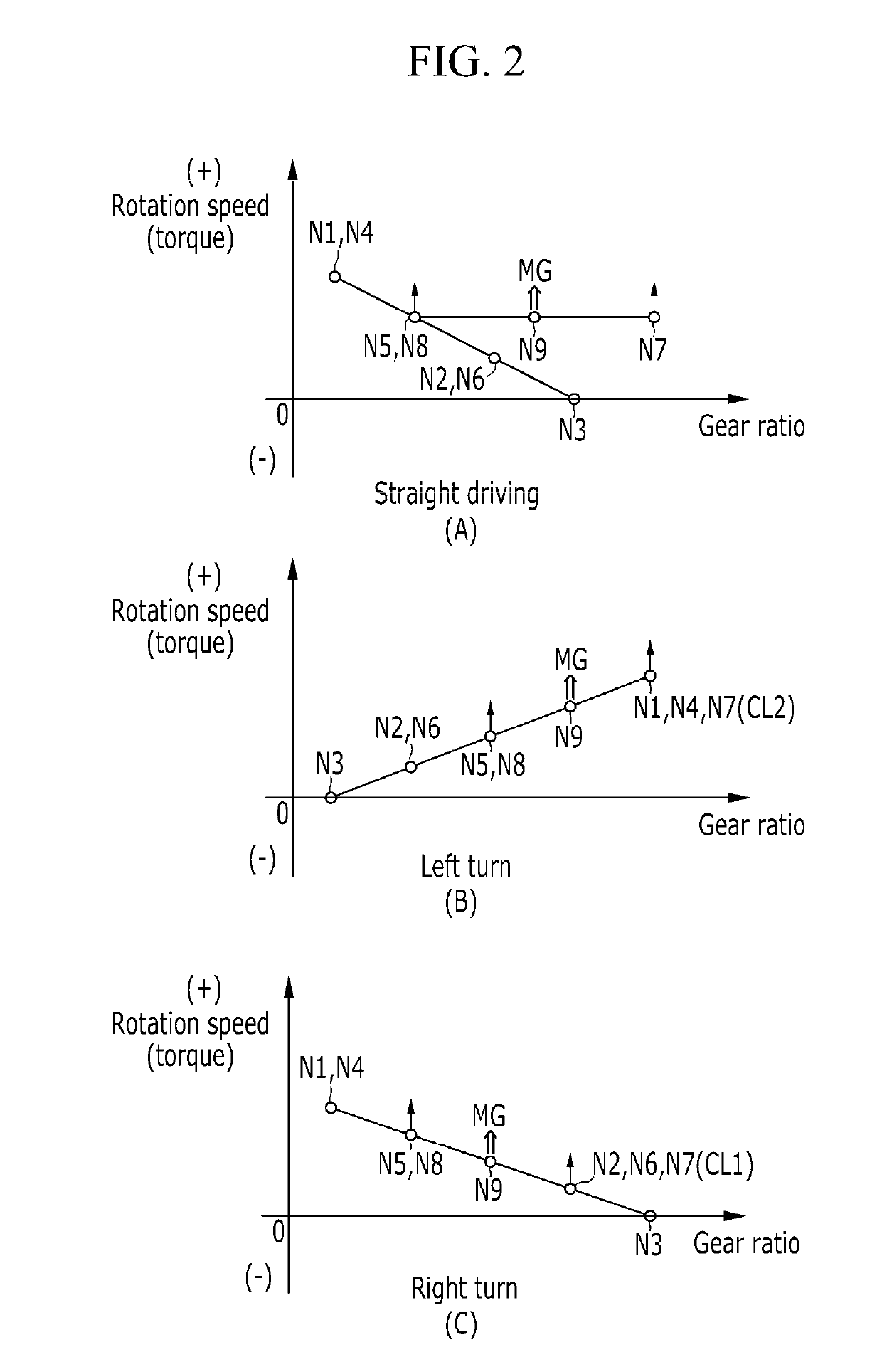

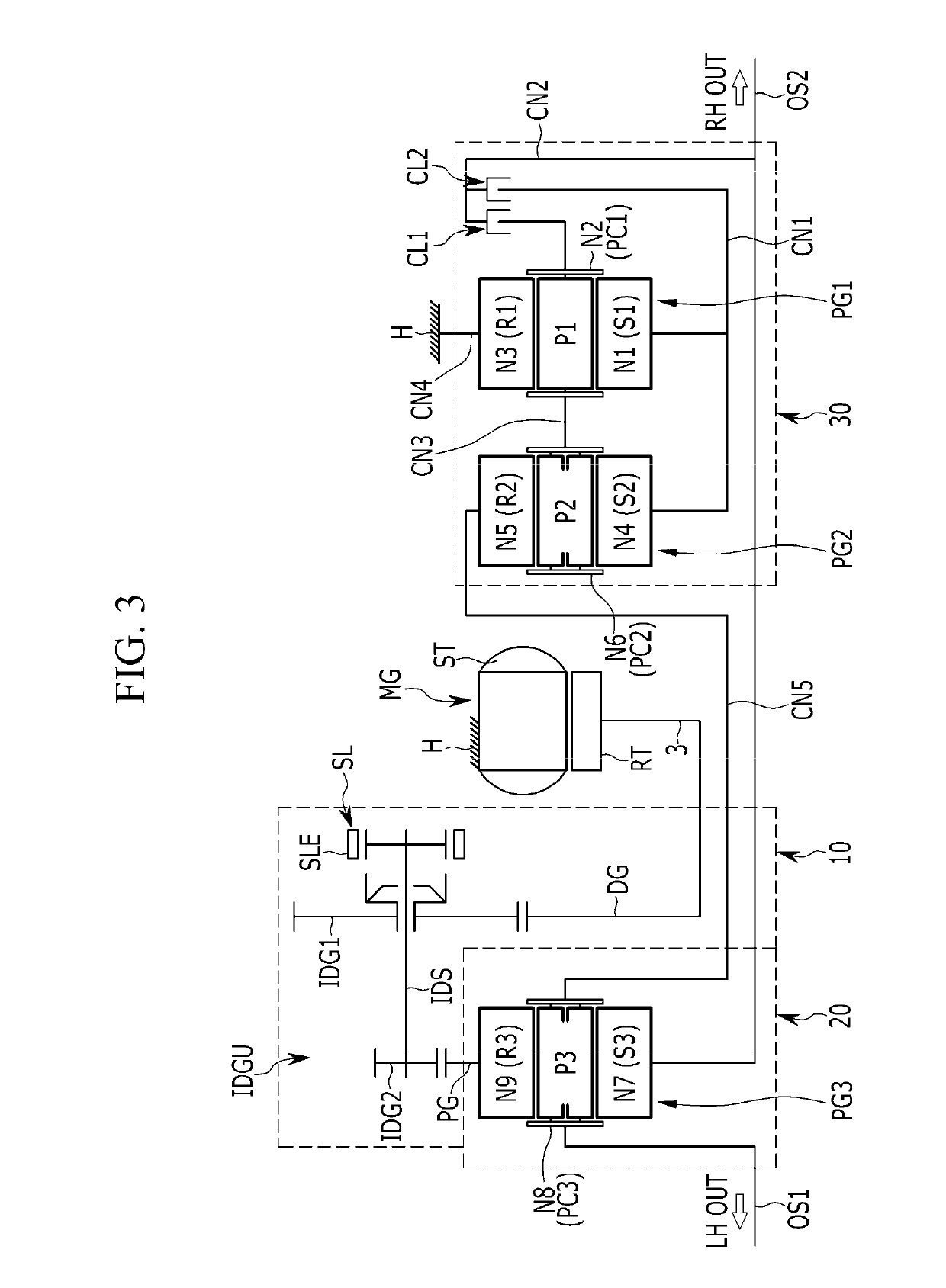

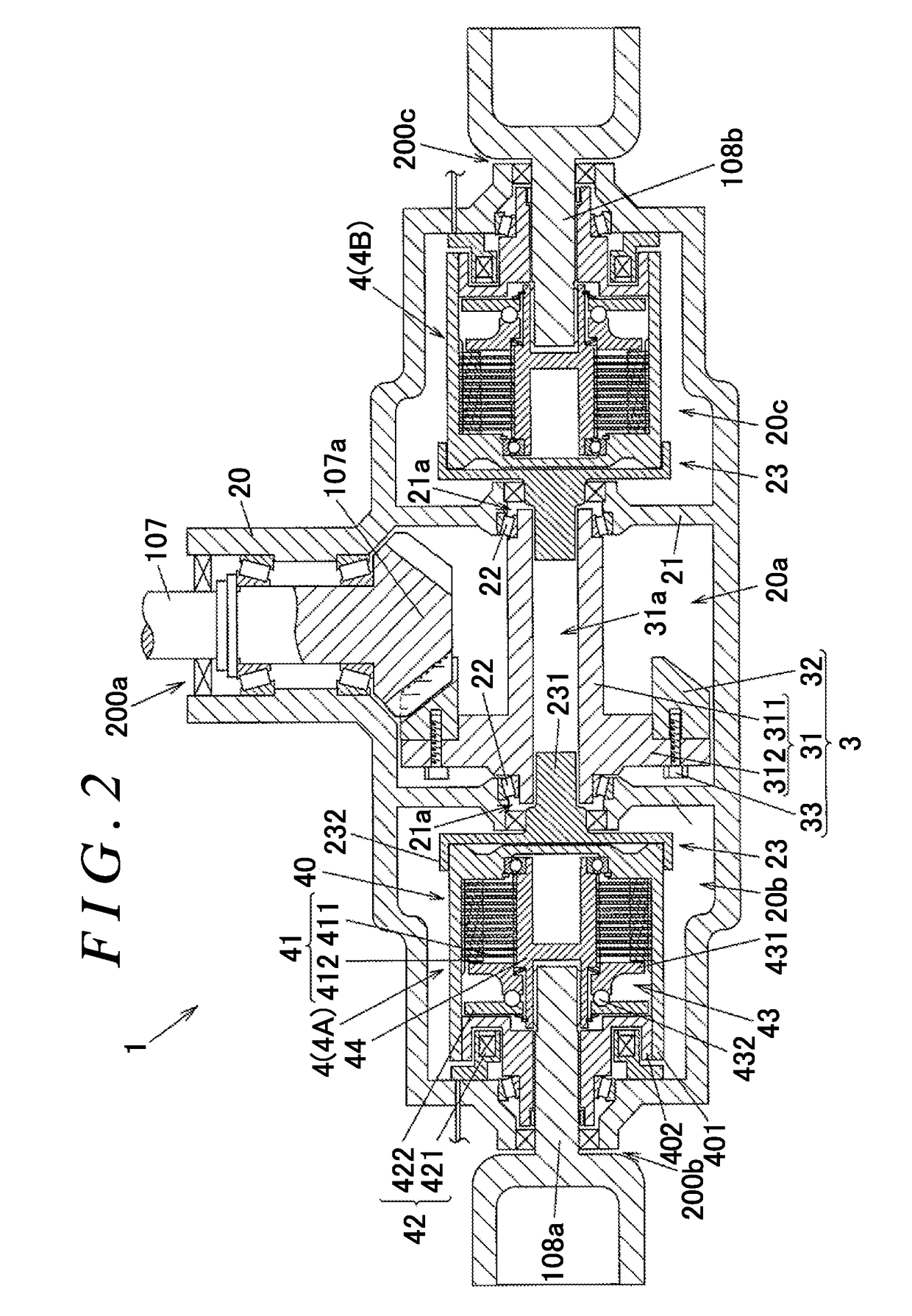

System for torque vectoring

ActiveUS20190176620A1Minimize torque lossImprove fuel economy performanceHybrid vehiclesElectric propulsion mountingCouplingControl theory

A torque vectoring system may include a first planetary gear set that may include first, second, and third rotation elements, wherein the first rotation element is selectively connectable to one of the left-side output shaft and the right-side output shaft through a coupling element, the second rotation element is selectively connectable to the one output shaft through a coupling element, and the third rotation element is fixedly connected to a housing; and a second planetary gear set that may include fourth, fifth, and sixth rotation elements, and the fourth rotation element is fixedly connected to the first rotation element, the fifth rotation element is connected to the differential such that power may be transmitted thereto, and the sixth rotation element is fixedly connected to the second rotation element.

Owner:HYUNDAI MOTOR CO LTD +1

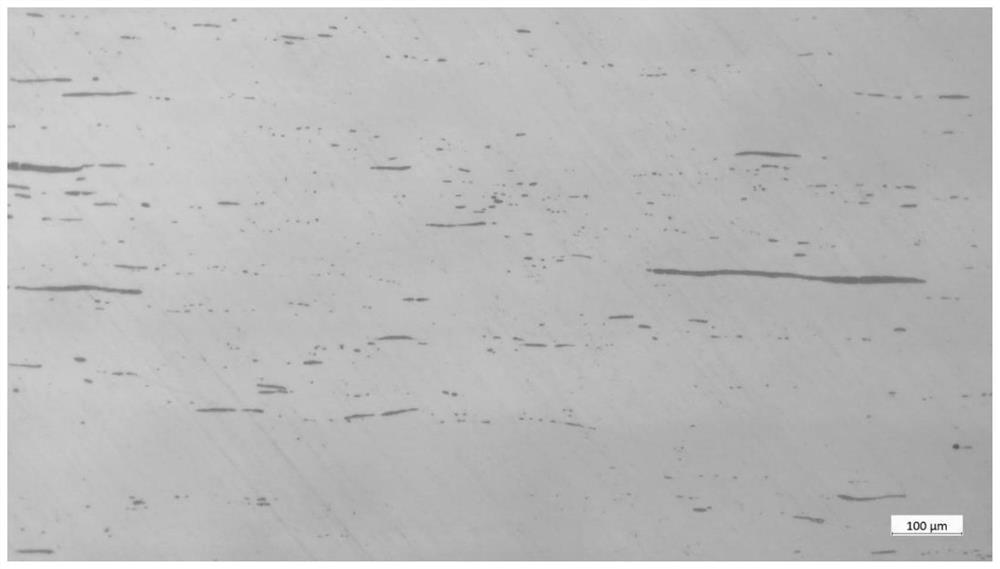

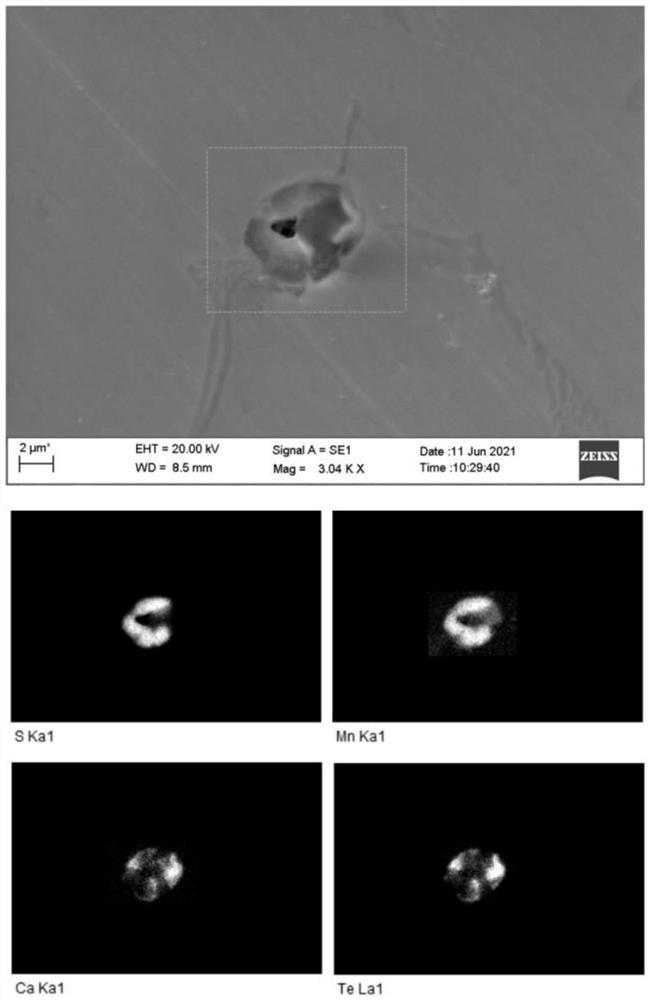

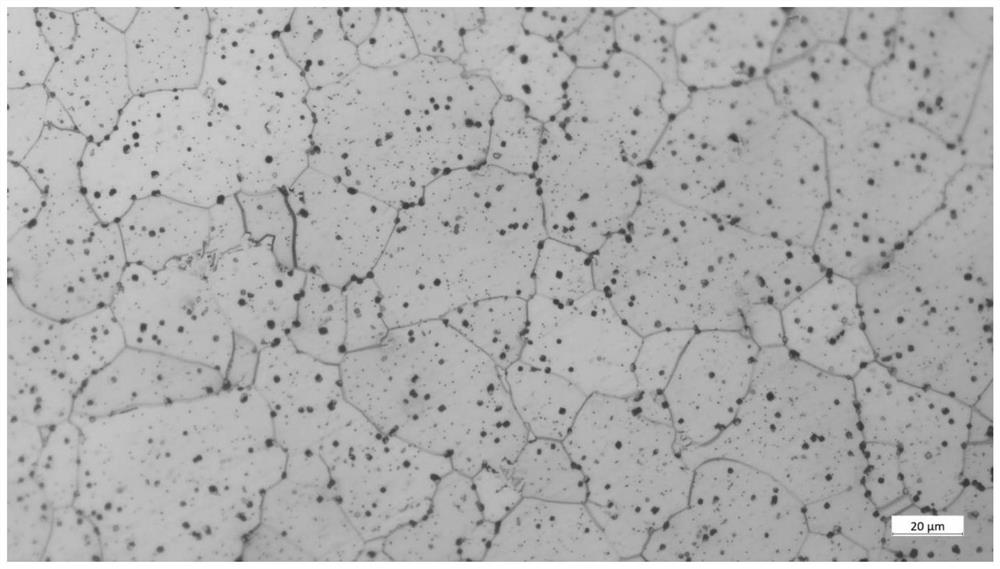

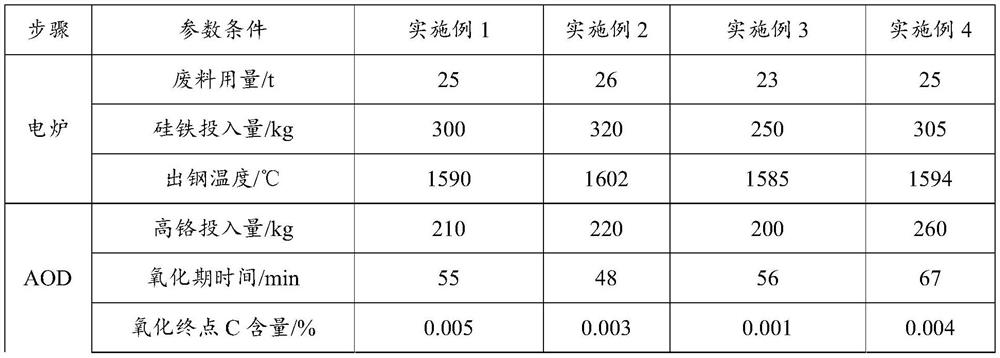

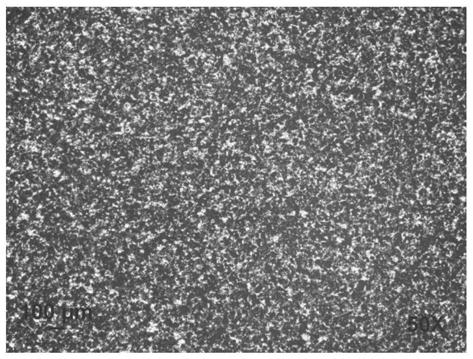

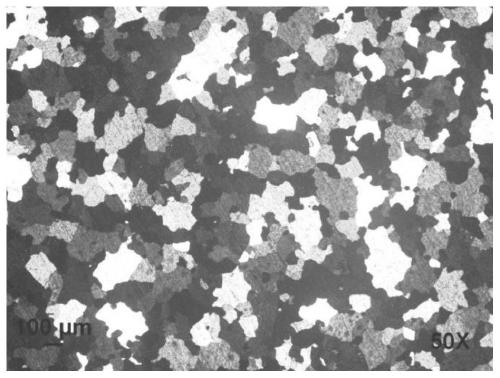

Ultra-free-cutting stainless steel subjected to calcium-tellurium-rare earth composite treatment and preparation method thereof

ActiveCN113684420AReduce wearSmall heterosexualMetal rolling arrangementsElectric arc furnaceSmelting process

The invention relates to ultra-free-cutting stainless steel subjected to calcium tellurium rare earth composite treatment and a preparation method thereof. Every 100 parts of ultra-free-cutting stainless steel subjected to calcium tellurium rare earth composite treatment comprises the following raw materials in parts by weight: less than or equal to 0.08 part of C, less than or equal to 1.00 part of Si, less than or equal to 2.0 parts of Mn, less than or equal to 0.060 part of P, 0.25-0.35 part of S, 8.5-10.0 parts of Ni, 17.0-19.0 parts of Cr, 0.002-0.008 part of Ca, 0.003-0.015 part of Te (tellurium), 0.002-0.012 part of Re, and the balance of iron and other impurities. The preparation method comprises the steps that the waste stainless steel is sequentially subjected to electric arc furnace smelting, AOD refining, LF refining, continuous steel casting, blank rolling and surface treatment so as to obtain the stainless steel. According to the ultra-free-cutting stainless steel subjected to calcium tellurium rare earth composite treatment, sulfides of the stainless steel are dispersed and evenly distributed, the turning performance and the mechanical performance of the stainless steel are excellent, and meanwhile, the purposes of reducing the influence of the sulfides on the mechanical performance and improving the machinability are achieved; and in addition, according to the preparation method, by optimizing the smelting process, the yield of a final stainless steel product can reach 95% or above, and the stainless steel product possesses better mechanical performance.

Owner:浙江青山钢铁有限公司

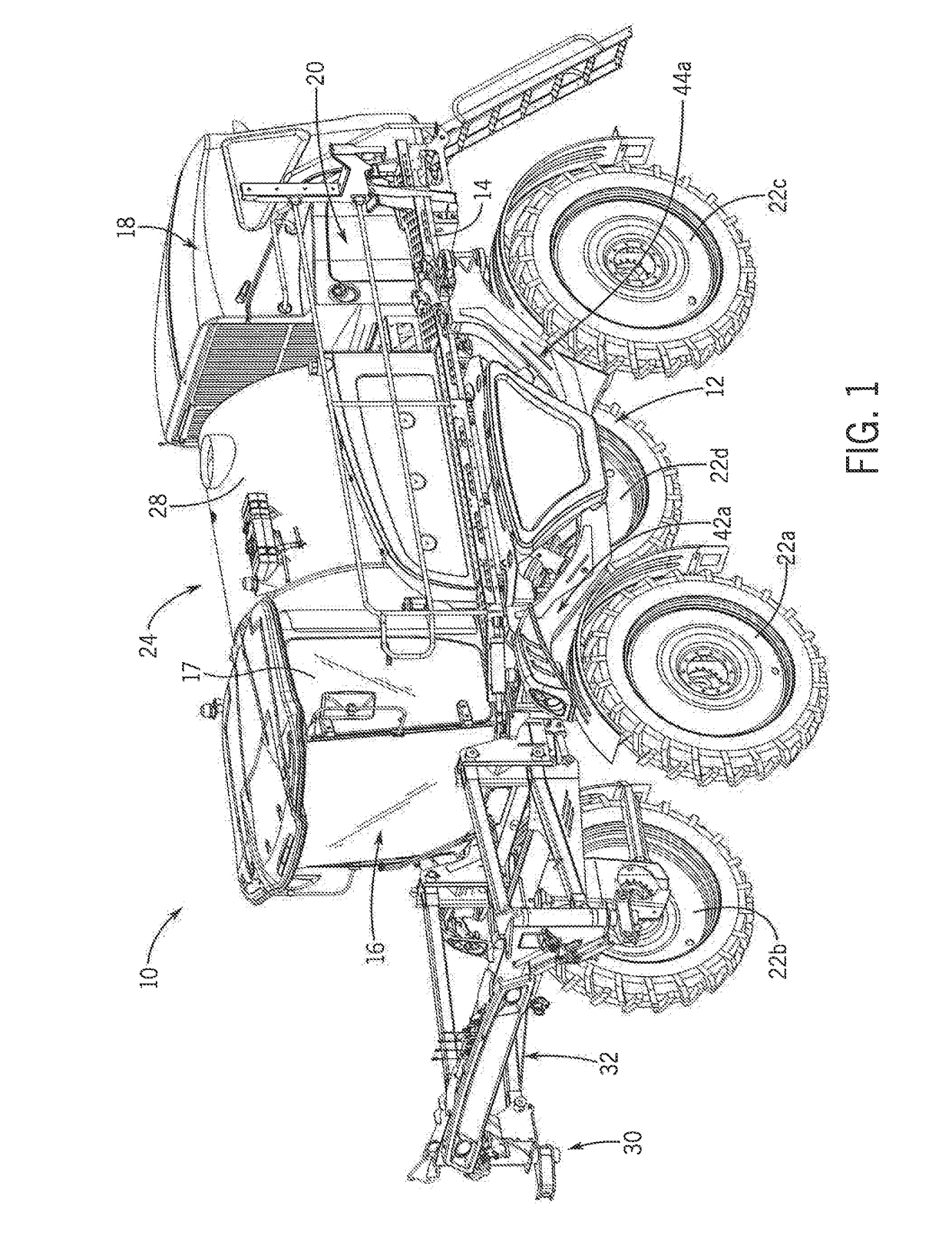

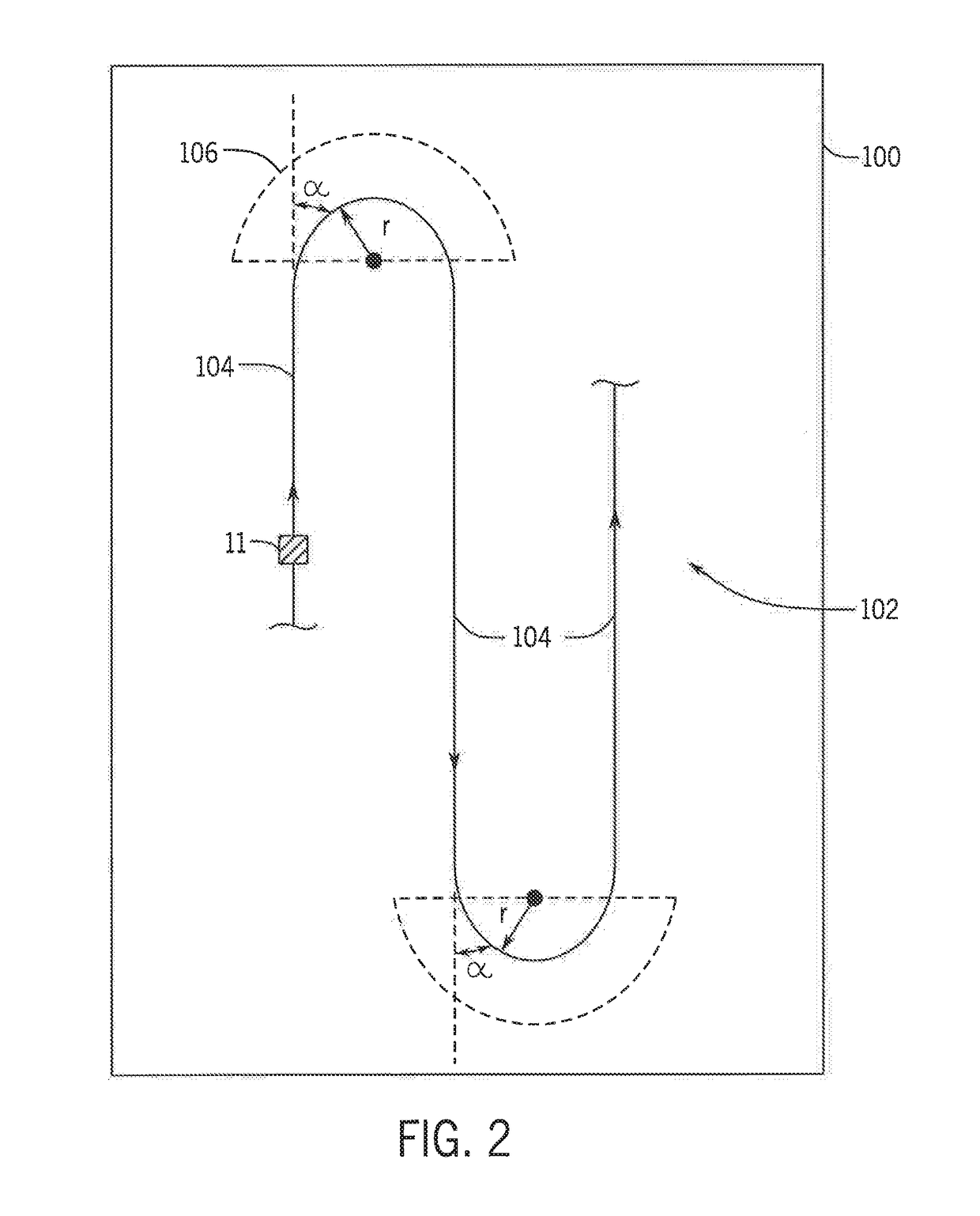

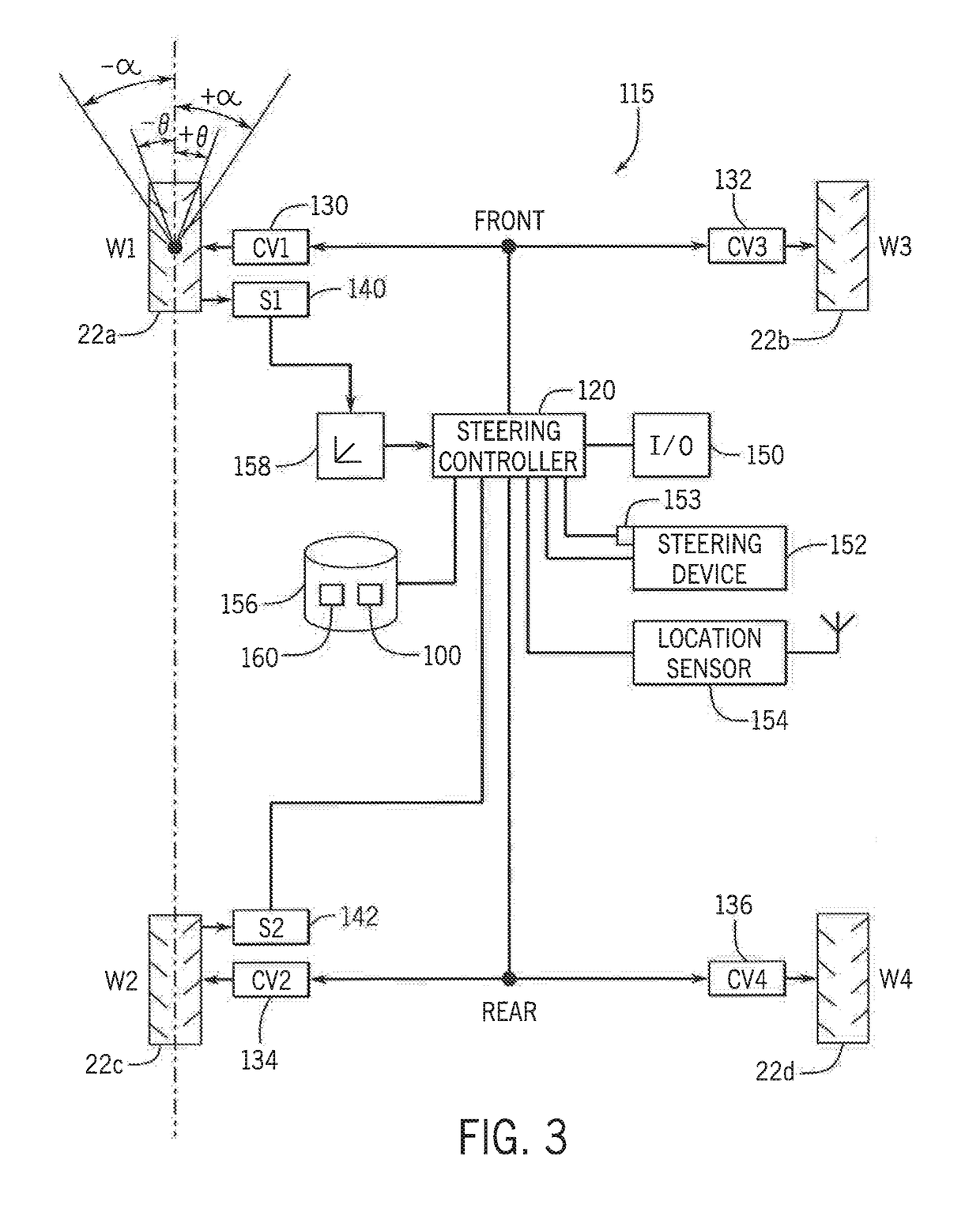

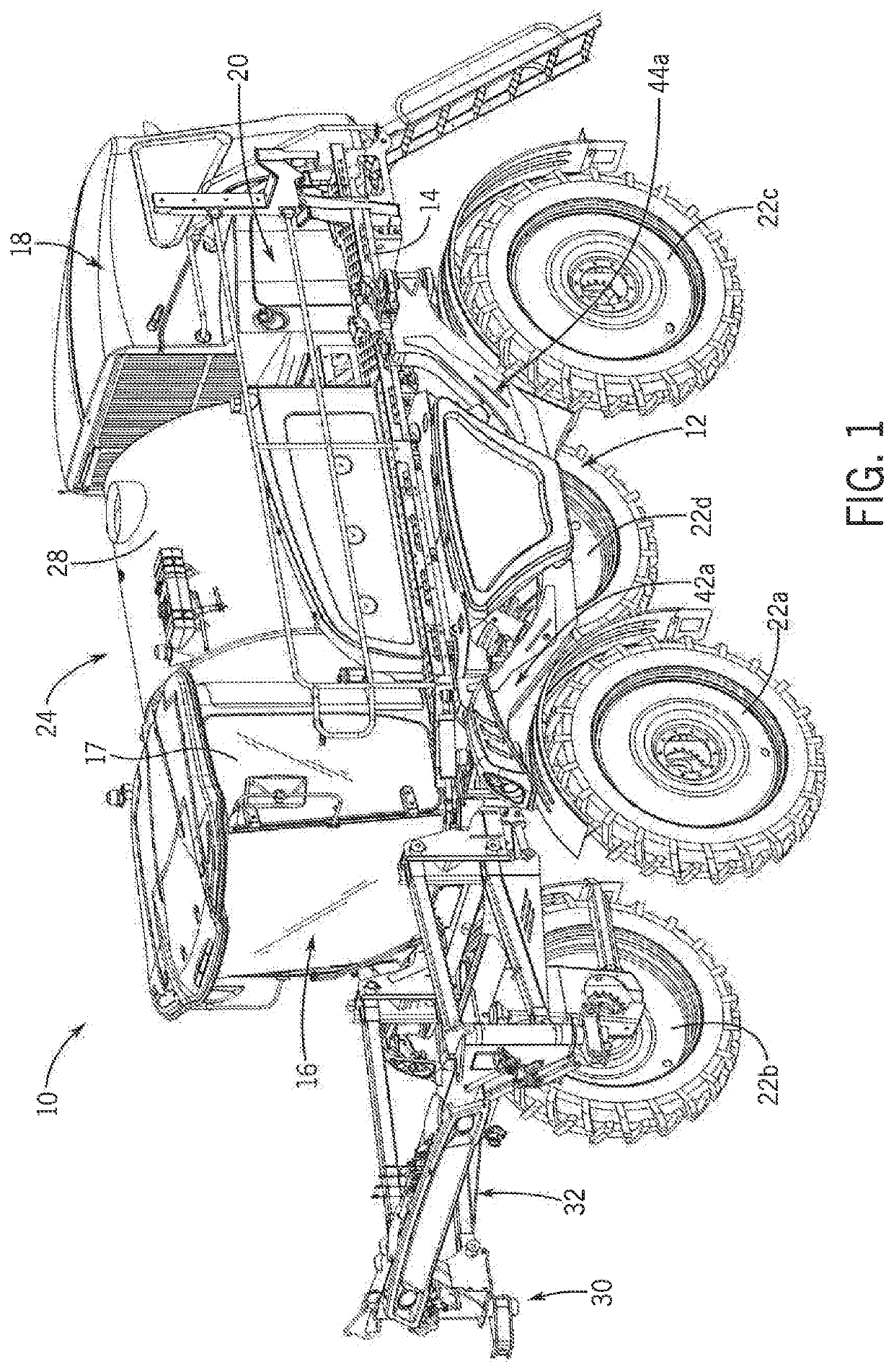

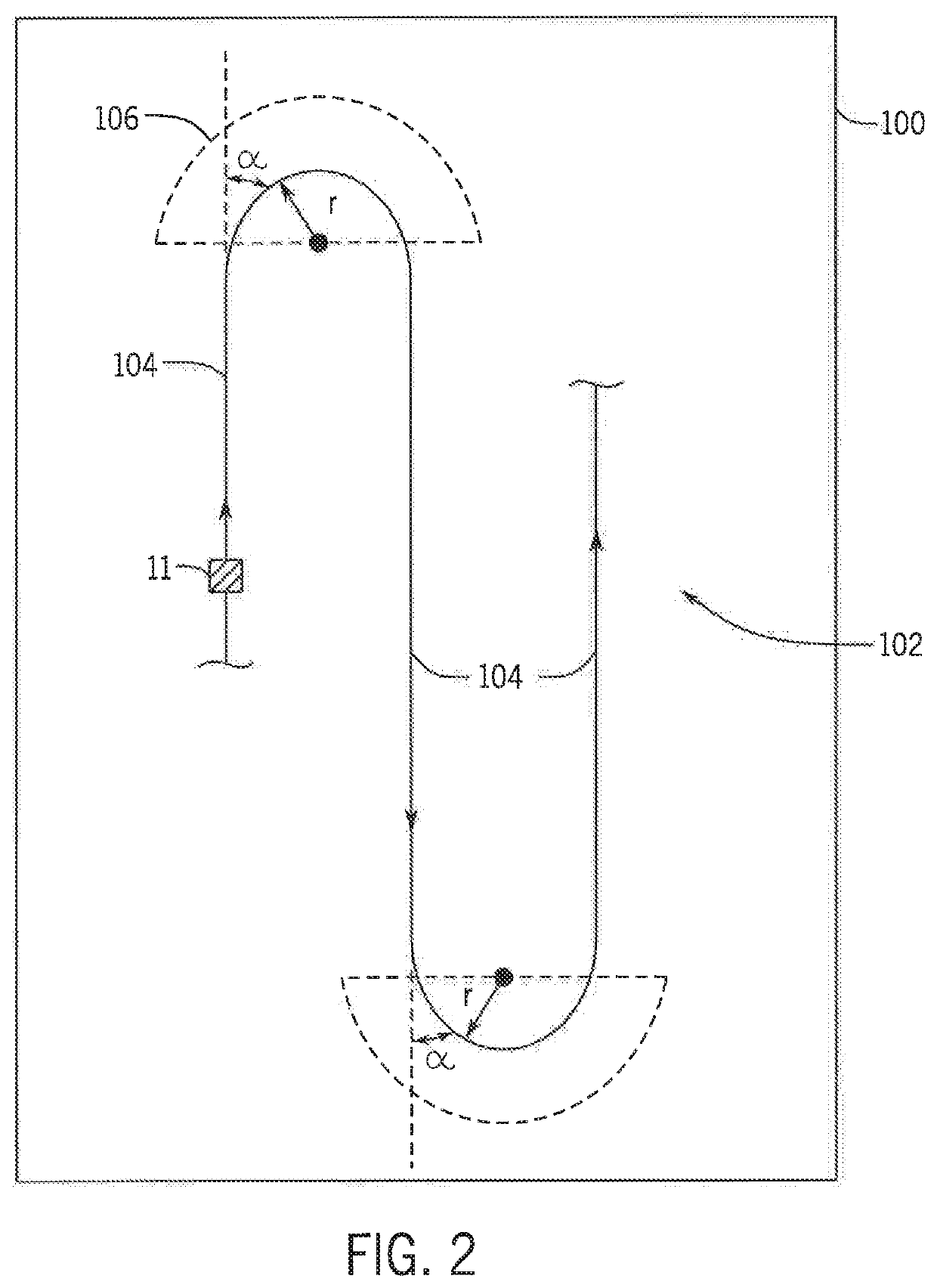

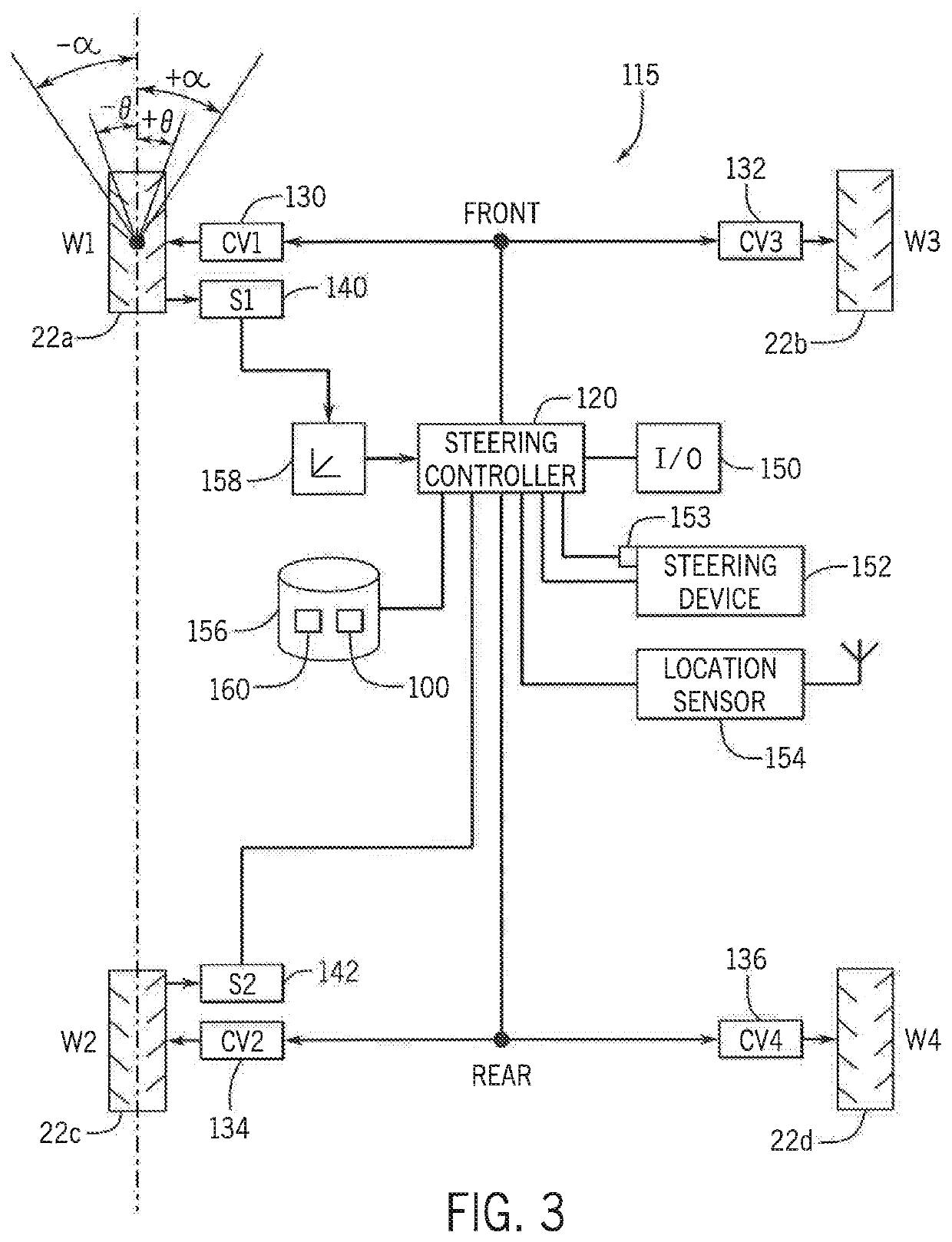

Automatic Steering With Selective Engagement Of Four-Wheel Steering

ActiveUS20190071115A1Improved turning performanceSteering linkagesGuiding agricultural machinesAutomatic steeringEngineering

Automatic steering and four-wheel steering are configured on an agricultural machine so that when automatic steering is enabled, a control system selectively activates and deactivates four-wheel steering depending on sensed turning or non-turning states of the machine. When automatic steering is enabled, the machine can automatically steer, such as according to a prescription map. In straightaway paths, corresponding to non-turning states, the control system can activate two-wheel steering. However, in the headlands of fields, corresponding to turning states, the control system can activate four-wheel steering. Such turning states can be determined based on the machines location on the map. Alternatively, such turning states can be determined based on sensed turning of the wheels. When an operator takes control of steering, such as by turning the steering wheel, automatic steering can disable, and the control system can activate four-wheel steering, to provide an optimum state for turning in the headlands of fields.

Owner:BLUE LEAF I P

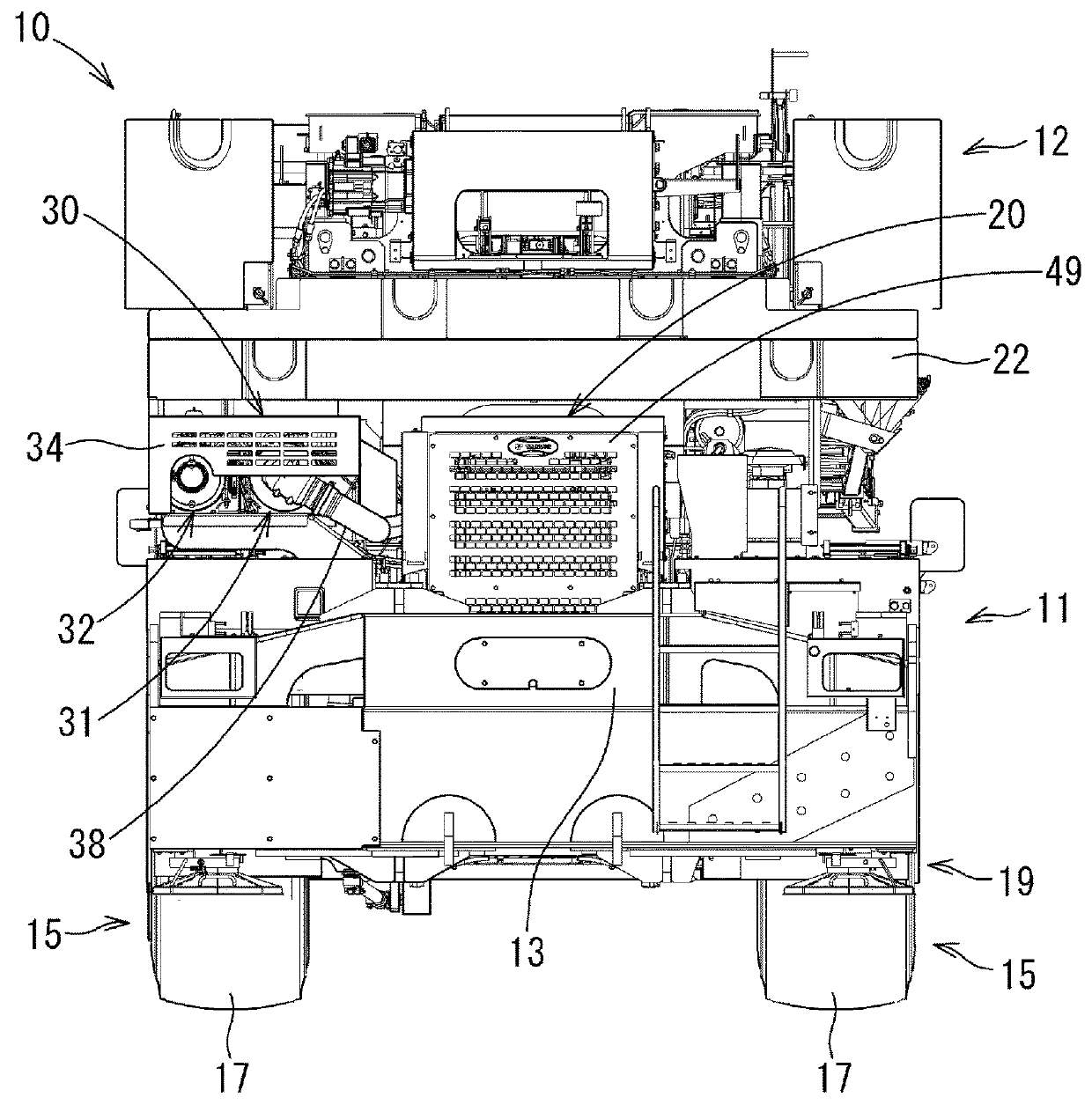

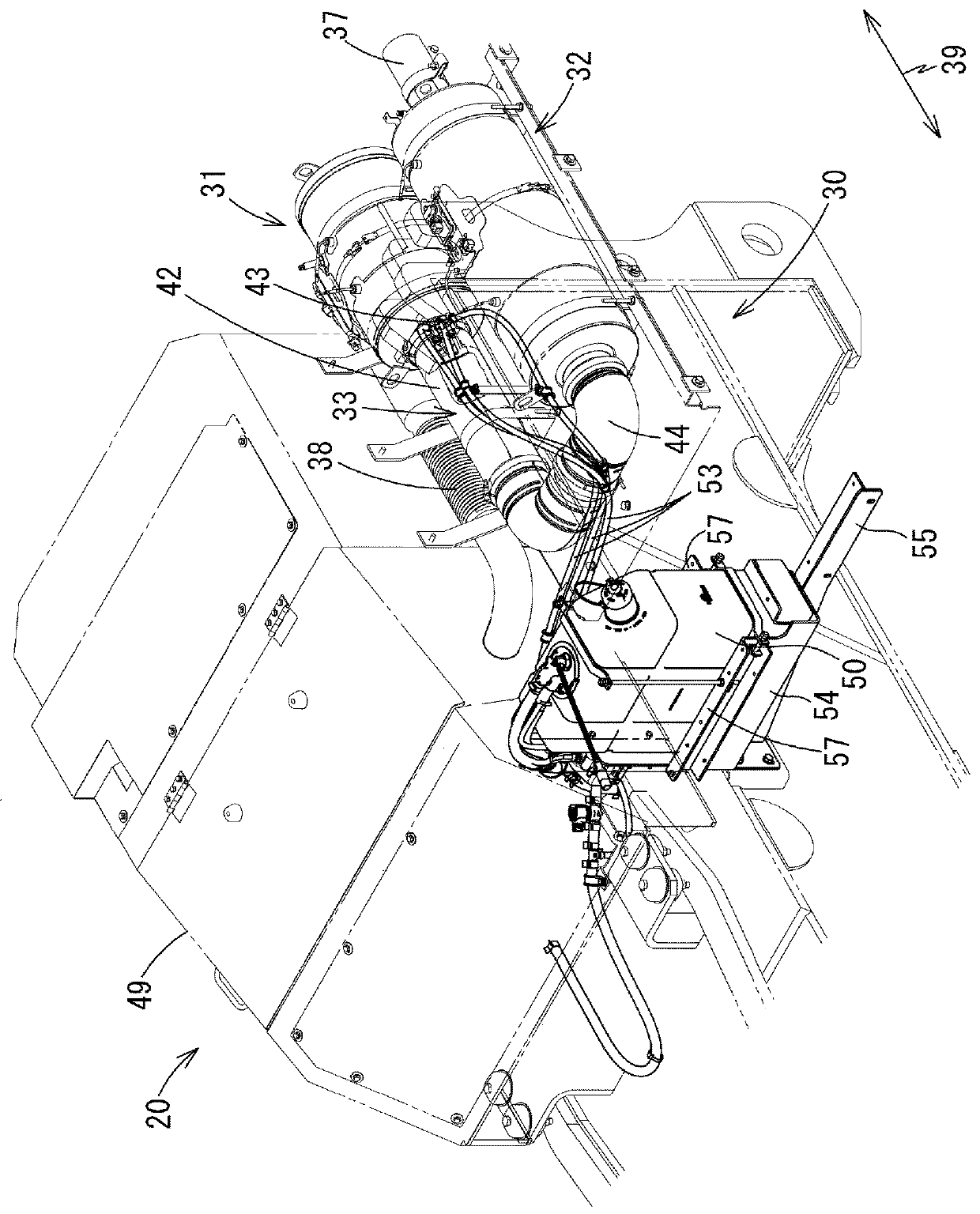

Exhaust emission control device for rough terrain crane

ActiveUS9469511B2Improved turning performanceEasy to operateInternal combustion piston enginesExhaust apparatusTerrainEngineering

A new rough terrain crane has an exhaust emission control device that has a DOC, a DRT, and a SCR. The DOC and the DRT are connected in series and disposed along a longitudinal direction of a vehicle. A rear end of the DOC is positioned at the front side relative to a rear end of an engine. The SCR is disposed in parallel to the DOC and both devices are disposed above a support member of a rear outrigger. The SCR is disposed on the upper side relative to the DOC at a position close to the engine.

Owner:TADANO LTD

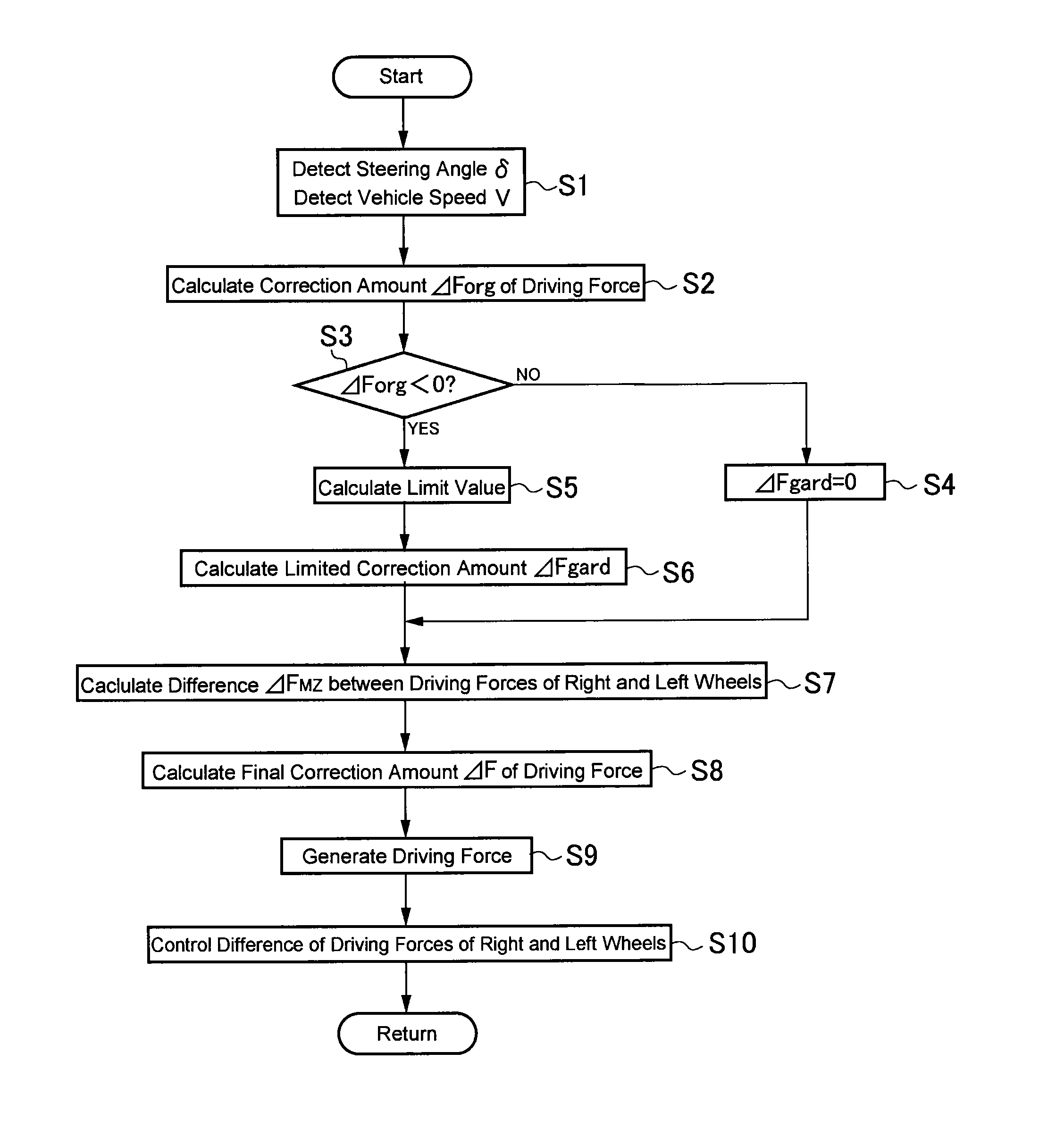

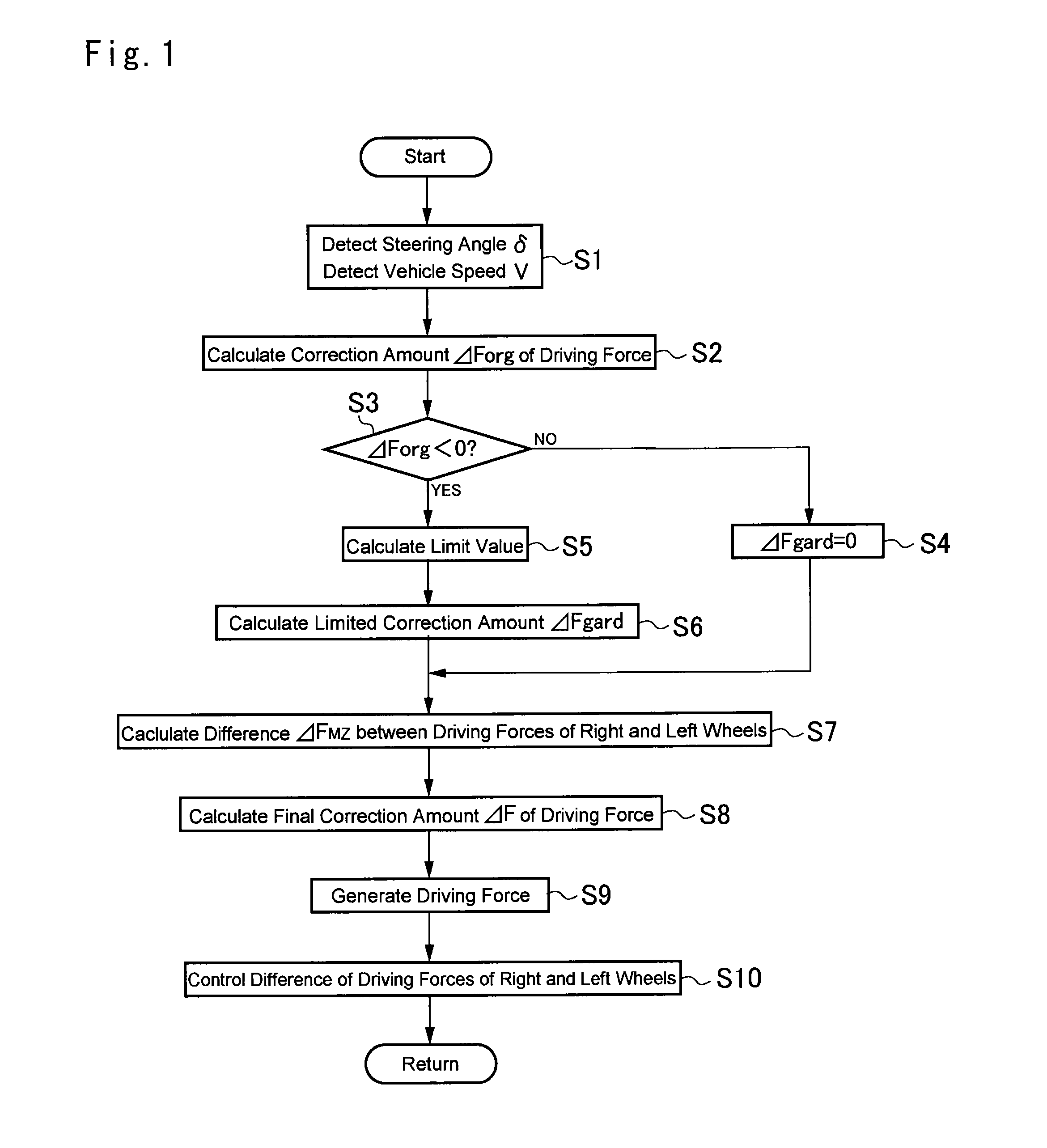

Vehicle control system

ActiveUS20150329109A1Turning performance is improvedImprove turning performance (or turning condition)Steering initiationsDigital data processing detailsControl systemDrive wheel

A vehicle control system is provided with a first driving force control means that controls a turning performance of a vehicle by controlling a driving force delivered from a prime mover to driving wheels so as to adjust the turning condition of the vehicle to an intended turning condition. The first driving force control means is configured to calculate a correction amount of the driving force required to adjust an actual turning condition of the vehicle to the intended turning condition, and to restrict the correction amount to zero or smaller so as not to increase the driving force if the correction amount is positive value.

Owner:TOYOTA JIDOSHA KK

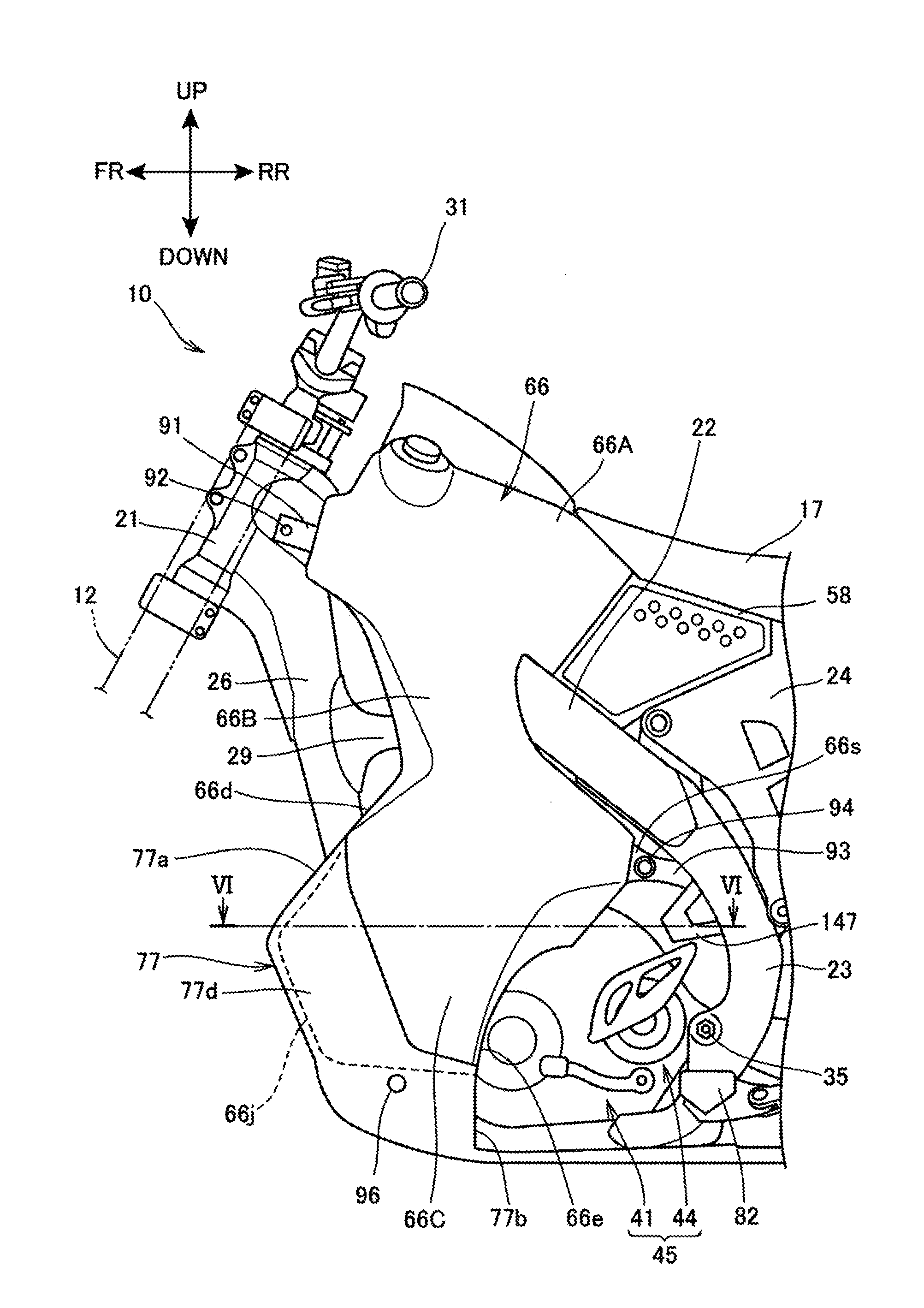

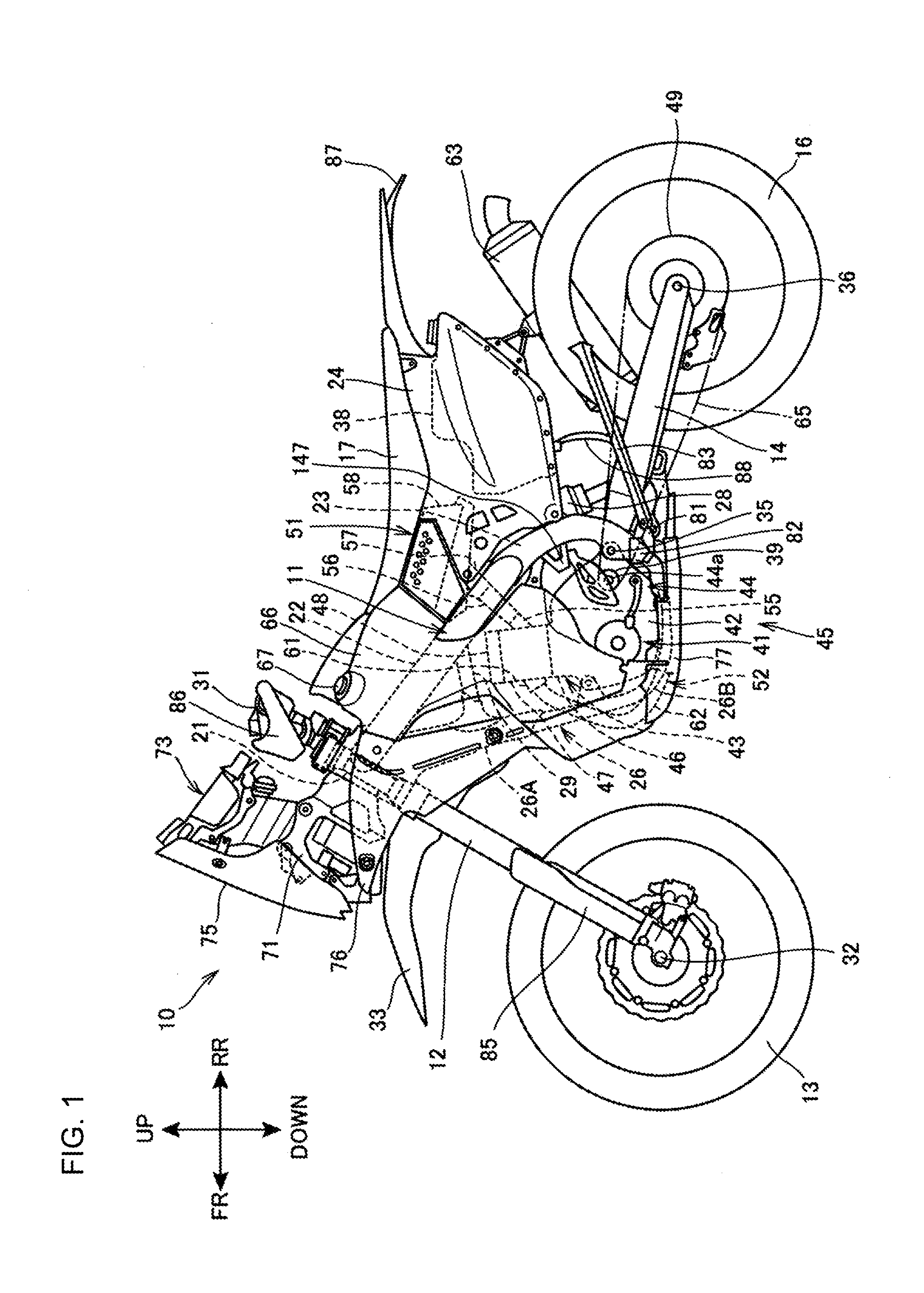

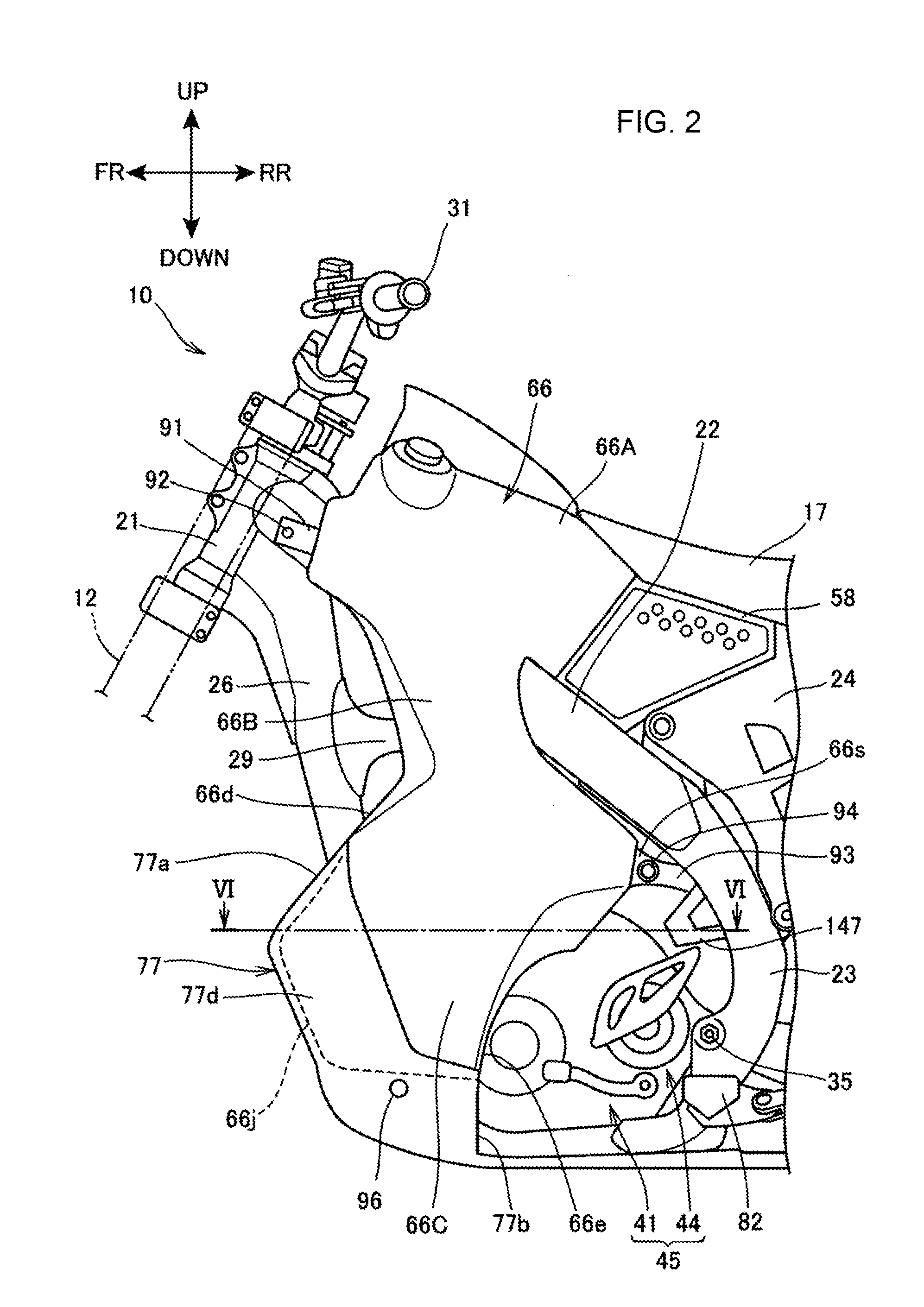

Electrical component mounting structure for saddle-riding type vehicle

An electrical component mounting structure for a motorcycle includes a vehicle body frame. The vehicle body frame includes: main frames extending downwardly toward rear from a head pipe, the main frames for suspending a power unit; and pivot frames extending downward from rear ends of the main frames to be disposed at left and right in a vehicle width direction. An electrical component including a first ECU is supported in this electrical component mounting structure. In this electrical component mounting structure, the power unit includes a crankcase and a cylinder portion that protrudes from the crankcase, and the first ECU is disposed, in a side view, anterior to the left and right pivot frames, posterior to the cylinder portion, and above the crankcase.

Owner:HONDA MOTOR CO LTD

Work vehicle

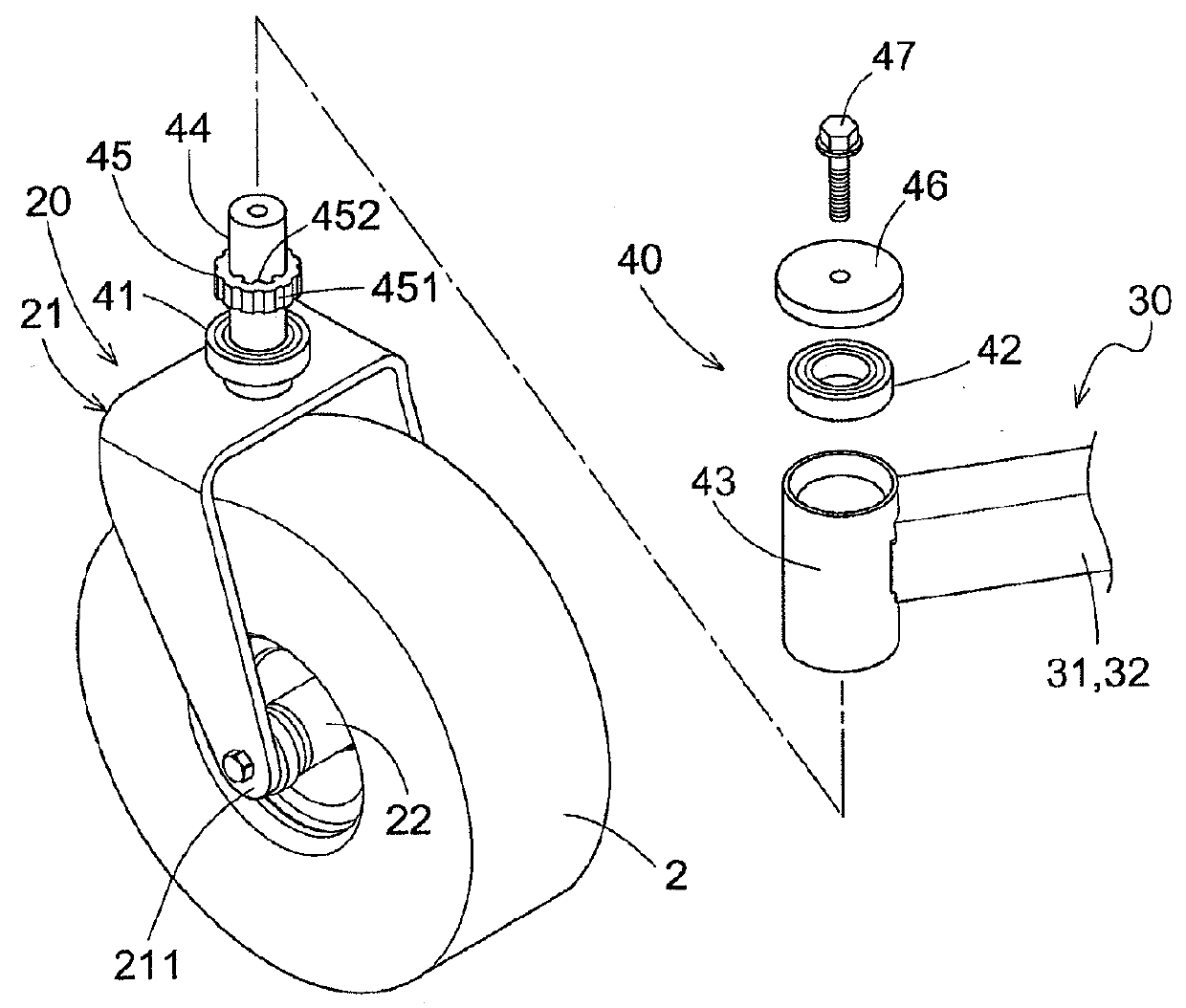

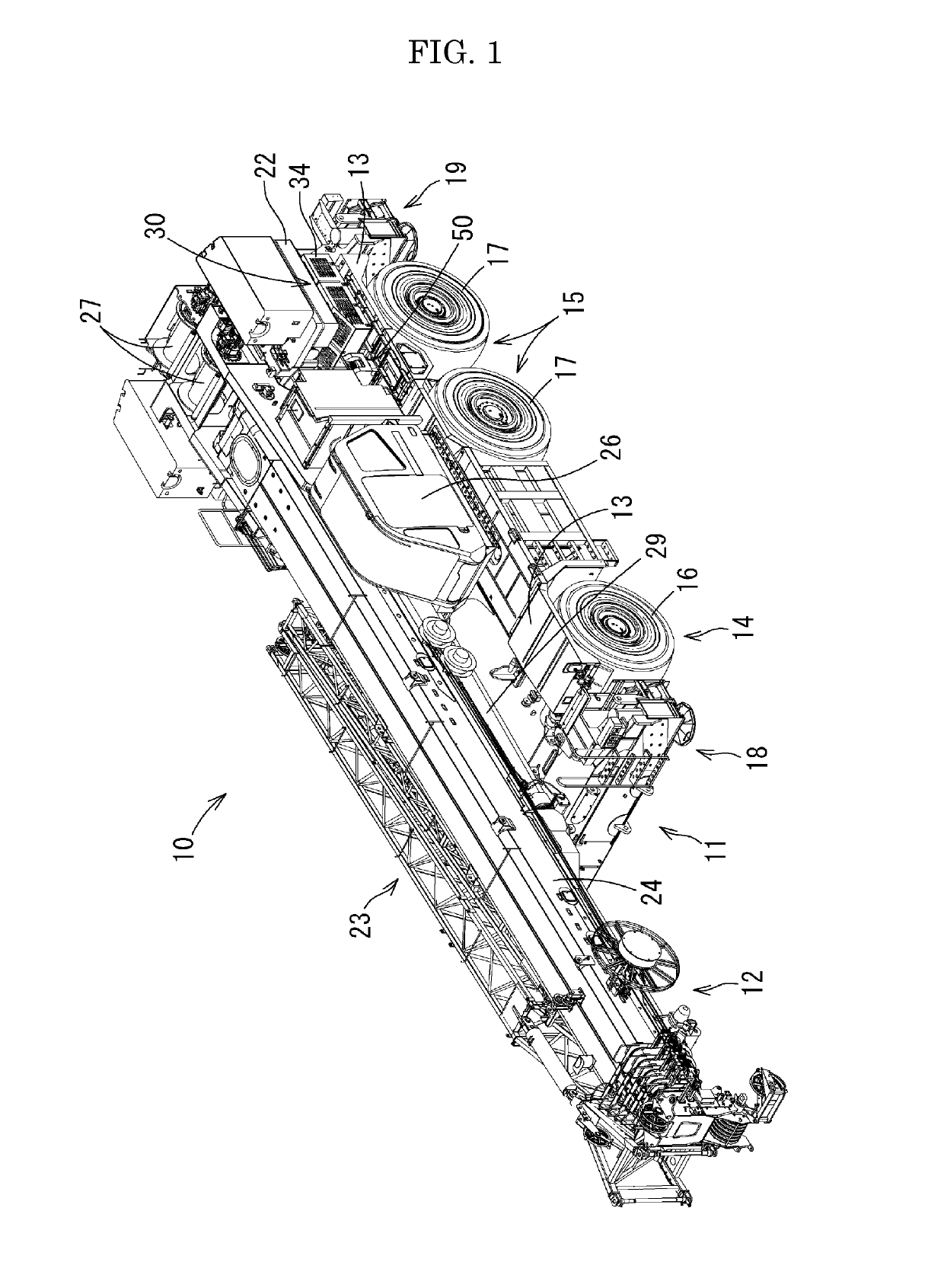

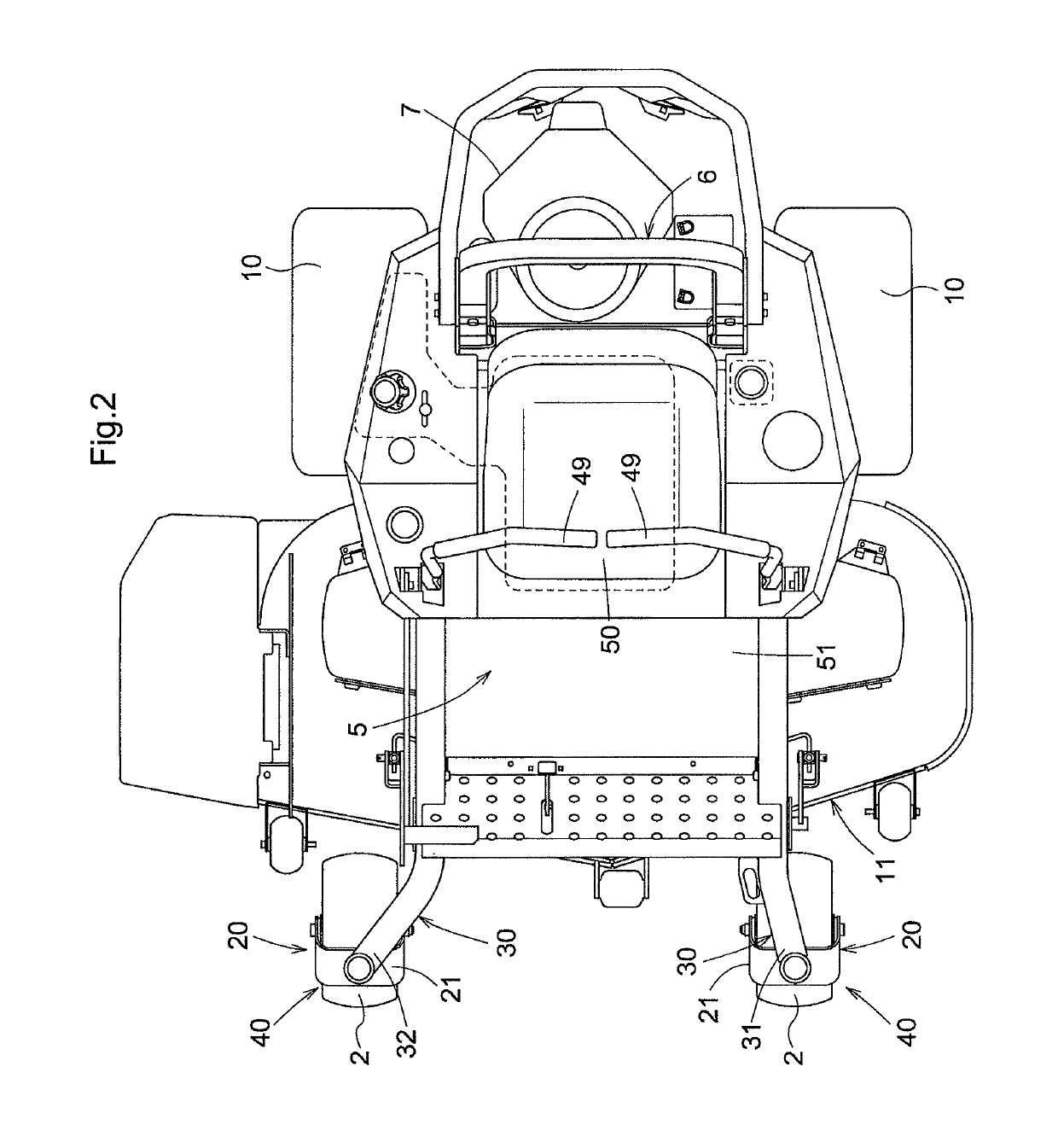

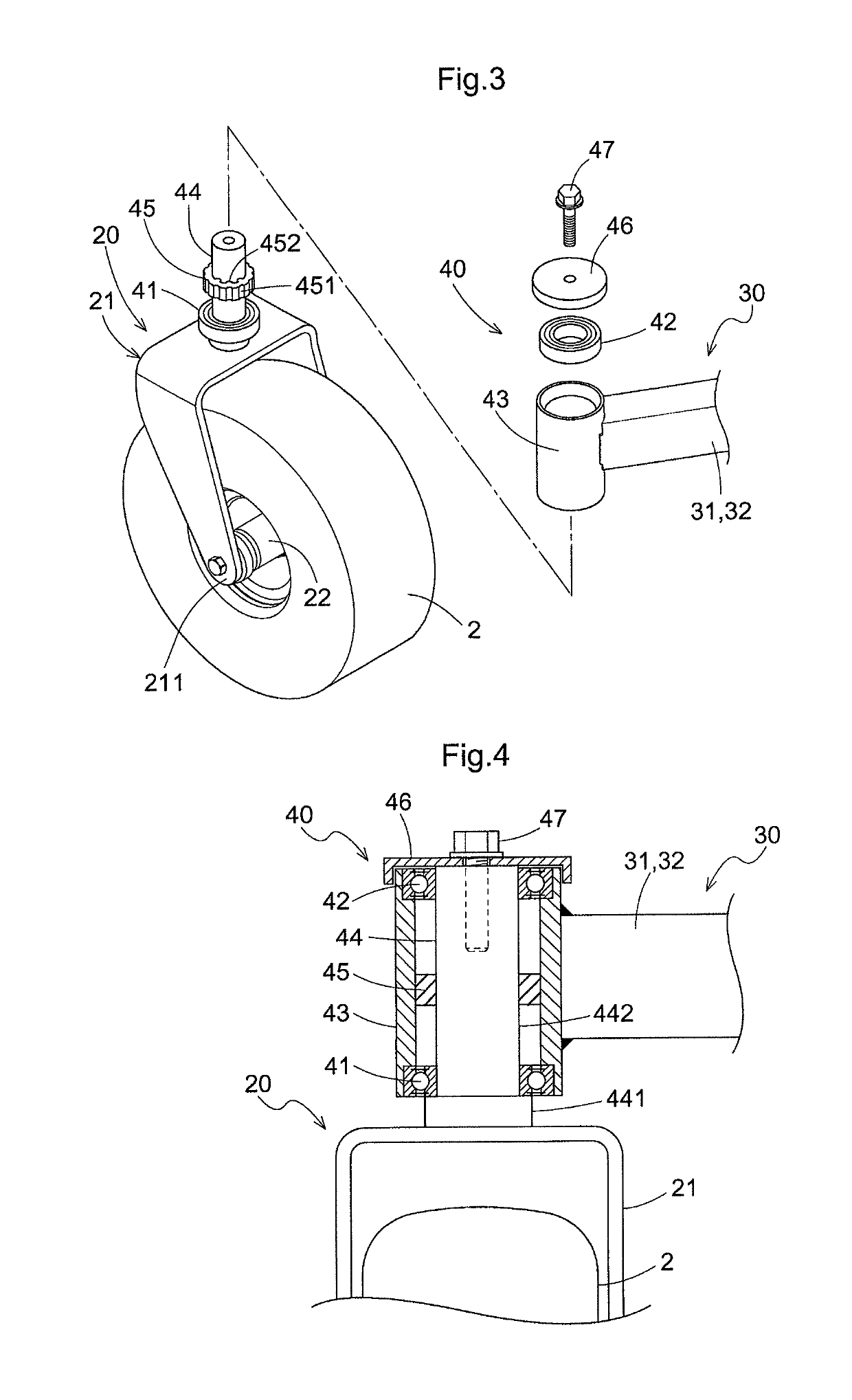

ActiveUS20180104987A1Improved turning performanceReduce chanceMowersSteering linkagesVehicle frameEngineering

A work vehicle includes a vehicle frame, a rotating connection unit provided in the vehicle frame, and a caster assembly connected to the rotating connection unit. The rotating connection unit includes a housing sleeve, a swivel post, a first bearing and a second bearing supporting the swivel post to be rotatable within the housing sleeve, and a rotation stopper disposed between the swivel post and the housing sleeve to stop rotation of the swivel post. The caster assembly includes a caster wheel, and a caster bracket connected to the swivel post to rotatably support the caster wheel.

Owner:KUBOTA LTD

High-performance soft magnetic stainless steel and preparation method thereof

PendingCN114606440AExcellent soft magnetic propertiesImprove corrosion resistanceMagnetic materialsMetal rolling arrangementsElectric furnacesCorrosion

The invention belongs to the field of stainless steel, and particularly relates to high-performance soft magnetic stainless steel and a manufacturing method thereof. The soft magnetic stainless steel comprises the following components in percentage by weight: less than or equal to 0.02% of C, 1.5-2.5% of Si, less than or equal to 0.8% of Mn, less than or equal to 0.03% of P, more than or equal to 0.15-0.35% of S, less than or equal to 0.4% of Ni, 13.0-15.0% of Cr, less than or equal to 0.02% of N, 0.2-0.8% of Mo, 0.15-0.30% of Nb, 0.005-0.012% of Re and the balance of iron and inevitable impurities. The preparation method comprises the steps that waste stainless steel is sequentially subjected to electric furnace smelting, AOD refining, LF refining, continuous casting, rolling and annealing, and the stainless steel is obtained. The stainless steel manufactured through the method is excellent in soft magnetic performance, high in saturation flux density and low in coercive force and residual magnetic flux density; meanwhile, stainless steel is good in corrosion resistance, and can work under various severe conditions; the stainless steel manufactured by the invention also has good machinability and good plasticity, and is beneficial to drawing and turning of downstream customers. In addition, the yield of the product prepared through the preparation method reaches 96% or above.

Owner:浙江青山钢铁有限公司 +1

Rough terrain crane

ActiveUS10273123B2Function increaseImproved turning performanceInternal combustion piston enginesExhaust apparatusTerrainLandform

An SCR-quipped rough terrain crane in which a urea water tank is laid out at the optimal position is provided. A rough terrain crane is equipped with an exhaust emission control device that is laterally adjacent to a diesel engine. The exhaust emission control device is provided with a urea water tank and is laid out in a rear portion of at a vehicle body. The urea water tank is disposed on a front side of the exhaust emission control device. The urea water tank is disposed in the vicinity of the left side of the diesel engine when viewed from the rear side of the vehicle.

Owner:TADANO LTD

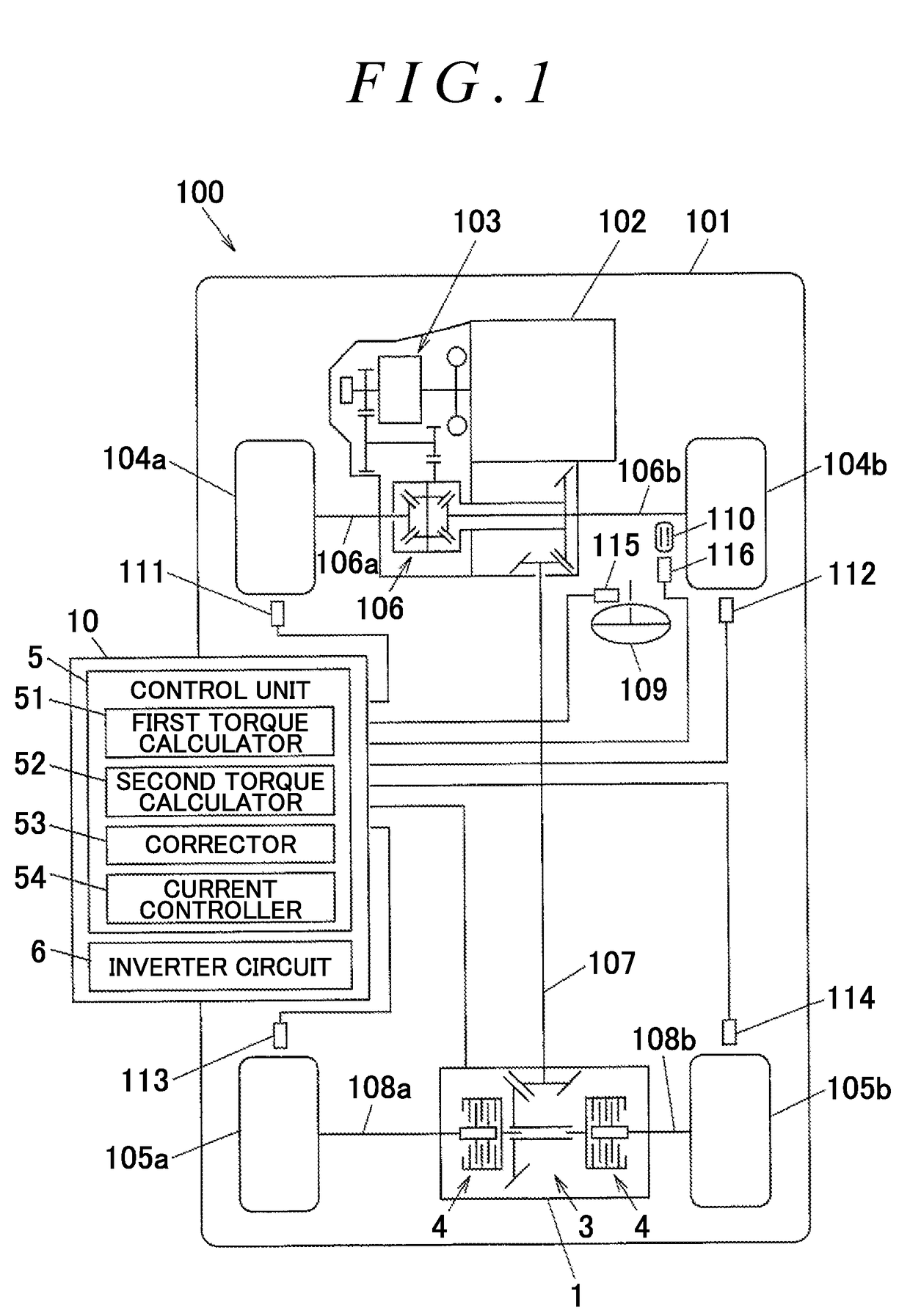

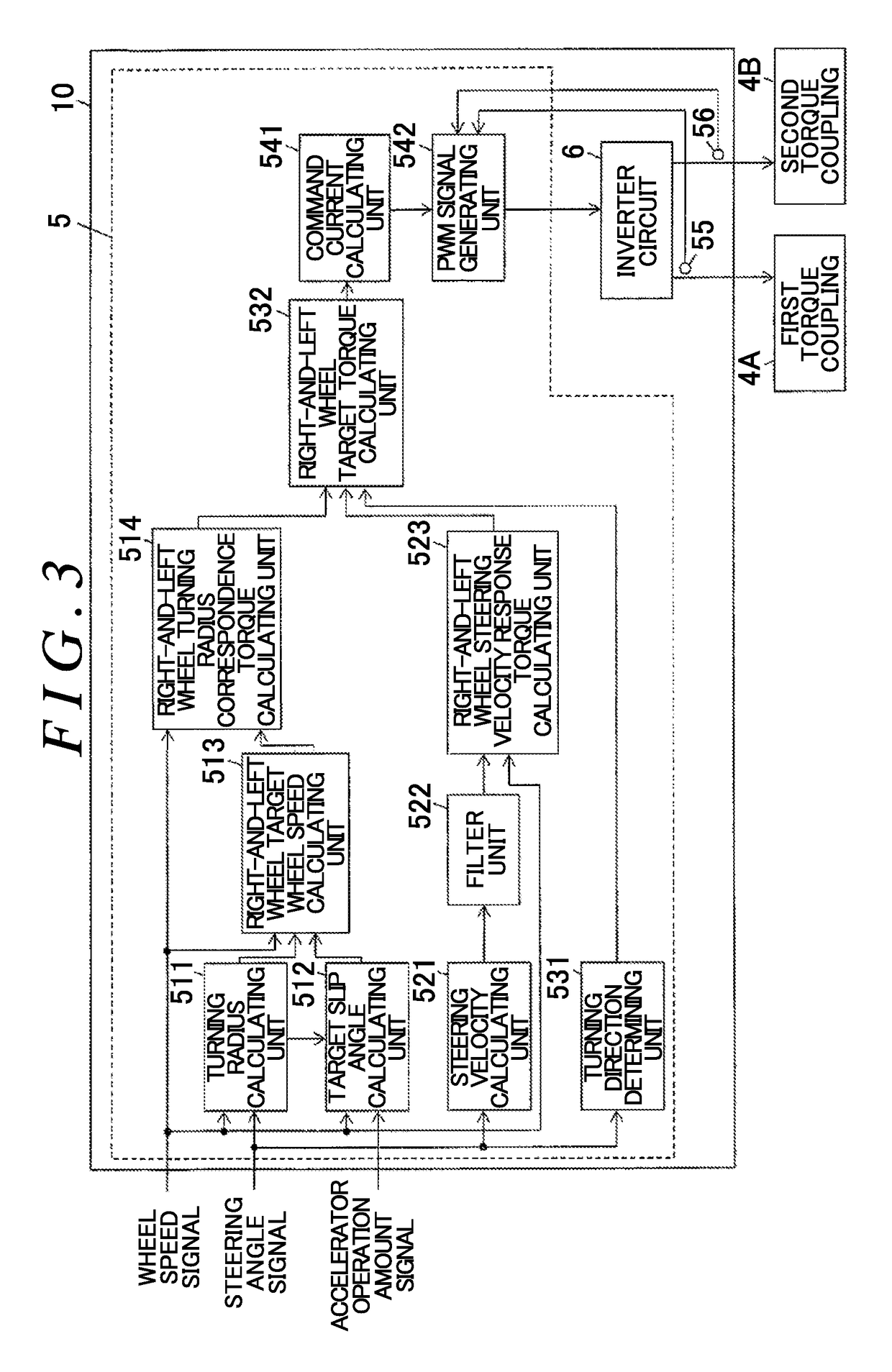

Driving force control apparatus and method for controlling vehicle

ActiveUS20190061523A1Improved turning performanceImprove performanceDifferential gearingsDriver input parametersPower flowSteering wheel

A driving force control apparatus includes a first torque calculator configured to calculate turning radius correspondence torques indicating the magnitudes of the driving forces to be transmitted to a right rear wheel and a left rear wheel based on a turning radius, a second torque calculator configured to calculate steering velocity response torques based on a steering velocity of a steering wheel and a vehicle speed, a corrector configured to calculate a corrected torque by correcting a turning radius correspondence torque of at least one of wheels on an inner side of turning and on an outer side of turning in accordance with the steering velocity response torque, and a current controller configured to supply currents to torque couplings so that driving forces based on the corrected torque are transmitted.

Owner:JTEKT CORP

Automatic steering with selective engagement of four-wheel steering

ActiveUS10625770B2Improved turning performanceSteering linkagesGuiding agricultural machinesAutomatic steeringSteering wheel

Automatic steering and four-wheel steering are configured on an agricultural machine so that when automatic steering is enabled, a control system selectively activates and deactivates four-wheel steering depending on sensed turning or non-turning states of the machine. When automatic steering is enabled, the machine can automatically steer, such as according to a prescription map. In straightaway paths, corresponding to non-turning states, the control system can activate two-wheel steering. However, in the headlands of fields, corresponding to turning states, the control system can activate four-wheel steering. Such turning states can be determined based on the machines location on the map. Alternatively, such turning states can be determined based on sensed turning of the wheels. When an operator takes control of steering, such as by turning the steering wheel, automatic steering can disable, and the control system can activate four-wheel steering, to provide an optimum state for turning in the headlands of fields.

Owner:BLUE LEAF I P INC

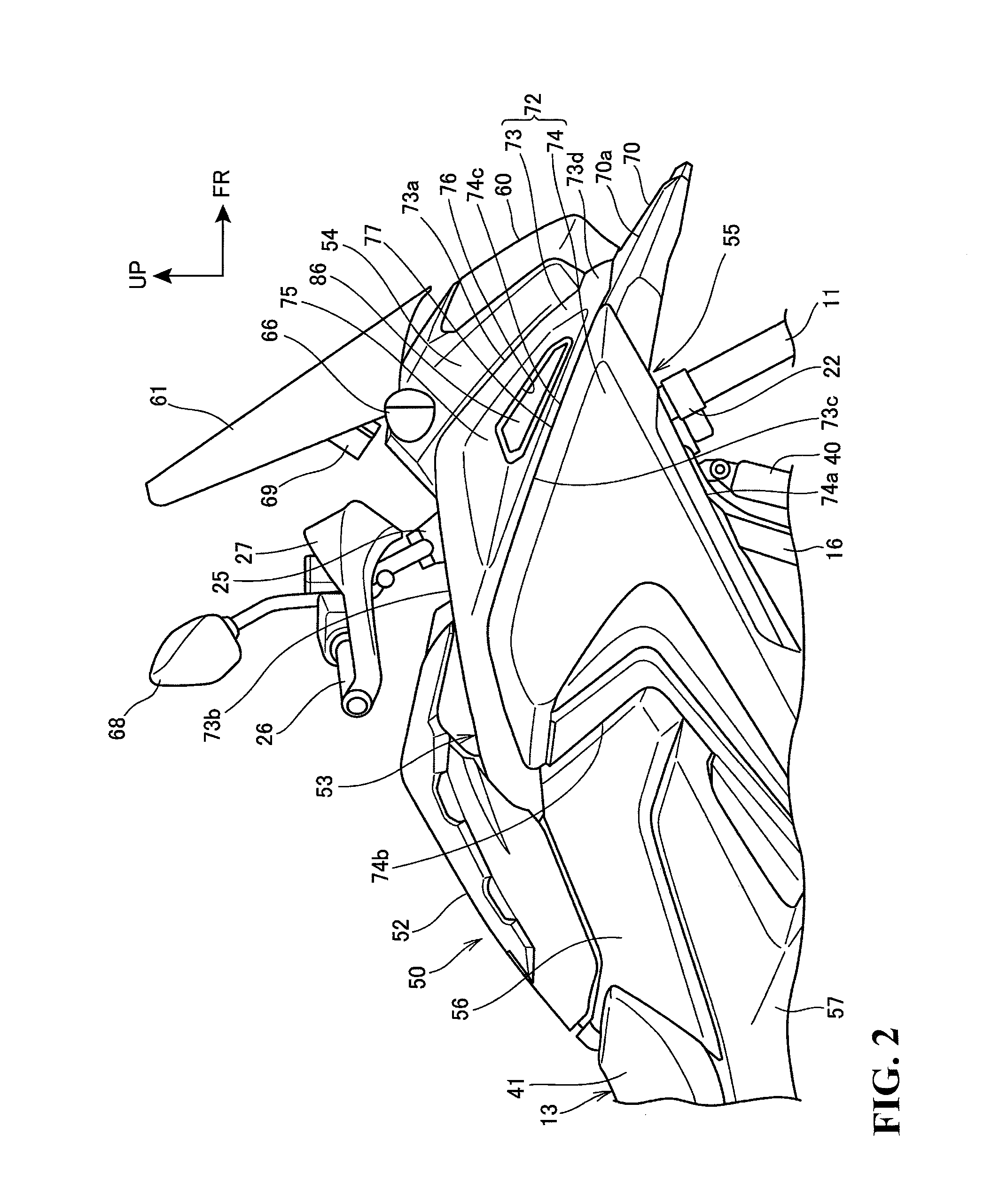

Side cover structure of saddle-ride-type vehicle

ActiveUS20160214672A1Good lookingImprove external appearanceWeather guardsMechanical engineeringEngineering

A side cover structure for enhancing the external appearance and turning performance of a saddle-ride-type vehicle. A side cover structure of a saddle-ride-type vehicle includes a head pipe with a frame extending rearwardly from the head pipe. Side covers cover the frame from left and right sides. A bent portion is bent toward the outside in a vehicle width direction from a base portion and is formed on the side cover. An opening is formed in the base plate portion positioned in the vicinity of the bent portion.

Owner:HONDA MOTOR CO LTD

Work vehicle

Owner:KUBOTA CORP

Automatic tilting vehicle

ActiveUS10639953B2Reduce energy consumptionReduce impactCyclesSteering linkagesGyroscopic momentControl cell

An automatic tilting vehicle is provided that includes left and right front wheels supported by knuckles, a steerable rear wheel, a vehicle tilting device, and a control unit. The vehicle tilting device includes a swing member, a tilt actuator for swing the swing member, and a pair of tie rods pivotally attached to the swing member and the knuckles. The control unit calculates a target lateral acceleration of the vehicle, estimates a lateral acceleration of the vehicle caused by the gyro moments of the wheels and calculates a target tilt angle of the vehicle based on a sum of the target lateral acceleration and the lateral acceleration caused by the gyro moments.

Owner:TOYOTA JIDOSHA KK

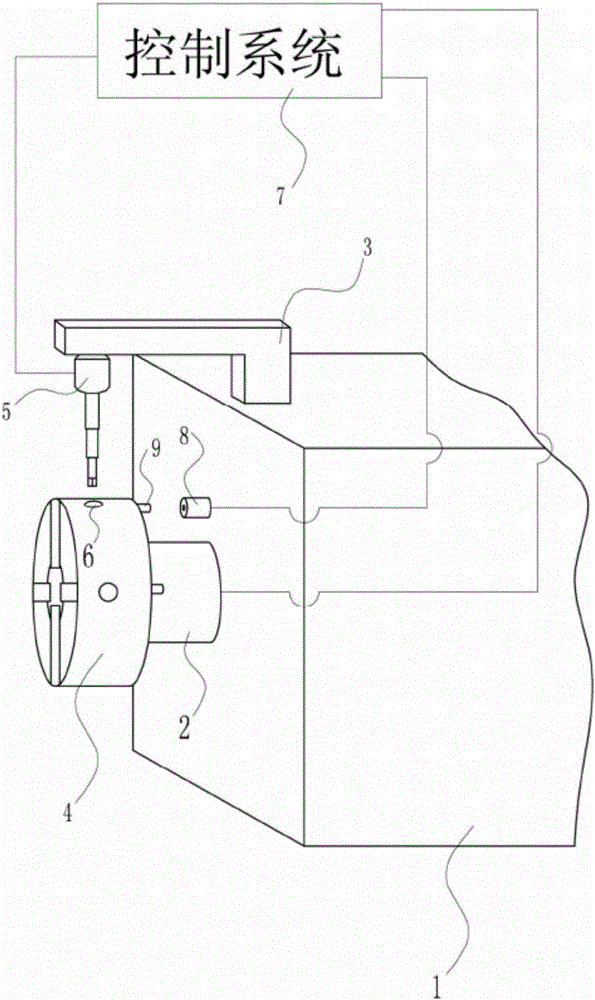

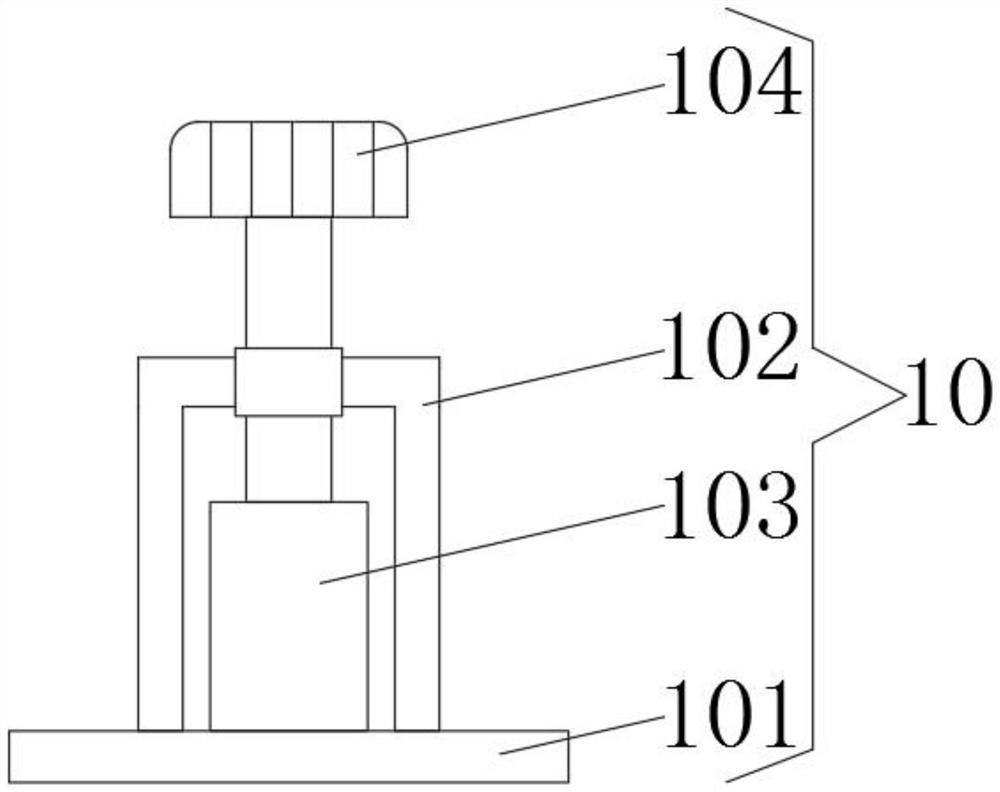

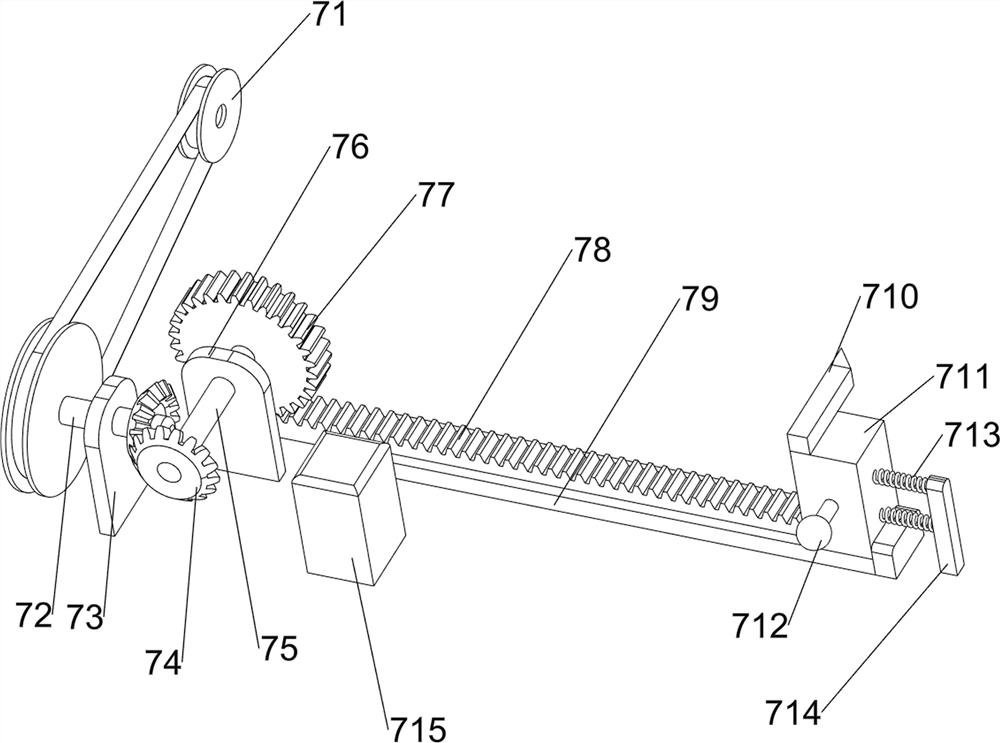

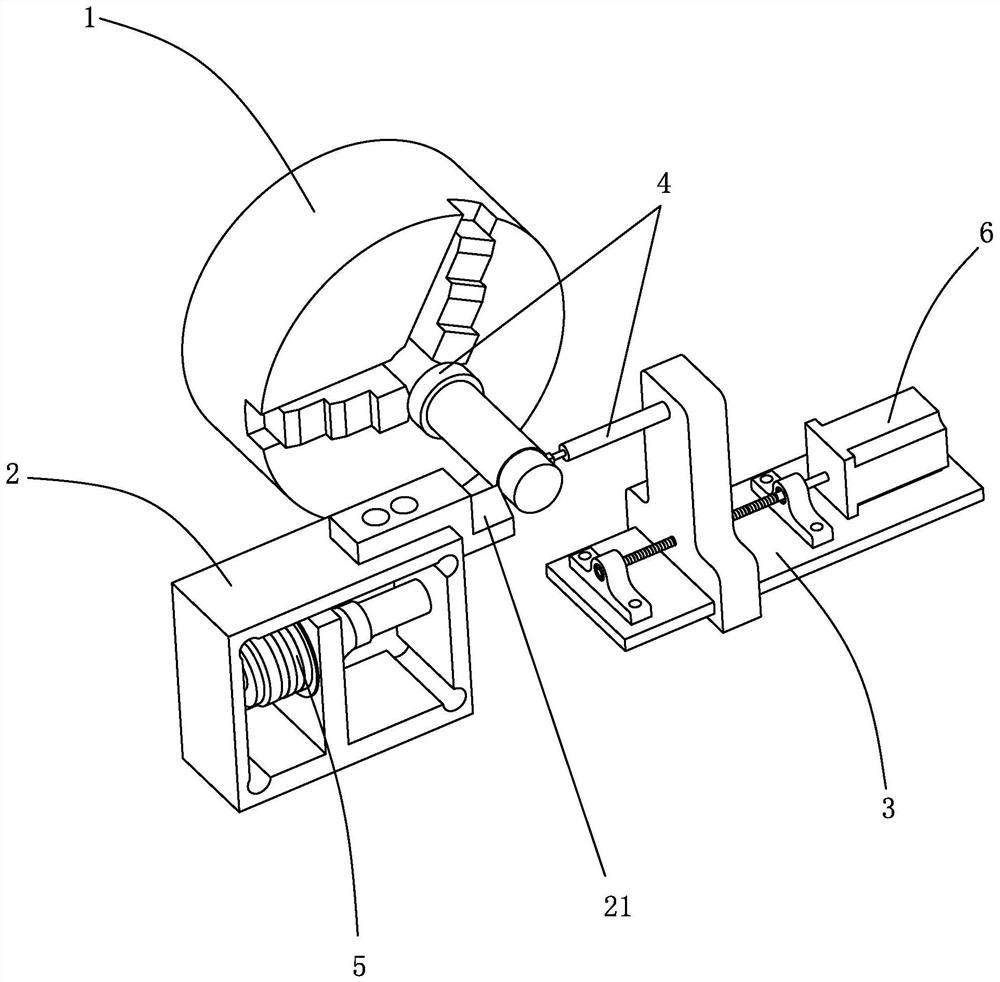

Uniformly-stressing tightening device

InactiveCN106493600ASame tightnessImproved turning performanceMetal working apparatusControl systemEngineering

The invention discloses a uniformly-stressing tightening device. The tightening device comprises a lathe headstock, a rotating shaft, a cross beam, a chuck, a tightening device body, winch inserting holes and a control system. The rotating shaft is arranged at the front part of the lathe headstock. The cross beam is arranged above the lathe headstock. The chuck is mounted on the rotating shaft. The tightening device body is arranged below the front end of the cross beam. The four wrench inserting holes are uniformly formed in the outer wall of the chuck in a spaced manner. The rotating shaft and the tightening device body are separately connected with the control system. The tightening device body comprises an electric wrench, a lifting motor, a lifting rod, a groove and a straight hexagon wrench. One end of the electric wrench is connected to the cross beam. Through adoption of the tightening device, the degrees of tightness of clamping jaws in fixing can be the same, the turning effect is good, time and labor are saved, and the working efficiency is improved.

Owner:新昌县儒岙镇衡翔机械厂

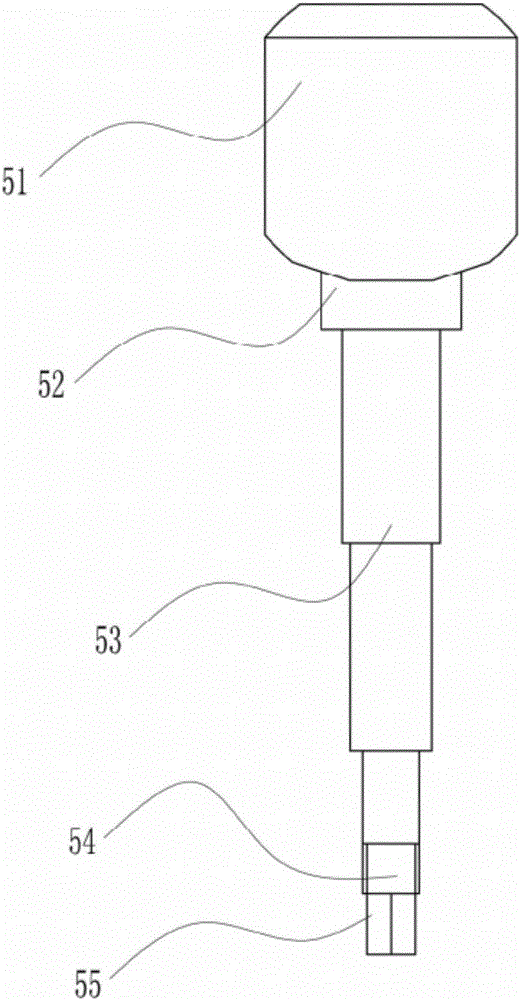

Clamping device for turning guide vane of gas turbine

InactiveCN111791073AEasy to clamp and fixPromote absorptionPositioning apparatusMaintainance and safety accessoriesGas turbinesPhysics

The invention discloses a clamping device for turning a guide vane of a gas turbine. The clamping device comprises a bottom frame, wherein an electric motor is fixedly connected to the bottom of the inner surface of the bottom frame, an output shaft of the electric motor is fixedly connected to a rotating rod, the top end of the rotating rod is fixedly connected to a rotating table, a clamping mechanism is arranged on the top of the rotating table, and an absorption mechanism is arranged one on side of the rotating table on the top of the outer surface of the bottom frame. By means of the clamping mechanism, the absorption mechanism and a decelerating rod, guide vanes of different sizes and thicknesses can be clamped and fixed well by the clamping mechanism, so that it is convenient for follow-up turning. Metal scrap generated in the turning process can be absorbed well by the absorption mechanism and is prevented from polluting the surrounding environment, so that the using effect isimproved. The electric motor drives the rotating table to rotate more precisely by means of the decelerating rod, so that a better turning effect can be exerted, and the clamping device has a certainpositive effect.

Owner:JIANGSU MARITIME INST

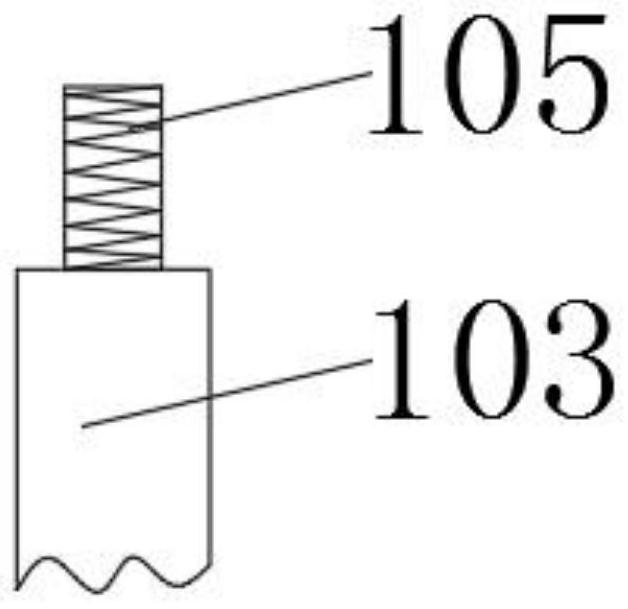

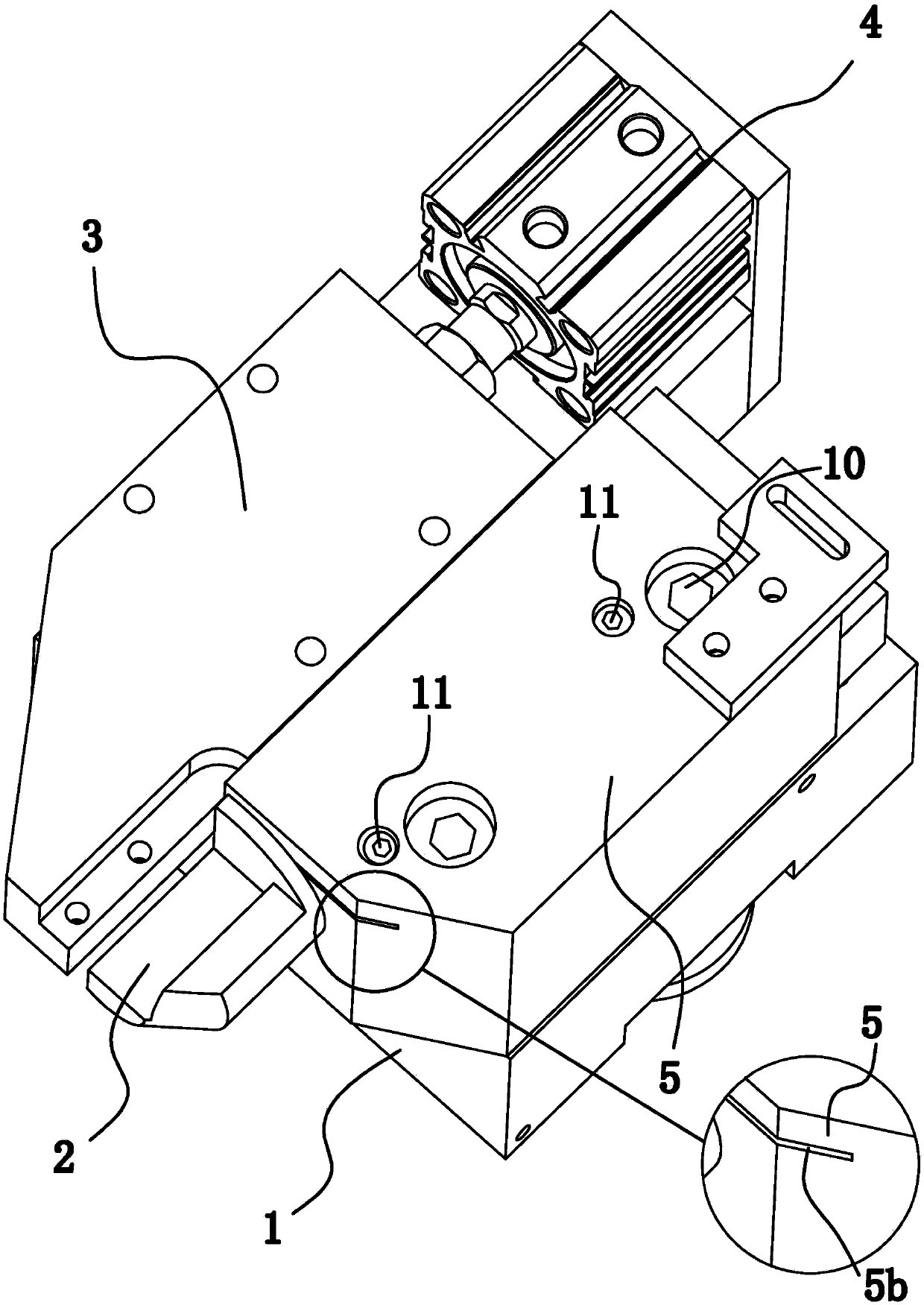

Tool rest structure for machine tools

PendingCN107812965AImproved turning performanceExtended service lifeLarge fixed membersLeft directionEngineering

The invention provides a tool rest structure for machine tools and belongs to the technical field of machinery. The structure solves the problem that the conventional tool rests cannot be adjusted. The tool rest structure for the machine tools comprises a base and a finishing tool rest, a roughing tool rest and a driving part which are all arranged on the base, wherein the driving part is capableof driving the roughing tool rest to move forward and backward relative to the base; an elastic adjusting block is also fixed on the base; the finishing tool rest is shaped like a long strip and extends along the forward and backward directions of the base; the front end of the finishing tool rest is used for mounting a finishing tool; the rear end of the finishing tool rest is shaped like a semicylinder; a half-round hole is formed in the adjusting block along the forward and backward directions of the base in a penetrating manner; the rear end of the finishing tool rest is inserted in the half-round hole; a long strip-shaped crushing groove is arranged in the wall of the half-round hole along the left and right directions of the base; the crushing groove length extends along the forwardand backward directions of the base; both ends of the crushing groove are open; and a detachable positioning mechanism which enables the upper side wall of crushing groove to downwards generate elastic deformation and the wall of the half-round hole to tightly press on the side wall of the rear end of the finishing tool rest is arranged in the crushing groove. The tool rest structure provided bythe invention has the advantage that positions of finishing tools and roughing tools can be adjusted.

Owner:TAIZHOU EASTERN CNC EQUIP CO LTD

Rough terrain crane

ActiveUS20180273351A1Increase temperaturePrevent degradationInternal combustion piston enginesExhaust apparatusTerrainLandform

An SCR-quipped rough terrain crane in which a urea water tank is laid out at the optimal position is provided. A rough terrain crane is equipped with an exhaust emission control device that is laterally adjacent to a diesel engine. The exhaust emission control device is provided with a urea water tank and is laid out in a rear portion of at a vehicle body. The urea water tank is disposed on a front side of the exhaust emission control device. The urea water tank is disposed in the vicinity of the left side of the diesel engine when viewed from the rear side of the vehicle.

Owner:TADANO LTD

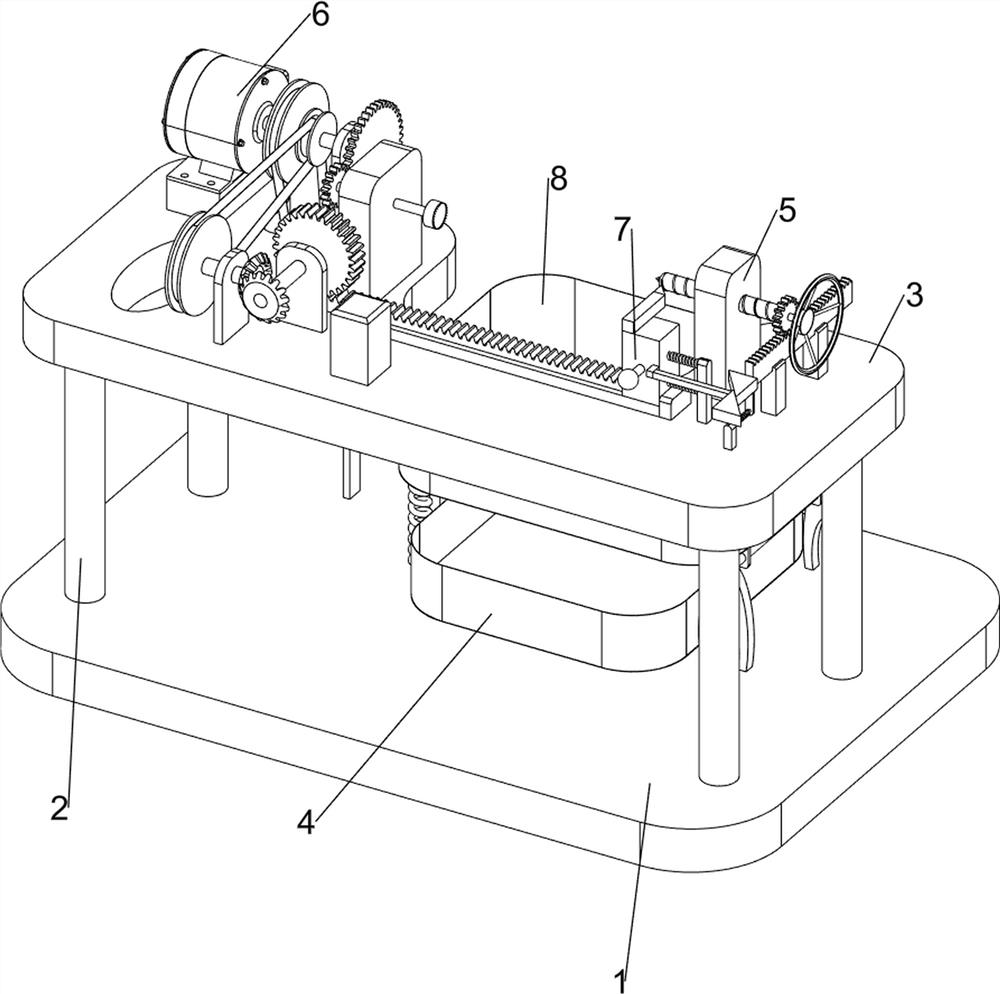

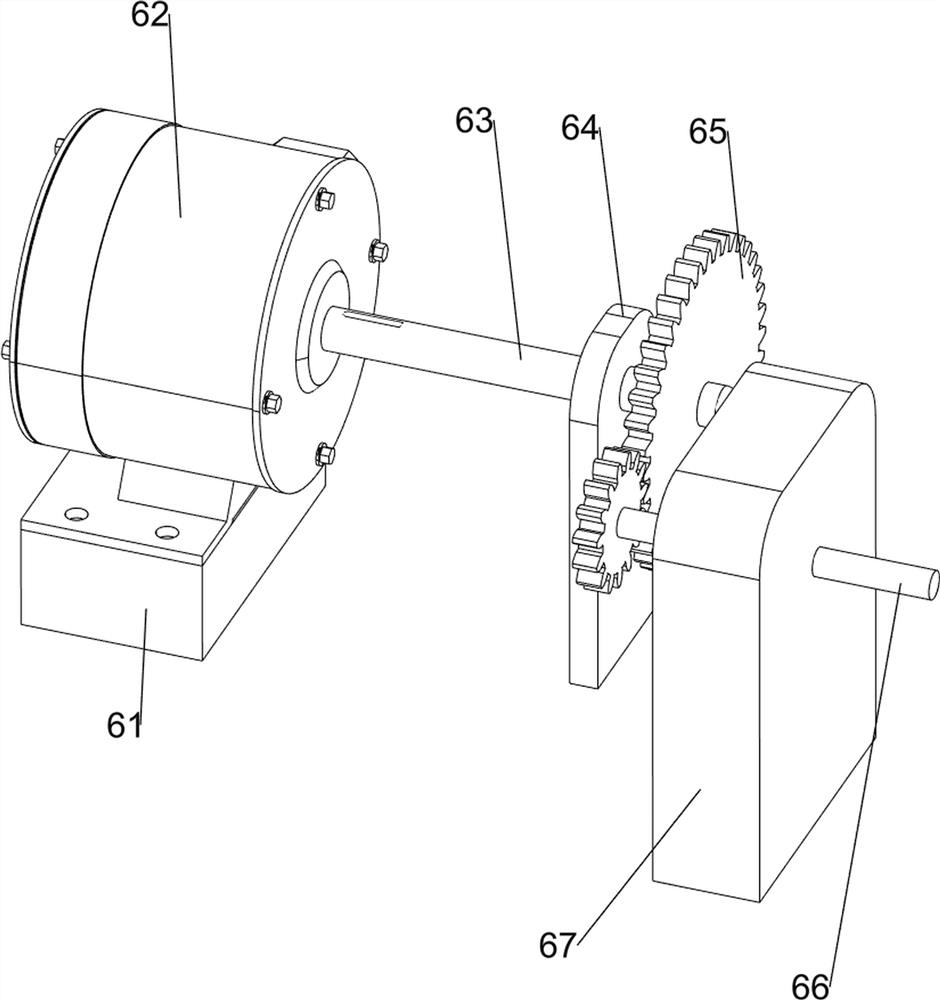

Turning type rolling pin manufacturing device

ActiveCN112757410AHigh speed rotationImprove work efficiencyWood-turning machinesWorkbenchIndustrial engineering

The invention relates to a manufacturing device, in particular to a turning type rolling pin manufacturing device. According to the turning type rolling pin manufacturing device provided by the invention, high-speed rotation of logs can be realized, the logs can be automatically and uniformly scraped, and scraped chippings can be stored in time. The turning type rolling pin manufacturing device comprises four supporting columns, a workbench, a collecting frame and a rotating mechanism; the supporting columns are arranged on a base; the workbench is arranged at the upper parts of the supporting columns; the collecting frame used for collecting chippings is placed on the base; and the rotating mechanism is arranged on the workbench. According to the turning type rolling pin manufacturing device, through cooperation of a clamping mechanism, the rotating mechanism and a turning mechanism, the effects of high-speed rotation and automatic and uniform log scraping are achieved; and through cooperation of a filtering mechanism and a discharging mechanism, automatic discharging is achieved, and meanwhile the scraped chippings are filtered and stored in time.

Owner:泰安泰悦食坊食品有限公司

A method for improving the turning workability of high-strength titanium alloy ingots

The invention provides a method for improving the turning machinability of a high-strength titanium alloy ingot. The method comprises the following steps: putting the high-strength titanium alloy ingot into a heat treatment furnace for high-temperature heat treatment; then, taking the high-strength titanium alloy ingot subjected to the high-temperature heat treatment out of the heat treatment furnace; carrying out rapid water cooling to 25-150 DEG C; and finally, subjecting the cooled high-strength titanium alloy ingot to turning machining by utilizing a lathe, wherein a tungsten-cobalt hard alloy is adopted as a turning machining tool during the turning machining process. According to the method provided by the invention, a high-temperature heat treatment and rapid cooling combined method is adopted, so that a single-phase alloy structure can be achieved, secondary precipitation phase strengthening can be avoided; and the strength of a material at a certain depth of the ingot surface can be reduced. Accordingly, the difficulty in turning machining of the ingot surface can be greatly reduced and the number of times that the turning machining tool is replaced can be reduced. Meanwhile, the machining efficiency can be improved and the production cycle can be shortened.

Owner:西安赛特思迈钛业有限公司

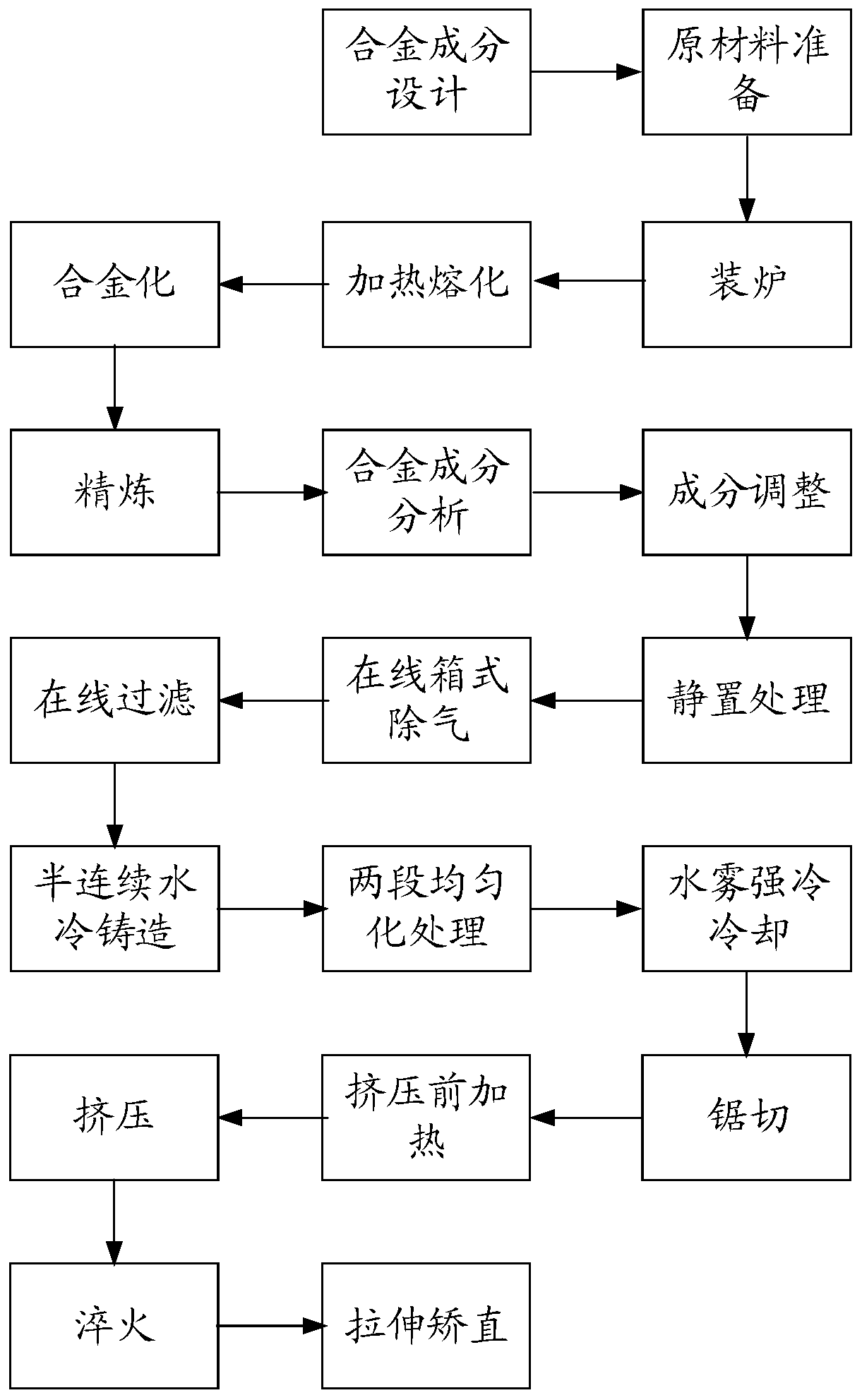

Aluminum alloy extruded bar and its preparation process

The invention relates to an aluminum alloy extruded bar and a preparation technology thereof. The aluminum alloy extruded bar comprises, by mass, 0.4-0.5% of Si, 0.5-0.6% of Fe, 0.15-0.20% of Cu, 1.0-1.2% of Mn, no more than 0.10% of Ti, less than 0.15% of other impurities, and the balance Al. The preparation technology comprises the following steps of smelting, alloying, refining, semi continuouswater-cooling casting, two-stage homogenizing treatment, water mist strong cooling, sawing, three-stage heating, quenching, stretching straightening and the like. The aluminum alloy extruded bar hasgood strength and machining performance and stable alloy fiber crystal crystallization.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

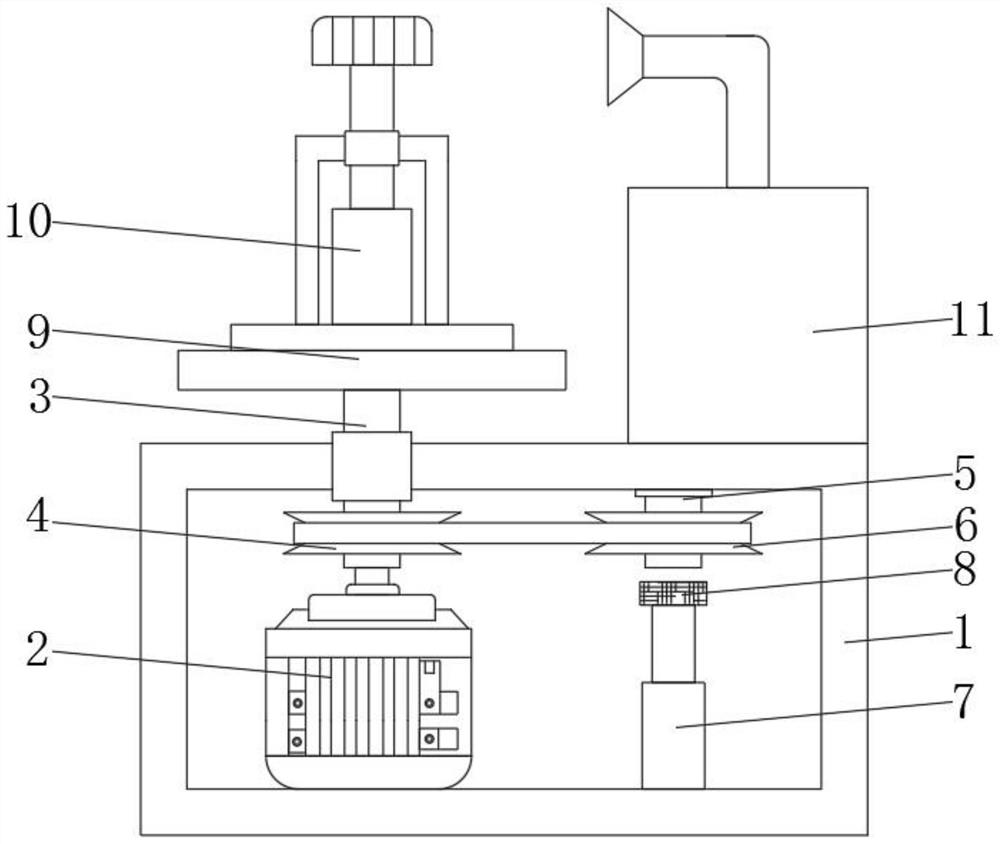

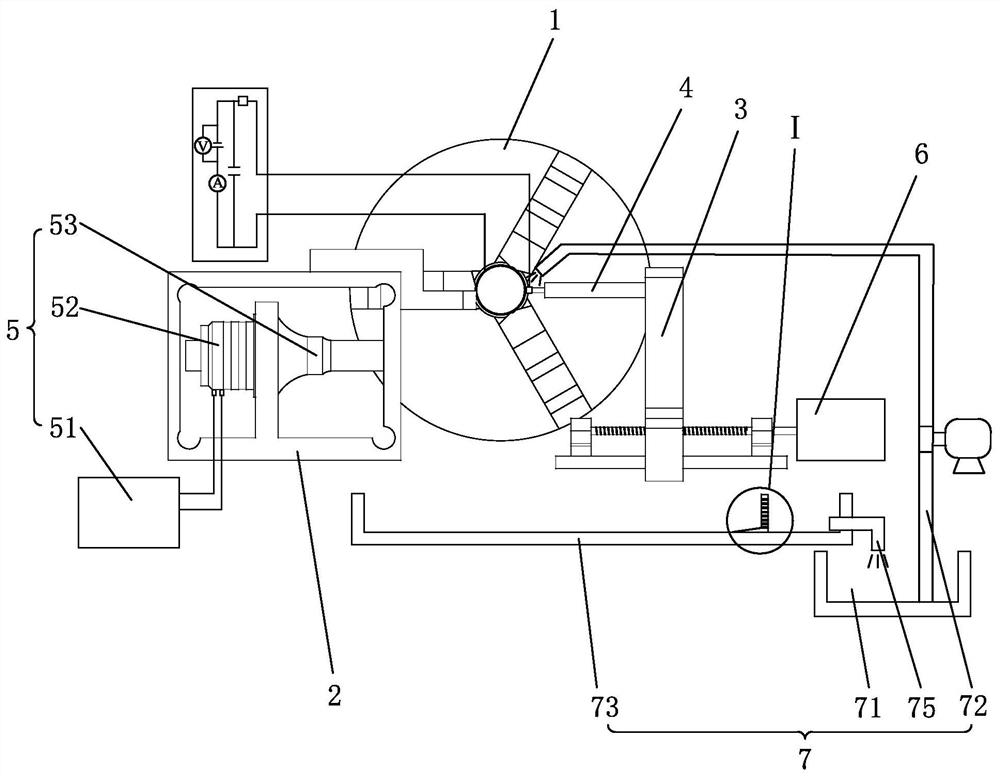

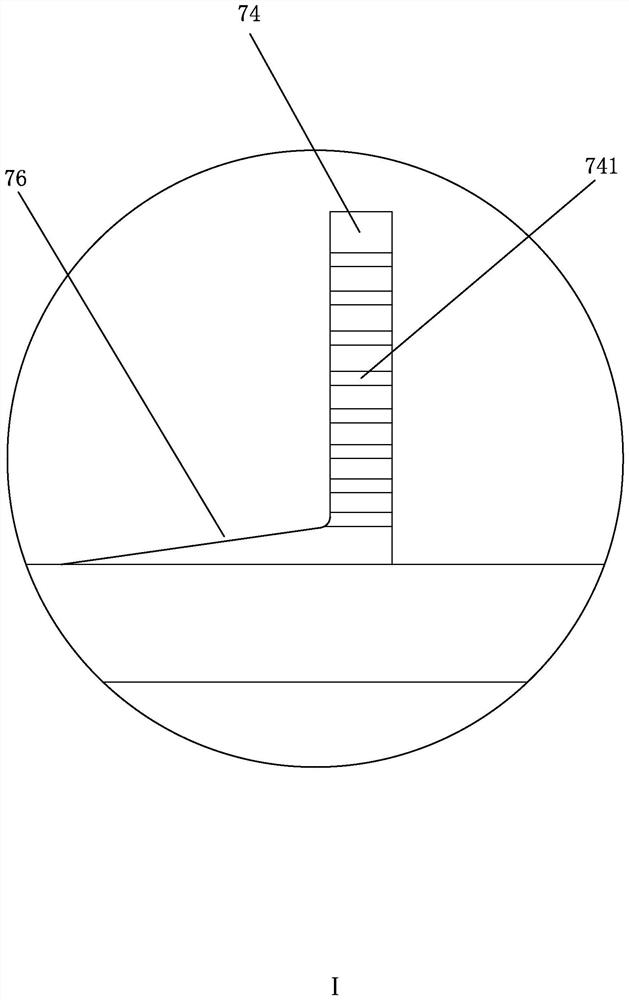

Electric spark assisted ultrasonic vibration turning combined machining equipment and method

PendingCN112809031AReduce the difficulty of turningReduce lossAuxillary equipmentElectrical-based machining electrodesEngineeringUltrasonic vibration

The invention discloses electric spark assisted ultrasonic vibration turning combined machining equipment. The electric spark assisted ultrasonic vibration turning combined machining equipment comprises a machine tool, a chuck arranged on the machine tool, a movable turning device which is arranged on one side of the upper portion of the machine tool and provided with a tool, an installation support which is arranged on the other side of the upper portion of the machine tool and connected with the movable turning device, a discharge heating device arranged on the installation support, and an ultrasonic generation device arranged on the movable turning device. The invention further discloses an electric spark assisted ultrasonic vibration turning combined machining method. According to the electric spark assisted ultrasonic vibration turning combined machining equipment and method, a workpiece can be turned while being discharged and heated, and therefore the workpiece can be heated and softened, the turning difficulty of turning the workpiece through a turning tool is lowered, the loss of the tool can be reduced so that the service life of the tool can be prolonged, the machining efficiency can be improved, and the efficient and precise turning effect can be achieved; and meanwhile, the tool can do high-frequency periodic vibration motion through the ultrasonic generation device, and therefore the prominent effects that the tool breaks chips, the cutting heating phenomenon is reduced, and the cutting force is reduced are achieved.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com