Tool rest structure for machine tools

A tool holder and machine tool technology, applied in the mechanical field, can solve the problems of difficult to guarantee the machining accuracy of the workpiece, the tool does not have the precise adjustment function, and the tool service life is reduced, and the effect of optimizing the tool turning performance, simple structure and improving the service life is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

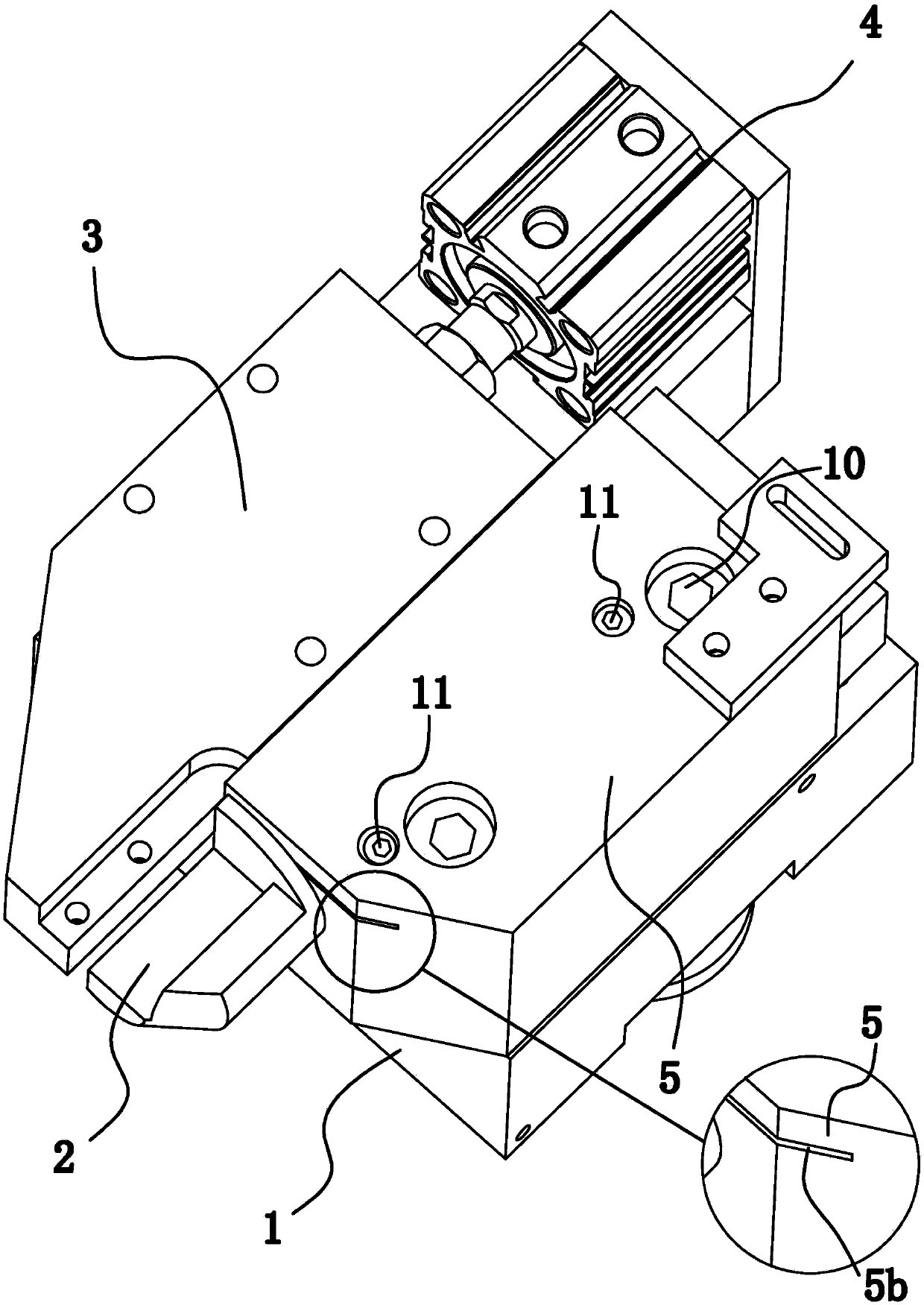

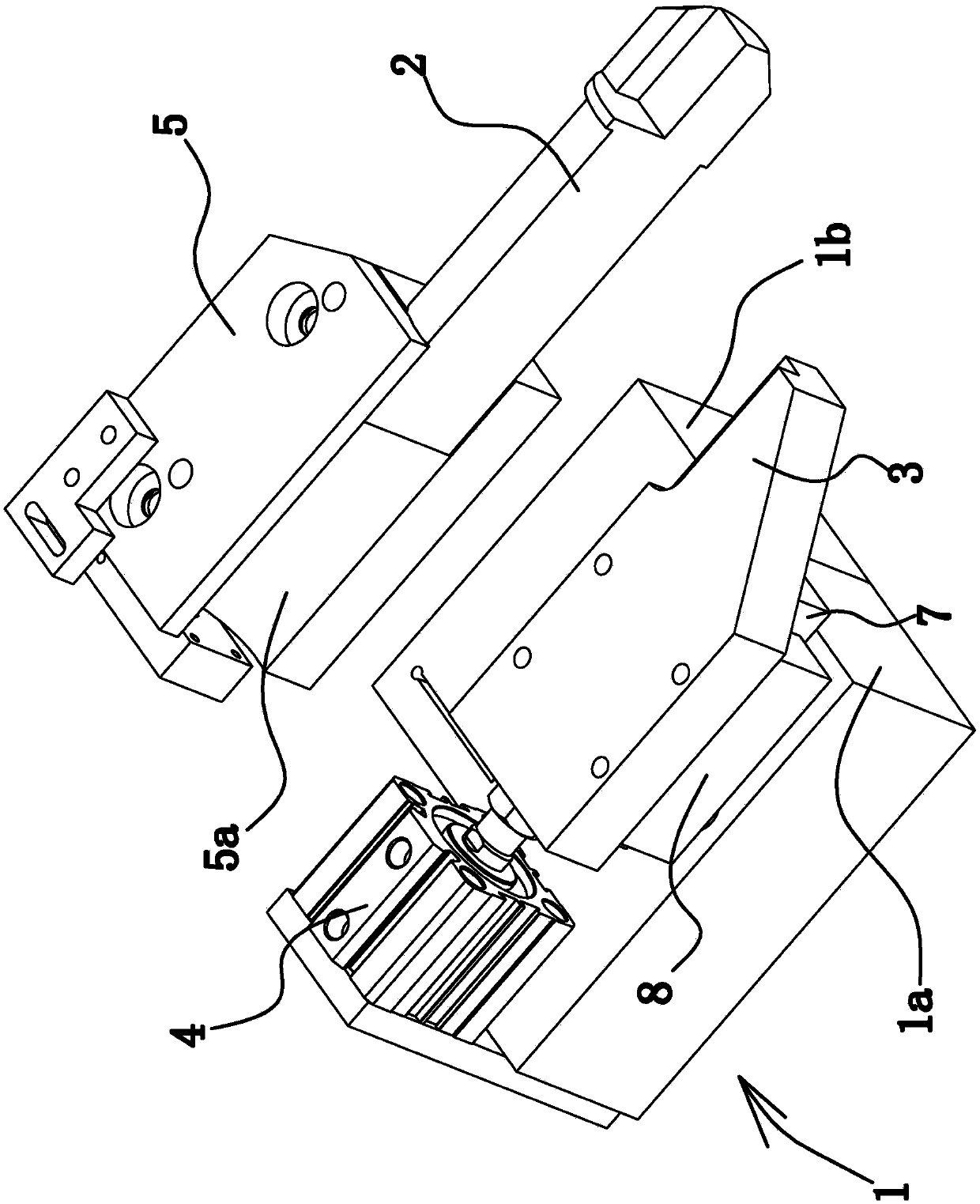

[0021] Such as Figure 1 to Figure 4 As shown, the structure of the tool holder for this machine tool is composed of a base 1, a fine tool holder 2, a rough tool holder 3, a driving part 4, an adjustment block 5, and the like. Wherein, the adjusting block 5 has elasticity, and its material can be spring steel or aluminum alloy.

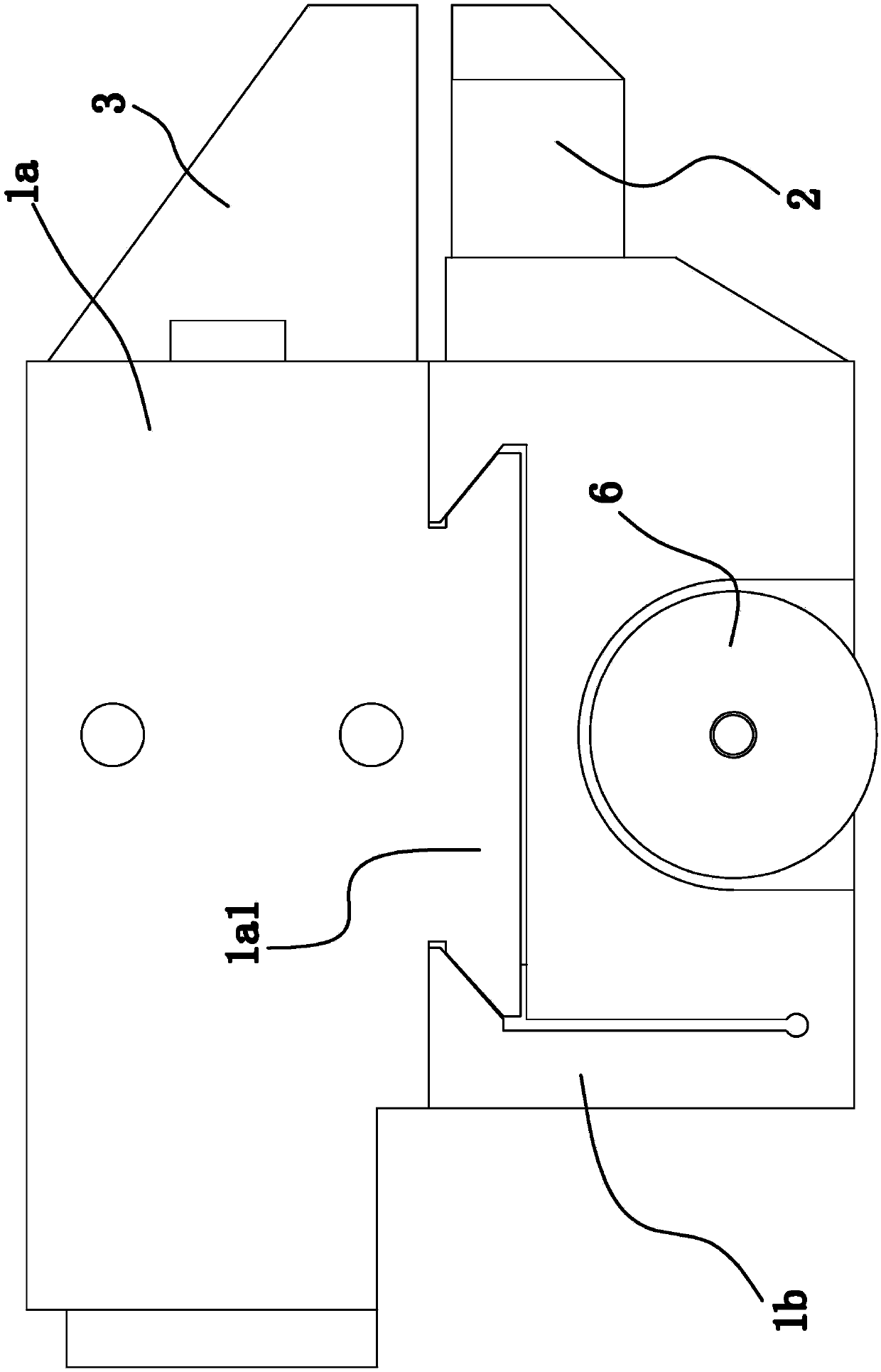

[0022] Specifically, as figure 2 with image 3 As shown, the base 1 includes a left base 1a and a right base 1b arranged side by side, wherein the right base 1b is provided with a dovetail groove along the vertical direction, and the left base 1a is correspondingly provided with a dovetail block 1a1, and the dovetail block 1a1 is located on the dovetail in the slot. During actual installation, the left base 1a is fixed on the machine bed, and with the cooperation of the dovetail block 1a1 and the dovetail groove, the right base 1b can slide up and down relative to the left base 1a. To further illustrate, the fit between the dovetail groove and th...

Embodiment 2

[0030] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the detachable locking structure includes a through hole vertically penetrating on the upper side wall of the crushing groove 5b. A screw is provided, the lower end of the screw is fixedly connected with the lower side wall of the crushing groove 5b, the upper end of the screw extends out of the through hole, and the upper end of the screw is screwed with a nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com