Mixed powder for powder metallurgy, method of manufacturing same, and method of manufacturing iron-based powder sintered body

A technology of powder metallurgy and manufacturing method, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low melting point, poor thermal conductivity, easy loss of cutting tools, etc., and achieve the effect of obvious function, reduced resistance and inhibition of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

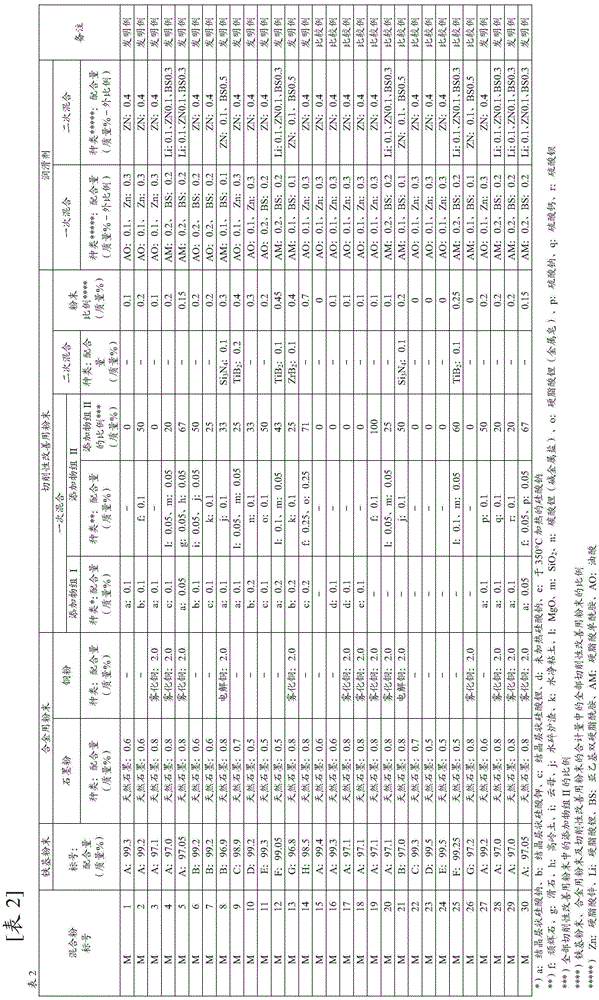

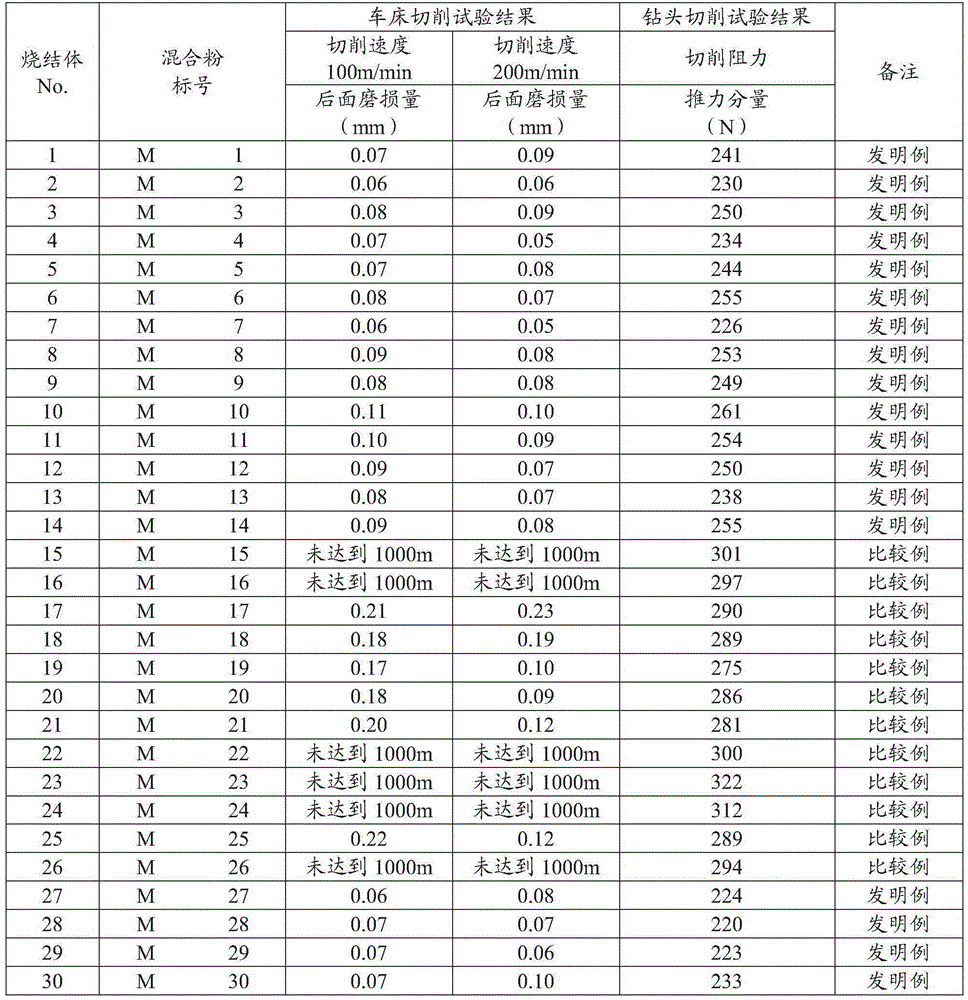

[0111] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to the following examples.

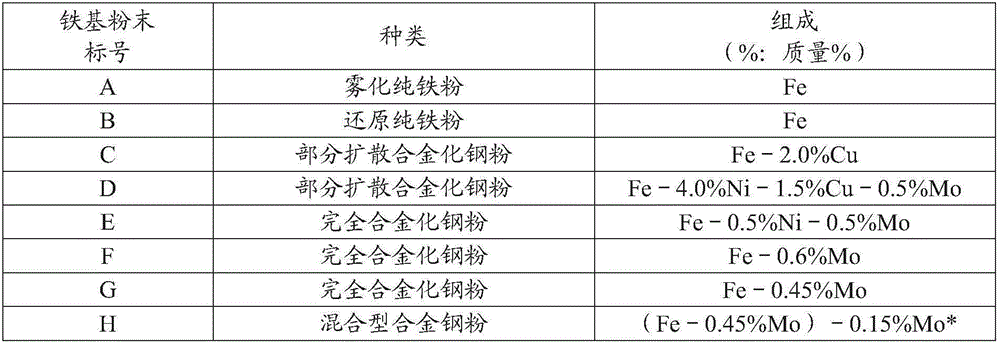

[0112] As the iron-based powder, the iron-based powders shown in Table 1 (average particle diameters: about 80 μm each) were used. In addition, the average particle diameter described below was calculated|required by the laser diffraction method.

[0113] Here, the iron-based powder used is as shown in Table 1, which is obtained by atomizing pure iron powder (A), reducing pure iron powder (B), and partially diffusing Cu as an alloying element to the surface of the iron powder and alloying it. Partial diffusion alloyed steel powder (C), partial diffusion alloyed steel powder (D) obtained by partially diffusing Ni, Cu, and Mo as alloying elements to the surface of iron powder and alloying, and pre-alloying Ni, Mo as alloying elements Prealloyed steel powder obtained by alloying (completely alloyed steel powder) (E), p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com