Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Improve water injection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly dust fall agent for coal mine

InactiveCN103450855ACohesion effect is goodQuick dustOther chemical processesActive agentSurface-active agents

The invention relates to the field of dust fall agents, in particular to an environment-friendly dust fall agent for a coal mine. The environment-friendly dust fall agent enables water mist on the surfaces of dust particles to quickly wet and permeate the insides of the dust particles, dust particle coagulation is quickened, dust particle sedimentation is quickened, and the dust fall agent is biodegradable. The environment-friendly dust fall agent for the coal mine comprises the following raw materials, by mass ratio, 60-100 parts of surface active agents, 5-30 parts of biodegradable high-molecular polymers, 20-60 parts of solvents, 6-20 parts of antifreezing agents and 0.5-4 parts of metal corrosion inhibitors. The dust fall agent is a concentrated solution, the ratio can reach 1: 1000 to 1: 5000, quick dust fall can be achieved, chloride salt is not contained, the agent is biodegradable after being sprayed, and therefore secondary environment pollution is avoided.

Owner:TAIYUAN RONGYUAN TECH CO LTD

Method for water distribution by sound wave remote control

ActiveCN101498211AReal-time monitoring of flow pressureEconomic Stratified Water Distribution TechnologySurveyFluid removalDistributorInjection well

The invention discloses a method using sound waves for water distribution of layer separation in a remote way, including the following steps: a, an intelligent water pipe column of water distribution is designed for descent: according to the parameter of a well condition, the pipe column of water distribution of layer separation is designed, a pipe column of water injection is connected with a water well anchor, and a plurality of sets of a short joint, a water blockage packer, a short joint, an intelligent water distributor and a short joint of sequential series connection are combined and connected to be assembled into a whole under the water well anchor; b, the water blockage packer is set: hydraulic pressure is pumped on the well hole to set the water blockage packer; c, distributing injection is prepared: ground equipment is used for pouring water into an oil pipe until the liquid level reaches the well hole; d, the command of layer separation and distributing injection is sent by a sound-wave generator on the well hole by the method using the sound-wave technology for controlling the underground action in a remote way on the ground, the command is transmitted to the underground, and after receiving the command, a sound-wave signal detector of the intelligent water distributor executes the action required by the command to realize the accurate water distribution of a separated injection well. The invention has reasonable design and reliable construction technology, and is the ideal method for the distributing injection of at least one water injection layer of the water injection well of the oil field.

Owner:CHINA PETROLEUM & CHEM CORP

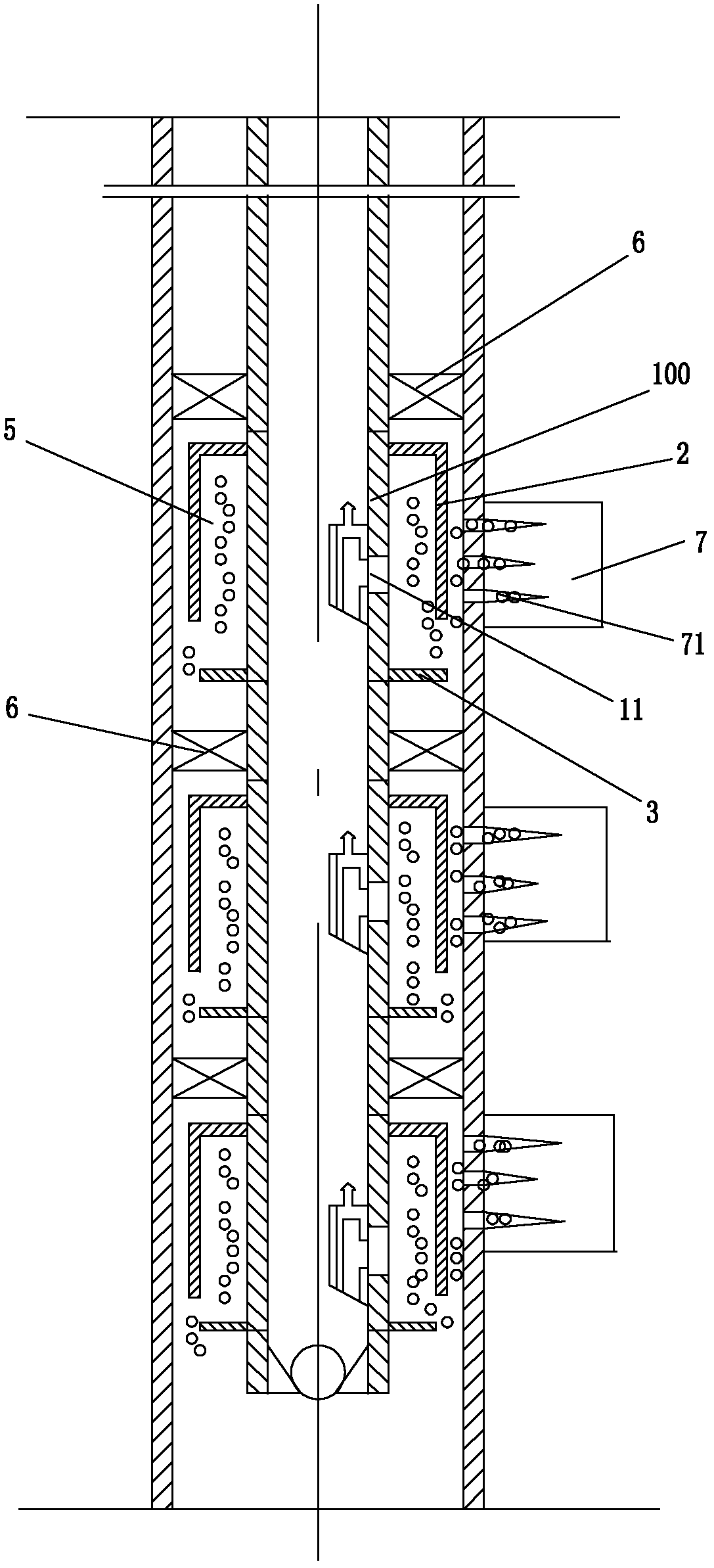

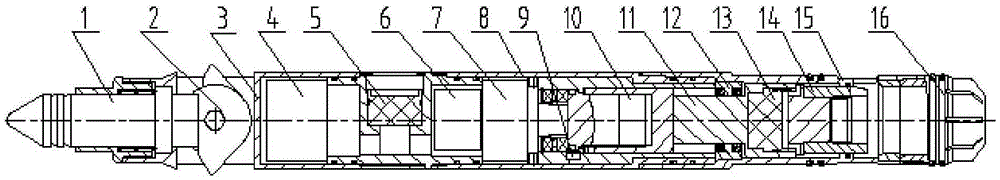

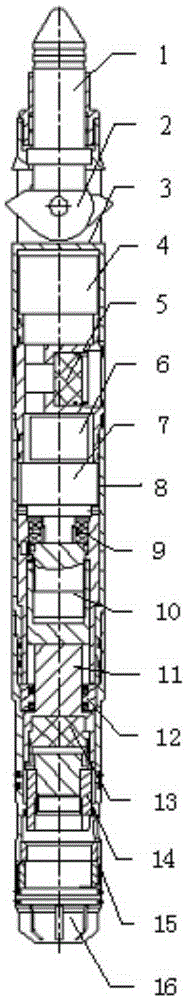

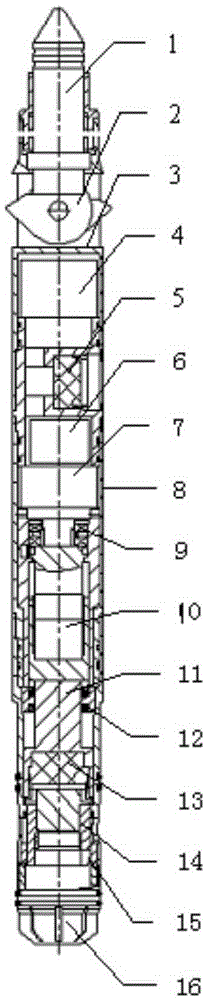

Subdivision water injection, ball-off and profile control integrated tubular column for water injection well of oilfield and process of tubular column

InactiveCN102606118AIncrease productionImprove oil recovery efficiencyFluid removalSealing/packingEngineeringWater well

The invention relates to a subdivision water injection, ball-off and profile control integrated tubular column for a water injection well of an oilfield. A plurality of special water distributors for subdivision water injection, ball-off and profile control of the water injection well are serially connected to form the integrated tubular column, packers are arranged among the special water distributors, and a ball valve is disposed at the bottom end of the integrated tubular column; the special water distributors for subdivision water injection, ball-off and profile control of the water injection well comprise water distributor bodies, and a ball containing basket is hermetically sleeved on the outer side of each water distributor body along the axial direction of the water distributor body and corresponds to a water outlet of the water distributor body; each ball containing basket is in the shape of an annular barrel, the upper end of each ball containing basket is hermetically connected to the outer wall of the corresponding water distributor body while an annular opening at the lower end of each ball containing basket is hermetically closed by an annular baffle plate, and each annular baffle plate is connected with the lower end of the corresponding ball containing basket via a shear pin; an inner cavity of each ball containing basket is communicated with the water outlet of the corresponding water distributor body; and subdivision water injection, ball-off and profile control selective plugging balls are arranged in the ball containing baskets. The profile control balls are fed in a subdivision water injection section to plug shot holes so as to adjust uneven interlayer water absorption, a water injection effect is improved, and accordingly crude oil production yield and oil production efficiency are improved.

Owner:PETROCHINA CO LTD

Low-gas permeability coal seam weakening and permeability increasing method combining presplitting and high-pressure water injection

ActiveCN105239983AImprove breathabilityImprove water injection effectFluid removalStress concentrationWater flow

The invention discloses a low-gas permeability coal seam weakening and permeability increasing method combining presplitting and high-pressure water injection. The method includes: using a drilling machine to construct a plurality of coal seam weakening and permeability increasing units to a working face gateway pre-exploiting coal seam side, presetting a corresponding presplitting device in one coal seam weakening and permeability increasing unit which comprises three drilled holes, detonating the presplitting device and then injecting high-pressure water into the coal seam weakening and permeability increasing unit, and stopping the water injection when water injection pressure drops suddenly, the corresponding dropped pressure is kept unchanged and stable pressure water flows out of the coal seam weakening and permeability increasing unit so as to complete the weakening and permeability increasing of the coal seam weakening and permeability increasing unit; performing weakening and permeability increasing on the next coal seam weakening and permeability increasing unit until the weakening and permeability increasing of a whole to-be-exploited coal seam are completed. The method has the advantages that presplitting is performed on deep coal surrounding high-pressure water injection holes, so that water injection influence radius is increased evidently, high-pressure water injection weakening speed is increased, and local coal stress concentration is avoided.

Owner:SHANDONG UNIV OF SCI & TECH

Deep hole blasting and static water injecting combining coal seam weakening method

The invention discloses a deep hole blasting and static water injecting combining coal seam weakening method which comprises the following steps: (1) arranging a plurality of groups of drill holes in the coal seam, wherein the drill holes in each group include a blasting hole and a control hole; (2) pushing hole protection pipes into the control holes one by one, and connecting the adjacent hole protection pipes by steel wires longitudinally in a winding way, wherein the diameter of each hole protection pipe is less than 10mm; (3) charging explosive cartridges into the hole protection pipes according to the linear loading density, pushing the hole protection pipes into the blasting holes one by one, sealing the blasting holes with yellow mud after loading is completed, and blasting; (4) injecting water into the blasting holes and the control holes at static pressure simultaneously through four seams of the hole protection pipes in the blasting holes and the control holes, and diffusing and permeating water into cracks generated by blasting to fully wet coal; and (5) recovering the hole protection pipes in the control holes after water injection is completed. After the drill holes are blasted, the drill holes can not collapse, and many cracks can be formed in the coal seam. In addition, because water can be injected into the coal seam through the blasting holes and the control holes, the strength of the coal seam can be reduced effectively.

Owner:SHANDONG UNIV OF SCI & TECH

Decompression and augmented injection agent for water injection well of low-permeability reservoir and preparation method thereof

ActiveCN106281288AImprove water injection effectReduce water injection pressureDrilling compositionPorosityCorrosion

The invention belongs to the technical field of oil and gas fieldchemistry and discloses a decompression and augmented injection agent for a water injection well of a low-permeability reservoir. The decompression and augmented injection agent comprises the following components by weight percent: 30%-35% of bisoctyl dimethyl ammonium chloride, 3%-7% of a fluorocarbon surfactant, 3%-5% of a non-ionic surface active agent, 5%-10% of ethylene diamine tetra (methylene phosphonic acid) sodium, 2%-5% of dimethyl ketoxime and 38-57% of water. The invention also provides a preparation method for the decompression and augmented injection agent. The decompression and augmented injection agent takes water solution as a transmitting medium and forms an ultrathin molecular film by depositing on the rock surface; the decompression and augmented injection agent has a function of changing the core wettability and clay anti-swelling property; the decompression and augmented injection agent also has multiple effects of corrosion inhibition, scale inhibition, sterilization, and the like, can effectively prevent the influence on the formation porosity caused by injected water corrosion products, scaling, bacteria, and the like, and can greatly promote the water injection effect of the water injection well of the low permeability reservoir. Being as a novel decompression and augmented injection agent with excellent decompression and augmented injection effects, the decompression and augmented injection agent has wide market prospect.

Owner:陕西森瑞石油技术开发有限公司

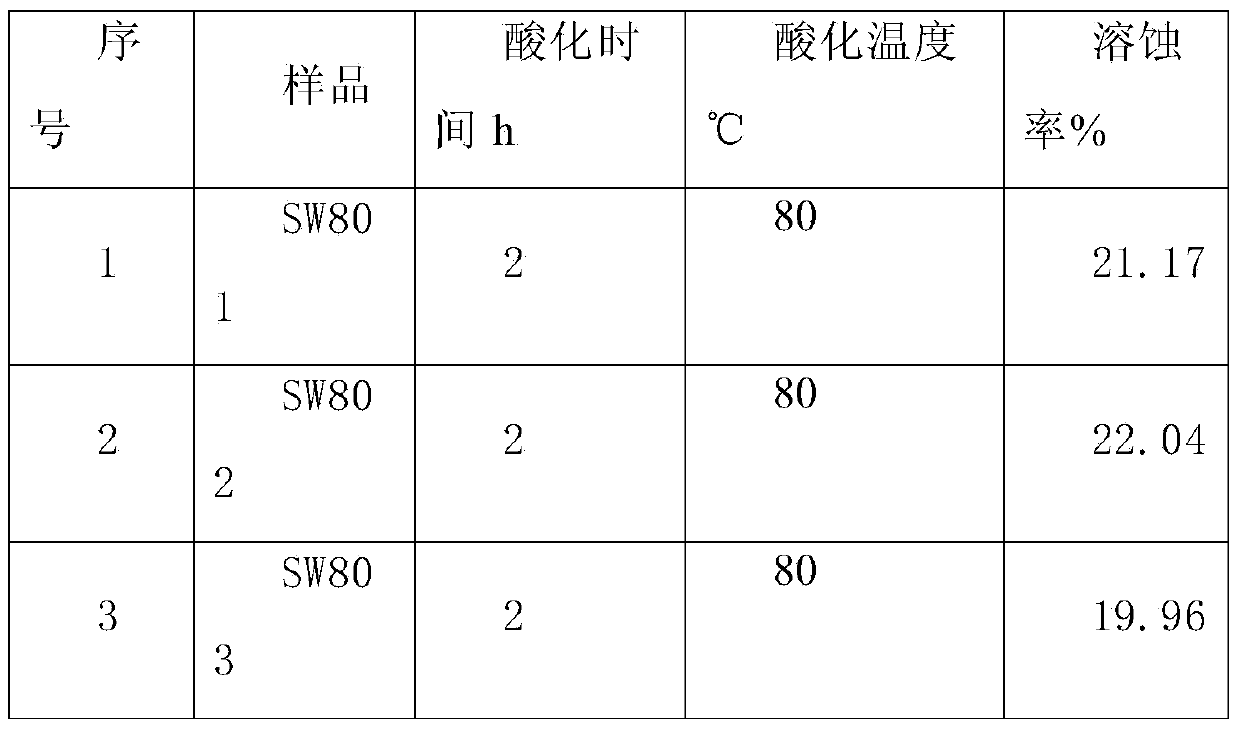

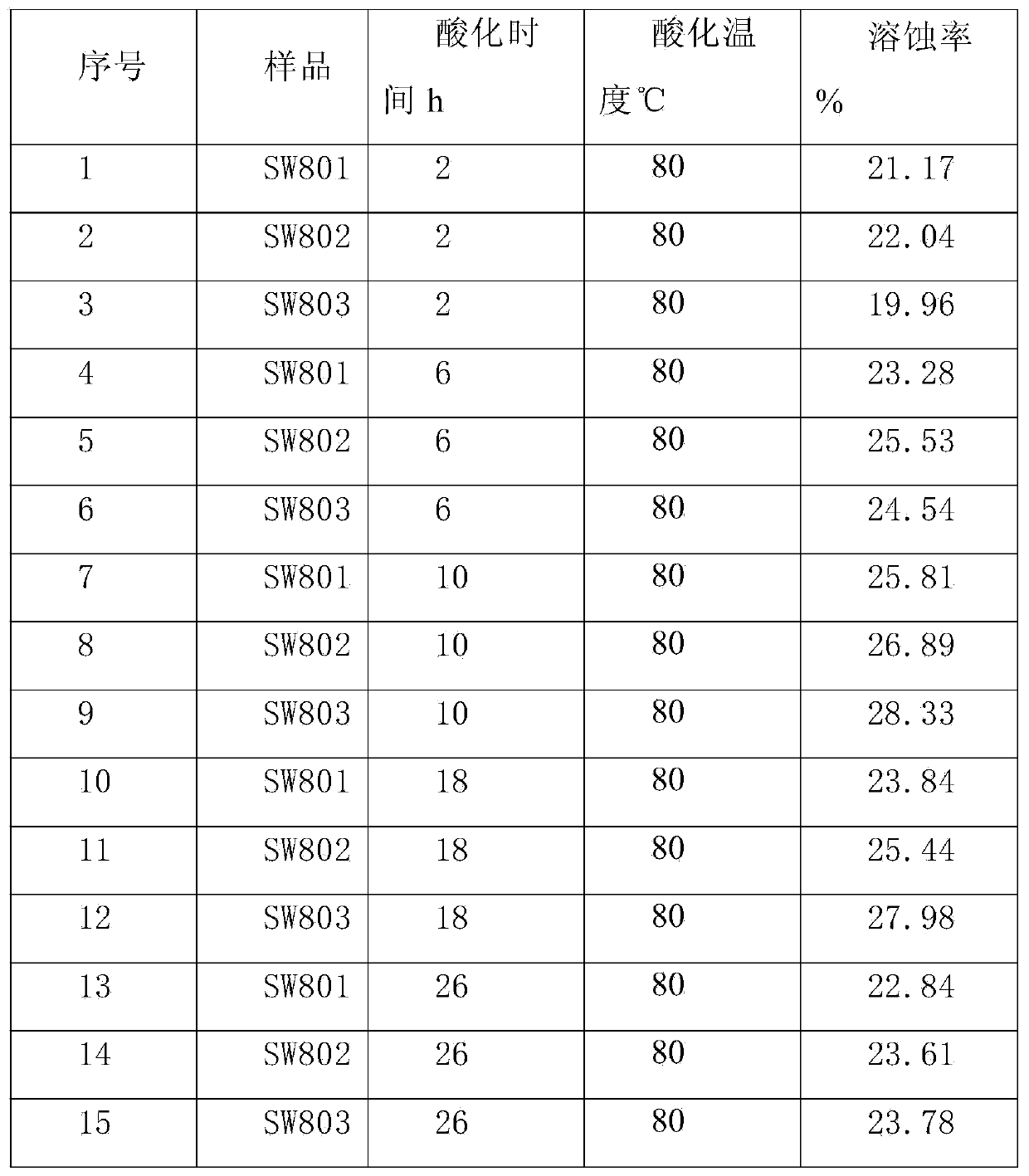

Retarded-acid acidizing fluid

InactiveCN103436247AProlong acidification timeImprove water injection effectDrilling compositionHydrofluoric acidReaction rate

The invention relates to the field of oilfield chemical applications and discloses retarded-acid acidizing fluid which is applied to the injection increase of water injection. The formula of the retarded-acid acidizing fluid comprises the following ingredients in percentage by mass: 10-14% of hydrochloric acid, 1-4% of hydrofluoric acid, 1-4% of acidification retarder, 1-2% of acidification a corrosion inhibitor, 0.1-0.5% of an iron ion stabilizer, 0.2-1% of a demulsification and discharge aiding agent, 1-2% of a clay stabilizer and 72.5-85.7% of water. According to the retarded-acid acidizing fluid, the acidification retarder is added into acid liquor, so that the acid-rock reaction time can be prolonged, the effective acting distance of active acids is increased, the effective rate of acidification is increased, and the aim of deep acidification can be achieved; the problem that the deep acidification cannot be achieved because a zone near a well is excessively corroded caused by the fact that the reaction rate between the conventional mud acids and stratum minerals is high can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Active fracturing reagent for softening coal rock

ActiveCN101781553AHigh softening coefficientPrevent spontaneous combustionDrilling compositionSpontaneous combustionCoal dust

The invention discloses an active fracturing reagent for softening coal rock, which is a series of special active fracturing reagents for softening coal rock through mixing a new compound surfactant, and is formed by mixing anionic surfactant (alkylbenzene sulfonate), nonionic surfactant (alkylphenol ethoxylates or fatty alcohol polyoxyethylene ether), adducts (aliphatic alcohol and ethylene oxide condensate) of nonionic surfactant to form a novel compounded surfactant, and then mixing with potassium chloride, sodium sulphate and water in a definite ratio. The reagent provided by the invention can be applied to improving water-supplying efficiency, preventing the top-board coal layer striking, reducing coal layer hardness coefficient to a large extent, strengthening coal layer caving ability, improving resource mining rate, lowering coal dust, and preventing the spontaneous combustion of machine and the coal layer, etc.

Owner:XIAN UNIV OF SCI & TECH

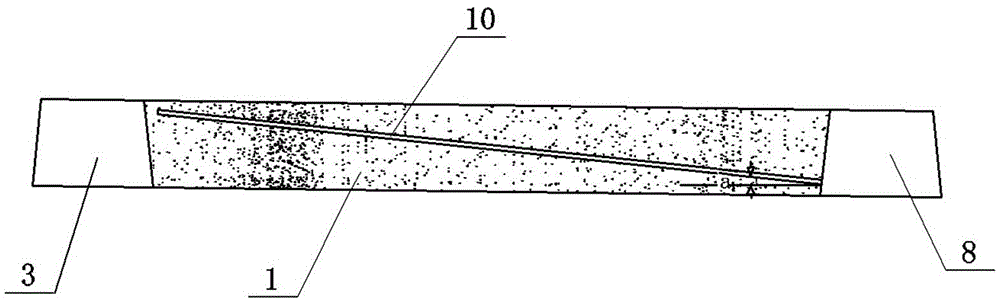

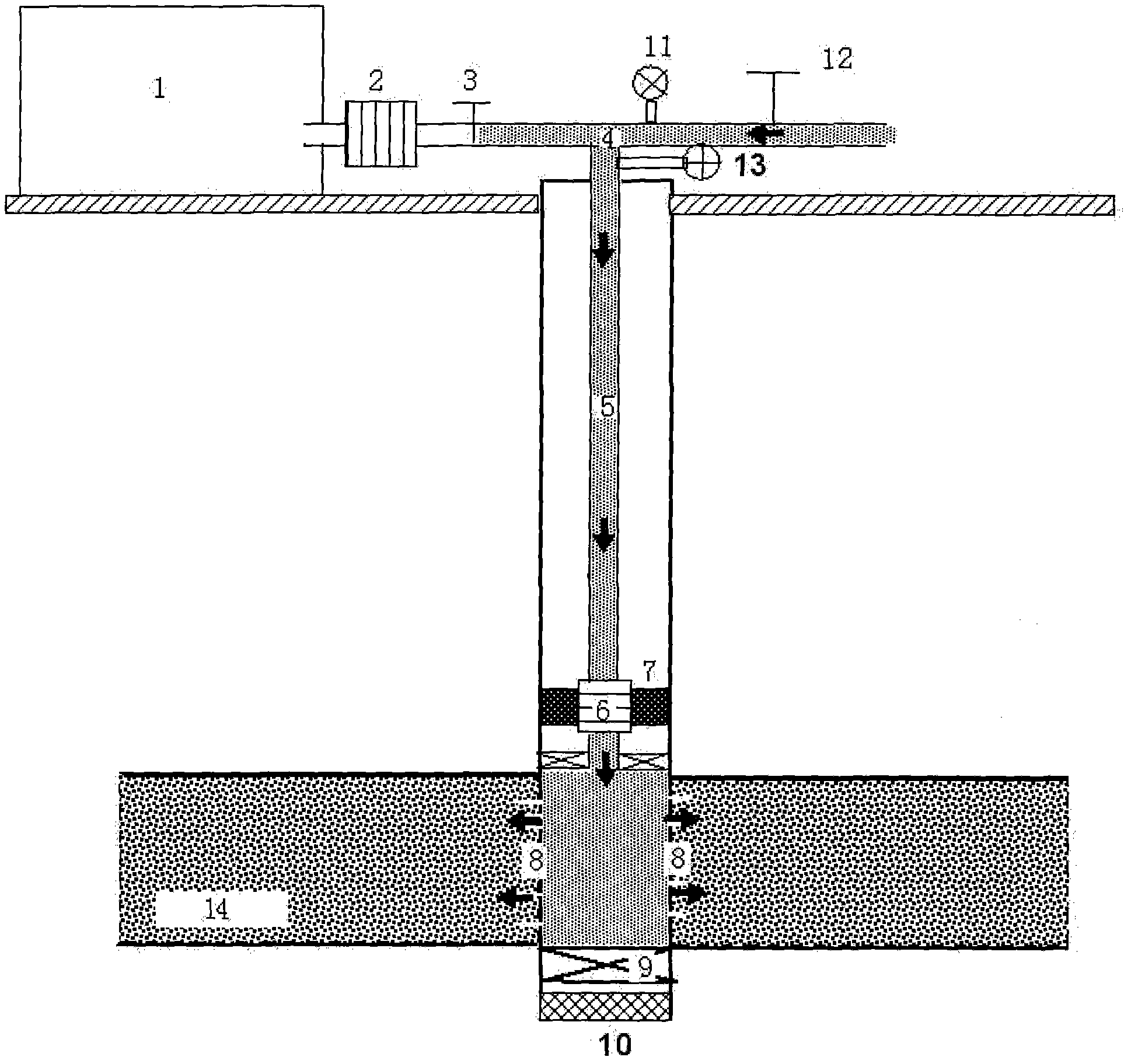

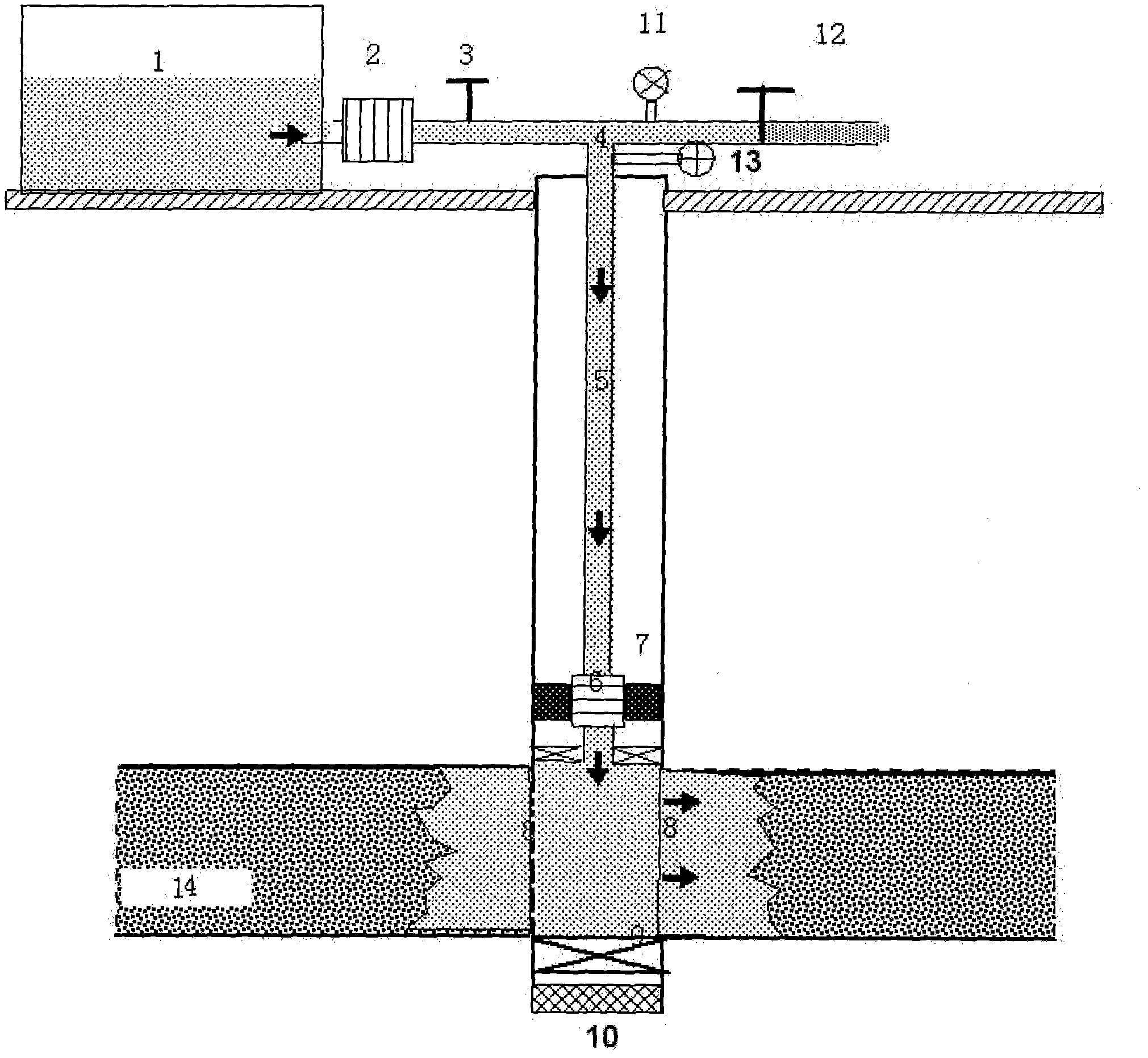

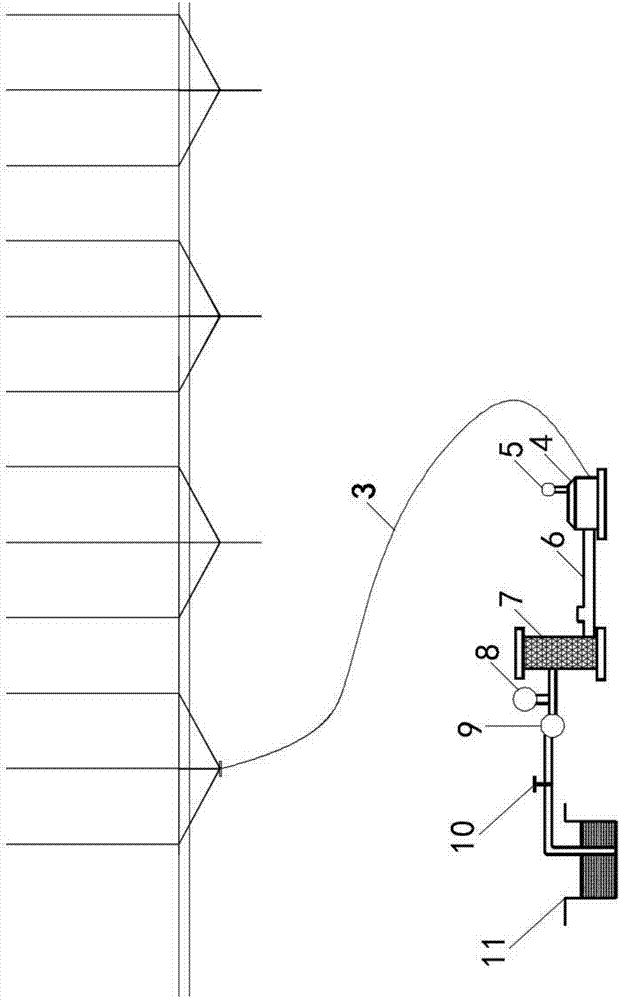

Efficient water injection method and device of hydraulic fracture permeability increase auxiliary coal seam

InactiveCN105422164AGood water permeabilityHigh densityDust removalFire preventionHydraulic fracturingHigh pressure water

The invention discloses an efficient water injection method and device of a hydraulic fracture permeability increase auxiliary coal seam. Before coal seam static pressure water injection, high pressure water generated by an emulsion pump is injected into a drilled static pressure water injection drilled hole through a high pressure pipeline, high pressure water is injected into a coal body fracture by means of the cutting and fracturing effect of a water wedge generated by the high pressure water on the coal seam on the periphery of the drilled hole to overcome the minimum principal stress and the anti-fracture pressure of the coal body, so that fractures are broadened, extended and communicated; in the fracturing process, quartz sand is added into the high pressure water, the quartz sand enters the fractures along with the high pressure water, the effect of a supporting agent is achieved, and the water injection drilled hole is connected to a static pressure pipeline to perform static pressure water injection on the coal seam after hydraulic fracturing is finished. Before static pressure water injection is performed, the breathability of a water pre-injection coal seam is increased, so that the coal seam water injection speed is increased, and the water injection efficiency and effect are improved. According to the method, no special emulsion pump is needed, the running time of the emulsion pump is short, the drilling construction work amount can be decreased, and the water injection working efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

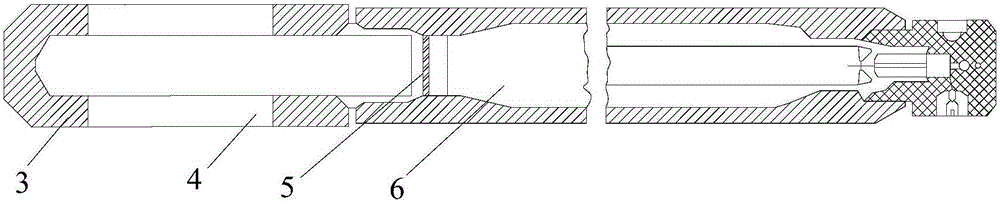

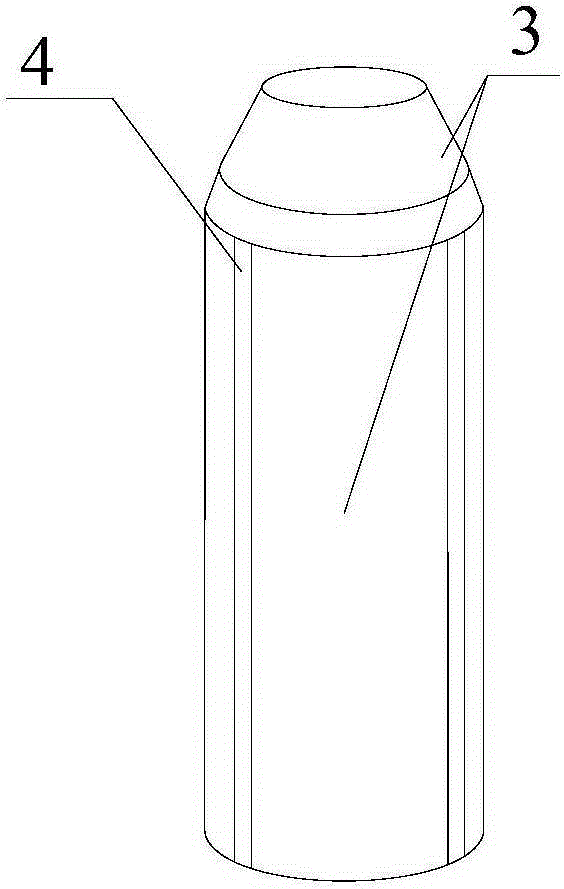

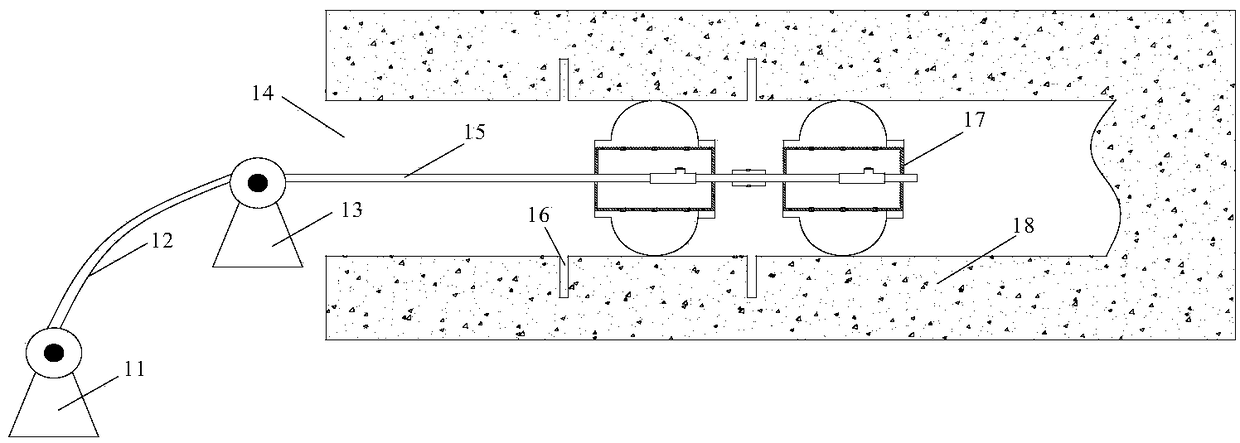

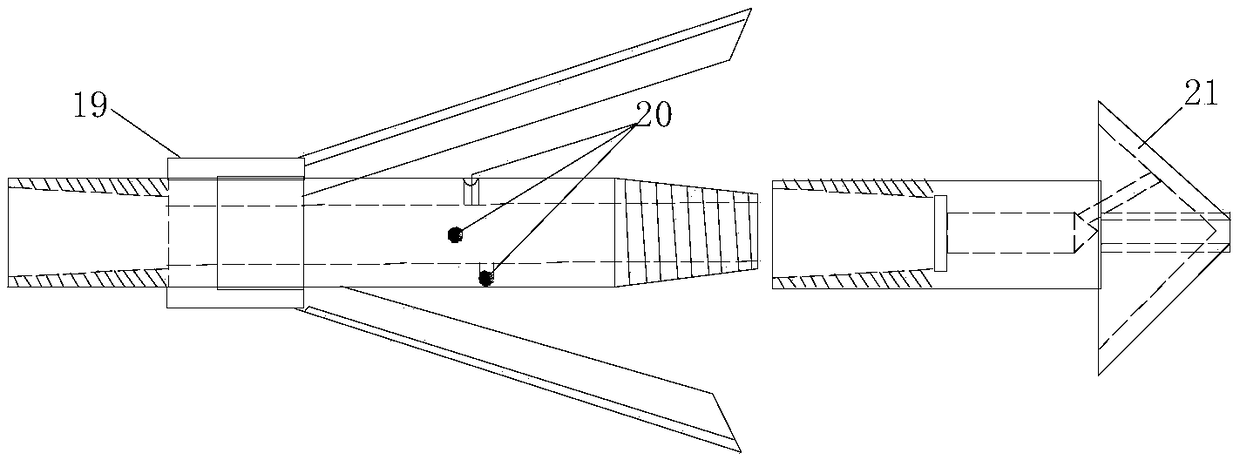

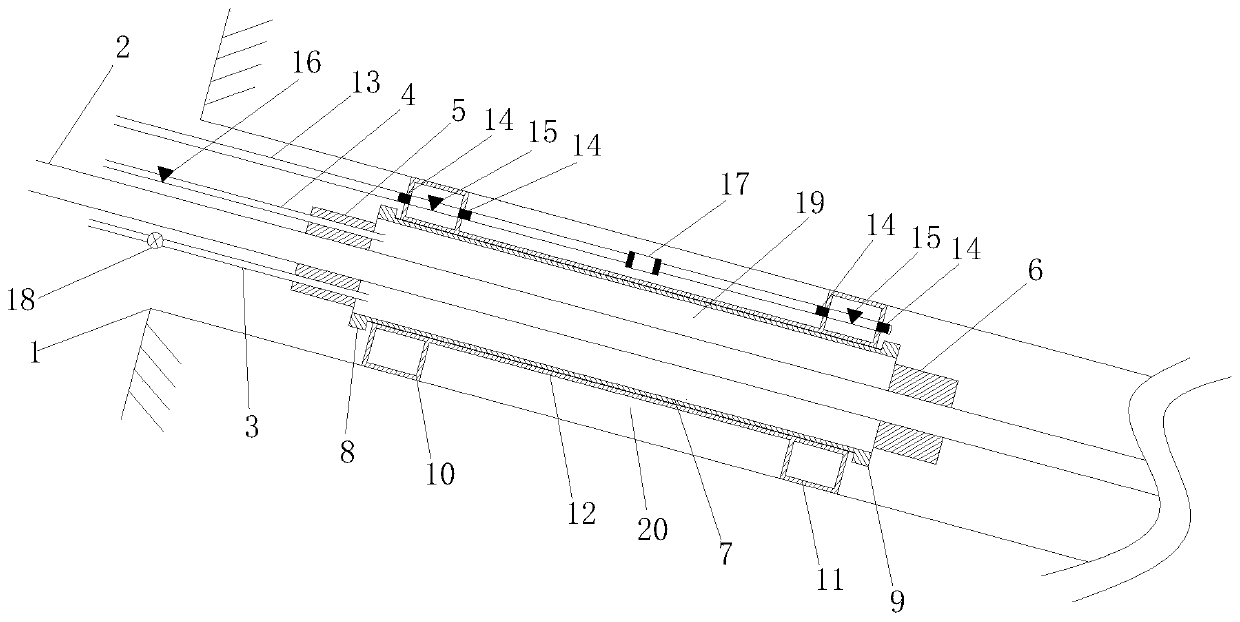

Downhole rapid slotting directional hydraulic fracturing system and method based on drilling machine power

ActiveCN108757000AImprove water injection effectReduce concentrationDrill bitsDisloding machinesPorosityHydraulic fracturing

The invention discloses a downhole rapid slotting directional hydraulic fracturing system and method based on drilling machine power. The directional hydraulic fracturing system comprises a water injection pump, and a high pressure rubber hose is arranged on the water injection pump to communicate with a drilling machine. A special sealing drill pipe for hydraulic fracturing is installed on the drilling machine, and the front section of the drill pipe is connected with directional hole packers in a threaded mode. Sealing rings are arranged at the threaded connected positions. The downhole rapid slotting directional hydraulic fracturing method comprises the main implementation steps of hole drilling, slotting, hole sealing and fracturing, specifically, a drilling and cutting integrated toolis installed at the front end of the drill pipe firstly, and after the hole drilling is completed, hydraulic slotting and anti-reflection pressure relief are performed without replacing a drill bit;after the slotting is completed, the drill bit is withdrawn, and the directional hole packers are installed and pushed to the predetermined positions for high-efficiency hole sealing; after the hole sealing is completed, high-pressure water injection fracturing is carried out, and high-pressure permeation is mainly used for increasing the fracture density and range, so as to improve the water injection effect of a high ground pressure and low porosity coal seam, effectively prevent and control rock burst, reduce dust concentration, prevent and control gas and prevent and control fires and other disasters.

Owner:SHANDONG UNIV OF SCI & TECH

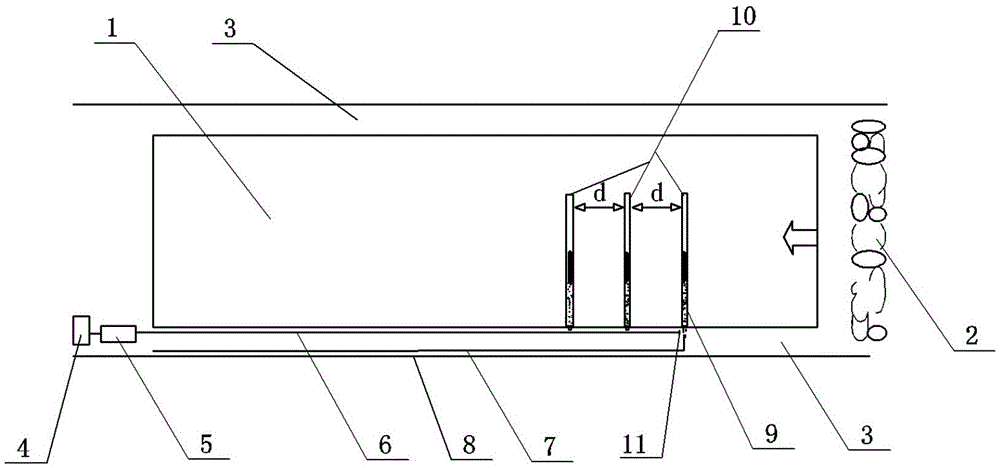

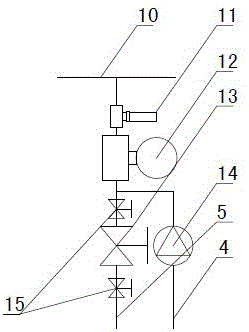

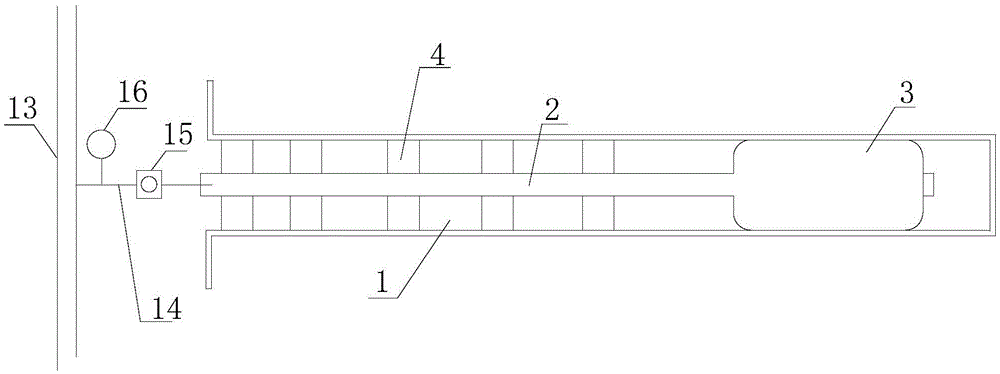

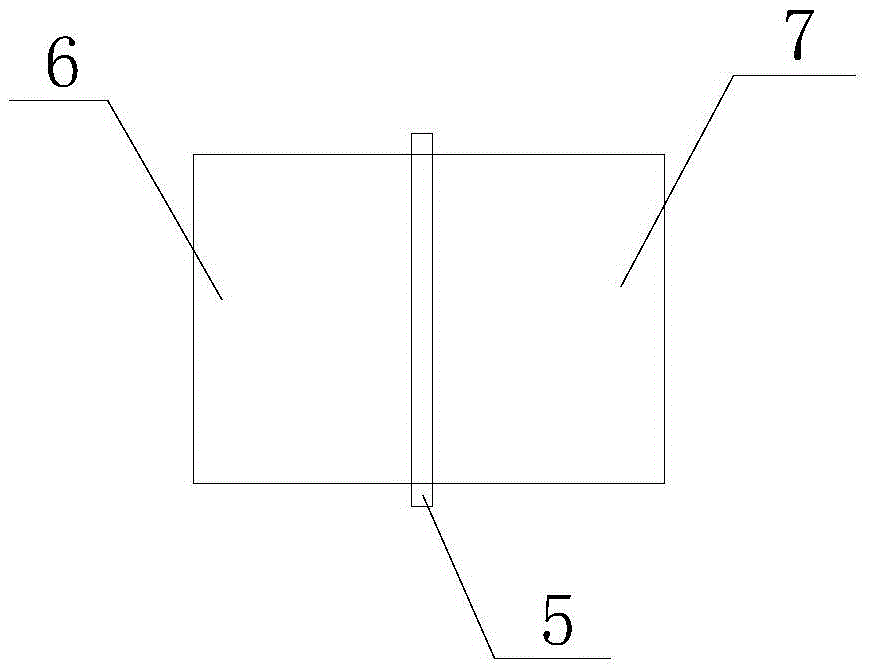

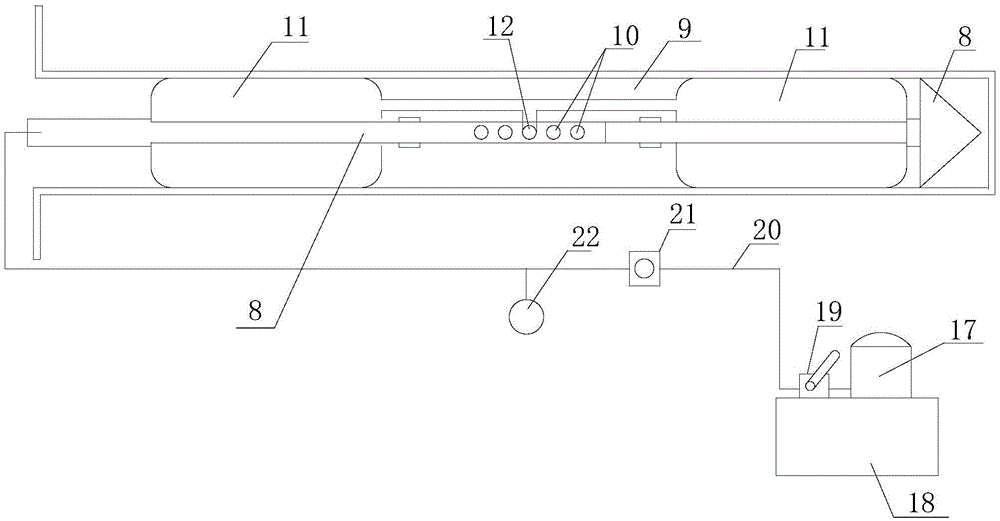

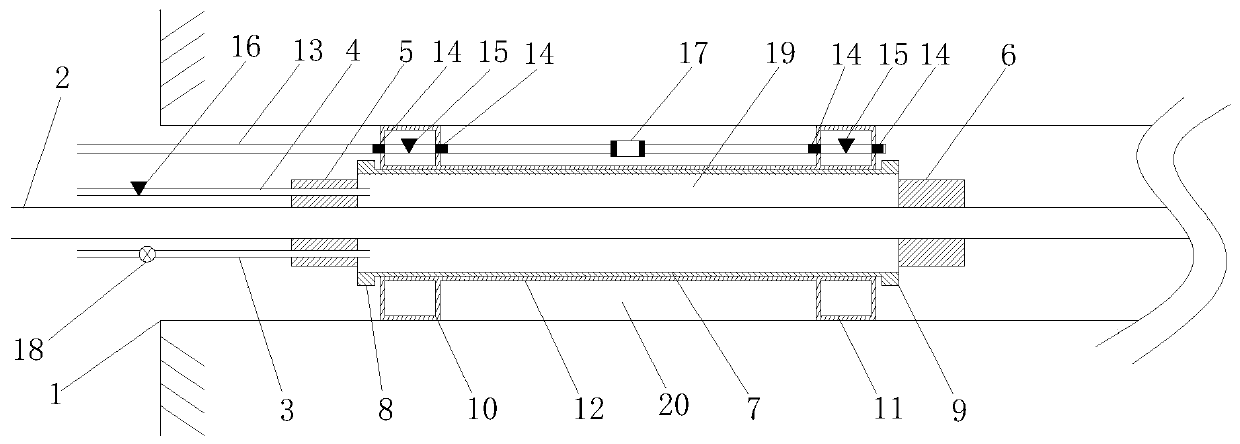

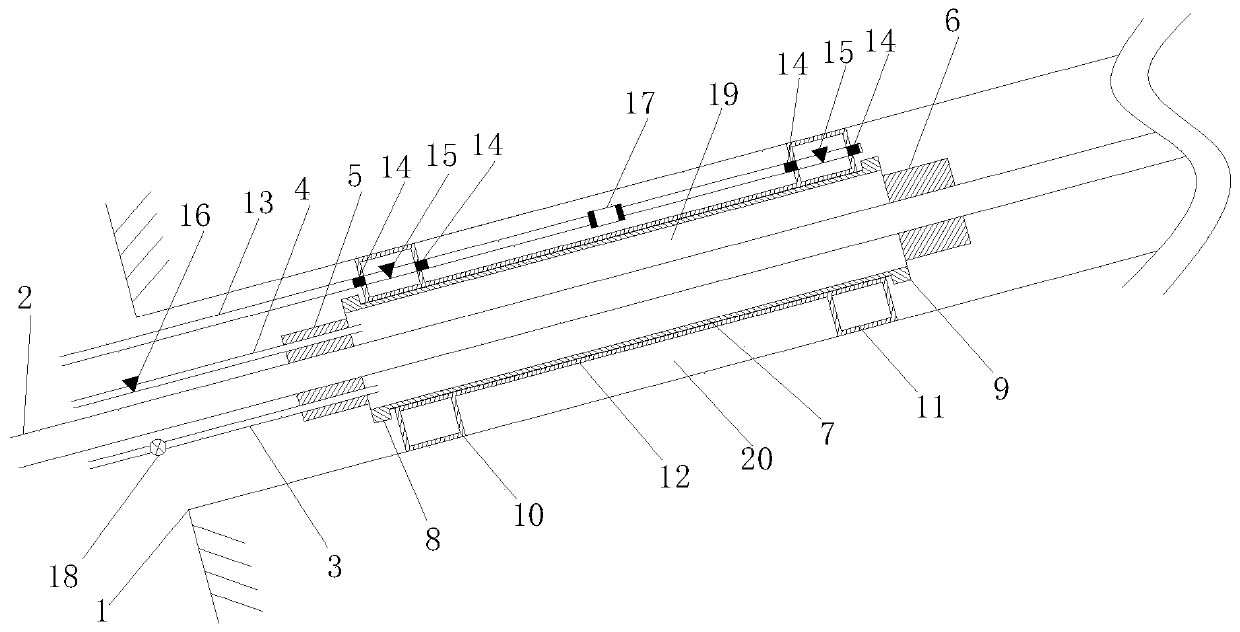

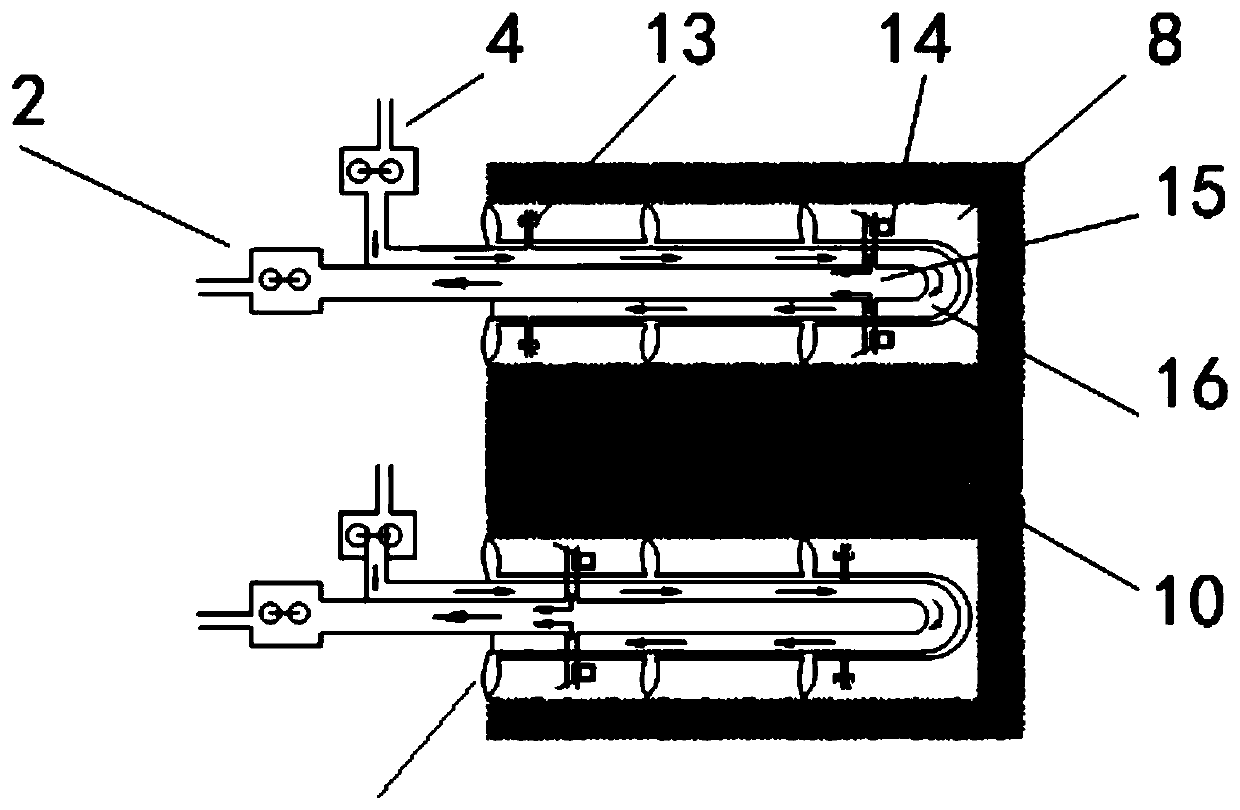

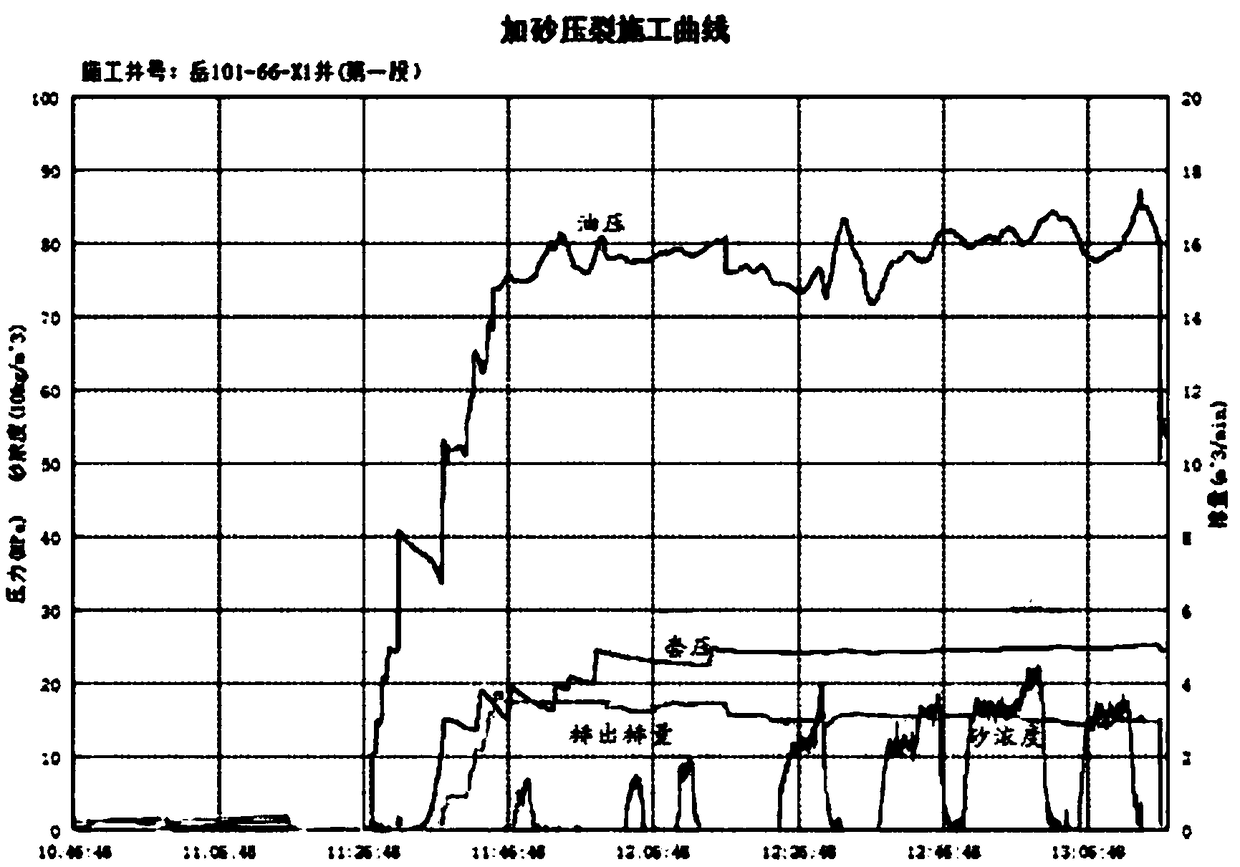

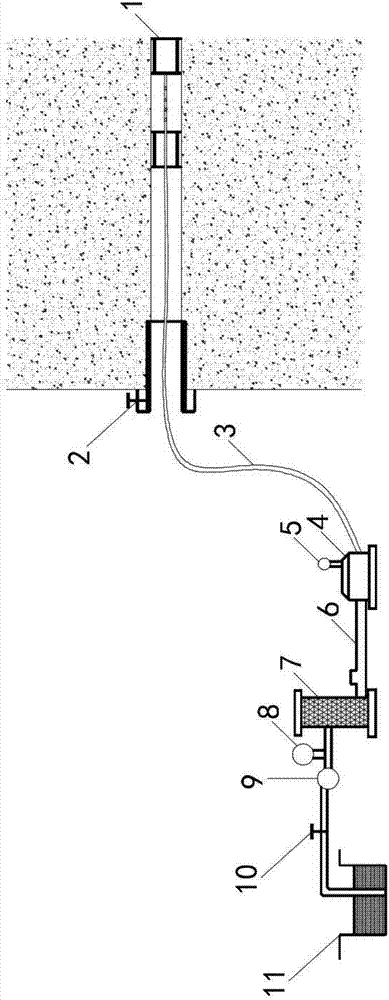

High-pressure hydraulic fracturing coal seam water injection system and automatic water injection monitoring method

ActiveCN105927266AImprove water injection effectTotal monitoringMining devicesDust removalHydraulic fracturingHigh pressure

The invention relates to a high-pressure hydraulic fracturing coal seam water injection system and an automatic water injection monitoring method, belonging to the field of technical equipment. The high-pressure hydraulic fracturing coal seam water injection system is characterized by comprising a plurality of water injection units (3) used for injecting water into a coal seam (22); an inlet and an outlet of a pressure pump (6) are respectively connected with a static pressure water injection pipeline (4) and a dynamic pressure water injection pipeline (5); the static pressure water injection pipeline (4) and the dynamic pressure water injection pipeline (5) are simultaneously connected with a pipeline part of the water injection units (3); the pressure pump (6) is connected with a control cabinet (9) and is controlled by the control cabinet (9); circuit parts of the water injection units (3) are simultaneously connected with the control cabinet (9). According to the high-pressure hydraulic fracturing coal seam water injection system and the automatic water injection monitoring method, a coal seam water injection way combining dynamic pressure and static pressure is realized by arranging the static pressure water injection pipeline and the dynamic pressure water injection pipeline, so that water injection pressure and water injection amount are accurately controlled, and the water injection effect is greatly improved.

Owner:SHANDONG TANGKOU COAL

Bio-enzyme well completion fluid

ActiveCN101781551AReduce corrosionPermeability Restoration EffectiveDrilling compositionPollutionPolymer

The invention discloses bio-enzyme well completion fluid. The well completion fluid is prepared from 1-10 parts of bio-enzyme parathion and 90-99 parts of water, or bioacid, acetic acid or metal-chelator are added to prepare the well completion fluid which is injected into an oil-gas well through a pump truck. The well completion fluid is absorbed at the surface layer of the drill core, can help to avoid reservoir pollution and corrosion to the downhole tools during the drilling operation, removes organic scales and inorganic sediment, thoroughly degrades the polymer, disperses the filter cakes, can permeate into the micro pore-throat, improves the water wetting effect, eliminates water lock damage, reduces the oil-water surface interface tension, improves the oil-gas permeability, and enables the oil-gas well to have the optimal production state and to achieve good economic benefit.

Owner:SUNCOO PETROLEUM TECH

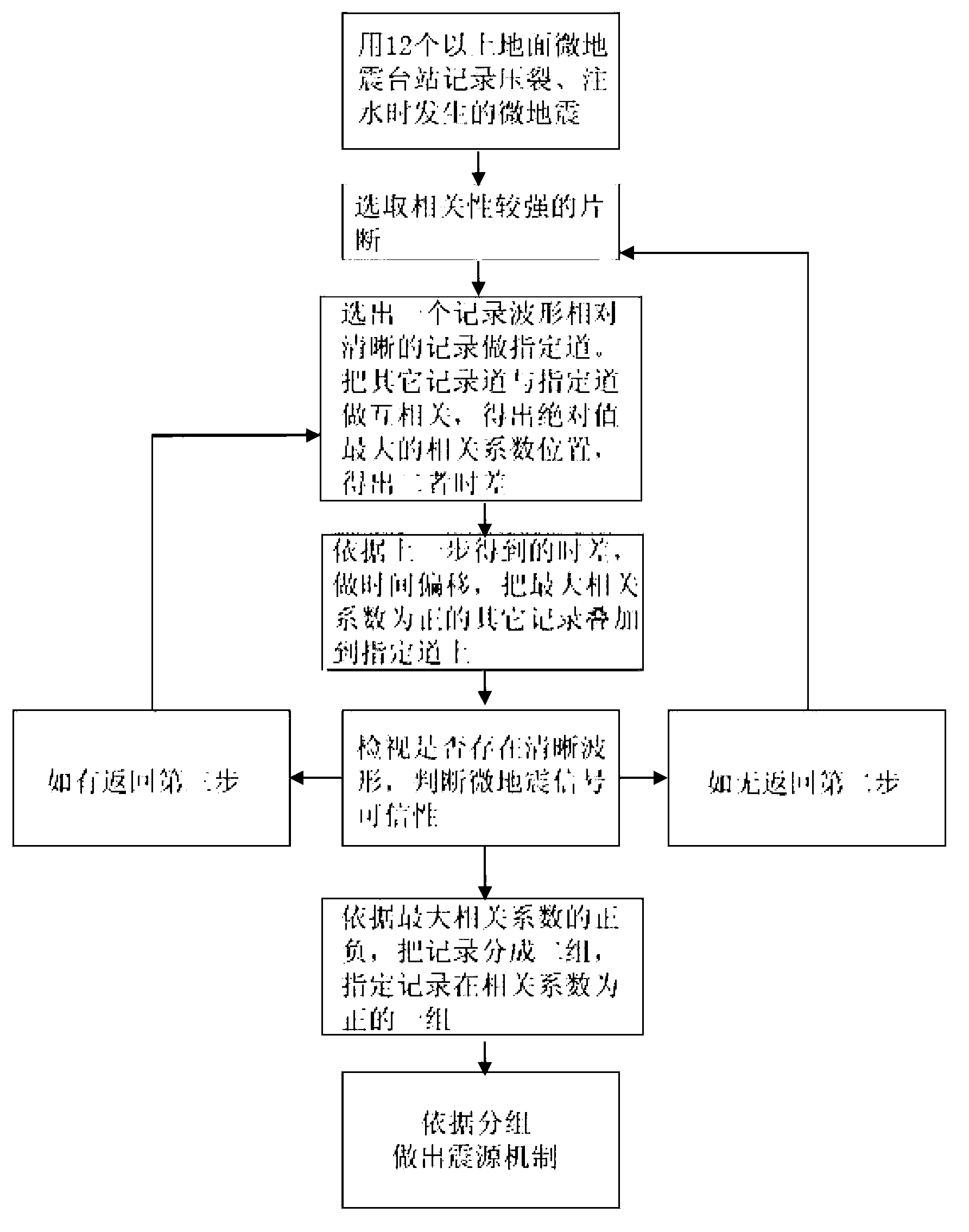

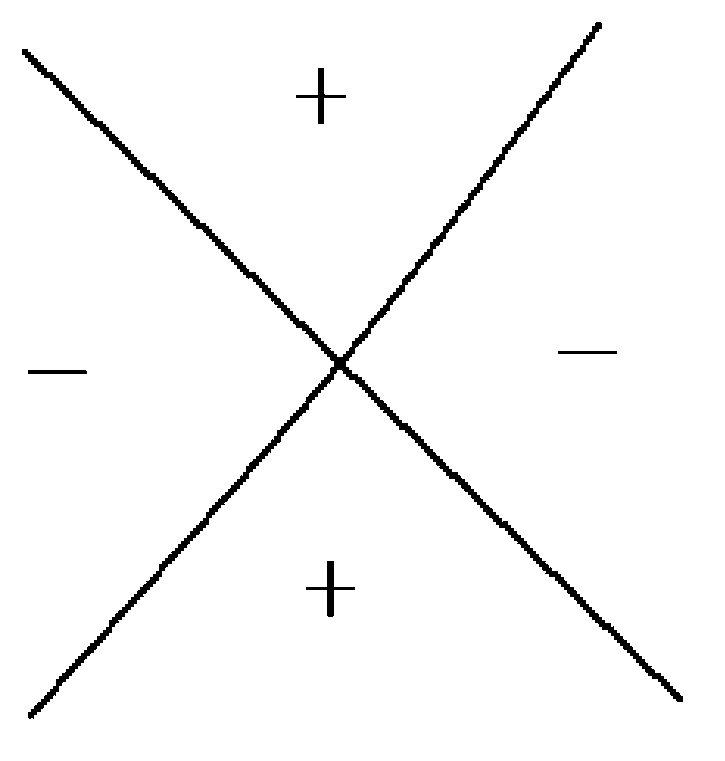

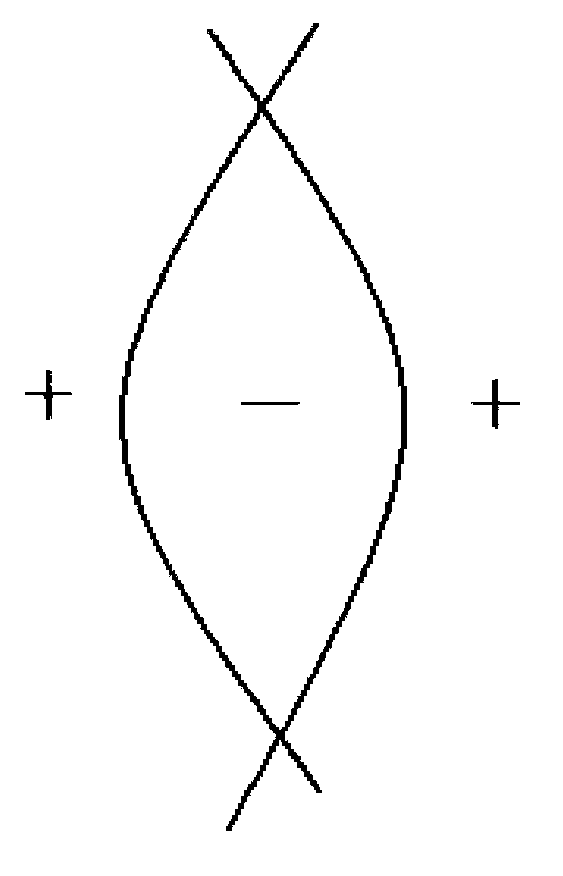

Method for carrying out earthquake source mechanism analysis by utilizing micro earthquakes

ActiveCN103076634AImprove the quality of interpretationImprove water injection effectSeismic signal processingPositive correlationTime difference

The invention relates to a method for carrying out earthquake source mechanism analysis by utilizing micro earthquakes. The method comprises the following steps that a plurality of earthquake recorders are arranged in different positions in the same monitoring region for monitoring; earthquake signal recording segments with high correlation are selected for processing; records with relatively clear wave forms are specified as a specified trace, other recording traces and the specified trace are subjected to cross-correlation processing, the correlation coefficient position with the maximum absolute value is obtained, and the time difference of the other recording traces and the specified trace is obtained; time migration is carried out, and other records with the positive maximum correlation coefficient are superposed on the specified trace; the earthquake wave form is displayed through superposition, and a plurality of traces of clear wave forms are obtained through migration and superposition for many times; and the records are divided into two groups according to the positive or negative of the maximum correlation coefficient, the specified recording trace is divided into the group with the positive correlation coefficient, and the earthquake source mechanism is made according to two kinds of symbols. The method has the advantages that the micro earthquake interpretation quality can be greatly improved, and bases are provided for the reliability of manual fracturing crack detection results.

Owner:刘建中

Method for enhancing water injecting capacity of hypotonic oil field by utilizing nano-powder material

InactiveCN103256032ASolve the problem of difficult water injectionImprove water injection effectFluid removalEngineeringSolvent

The invention relates to a method for enhancing the water injecting capacity of a hypotonic oil filed by utilizing a nano-powder material. A turbid liquid injection increasing agent with the concentration of 2 percent is prepared by nano-powder and an oil-soluble solvent and injected into an injection increasing segment stopper of the nano-powder material from a water injection well pipe pillar, the injection increasing agent of 5 cubic meters is injected in an oil layer of every meter by thickness, a pump is stopped and a well is closed for 72 hours, isometric inverted discharged liquid is injected in well opening production and then water is injected. According to the method for enhancing the water injecting capacity of the hypotonic oil field by utilizing the nano-powder material, the selective and moistening nano-powder material is injected to the hypotonic oil layer, by absorption of the surfaces of rock hole gaps with the material, the properties of the surfaces of the rock hole gaps are changed, therefore, aqueous phase permeability is improved, improvement of the water injection capacity of a hypotonic oil reservoir is achieved, and the problem of difficulty in water injection of the hypotonic oil layer is solved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

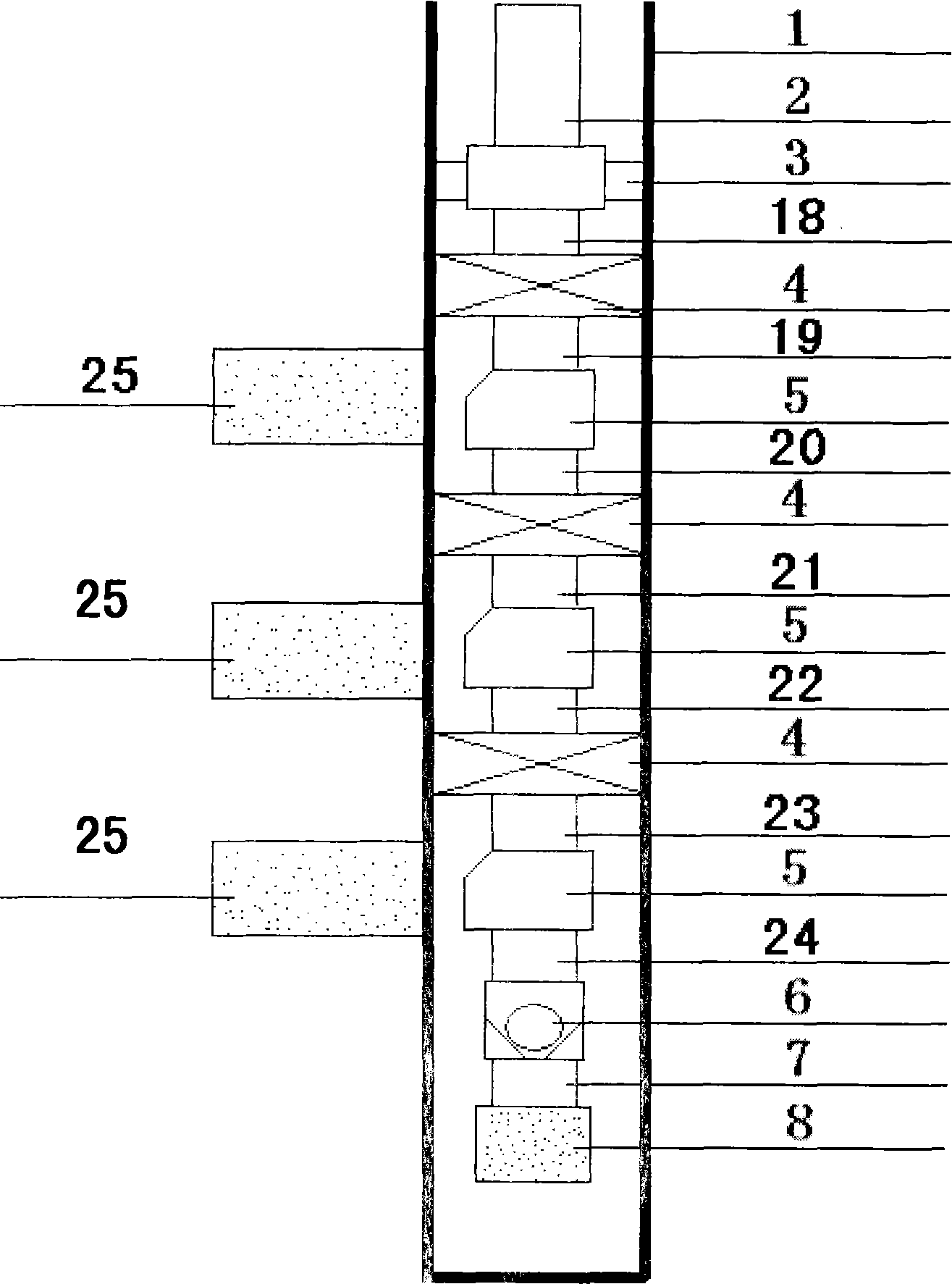

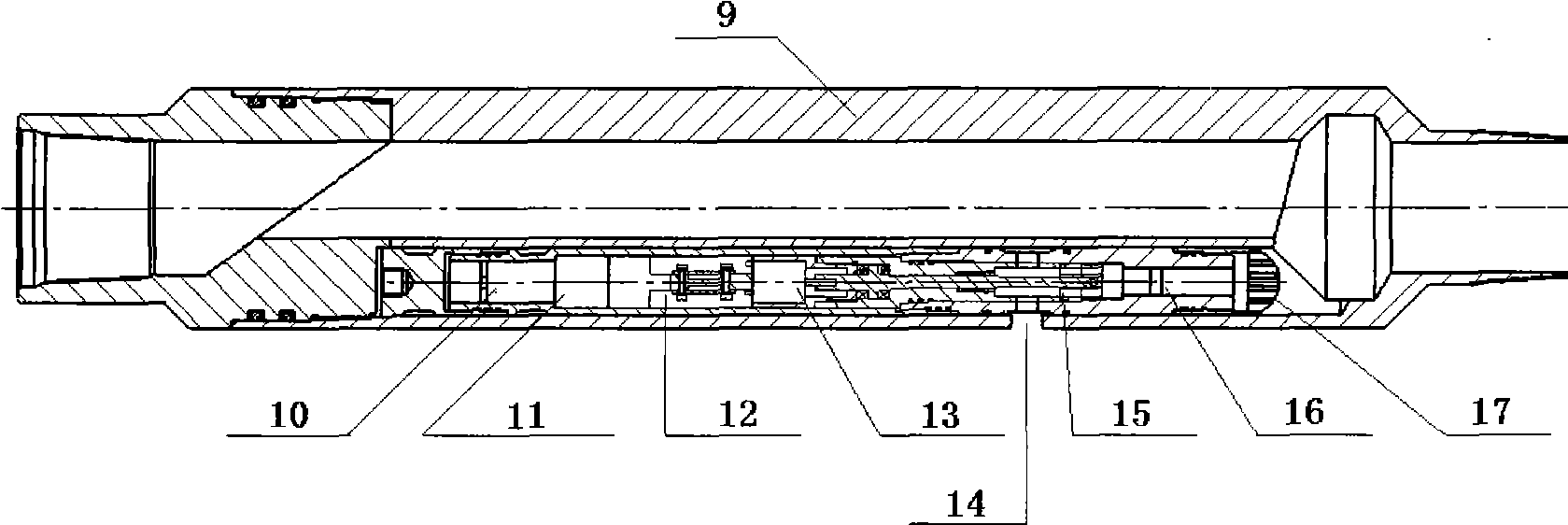

Three-layer separate injection string and three-layer separate injection method for oil well

InactiveCN103806884AQuick and easy water dispensingExtended service lifeFluid removalOil wellSteel ball

The invention discloses a three-layer separate injection string and a three-layer separate injection method for an oil well. The three-layer separate injection string comprises an outer pipe combination and an inner pipe combination, wherein the outer pipe combination comprises a large oil pipe, a first expanding packer, a division water distributor, a small oil pipe, a second expanding packer, a constant pressure switch and a ball seat which are fixedly connected sequentially from top to bottom; the inner pipe combination comprises the small oil pipe and a division insertion pipe, the division insertion pipe can be correspondingly abutted against a sliding sleeve in the division water distributor, and a gap is reserved between a non-insertion section of the division insertion pipe and a barrel of the division water distributor; the string is tripped in the designated location of a sleeve, and a steel ball is put on the ball seat; and setting pressure of the first expanding packer and setting pressure of the second expanding packer are smaller than shearing pressure of a shear pin of the constant pressure switch. The three-layer separate injection string is simple in structure and convenient to operate, not only can realize three-layer separate water injection and well washing, but also improves the water injection effect and the flexibility of water injection and well washing deployment greatly.

Owner:PETROCHINA CO LTD

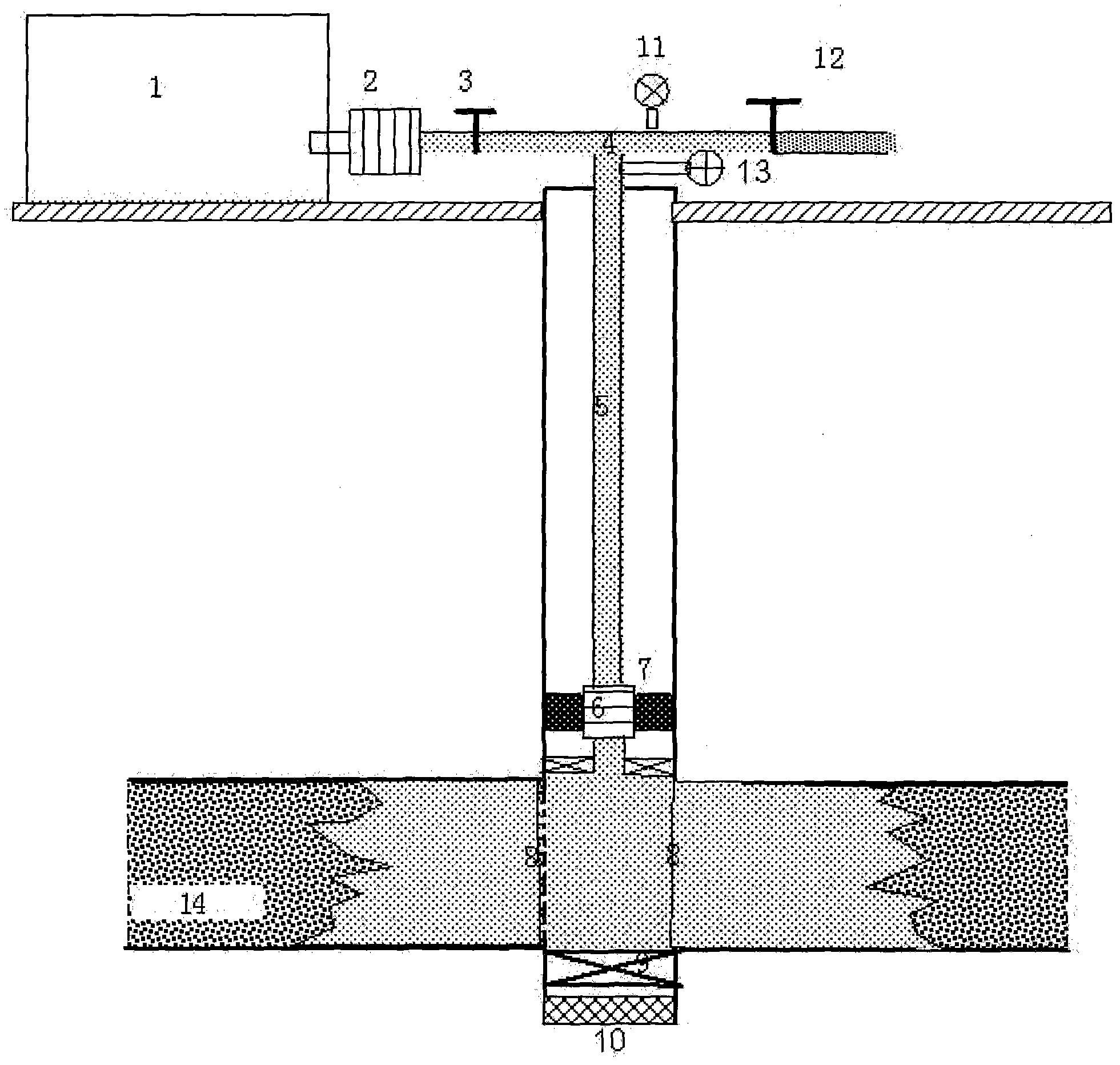

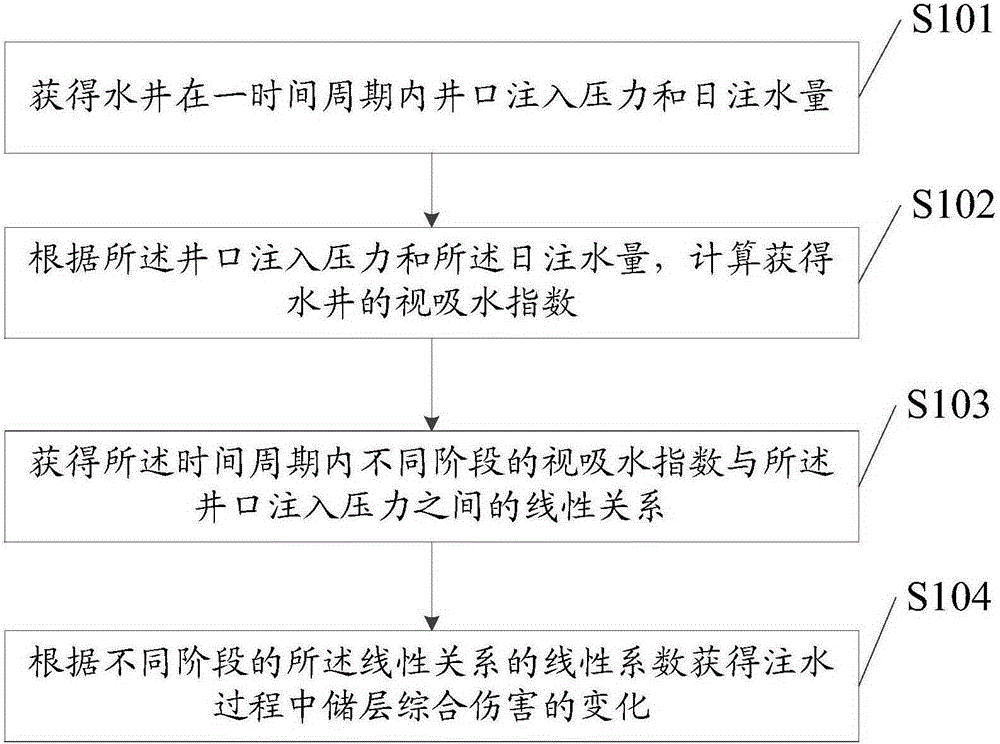

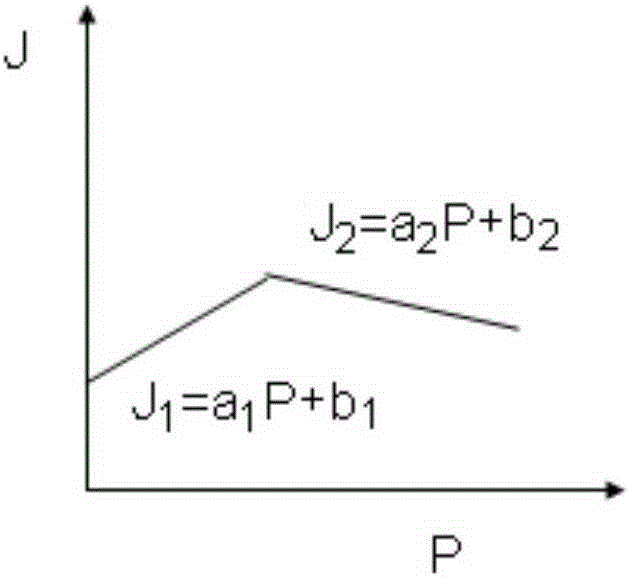

Method and apparatus for acquiring reservoir comprehensive damage during water injection process

ActiveCN105298483AReduce damageImprove water injection effectBorehole/well accessoriesInjection pressurePhases of clinical research

The invention discloses a method and apparatus for acquiring reservoir comprehensive damage during a water injection process. The method comprises following steps: acquiring the wellhead injection pressure and daily water injection amount of a well in a time period; calculating apparent injectivity indexes of the well according to the wellhead injection pressure and daily water injection amount; acquiring linear relations of the apparent injectivity indexes and the wellhead injection pressure at different stages of the time period; and acquiring the change of the reservoir comprehensive damage during the water injection process according to linear coefficients of the linear relations at the different stages. According to the technical scheme mentioned above, a technical problem in the prior art that the change of the reservoir comprehensive damage cannot be determined is solved, and technical guidance is provided for intensified injection measures for water injection wells, so that the damage degree can be reduced, and the water injection capability is enhanced.

Owner:PETROCHINA CO LTD

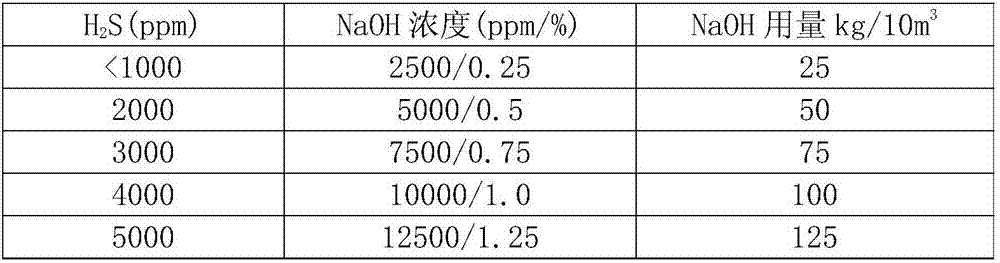

Method for treatment of hydrogen sulfide in oil well

ActiveCN106968639AEfficient removalGrowth inhibitionSurveyFlushingSulfate-reducing bacteriaOperability

The invention discloses a method for treatment of hydrogen sulfide in an oil well. The method comprises the following steps that (1) a hydrogen sulfide treatment technological pipe column is placed down; (2) a sodium hydroxide solution is used for well washing firstly, and then water is used for well washing; (3) a water reagent is used, and the water absorbing index is figured out under the pressure intensity of 18 MPa; (4) a sulfate reducing bacterium inhibitor solution is injected in a squeezed mode, water is injected for substituting, and the treatment radius of the oil well is 2-4 m; (5) a tetrakis hydroxymethyl phosphonium sulfate (THPS) bactericide solution is injected in a squeezed mode, and water is injected for substituting; and (6) the well is closed to conduct reaction for 10 days, and the well is opened to conduct normal production. According to the method for treatment of the hydrogen sulfide in the oil well, hydrogen sulfide gas and ferrous sulfide scale can be effectively eliminated, growth of sulfate reducing bacteria in a stratum can be effectively inhibited, and thus the oil can recover normal production; and the blank that due to water injection, the hydrogen sulfide content of the stratum exceeds the standard, and treatment is conducted is filled up, and the method has the advantages of being simple, high in operability, effective, practical and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

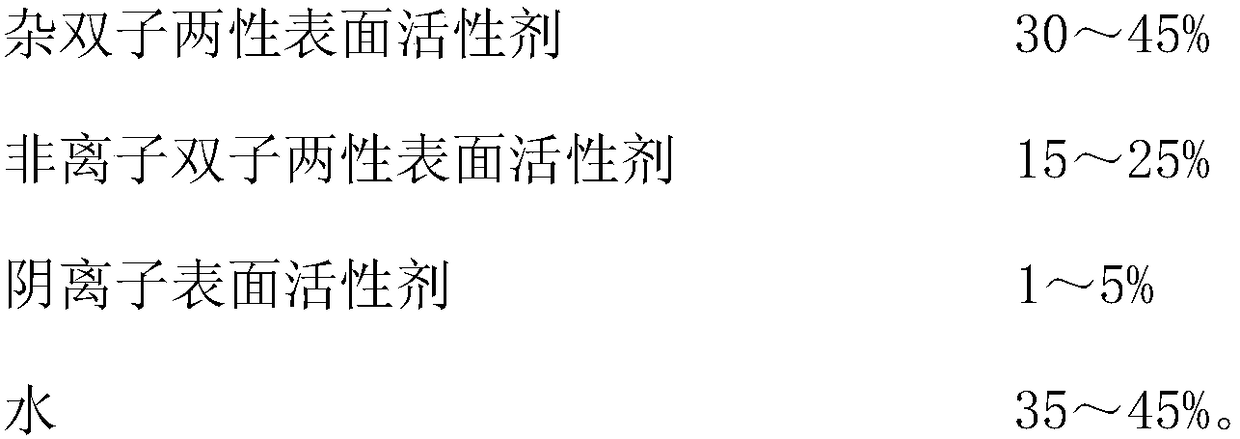

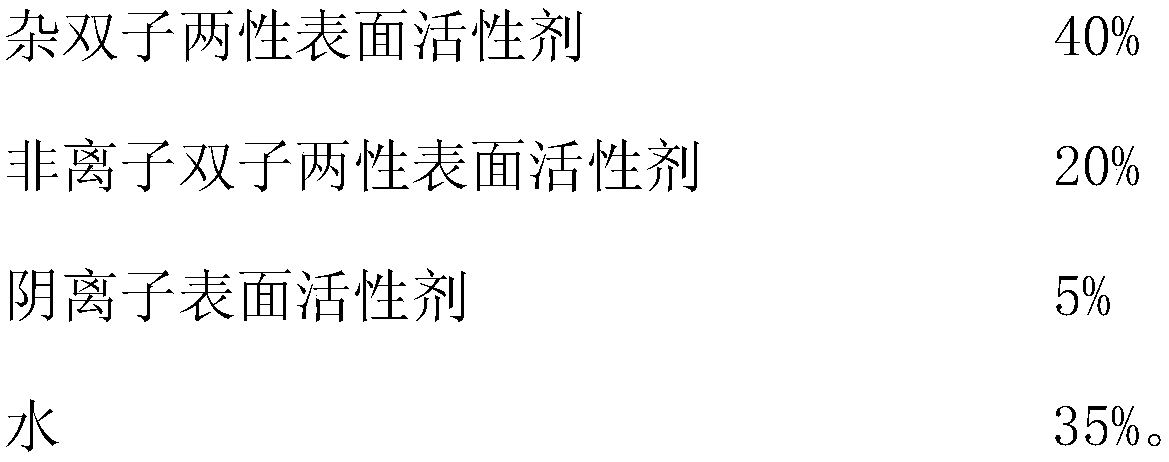

A decompression and injection-stimulation gemini surfactant system for oil fields and a preparing method thereof

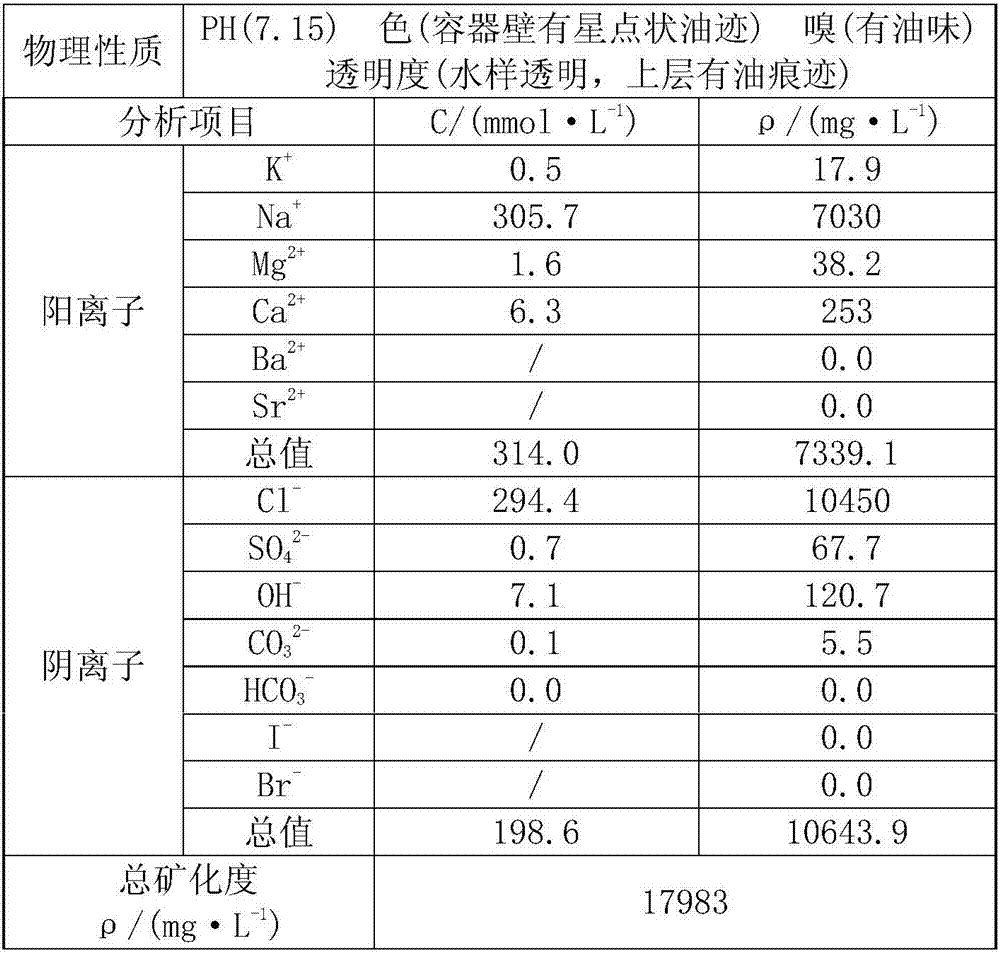

InactiveCN109111908AReduce water injection pressureIncrease the areaDrilling compositionSalt resistanceSalt content

A decompression and injection-stimulation gemini surfactant system for oil fields and a preparing method thereof are provided. The system is a mixed system consisting of a heterogemini amphoteric surfactant as a main component, a nonionic amphoteric gemini surfactant as an auxiliary agent, an anionic surfactant and water. Compared with products in the prior art, the system has a wide spectrum anda wide adaption range; the system has a wide application concentration range, and the interfacial tension of the system can still be 10<-3> mN / m with a low application concentration (0.1%); the systemhas good wettability, high permeability, high oil washing efficiency, and good salt resistance, and is free of precipitate and turbid phenomena in an aqueous solution having a salt content of 100,000ppm (with the content of calcium and magnesium ions being 5,000 ppm); the system is resistant to high temperature and wide in application temperature range; the system is neutral, free of organochlorine and free of alkali and does not cause harm to stratums; and the system can greatly reduce water injection pressure for a water injection well and increase the water injection efficiency.

Owner:东营利丰化工新材料有限公司

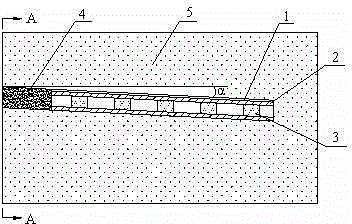

High-low-pressure subarea fracturing anatonosis type coal seam water injection method

ActiveCN105649625AImprove permeabilityImprove water injection effectUnderground miningDust removalSlagMolecular materials

The invention discloses a high-low-pressure subarea fracturing anatonosis type coal seam water injection method. The method comprises the steps that drilling, hole sealing and water injecting are carried out on a coal face dynamic pressure area; drilling, hole sealing and water injecting are carried out on a coal face static pressure area; the coal face dynamic pressure area is a coal seam area distancing from the coal wall of a working face by 70-150 meters, and the coal face static pressure area is a coal seam area distancing from the coal wall of the working face by over 150 meters. The subarea coal seam drilling and water injecting mode is adopted, a twisted drill stem is selected as a drill stem adopted in the coal face dynamic pressure area, which is beneficial for discharging slag; moreover, a water powder swelling type hole sealing device and a high-molecular-material plugging structure are adopted for combined hole sealing, and then low-pressure water injecting is carried out; the coal face static pressure area is drilled multiple times by the adoption of a sectional type drilling implementation method, meanwhile, a three-ridge drill stem is selected, the contact area between the drill stem and the hole wall is reduced, and the phenomenon of tool sticking is prevented; high-pressure water injection is implemented to increase permeability of a coal seam, so that the coal seam water injection is optimal, and drilling and water injection efficiency are improved.

Owner:SHANDONG UNIV OF SCI & TECH

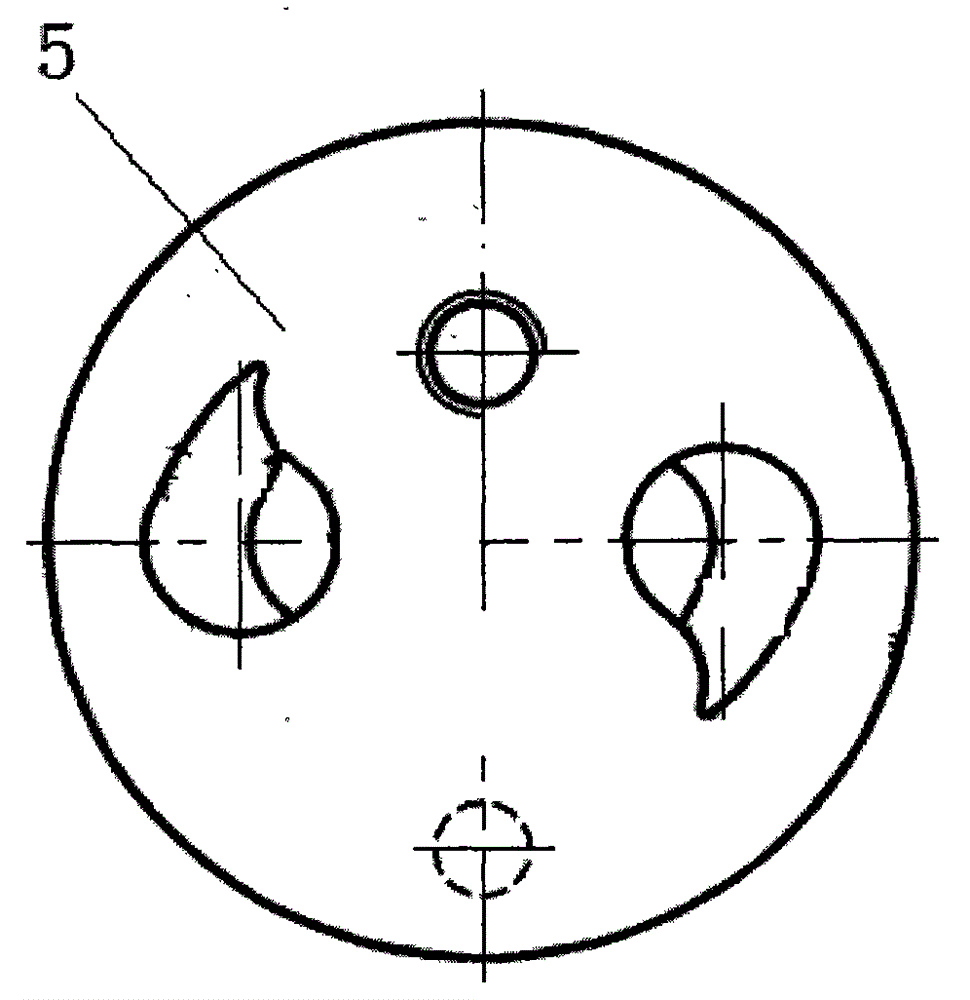

Dual-purpose hole sealing device for gas extraction and coal seam water injection and using method thereof

ActiveCN110145272AImprove gas drainage or water injection effectReduce sealing costSealing/packingCoalWater pipe

The invention discloses a dual-purpose hole sealing device for gas extraction and coal seam water injection and a using method thereof. The dual-purpose hole sealing device consists of an extraction tube / water injection tube, a high-elasticity rubber tube, an integrated type elastic bag which is formed by inside and outside sealing elastic bags and a connecting tube thereof, and a grouting tube, wherein the extraction tube / water injection tube passes through the rubber tube, and is in sealing connection to two ends of the rubber tube; the water inlet tube and a water drainage tube are separately equipped with a switch and a one-way valve; the integrated type elastic bag covers the rubber tube; the grouting tube passes through the inside and outside sealing elastic bags which are in sealingconnection to the grouting tube, one-way valves are arranged in the inside and outside sealing elastic bags, and explosion valves are arranged between the inside and outside sealing elastic bags. Theusing method for the dual-purpose hole sealing device comprises the following steps: injecting water, grouting, grouting towards a grouting space through the explosion valves, stopping grouting, re-injecting water before slurry is solidified to keep water pressure constant, and taking out the extraction tube and the rubber tube to repeatedly use after gas extraction or water injection is accomplished. The dual-purpose hole sealing device can completely remove gas in the grouting space, eliminates appearance of drilling cracks and increases a crack sealing range in drilling surrounding rock bykeeping grouting pressure constant, and increases gas extraction amount or improves water injection effect.

Owner:LIAONING TECHNICAL UNIVERSITY

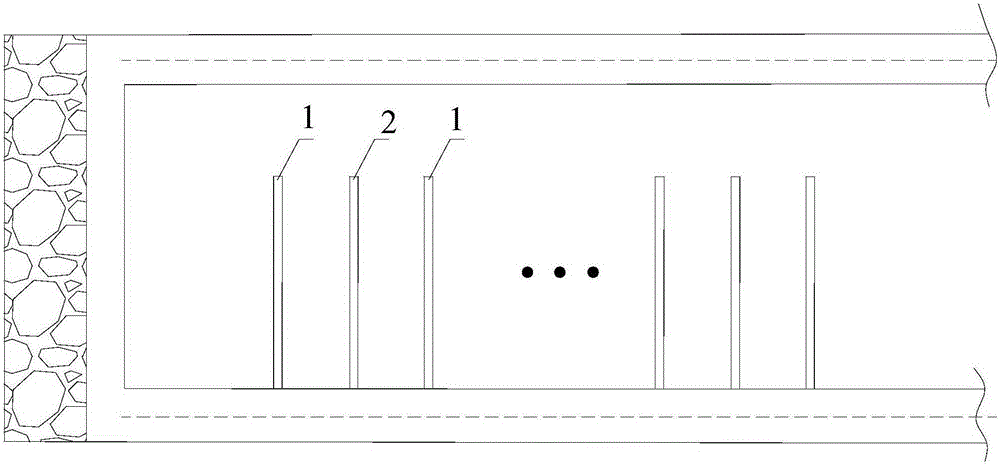

Rock burst preventing method for blast and injection of water-coupled softened coal body

InactiveCN106884656ABreach of integrityImprove water injection effectDisloding machinesUnderground miningGeomorphologyRock burst

The invention discloses a rock burst preventing method for a blast and injection of water-coupled softened coal body, and is suitable for rock burst disaster prevention of coal mining, and in particular to rock burst prevention of a tight and hard coal bed which is hard to inject water to soften. The method disclosed by the invention comprises the following steps: firstly, constructing water injection holes and blast holes in a coal wall of a lane, wherein the water injection holes and the blast holes are alternately formed, that is, the blast holes are formed between two adjacent water injection holes; then performing loose blasting on the coal body through the blast holes to relieve the pressure of the coal body and form blast gaps in the coal body; and then injecting water into the coal body in the water injection holes to soften the coal body. Gaps are distributed by taking the blast holes as the center in coal body blast, so that the water injection property of the coal body is increased. After blast, the coal body is injected with water, so that the water injection resistance is reduced and the water injection rate is increased; the coal bed which is originally hard to inject water, or even is hardly injected with water to soften, is injected with water to soften, so that the rock burst disaster is effectively prevented. The method is simple to operate, safe and practical and good in pressure relieving effect.

Owner:CHINA UNIV OF MINING & TECH

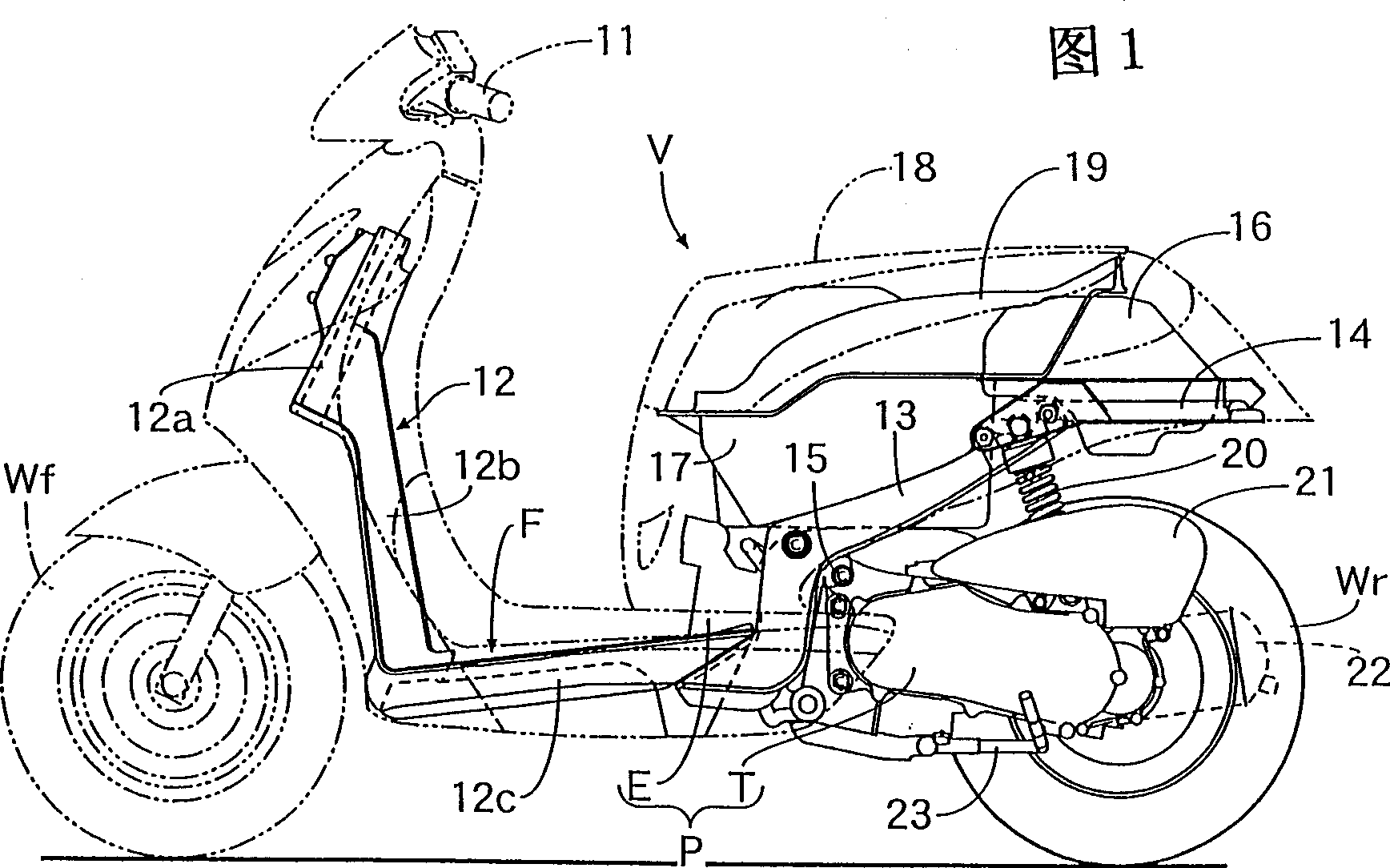

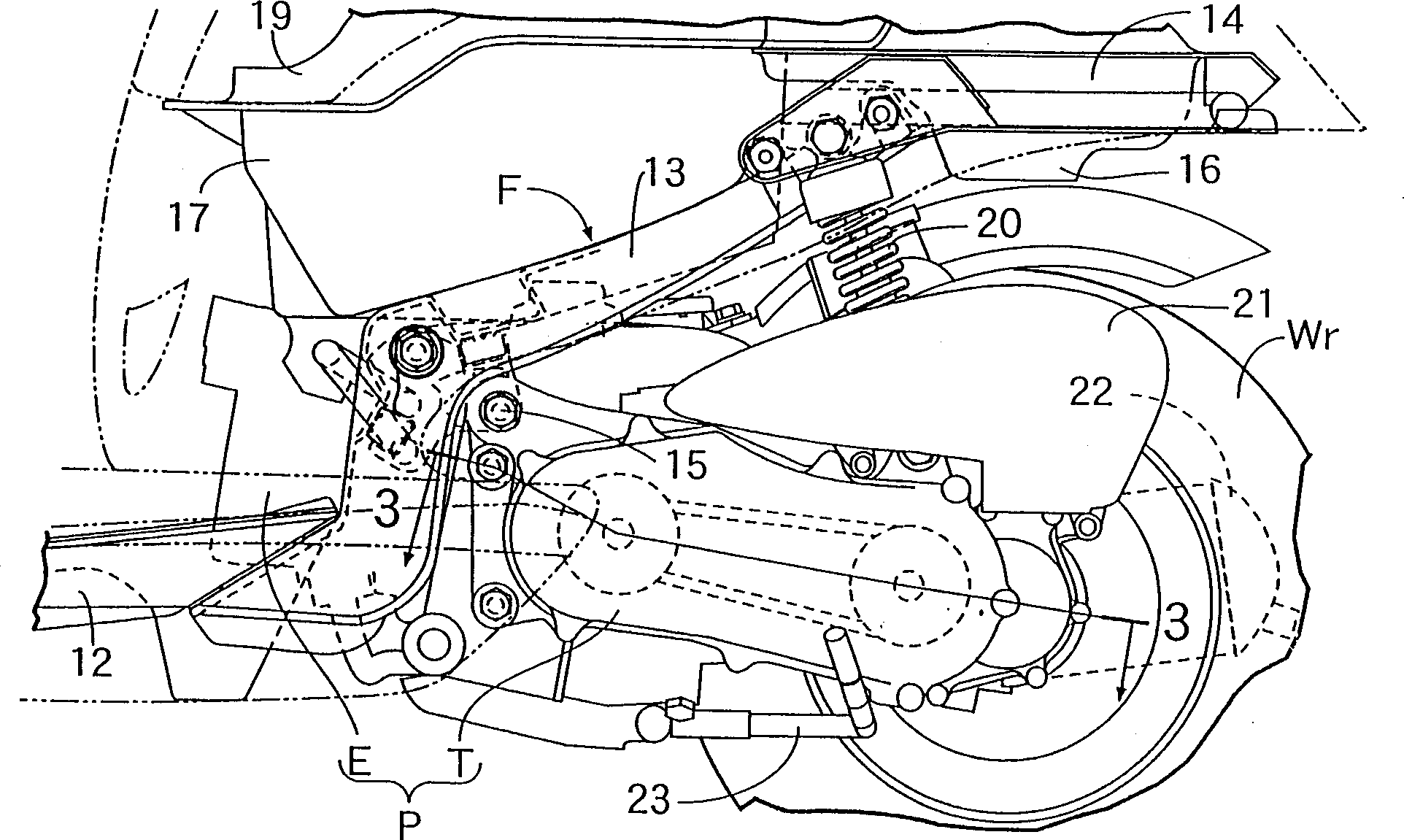

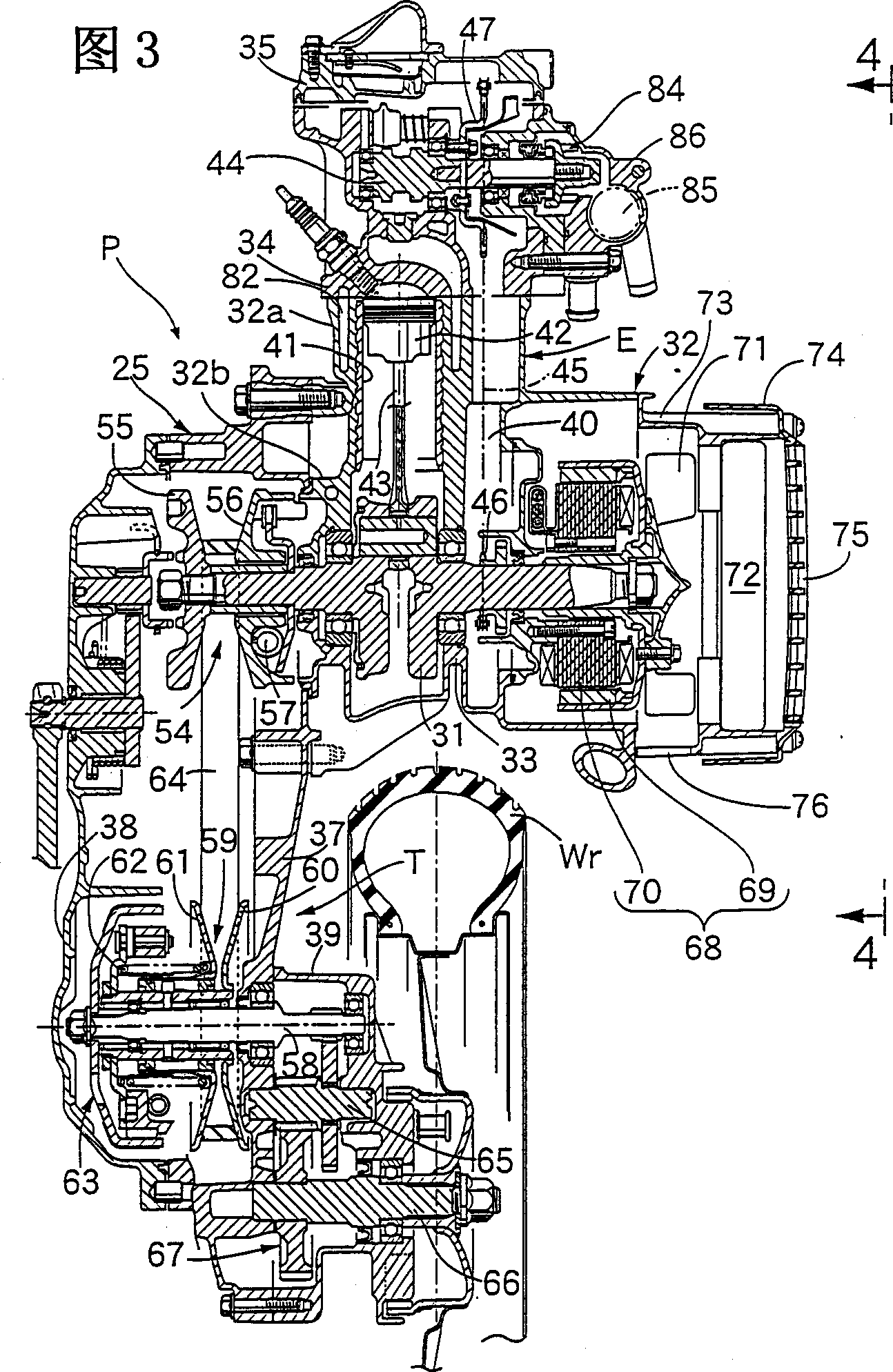

Radiator mounting structure in vehicles

InactiveCN1350111AAvoid increasing costsImprove water injection performanceLiquid coolingCycle equipmentsIn vehicleWater jacket

In a vehicle in which an engine main body is mounted to a vehicle body frame in an attitude in which an axis line of a cylinder bore is substantially in line with a front and rear direction of the vehicle body frame and a radiator constituting a portion of a cooling apparatus capable of circulating cooling water of a water jacket is attached to the engine main body at a side of the cylinder bore, to promote air bleeding performance and water filling performance in the cooling apparatus while avoiding an increase in cost. Therefor, a water filling cap 88 is attachably and detachably mounted to an upper end of a water filling pipe 87 extended upwardly from one end portion of an upper tank 77 in line with a front and rear direction of a vehicle body frame and a radiator 72 is attached to an engine main body 25 in an attitude of being inclined to a horizontal face such that the water filling cap 88 is disposed at a topmost position in a cooling apparatus 83.

Owner:HONDA MOTOR CO LTD

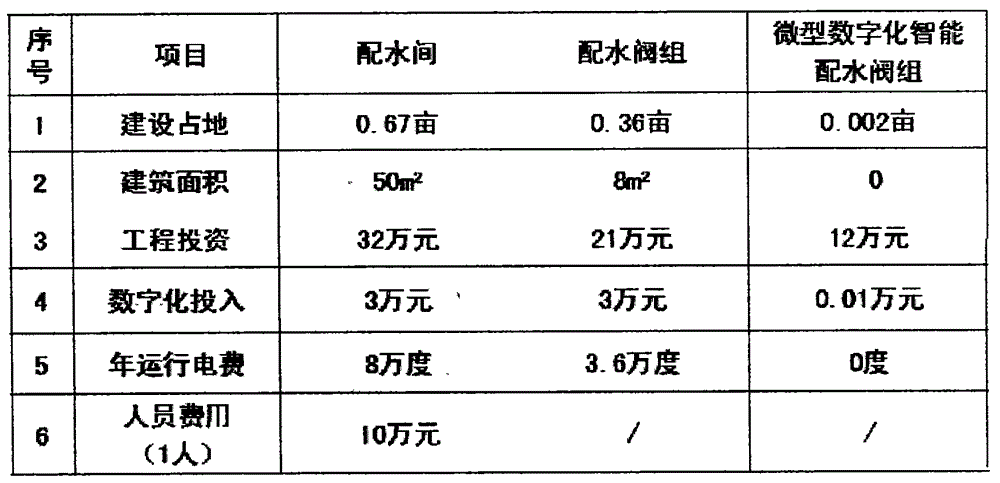

Injection allocation method of internet-of-things solar terminal

ActiveCN105239974ASolve large volume (at least 8m

<sup>3</sup>

above disadvantagesImprove flat ground tensionClimate change adaptationPhotovoltaicsComputer terminalEngineering

The invention relates to the technical field of oil wells, in particular to an injection allocation method of an internet-of-things solar terminal. Instantaneous flow, cumulative flow and instantaneous pressure of a division header pipe and of division branch pipes are acquired at all times; if water injection for a single well is required, gate valves of other diversion branch pipes are closed; if water injection for multiple wells is required for boosting, valve blocks of the gate valves and diversion valves on the diversion branch pipes of the wells requiring water injection are opened; when water injection for one well, namely cumulative flow, reaches 90% of target flow, the diversion valve corresponding to the single well is closed gradually; the acquired instantaneous flow, cumulative flow and instantaneous pressure data are transmitted through an internet-of-things terminal, namely an antenna. The high-precision measurement of parameters such as pressure, instantaneous flow and cumulative flow and the accurate control of a water injection apparatus are achieved effectively using high-performance intelligent precise-control integrated instruments.

Owner:XIAN INT INSTR MEASURE & CONTROL EQUIP

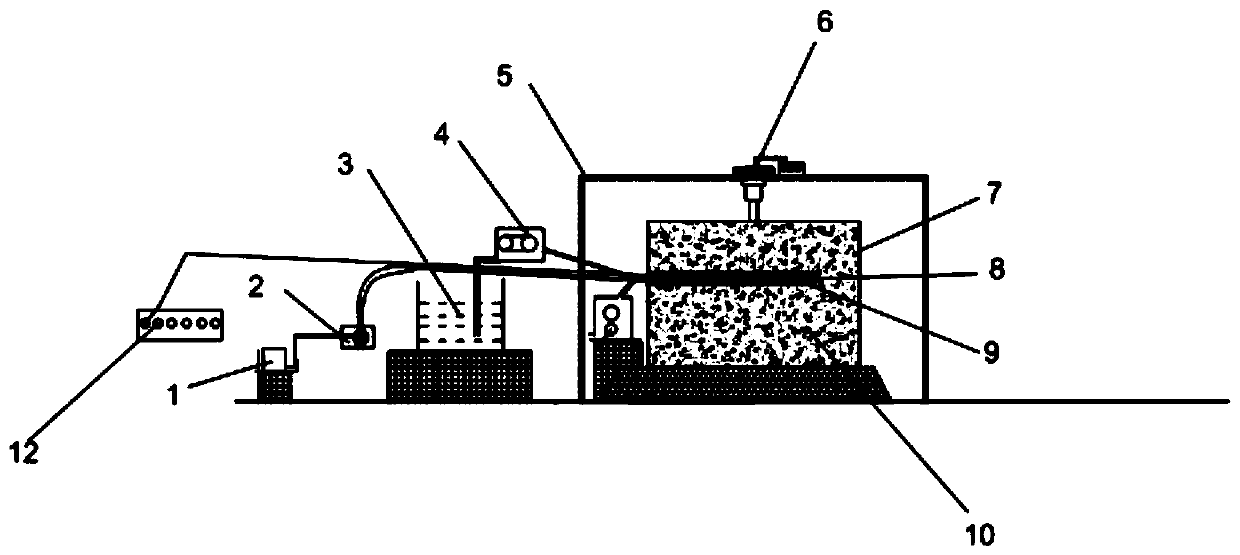

Integrated experimental device and method for preventing and treating coal mine composite dynamic disasters

ActiveCN110017164AReduce gas contentImprove water injection effectGas removalThermodynamicsSoil science

The invention discloses an integrated experimental device and method for preventing and treating coal mine composite dynamic disasters. Water injection and gas extraction are carried out by using thesame borehole segment, the impact tendency of a coal bed is reduced and gas is displaced through water injection, the water injection effect of the coal bed can be improved when the gas pressure in the coal bed is reduced through gas extraction, and the problem that water injection is difficult for the coal bed with high gas pressure and low permeability in deep mining can be solved. The device has the advantages that water injection and extraction can be carried out intermittently and repeatedly at the same time, the water injection effect of the deep high-stress low-permeability coal bed isgreatly improved, and the risk of rock burst and gas outburst composite dynamic disasters is reduced.

Owner:LIAONING UNIVERSITY

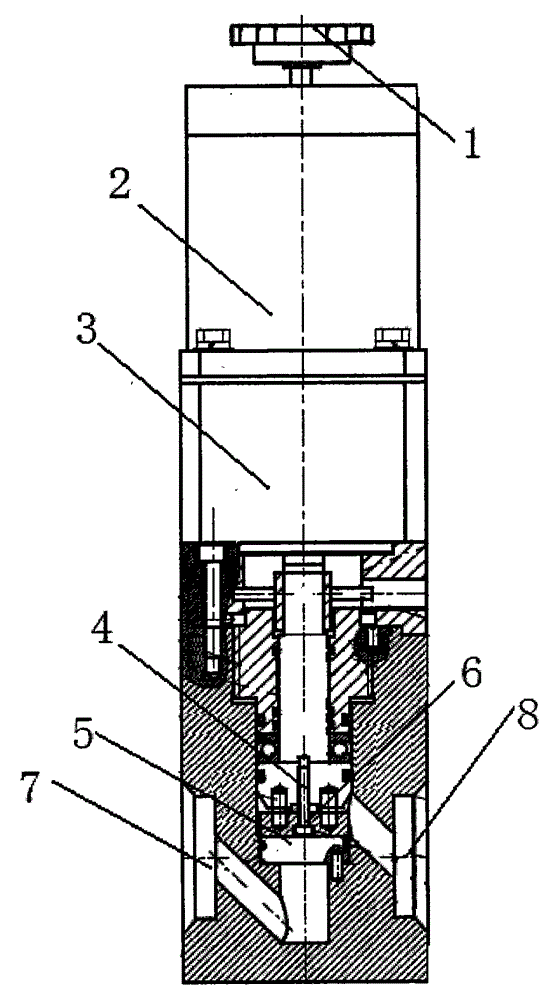

Water nozzle for water injection well in oil field

InactiveCN105257267AGuaranteed water injectionImprove water injection effectFluid removalOpen adjustmentOil field

The embodiment of the invention provides a water nozzle for a water injection well in an oil field. The water nozzle for the water injection well in the oil field comprises an opening determination device, an opening adjustment device, a piston rod and a valve, wherein the opening determination device is used for automatically collecting the current formation pressure data according to a preset period, and determining the current opening, corresponding to the formation pressure data, of the valve; the opening adjustment device is connected with the opening determination device and the piston rod, and is used for pushing the piston rod to move forwards or backwards according to the determined current opening; the valve is fixed on the piston rod, and is used for moving forwards or backwards along with the piston rod, so as to reach the determined current opening. With the adoption of the scheme, the formation pressure can be automatically collected according to the period, and the opening of the valve can be adjusted according to the formation pressure, so that the water injection effect is improved, the injected water volume of the stratum where a blanking plug is positioned is guaranteed, and the amount of labor of manual measurement and adjustment is reduced.

Owner:PETROCHINA CO LTD

Preparation method of normal temperature crosslinking aluminum crosslinker for shale gas fracturing fluid

ActiveCN108690064AReduce corrosionGlue in good conditionGroup 3/13 element organic compoundsDrilling compositionFracturing fluidTemperature resistance

The invention relates to a preparation method of a normal temperature crosslinking aluminum crosslinker for a shale gas fracturing fluid. The preparation method includes the steps: firstly, dissolvingaluminum ion auxiliaries in water to prepare first mixed solution; heating the first mixed solution to reach the temperature of 50-80 DEG C, stirring the first mixed solution and adding an organic matter serving as a complex ligand to obtain second mixed solution; secondly, performing thermostatic reaction on the second mixed solution for 2-4 hours and keeping the second mixed solution clear andtransparent; adding pH (potential of hydrogen) regulators into the second mixed solution and adjusting the pH value of the second mixed solution to be 6.0-8.0 to obtain faint yellow homogeneous transparent liquid. The pH of the crosslinker prepared by the preparation method is 6-8, and corrosion of oil pipe equipment and the like is reduced. Effective crosslinking components are released at normaltemperature and can be crosslinked with low-concentration hydrolytic polyacrylamide in fracturing construction to form a stable gel system, the crosslinker has performances such as strong viscous elasticity, high temperature resistance and high salinity resistance, a most permeable zone can be limitedly plugged, water injection effects are improved, and gas well recovery ratio is increased.

Owner:SICHUAN WELDON CHEM

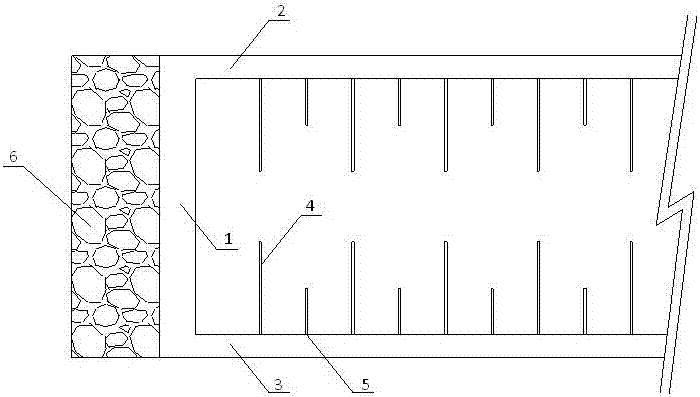

Long-distance deep hole water injection process for coal bed of fully mechanized work surface

InactiveCN102434188AGeneration of controlImprove water injection effectDust removalFire preventionMining engineeringCoal dust

The invention relates to a long-distance deep hole water injection process for a coal bed of a fully mechanized work surface, which can be used for improving the production efficiency and has a good dust removing effect. The long-distance deep hole water injection process comprises the following steps of: a, drilling a driller nest at a coal wall of a construction site of a drilling work surface in advance; b, drilling holes in the driller nest in an extension direction of a roadway; and c, blocking the drilled holes by a hole packer comprising a high-pressure glue expansion pipe, a safe valve and a fast joint, and completely inserting the hole packer into each drilled hole so as to communicate a work field water path with the hole packer, thereby realizing hole package because the high-pressure glue expansion pipe is expanded under the action of water pressure. Four holes are drilled in the step b, wherein the distance between each of two upper holes and a top plate of the roadway is 1 / 3 of height of the roadway, the distance between each of two upper holes and a side wall of the roadway is 1 / 3 of width of the roadway, the distance between each of two lower holes and a base plate of the roadway is 1 / 3 of the height of the roadway, and the distance between each of two lower holes and the side wall of the roadway is 1 / 3 of width of the roadway. According to the long-distance deep hole water injection process disclosed by the invention, the regular construction of a drilling head is not influenced, the production efficiency is improved to a certain extent, the generation of coal dust is effectively controlled from the source, the dust removing effect is good, and the safe production is ensured.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

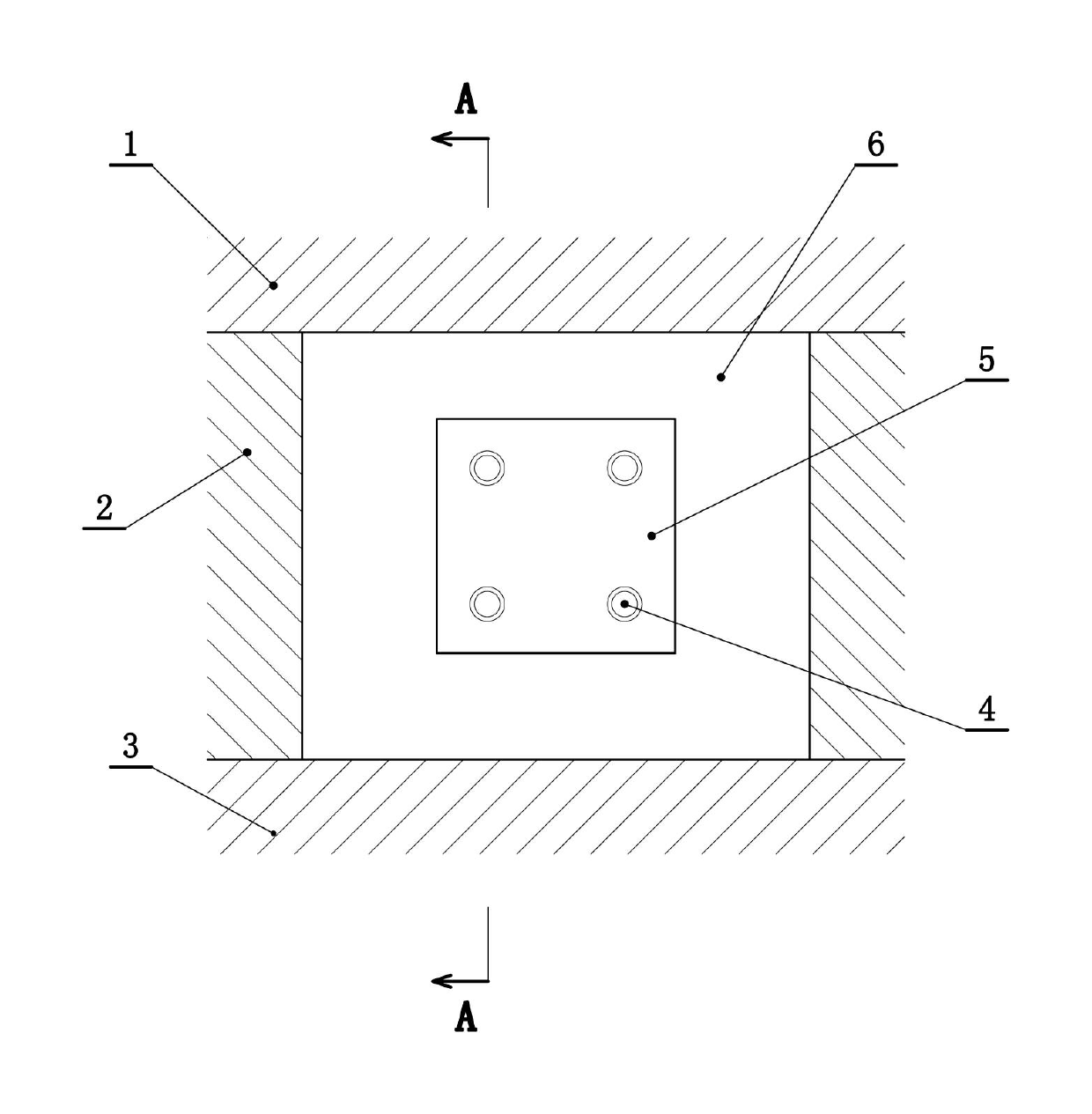

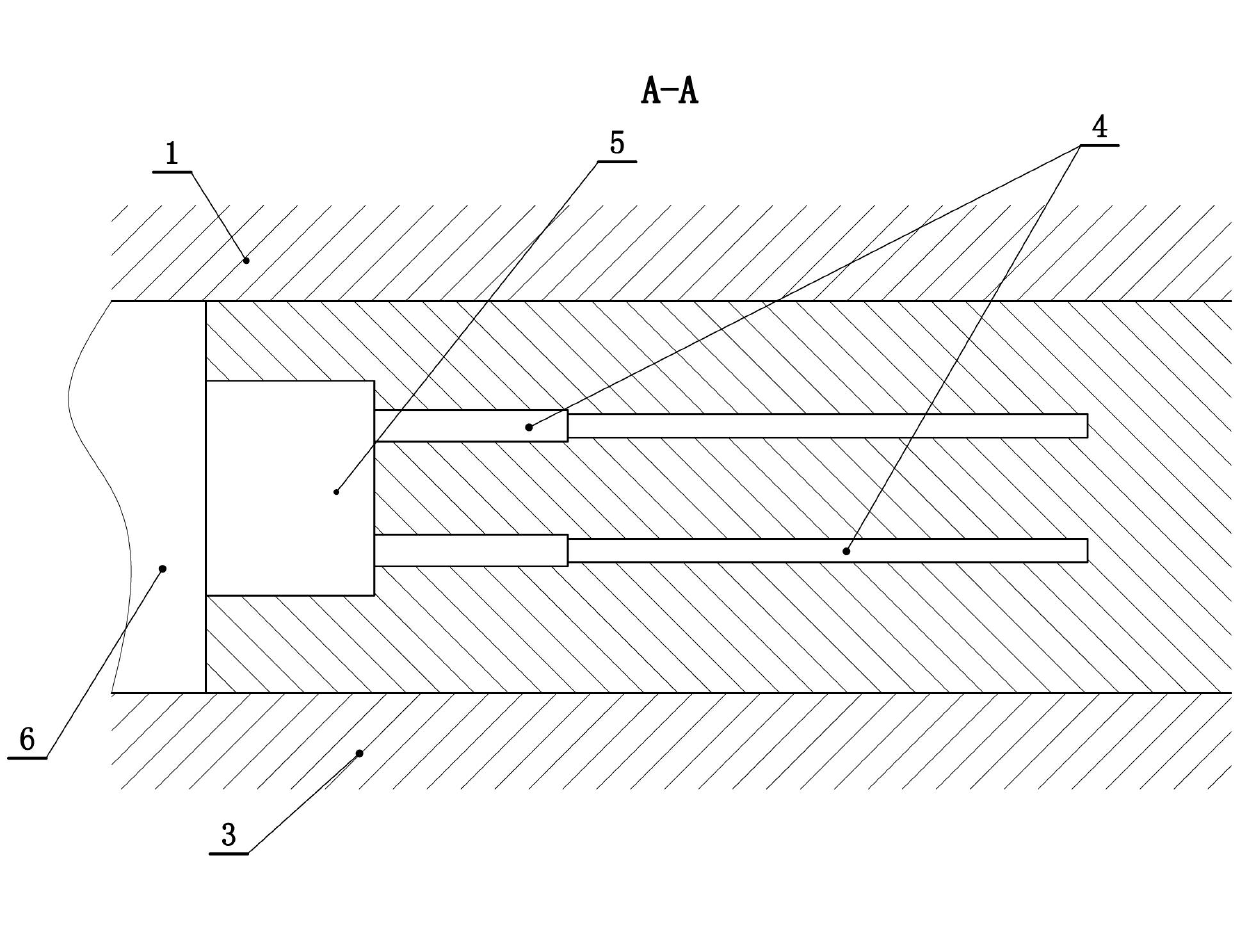

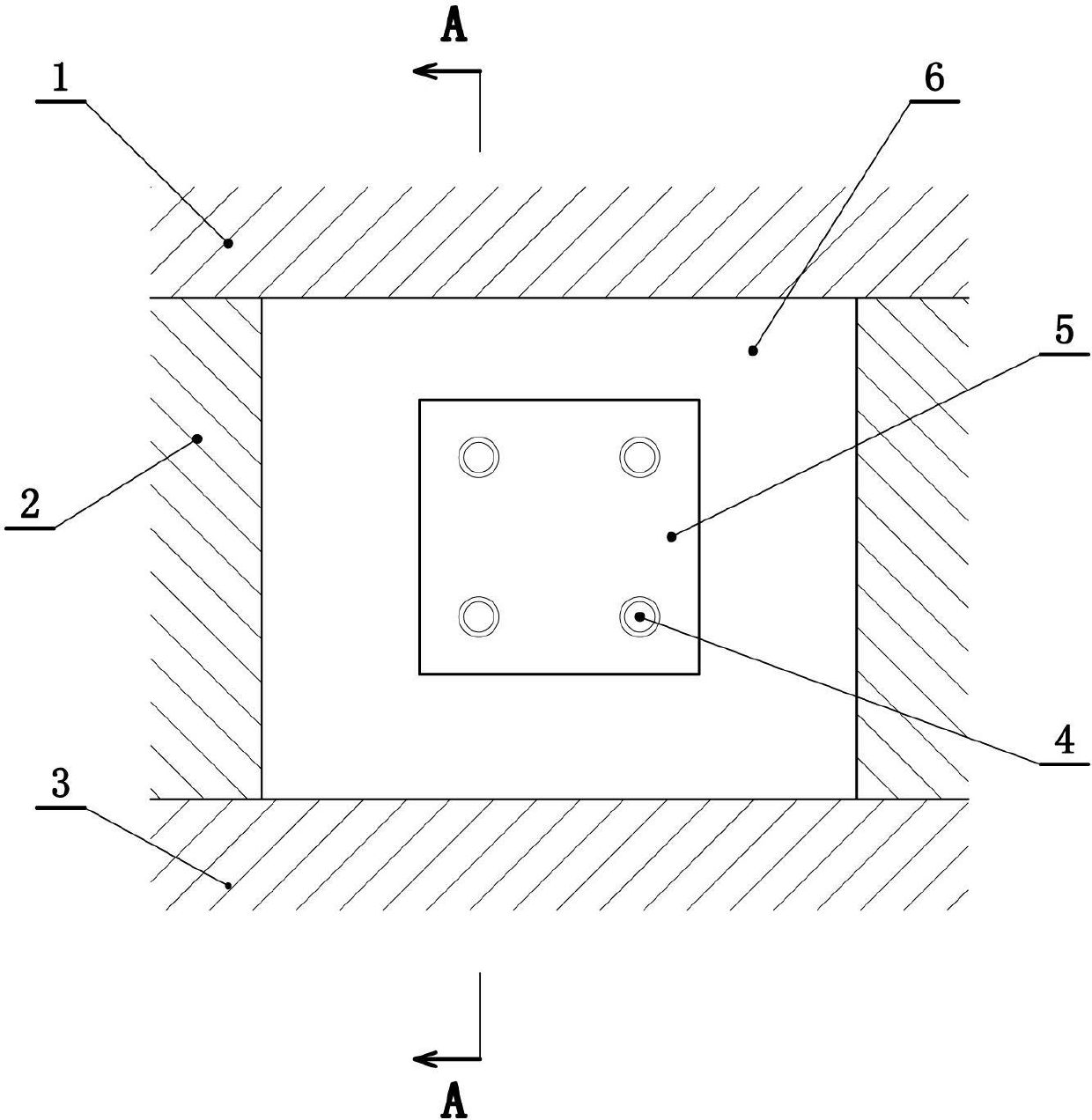

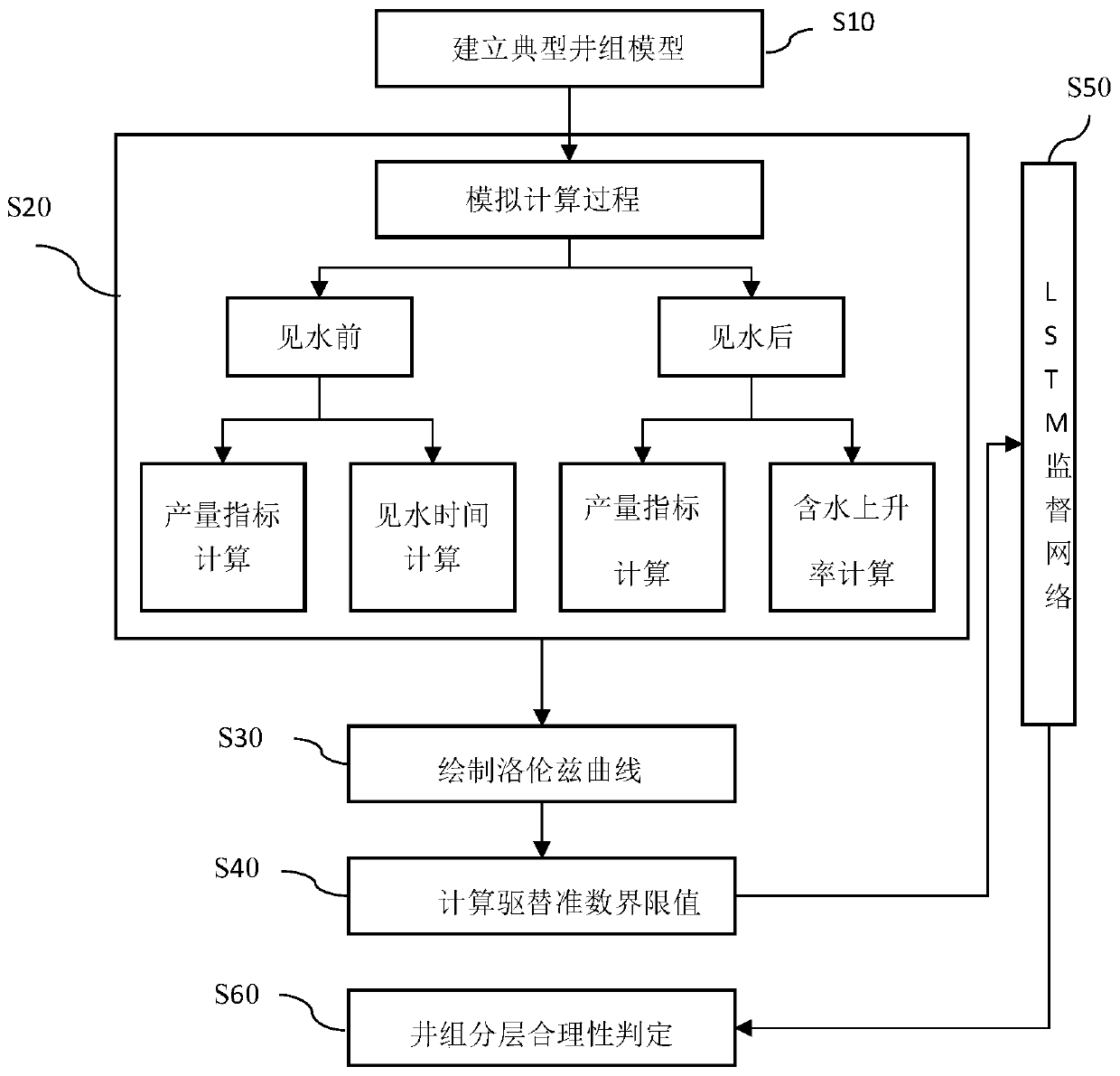

Reasonable layering method of water injection oil reservoir

ActiveCN110765624AImprove accuracyAddress subjectivityClimate change adaptationFluid removalSoil scienceOil field

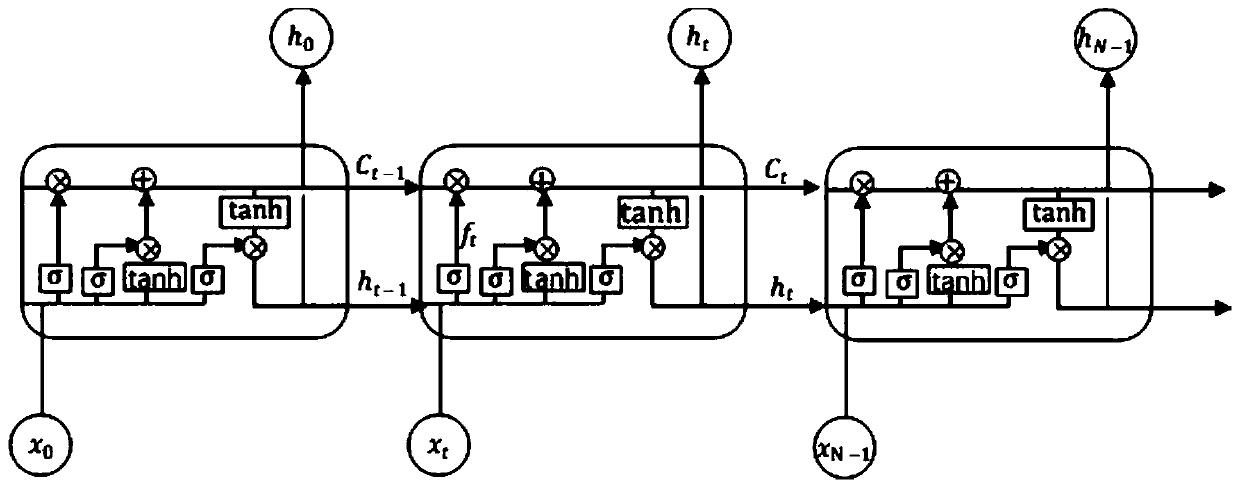

A reasonable layering method of a water injection oil reservoir comprises the steps: S10, establishing a plurality of typical injection-production well group models; S20, performing numerical simulation of multi-layer commingled injection; S30, drawing a Lorentz curve according to the simulated cumulative percentage and yield cumulative contribution rate of each layer of reserves before water breakthrough; drawing a Lorentz curve according to the cumulative percentage of reserves of each layer after water breakthrough and the cumulative contribution rate of the yield to obtain Lorentz coefficients before and after water breakthrough; S40, calculating equilibrium displacement criteria before and after water breakthrough; S50, introducing an LSTM neural network to carry out simulation rationality supervision to obtain a final equilibrium displacement criterion threshold value; and S60, judging the layering rationality of the well group. According to the invention, the Lorentz coefficientis introduced as an evaluation standard, the water breakthrough time level difference of each layer before water breakthrough and the water content rise rate level difference of each layer after water breakthrough which comprehensively consider each dynamic and static factor are taken as economic and technical boundaries of layered water injection. The situation that injected water is not evenlydistributed in the longitudinal direction is improved, the accuracy of oilfield flooding stratification evaluation is improved, the flooding utilization rate is increased, and the method is an effective measure for improving the flooding effect.

Owner:CHINA PETROLEUM & CHEM CORP +2

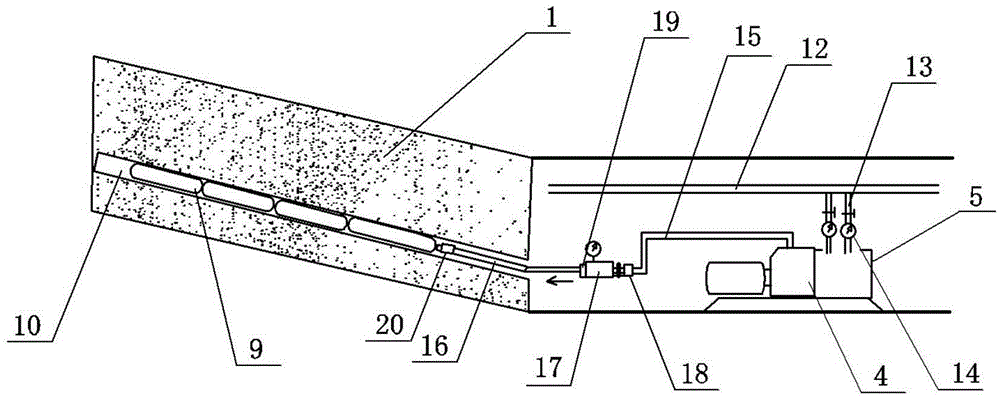

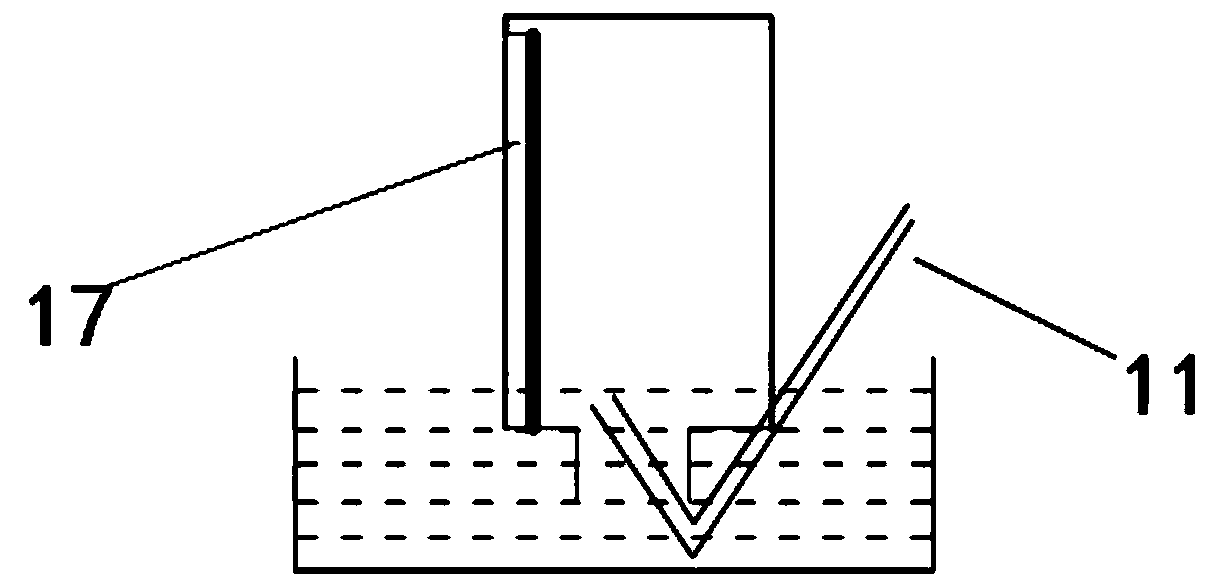

Experimental apparatus for softening hard coal seam through water injection, and application method thereof

ActiveCN107290223ASolve the problem of using mechanized miningSolve technical problems that cannot maintain pressureMaterial strength using tensile/compressive forcesHigh pressure waterEngineering

The invention relates to an experimental apparatus for softening a hard coal seam through water injection, and an application method thereof. The experimental apparatus is provided with a double-end plugging and fracturing device; the double-end plugging and fracturing device comprises a packer; and the packer comprises an outer packer and an inner packer arranged along the length direction of the packer at an interval, and the outer packer and the inner packer are in flexible connection, so enclosed space is formed by a packing section located between the outer packer and the inner packer after pressurization of the outer packer and the inner packer. A high-pressure water injection pump is employed for water injection so as to facture a coal body in the packing section, so the frequent technical problem of incapability of maintaining a pressure during high-pressure water injection can be overcome and conditions are created for subsequent low-pressure infiltration of the coal seam; and the experimental apparatus is simple in structure, good in water injection effect and capable of realizing water injection and pressure maintenance so as to ensure low-pressure infiltration, and thus, the coal seam is effectively softened, the consumption of cutting picks is reduced, and problems in mechanical exploitation of hard coal seams are fundamentally overcome.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Composite gel type profile control agent for oil field water injection well and application thereof

InactiveCN103881671AStir wellEffectively adjust for differencesFluid removalDrilling compositionEconomic benefitsSuspending Agents

The invention provides a composite gel type profile control agent for an oil field water injection well. The composite gel type profile control agent comprises the following components in percentage by weight: 2% of dispersing agents, 0.6% of suspending agents, 0.4% of thiocarbamide, 0.5% of red vitriol and the balance of water. The composite gel type profile control agent for the oil field water injection well, which is provided by the invention, can be used for effectively regulating the water injection interlayer difference of the water injection well and enhancing the water injection effect, thereby increasing the producing reserve of a low-permeability oil reservoir, enhancing the recovery rate, increasing the output and enhancing the economic benefit.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com