Experimental apparatus for softening hard coal seam through water injection, and application method thereof

A coal seam water injection and experimental device technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as increased consumption of picks, unsatisfactory water injection effects, mechanical accidents of coal shearers, etc. , to achieve the effects of weakening the coal seam, solving mechanized mining, and ensuring low-pressure infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

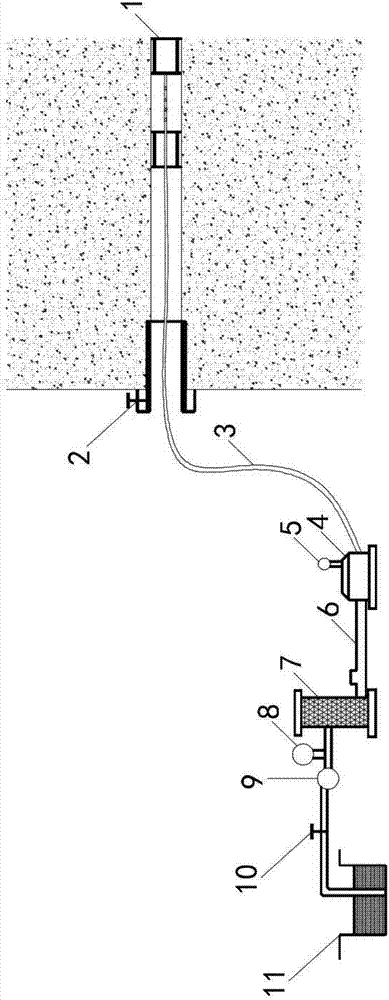

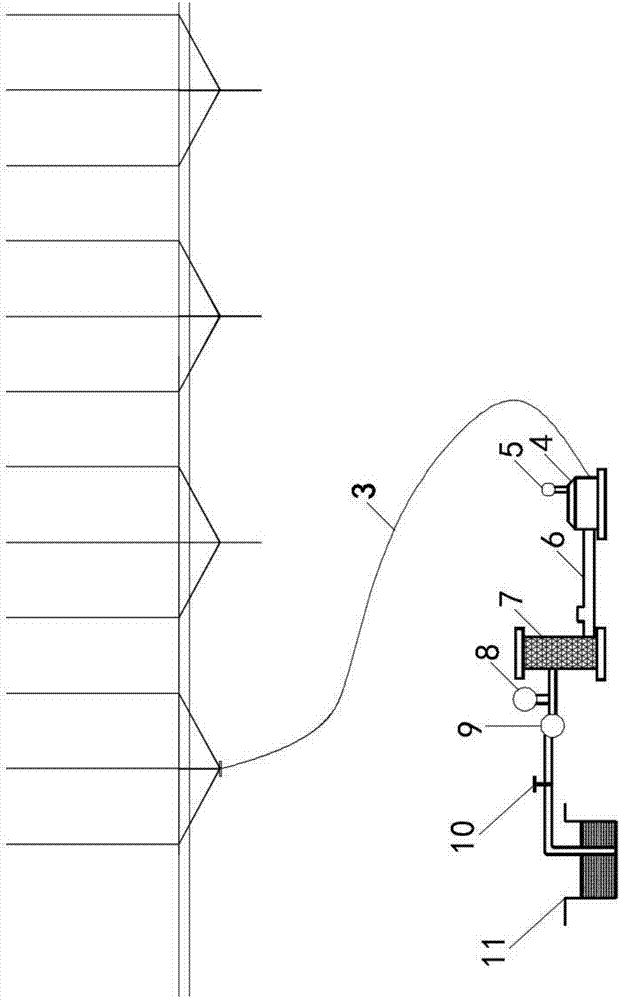

[0030] see figure 1 and 2 , shows the hard coal seam water injection weakening experimental device and its application method of the present invention.

[0031] Such as figure 1 As shown, the hard coal seam water injection weakening experimental device includes an orifice pipe 2, a double-ended plugging fracturing device, a high-pressure water injection pipe 3, a high-pressure water injection pump 4, a low-pressure rubber hose 6, a filter 7 and a water suction pipe.

[0032] The orifice pipe 2 is fixedly socketed and installed on the outer end of the coal seam borehole, and is used to support and fix the double-ended plugging fracturing device and the high-pressure water injection pipe 3 .

[0033] The double-end plugging fracturing device is set in the coal seam borehole, and the double-end plugging fracturing device includes a packer 1, and the packer 1 is composed of outer seals distributed at intervals along its length direction and flexibly connected. A spacer and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com