Method for enhancing water injecting capacity of hypotonic oil field by utilizing nano-powder material

A nano-powder, oilfield water injection technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of reducing the sweeping coefficient of water injection, difficulty in production, small size of seepage channels, etc., and improve water injection capacity. , Improve the permeability of water phase and solve the effect of water injection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

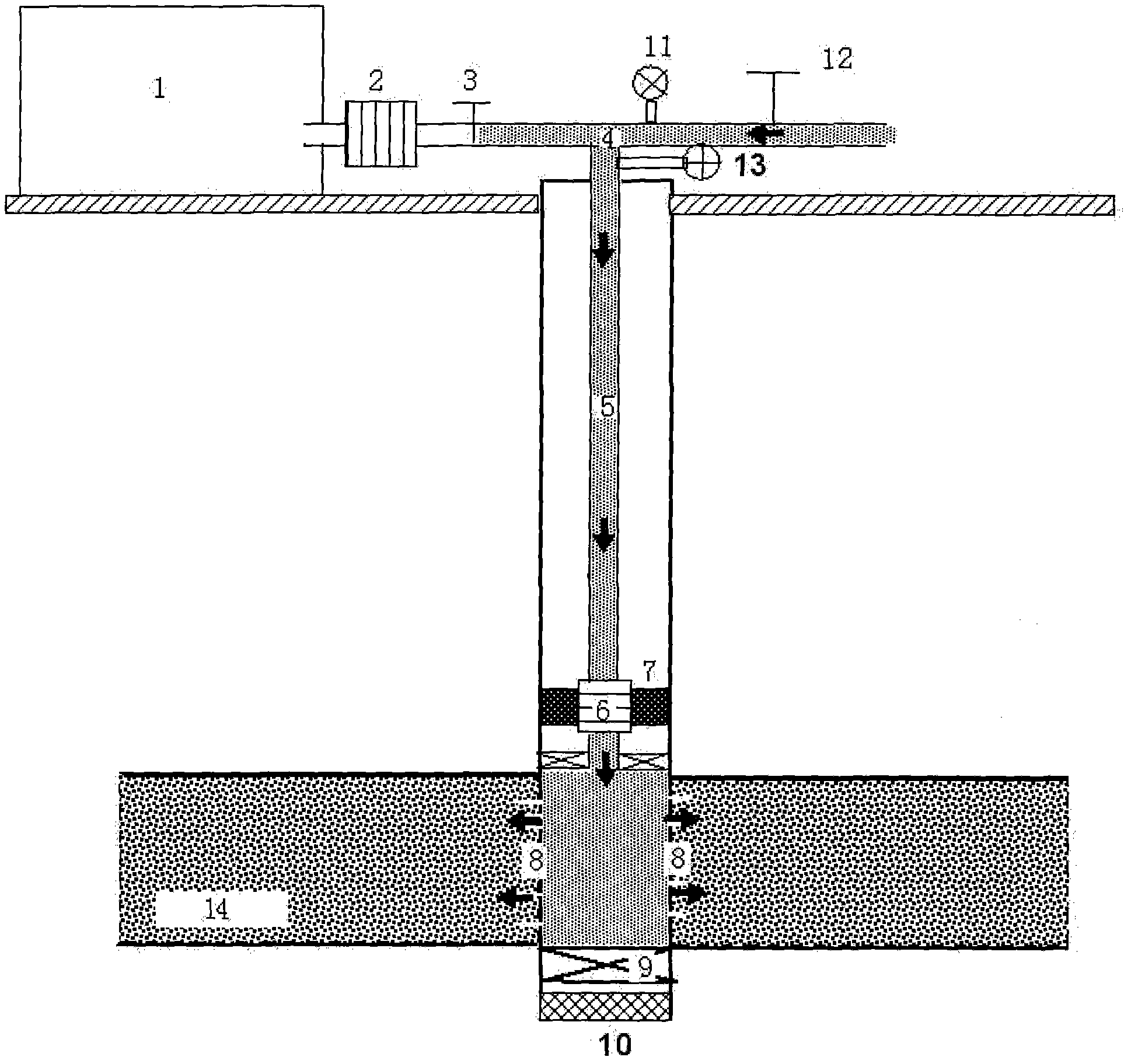

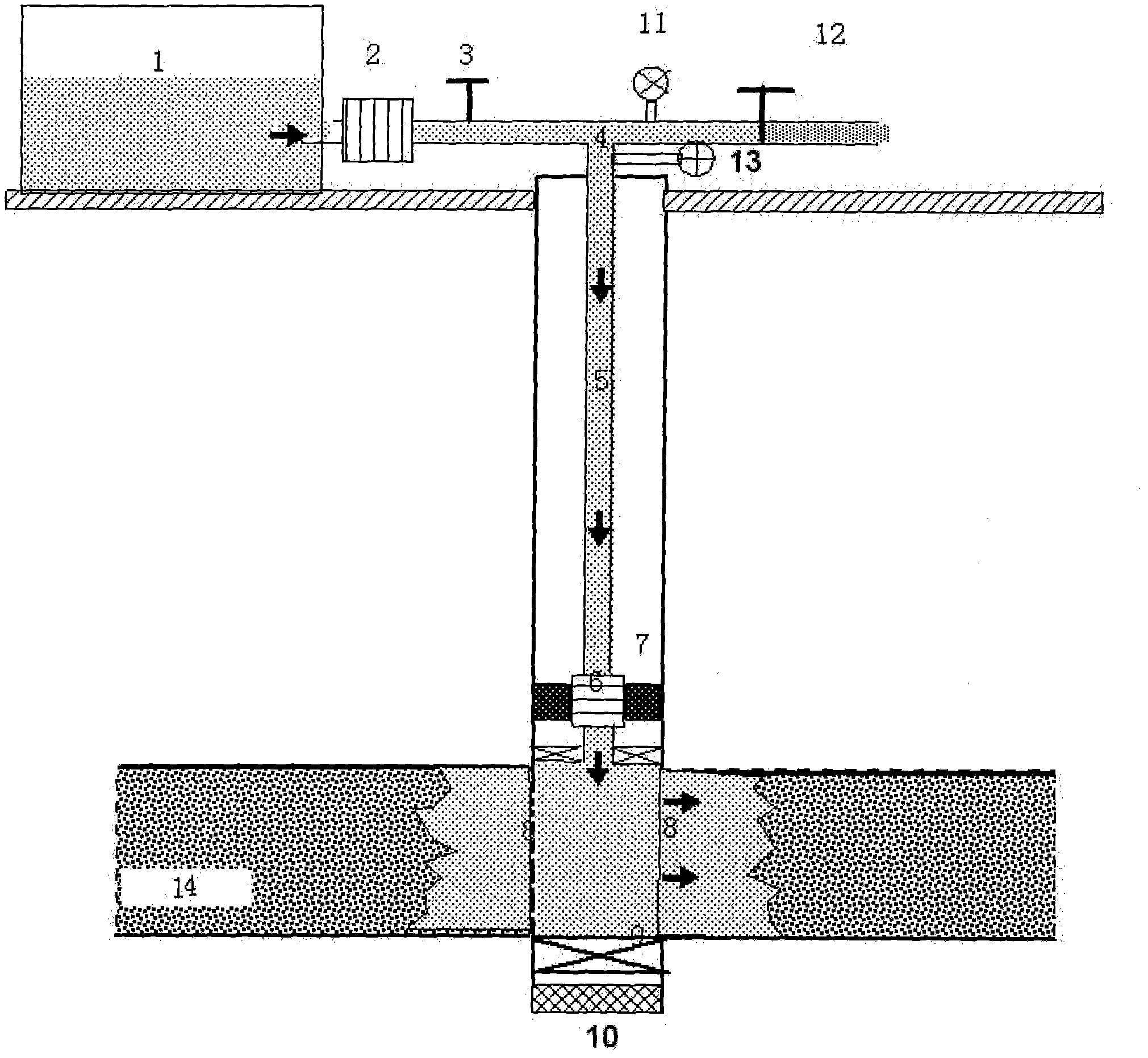

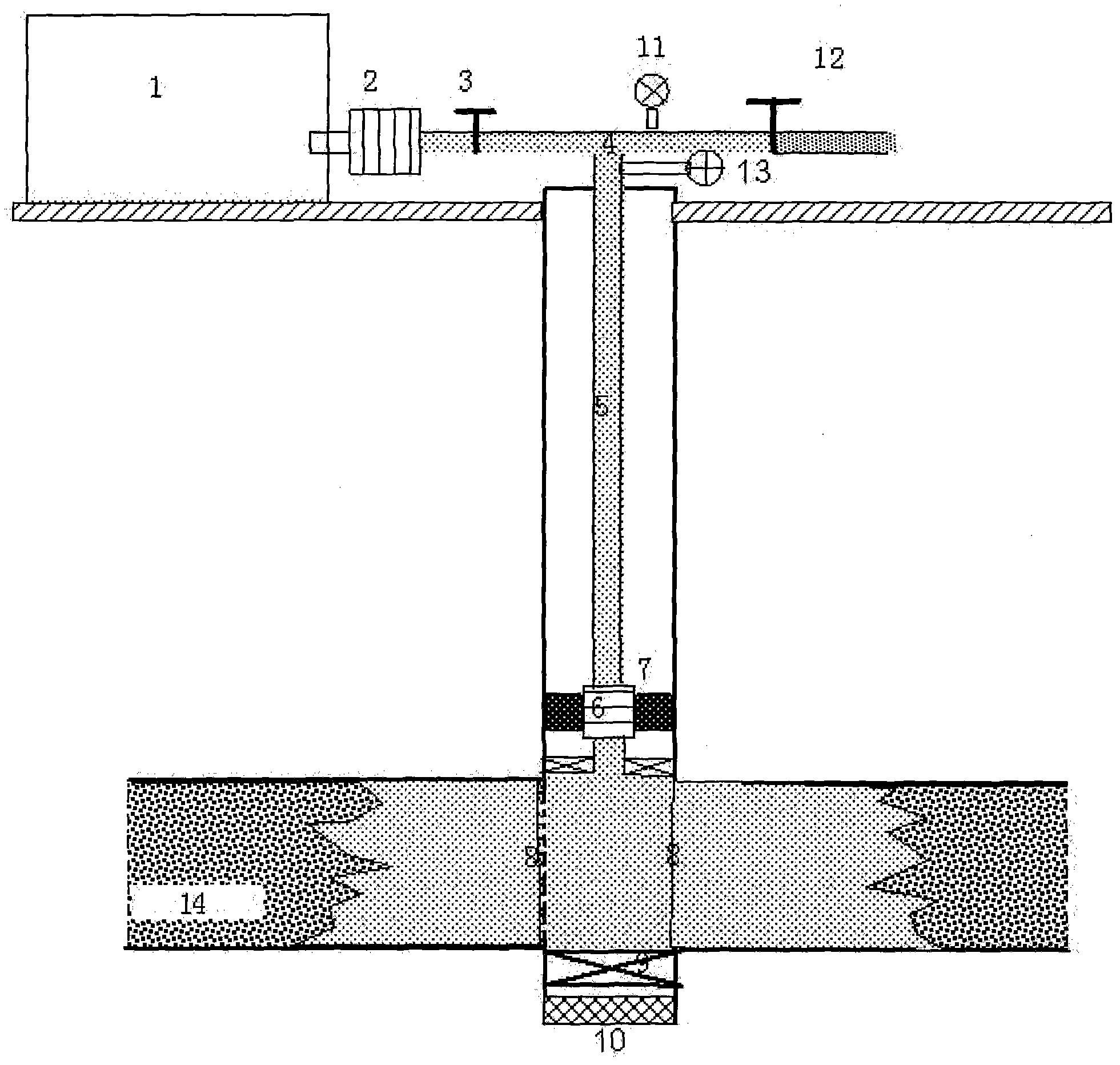

[0023] Please refer to the attached figure 1 To attach Figure 4 As shown, the present invention is a method for enhancing the water injection capacity of low-permeability oil fields by using nano-powder materials, which includes the following process steps:

[0024] 1), configure the treatment agent with container 1, injection pump 2, treatment agent injection valve 3, tee pipe 4, injection-production string 5, reverse flow pump 6, pipe string divider 7, bottom hole divider 9, pressure gauge 11. The water injection valve 12 and the flow meter 13 are installed; wherein, the top end of the injection-production string 5 extends out of the ground, and the bottom end is inserted into the water injection layer 14, and extends to the bottom of the well 10; the treatment agent configuration container 1, injection pump 2. The treatment agent injection valve 3, the tee pipe 4, and the injection-production string 5 are sequentially connected; the string splitter 7 is accommodated in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com