A decompression and injection-stimulation gemini surfactant system for oil fields and a preparing method thereof

A twin-type, surfactant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor effect of measures, reduced water injection capacity, high water injection pressure, etc., to increase the water flooding swept area and swept The effect of high volume, high permeability and high oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

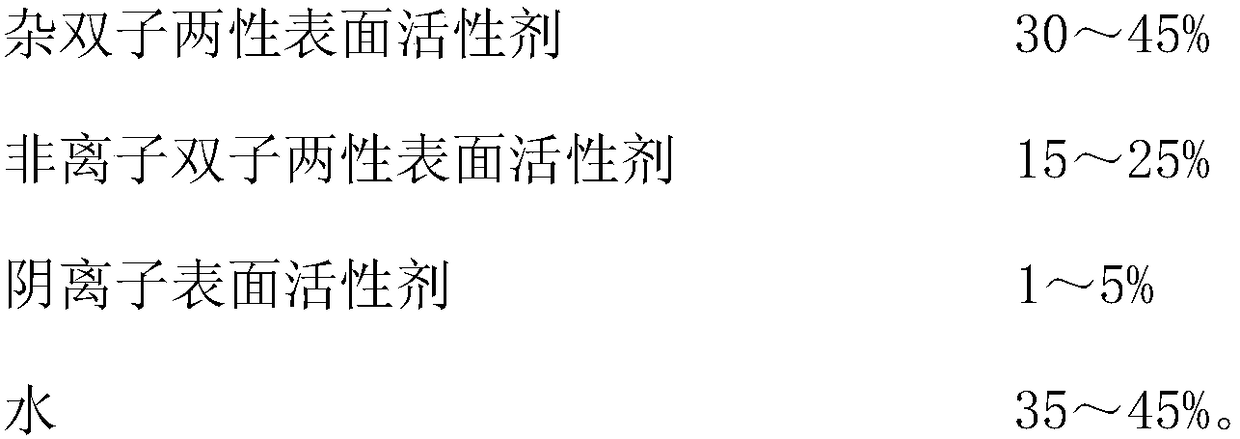

Method used

Image

Examples

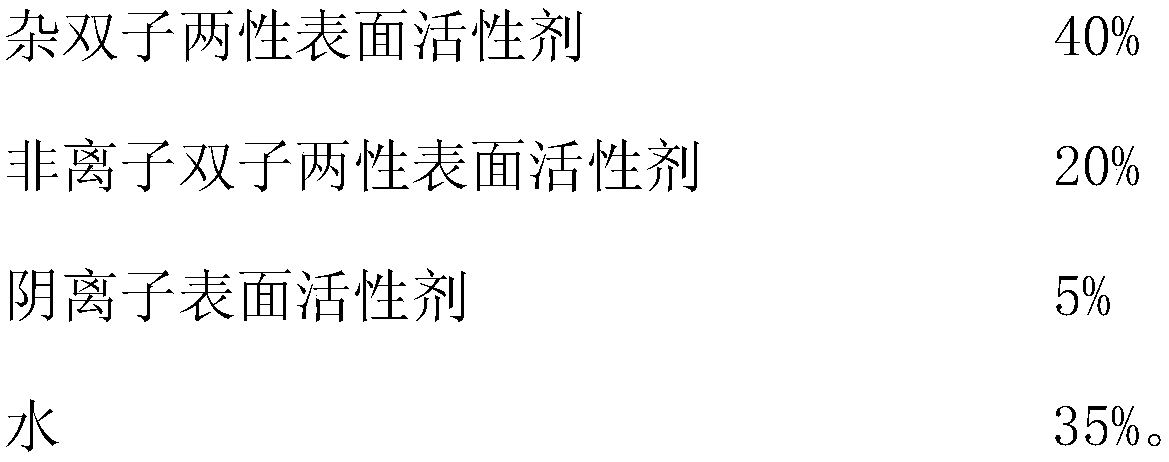

Embodiment 1

[0025] (1) Under normal temperature and pressure, add 35kg of water into the reaction kettle, start stirring, then add 40kg of heterogemini amphoteric surfactant (Xi'an Dingbowei Environmental Protection Technology Co., Ltd. Penetration King), and fully stir for 20 minutes;

[0026] (2) After stirring evenly, add 20 kg of nonionic amphoteric surfactant (carboxylate symmetric type succinic acid diester gemini surfactant), and continue to stir for 20 minutes;

[0027] (3) Add 5 kg of anionic surfactant sodium dodecylbenzenesulfonate after fully stirring, and continue stirring for 30 minutes to obtain the pressure-reducing and increasing-injection surfactant product.

Embodiment 2

[0029] (1) Under normal temperature and pressure, add 40kg of water into the reaction kettle, start stirring, then add 30kg of heterogemini amphoteric surfactant (Xi'an Dingbowei Environmental Protection Technology Co., Ltd. Osmotic King), and fully stir for 15 minutes;

[0030] (2) After stirring evenly, add 25 kg of nonionic amphoteric surfactant (biquaternary ammonium carboxymethyl sodium salt amphoteric gemini surfactant) and continue to stir for 25 minutes;

[0031] (3) After fully stirring, add 5 kg of anionic surfactant sodium diisobutylnaphthalene sulfonate, and continue stirring for 35 minutes to obtain the depressurizing and increasing injection surfactant product.

Embodiment 3

[0033] (1) Under normal temperature and pressure, add 39kg of water into the reaction kettle, start stirring, then add 45kg of heterogemini amphoteric surfactant (Xi’an Dingbowei Environmental Protection Technology Co., Ltd. Penetration King), and fully stir for 25 minutes;

[0034] (2) After stirring evenly, add nonionic amphoteric surfactant (biquaternary ammonium carboxymethyl sodium salt amphoteric gemini surfactant) 15kg, continue to stir for 15 minutes;

[0035] (3) After fully stirring, add 1 kg of anionic surfactant α-olefin sulfonate sodium, and continue stirring for 25 minutes to obtain the pressure-reducing and increasing injection surfactant product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com