High-pressure hydraulic fracturing coal seam water injection system and automatic water injection monitoring method

A technology for hydraulic fracturing and coal seam water injection, which is applied to earth-moving drilling, safety devices, mining devices, etc., can solve problems such as difficult management, occupation of labor, and inability to accurately control water injection pressure and water injection volume, so as to improve water injection. effect, easy to judge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

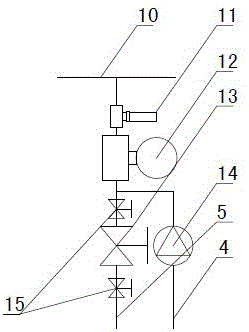

[0030] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0031] Such as figure 1 As shown, the high-pressure hydraulic fracturing coal seam water injection system includes a control box 9, one end of the feed switch 8 is connected to the control box 9, and the other end is connected to the booster pump 6 through the start-stop sensor 7. The inlet of the pressurizing unit of the pressurizing pump 6 is connected with a static pressure water injection pipeline 4, and the water in the static pressure water injection pipeline 4 is pressurized by the pressurizing unit of the pressurizing pump 6, and is driven by the outlet port of the pressurizing unit. The pressure water injection pipeline 5 outputs, the dynamic pressure water injection pipeline 5 is connected in a plurality of water injection units 3 arranged side by side, and the static pressure water injection pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com