Method for treatment of hydrogen sulfide in oil well

A technology for hydrogen sulfide and oil wells, which is applied in chemical instruments and methods, earthwork drilling, wellbore flushing, etc. It can solve problems such as high sulfate ion content, abnormal production of oil wells, and safety issues, so as to improve water injection effect and control Effective, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Control the method that hydrogen sulfide content exceeds the standard in the oil well

[0024] First determine the cause of hydrogen sulfide generation, and then formulate hydrogen sulfide treatment methods, as follows:

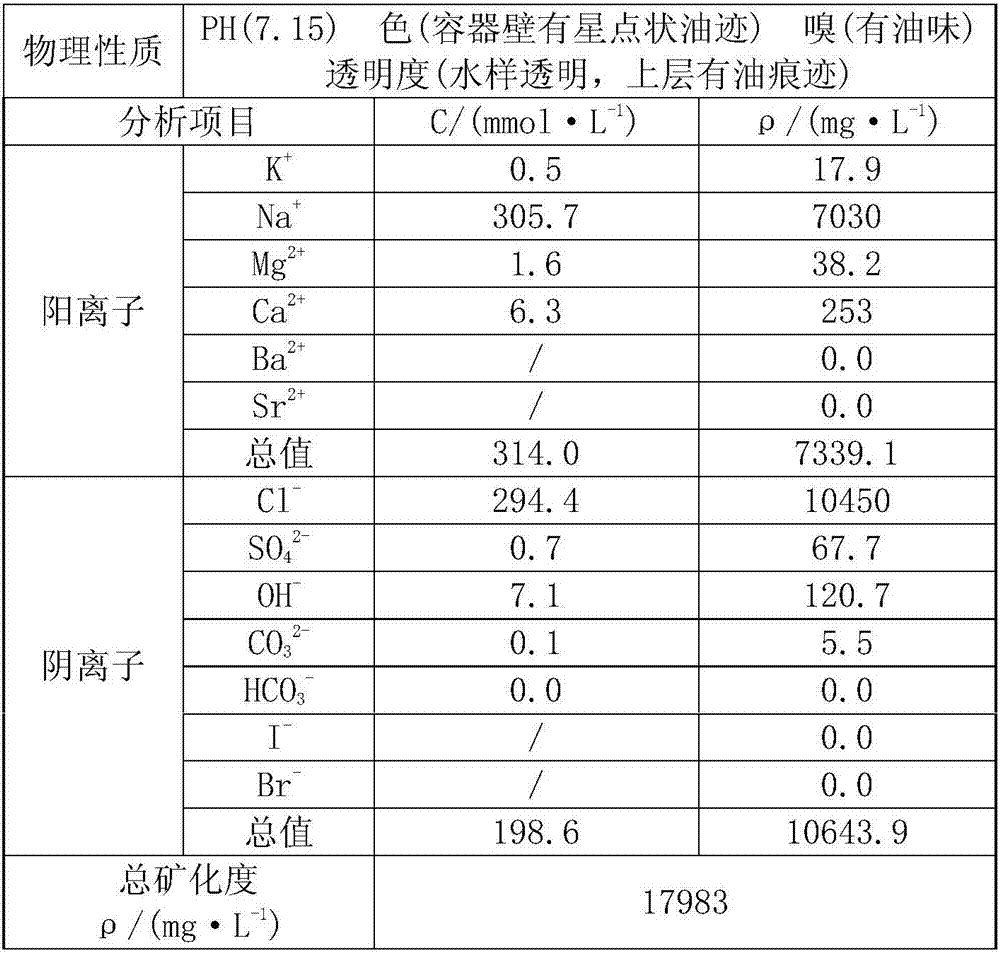

[0025] 1. Laboratory analysis of block core, oil-water mineral composition and injected water

[0026] Through the analysis of the sulfur content of the sulfur-containing minerals in the core of the block, the analysis of the sulfur content of the oil and water produced in the formation, and the analysis of the sulfate ion in the injected water, the cause of the hydrogen sulfide generation is determined.

[0027] (1) Sulfur content analysis of block core sulfur-bearing minerals

[0028] In order to know whether the stratum of the block contains the parent rock material that forms hydrogen sulfide gas, the core of the block was taken for X-ray diffraction whole-rock analysis (Table 2), and the mineral identification was carried out. The re...

example 1

[0071] Example 1 Hydrogen sulfide treatment and effect in Well WBC74-X13 of Dongsheng Company

[0072] (1) Construction background

[0073] Well WBC74-X13 has a single well controlled reserve of 150,000 tons. It was put into production in February 2009, with an initial daily liquid of 1.0 tons and a water cut of 20%. Well Shouchang 74-Gengeng 14 water injection has achieved obvious effects (since October 2010), the whole well accumulated 2670 tons of oil and 3212 cubic meters of water. On September 10, 2012, the hydrogen sulfide exceeded the standard to 1300PPm, and the well was sealed and closed on November 10, 2012. Before closing the well, the daily liquid was 9.0 tons, the daily oil was 4.2 tons, and the water cut was 53%.

[0074] (2) Construction purpose

[0075] Utilize formation hydrogen sulfide treatment technology to treat excess hydrogen sulfide, restore production, and ultimately increase oil recovery.

[0076] (3) Construction effect

[0077] The well was tre...

Embodiment 2

[0078] Embodiment 2 A kind of method of controlling hydrogen sulfide in oil well

[0079] Proceed as follows:

[0080] (1) Lower hydrogen sulfide treatment process pipe string: the lower pen tip at the bottom of the pipe string, and the upper part is connected to N80 flat oil pipe, so that the pen tip is located in the middle of the oil layer to be treated;

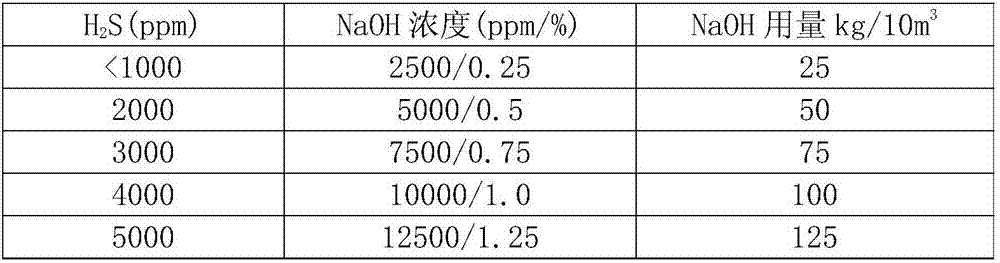

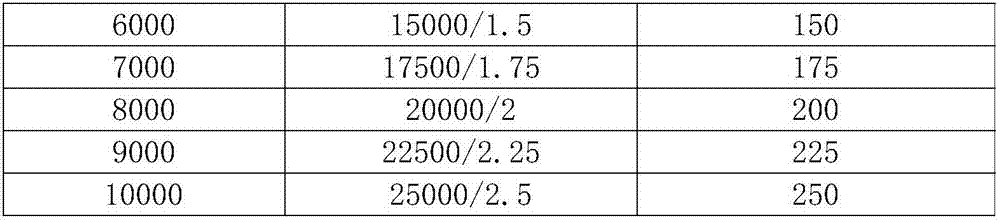

[0081] (2) Wash the well with sodium hydroxide solution first, and then wash the well with water; the amount of liquid used is 2 times the volume of the wellbore; the pH value of the liquid returned from the well washing at the end of the well washing is 7.0; the concentration of the sodium hydroxide solution is hydrogen sulfide 2.5 times the gas concentration, and not less than 25kg / 10m 3 ;

[0082] (3) Extrude with water, calculate the water absorption index at 18MPa, and test the normal injection amount of the agent during construction;

[0083] (4) Squeeze injection of sulfate-reducing bacteria inhibitor solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com