Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve waste removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of composite refining agent of aluminum alloy

The invention relates to a preparation method of a composite refining agent of an aluminum alloy, and belongs to the technology field of refining agent. The composite refining agent of the aluminum alloy prepared by the invention comprises chloride, fluoride and nitrate, wherein the chloride is the main component of the refining agent with high hygroscopicity; sodium chloride and potassium chloride have good coverage performance and are the basis of the refining agent; hexachloroethane is easy to store, easy to use, has a good purifying effect, and has a grain refining effect; since the loosehexachloroethane and aluminum alloy liquid will react violently, the hexachloroethane and sodium fluorosilicate are pressed together and granulated to improve the purification effect of the hexachloroethane; sodium fluoride can cause the oxide film to mechanically fall off and dissolve in the solvent, thereby playing a purifying function ; the addition of fluoride in the refining agent has an effect of adsorbing and dissolving aluminum oxide; the fluoride accelerates the process of adsorbing hydrogen and inclusions in an aluminum liquid by the refining agent, promotes the migration of the inclusions to the interface and improves the efficiency of the inclusion removal.

Owner:FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

Facility and operating method for clearing away floating garbage in reservoir by utilizing natural energy

InactiveCN103643661AAchieve containerization and densificationImprove waste removal efficiencyWater cleaningWater reservoirSUSPENDING VEHICLE

The invention discloses a facility and an operating method for clearing away floating garbage in a reservoir by utilizing natural energy, and belongs to the technical field of water conservancy projects. The facility consists of a pipeline system, a garbage collecting and screening device and a garbage collecting, storing and outputting device, wherein the pipeline system is used for collecting and conveying floating garbage; the garbage collecting and screening device is arranged at an inlet of a pipeline; the garbage collecting, storing and outputting device is arranged at an outlet of the pipeline; the garbage collecting and screening device floats in a floating garbage gathering area and consists of an annular float tank, garbage screening fences and an operating platform; and the annular float tank is submerged underwater, central space is connected with a garbage collection port and a pipeline, the screening fences are mounted on the periphery of the annular float tank, and the operating platform is mounted above the water surface. The floating garbage enters the pipeline with water flow to form a vortex, gathers towards the garbage collection port with the vortex, enters the pipeline after screened and is conveyed to a garbage collecting, storing and outputting device on one side of the downstream of a dam. Garbage packaging cages collect and store garbage discharged from the outlet of the pipeline and are hoisted in and out by a crane at a dam crest.

Owner:马向前 +2

Efficient water treatment agent

InactiveCN107585918AReduce use costAchieve precipitation effectWater contaminantsWaste water treatment from metallurgical processCalcium hydroxideWater quality

The invention relates to the technical field of wastewater treatment and in particular relates to an efficient water treatment agent. The formula of the efficient water treatment agent comprises the following raw materials in percentage by weight: 40 percent to 50 percent of calcium hydroxide, 35 percent to 40 percent of aluminum hydroxide, 5 percent to 8 percent of sodium hydroxide, 2 percent to5 percent of diatomite, 2 percent to 5 percent of a phosphorus removal agent, 1 percent to 3 percent of a heavy metal removal agent and 1 percent to 2 percent of a coagulant. The efficient water treatment agent provided by the invention has the characteristics of low wastewater treatment cost, good output water quality, simplicity in utilization, high waste removal efficiency and the like and is agood neutralizing agent for electronic electroplating and chemical wastewater treatment.

Owner:中山市中康化工科技有限公司

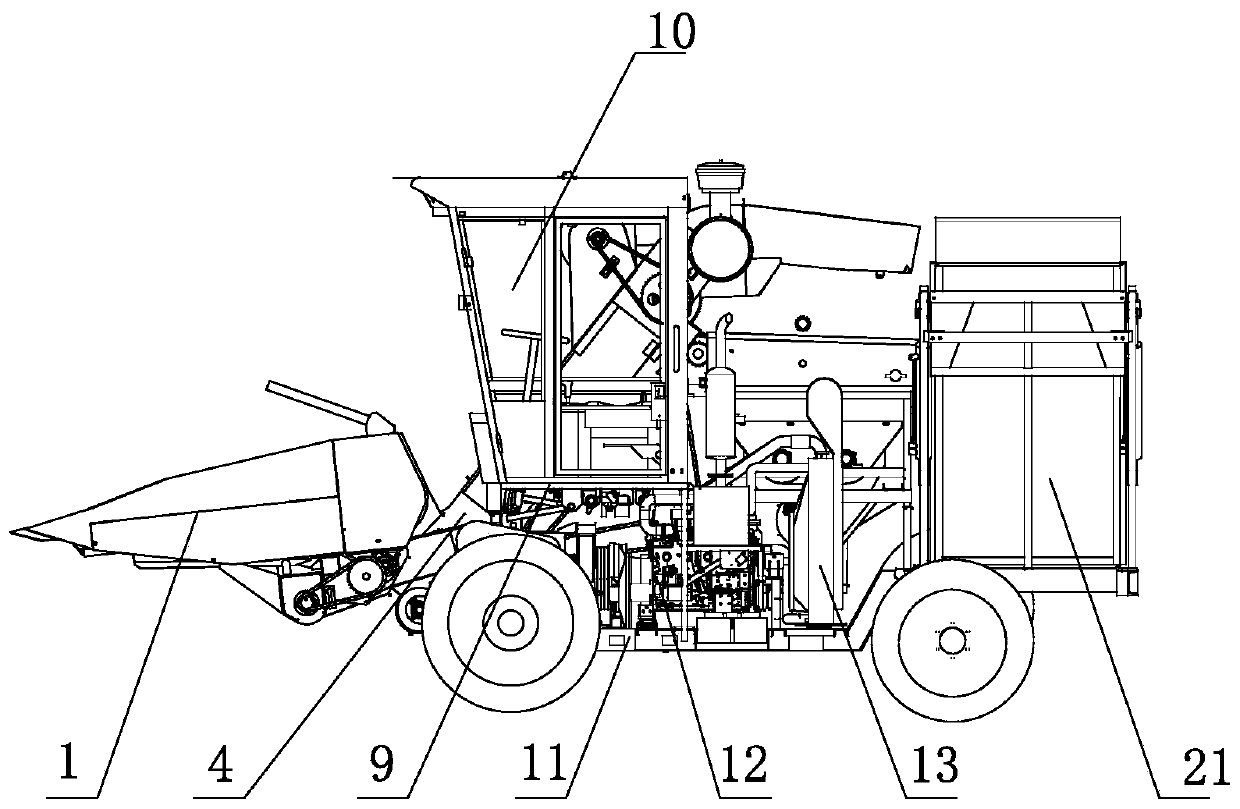

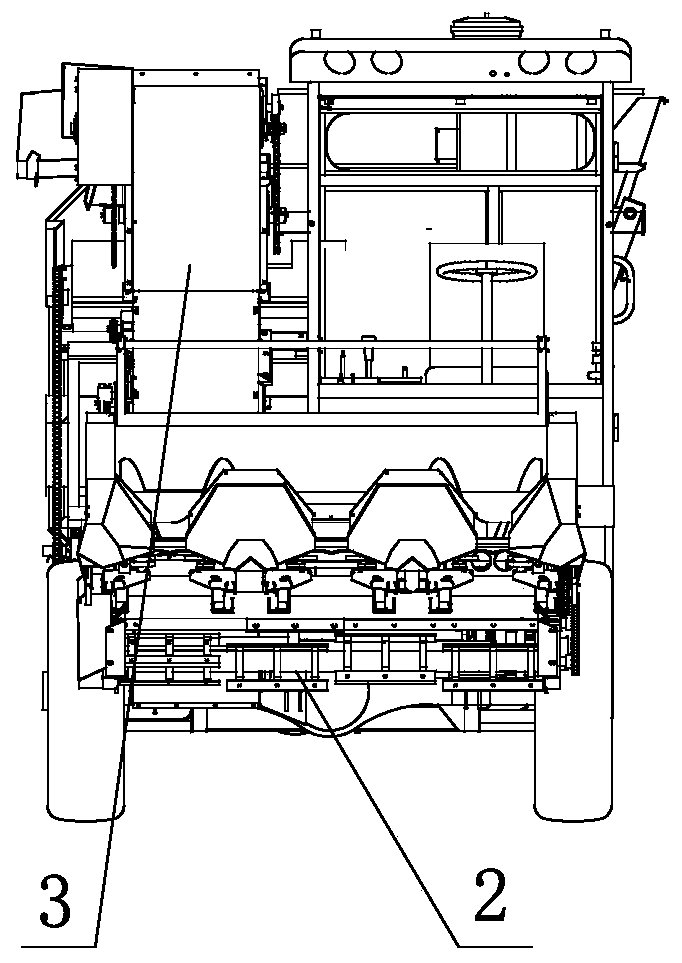

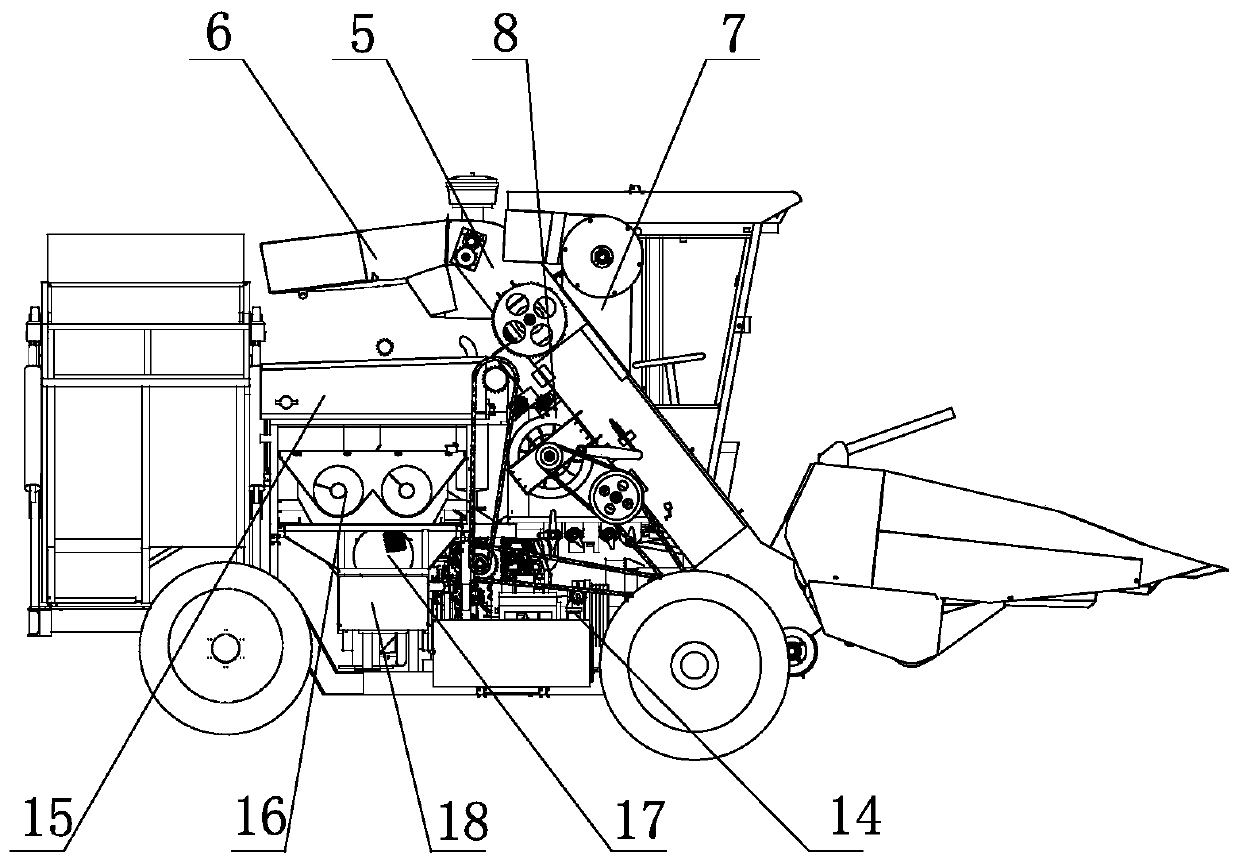

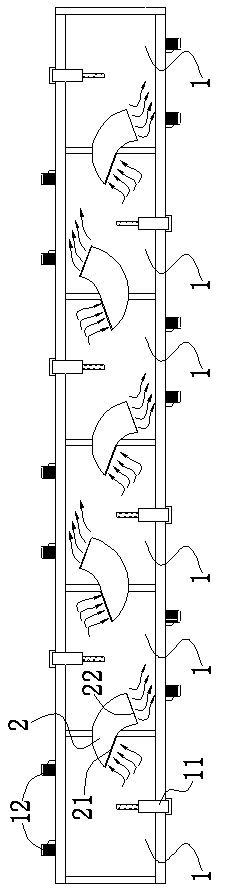

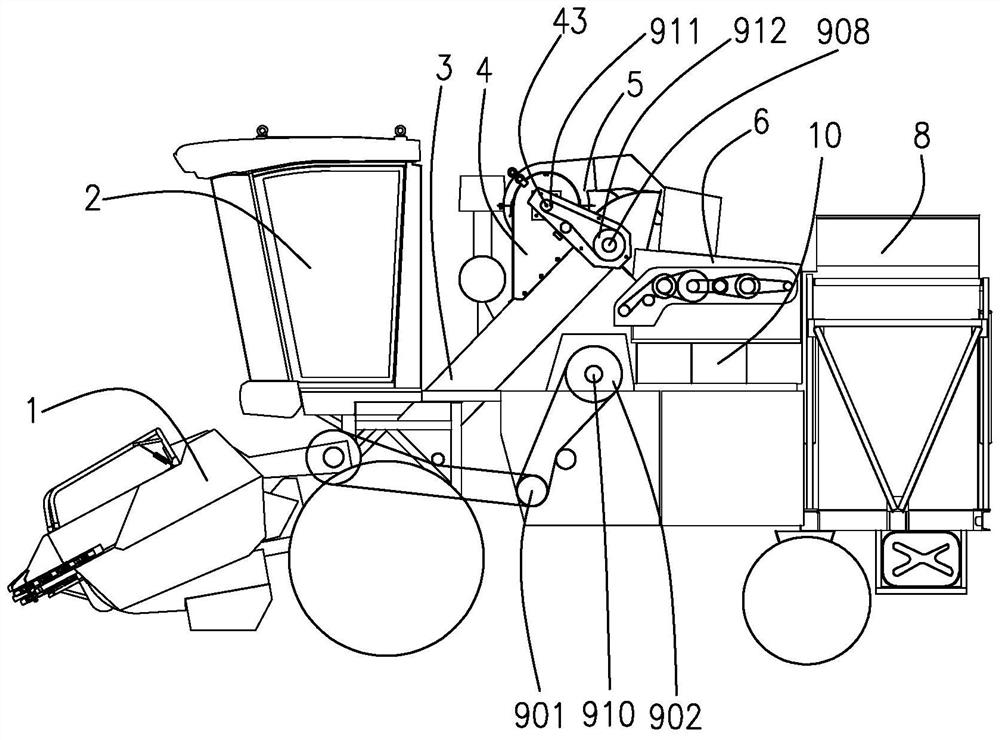

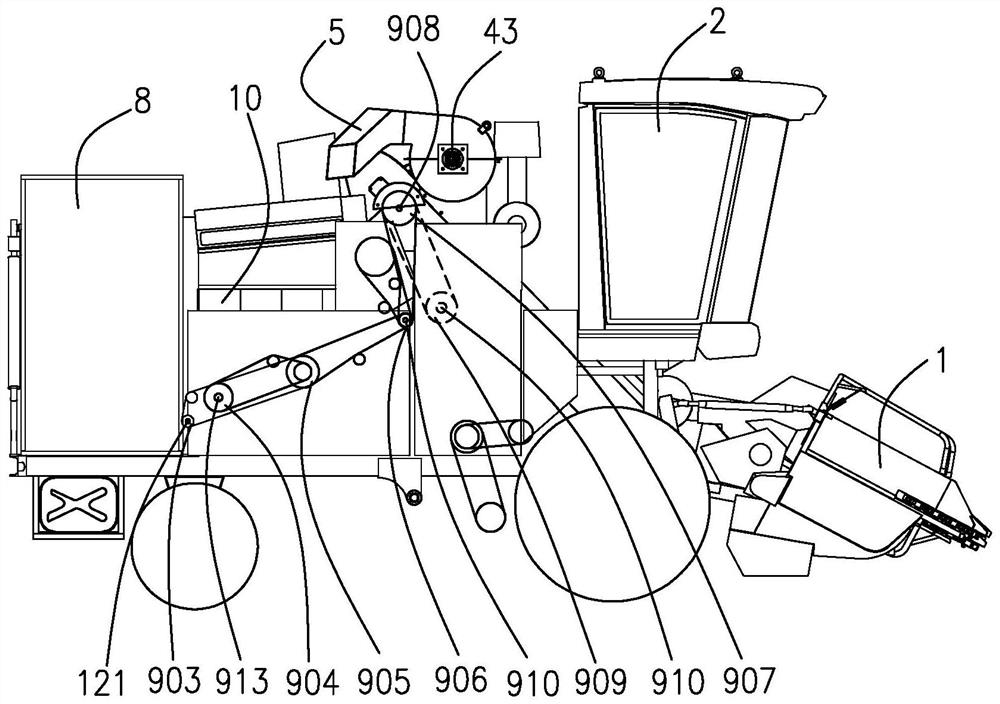

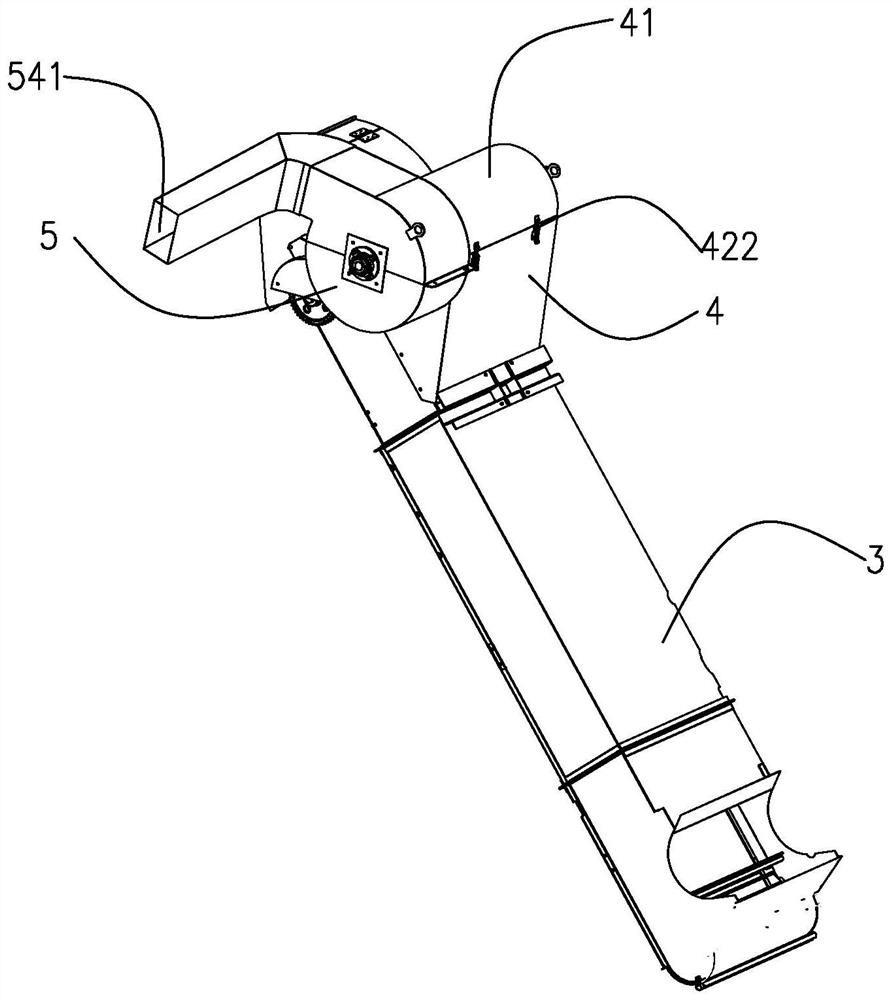

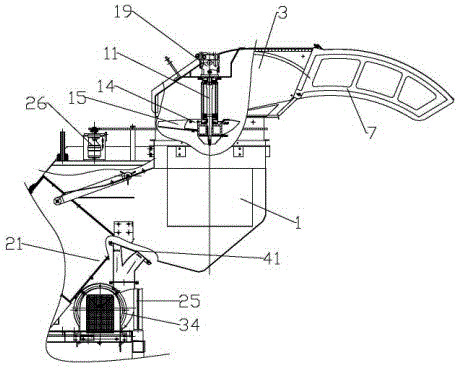

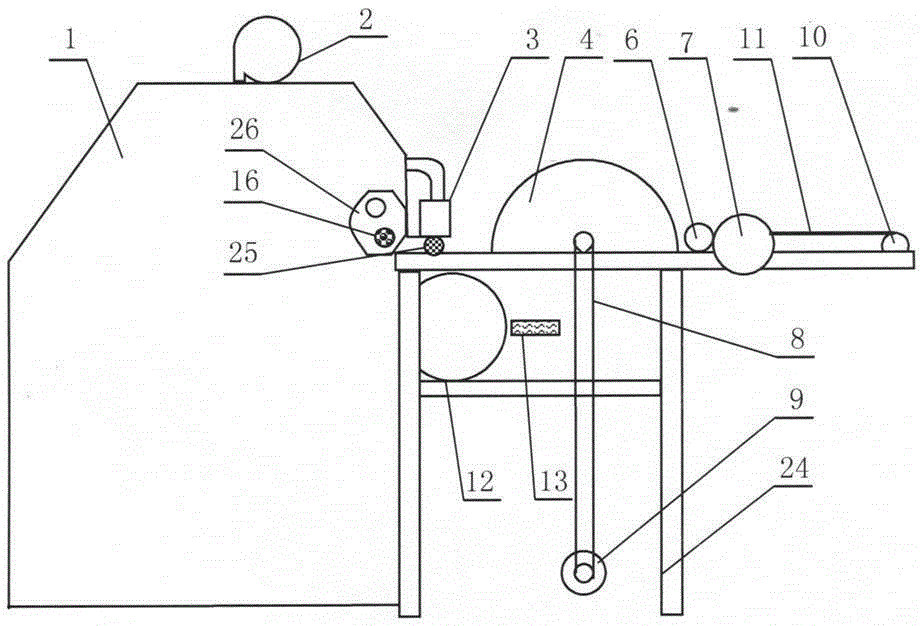

Three-row time-sharing four-wheel-drive hill corn harvester

PendingCN111034460ACompact structureImprove stabilityMowersAgricultural undercarriagesDrive shaftAgricultural engineering

The invention belongs to the field of agricultural machinery, and specifically relates to a three-row time-sharing four-wheel-drive hill corn harvester. The three-row time-sharing four-wheel-drive hill corn harvester comprises a chassis assembly which comprises a power system, a walking chassis system and a driving system, wherein the power system is connected with a gearbox; the first end of thegearbox is connected with front wheels through a front drive transmission shaft; the second end of the gearbox is connected with rear wheels through a rear drive transmission shaft; a clutch is connected with and arranged between the gearbox and the rear drive transmission shaft; the rear drive transmission shaft obtains transmission force output by the gearbox according to the clutch state of theclutch; and the front drive transmission shaft obtains transmission force output by the gearbox all the time. The three-row time-sharing four-wheel-drive hill corn harvester provided by the inventionis compact in overall structure, ultralow in gravity center, good in stability, high in climbing capacity, comfortable in operation environment, high in harvesting efficiency, capable of achieving time-sharing four-wheel-drive operation and applicable to operation in large hilly land parcels.

Owner:SHANDONG JUMING MASCH CO LTD

Filler for acid-base neutralization

InactiveCN103145220AImprove reusabilityImprove waste removal efficiencyWater/sewage treatmentInitial treatmentWastewater

The invention relates to a filler for acid-base neutralization. The filler comprises the raw materials of, by weight, 50-60% of magnesium powder or copper powder, 1-5% of active carbon and 2-5% of silicon dioxide, and is prepared by mixing the above raw materials. The filler provided by the invention can be used for treating acidic, basic and neutral wastewater, and the addition of other substances such as a pH regulating agent in the treatment process in not needed; the filler is fast, convenient and high in waster-removing efficiency, can greatly improve the reuse of wastewater, and is especially suitable for the initial treatment of wastewater in industries of printing and dyeing, pharmacy, petroleum, chemical engineering, heavy metals and others, with very ideal treatment effects.

Owner:赵艳姝

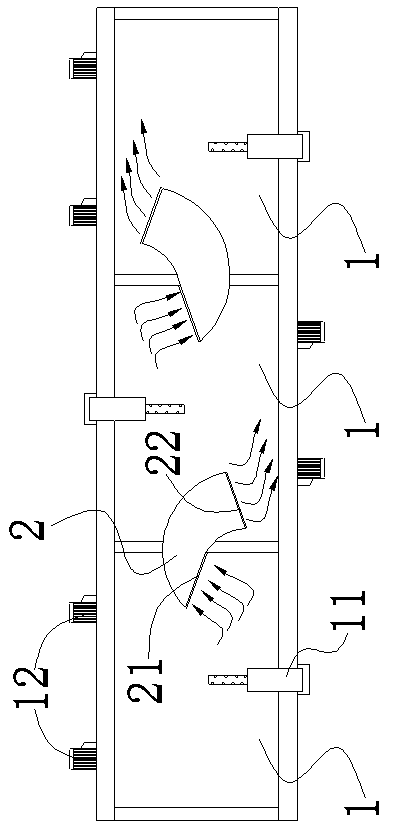

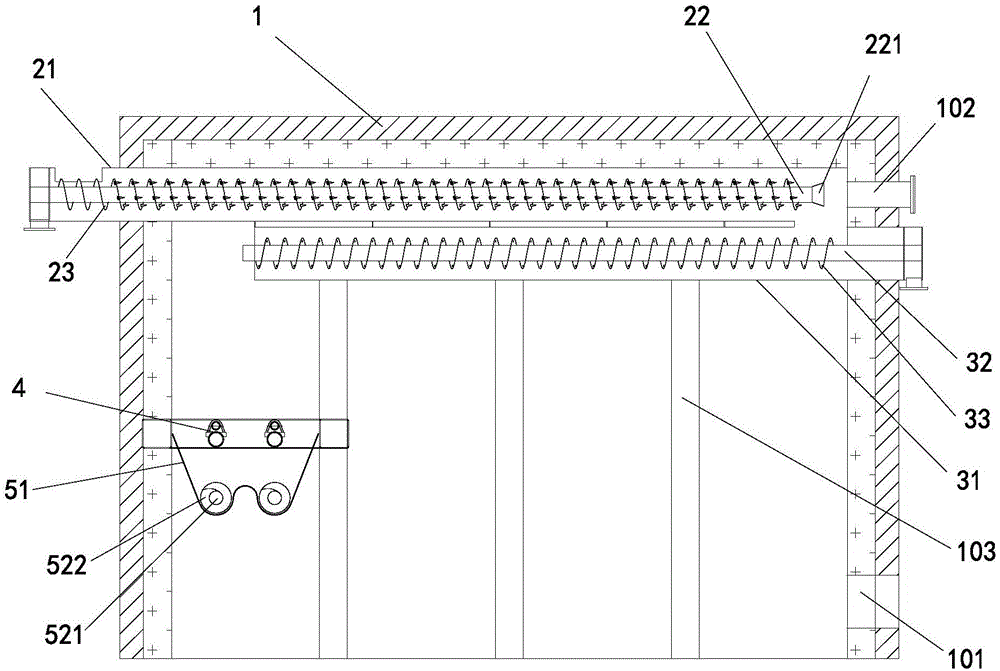

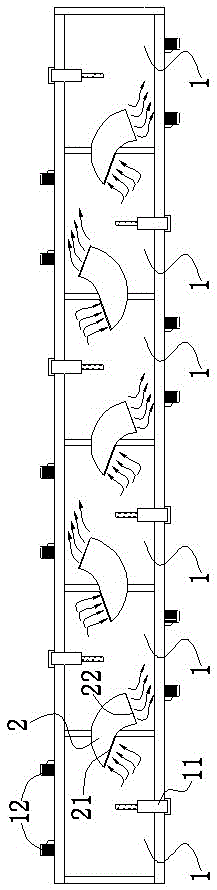

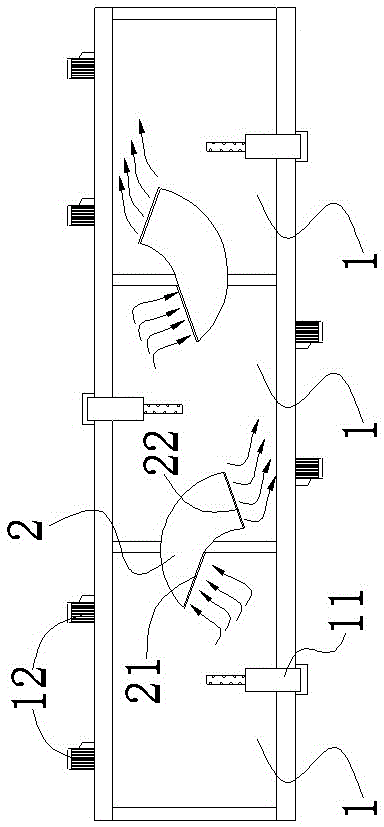

Setting machine thermal-cycling and waste-removing system

InactiveCN103741421ARealize inner loopReduce energy consumptionHeating/cooling textile fabricsDrying solid materialsToxic materialEngineering

The invention discloses a setting machine thermal-cycling and waste-removing system which comprises a cloth feeding device, and a plurality of drying rooms which are connected with the cloth feeding device and are connected with each other in an end-to-end manner; one side of each drying room is provided with a heating device, and the other side is provided with a pair of blower fans; an upper air channel and a lower air channel which are communicated with the pair of blower fans are disposed in each drying room; connecting pipes are disposed between at least two or more than two drying rooms; an air inlet is disposed at one end of each connecting pipe, and an air outlet is disposed at the other end of each connecting pipe; the air inlet is disposed near the heating device of the drying room, and the air outlet is disposed near the pair of blower fans of the drying room. The advantages of the system of the invention are that being different from current heat recovery systems with a single drying room, the system realizes internal circulation of hot air between drying rooms; with the disposed waste-removing device, the system can not only recover residual heat energy, but also remove waste gas, oil smoke and toxic substances generated during setting process, and realizes the effects of discharge reduction and environment protection.

Owner:张子军

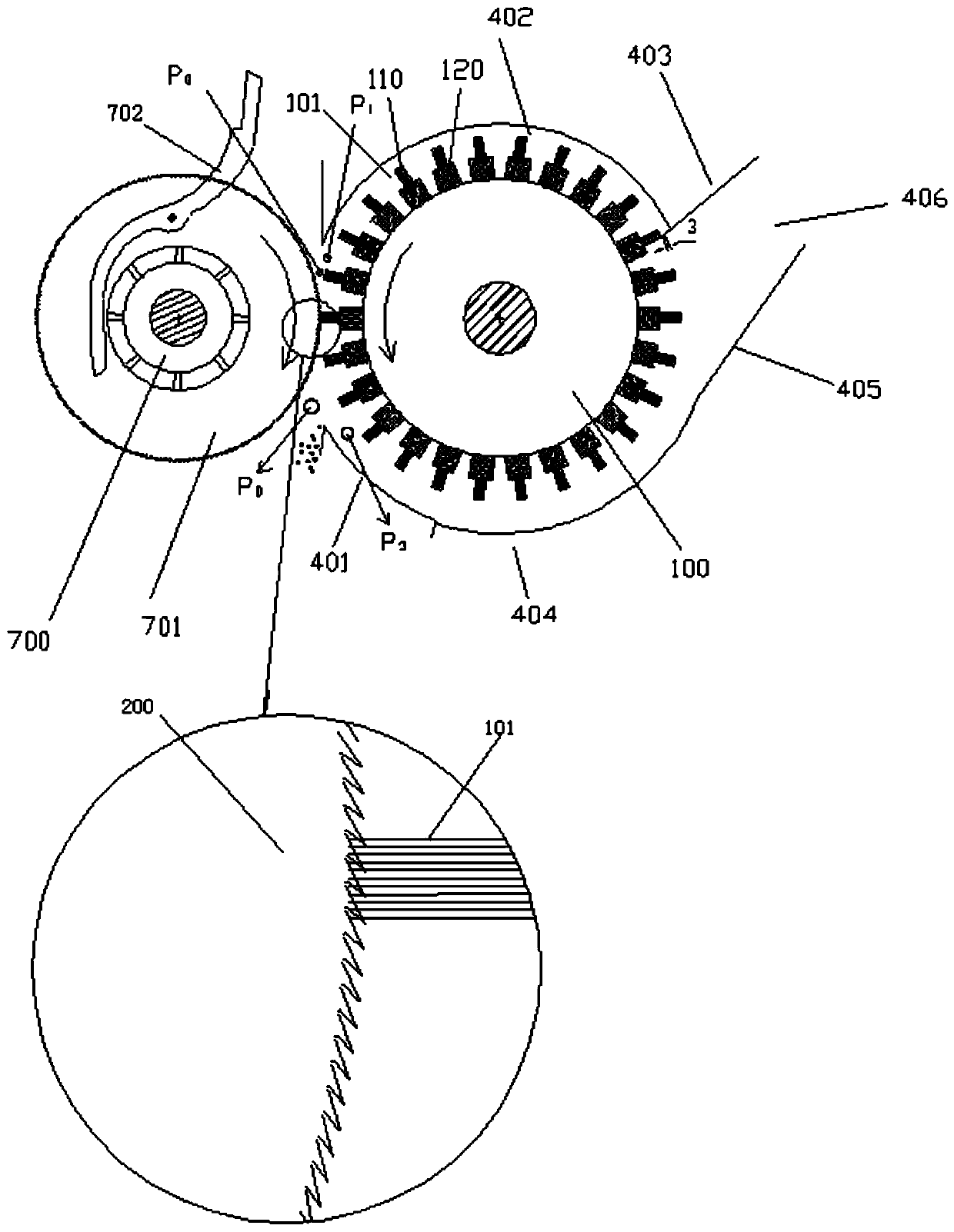

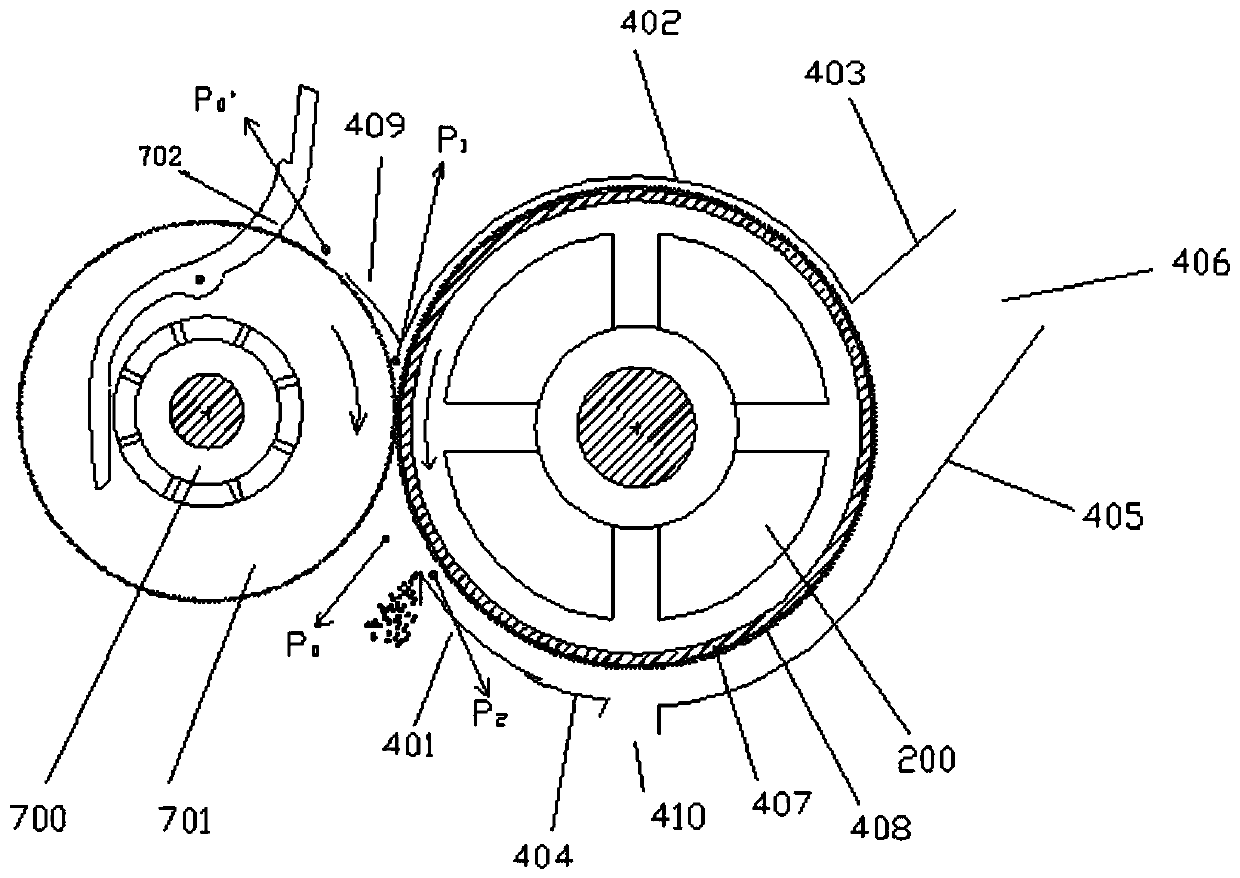

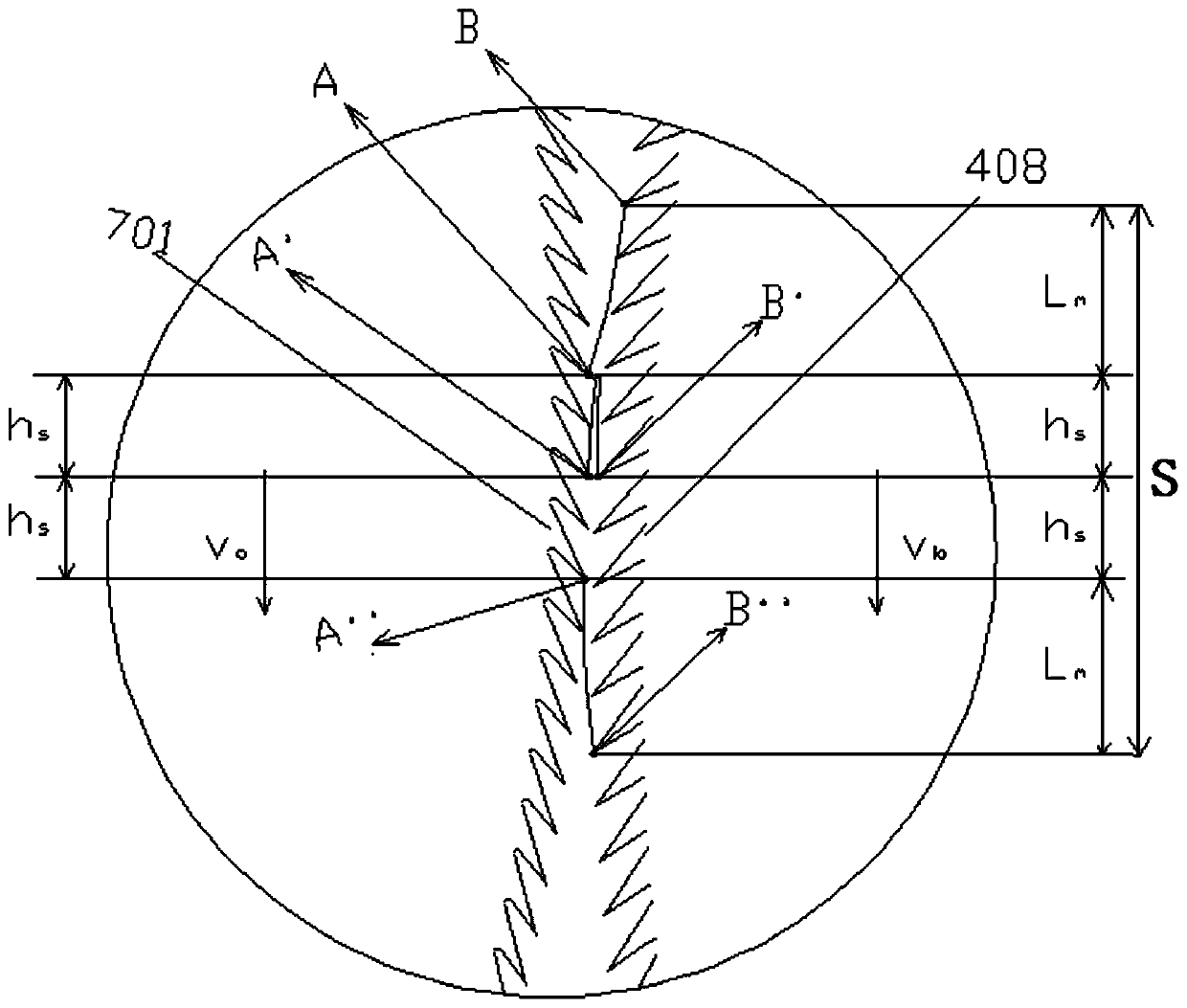

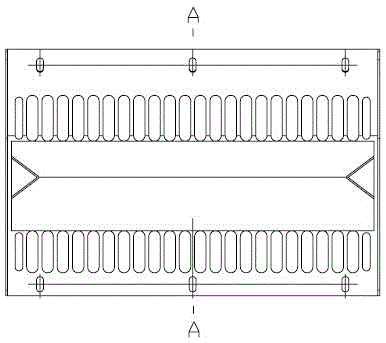

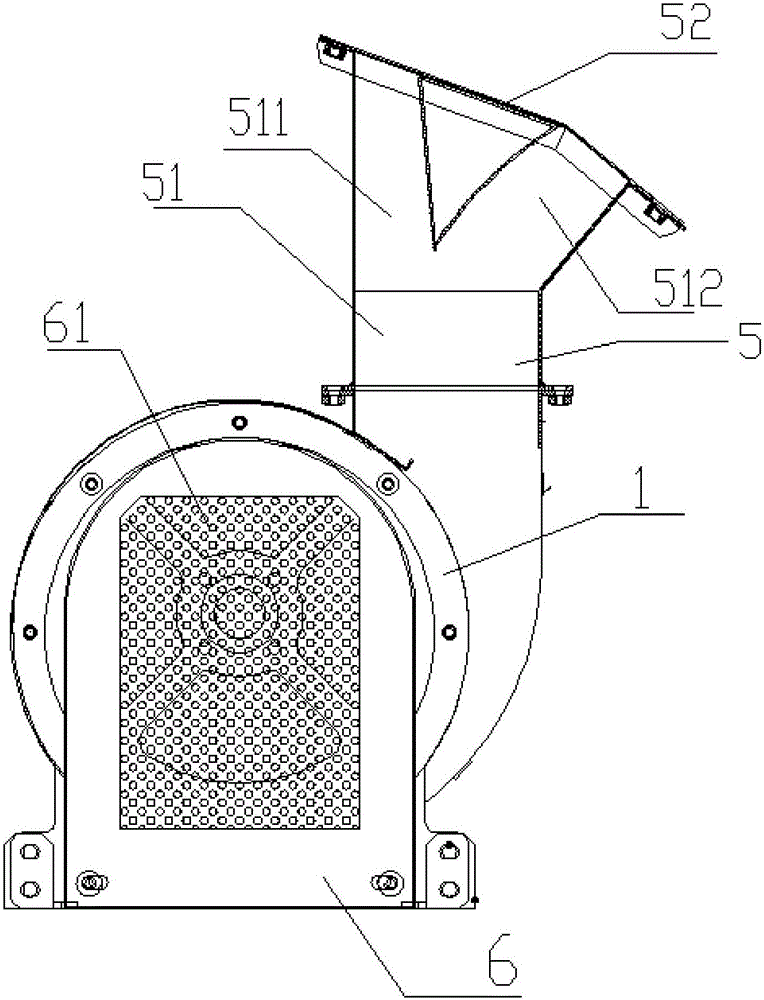

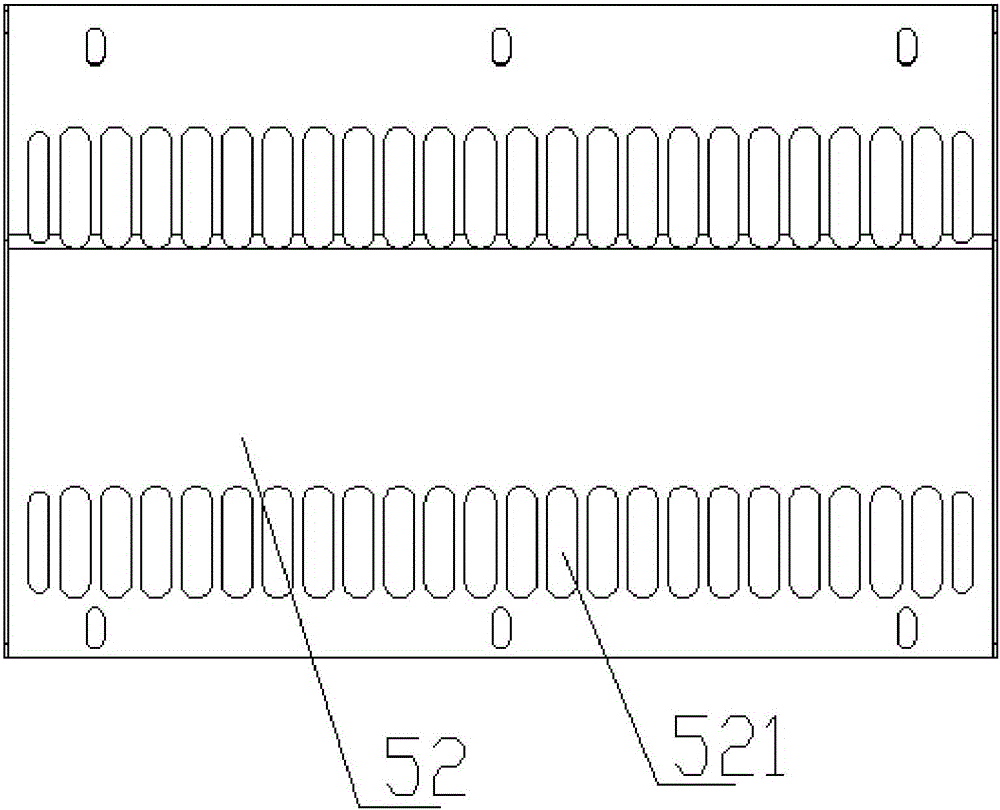

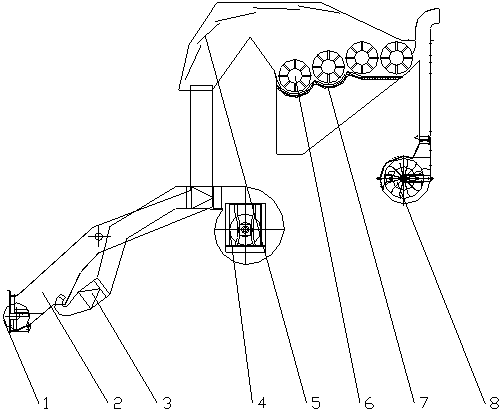

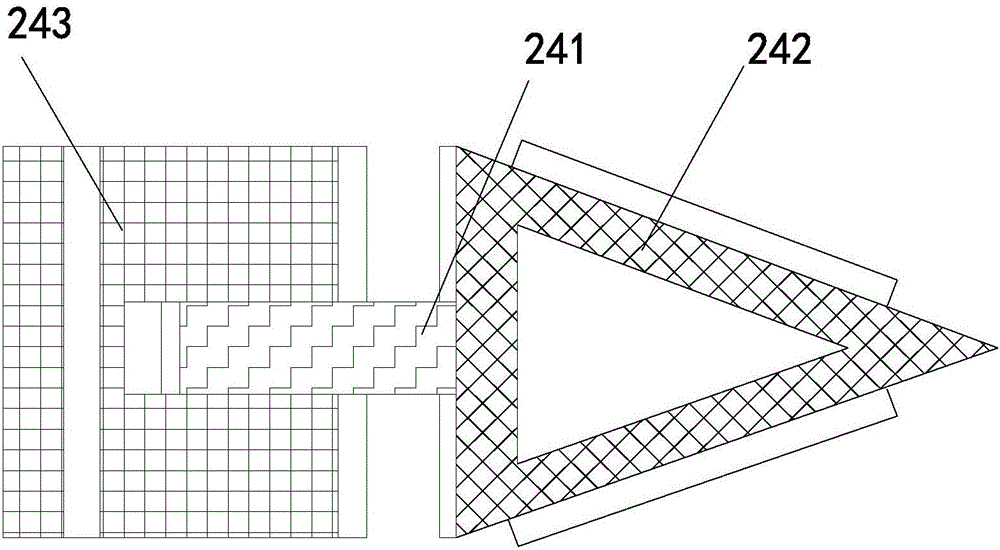

Cotton fiber impurity removing device and method based on cotton fiber transfer device

PendingCN110607564AEfficient impurity removal principleImprove waste removal efficiencyVegetable fibre separation from seedsFiberEngineering

The invention discloses a cotton fiber transfer device, which comprises a cotton supporting plate, an upper cover plate, a saw blade roller, a licker-in roller and a saw blade rear cover plate. The distance between the saw blade roller and the licker-in roller and the radian of the saw blade roller covered by the saw blade rear cover plate can be set such that the number N of turns required by cotton fiber transferring can be attained; according to a critical diameter formula of a cyclone separator, the speed and diameter of the saw blade roller can be set according to a critical diameter formula of a cyclone separator such that thickness B distribution of a generated cotton fiber floating layer is attained; a lowest linear speed ratio of the licker-in roller to the saw blade roller is setaccording to chord lengths S of intersection areas of the cotton fiber floating layers having different thicknesses B with the licker-in roller. The cotton fiber impurity removal device is additionally provided with an impurity removal plate, a rear cover plate, an air supplement opening and an upper cover plate on the basis of the cotton fiber transfer device, mounting parameters are refined, and therefore, noise reduction and impurity removal are achieved.

Owner:HUBEI BAIAO TECH

Micro-electrolytic metal filler

InactiveCN103043752AImprove reusabilityImprove waste removal efficiencyWater/sewage treatmentInitial treatmentTherapeutic effect

The invention relates to a micro-electrolytic metal filler. The micro-electrolytic metal filler comprises the following preparation raw materials in percentage by weight: 60-70% of iron powder or copper powder, 2-4% of carbon and 3-5% of silicon and is prepared by mixing. The micro-electrolytic metal filler disclosed by the invention can be used for direct treatment of acidic, alkaline and neutral wastewater, an acid-base blender, activated carbon and other substances do not need to be added during the treatment process, the operation is convenient and fast, the waste removal efficiency is high, the reutilization property of the wastewater can be greatly improved, the micro-electrolytic metal filler is particularly suitable for initial treatment of the wastewater in printing and dyeing, pharmacy, petroleum, chemical engineering, heavy metals and other industries, and the treatment effect is very ideal.

Owner:吕智杰

Filler used for wastewater purification

InactiveCN102887568AImprove reusabilityImprove waste removal efficiencyWater/sewage treatmentChemical industryTherapeutic effect

The present invention provides a filler used for wastewater purification. The filler is prepared by mixing the components by weight: 50-60% of copper powder, 10-20% of zinc powder, 5-10% of bamboo charcoal powder, and 3-5% of silicon. The filler can be directly used for handling acidic, alkaline and neutral wastewater. An acid-base neutralizer, activated carbon and other substances are not needed in the treating processes. The filler is convenient, fast, and high in waste-removing efficiency, can greatly improve the reuse of wastewater, is especially suitable for original wastewater treatment in printing and dyeing industry, pharmaceutical industry, petroleum industry, chemical industry, heavy metal industry and other industries, is very ideal in treatment effect and suitable for promotion application.

Owner:张宇

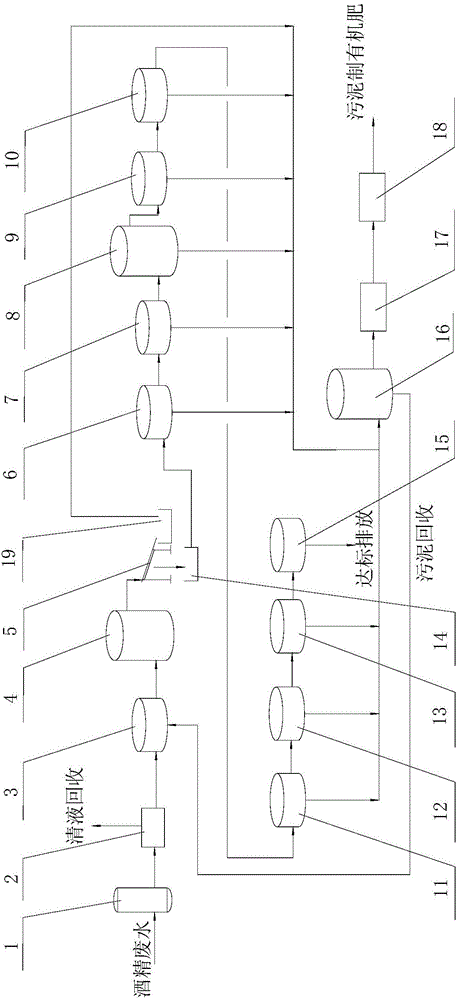

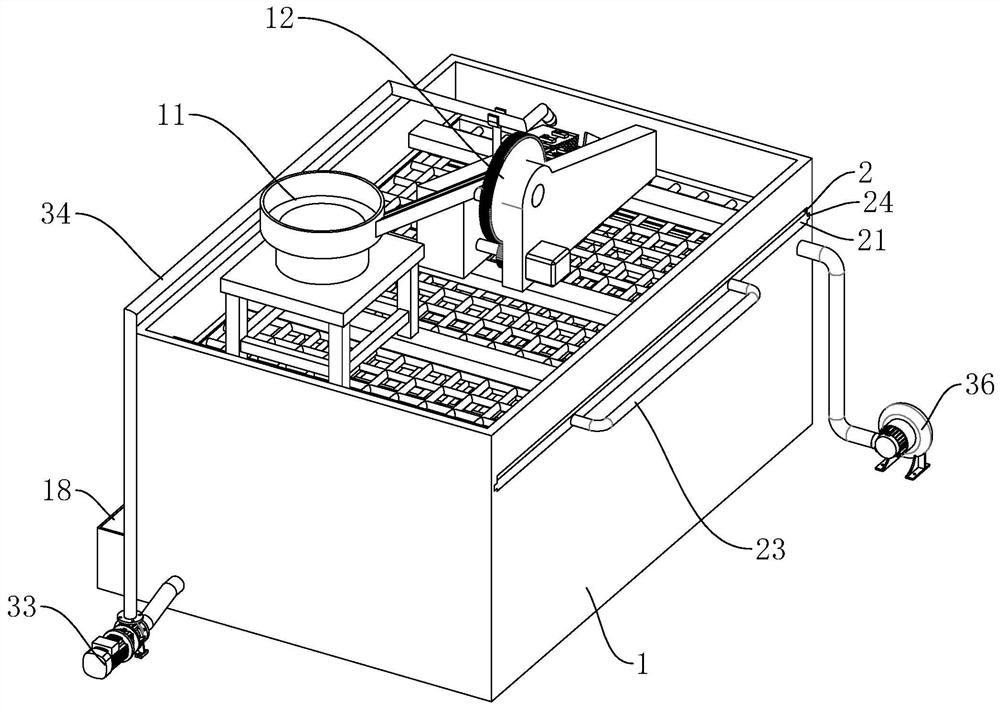

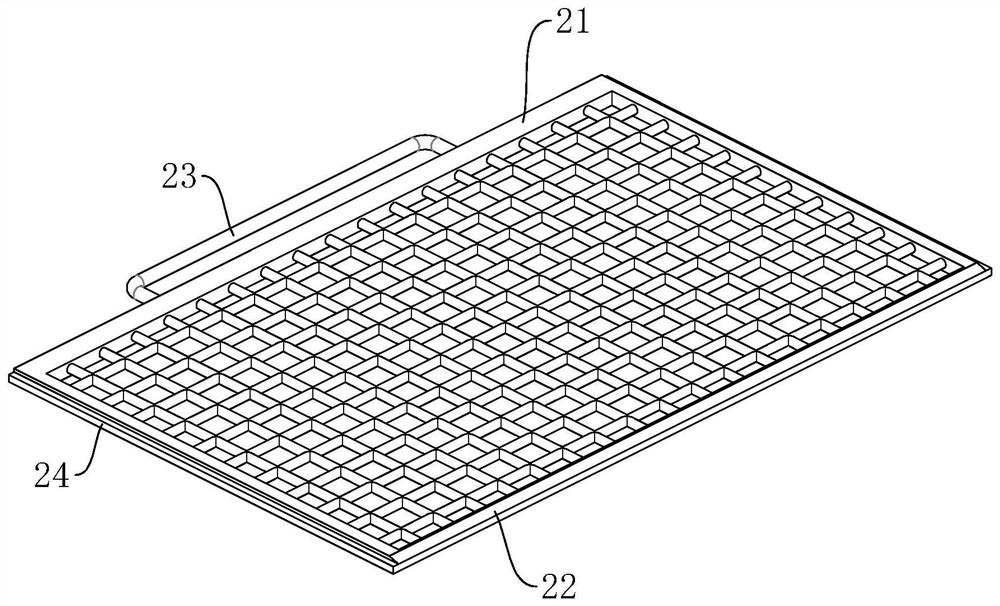

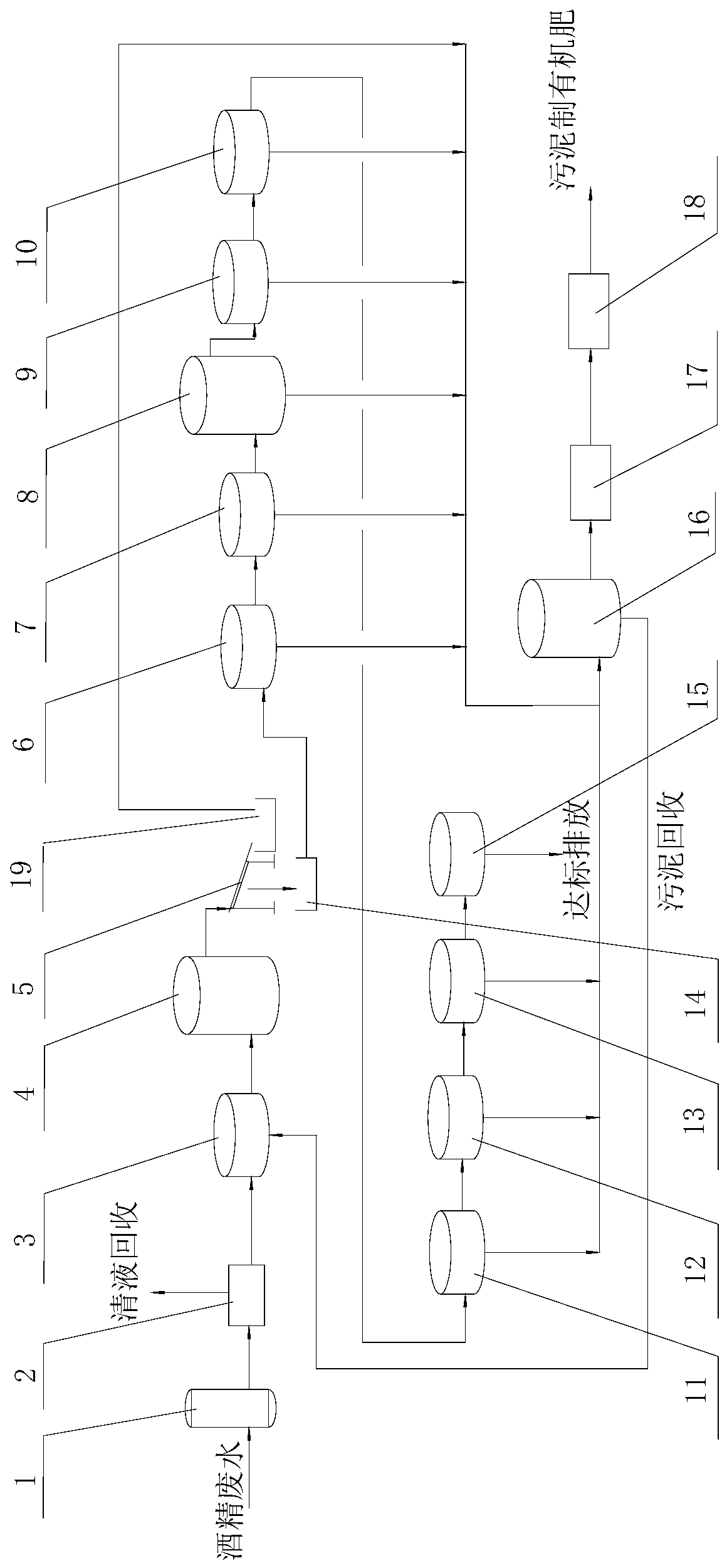

Starch alcohol wastewater treatment system and method

ActiveCN106315983AIncrease load factorEvenly distributedWater/sewage treatment by centrifugal separationSludge treatmentAerobic treatment systemAlcohol

The invention relates to an environment-friendly wastewater treatment process, in particular to a starch alcohol wastewater treatment system and method. The method comprises the steps of pretreatment, primary anaerobic treatment, secondary anaerobic treatment, secondary aerobic treatment, sludge treatment and the like. A CSTR, a UASB anaerobic reactor and an SBR aerobic treatment system are combined for treating the starch wastewater; meanwhile, the recovery of waste gas and waste slag in the wastewater treatment process is enhanced; the resource utilization rate is enhanced; the goal of further enhancing the waste slag and waste gas utilization in the wastewater treatment process is achieved; the cost is reduced; meanwhile, the operation efficiency of the equipment is ensured; the goal of discharging the wastewater in a standard reaching way is achieved.

Owner:GUANGXI LUOCHENG KECHAO FOUND SCI & TECH DEV

Fine electrolytic mixture

InactiveCN103145221AImprove reusabilityImprove waste removal efficiencyWater/sewage treatmentElectrolysisWastewater

The invention provides a fine electrolytic mixture which is prepared by fully mixing zinc powder, graphite powder and silica fume according to a certain percent, refining in a pulverizer and preparing. The mixture can directly treat acidic, alkaline and neutral waste water, is free of adding a PH blender, active carbon and other substances during a treating process. The mixture is convenient, fast and high in waste removing efficiency, can greatly improve recyclability of the waste water, and is especially suitable for pre-treatment of waste water of dyeing, pharmacy, petroleum, chemical, heavy metals and other industries and quite ideal in treating effects.

Owner:刘洪群

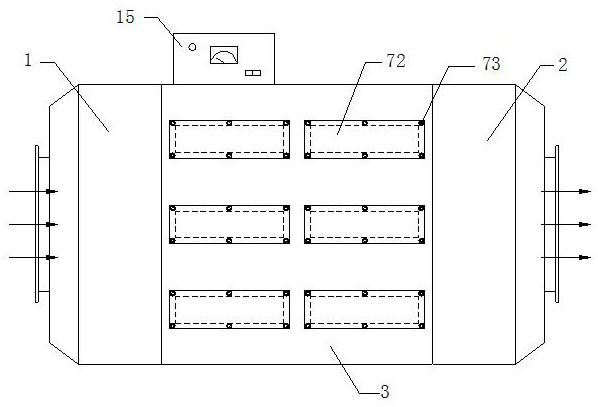

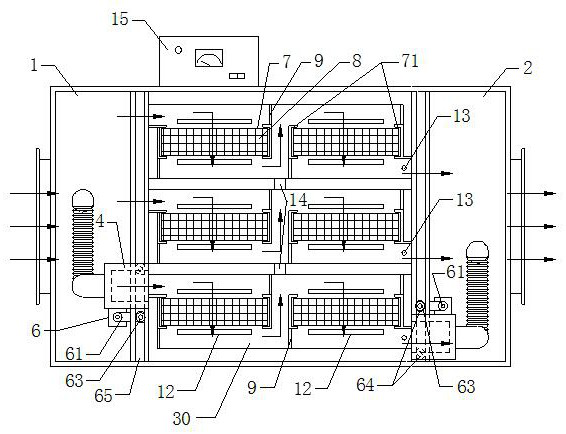

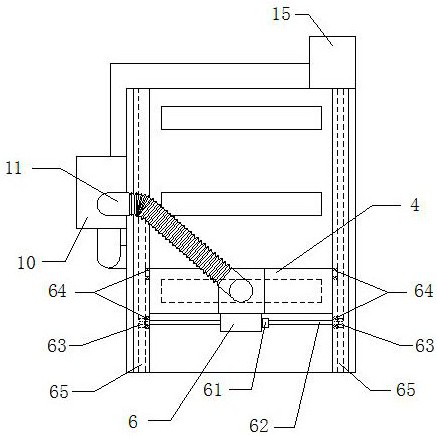

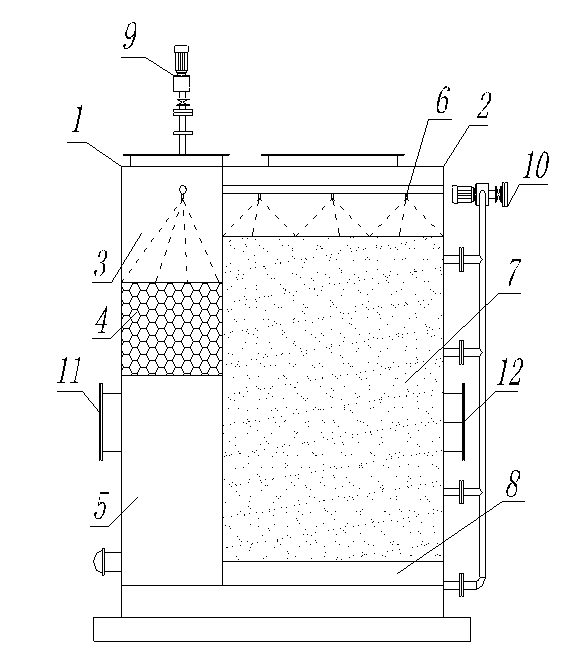

Multifunctional waste gas treatment equipment

PendingCN111672266AImprove waste removal efficiencyLow costGas treatmentDispersed particle separationTemperature controlProcess engineering

The invention relates to multifunctional waste gas treatment equipment comprising a heat insulation container, an opening and closing device, a temperature control system and a controller unit; at least two waste gas treatment chambers are arranged in the heat insulation container, wherein each waste gas treatment chamber is provided with a gas inlet and a gas outlet, the opening and closing device is used for alternately and circularly closing part of the waste gas treatment chambers, each waste gas treatment chamber is provided with a gas flow guide partition plate, a temperature control system and at least one waste removal material placing device, and each waste removal material placing device is filled with a waste removal material unit and provided with a supporting movable device. According to the waste gas treatment equipment disclosed by the invention, waste gas entering from the gas inlet is adsorbed by the waste removal material unit positioned in the heat insulation container; the controller unit starts and stops the opening and closing device and the temperature control system to circularly adsorb, desorb and decompose the waste gas in each waste gas treatment chamber,integrates adsorption, desorption and decomposition treatment systems of the waste gas, and is simple in structure, convenient to operate, safe, reliable, recyclable, economical, environment-friendlyand suitable for wide popularization and application.

Owner:泉州市育立环境科技有限公司

Zea mays L. harvester

ActiveCN112913467ALow costLow failure rateMowersSaving energy measuresReciprocating motionControl theory

The invention provides a Zea mays L. harvester, The invention provides a Zea mays L. harvester, which comprises a first impurity discharging fan part, a first installation shaft, a vibrating sieve, an eccentric chain wheel shaft, a second impurity discharging fan part and a second installation shaft, wherein the first installation shaft is cooperated with the first impurity discharging fan part to drive the first impurity discharging fan part; the vibrating sieve is used for carrying out vibration cleaning on fallen Zea mays L. kernels; the eccentric chain wheel shaft drives the vibrating sieve to carry out reciprocating motion; the second impurity discharging fan part is arranged on the tail part of the vibrating sieve for blowing out stems and bracteal leaves which fall from the vibrating sieve and is used for realizing further cleaning of the Zea mays L. kernels; the second installation shaft is cooperatively connected with the second impurity discharging fan part to drive the second impurity discharging fan part to rotate; the first impurity discharging fan part comprises a first impurity discharging fan; the second impurity discharging fan part comprises a second impurity discharging fan; the eccentric chain wheel shaft is arranged between the first installation shaft and the second installation shaft; the first installation shaft, the second installation shaft and the eccentric chain wheel shaft are arranged in parallel; and the axial line of the eccentric chain wheel shaft is not positioned in a plane formed by the axial line of the first installation shaft and the axial line of the second installation shaft.

Owner:常州常发重工科技有限公司

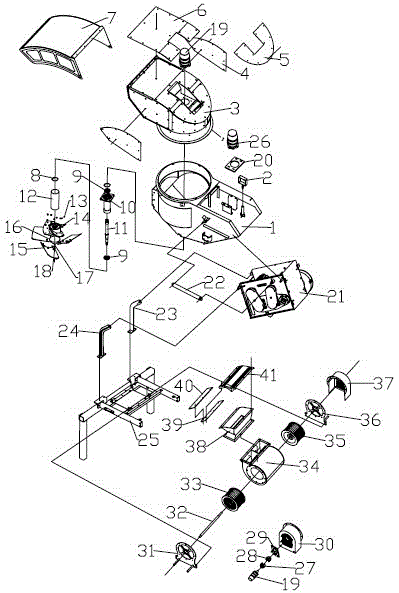

Trash removal device on sugarcane harvester

The invention discloses a sundry removing device for a sugarcane harvester. The sundry removing device comprises an upper fan and a lower fan, wherein the upper fan comprise a driving box, an upper fan motor, a fan shaft and a fan installing base; the driving box comprises an outlet cavity and a circular cavity base on the lower part; the circular cavity base is connected with the outlet cavity; the driving box is arranged on the fan installing base; a fan blade mechanism is arranged on the fan shaft; the fan shaft is arranged vertically; the upper fan motor is fixed on the driving box; the upper fan motor is connected with the fan shaft; the fan installing base is provided with a cylindrical cavity, a sugarcane discharging cavity and a sugarcane charging cavity which are communicated with one another; the sugarcane discharging cavity and the sugarcane charging cavity are formed below the cylindrical sugarcane; the sugarcane discharging cavity and the sugarcane charging cavity are formed opposite to each other on left and right sides; a sealing cover plate is provided with two paths of air outlets; wind is blown upwards through one path of air outlet; the other path of air outlet is used for obliquely blowing wind to the inlet position of the upper fan. By adopting the structure, the sugarcane leaf peeling efficiency of sugarcane can be increased effectively, and the impurity content of sugarcane segments is lowered effectively.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

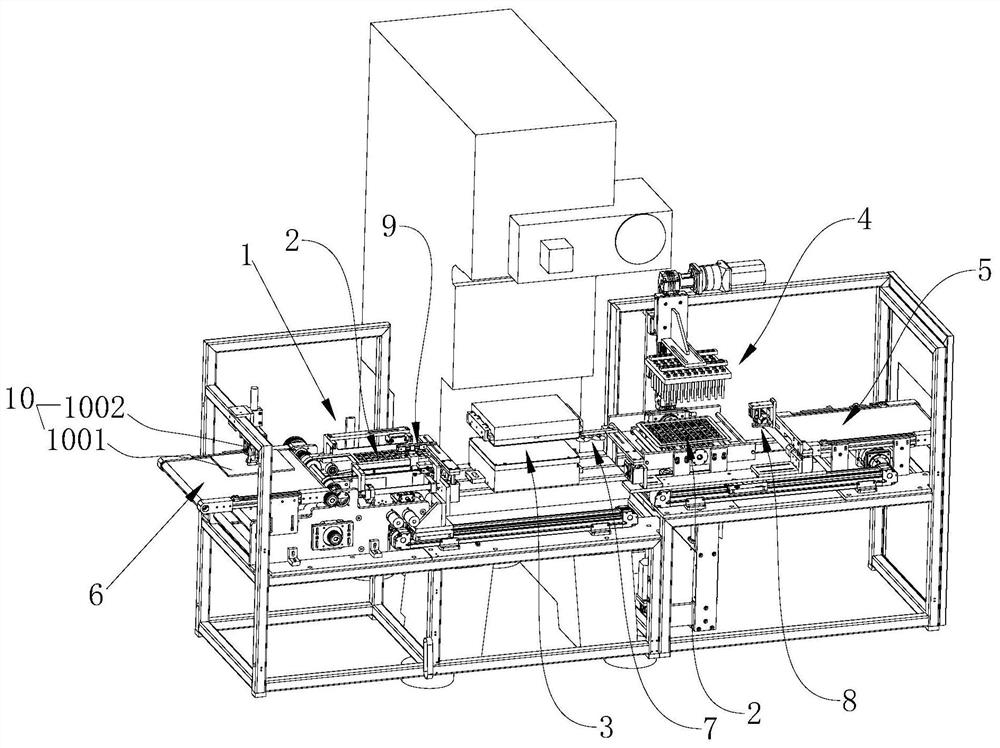

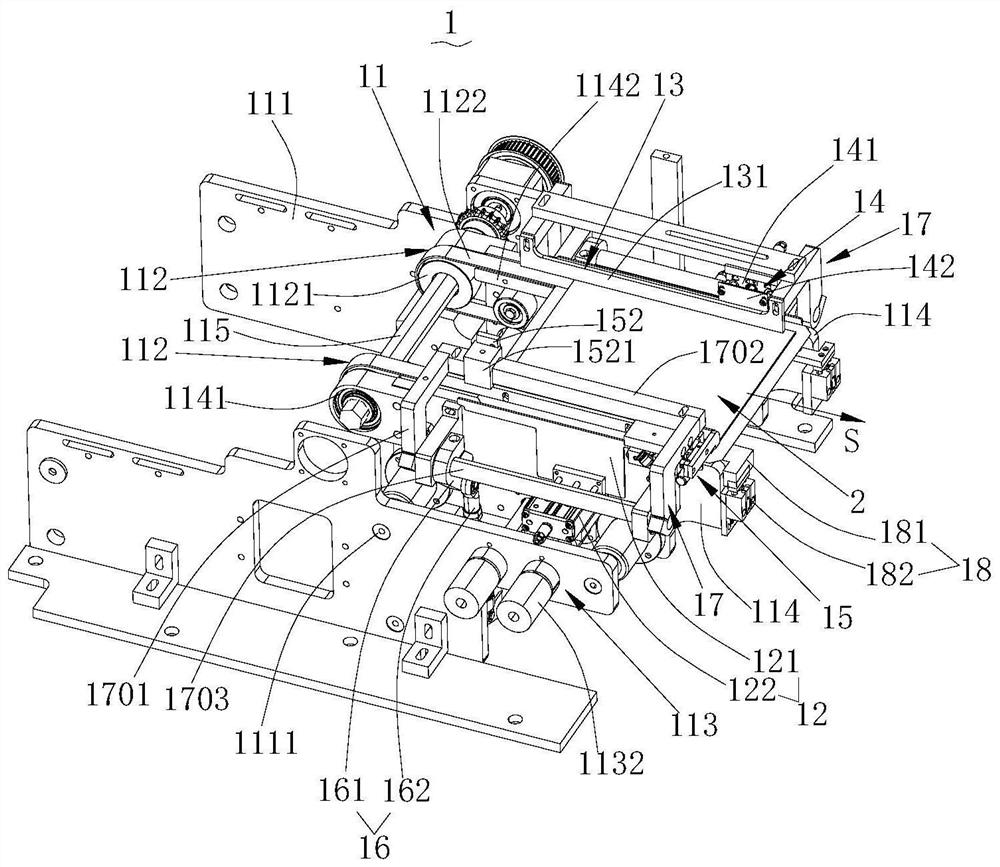

Punching and waste discharging technology for packaging box material plate

The invention discloses a punching and waste discharging technology for a packaging box material plate, and relates to the technical field of packaging processing. The punching and waste discharging technology for the packaging box material plate comprises the steps that S1, the packaging box material plate is positioned and punched; S2, posture adjustment is conducted on the punched packaging box material plate, so that a paperboard of the packaging box material plate is located below surface paper; S3, waste materials are ejected out in the direction from the surface paper of the packaging box material plate to a paper plate; and S4, the packaging box paperboard subjected to waste removal is discharged. After the posture of the punched packaging box material plate is adjusted, the waste materials are ejected, so that waste material collection is facilitated, and damage to the surface paper is reduced.

Owner:佛山常晟智能科技有限公司

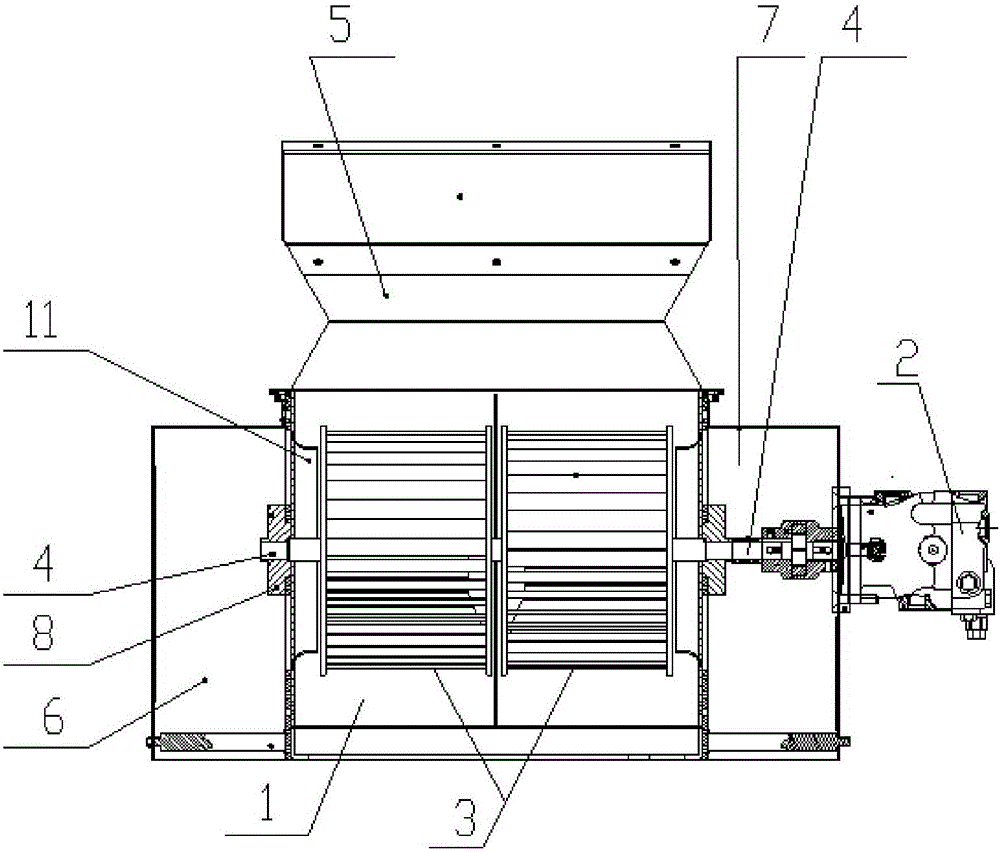

Impurity removing and air discharging machine for cane harvester

The invention discloses an impurity removing and air discharging machine for a cane harvester. The machine comprises a rotary bellow, a motor, impellers, a bellow shaft, a left air inlet box, a right air inlet box, a guide bin and an air outlet cover plate, wherein the motor is connected with the bellow shaft through a coupler, the bellow shaft is connected with the two impellers through keys, the two impellers are arranged in the rotary bellow, arc-shaped flanges are arranged on the inner walls of the left end face and right end face of the rotary bellow, the bellow shaft penetrates through center through holes of the arc-shaped flanges, bearings are arranged at the centers of the outer walls of the left end face and right end face of the rotary bellow, and the bellow shaft is connected with the bearings; the outer walls of the left end face and right end face of the rotary bellow are connected with the left air inlet box and the right air inlet box respectively, an air outlet of the rotary bellow is in butt joint with the guide bin, and the guide bin comprises a guide cavity and the air outlet cover plate; the lower end of the guide cavity is connected with the air outlet of the rotary below, and the guide cavity is divided into an upper air chamber and a side air chamber from the middle section of the body of the guide cavity; the upper end face of the guide cavity is connected with the air outlet cover plate, and a plurality of exhaust holes are formed in the air outlet cover plate.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

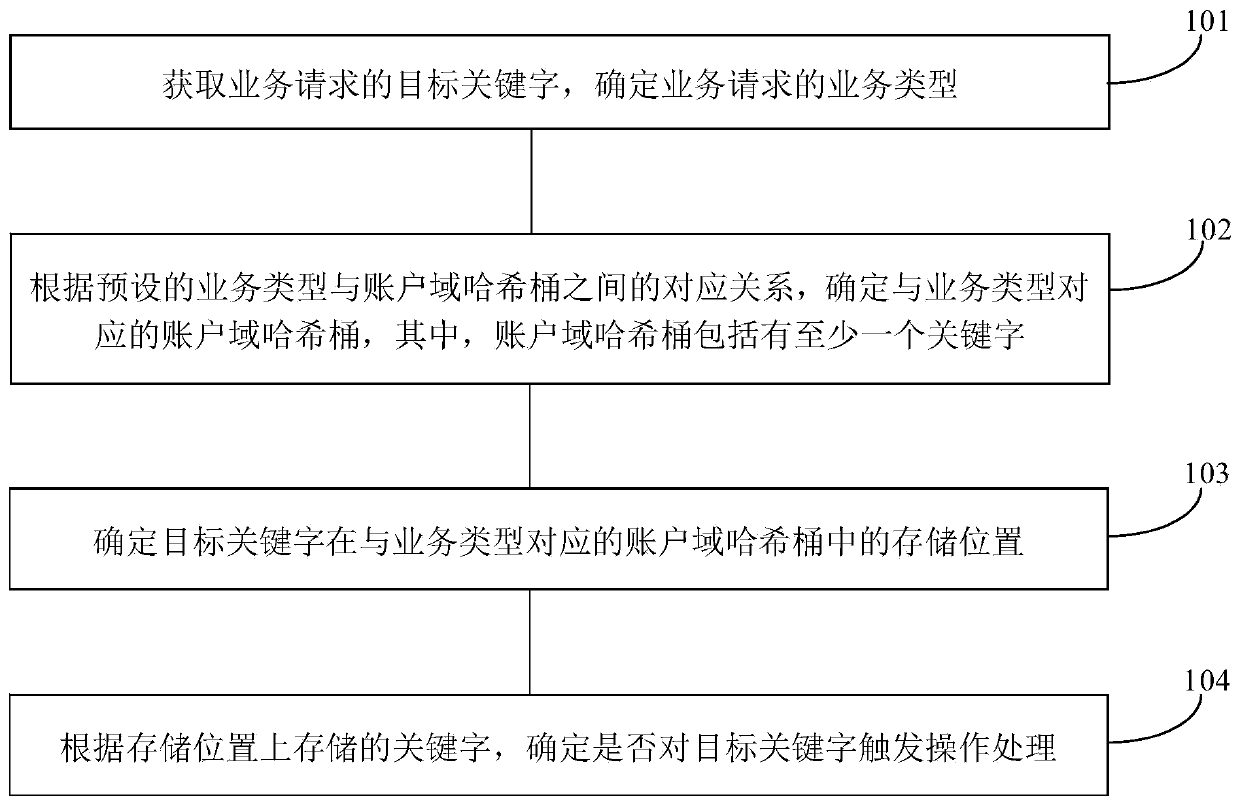

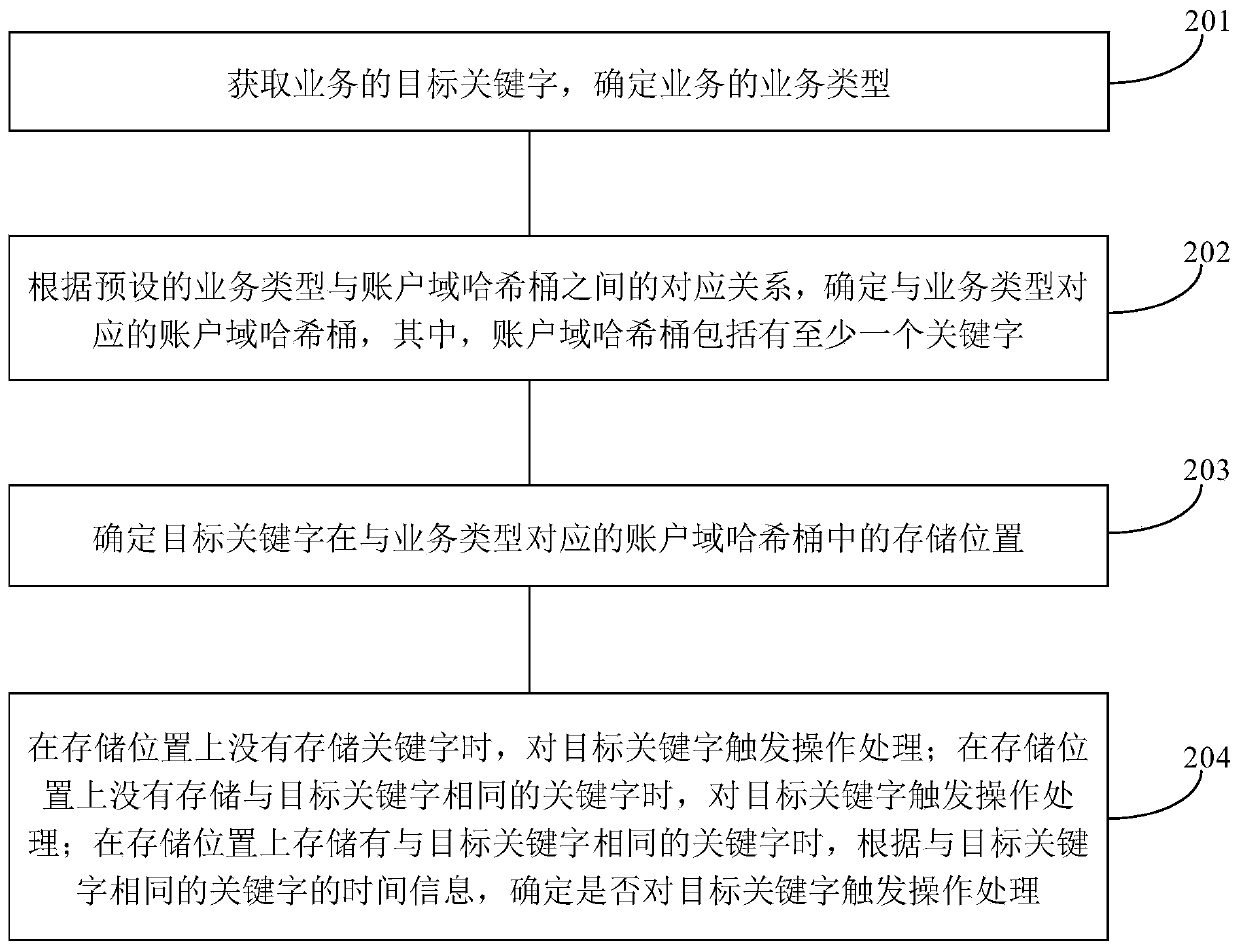

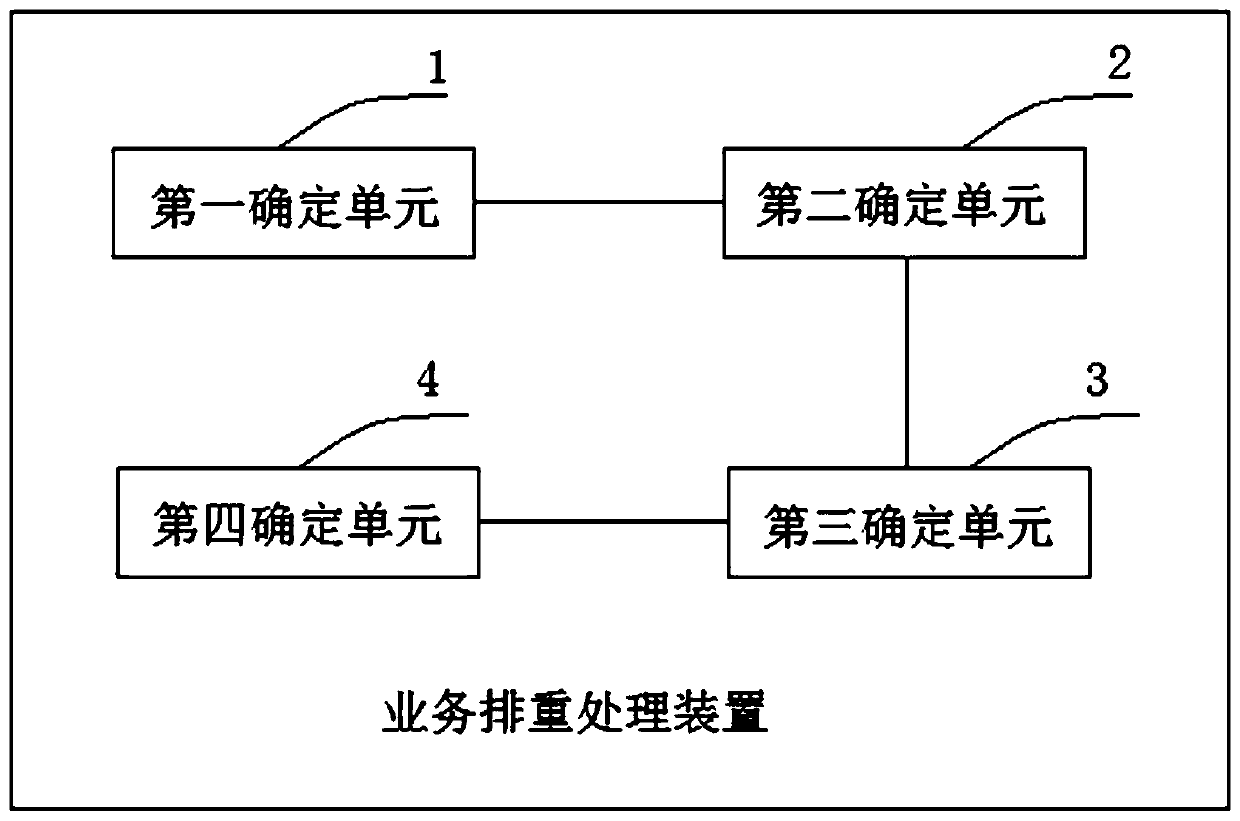

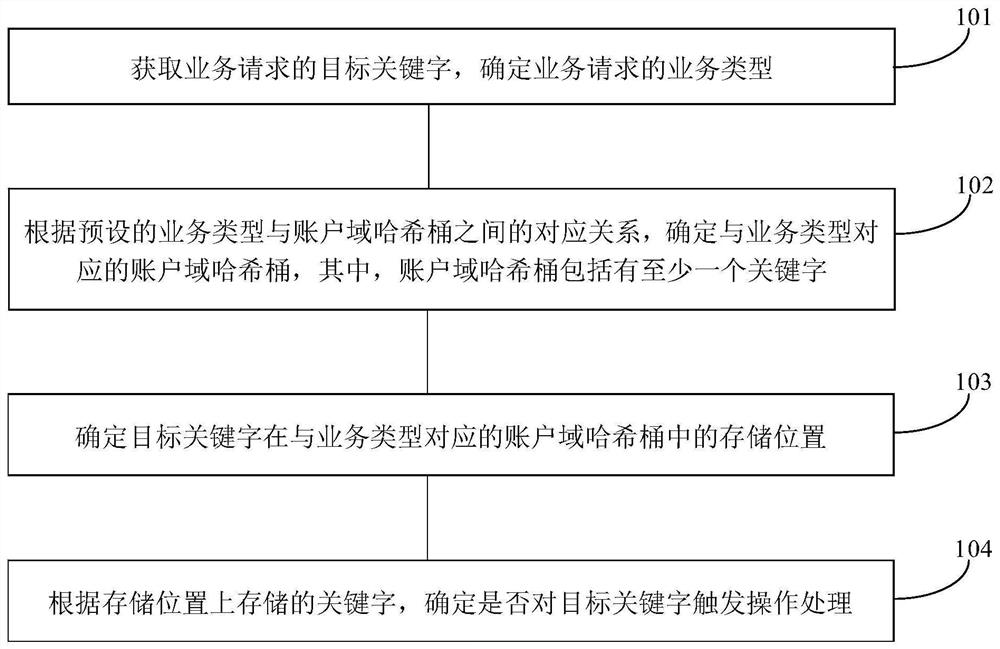

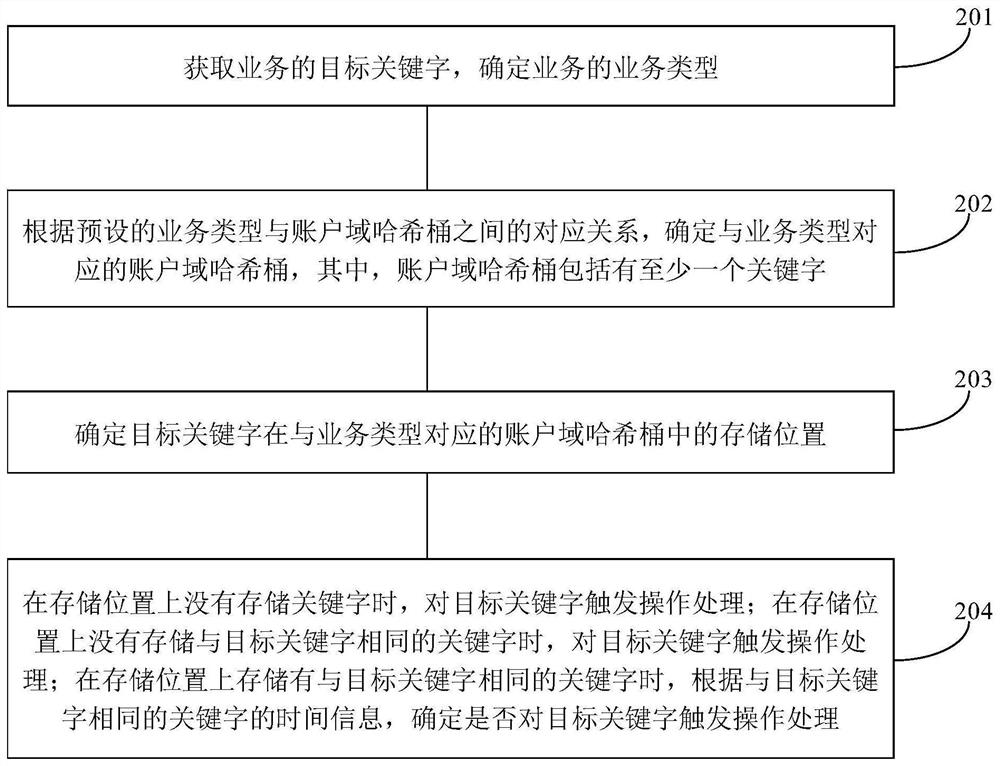

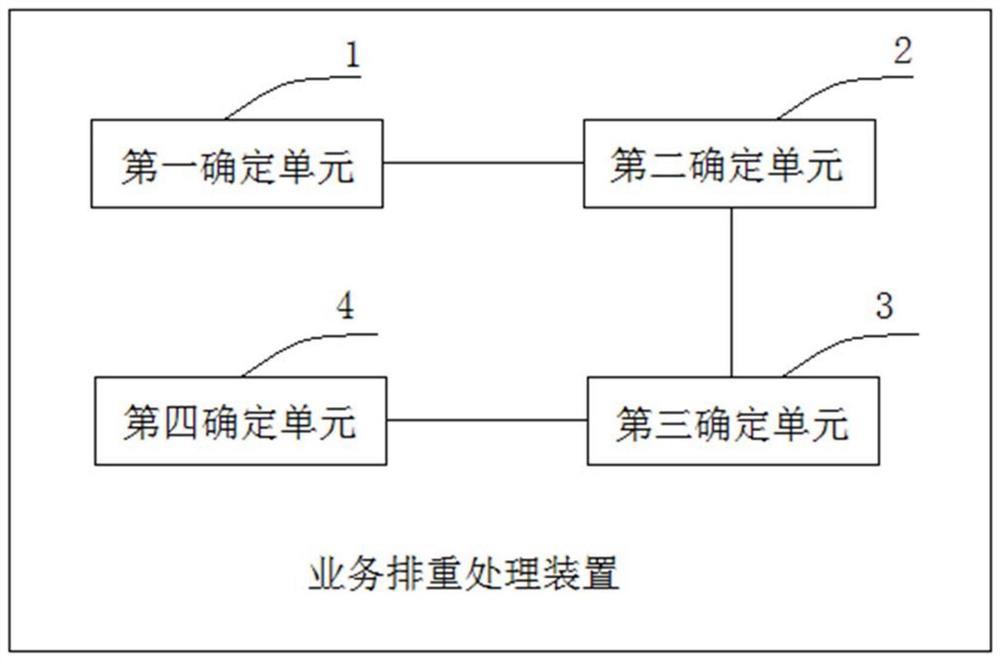

Service rearrangement processing method and device

ActiveCN109976896ALess weight removal workloadShort timeProgram initiation/switchingDatabase indexingWorkload

The invention provides a service rearrangement processing method, device and equipment and a storage medium, wherein the method comprises the steps of obtaining a target keyword of a service, and determining the service type of the service; determining an account domain hash bucket corresponding to the service type according to a preset corresponding relationship between the service type and the account domain hash bucket, the account domain hash bucket comprising at least one keyword; determining a storage position of the target keyword in an account domain hash bucket corresponding to the service type; and determining whether to trigger operation processing on the target keyword or not according to the keyword stored in the storage position, so that the service rearrangement processing is carried out according to the service type of the service request, the service rearrangement workload is small, the consumed time is short, and the service rearrangement efficiency can be effectivelyimproved. The service duplicate removal processing is carried out by using the Hash bucket to quickly calculate the duplicate removal result, so that the service duplicate removal efficiency is high,and the efficient operation of the service processing work is ensured.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Corn harvester exhaust fan system

InactiveCN105027856BReduce power consumptionLow costSaving energy measuresThreshersImpurityEnergy conservation

Owner:潍坊昌荣机械有限公司

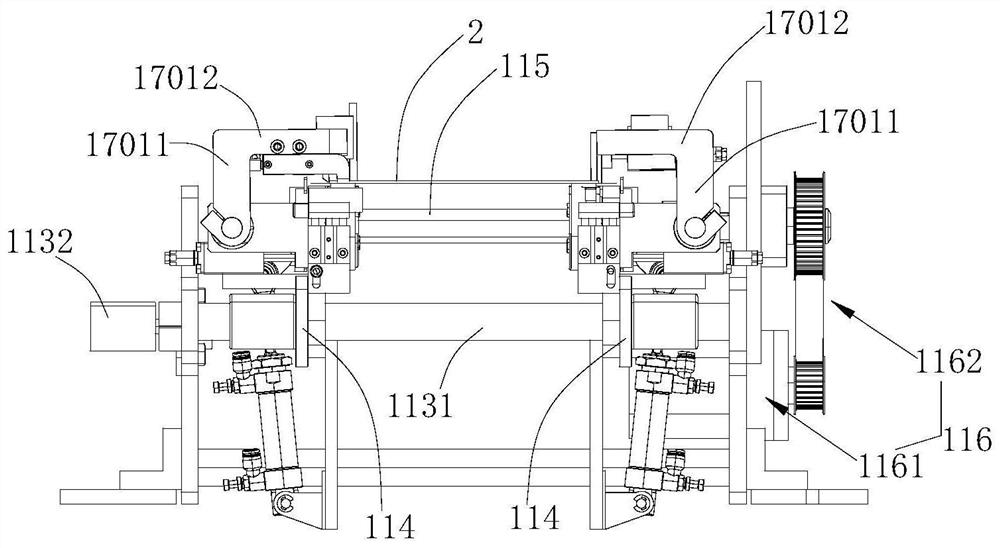

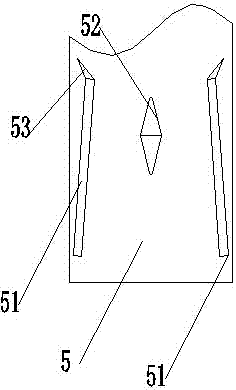

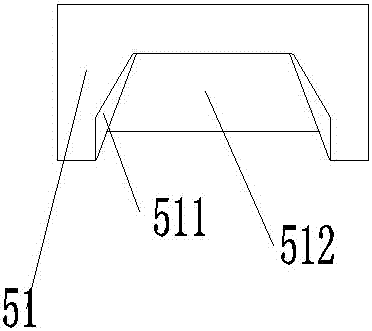

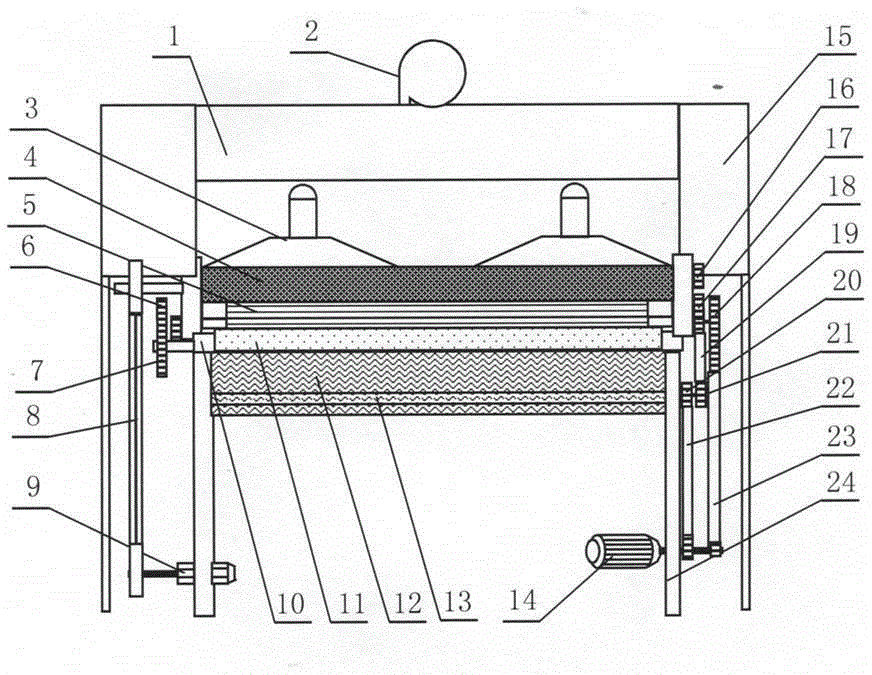

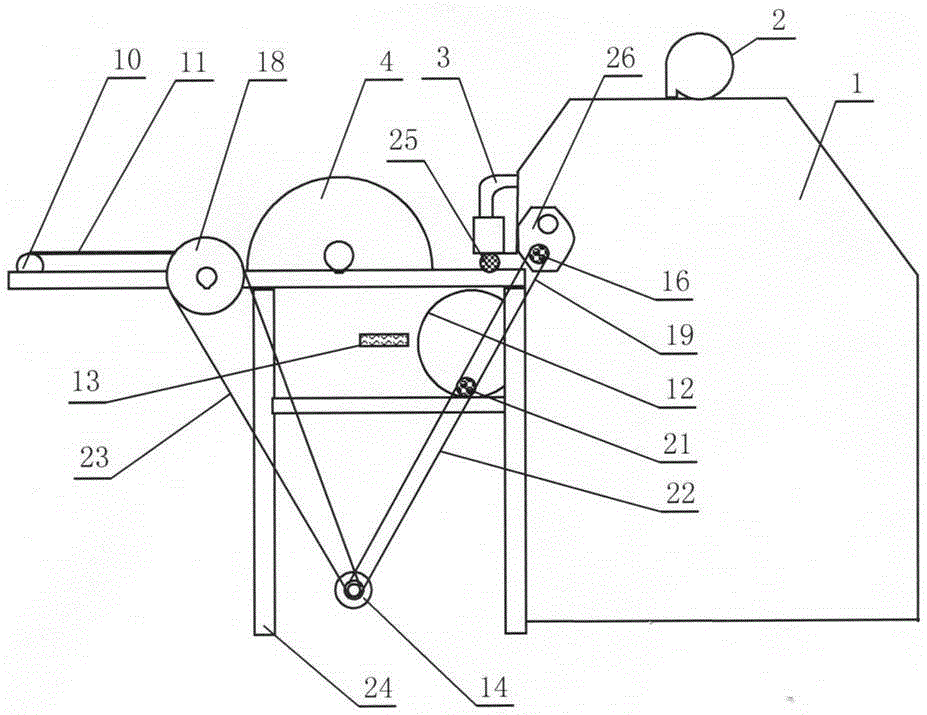

Multi-functional double row high output carding machine

InactiveCN103966702BMultifunctionalImprove waste removal efficiencyCarding machinesDischarge efficiencyBlack point

The invention discloses a multifunctional double-impurity-discharging high-yield carding machine. The problem that an existing device is small in application range, low in yield and large in impurity amount is solved. The multifunctional double-impurity-discharging high-yield carding machine is characterized in that a duct collection fan is arranged at the top of a cotton carding machine, and a duct collection pipe and a dust collector are arranged at the front opening position. A licker-in, a motor, a roller, a dust discharging cage, an impurity-discharging plate, a cotton pressing roller and a speed reducing motor are arranged between the front portion of the cotton carding machine and a cotton feeding curtain. Broken cotton seeds, dust and other impurities left in a cotton ginning process are removed through the high-speed licker-in, the dust discharging cage, the impurity-discharging plate and the like, and cotton wool, dust and other tiny and small impurities are removed through the duct collection fan, the duct collection pipe and the dust collector. The multifunctional double-impurity-discharging high-yield carding machine can fluffing cotton and silk floss, improves the impurity-discharging efficiency by 95% and is good in impurity-discharging effect, and a wooden bucket is free of cotton seeds, break-marks, black points and other impurities. The production efficiency is improved, the yield is doubled, and the multifunctional double-impurity-discharging high-yield carding machine can be used for carding the silk floss, used cotton, new cotton, cashmere wool and the like and is wide in application range.

Owner:淮北市淮棉棉机厂

Preparation method of iron-carbon micro-electrolytic filler

ActiveCN108609694BIncrease electrolysis rateImprove waste removal efficiencyWater/sewage treatmentElectrolysisIron powder

The invention relates to a preparation method of iron-carbon micro-electrolysis filler, which includes the following steps: mixing iron powder, aluminum slag and a surfactant and performing granulation and roasting to prepare iron-aluminum microspheres; mixing copper chip and carbon powder and performing granulation and roasting to prepare copper-carbon microspheres; mixing the iron-aluminum microspheres and copper-carbon microspheres with perlite, micalex, vermiculite and kaolin and compressing the mixture to form a filler green body; calcining the filler green body at high temperature to produce the iron-carbon micro-electrolysis filler. The iron-carbon micro-electrolysis filler can reach more than 93% in porosity, is uniform in pore diameter being controlled within 1.0-1.8 mm, and is high in removal rate of COD in sewage, which satisfies treatment standard of green ecological city.

Owner:ZHEJIANG NORMAL UNIVERSITY

Pneumatic auxiliary transportation and cleaning device in chili harvesting

PendingCN110199671AReduce chanceImprove waste removal efficiencyMowersFood treatmentEngineeringMechanical engineering

The invention relates to a pneumatic auxiliary transportation and cleaning device in chili harvesting . The pneumatic auxiliary transportation and cleaning device comprises a chili picking roller, a chili transportation channel, a main fan, a fluid guide and elastic finger rollers. Through the pneumatic auxiliary transportation and impurity removal device, the design concept of 'fine impurities first and coarse impurities second' is adopted to reduce the probability of secondary impurities of the picked chili, and the efficiency of impurity removal is greatly improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Controllable crossbreeding corn producing method

The controllable hybrid corn producing process includes the following steps: preparing hybrid seed via selecting corn self selecting line with green converting leaf color mark; propagation breeding and auxiliarily roguing to eliminate false self selecting line seedling without leaf color mark while reserving true self selecting line seedling with leaf color mark; and roguing in field production via drawing off seedling with leaf color mark while the seedling grows to 1-3 leaves. The said production process of monitoring hybrid corn is saving in time, high in roguing efficiency.

Owner:BEIJING KINGS NOWER SEED S&T

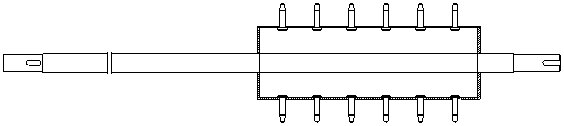

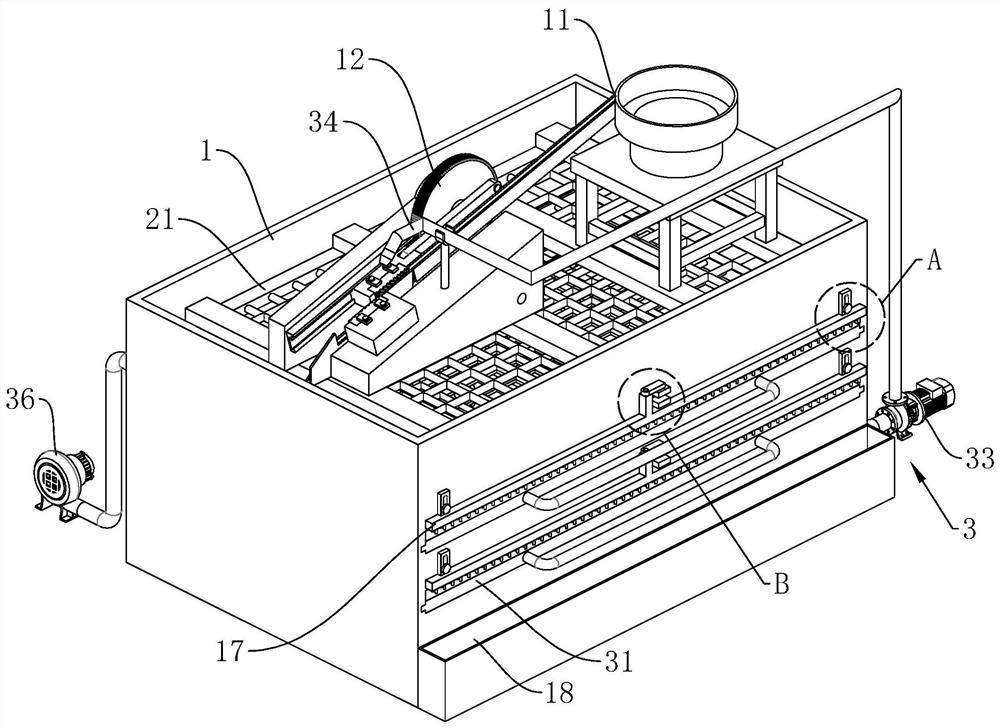

Efficient moisture-removing type sludge treatment device

InactiveCN105923955AImprove warm-up effectImprove waste removal efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMoistureSludge

The invention provides an efficient moisture-removing type sludge treatment device which comprises a mounting tank, a first sludge conveying mechanism, a second sludge conveying mechanism, a burning mechanism and an impurity draining mechanism, wherein a gas outlet is formed on the mounting tank; the first sludge conveying mechanism comprises a first feeding pipe, a first driving rod, a first spiral blade and a plurality of conveying auxiliary devices; a gas conducting channel is arranged in the first driving rod; a feeding port and a discharging port are formed in the first feeding pipe; each of the conveying auxiliary devices comprises a screw rod, a conical baffle block and an auxiliary fixing block; a plurality of check rails are mounted on the periphery of the conical baffle block; the second sludge conveying mechanism comprises a second feeding pipe, a second driving rod and a second spiral blade; the impurity draining mechanism comprises a material receiving frame and at least one impurity removing auxiliary device; the impurity removing auxiliary device comprises a third driving rod and two third spiral blades. The efficient moisture-removing type sludge treatment device is simple in mechanism, is capable of effectively increasing the temperature before sludge burning and capability of reducing the water in the sludge.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Ultrafine high-efficient electrolytic material

InactiveCN103043751AImprove reusabilityImprove waste removal efficiencyWater/sewage treatmentInitial treatmentTherapeutic effect

The invention relates to an ultrafine high-efficient electrolytic material. The ultrafine high-efficient electrolytic material is prepared by taking zinc powder, graphite powder and silicon powder as preparation raw materials, fully mixing according to a certain proportion, and then placing into a crushing machine for fining. The ultrafine high-efficient electrolytic material disclosed by the invention can be used for direct treatment of acidic, alkaline and neutral wastewater, an acid-base blender, activated carbon and other substances do not need to be added during the treatment process, the operation is convenient and fast, the waste removal efficiency is high, the reutilization property of the wastewater can be greatly improved, the ultrafine high-efficient electrolytic material is particularly suitable for initial treatment of the wastewater in printing and dyeing, pharmacy, petroleum, chemical engineering, heavy metals and other industries, and the treatment effect is very ideal.

Owner:赵强

Styling machine thermal cycle and waste removal system

InactiveCN103741421BRealize inner loopReduce energy consumptionHeating/cooling textile fabricsDrying solid materialsThermal energyToxic material

The invention discloses a setting machine thermal-cycling and waste-removing system which comprises a cloth feeding device, and a plurality of drying rooms which are connected with the cloth feeding device and are connected with each other in an end-to-end manner; one side of each drying room is provided with a heating device, and the other side is provided with a pair of blower fans; an upper air channel and a lower air channel which are communicated with the pair of blower fans are disposed in each drying room; connecting pipes are disposed between at least two or more than two drying rooms; an air inlet is disposed at one end of each connecting pipe, and an air outlet is disposed at the other end of each connecting pipe; the air inlet is disposed near the heating device of the drying room, and the air outlet is disposed near the pair of blower fans of the drying room. The advantages of the system of the invention are that being different from current heat recovery systems with a single drying room, the system realizes internal circulation of hot air between drying rooms; with the disposed waste-removing device, the system can not only recover residual heat energy, but also remove waste gas, oil smoke and toxic substances generated during setting process, and realizes the effects of discharge reduction and environment protection.

Owner:张子军

Screw thread rolling machine

ActiveCN112122518AReduce collectionReduce the probability of the mixture falling into the bodySievingScreeningProcess engineeringScrew thread

The application relates to a screw thread rolling machine comprising a machine body, a feeding mechanism used for feeding screw blanks, and a thread rolling mechanism used for rolling threads of the screw blanks conveyed through the feeding mechanism; a first sliding chute is formed in one outer side wall of the machine body in the length direction of the machine body, and a screw filtering screenused for filtering impurities is arranged in the first sliding chute slidably; and the screw filter screen is located below the thread rolling mechanism and the feeding mechanism, and a recycling mechanism used for recycling waste materials is arranged in the machine body, and located below the screw filter screen. According to the screw thread rolling machine, impurities and screws falling intothe machine body are filtered through the screw filter screen, and the probability that the waste materials and impurities fall into the machine body in a mixed mode is effectively reduced; the effective filtering of the impurities and the effectively collection of the waste materials are achieved, and the waste materials falling into the machine body are further collected through the recycling mechanism; the waste cleaning difficulty is reduced, and the effect of improving the waste cleaning efficiency is achieved; and meanwhile, the waste materials can be further recycled, and the economic benefits are improved.

Owner:苏州市晋元紧固件有限公司

A kind of starch alcohol wastewater treatment system and method

ActiveCN106315983BIncrease load factorEvenly distributedWater/sewage treatment by centrifugal separationSludge treatmentAerobic treatment systemResource utilization

The invention relates to an environment-friendly wastewater treatment process, in particular to a starch alcohol wastewater treatment system and method. The method comprises the steps of pretreatment, primary anaerobic treatment, secondary anaerobic treatment, secondary aerobic treatment, sludge treatment and the like. A CSTR, a UASB anaerobic reactor and an SBR aerobic treatment system are combined for treating the starch wastewater; meanwhile, the recovery of waste gas and waste slag in the wastewater treatment process is enhanced; the resource utilization rate is enhanced; the goal of further enhancing the waste slag and waste gas utilization in the wastewater treatment process is achieved; the cost is reduced; meanwhile, the operation efficiency of the equipment is ensured; the goal of discharging the wastewater in a standard reaching way is achieved.

Owner:GUANGXI LUOCHENG KECHAO FOUND SCI & TECH DEV

Waste water treatment filling material

InactiveCN106809917AImprove reusabilityImprove waste removal efficiencyWater/sewage treatmentTherapeutic effectPetroleum

The invention is a filler for waste water treatment. The preparation raw materials are, by weight percentage, 60-70% of copper powder, 5-15% of magnesium chloride, 10-20% of activated carbon, 5-15% of silicon powder, and 5-15% of talc powder , prepared by mixing. The present invention can directly treat acidic, alkaline and neutral wastewater without adding other substances such as acid-base blending agent during the treatment process, which is convenient, fast, and has high waste removal efficiency, and can greatly improve the reusability of wastewater, especially It is suitable for primary treatment of wastewater in printing and dyeing, pharmaceutical, petroleum, chemical, heavy metal and other industries, and the treatment effect is very ideal.

Owner:周子童

Business deduplication processing method and device

ActiveCN109976896BLess weight removal workloadShort timeProgram initiation/switchingDatabase indexingDatabaseOperating system

The present application provides a business deduplication processing method, device, device, and storage medium, wherein the method includes: obtaining the target keyword of the business, determining the business type of the business; The corresponding relationship between, determine the account domain hash bucket corresponding to the business type, wherein the account domain hash bucket includes at least one keyword; determine the storage location of the target keyword in the account domain hash bucket corresponding to the business type ; Determine whether to trigger operation processing on the target keyword according to the keyword stored in the storage location. It realizes the business deduplication process according to the business type of the business request, and the business deduplication workload is small and the time is short, which is conducive to effectively improving the efficiency of the business deduplication; it realizes the business deduplication process by using the hash bucket to quickly calculate the deduplication result , the efficiency of business deduplication is high, which is conducive to ensuring the efficient operation of business processing.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Novel washing filtering device

InactiveCN103418181ASimple structureImprove waste removal efficiencyFiltration circuitsWater storageFilter media

The invention relates to a novel washing filtering device comprising a left cavity and a right cavity; the left cavity consists of a washing chamber, a filling chamber and a left water storage chamber from top to bottom; the right cavity consists of a porous filtering chamber, a filter media chamber and a right water storage chamber; a washing spraying pump is disposed on the top of the left cavity; and a filtering spraying pump is disposed one side surface of the right cavity. The novel washing filtering device is simple in structure and good in waste removal effect.

Owner:TAICANG ZIWU ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com