Corn harvester exhaust fan system

A technology of corn harvester and fan system, applied in agricultural machinery and implements, agricultural machinery equipment, threshing equipment, etc., can solve the problems of low waste removal efficiency, complex transmission structure, high cost, etc., to reduce power consumption and simplify transmission structure , the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

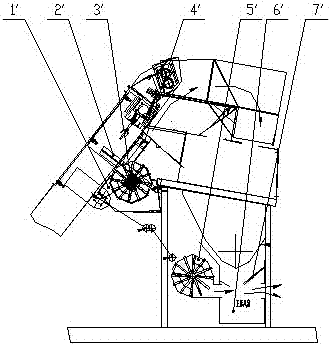

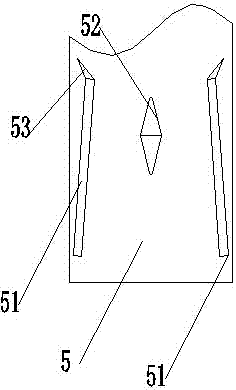

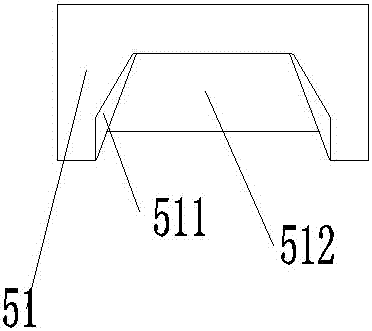

[0029] Examples, as attached figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 And Figure 5 As shown, the impurity exhaust fan system of the corn harvester includes an elevator 8 and a peeling frame 9. The main fan bracket 2 is located between the elevator 8 and the peeling frame 9, and the main fan bracket 2 is fixed with a main fan 1. The air duct 5 is connected between the main fan 1 and the recovery bin 6.

[0030] The main fan 1 is equipped with a bearing 3, the bearing 3 is fixed on the main fan bracket 2, and the air duct 5 is connected and fixed to the main fan 1 and the recovery bin 6. The recovery bin 6 is installed on the peeling frame, and the deflector 7 is in the Recycle bin 6.

[0031] The screen 11 is also included. Between the recovery bin 6 and the screen 11 is a negative pressure air chamber 12.

[0032] When working, the main fan 1 rotates, and the wind is sucked into the air duct 5 through the opening on the recovery bin 6. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com