Multi-functional double row high output carding machine

A high-yield and multi-functional technology, used in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of elastic cotton can not elastic cotton, elastic cotton can not elastic cotton, many impurities, etc., to save electricity, the scope of application Wide and good effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

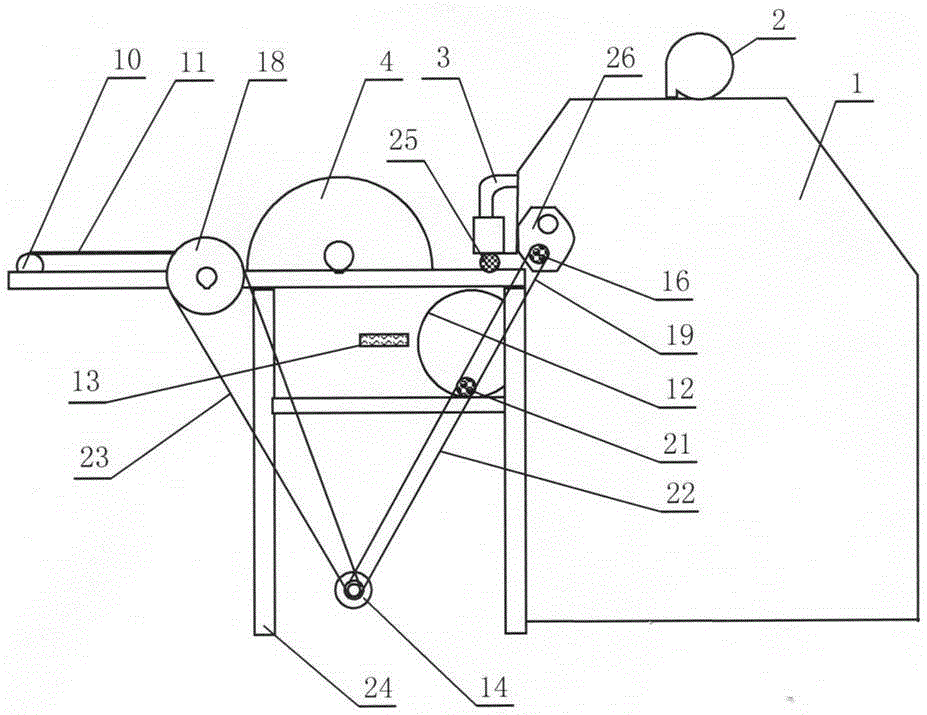

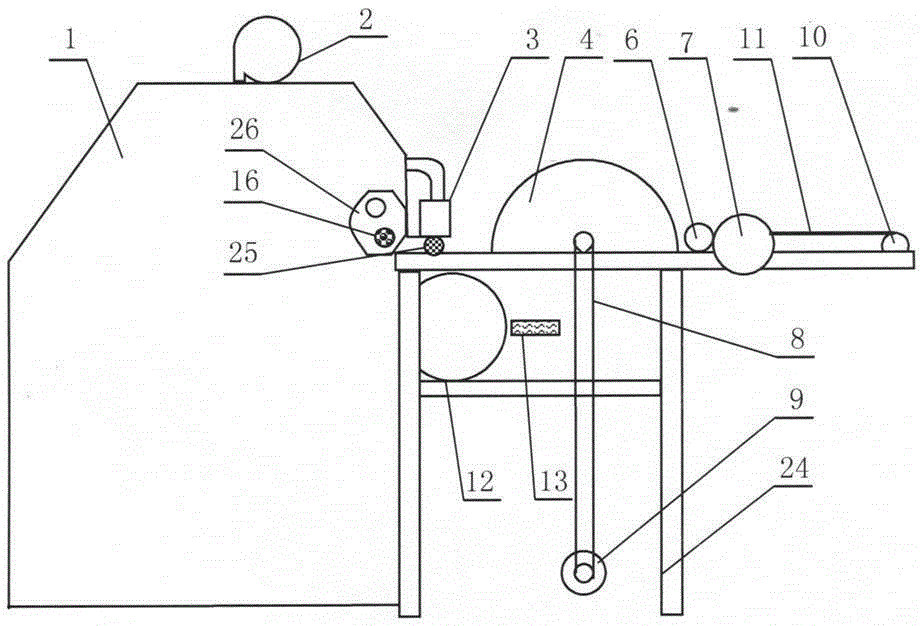

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

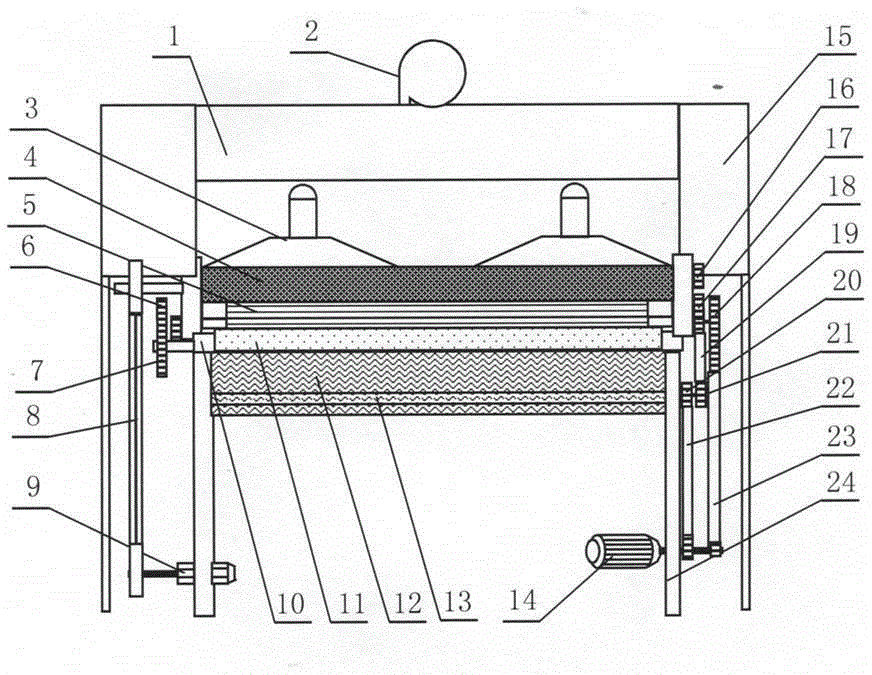

[0016] Such as figure 1 As shown, the present invention includes carding machine 1, protective cover 15, cotton feeding roller 10, cotton feeding curtain 11, toothed roller 26, support 24 etc. The top of the carding machine 1 is provided with a dust suction fan 2, and the front mouth is provided with a dust suction pipe and a vacuum cleaner 3, which are used to remove tiny and small impurities such as cotton wool and dust; between the front of the carding machine 1 and the cotton feeding curtain 11 Licker-in roller 4, roller 5, motor 9, dust cage 12, miscellaneous plate 13, cotton pressing roller 25, reduction motor 14, etc. are arranged between them.

[0017] There is one licker-in roller 4 with a rotating speed of 1900-2000rpn, connected to a motor 9 by a licker-in roller belt 8 .

[0018] combine figure 2 , image 3 As shown, there are two pressing rollers 25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com