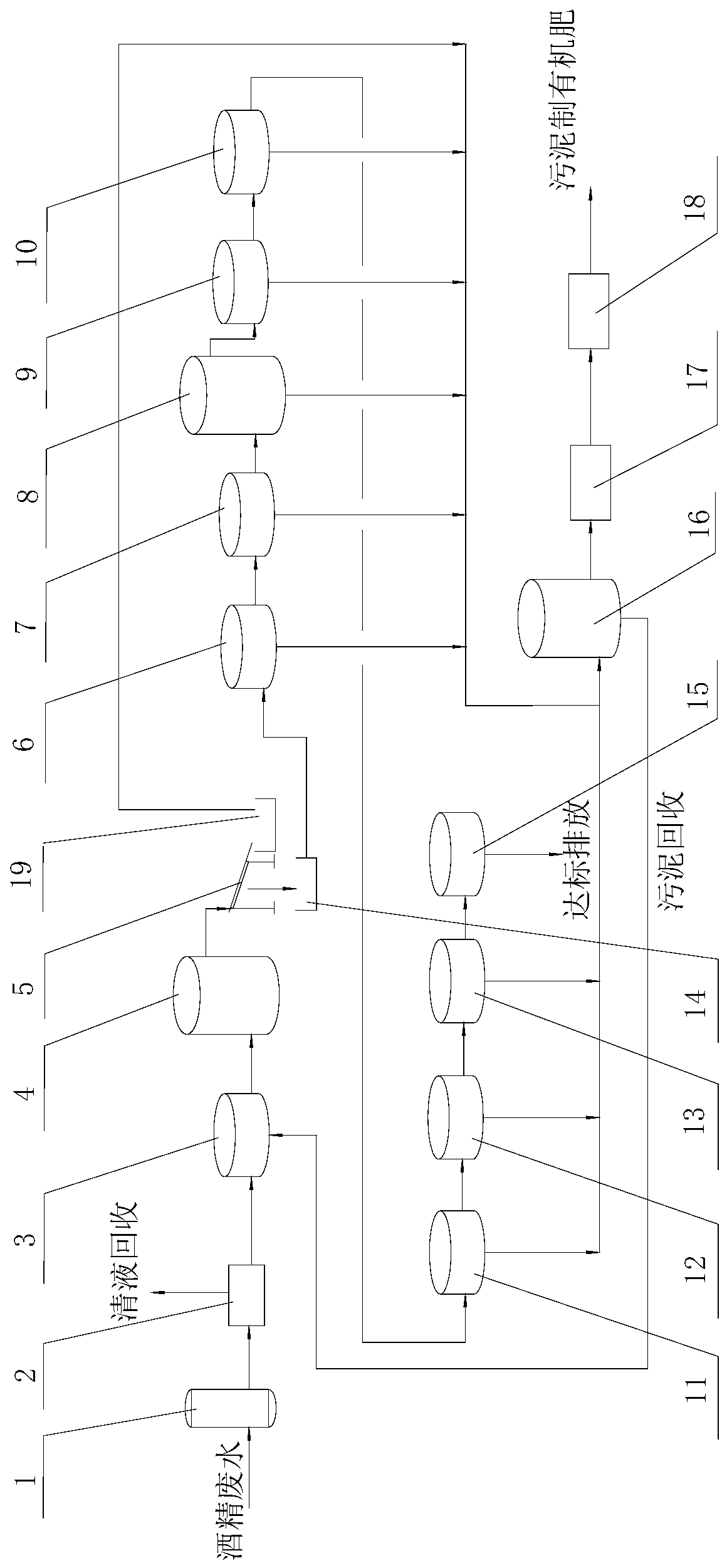

A kind of starch alcohol wastewater treatment system and method

A technology of alcohol wastewater and treatment system, which is applied in the direction of food industry wastewater treatment, sedimentation treatment, natural water treatment, etc. It can solve the problems of high cost of starch wastewater, large floor area, complex equipment, etc., and achieve high COD load rate, The effect of reducing work stress and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The waste water and distiller's grains produced in the alcohol processing section are collected by the waste liquid storage tank, and then centrifugally separated by a centrifuge. The organic wastewater is monitored and adjusted. When the suspended content of organic matter in the waste liquid reaches 30g / L, the waste liquid is pumped into the first-stage anaerobic reactor for anaerobic reaction. The first-stage anaerobic reactor is selected from the CSTR anaerobic reactor. , the reaction temperature is 50°C, the pH value of the reaction is 6, and the volume load of COD is 300kg / (m 3 d), after 50 days of stable operation, the concentration of suspended solids in the feed wastewater can be increased to 4000mg / L, and the volume load of COD is 800kg / (m 3 d); The diameter of the methanogenic phase granular sludge is 1mm-3mm, and the sludge concentration is 70kg / m 3 The reaction time is 4 days. The biogas generated by the primary anaerobic reaction is recycled through the b...

Embodiment 2

[0042] The waste water and distiller's grains produced in the alcohol processing section are collected by the waste liquid storage tank, and then centrifugally separated by a centrifuge. The organic wastewater is monitored and adjusted. When the suspended content of organic matter in the waste liquid reaches 50g / L, the waste liquid is pumped into the first-stage anaerobic reactor for anaerobic reaction. The first-stage anaerobic reactor is the CSTR anaerobic reactor. , the reaction temperature is 55°C, the pH value of the reaction is 7, and the volume load of COD is 500kg / (m 3 d), after 60 days of stable operation, the concentration of suspended solids in the feed wastewater can be increased to 4500mg / L, and the volume load of COD is 1200kg / (m 3 d); The diameter of the methanogenic phase granular sludge is 1mm-3mm, and the sludge concentration is 150kg / m 3 The reaction time is 6 days. The biogas generated by the first-stage anaerobic reaction is recovered through the biogas p...

Embodiment 3

[0044] After the waste water and distiller's grains produced in the alcohol processing section are collected in the waste liquid storage tank, they are centrifugally separated by a centrifuge, and the clear liquid is recycled to the crushing section of the starch alcohol processing section for mixing. The organic wastewater in the liquid storage tank is monitored and adjusted. When the suspended content of organic matter in the waste liquid reaches 40g / L, the waste liquid is transferred to the first-stage anaerobic reactor by pump for anaerobic reaction. The first-stage anaerobic reactor uses CSTR anaerobic reactor. Oxygen reactor, the reaction temperature is 52°C, the pH value of the reaction is 6.5, and the volume load of COD is 400kg / (m 3 d), after 55 days of stable operation, the concentration of suspended solids in the feed wastewater can be increased to 4200mg / L, and the volume load of COD is 1000kg / (m 3 d); the diameter of the methanogenic phase granular sludge is 1mm-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com