Cotton fiber impurity removing device and method based on cotton fiber transfer device

A transfer device, cotton fiber technology, applied in the direction of separating plant fibers from seeds, etc., can solve the problems of low impurity removal efficiency, large noise pollution and air pollution of sawtooth fluffing machine, and achieve a significant offset effect and reduce windward resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

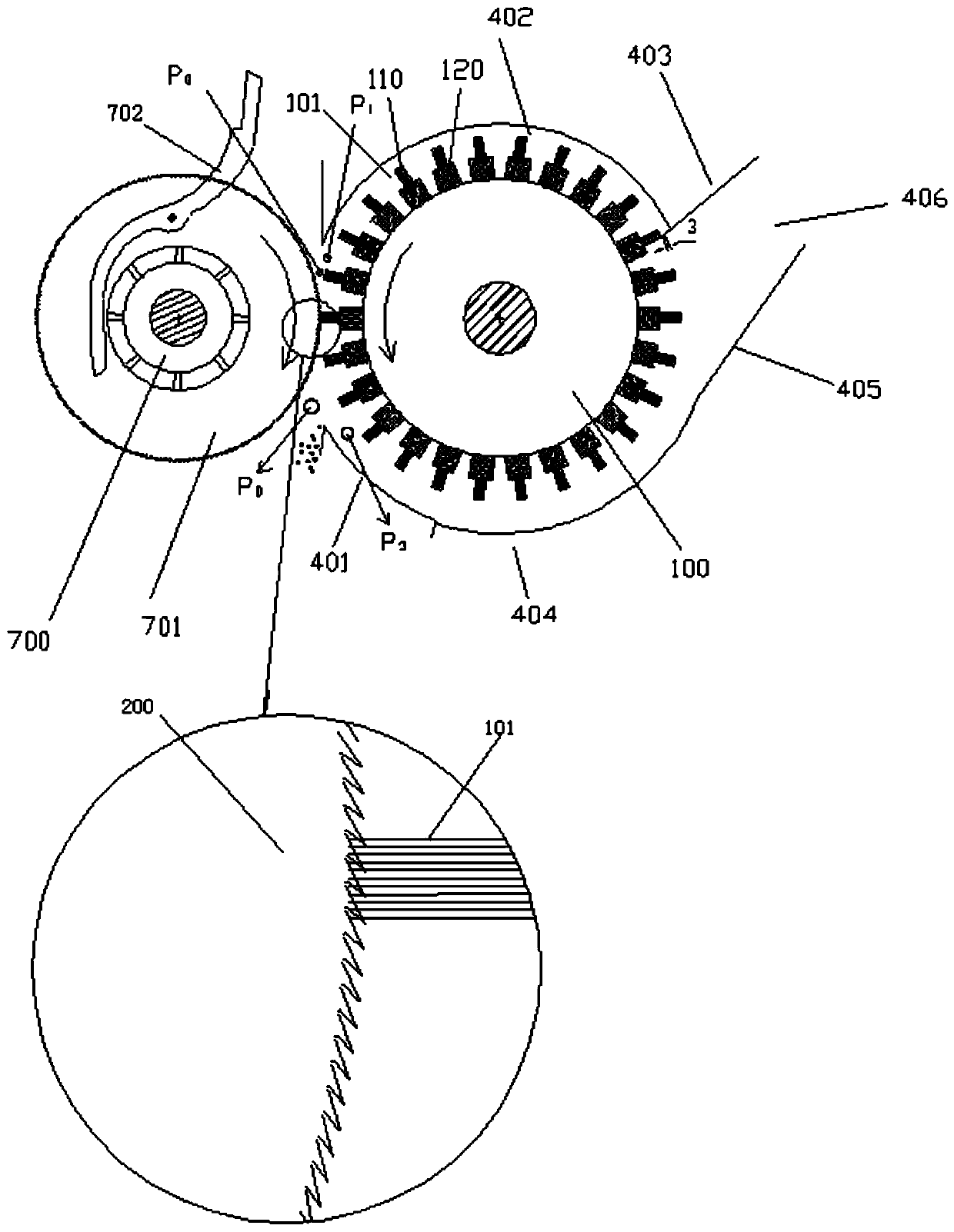

Embodiment 1

[0084] A high-efficiency cotton fiber impurity removal device based on a splint roller, a splint roller 200 and a saw blade roller 700 are set up between the box boards on both sides, and the diameter of the splinter roller is larger than that of the saw blade roller Diameter, the effective length of the thorn roller is greater than the effective length of the saw roller, the thorn roller and the saw roller are arranged and driven in the following way, between the saw roller and the thorn roller The cotton brushing area is formed between the cylinders: the thorn roller and the saw roller are axially parallel; the distance x between the thorn roller and the saw roller surface is kept at 0.6 mm; the thorn roller 200 and the saw roller 700 are formed by The driving device drives the rotation, and the direction of rotation is opposite. The linear speed of the thorn roller is greater than that of the saw roller, so that the cotton fiber rotates with the saw roller to form a floating...

Embodiment 2

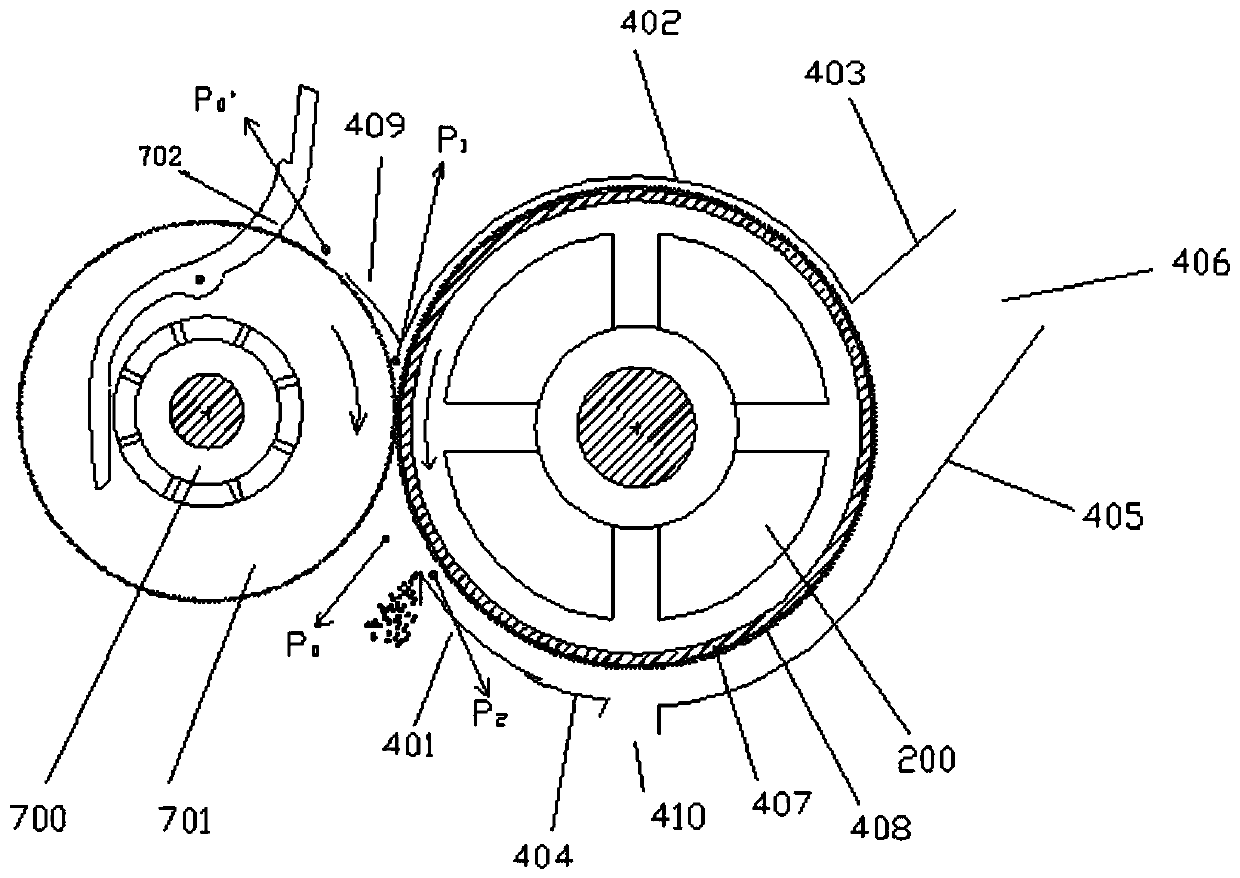

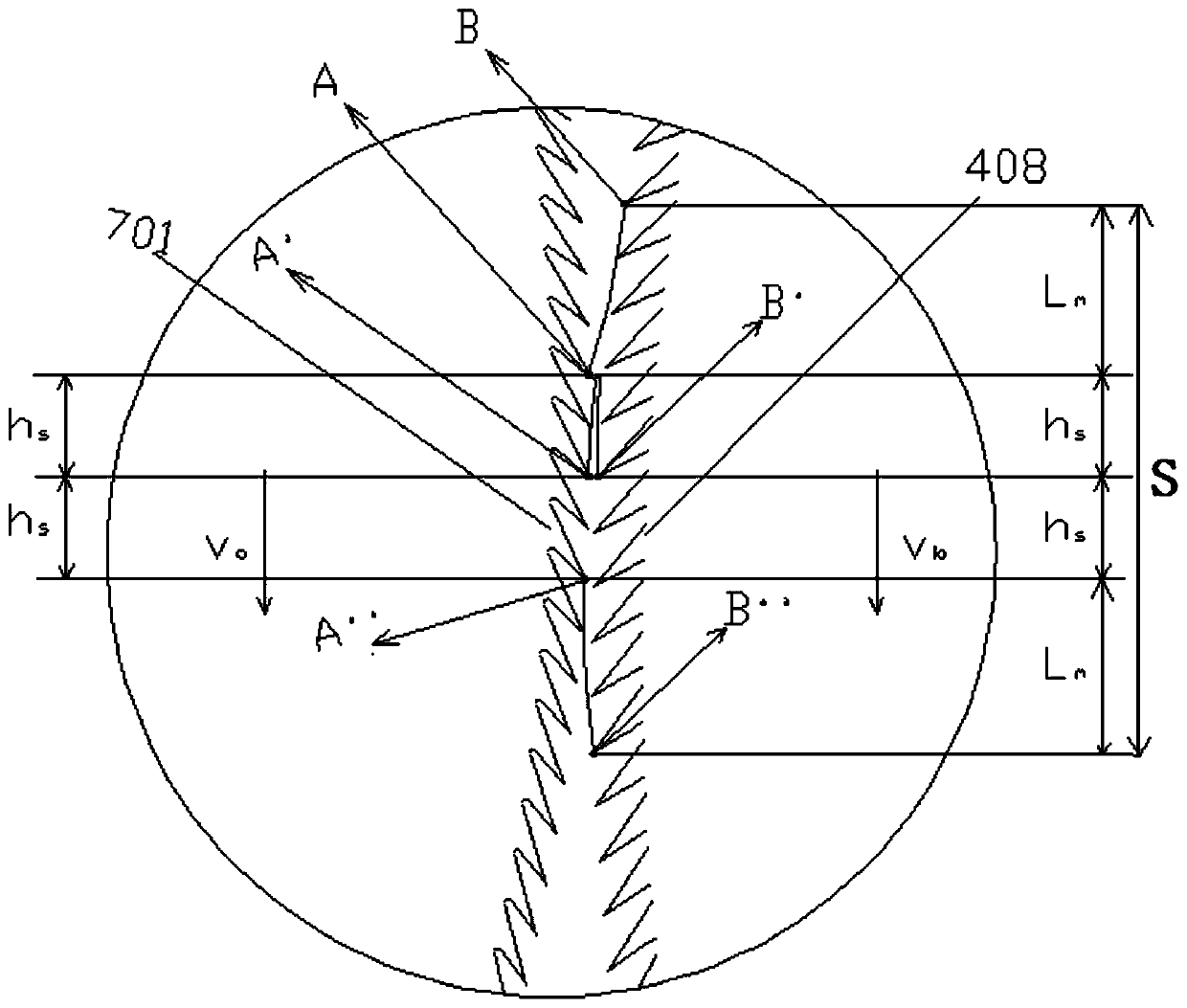

[0110] Such as figure 2A high-efficiency fiber removal device based on the barbed roller, the diameter of the saw blade roller of the sawtooth stripping machine is 320mm, the working length of the saw roller is 1024.25mm, and the speed is 700 rpm; the diameter of the barbed roller is 400mm, The working length of the barbed roller is 1070mm, and the barbed layer 408 composed of 109 comb racks and card clothing is evenly wound on the surface of the barbed roller shell 407 along the circumference, and the barbed winding distance is 2mm. The surface of the barbed roller housing 407 is distributed in the same direction of rotation or arranged perpendicular to the surface of the barbed layer, the height of the comb rack is 3 mm, and the radius R of the barbed layer 408 is 1 =203mm, the volume ratio of the comb rack to the volume of the barbed layer 408 is 40%, the rotating speed of the barbed roller is 1440 rpm; the axial gap between the saw blade roller and the barbed roller is 0....

Embodiment 3

[0114] Such as Figure 6 , a high-efficiency fiber removal device based on the barbed roller, the diameter of the saw blade roller of the sawtooth stripping machine is 320mm, the working length of the saw roller is 1024.25mm, and the speed is 390 rpm; the diameter of the barbed roller is 250mm , the working length of the barbed roller is 1070mm, the barbed layer 408 composed of 109 comb racks and card clothing is evenly wound on the surface of the barbed roller shell 407 along the circumference, the barbed winding distance is 2mm, all the barbed racks Distributed toward the same rotation direction on the surface of the barbed roller shell 407 or arranged perpendicular to the surface of the barbed bar layer, the comb rack is 3 mm high, and the radius R of the barbed bar layer 408 is 1 =128.5mm, the volume ratio of the comb rack to the volume of the barbed layer 408 is 40%, the speed of the barbed roller is 2100 rpm; the axial gap between the saw blade roller and the barbed roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com