Impurity removing and air discharging machine for cane harvester

A harvester, sugarcane technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low degree of mechanization, high cost of cane sugar production, lack of competitiveness, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

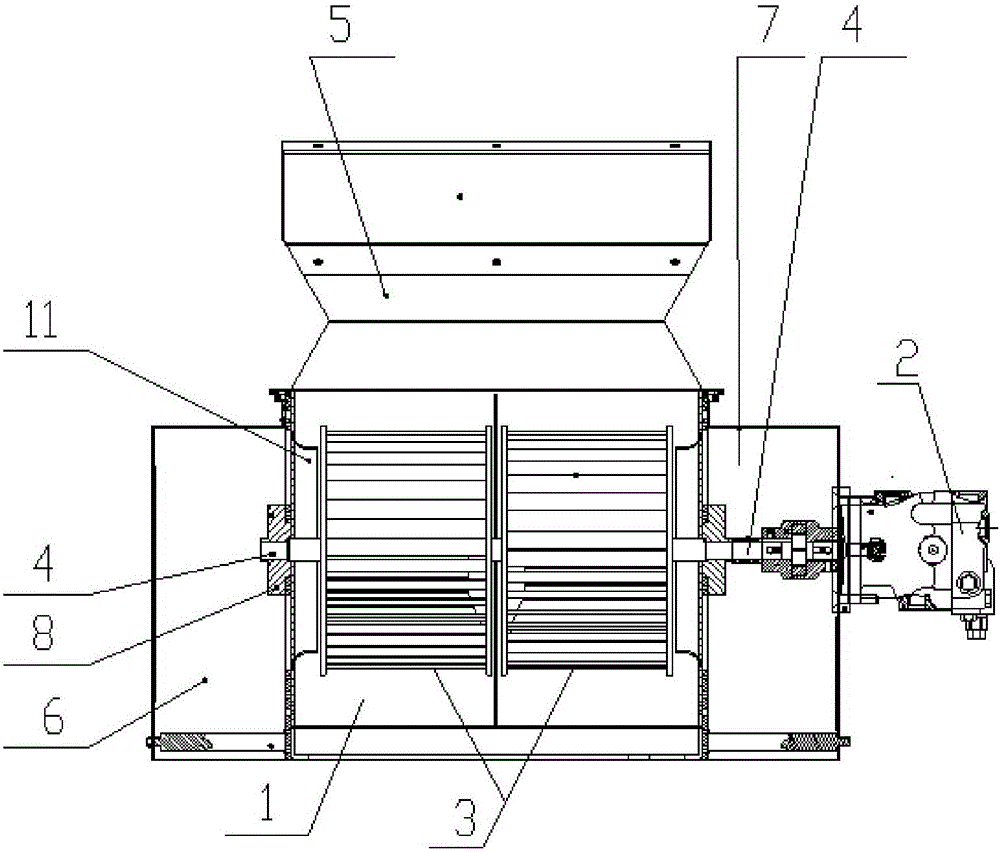

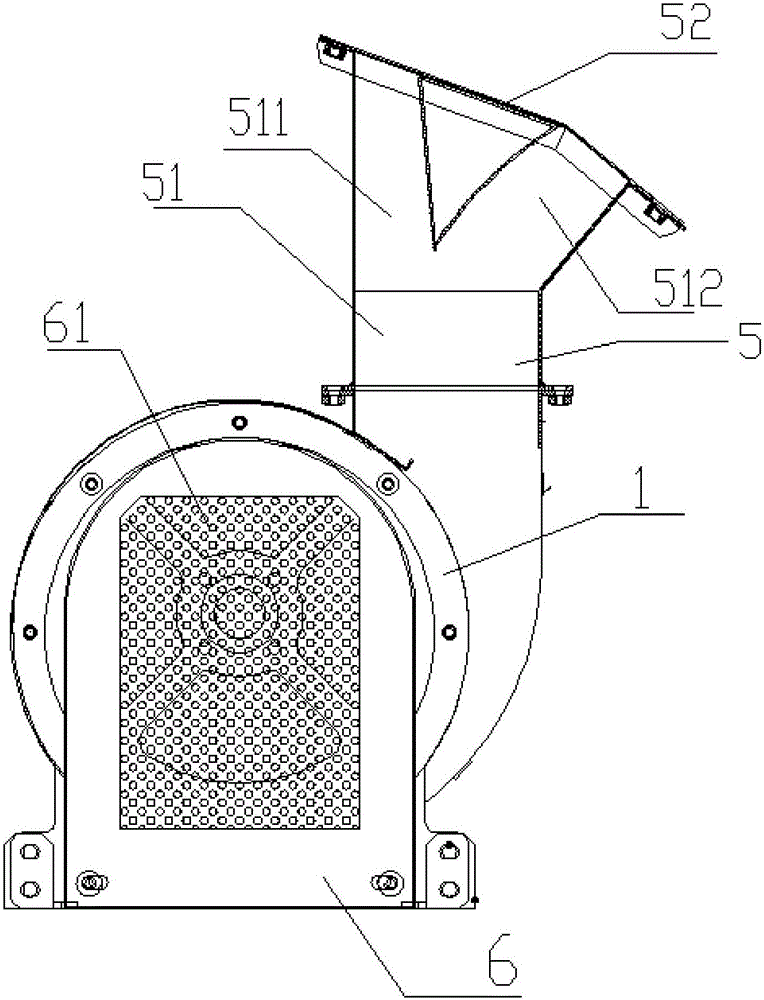

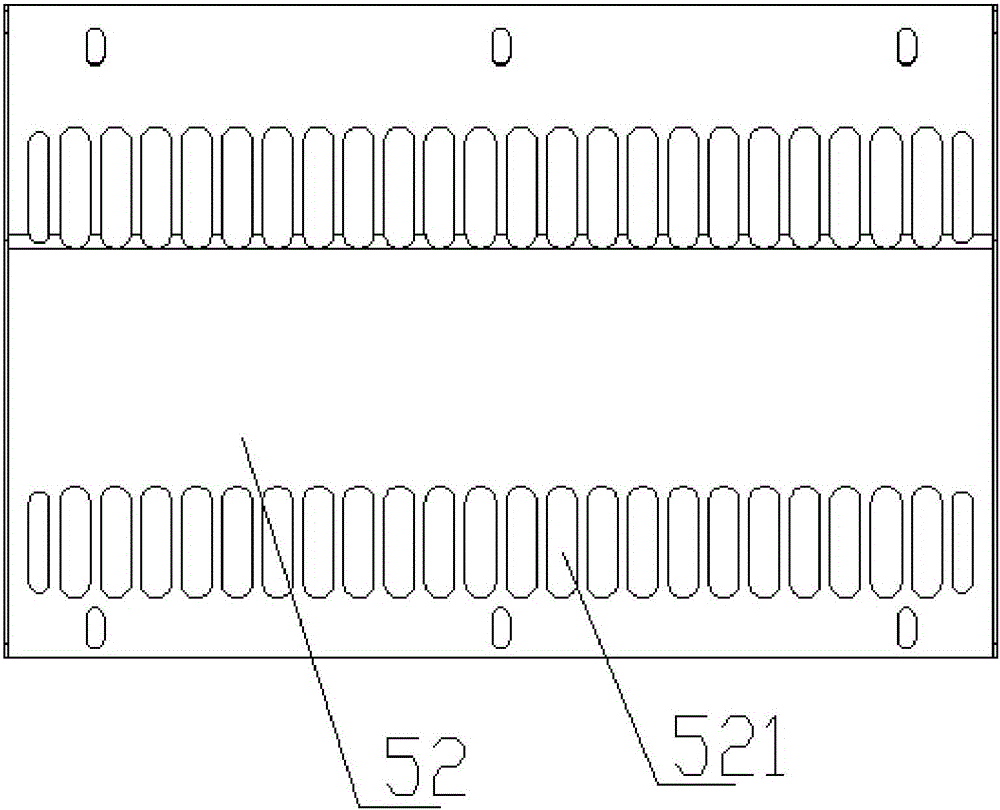

[0018] Combined with Figure 1, figure 2 , image 3 , Figure 4 , which describes the specific implementation of the present invention in detail, but does not limit the claims in any way.

[0019] As shown in Figures 1, 2, 3, and 4, a blower for exhausting waste of a sugarcane harvester includes a rotary body bellows 1, a motor 2, an impeller 3, a left air inlet box 6, a right air inlet box 7, a diversion chamber 5, The air outlet cover plate 52, the motor 2 is connected to the bellows shaft 4 through a coupling, and the bellows shaft 4 is connected to two impellers 3 through a key. The inner wall is also provided with an arc-shaped flange 11, and the bellows shaft 4 passes through the central through hole of the arc-shaped flange 11. Bearings are provided at the center of the outer walls of the left and right end surfaces of the rotary bellows 1, and the bellows shaft 4 is connected with the bearings.

[0020] The outer walls of the left and right end faces of the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com