Efficient moisture-removing type sludge treatment device

A technology for sludge treatment and dehydration, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. requirements and other issues, to achieve the effects of reducing moisture, high impurity removal efficiency, and improving preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

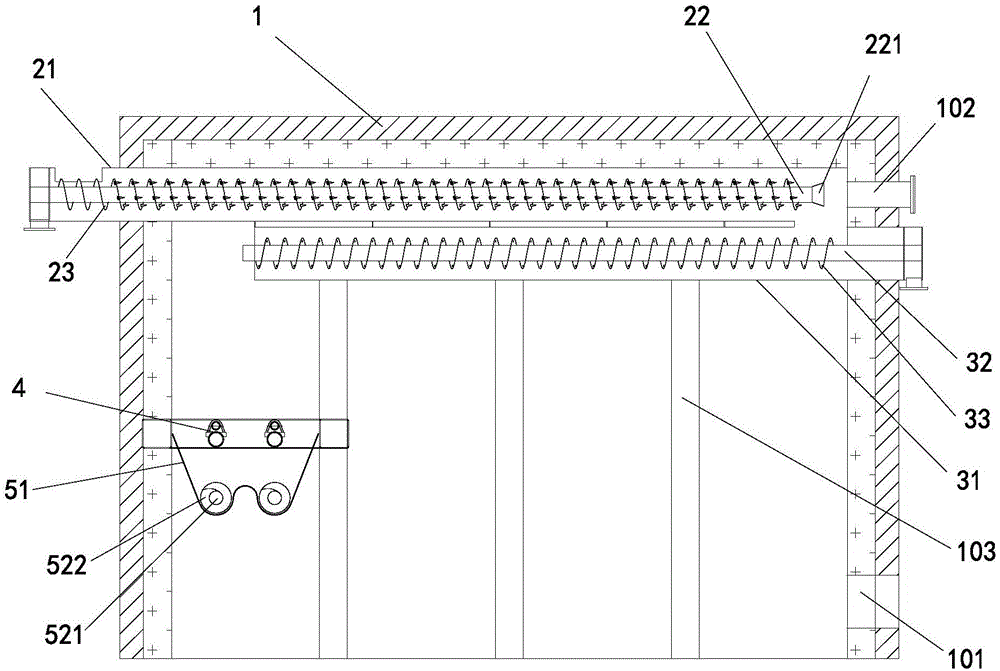

[0020] refer to figure 1 and figure 2 As shown, a kind of high-efficiency dehydration type sludge treatment equipment proposed by the present invention includes an installation box, a first sludge conveying mechanism, a second sludge conveying mechanism, an incineration mechanism 4 and a miscellaneous discharge mechanism. Air port 101;

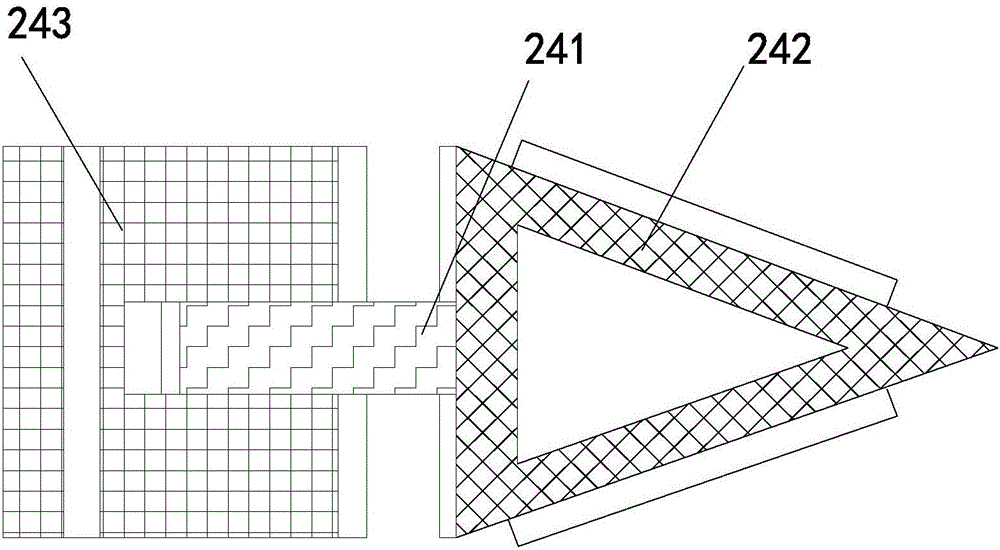

[0021] The first sludge conveying mechanism includes a first feeding pipe 21, a first driving rod 22, a first screw blade 23 and a plurality of auxiliary conveying devices. The first feeding pipe 21 is installed on the upper part of the installation box, and the first end of the first driving rod 22 is Rotatably installed on the first feeding pipe 21, the second end of the first driving rod 22 extends into the first feeding pipe 21, the first driving rod 22 is provided with an air guiding channel, and the air guiding channel is along the axis of the first driving rod 22 To pass through the first driving rod 22, the first feeding pipe 21, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com