Punching and waste discharging technology for packaging box material plate

A packaging box and material board technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of inconvenient collection of punching and discharging waste, achieve convenient and quick adjustment, high waste removal efficiency, and reduce design difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

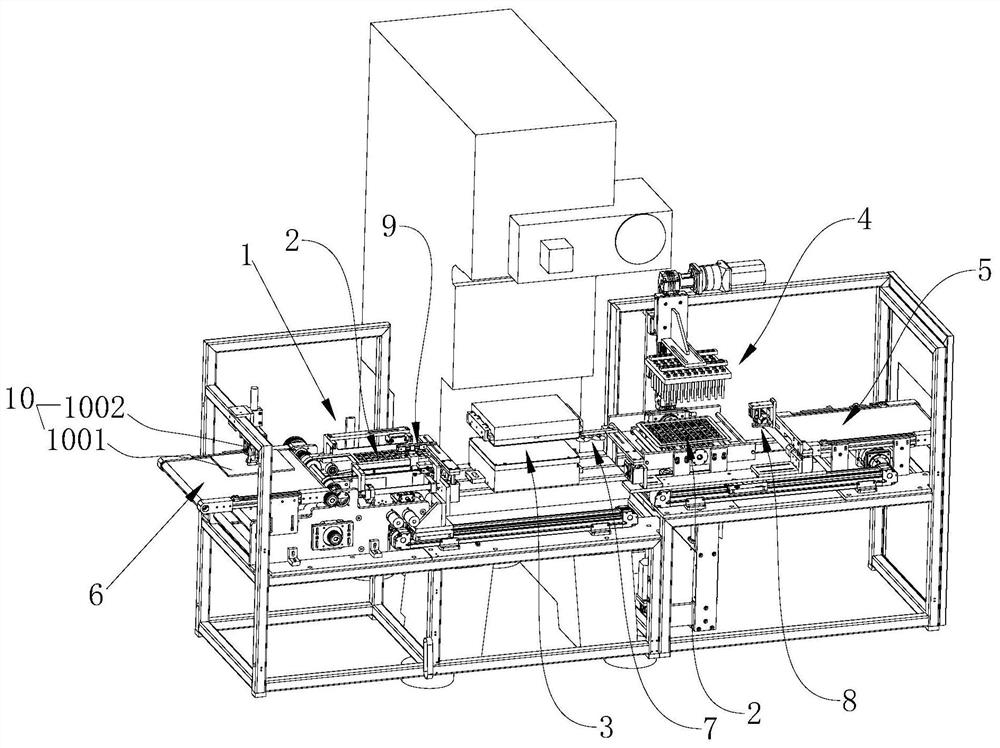

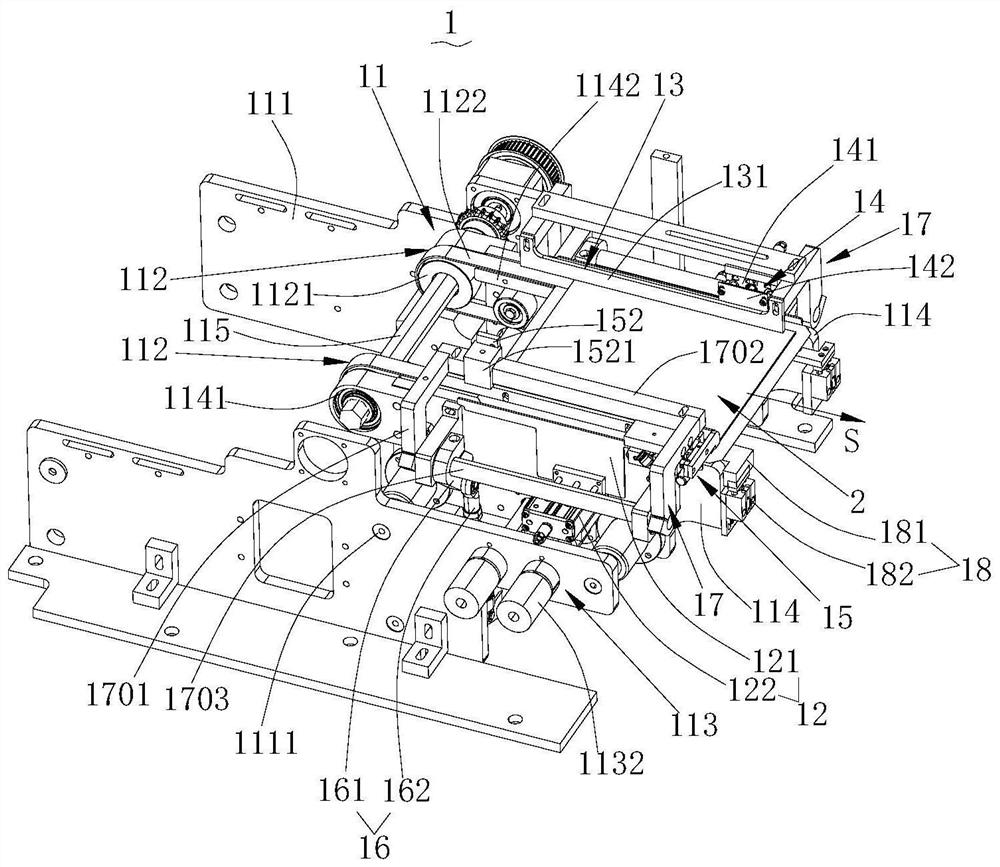

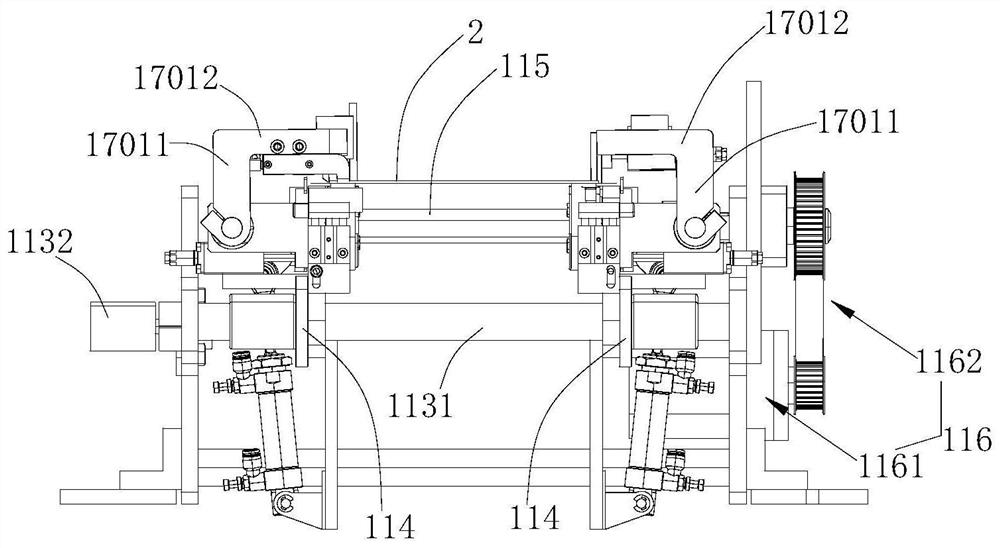

[0080] refer to figure 1 , the invention discloses a punching production line for packaging box material boards. The punching production line includes a feeding conveyor belt 6, a packaging box material board automatic positioning device 1, a punching device 3, a waste discharge device 4, a lower The material conveyor belt 5 is also provided with a first material transfer assembly 7 between the punching device and the waste discharge device. The first material transfer assembly 7 moves the punched packaging box material plate 2 to the rotary platform, and the waste discharge device A second material-moving component 8 is arranged between the device 4 and the unloading conveyor belt 5 , and the second material-moving component 8 moves the waste-discharged packaging box material plate 2 from the waste-discharging device 4 to the unloading conveyor belt 5 .

[0081] A positioning material shifting device 9 is also arranged between the packaging box material plate automatic positi...

Embodiment 2

[0179] This embodiment discloses a punching-cutting and waste-discharging process for packaging box material boards, using a punching-cutting waste-discharging production line for packaging box material boards 2 in Embodiment 1, including:

[0180] Step S1: Positioning and punching the material board 2 of the packaging box;

[0181] Among them, the punching waste discharge process of the packaging box material plate 2 also includes:

[0182] Step S2: Adjust the posture of the die-cut packaging box material board 2 so that the cardboard 202 of the packaging box material board 2 is located under the face paper 201;

[0183] Step S3: the waste material is ejected from the direction of the face paper 201 to the cardboard 202 of the packing box material board 2;

[0184] Step S4: Blanking the discarded packaging box cardboard 202.

[0185] Among them, step S1.0 before step S1.1, step S1.0: when the incoming material detection sensor detects that there is a packing box material pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com