Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve production processing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave pest killing method for grain products such as rice, beans, wheat

InactiveCN102986864AAchieve pest controlComplete production processSeed preservation by heatingCold airAgricultural science

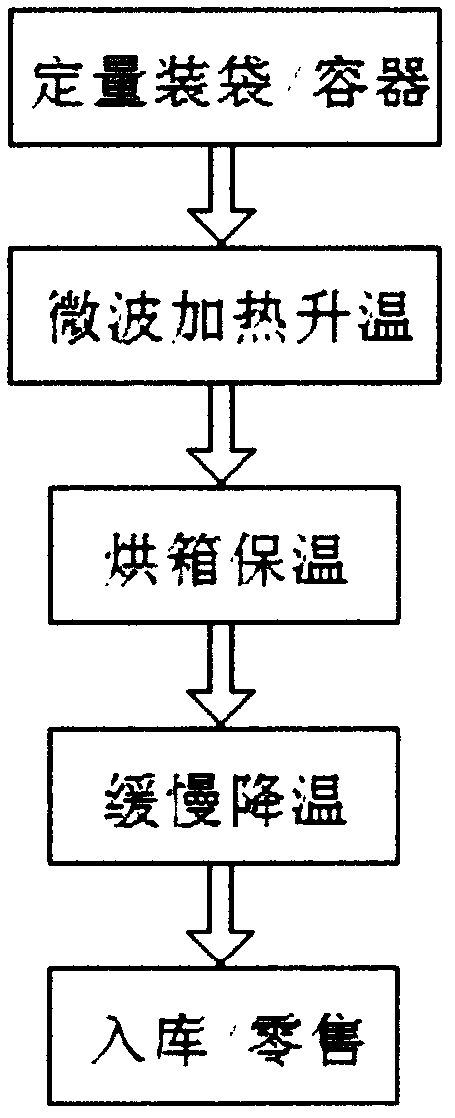

The invention discloses a microwave pest killing method for grain products such as rice, beans, wheat and the like for grain raw material or processed grain, which is applicable to the grain products before being put in storage or taken out of storage. The microwave pest killing method for grain comprises the following steps: (1) quantitatively putting the grain product into a pored packing bag or nonmetal container; (2) uniformly heating to 40-70 DEG C in a box-type or tunnel-type industrial microwave oven; (3) setting temperature to 50-70 DEG C in a tunnel-type thermal insulation oven, and keeping the temperature for 3-15 minutes; (4) slowly reducing the temperature of the container or the packing bag to below 40 DEG C in a cooling channel in a cold air environment; and (5) storing the product or selling at retail. The method disclosed by the invention is a pure physical pest killing technology, and can completely kill the adults, larvae and eggs in the grains of rice and beans while maintaining the original quality and flavor of the grain products such as rice, beans, wheat and the like.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

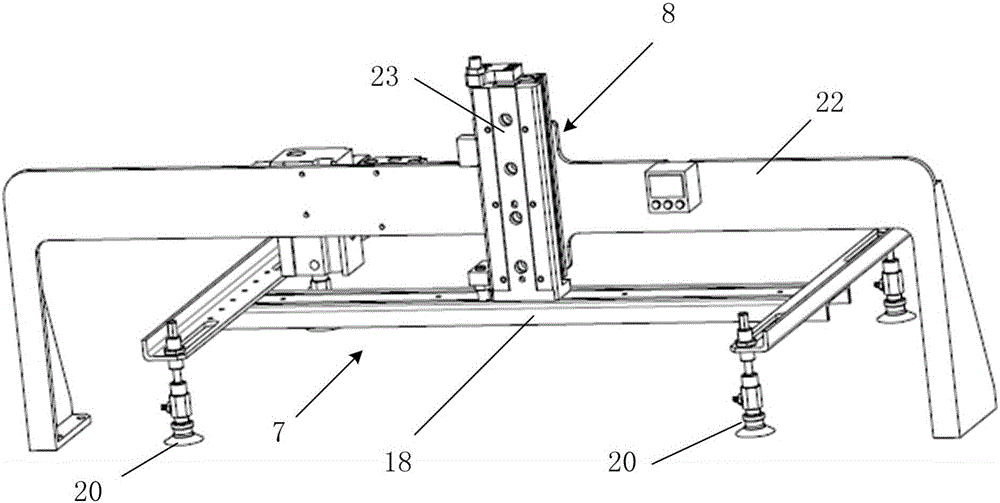

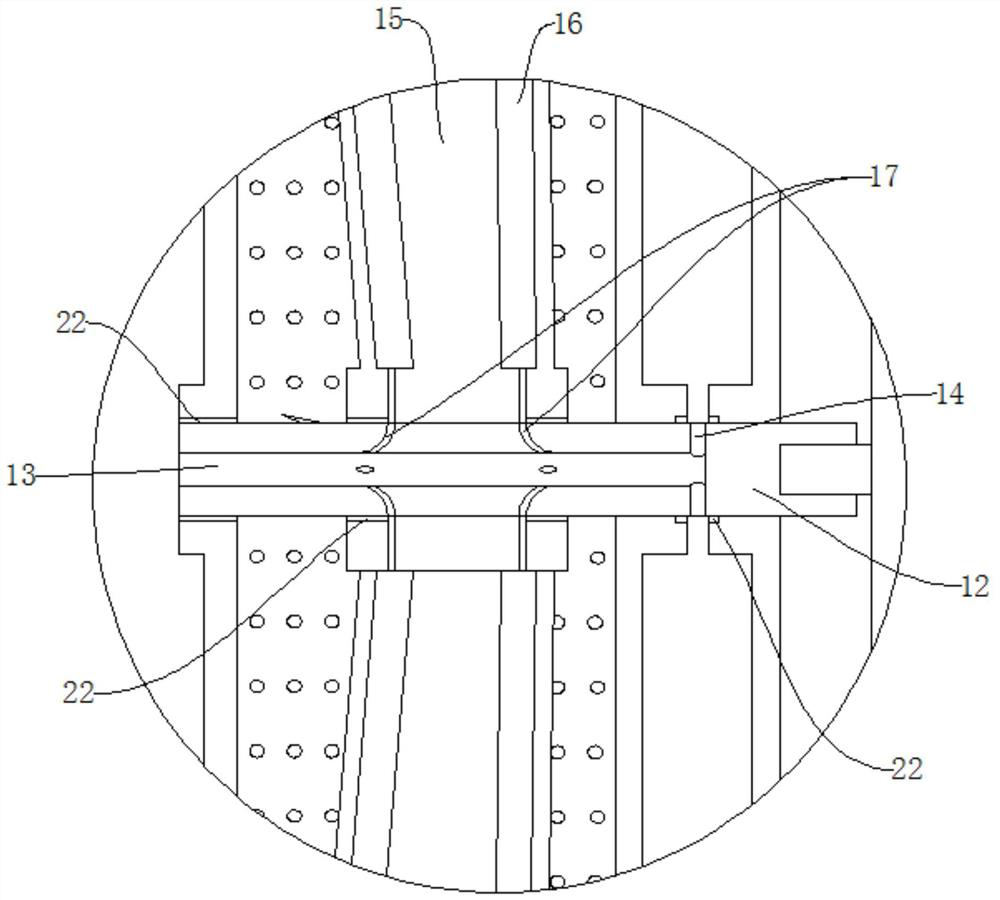

Single body feeding and discharging machine for manufacturing LCD products

InactiveCN105692199AReduce defective rateReduce the risk of badConveyorsConveyor partsProduction lineEngineering

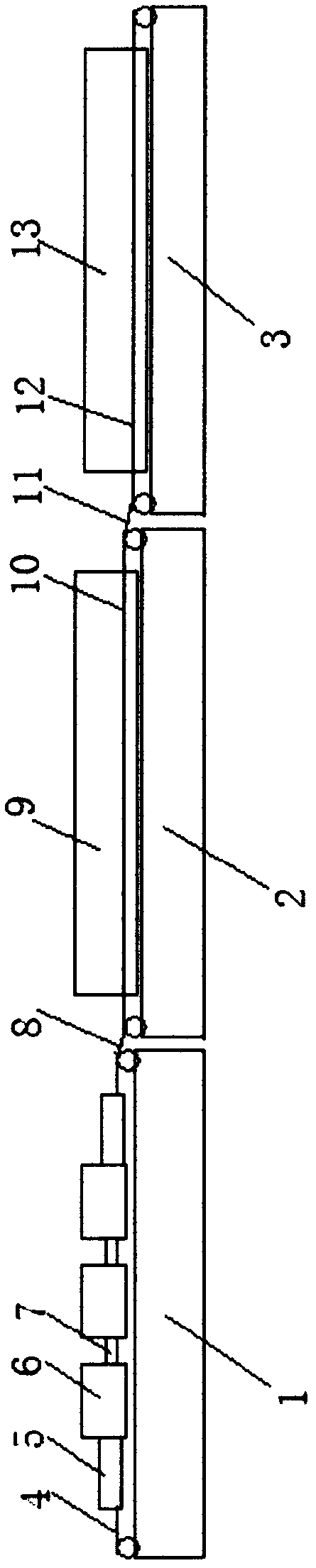

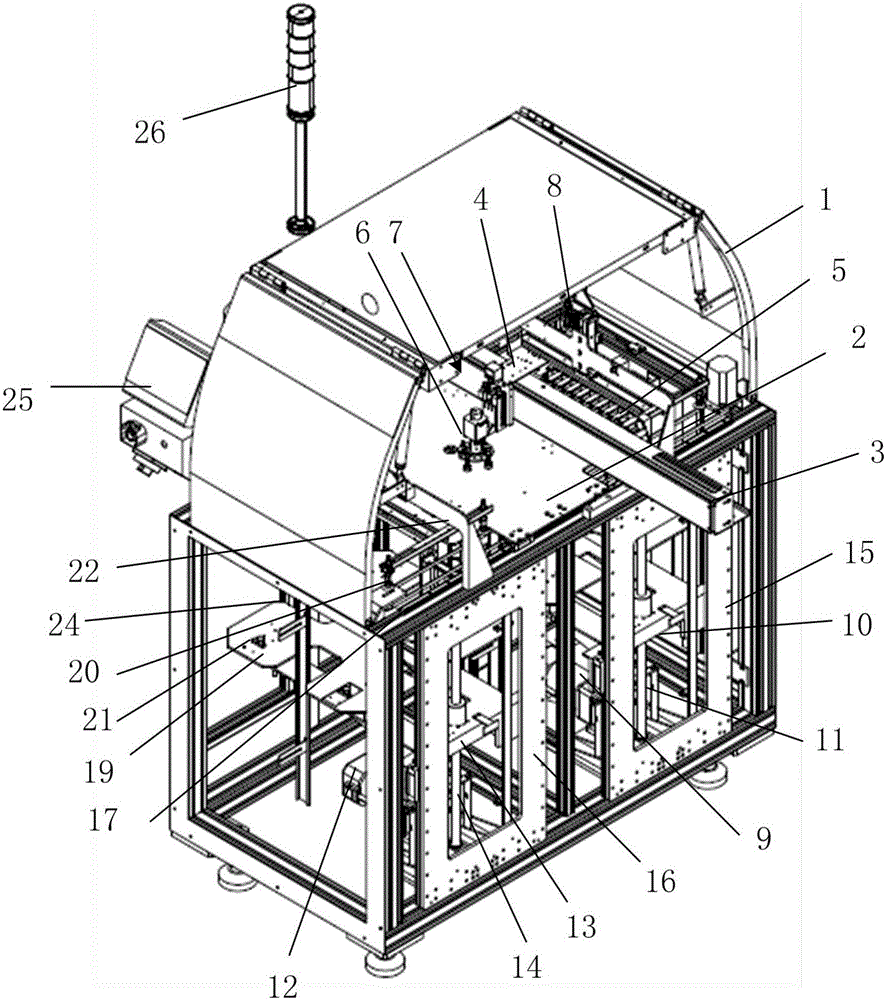

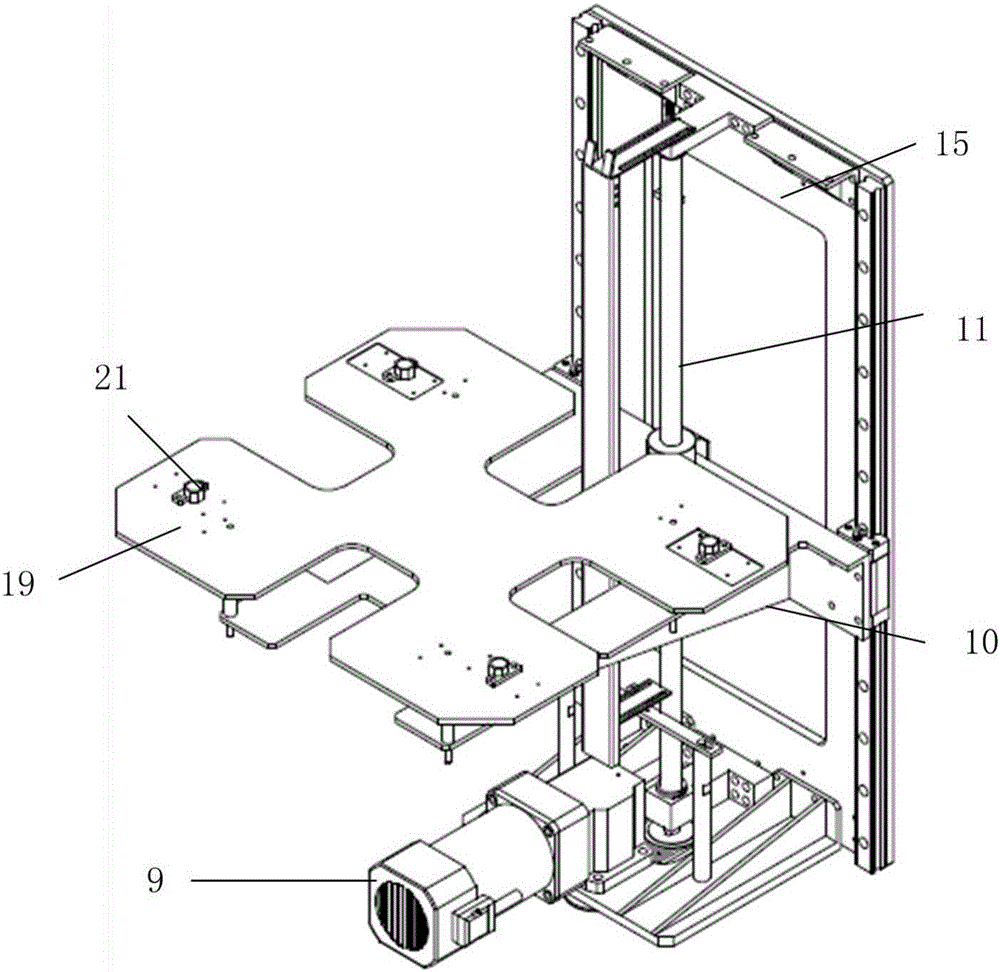

The invention relates to a single loading and unloading machine for the manufacture and processing of LCD products, comprising a loading and unloading frame and a lifting unit, a suction unit and a conveying unit arranged in the loading and unloading frame, and the suction unit and the lifting unit are arranged There is a sliding platform that moves in the horizontal direction. The conveying unit includes a conveying shaft and a matching slider. One end of the slider is connected to the mechanical arm and the other end is connected to the suction device. The lifting unit includes a motor mechanism and a lifting platform mechanism for placing the feeding tray. and a sliding shaft mechanism, the motor mechanism drives the lifting platform mechanism to move up and down along the sliding shaft mechanism, and the suction unit includes a suction cup mechanism and a cylinder mechanism that drives the suction cup mechanism to move. The device of the invention can make the operator and the product zero-contact, can effectively reduce the defective rate of the product, improve the production efficiency of the product, and meet the requirements of loading and unloading in various links of the LCD product production line, thereby saving manpower and reducing product cost.

Owner:SUZHOU PROTECH PRECISION IND CO LTD

Alpha linolenic acid cryogenic separation and purification method

InactiveCN102030629AChange concentrationComplete production processFatty acids production/refiningCarboxylic compound separation/purificationNemorensic acidAlpha-Linolenic acid

The invention discloses an alpha linolenic acid cryogenic separation and purification method, comprising the steps of: uniformly mixing oil rich in alpha linolenic acid and acetone or a methanol solvent according to a volume ratio of 1:(3-6), placing a container containing the mixed solution in an environment at (-30)-(-60) DEG C for refrigeration, separating and removing crystals at low temperature when the temperature reaches (-30)-(-60) DEG C, and desolventizing the solution to remove the solvent accounting for 20-30% of the total volume; repeating the steps of refrigeration, crystal removal and desolventization for 3-5 times for separating and removing the crystals; and after circularly removing the crystals for 3-5 times, repeating the steps of refrigeration and crystal removal once again when the volume ratio of the alpha linolenic acid to the solvent reaches 1:(2-3), and desolventizing the finally obtained mixed solution to obtain the alpha linolenic acid. The method is a pure physical cryogenic separation technology and can improve product quality and yield stability, and the concentration of the obtained alpha linolenic acid is above 80%.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

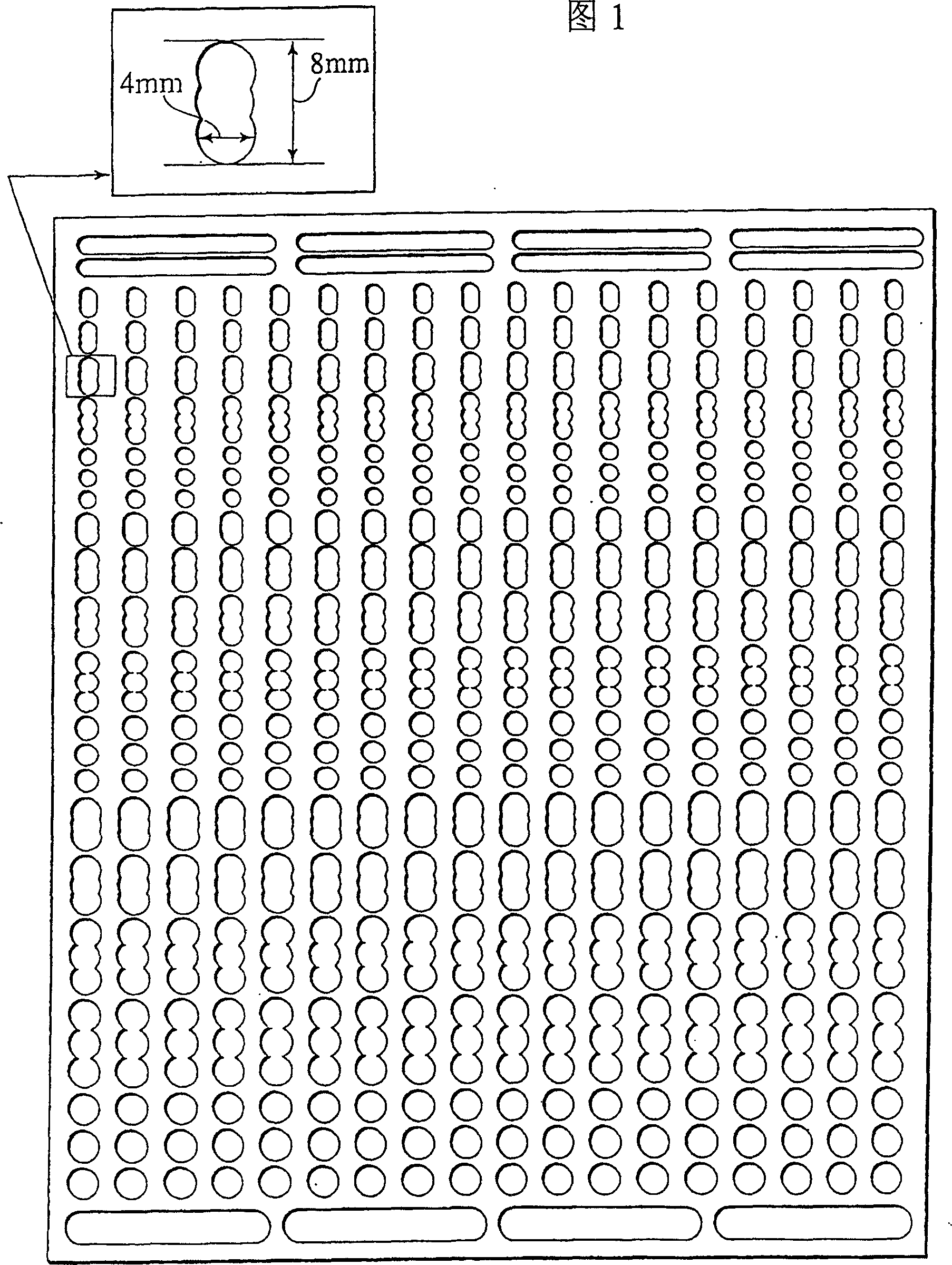

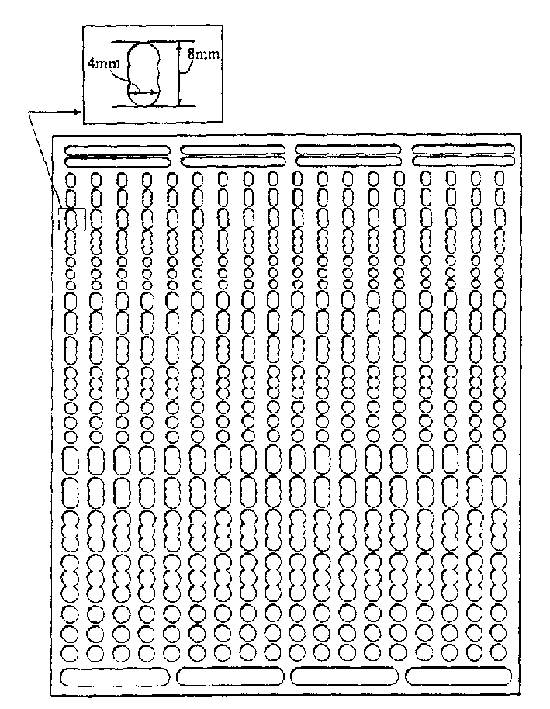

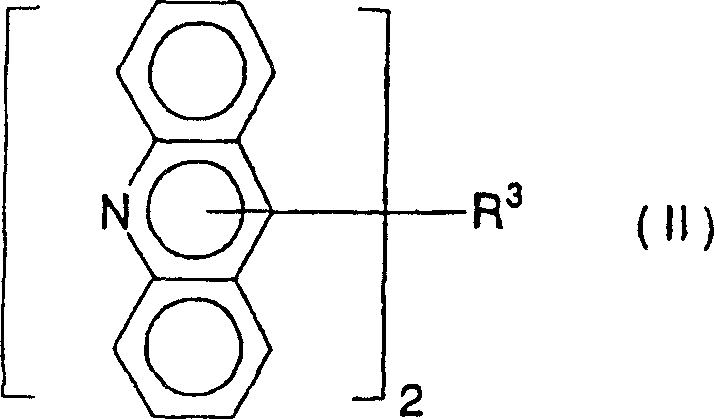

Photosensitive resin compsn., photosensitive element, prodn. method for resist pattern and prodn. method for printed circuit board

InactiveCN1432141AImprove reliabilityPrevent intrusionRadiation applicationsPhotosensitive material processingPolymer scienceSpray nozzle

A photosensitive resin composition is here disclosed which satisfies the following (1) and (2): (1) when a 1.0 wt % aqueous sodium carbonate solution is sprayed by a spray on a layer of the photosensitive resin composition having a thickness of 37 to 42 mum under the following conditions, the photosensitive resin composition layer being able to be removed within 20 seconds, the above conditions being that an internal diameter of a nozzle of the spray is 1.2 mm, a spraying pressure is 0.05 MPa, and a distance between a point of the spray nozzle which is closest to the photosensitive resin composition layer and the photosensitive resin composition layer is 50 mm; and (2) when the 1.0 wt % aqueous sodium carbonate solution is sprayed three times for 36 seconds under the above conditions on a cured film obtained by laminating a layer of the photosensitive resin composition having the above thickness on a copper-clad laminate having 18 three-continuous holes in which 3 holes each having a diameter of 6 mm are continuously integrated and which has a length of 16 mm, and then photo-curing the layer with an exposure capable of curing 24 steps in a 41-step tablet, the number of holes where the cured film is broken being 5 or less.

Owner:RESONAC CORPORATION

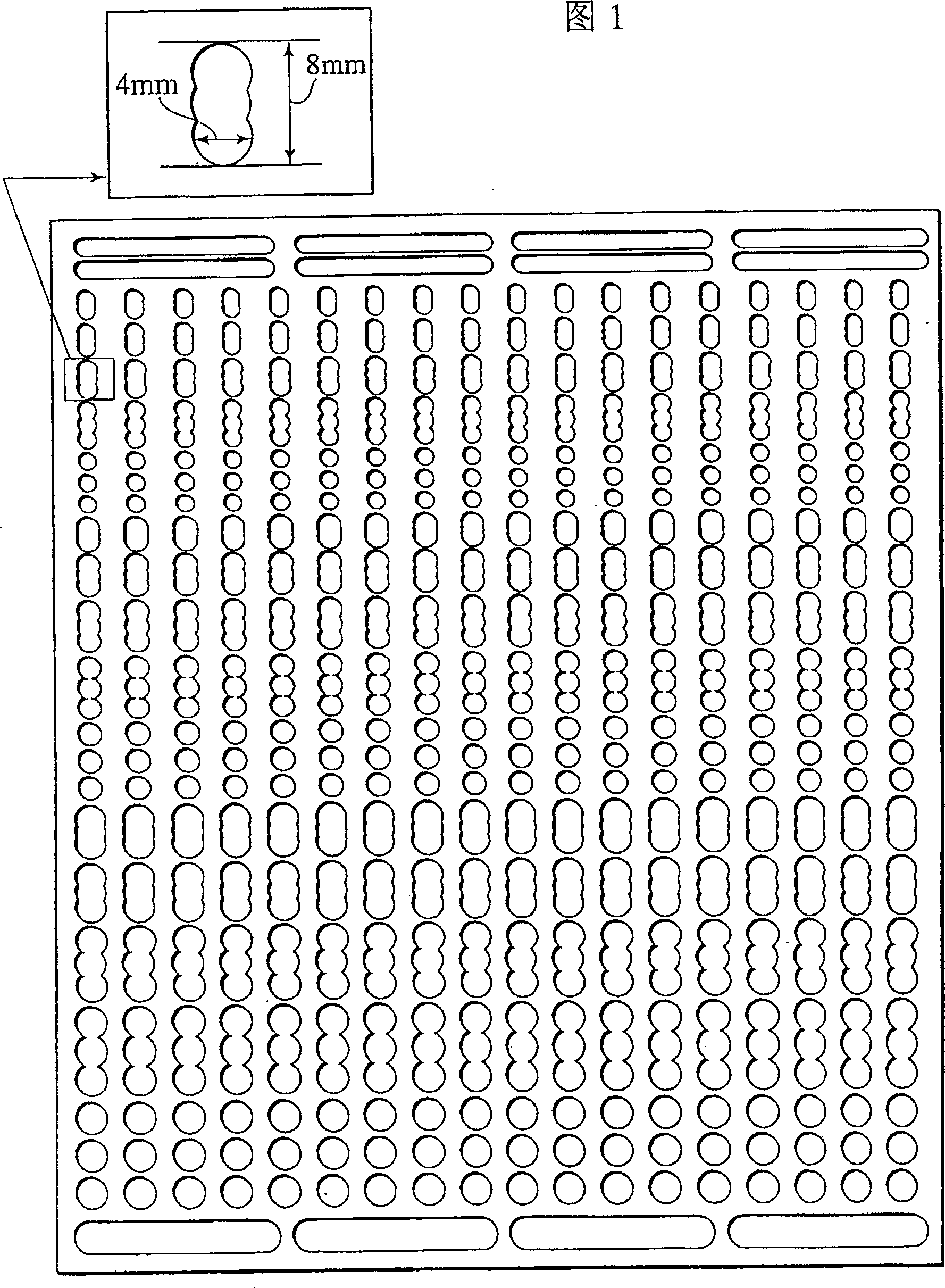

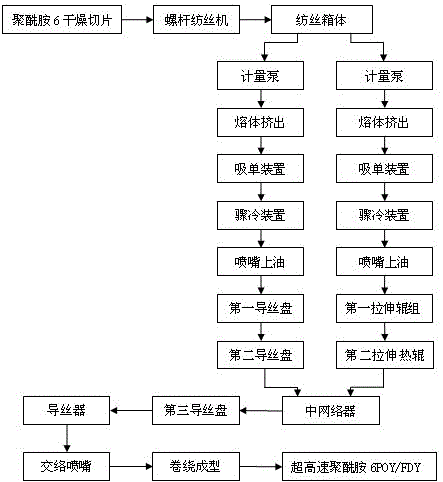

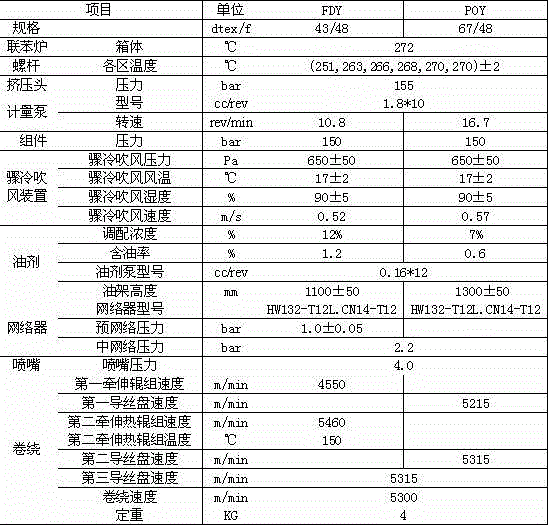

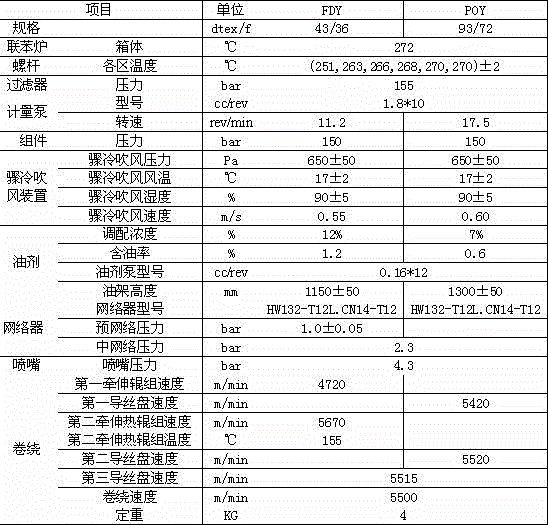

Polyamide 6 POY/FDY composite fibre and preparation method for same

InactiveCN103981580AImprove uniformityShort production processMelt spinning methodsUltra high speedYarn

The invention relates to a polyamide 6 POY / FDY composite fibre and a preparation method for the same. According to the preparation method, polyamide 6 dry slices are input in a screw rod, heated, melted and filtered, and then enter a spinning manifold, a spinning melt is extruded from two metering pumps, a spinning assembly and the micropores of two spinneret plate, cooled by the blowing of a quenching ring and cured to form two bundles of yarns, and one bundle of the yarns is subjected to nozzle oiling, pre-networking, secondary nozzle oiling, and stretching and heat-setting between a first stretching roll group and a second stretching roll group to obtain polyamide 6 FDY; the other bundle of the yarns is subjected to nozzle oiling, a first yarn guide disc and a second yarn guide disc to obtain polyamide 6 POY; the polyamide 6 FDY and the polyamide 6 POY are input in a central networking device and a third yarn guide disc simultaneously, and subjected to compounding through nozzles and ultra-high-speed winding forming to prepare the polyamide 6 POY / FDY composite fibre. According to the polyamide 6 POY / FDY composite fibre and the preparation method disclosed by the invention, a pneumatic spinning quenching technology is used, thus increasing the spinning speed; the features of fast production speed, high yield, low cost, energy conservation and emission reduction, good product quality and the like are achieved.

Owner:SUZHOU UNIV

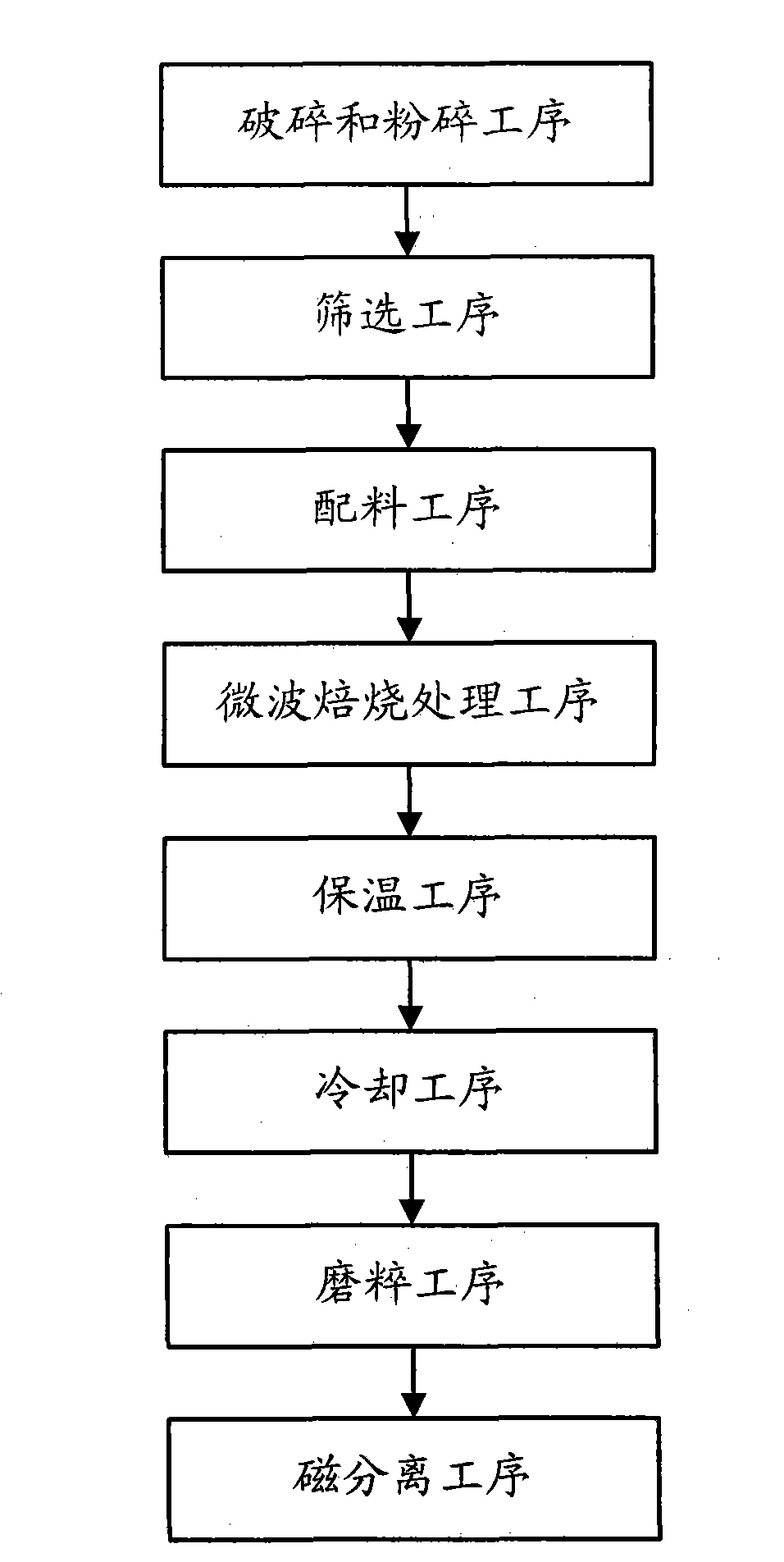

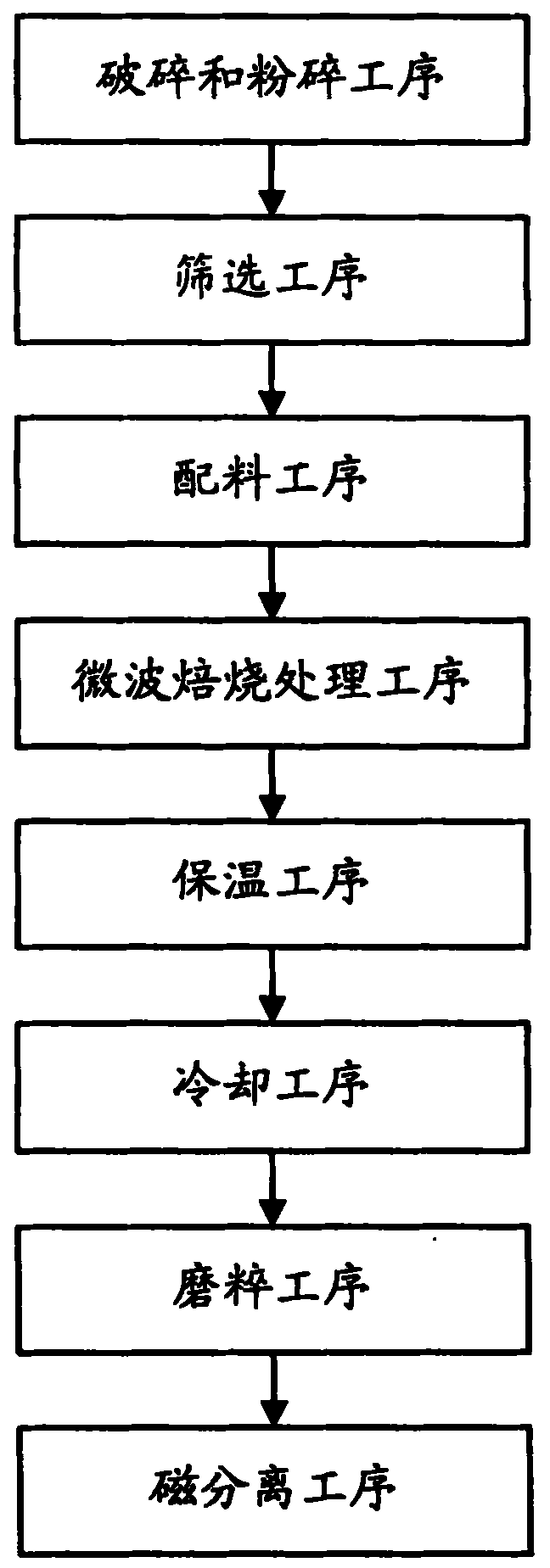

Method for converting natural non-magnetic iron ore into magnetite

InactiveCN102168170AIncrease profitComplete production processSievingScreeningMicrowave methodMagnetite

The invention discloses a method for converting natural non-magnetic iron ore into magnetite by a microwave method, and particularly relates to a method for converting non-magnetic iron ore such as natural limonite, hematite and siderite into the magnetite through processes of crushing, smashing, sieving, mixing, microwave roasting treatment, heat preservation, cooling, grinding, magnetic separation and the like. In the method, the production process is intact, the mechanization degree is high, production processing cycle is shortened, production processing speed is improved, the conversion rate of a magnetite powder product is high, and the continuous production can be realized; and the device simultaneously has the characteristics of energy conservation and high efficiency, and can improve the quality of products and the stability of the yield.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

High-speed intelligent laser cutting equipment and application method thereof

PendingCN113385832AReduce labor intensityRealize continuous processingLaser beam welding apparatusLaser cuttingMachining

The invention relates to the technical field of laser cutting, and discloses high-speed intelligent laser cutting equipment. The equipment comprises a mounting plate, wherein a feeding mechanism and a cutting mechanism are arranged at the top of the mounting plate, and a limiting mechanism is arranged on the surface of the cutting mechanism. According to the high-speed intelligent laser cutting equipment andan application method thereof, through cooperative work of the feeding mechanism, the cutting mechanism and the limiting mechanism, continuous machining of the device can be achieved, assistance of workers beside is not needed, so that the production and machining speed of the device can be greatly increased; the intelligent automation degree of the device is high, and much labor cost can be saved; the limiting mechanism can automatically clamp and fix a workpiece, the situation that the cutting size does not conform to the technology due to shaking during cutting is prevented, the labor intensity of the workers can be reduced, and the practicability of the device is greatly improved; and the feeding mechanism can be automatically adjusted according to the thickness of a machined workpiece, and the practicability is improved.

Owner:孙明元

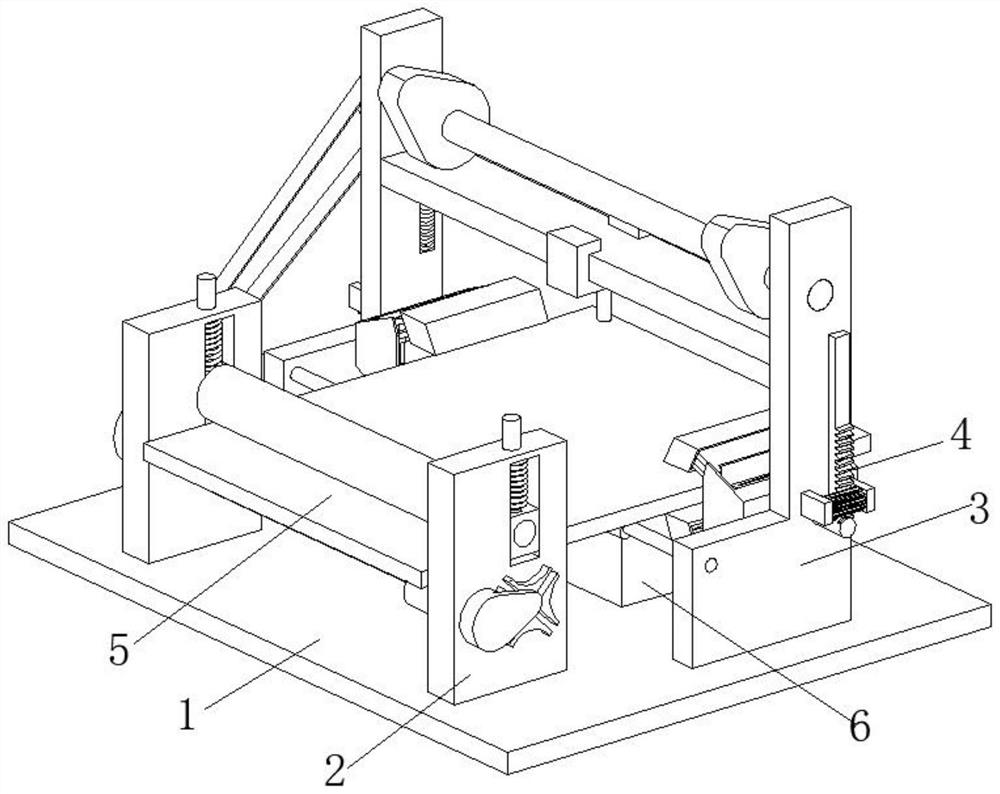

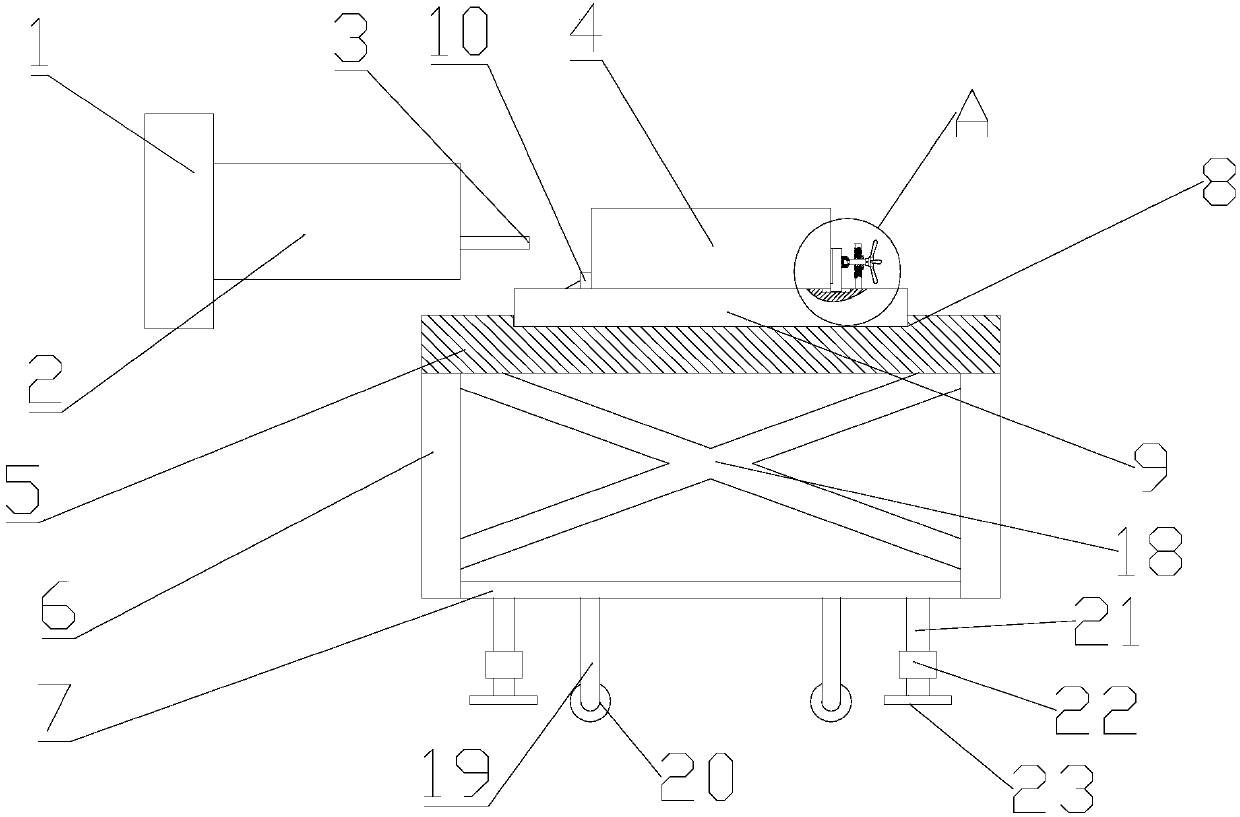

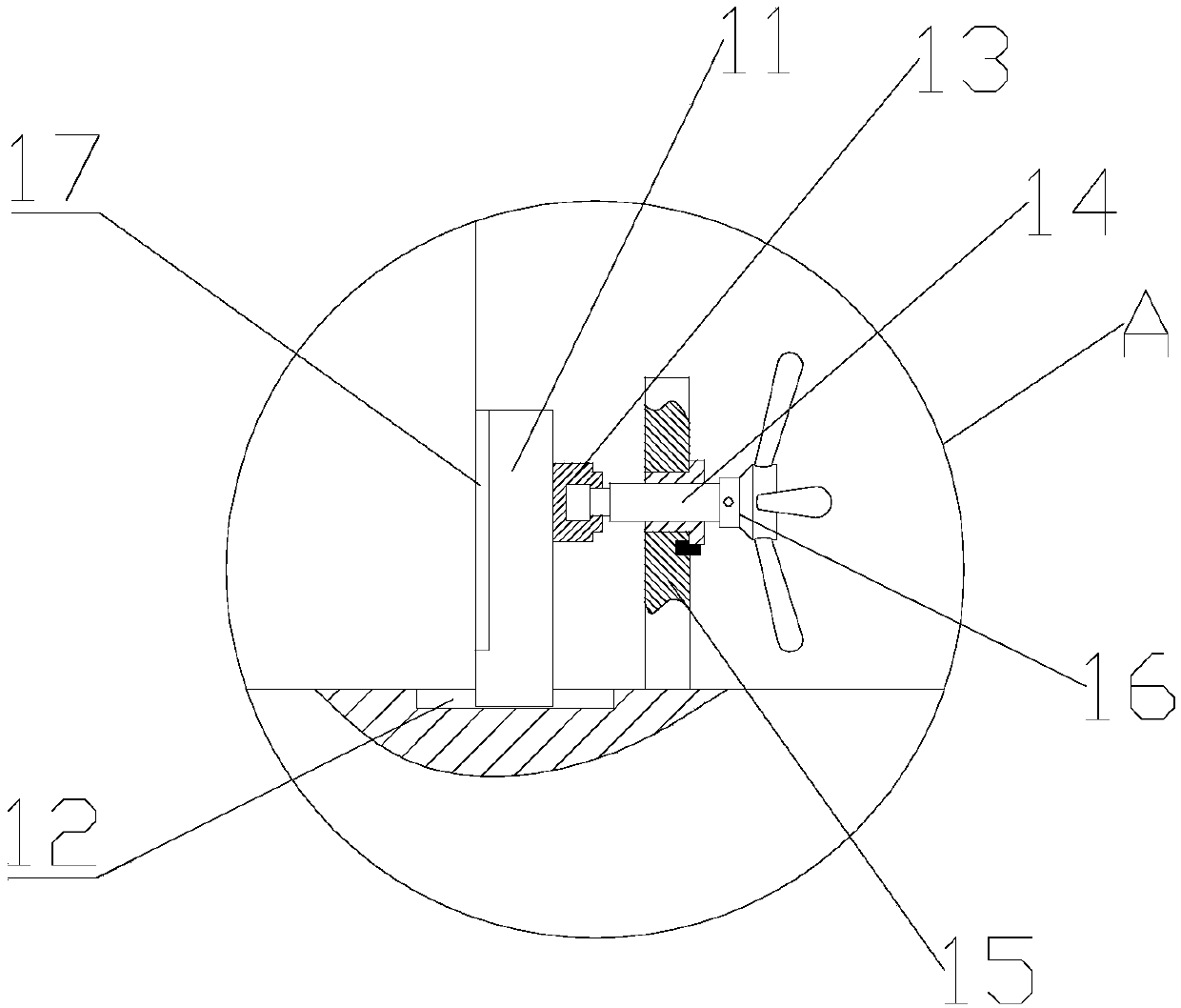

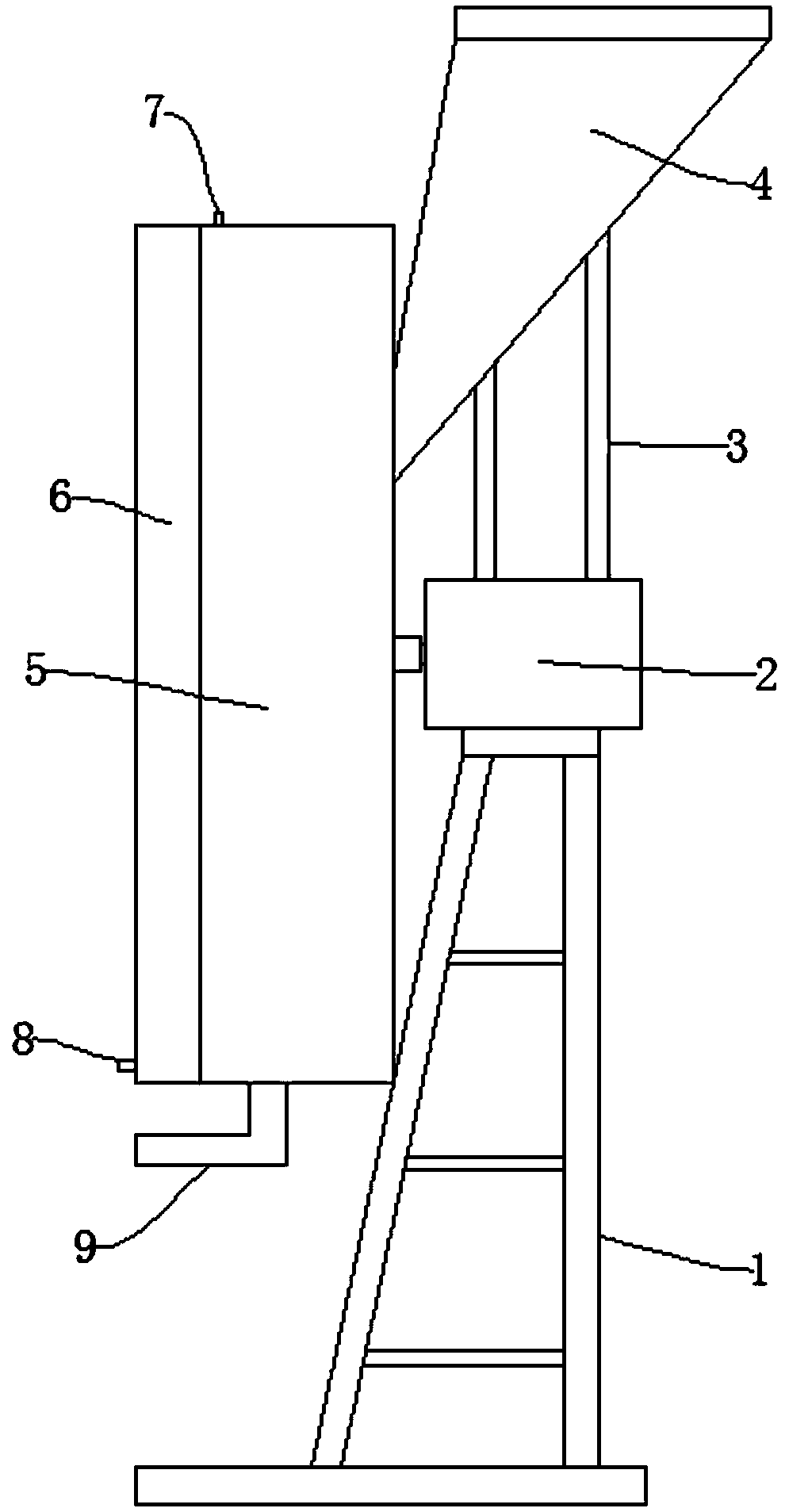

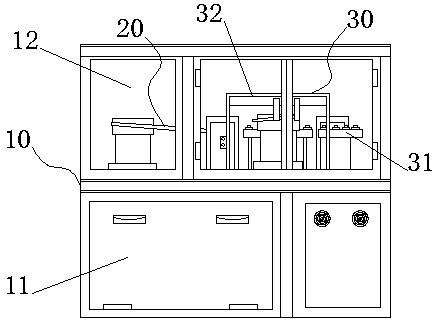

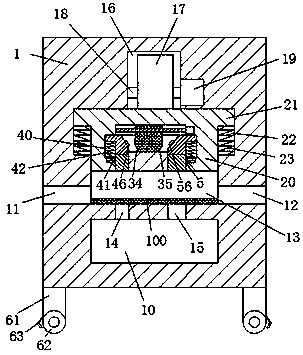

Automatic detecting device for selenium drum of printer

InactiveCN109655639AImprove production processing speedFast positioningWork holdersMeasurement instrument housingEconomic benefitsAgricultural engineering

The invention relates to the technical field of selenium drum detection equipment, in particular to an automatic detecting device for a selenium drum of a printer. The automatic detecting device comprises a hydraulic push rod, a detecting device body, a detection probe, the selenium drum of the printer, a work platform, a supporting rod and a bottom plate; the selenium drum of the printer is fixedon a mounting platform through a fixed baffle and a movable pressing plate, the bottom of the movable pressing plate is slidably mounted in a slide groove B, the slide groove B is formed in the mounting platform, the right side wall of the movable pressing plate closely fits the left side face of a push block, the right side face of the push block is fixedly welded to the left end of a threaded rod, the threaded rod is installed on a mounting plate through a thread, the bottom of the mounting plate is fixedly welded to the upper end face of the mounting platform, and a rotary handle is fixedly welded to the right end of the threaded rod; the mounting platform is slidably mounted in a slide groove A. The automatic detecting device is simple in structure and low in cost, the efficiency of detecting the selenium drum of the printer can be effectively improved, the speed of producing and processing the selenium drum of the printer is greatly increased, and economic benefits of enterprisesare effectively increased.

Owner:中山市飞溙电子科技有限公司

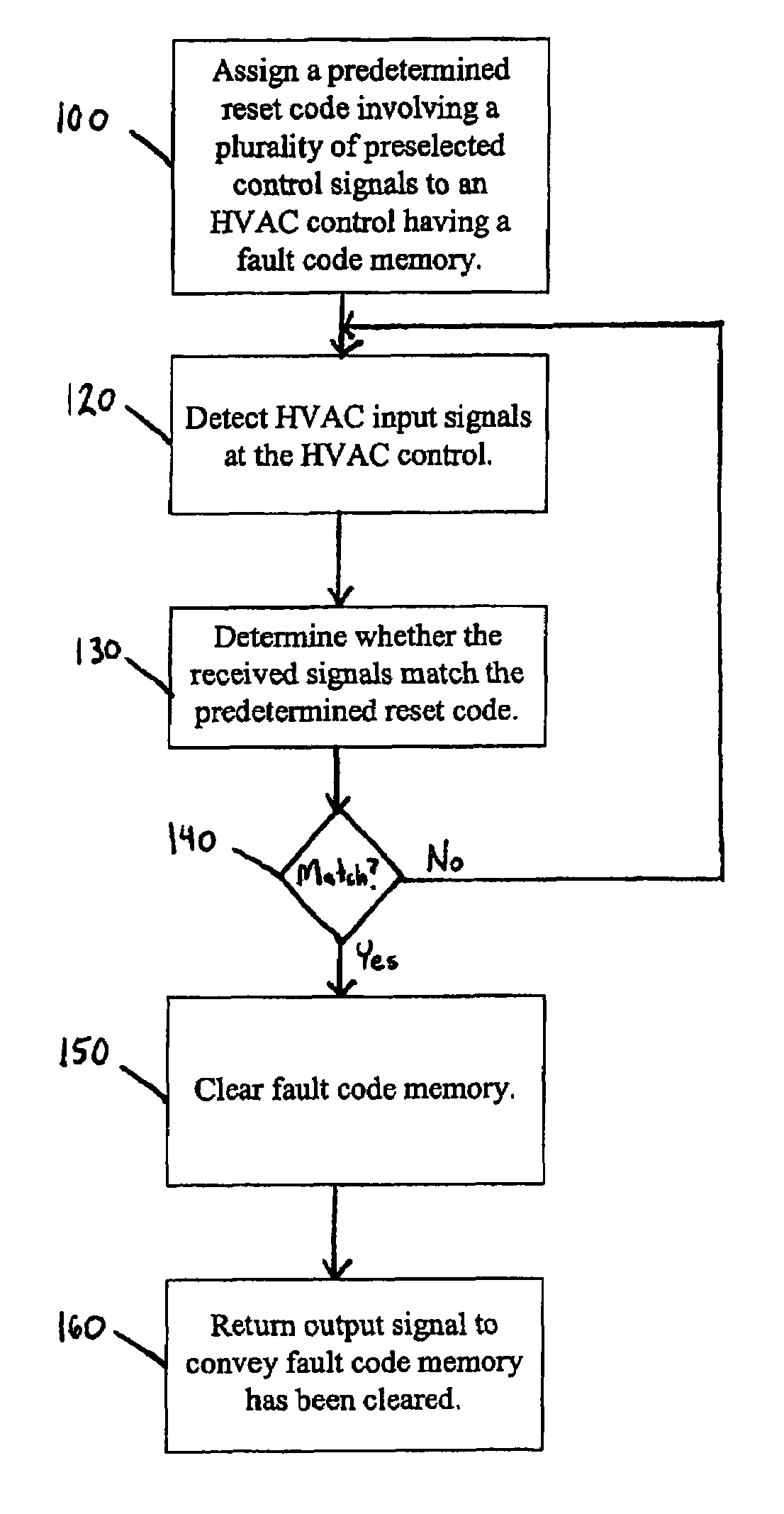

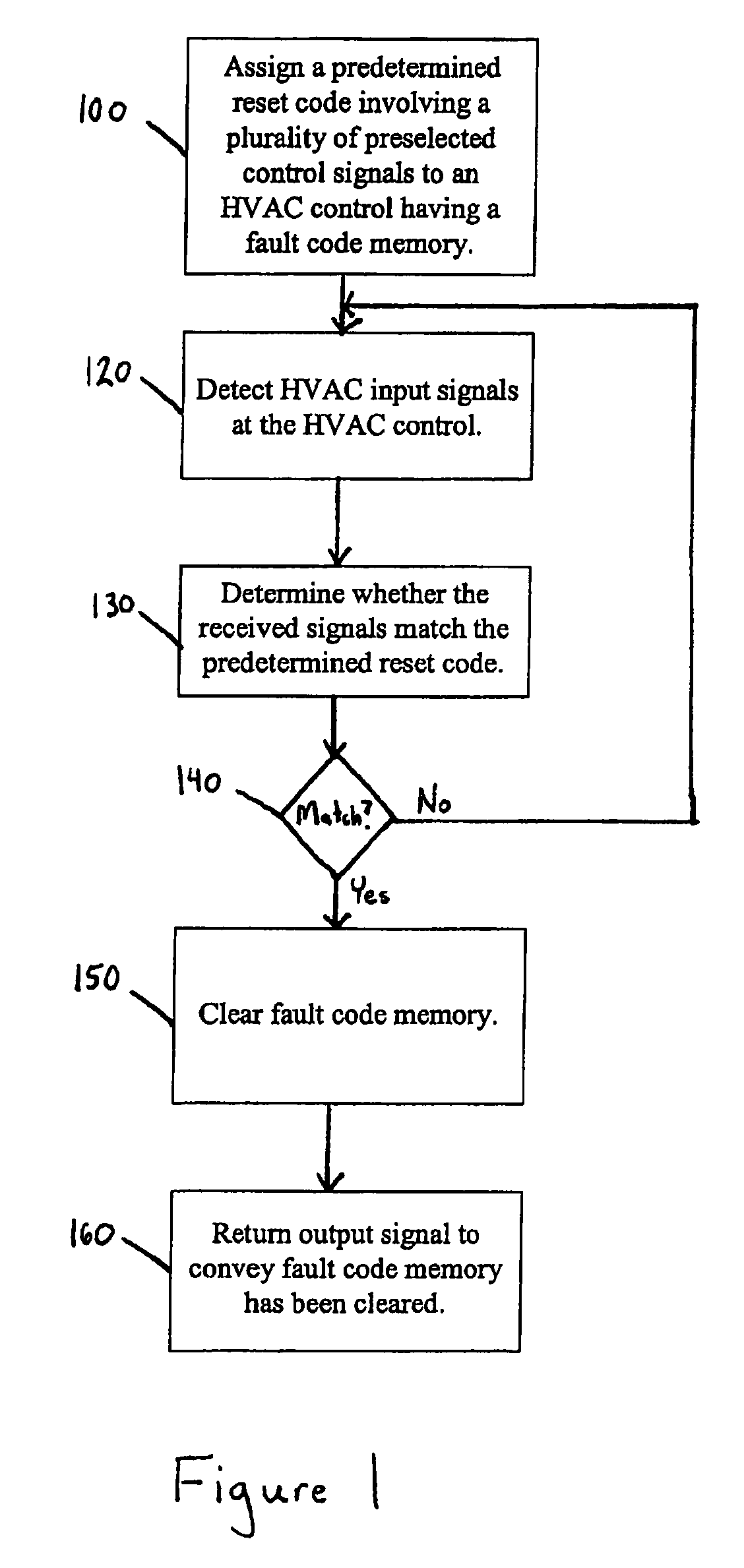

Method of clearing an HVAC control fault code memory

InactiveUS7299111B2Decrease and eliminates human interventionReduce usageProgramme controlSampled-variable control systemsControl signalHVAC control system

A method of clearing an HVAC control fault code memory is disclosed. The method includes assigning a predetermined reset code to an HVAC control system, the predetermined reset code comprising a plurality of control signals receivable by the HVAC control system, detecting control signals at the HVAC control system, determining whether the detected HVAC control input signals match the predetermined reset code and clearing a fault code memory of the HVAC control system in response to control signals matching the predetermined reset code.

Owner:YORK INT CORP

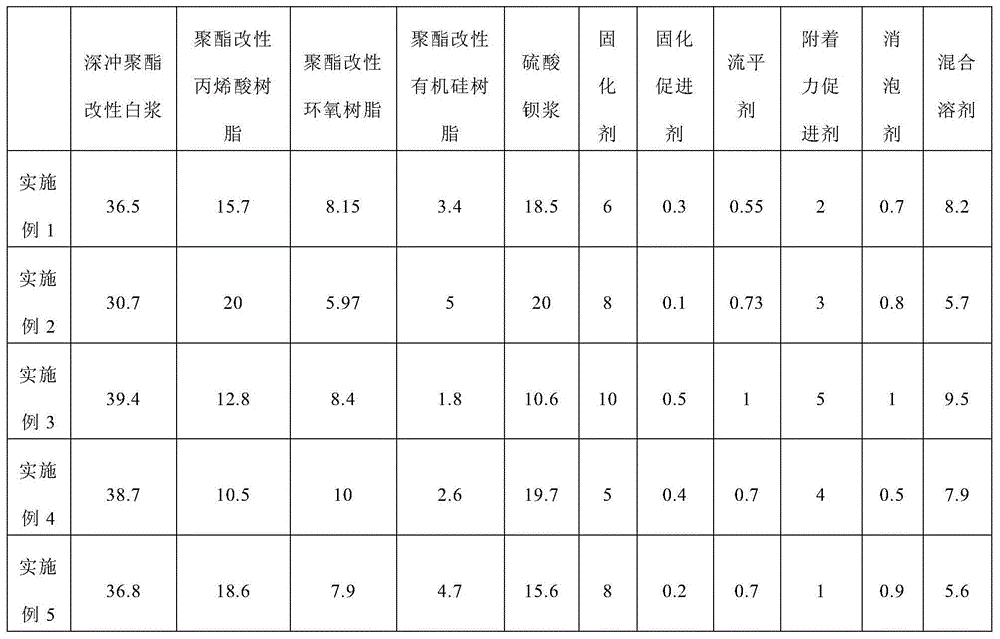

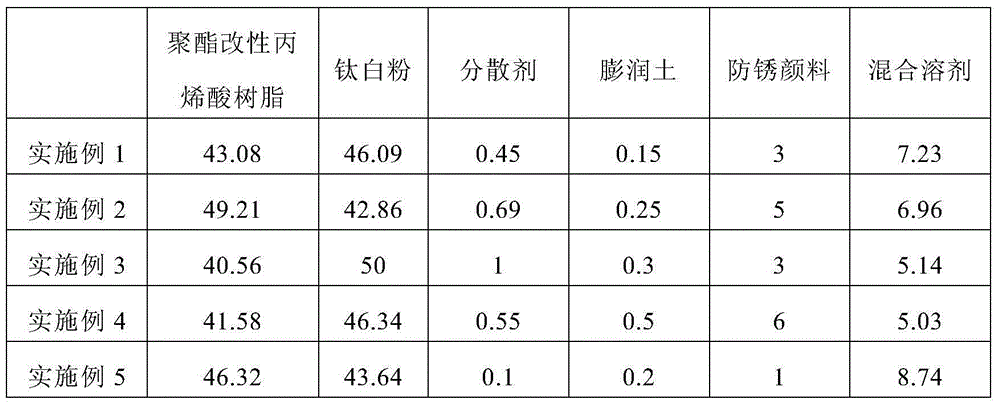

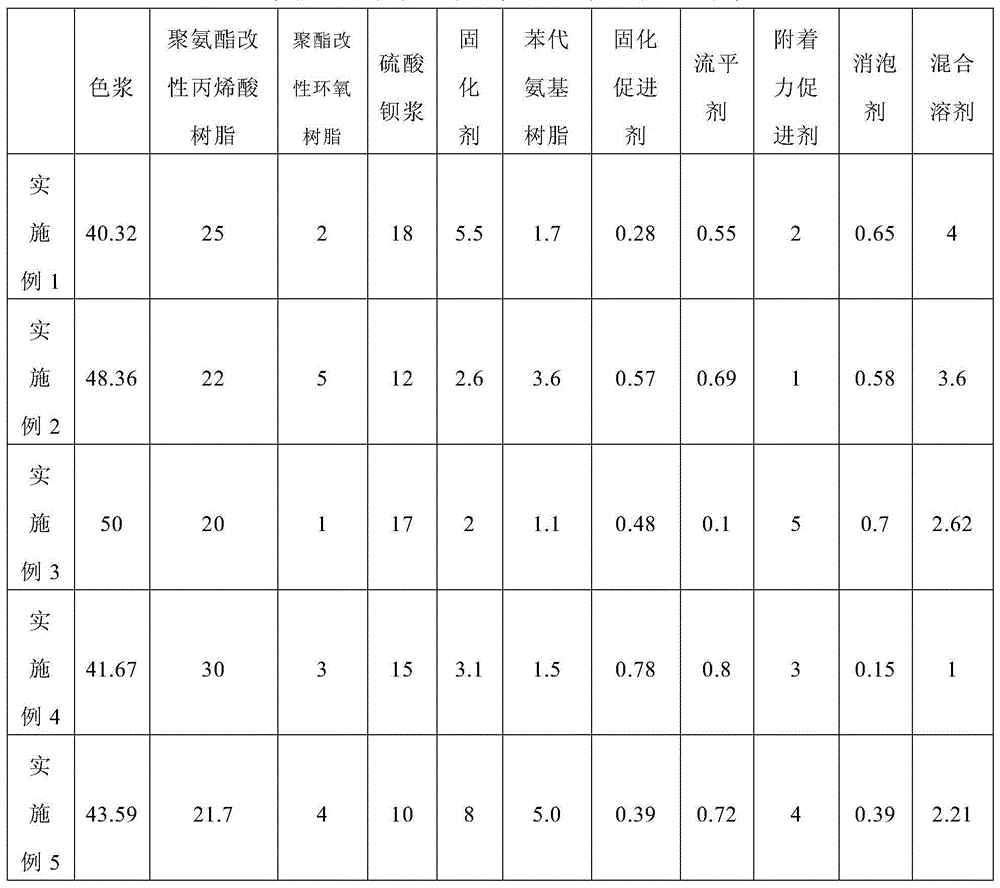

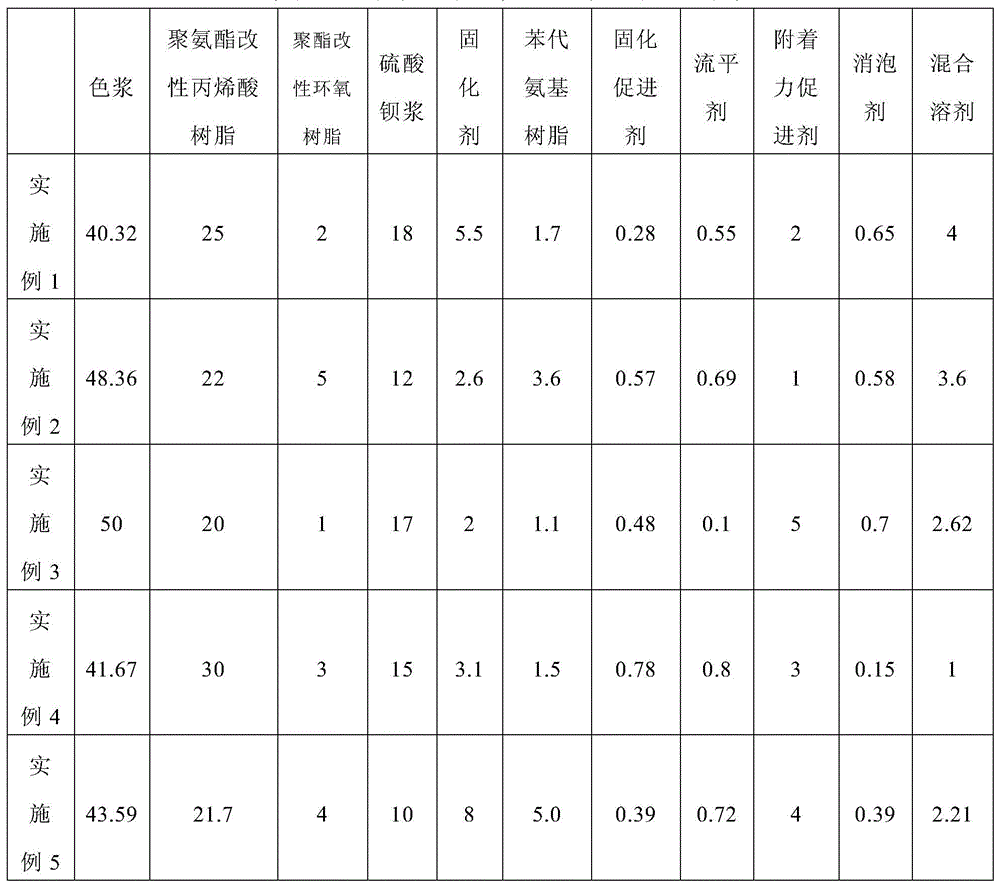

Acrylic modified energy-saving environment-friendly roller-coating paint for metal deep drawing sheets and application method thereof

ActiveCN104817936AStrong adhesionImprove ductilityPretreated surfacesEpoxy resin coatingsMetal sheetDeep drawing

The invention provides an acrylic modified energy-saving environment-friendly roller-coating paint for metal deep drawing sheets and an application method thereof. The paint comprises a white primer and a finish paint. The paint has the advantages of high adhesive force, favorable ductility, high temperature resistance and long service life, changes the processing technique of the metal sheet products, simplifies the processing procedure, centrally completes the roller coating treatment on the metal deep drawing sheet, and does not need to independently arrange any spray workshop.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Water-cooled pulverizer for processing raw materials for food production

InactiveCN108970757AImprove production processing speedImprove production and processing efficiencyGrain treatmentsBiochemical engineeringFood material

The invention discloses a water-cooled pulverizer for processing raw materials for food production, which comprises a rack and a high-speed motor fixedly installed on the rack, wherein a pulverizing cover fixedly connected with the rack is arranged on the side of the high-speed motor, a cover door is buckled on the side of the pulverizing cover, a material feeding funnel connected with the insideof the pulverizing cover is installed at the upper side end of the pulverizing cover, and a material discharge tube is arranged on the lower surface of the pulverizing cover. The water-cooled pulverizer for processing raw materials for food production has the beneficial effect that the water-cooled pulverizer can realize water cooling of pulverizing blades and whole pulverizer housing, so as to ensure that the temperature of the pulverizing blades is not too high, thereby allowing the pulverizer to work for a long time, which further enhances the production and processing speed and efficiencyof raw food materials, and the pulverizer is of a good practicability.

Owner:河南金土商贸有限公司

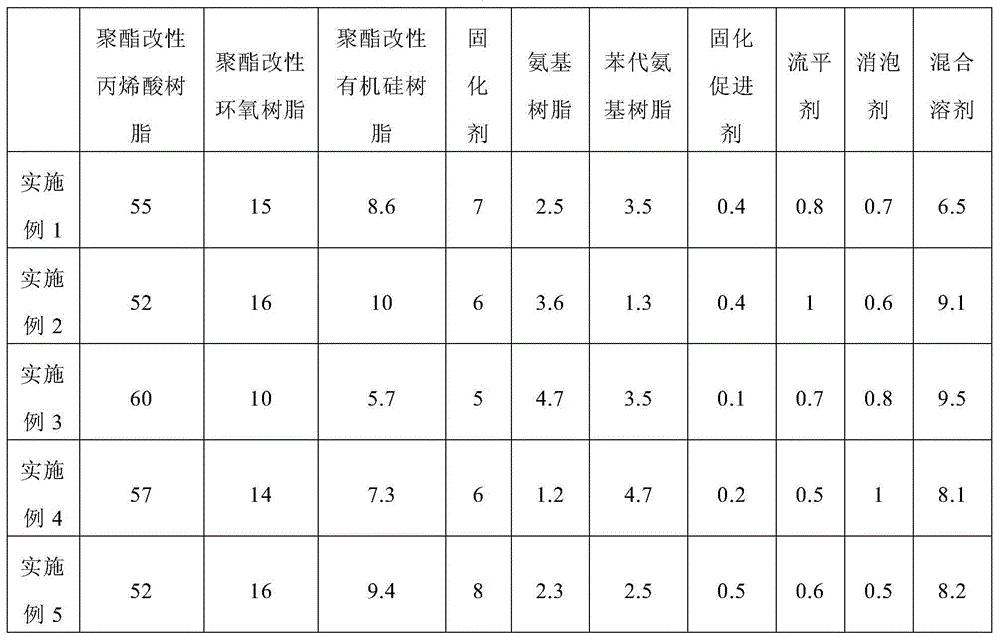

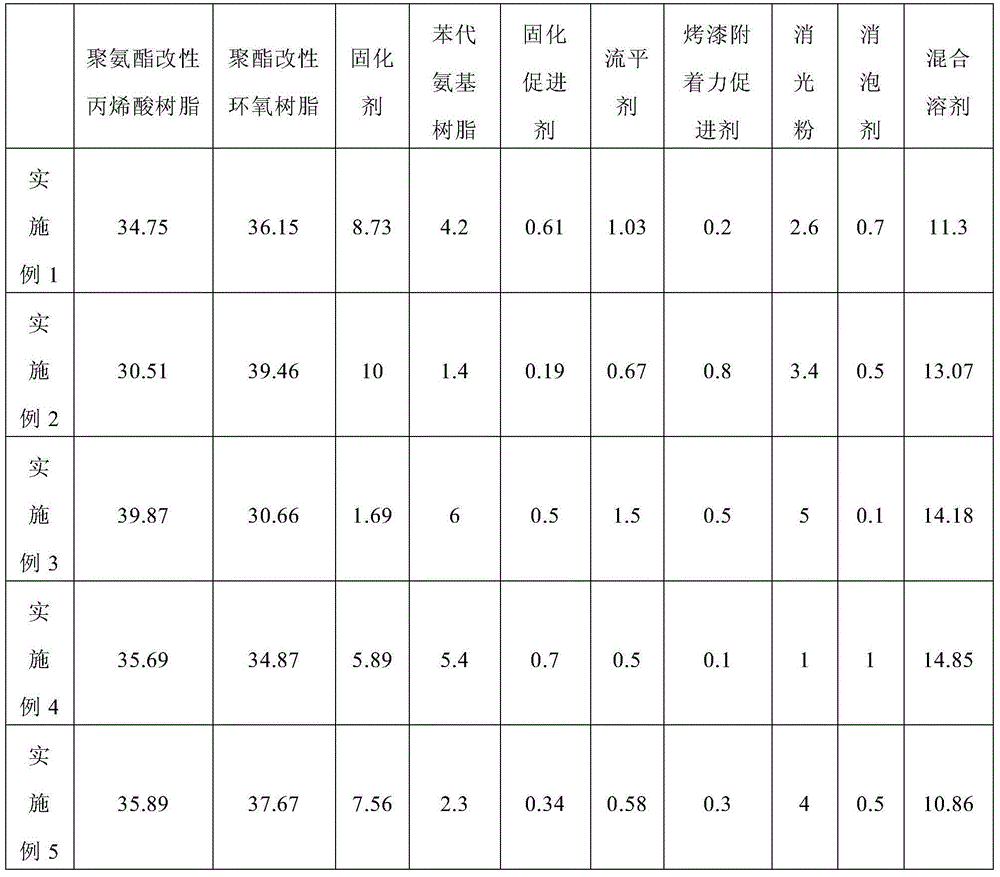

Energy-saving and environment-friendly roller coating paint for printing plate and application method of energy-saving and environment-friendly roller coating paint

ActiveCN104817950AStrong adhesionImprove ductilityPolyurea/polyurethane coatingsEpoxy resin coatingsEngineeringMechanical engineering

The invention provides an energy-saving and environment-friendly roller coating paint for a printing plate and an application method of the energy-saving and environment-friendly roller coating paint. The paint comprises a priming paint and a finish paint. The paint is high in adhesive force, good in ductility, heat-resistant and long in service life; the processing technology for printing plate products is changed; the processing procedures are simplified; roller coating treatment is intensively finished on a panel of the printing plate; and a painting workshop does not need to be independently arranged.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Paper card packaging box for household electric appliances

ActiveCN109606890ASimplify the shipping processDifficulty of SimplificationPackaging vehiclesContainers for machinesEnvironmental resistanceBiochemical engineering

The invention discloses a paper card packaging box for household electric appliances. The paper card packaging box comprises a packaging box body, a limiting structure, a buffering structure, whereinthe limiting structure is arranged in the packaging box body, and is used for defining and fixing the household electric appliances; the buffering structure comprises first buttering structures for buffering the periphery of the bottom of the household electric appliances, and a second buffering structure for buffering the central position of the bottom of the household electric appliances; and the packaging box body, the limiting structure and the buffering structure are respectively formed through folding a paper card board. Through the limiting structure, the first buffering structures andthe second buffering structure, which mutually cooperate, the problems that in the prior art, the shock resistance and the falling resistant capacity of a paper packaging box are poor, the household electric appliances cannot be effectively protected, and foam buffer blocks need to be additionally arranged in the paper packaging box, so that the paper card packaging box does not conform to environmental-friendly requirements and the use cost is high, are solved.

Owner:GREE ELECTRIC APPLIANCES INC

Multi-layer cold and hot sharing vacuum freeze-drying system

PendingCN112197517AImprove efficiencyImprove energy savingDrying solid materials without heatHeating arrangementCooling towerThermodynamics

The invention relates to a multi-layer cold and hot sharing vacuum freeze-drying system. The system comprises a pre-freezing unit, a dehydration unit, a negative pressure unit and a heat pump unit. Aproduct is dehydrated in the dehydration unit after being frozen in the pre-freezing unit, and the dehydration unit ensures that the interior of the dehydration unit is in negative pressure through the negative pressure unit. The heat pump unit comprises a high-temperature side heat pump assembly and a low-temperature side heat pump assembly, a high-temperature condenser of the high-temperature side heat pump assembly provides heat energy for the interior of the dehydration unit, and the low-temperature side heat pump assembly provides cold energy for the pre-freezing unit and the dehydrationunit. The system simultaneously meets the requirements for the amount of cold energy and heat energy in a pre-freezing process and a vacuum drying process; existing conventional steam systems, hot oilsystems and other systems are omitted; heat dissipation equipment such as an external cooling tower required by an existing system is also omitted; and a low-temperature condenser is adopted as a water removal device in the dehydration unit, it can be guaranteed that the water removal device is free of frosting and freezing phenomena, the system efficiency is high, the energy-saving effect is obvious, and the production and processing speed is increased.

Owner:SIFANG TECH GRP CO LTD

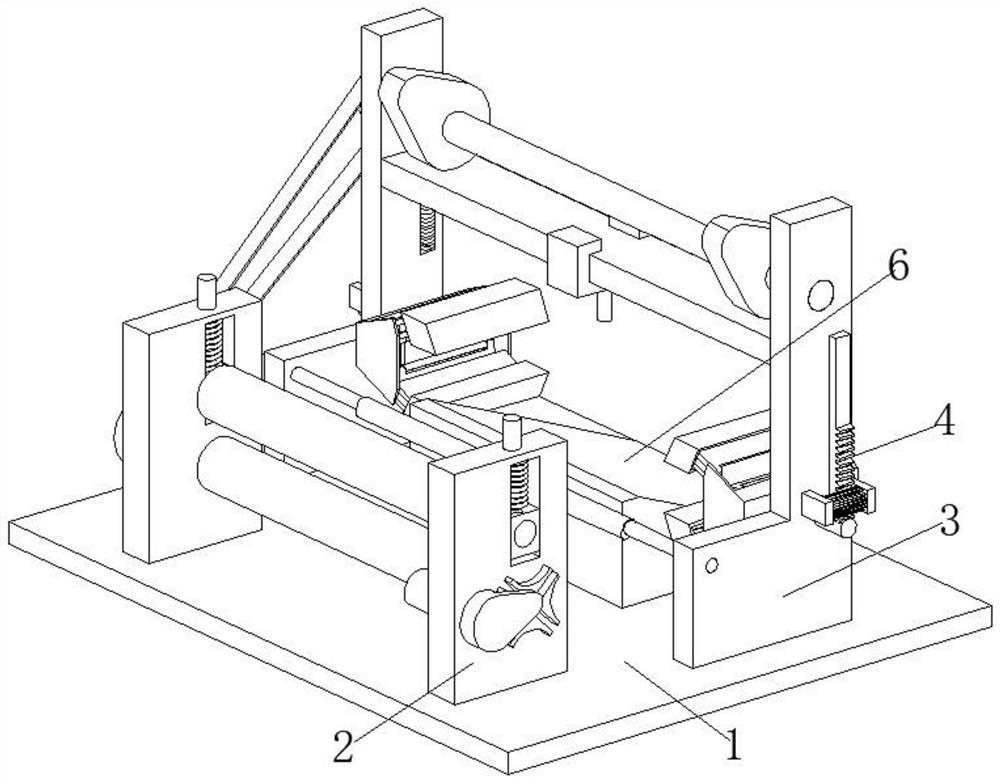

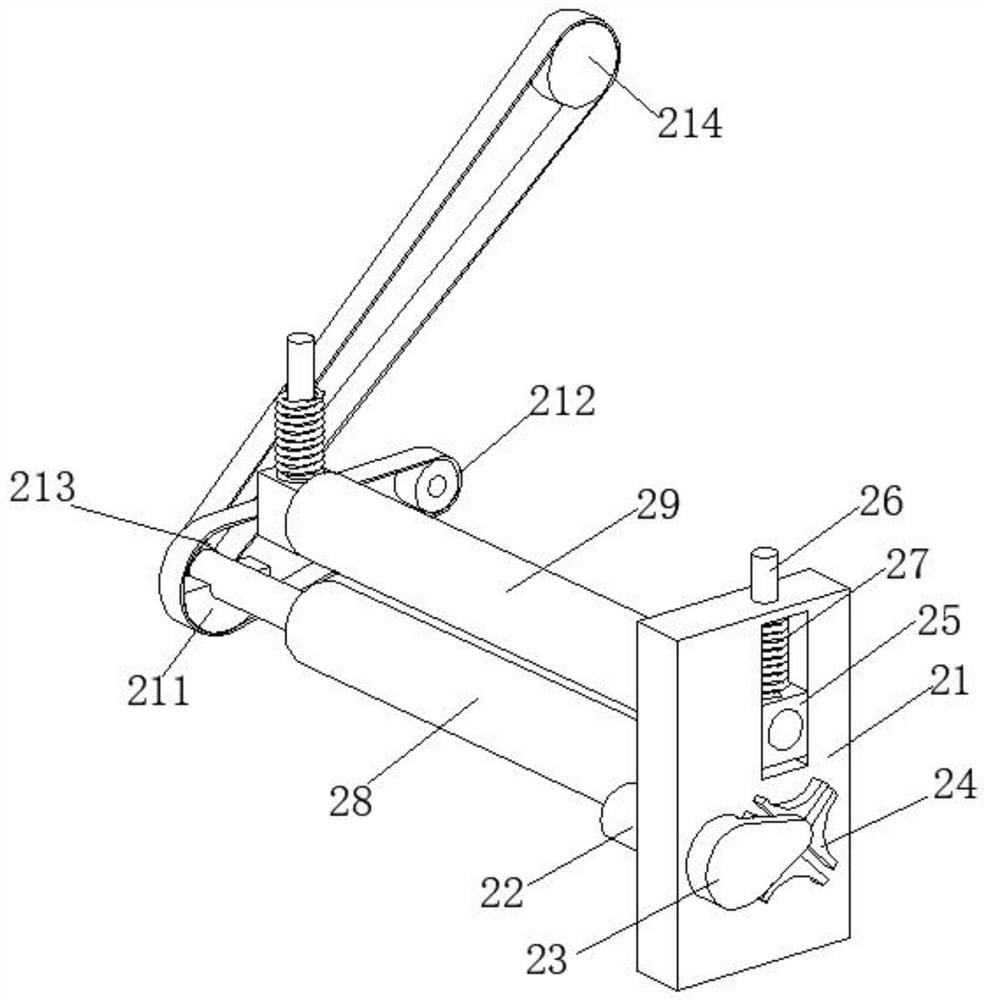

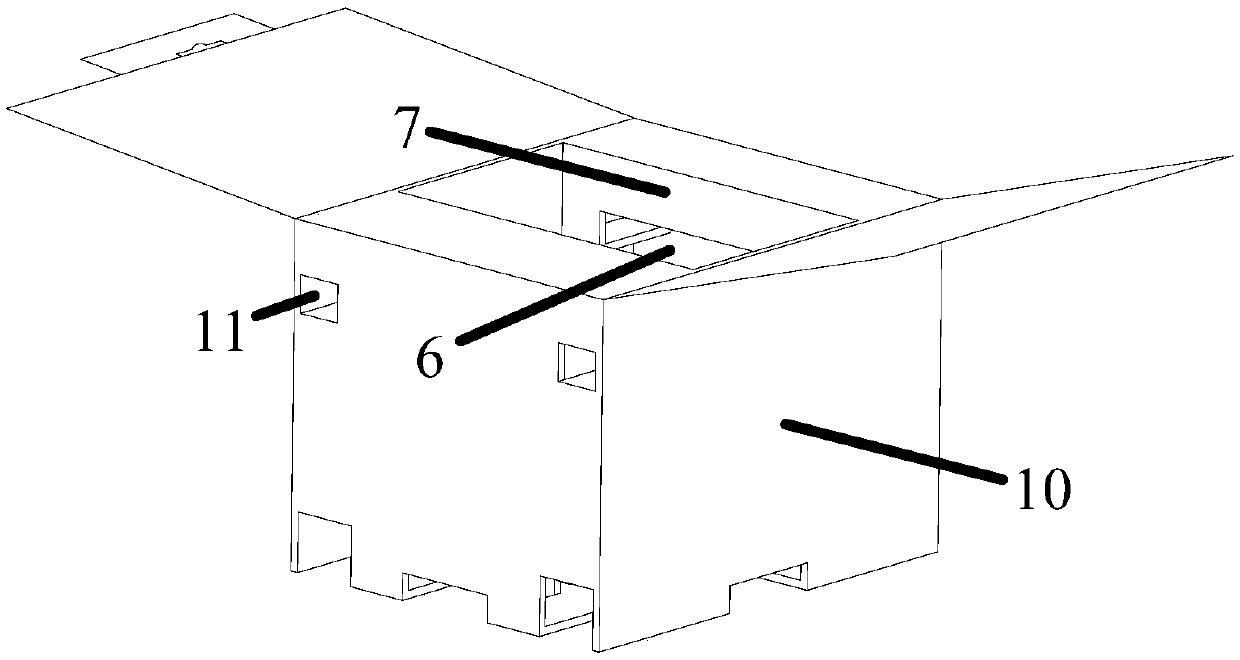

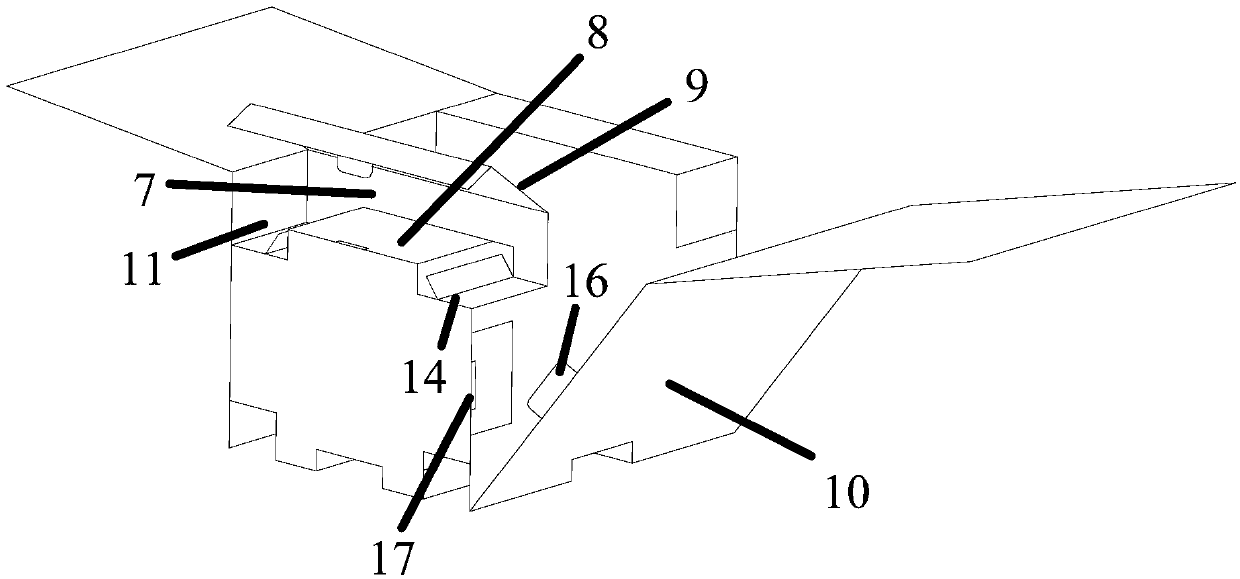

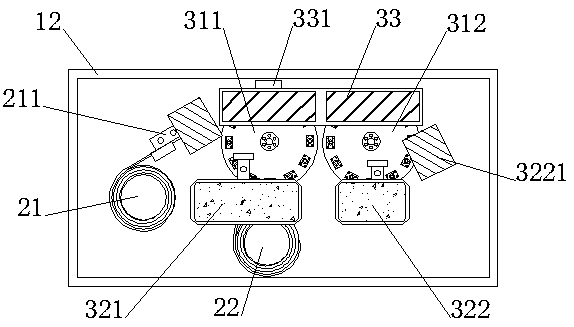

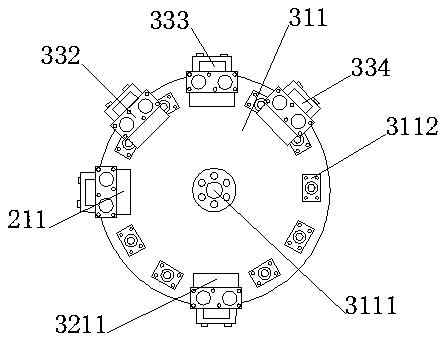

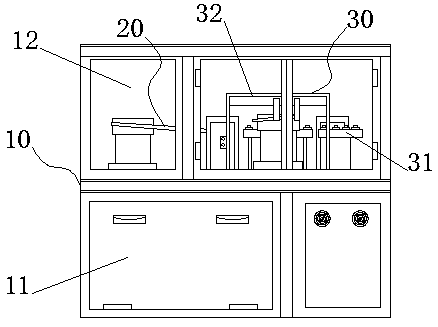

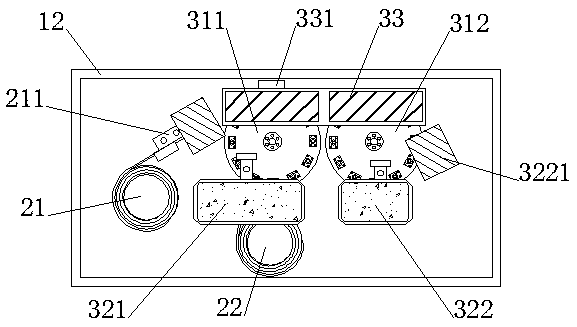

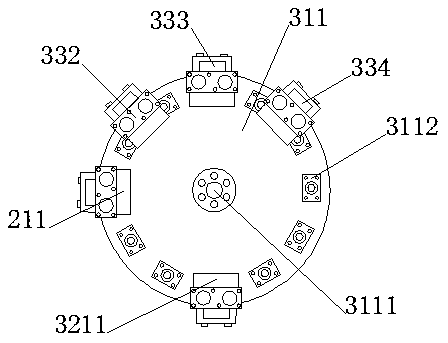

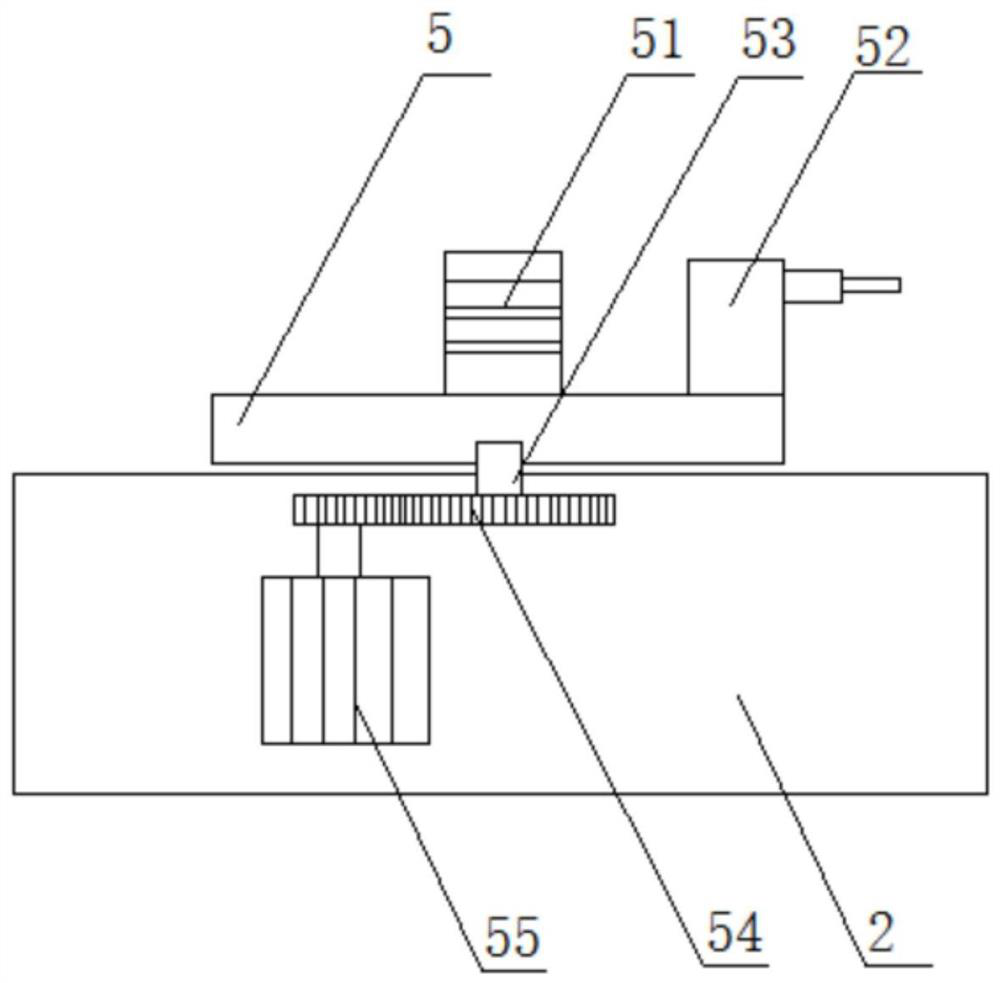

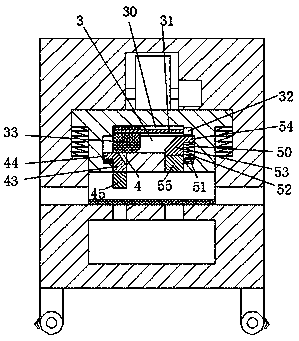

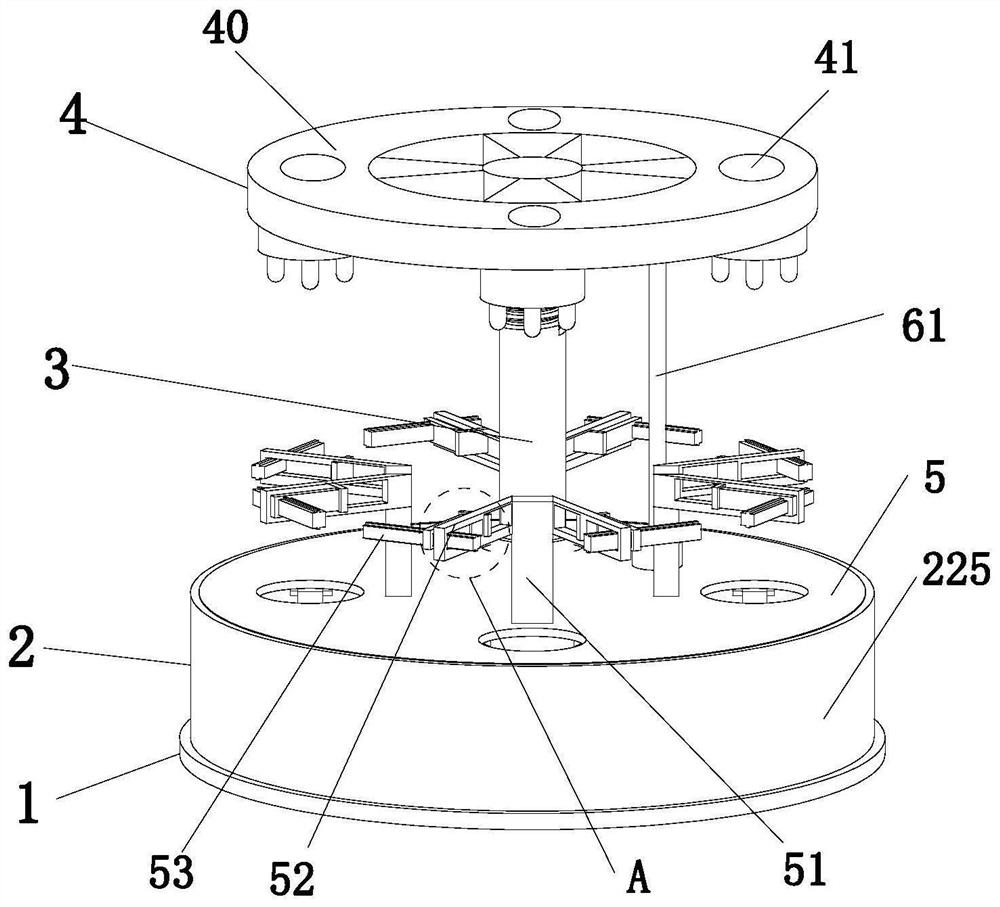

Automatic assembly machine of jumper quick-connection joint

ActiveCN108242757AReduce usageImprove production processing speedContact member assembly/disassemblyContinuous/uninterruptedEngineering

The invention discloses an automatic assembly machine of a jumper quick-connection joint. The machine comprises a body component, a feeding component and an assembly component. The body assembly comprises a power box and an assembly box which is fixed to an upper side of the power box. The feeding component comprises a POST loading tray and a T-shaped sheet loading tray. The POST loading tray andthe T-shaped sheet loading tray are fixed to an inner upper surface of the assembly box and are electrically connected to an external power supply. The outer sides of the POST loading tray and the T-shaped sheet loading tray are connected to a loading cylinder. The processing of jumper quick-connection joints is set to be an automatic production mode, the device is provided with two rotary assembly turntables and is provided with a vibration supply tray of a raw material and an assembly cylinder, the continuous uninterrupted assembly processing of jumper joint workpieces is achieved, the automation of production is improved, the use of labor is reduced, the speed of production and processing is greatly improved, and the product quality is ensured.

Owner:苏州毕毕西通讯系统有限公司

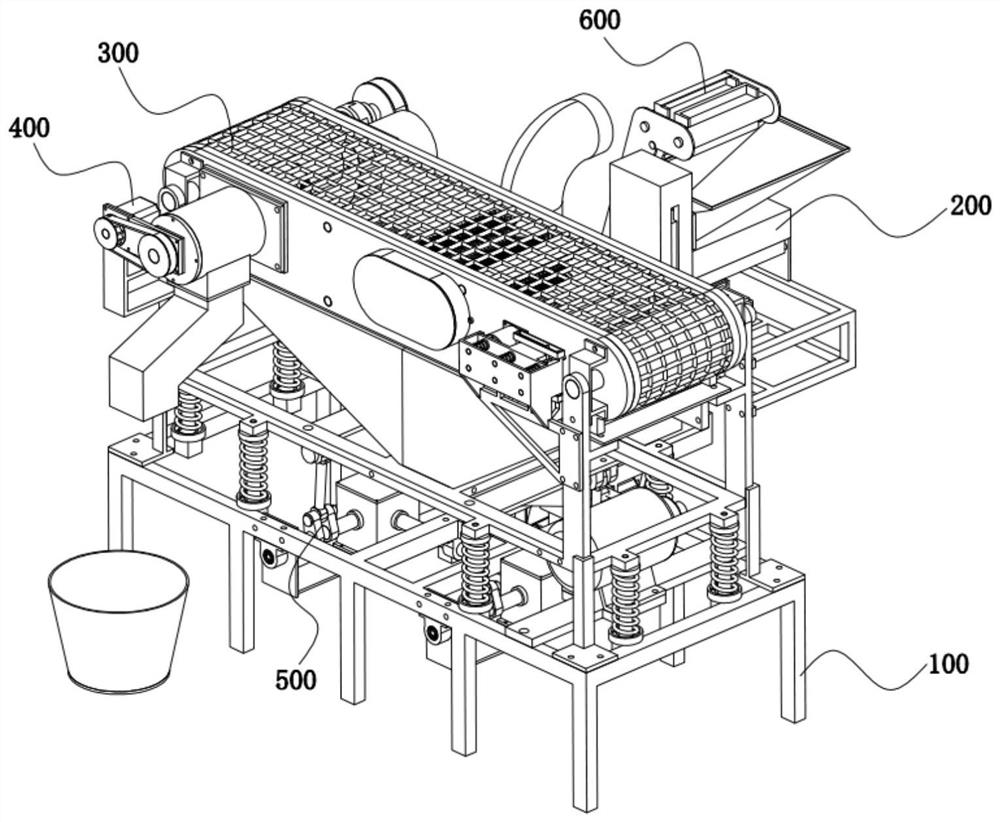

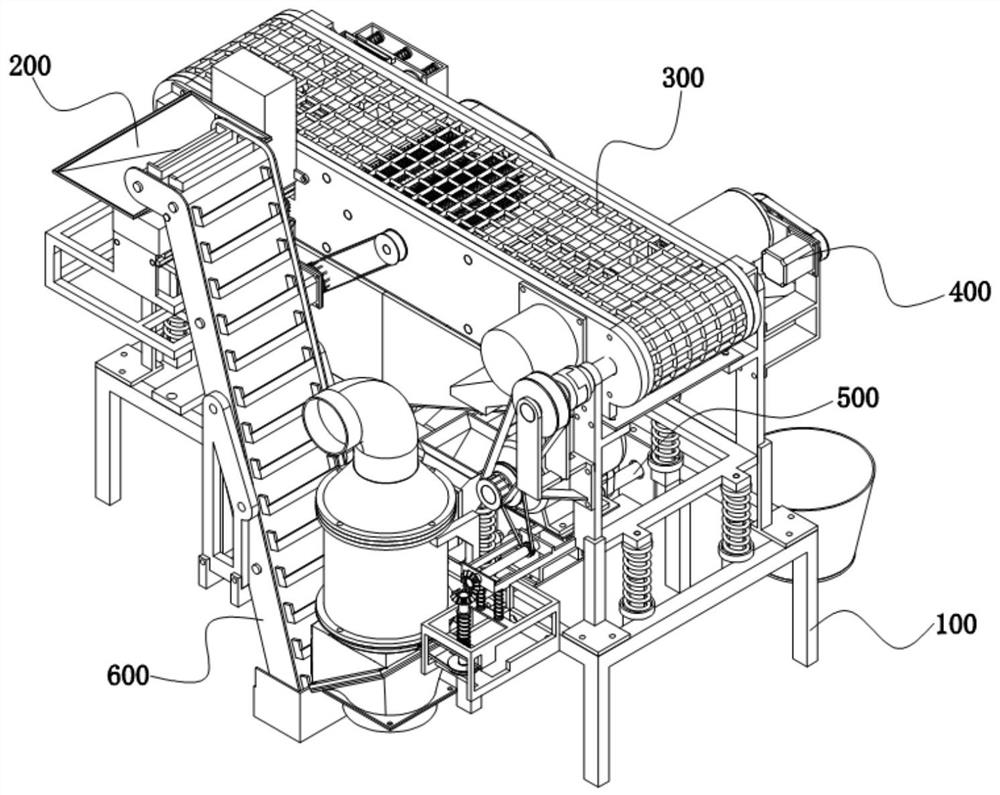

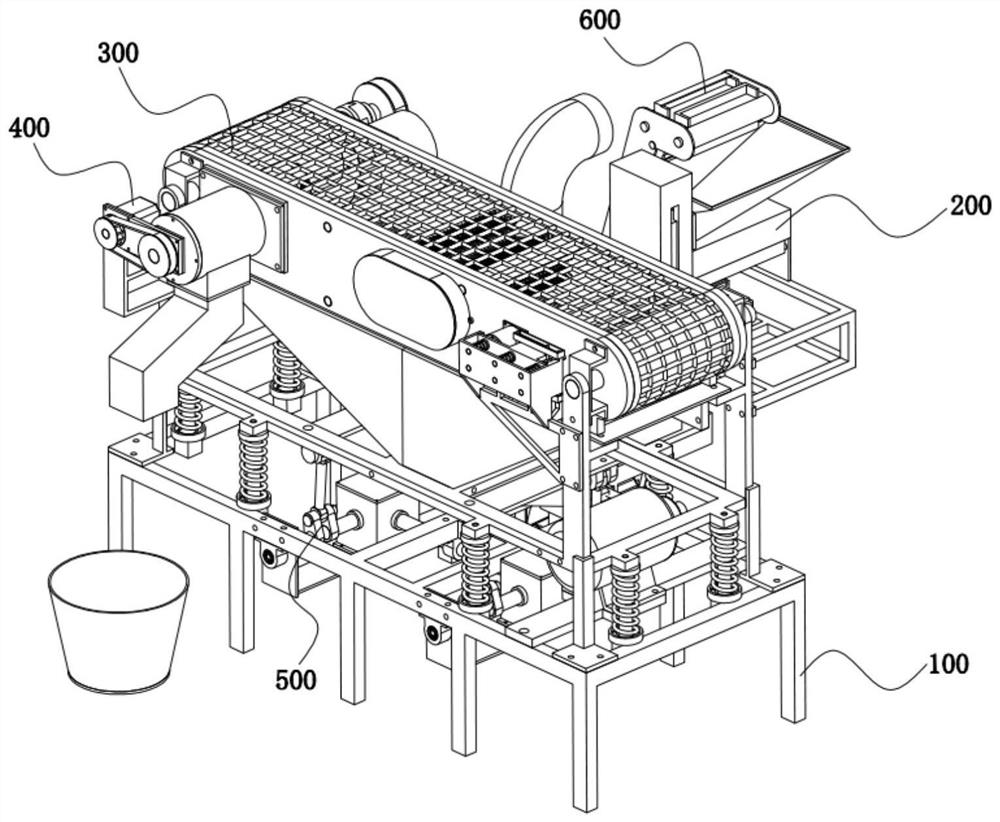

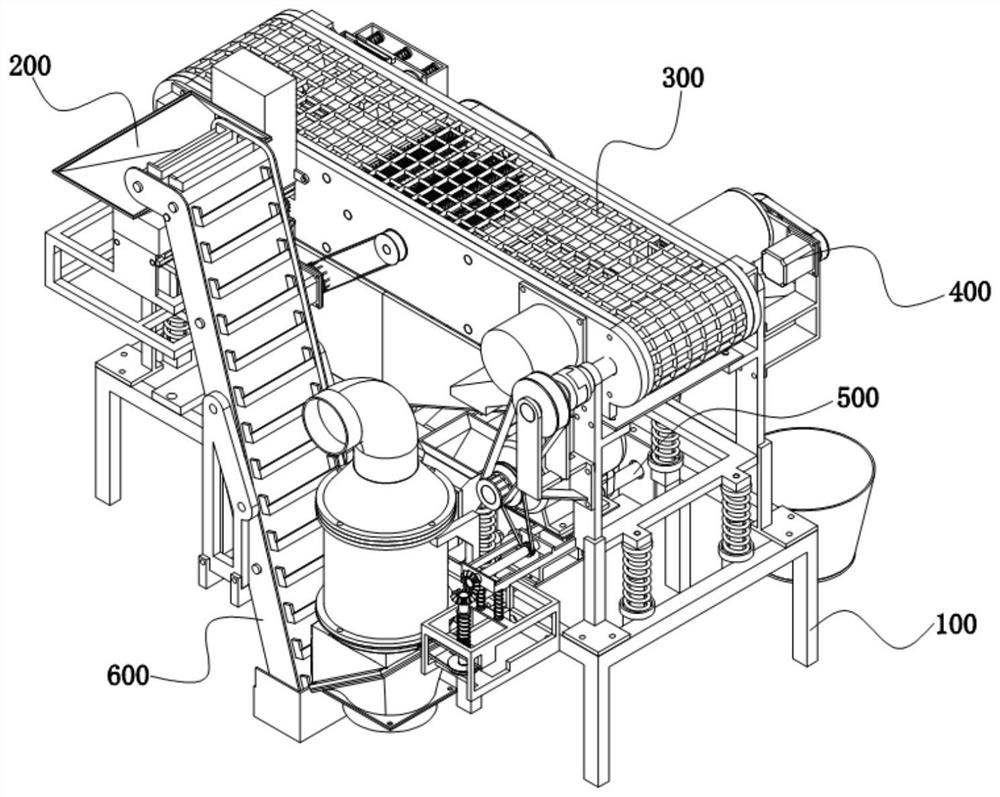

Automatic dust and impurity removal system applied to deep processing of traditional Chinese medicinal materials

PendingCN113333346AImprove production and processing efficiencyImprove economyGas current separationCleaning using toolsMedicinal herbsDust control

The invention provides an automatic dust and impurity removal system applied to deep processing of traditional Chinese medicinal materials. The automatic dust and impurity removal system comprises a mounting frame body, a feeding device, a cleaning device, a discharging device, a moving device and a transfer device are mounted on the mounting frame body, and the feeding device is used for guiding the medicinal materials carrying dust and impurities into the cleaning device. The cleaning device is used for conducting dust and impurity removal cleaning on guided-in medicinal materials, the discharging device is used for guiding out the uncleaned medicinal materials for secondary cleaning and outwards conveying and collecting the cleaned medicinal materials, and the moving device is used for assisting separation of the medicinal materials and impurities and dust through movement. The transfer device is used for guiding the uncleaned medicinal materials into the feeding device; According to the automatic dust and impurity removal system, fed medicinal materials carrying dust and impurities can be automatically cleaned, and the dust and the impurities are separated and then discharged outwards, so that pure medicinal materials are collected, manpower and time are saved, and the production and processing efficiency and the economic value of the medicinal materials are improved.

Owner:安徽途艺洛机电技术有限公司

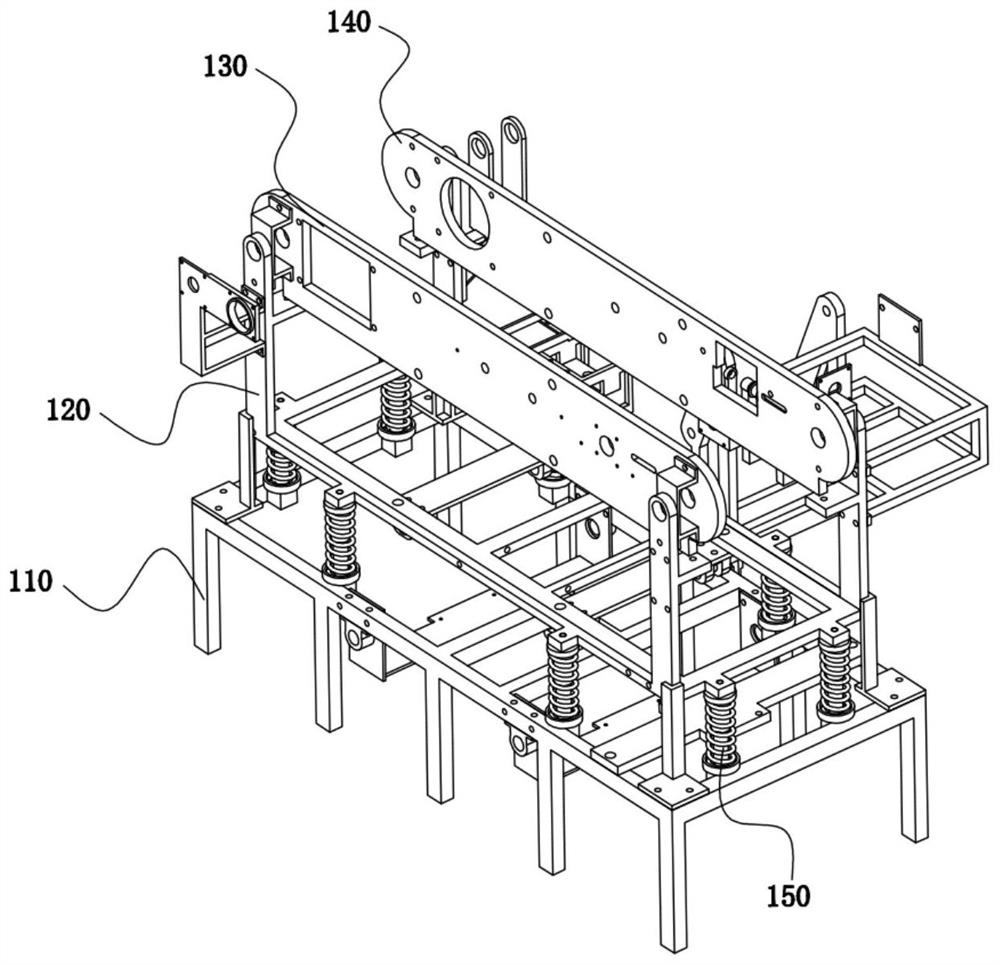

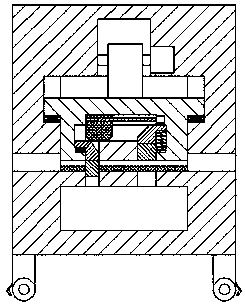

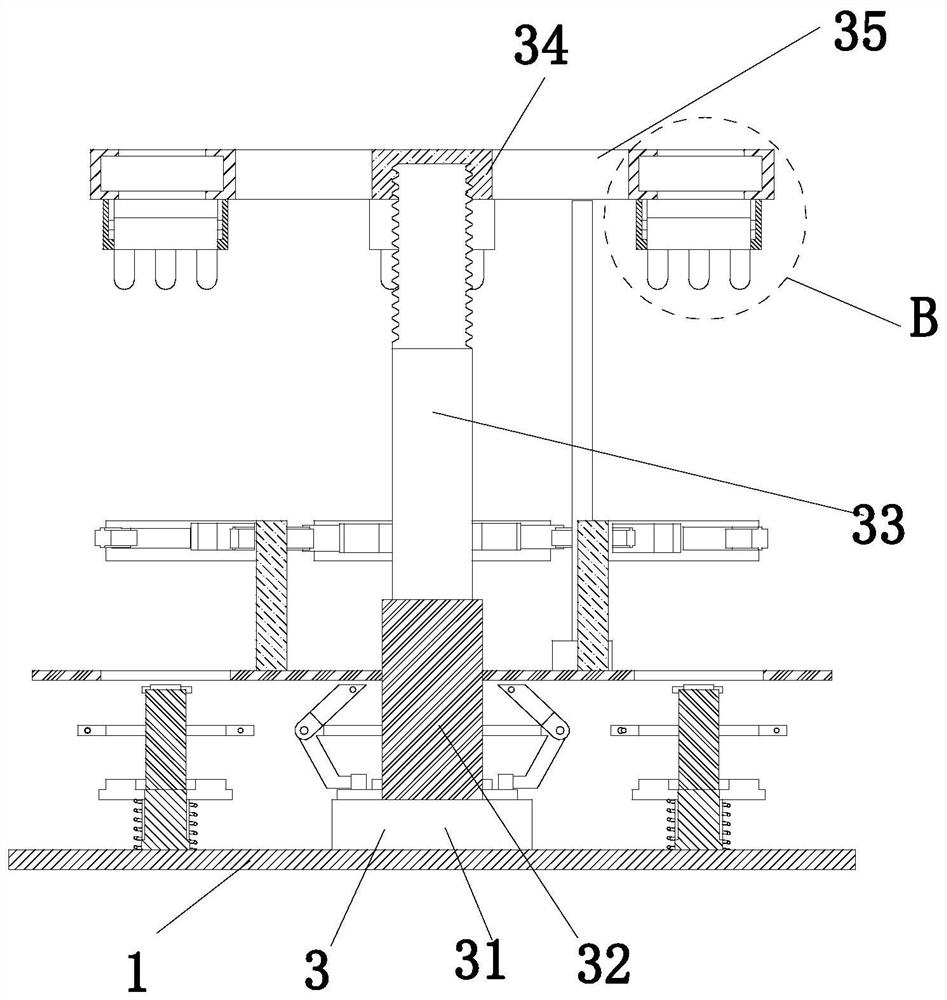

Friction block production device and friction block production method

PendingCN110788336ANo position shiftAccurate and effective pressingTurbinesOther manufacturing equipments/toolsMolding machineEngineering

The invention relates to a friction block production device and a friction block production method. The friction block production device comprises a mixing mechanism, a pressing and forming mechanismand a pressing and sintering mechanism, wherein the mixing mechanism mixes and stirs materials to form a mixed material; the pressing and forming mechanism comprises a pre-pressing mechanism and a primary pressing mechanism;, the pre-pressing mechanism pre-presses the mixed material, the primary pressing mechanism re-presses the pre-pressed mixed material and the pressure of the pre-pressing mechanism is smaller than a pressure value of the primary pressing mechanism; and the pressing and sintering mechanism pressurizes and sinters the pressed and formed mixed material. The friction block production device solves the problem that the compact density of a friction block is low and the friction block even has cracks as the compact will expands elastically to increase the volume as a result of release of elastic stress after an existing friction block is pressed.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

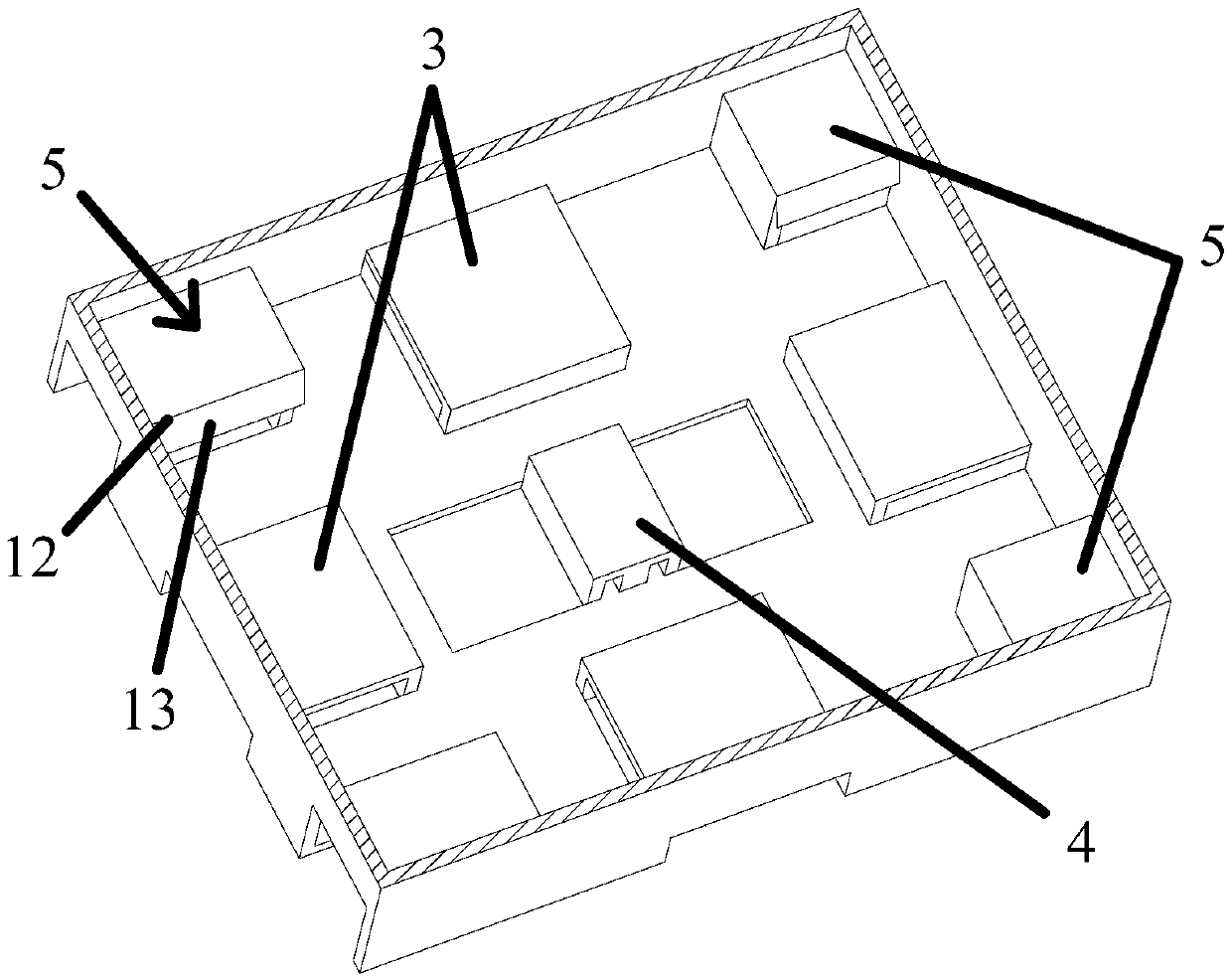

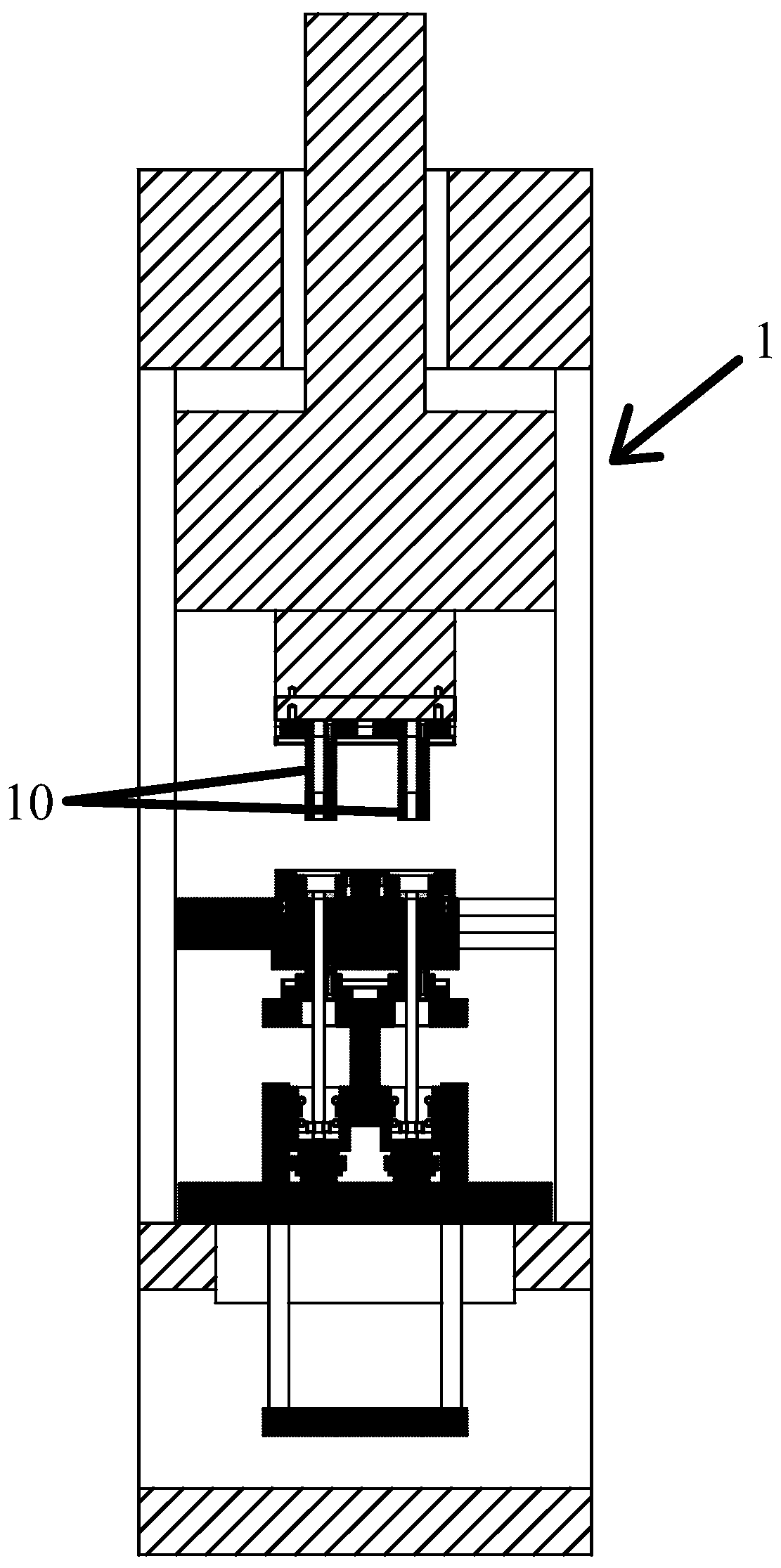

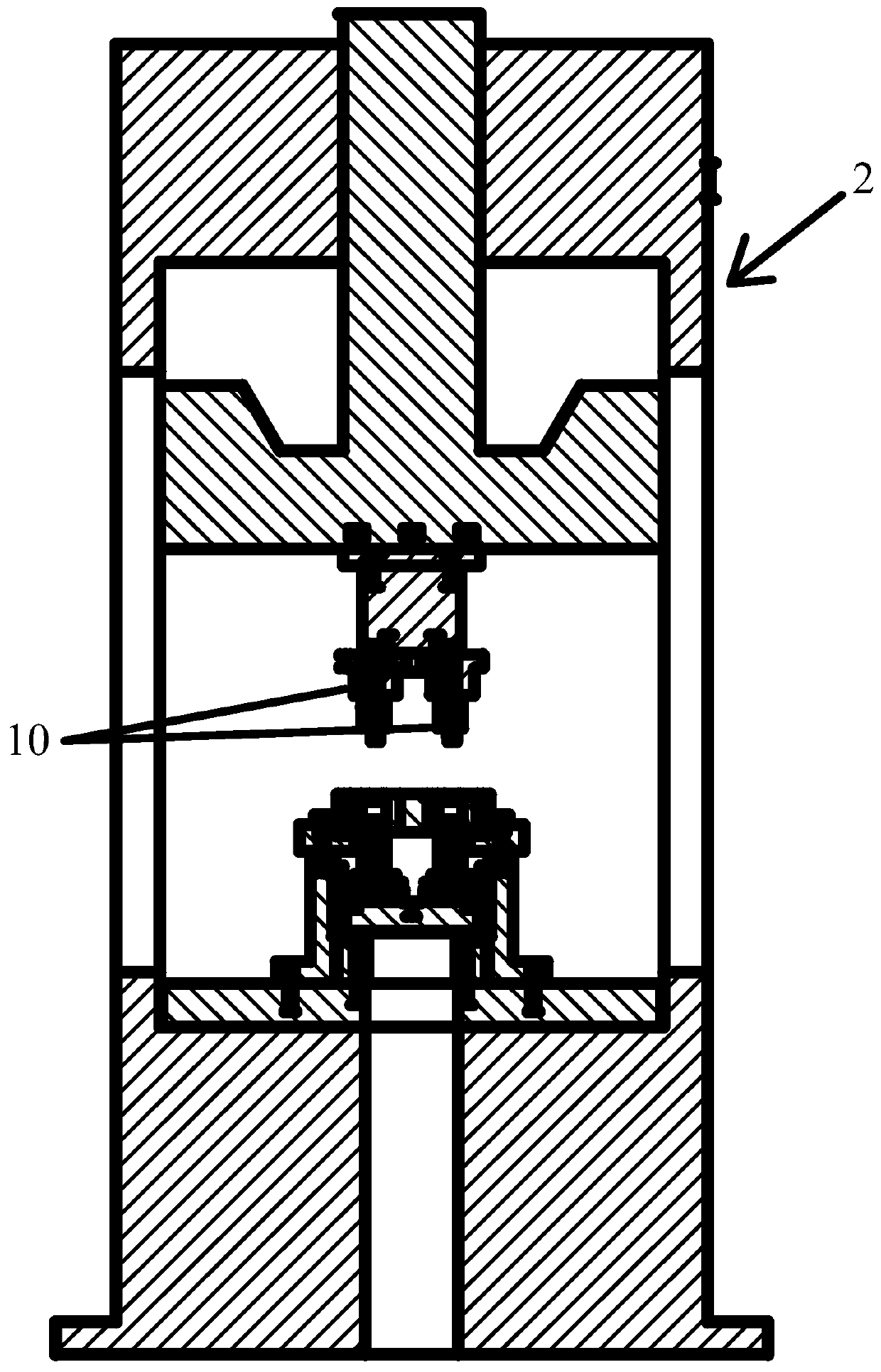

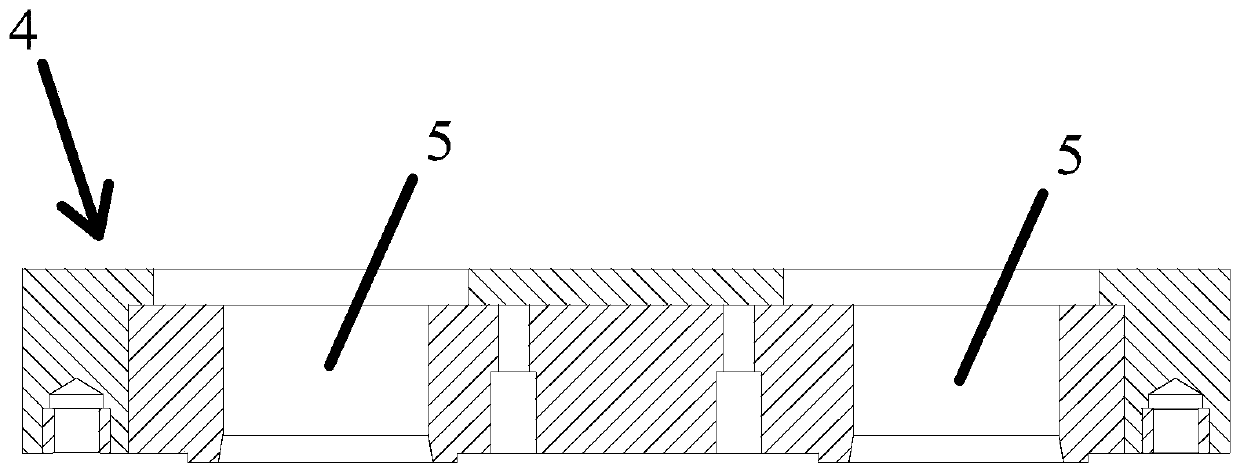

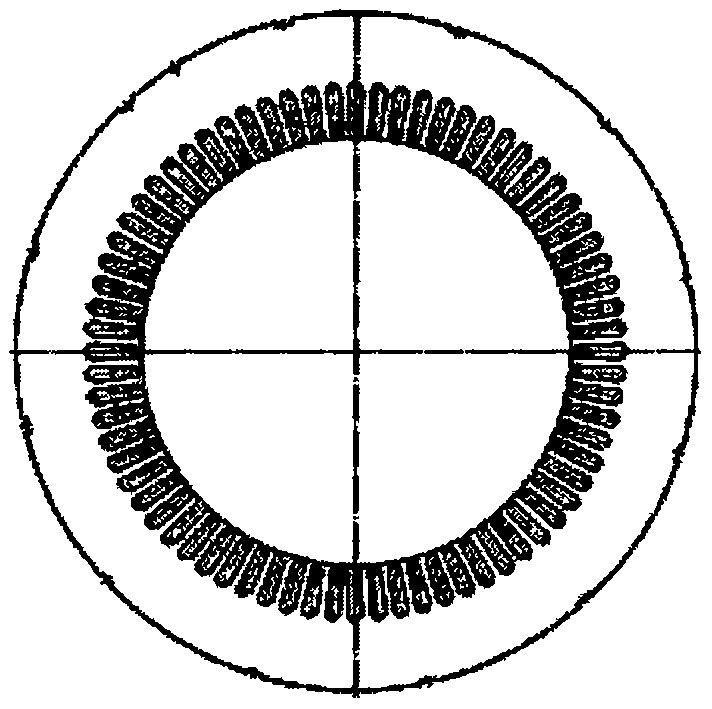

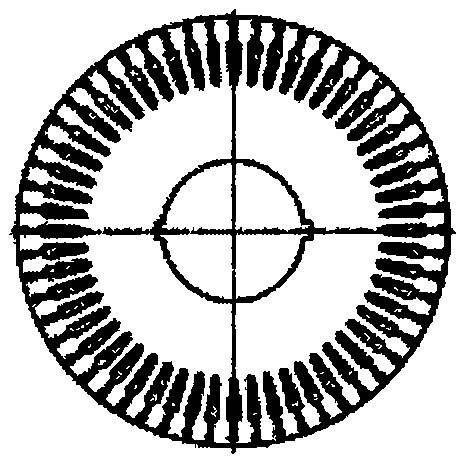

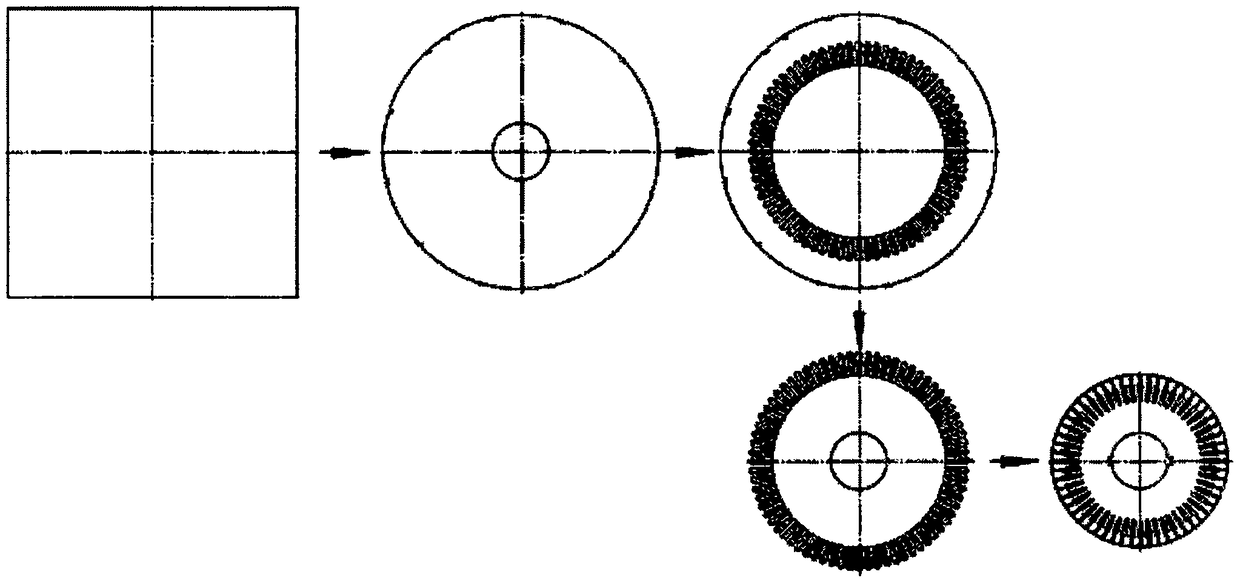

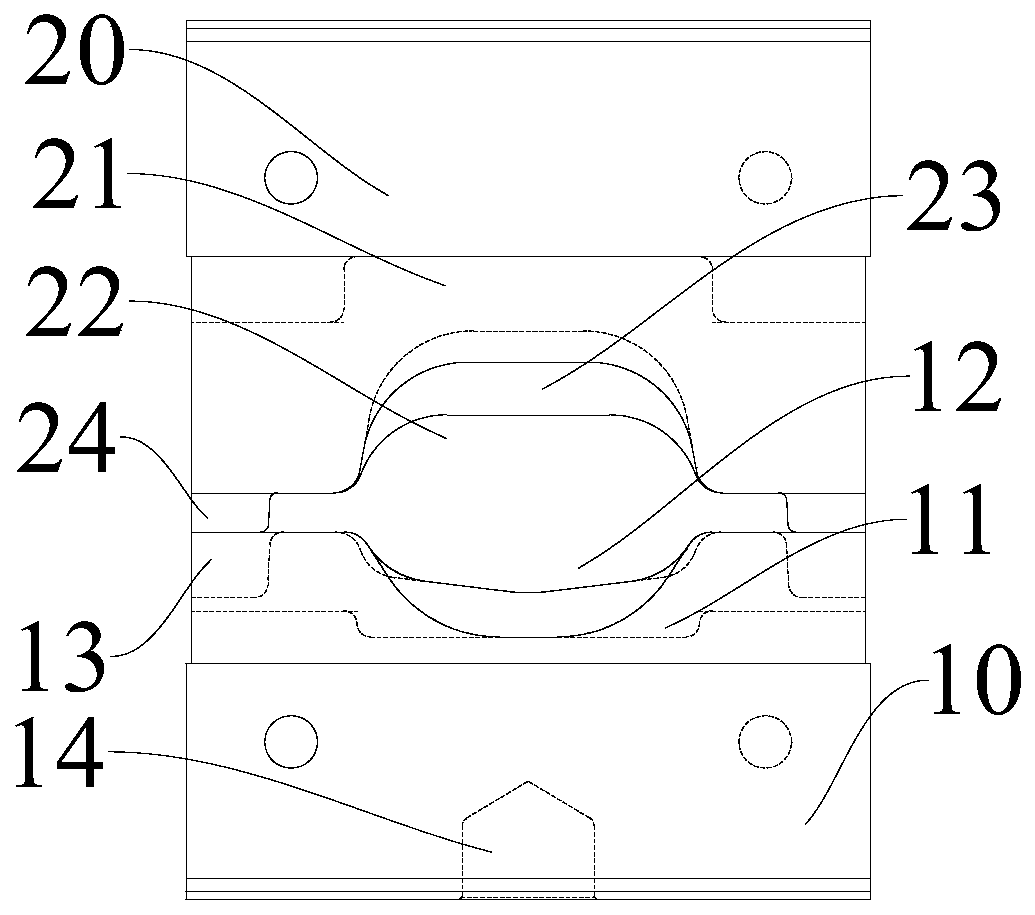

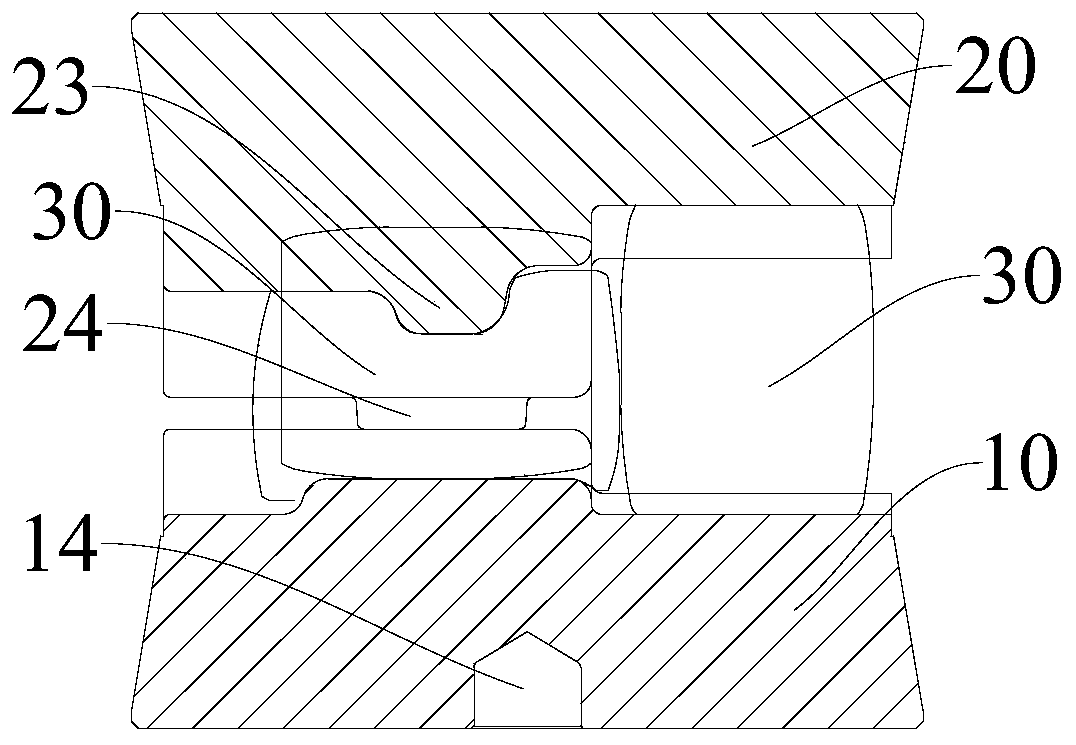

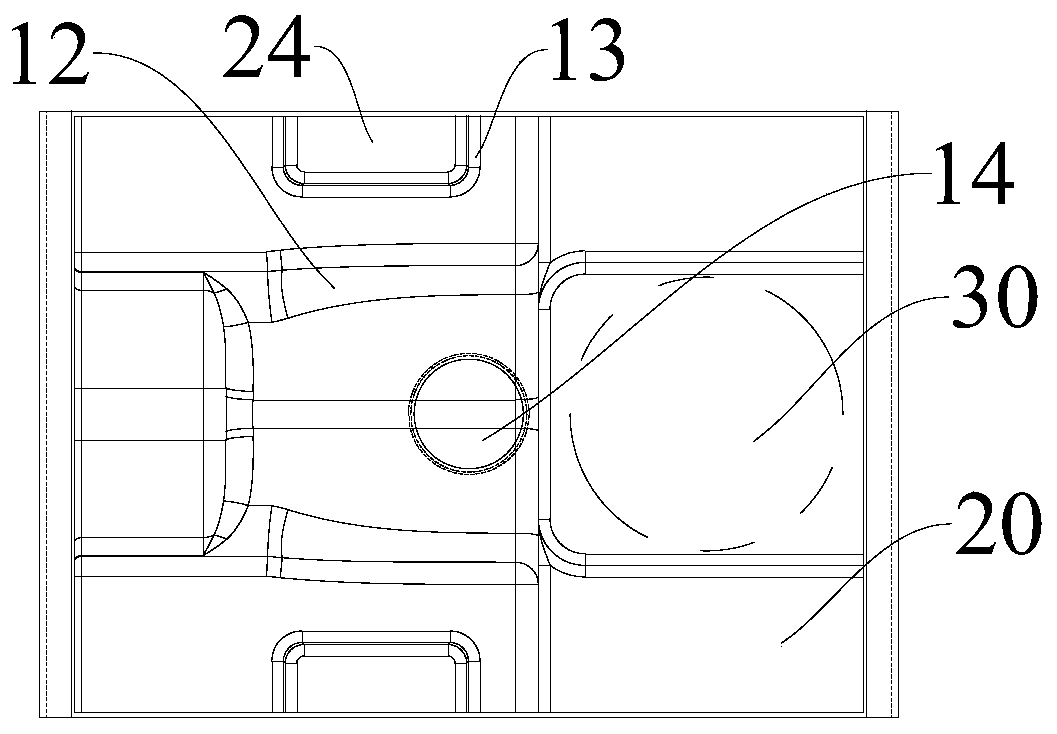

Motor stator full double type belt cutting groove-shaped waste mold and machining method

PendingCN109351842AReduces the number of steps required to calibrate positioningReduce usageConvex structureAgricultural engineering

The invention discloses a motor stator full double type belt cutting groove-shaped waste mold. The motor stator full double type belt cutting groove-shaped waste mold is used for machining a motor stator, and comprises an upper mold base, a lower mold base, a stator groove profile convex mold with a groove profile convex structure corresponding to motor stator groove profiles, a shaft hole concavemold with a concave structure corresponding to a shaft hole of a motor stator, a stator concave and convex mold block disposed above the lower mold base and a heavy-duty rectangular spring disposed between the shaft hole concave mold and the lower mold base. The groove profile convex structure is arranged in a circular array mode according to the number of the motor stator groove profiles, and can punch and cut a stator groove profile of a motor rotor. The stator concave and convex mold block has a stator concave and convex mold block inner diameter corresponding to the inner diameter of thestator and a stator concave and convex mold block outer diameter corresponding to the outer diameter of the stator. The heavy-duty rectangular spring can elastically support the shaft hole concave mold and enables the shaft hole concave mold to be with the same upper surface level as the stator concave and convex mold block. The motor stator full double type belt cutting groove-shaped waste mold can effectively improve the machining efficiency and the accuracy of machined products.

Owner:SHAANXI WEIHE TOOLS CO LTD

An automatic assembly machine for jumper quick-plug connectors

ActiveCN108242757BReduce usageImprove production processing speedContact member assembly/disassemblyContinuous/uninterruptedEngineering

The invention discloses an automatic assembly machine of a jumper quick-connection joint. The machine comprises a body component, a feeding component and an assembly component. The body assembly comprises a power box and an assembly box which is fixed to an upper side of the power box. The feeding component comprises a POST loading tray and a T-shaped sheet loading tray. The POST loading tray andthe T-shaped sheet loading tray are fixed to an inner upper surface of the assembly box and are electrically connected to an external power supply. The outer sides of the POST loading tray and the T-shaped sheet loading tray are connected to a loading cylinder. The processing of jumper quick-connection joints is set to be an automatic production mode, the device is provided with two rotary assembly turntables and is provided with a vibration supply tray of a raw material and an assembly cylinder, the continuous uninterrupted assembly processing of jumper joint workpieces is achieved, the automation of production is improved, the use of labor is reduced, the speed of production and processing is greatly improved, and the product quality is ensured.

Owner:苏州毕毕西通讯系统有限公司

Water-cooled flour making machine for raw material processing of food production

InactiveCN108970757BImprove production processing speedImprove production and processing efficiencyGrain treatmentsElectric machineryProcess engineering

Owner:河南金土商贸有限公司

A kind of energy-saving and environment-friendly roller coating paint for printing plate and using method thereof

ActiveCN104817950BStrong adhesionImprove ductilityPolyurea/polyurethane coatingsEpoxy resin coatingsEngineeringEnvironmentally friendly

The invention provides an energy-saving and environment-friendly roller coating paint for a printing plate and an application method of the energy-saving and environment-friendly roller coating paint. The paint comprises a priming paint and a finish paint. The paint is high in adhesive force, good in ductility, heat-resistant and long in service life; the processing technology for printing plate products is changed; the processing procedures are simplified; roller coating treatment is intensively finished on a panel of the printing plate; and a painting workshop does not need to be independently arranged.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

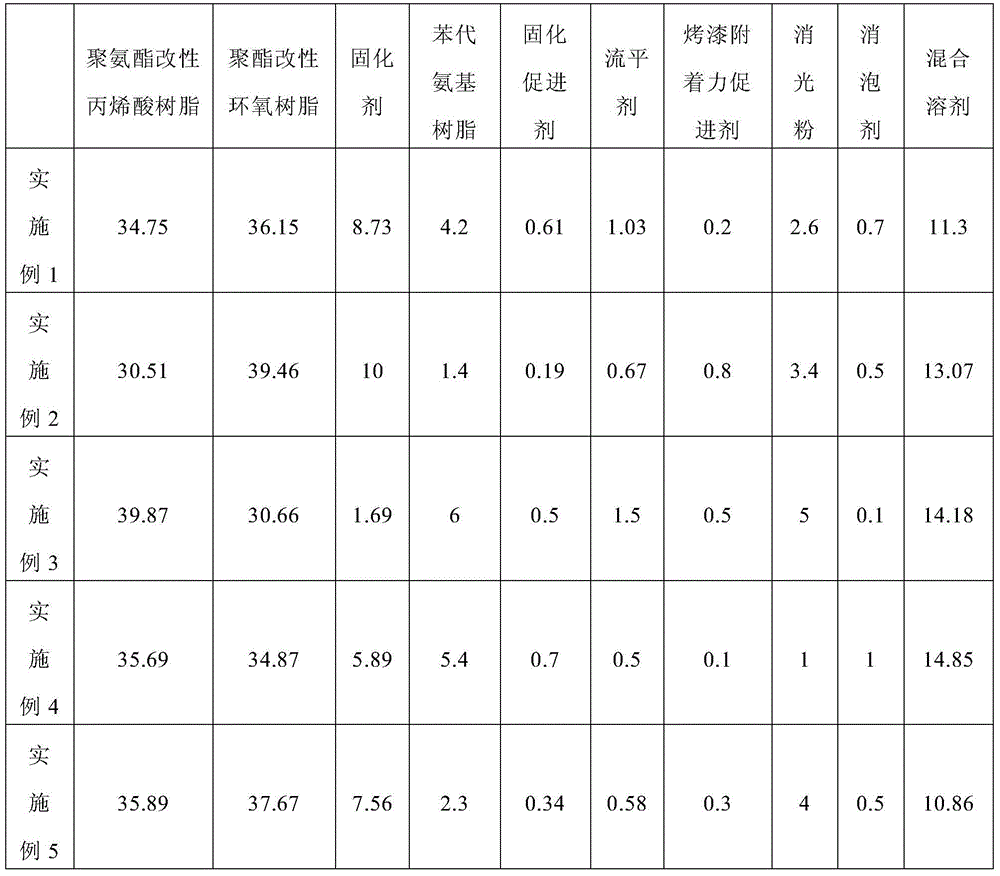

Method to separate enriched Z and E types of 3-chloro-2-(4-fluorophenyl)-1-(2-chlorophenyl)propylene

InactiveCN108530263AShorten the production and processing cycleImprove production processing speedOrganic chemistry methodsHalogenated hydrocarbon separation/purificationOrganic solventMixed solution

The invention discloses a method to separate enriched Z and E types of 3-chloro-2-(4-fluorophenyl)-1-(2-chlorophenyl)propylene, comprising the steps of (1) mixing a mixed solution, having rich Z and Etypes of 3-chloro-2-(4-fluorophenyl)-1-(2-chlorophenyl)propylene with an organic solvent in a volume ratio of 1:(1-7.5) such that the mixed solution is fully dissolved in the organic solvent to obtain a first solution; (2) freezing a container with the first solution at the low temperature of -70 DEG C to -90 DEG C; (3) after the solution of step (2) layers, separating to obtain supernate so thatE-type solution is obtained; (4) after material left after the separation of step (3) is frozen into solid, thawing the solid at the temperature of -20 DEG C to -30 DEG C; (5) after the solid of step(4) thaws, and collecting thawed liquid that is Z-type solution. The method herein is a purely-mechanical freeze-separation method; the product obtained has high purity, free of nature change, good in performance stability, and higher in quality and yield stability.

Owner:SOUTHEAST UNIV

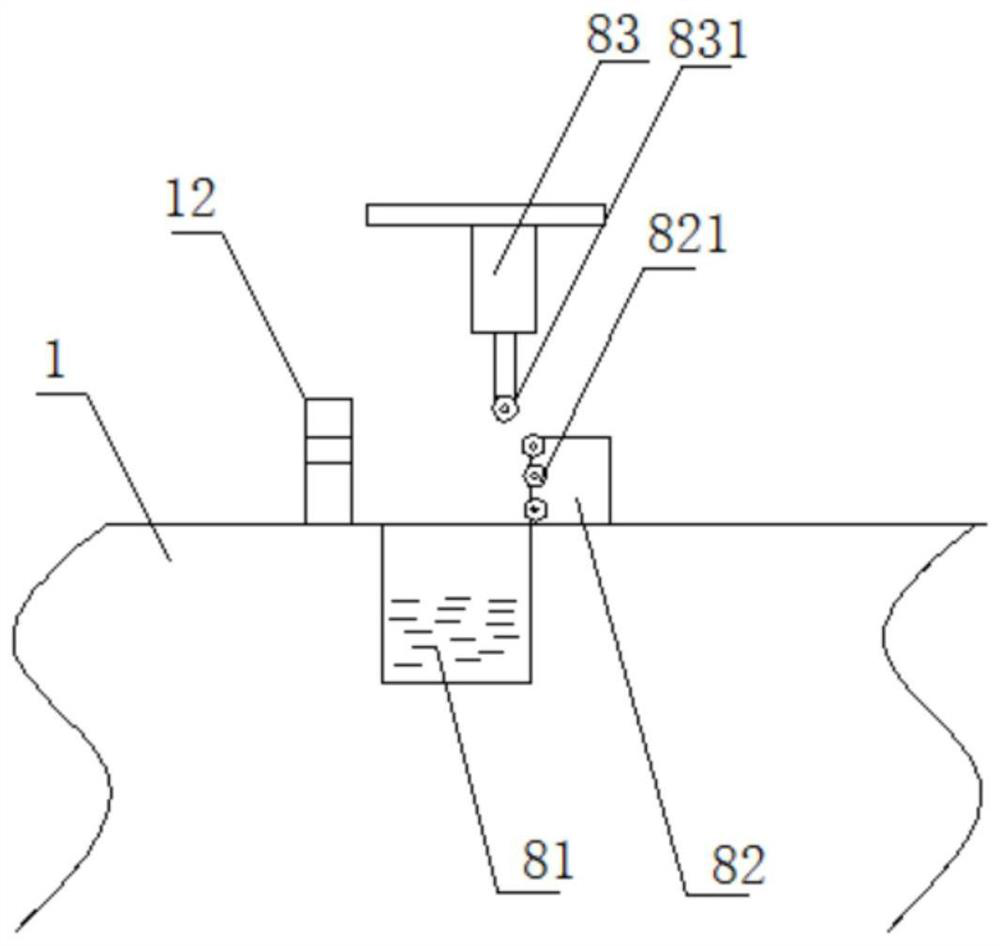

Single-head terminal machine with the function of rubbing and dipping tin and its control method

ActiveCN110021866BDip tin to achieveShorten the delivery pathVehicle connectorsLine/current collector detailsCable transmissionMachine

The present invention discloses a single-ended terminal machine with end twisting and tin-sticking functions and a control method. The machine comprises a machine base that is provided with a feedingsupport arm on the one end and an unloading support arm on the other end. The feeding support arm is provided with a first alignment mechanism and a horizontal turning plate comprising a driving roller and a discharging nozzle. The machine base is provided with a wire-cutting stripping mechanism, a wire-twisting mechanism, a tin-sticking mechanism and a second alignment mechanism along the discharge direction successively. The tin-sticking mechanism comprises a tin-sticking tank, a tin-sticking stand at the edge of the tin-sticking tank and a telescopic arm vertically downwards above the tin-sticking tank. The present invention has effects as follows: simple structure, convenient installation and control, reasonable design and allocation of the wire-twisting mechanism and the tin-stickingmechanism to accommodate processing and production of single-ended terminal harness, reduction of cable transmission path as much as possible, improvement of production and processing speed, strong adaptability of product and low damage rate.

Owner:重庆市萱恒电子科技有限公司

Photosensitive resin compsn., photosensitive element, prodn. method for resist pattern and prodn. method for printed circuit board

InactiveCN1228688CPrevent intrusionPrevent bad conductionRadiation applicationsPhotosensitive material processingSpray nozzleCopper

Owner:RESONAC CORPORATION

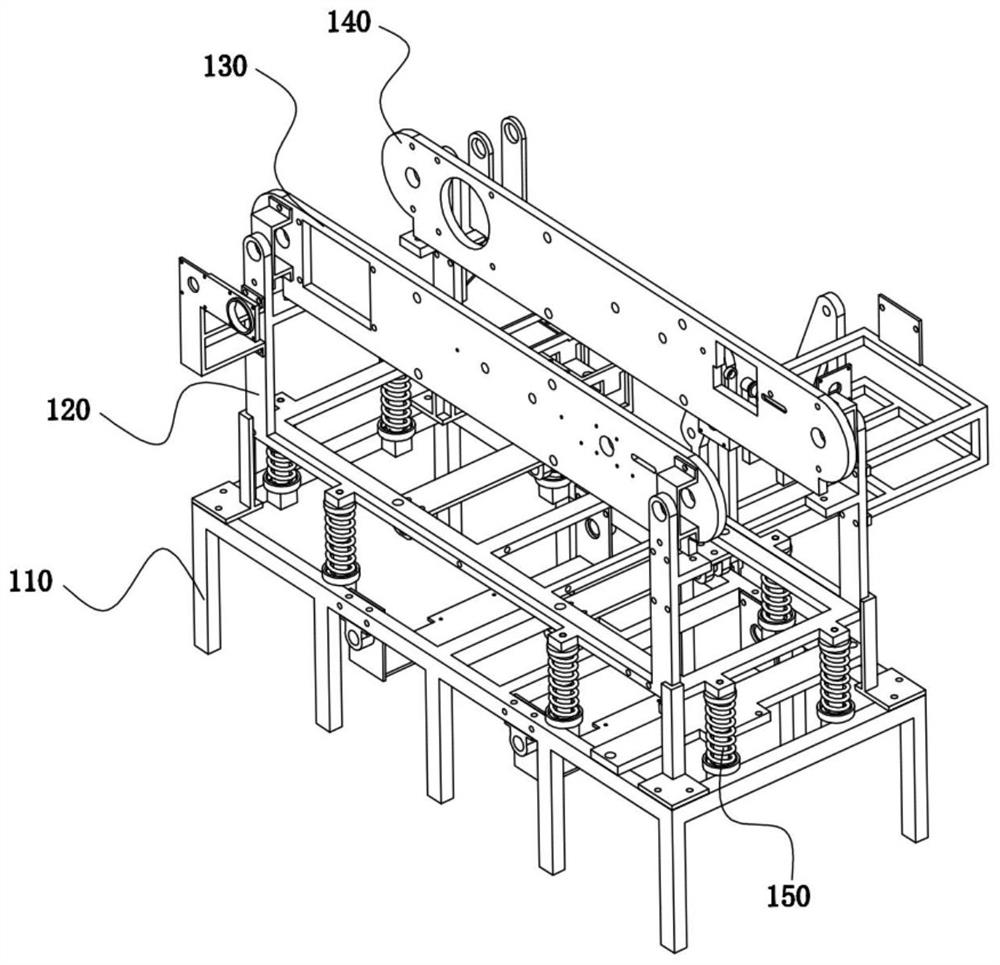

Assembly for automatically removing dust and impurities from medicinal materials

PendingCN113210313AImprove production and processing efficiencyImprove economyGas current separationCleaning using toolsMedicinal herbsStructural engineering

The invention provides an assembly for automatically removing dust and impurities from medicinal materials. The assembly comprises a mounting rack. A cleaning device is mounted on the mounting rack and is used for performing dust and impurity removal cleaning on the guided-in medicinal materials carrying dust and impurities. The mounting rack is arranged on the ground and comprises a fixing frame for playing a fixing and supporting role, a moving frame and retarding components are arranged on the fixing frame, and the retarding components are arranged between the fixing frame and the moving frame and are used for buffering the movement of the moving frame. A connecting plate I and a connecting plate II are arranged on the moving frame and are positioned above the moving frame. According to the assembly, the medicinal materials carrying dust and impurities can be automatically cleaned, and the dust and the impurities can be discharged after being separated out, so that pure medicinal materials are obtained, manpower and time are saved, the medicinal material production and processing efficiency is improved, and the economic value of the medicinal materials is improved.

Owner:安徽途艺洛机电技术有限公司

Control method of forging blank-making device used for commercial vehicle steering engine piston

InactiveCN110883296AImprove production and processing efficiencyImprove production processing speedUpsetting pressesSwagging pressesMaterial consumptionMaterial distribution

The invention discloses a control method of a forging blank-making device used for a commercial vehicle steering engine piston. The control method comprises the following steps of S1, putting a steering engine piston blank into a lower upsetting groove, moving an upper die seat downwards, and upsetting and pressing the steering engine piston blank through a condition that an upper upsetting grooveis cooperated with the lower upsetting groove; S2, after the upsetting of the steering engine piston blank is completed, moving an upper die seat upwards, and horizontally pushing an upper end of thesteering engine piston blank, wherein the steering engine piston blank enters into a lower extrusion groove; and S3, moving the upper die seat downwards, wherein an upper extrusion groove and a lowerextrusion groove are cooperated to extrude the steering engine piston blank. A forging blank making device is cooperated with a hot die forging press, in a blank manufacturing step, upsetting and extrusion combined machining are performed on the steering engine piston blank, an upsetting-extruding composite technology can be used to make material distribution of the blank be more reasonable relative to a die cavity, and material consumption of a single piece is reduced by 0.5 kg so that a material utilization rate is increased, a forging streamline can be improved, and then production and machining efficiency and a speed of a steering engine piston can be increased.

Owner:SHANDONG JINMA INDAL GROUP

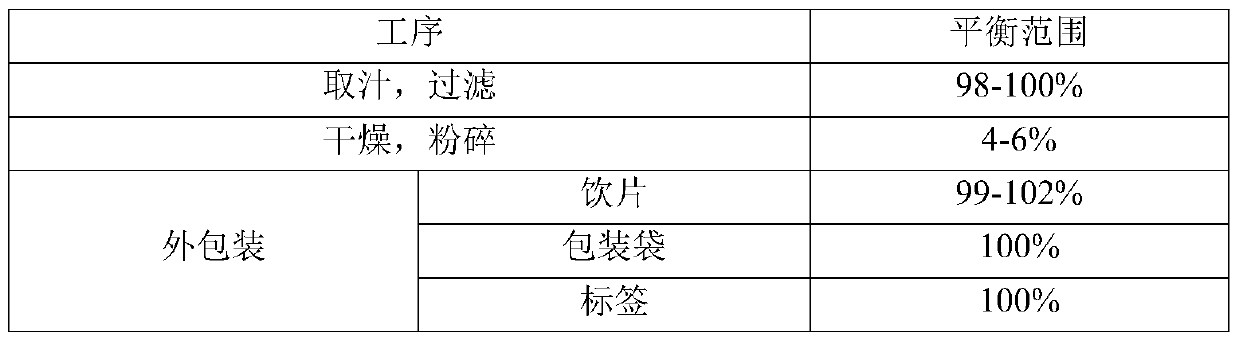

A kind of pig gall powder processing technology

ActiveCN104473967BImprove qualityImprove production processing speedPowder deliveryMetabolism disorderBile JuiceTG - Triglyceride

The invention discloses a pig gall powder preparing process. The process comprises the steps that pig bile is fetched and conveyed into a first drying device, and steam is led into the first drying device to heat the pig bile to 50-70 DEG C; the air pressure in the first drying device is adjusted to be lower than the atmospheric pressure for drying under reduced pressure; when the relative density of materials reaches 0.8-1.25, the pig bile is cooled down to below 30 DEG C, the materials are taken out, placed into a heated air circulation constant-temperature drying oven for drying at the temperature ranging from 40 DEG C to 70 DEG C with the traying thickness ranging from 1 cm to 2 cm, smashed and filtered through a screen with the mesh ranging from 80 to 100 to obtain pig gall powder medicinal slices, and then the pig gall powder medicinal slices are packaged into finished products. Pig gall powder prepared from the pig bile is excellent in quality, and the major component of the pig gall powder is taurohyodeoxycholic acid sodium hydrate which has the effects of clearing heat, moistening dryness, relieving cough and asthma and detoxifying; the pig gall powder is rich in cholanic acid, can effectively inhibit forming of bile acid, dissolve fat and reduce cholesterol and triglyceride in blood and has a good curative effect on various types of hyperlipemia.

Owner:四川神农药业有限公司

Punching equipment

InactiveCN108213184AHigh precisionEasy stampingShaping toolsPerforating toolsPunchingArchitectural engineering

The invention discloses punching equipment. The punching equipment comprises a machine body. Supporting legs are fixedly arranged on the periphery of the bottom face of the machine body. Movable rolling wheels are fixedly arranged at the bottoms of the supporting legs. Damper brakes used for fixing the movable rolling wheels are fixedly arranged at the outer sides of the bottoms of the supportinglegs. A first slippage groove and a containing groove are formed in the machine body. A first through groove and a second through groove are formed between the first slippage groove and the containinggroove in a connecting mode. The first through groove is located in the left side of the second through groove. An exiting groove and an entering groove connected with the outside of the machine bodyare equally formed in the left end and the right end of the bottom of the first slippage groove. A punching slippage block capable of sliding up and down is formed in the first slippage groove. Firstcontaining grooves are equally formed in the left end wall and the right end wall of the first slippage groove. The punching equipment is simple in overall structure, safe and reasonable in design and low in manufacturing and production cost. The punching equipment is accurate in punching machining precision, high in stability and capable of decreasing defective goods produced in the board punching process.

Owner:徐萍

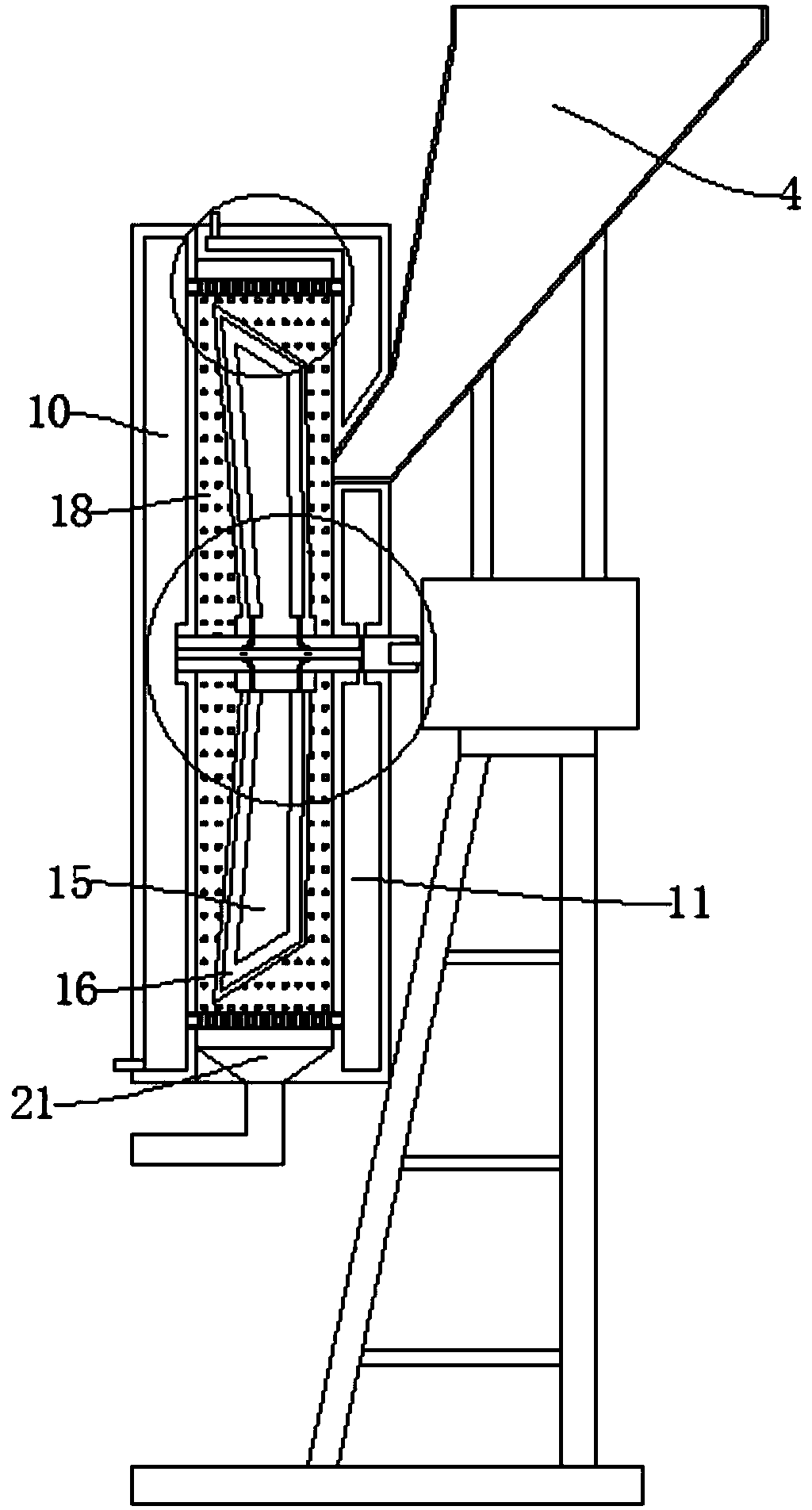

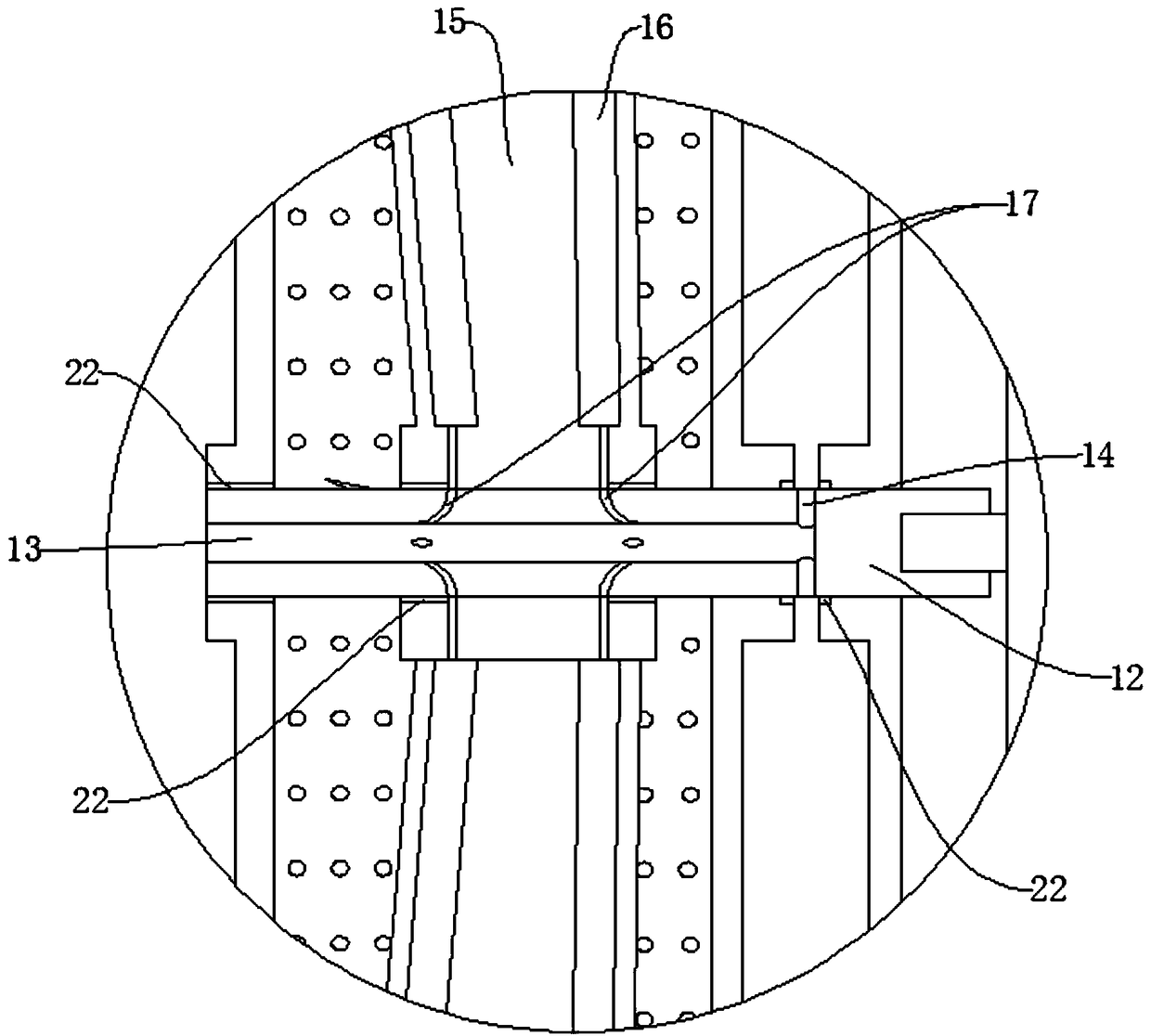

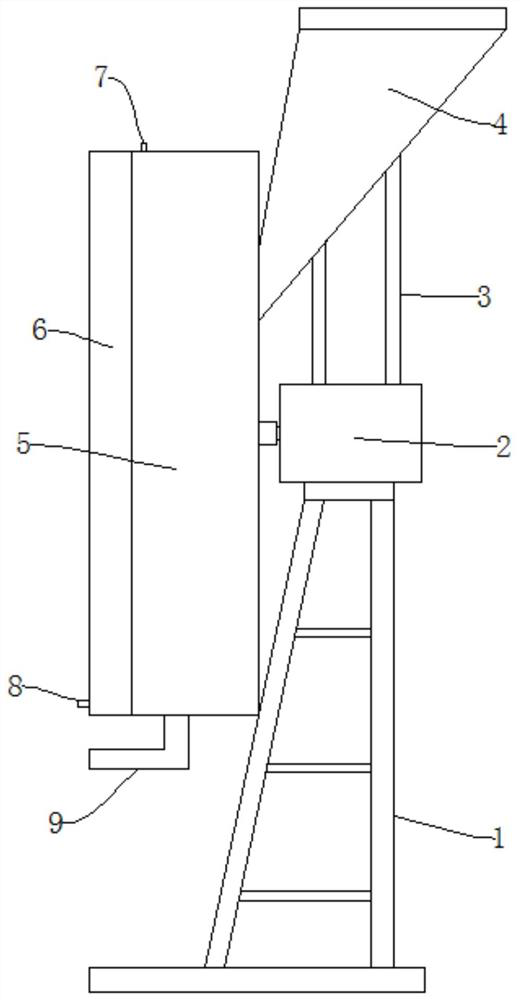

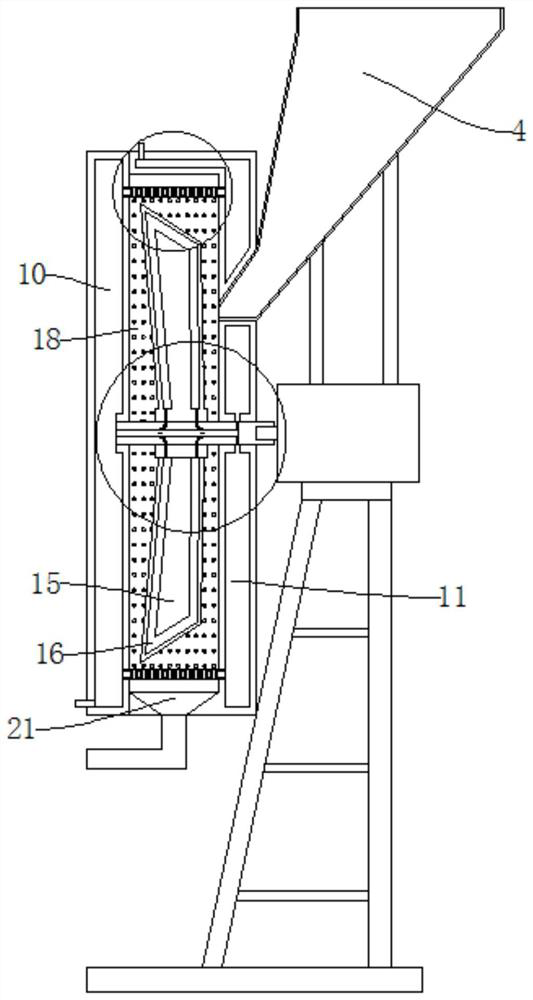

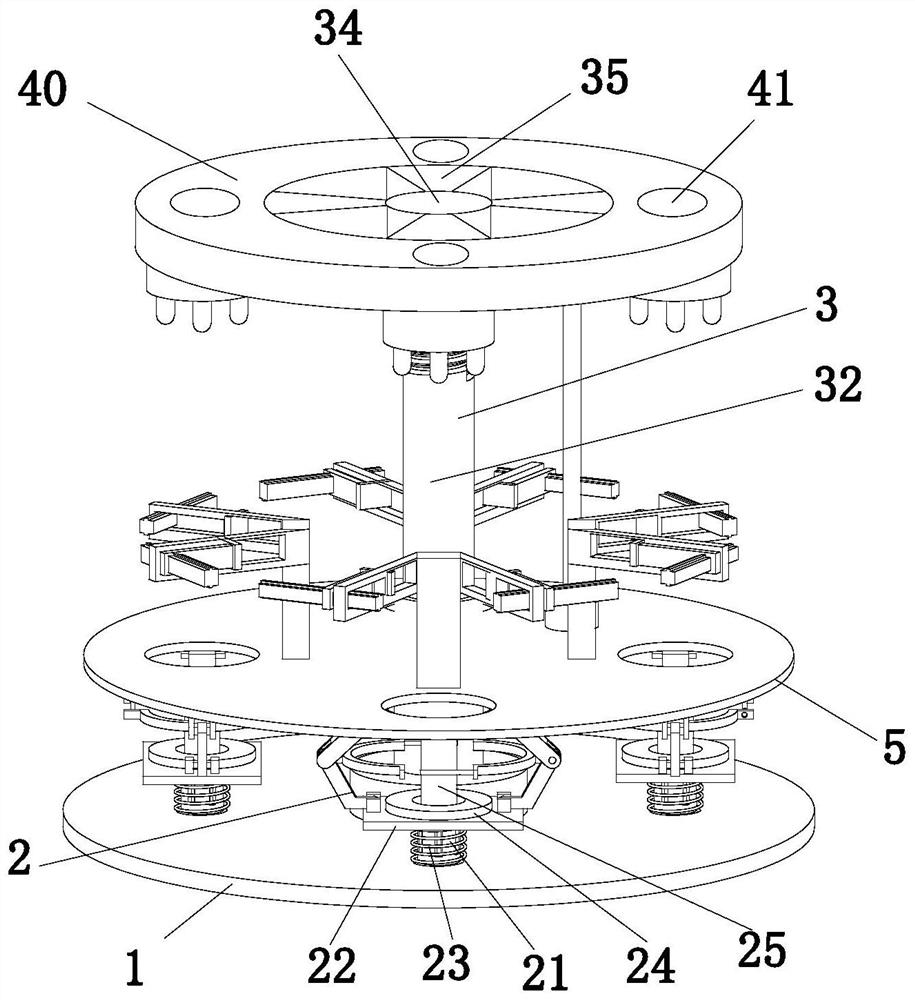

Heat preservation steel pipe polyurethane heat preservation layer manufacturing and processing system

ActiveCN113021715AImprove production processing speedReduce pouring unevennessTubular articlesThermodynamicsProcess engineering

The invention relates to a heat preservation steel pipe polyurethane heat preservation layer manufacturing and processing system which comprises a base, positioning and clamping mechanisms, a driving mechanism, a pouring mechanism and a top plate, the positioning and clamping mechanisms are installed above the base and evenly distributed in the circumferential direction of the base, and the pouring mechanism is arranged above the positioning and clamping mechanisms. The top plate is mounted between the positioning and clamping mechanisms and the pouring mechanism, and the driving mechanism is mounted in the middle of the base. According to the system, the design concept of a combined preparation structure is adopted for processing of polyurethane heat preservation steel pipes, the arranged driving structure can achieve detachable separation of the pouring mechanism and the positioning and clamping mechanisms. The system can be suitable for machining heat preservation steel pipes of different lengths, on the basis, the arranged annular positioning and clamping mechanisms can achieve simultaneous processing of a plurality of heat preservation steel pipes, and then the manufacturing and processing speed of the heat preservation steel pipes is increased.

Owner:江苏德新管道科技有限公司

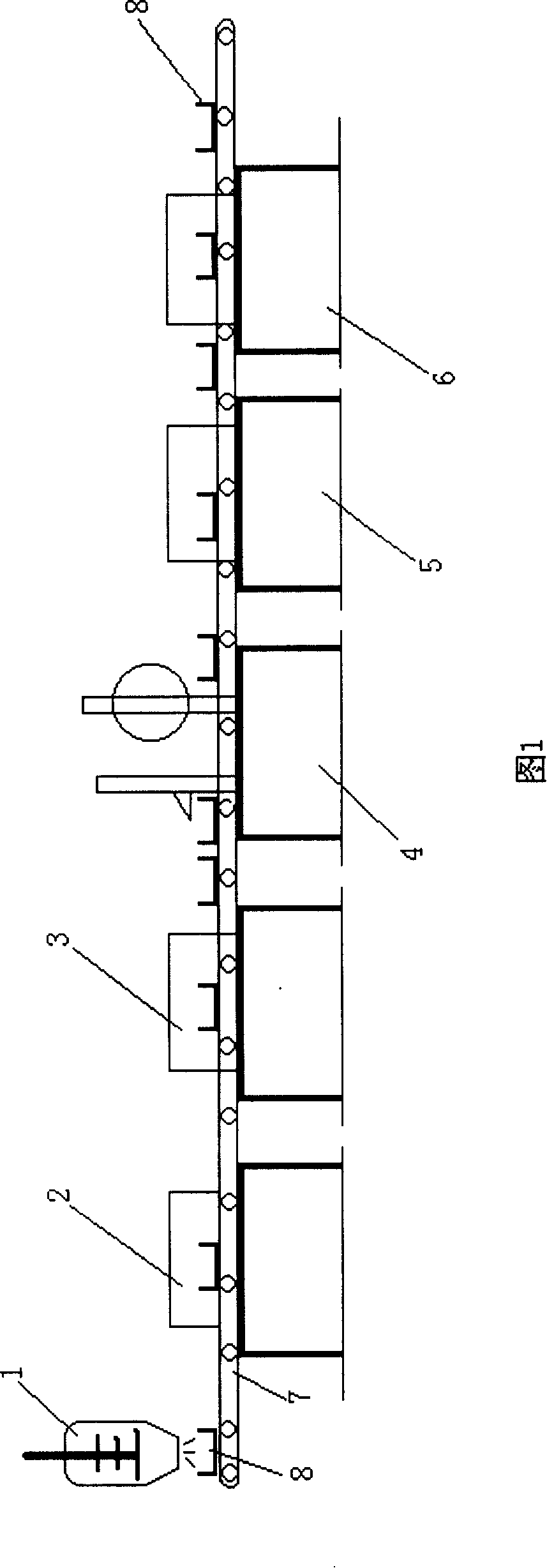

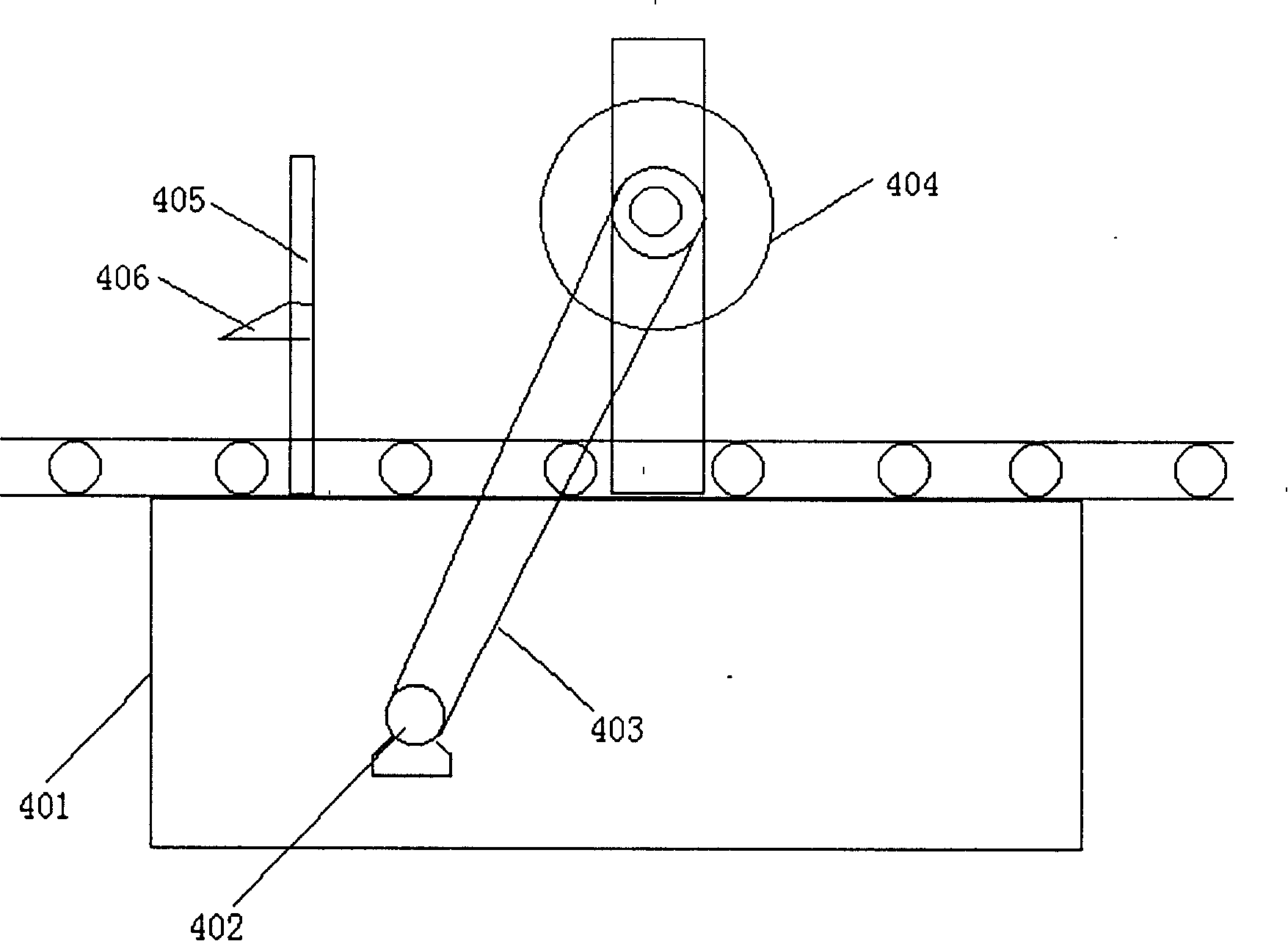

Light wall board producing process and apparatus

InactiveCN1846958BComplete production processHigh degree of mechanizationCeramic shaping apparatusGlass fiberAdhesive

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com