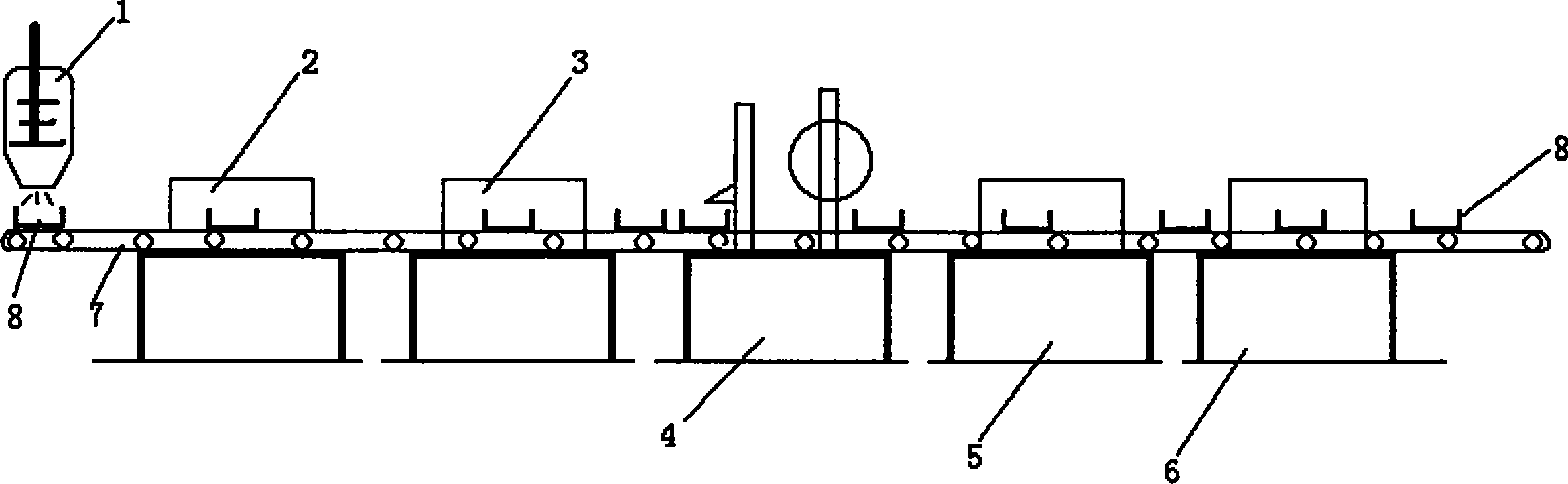

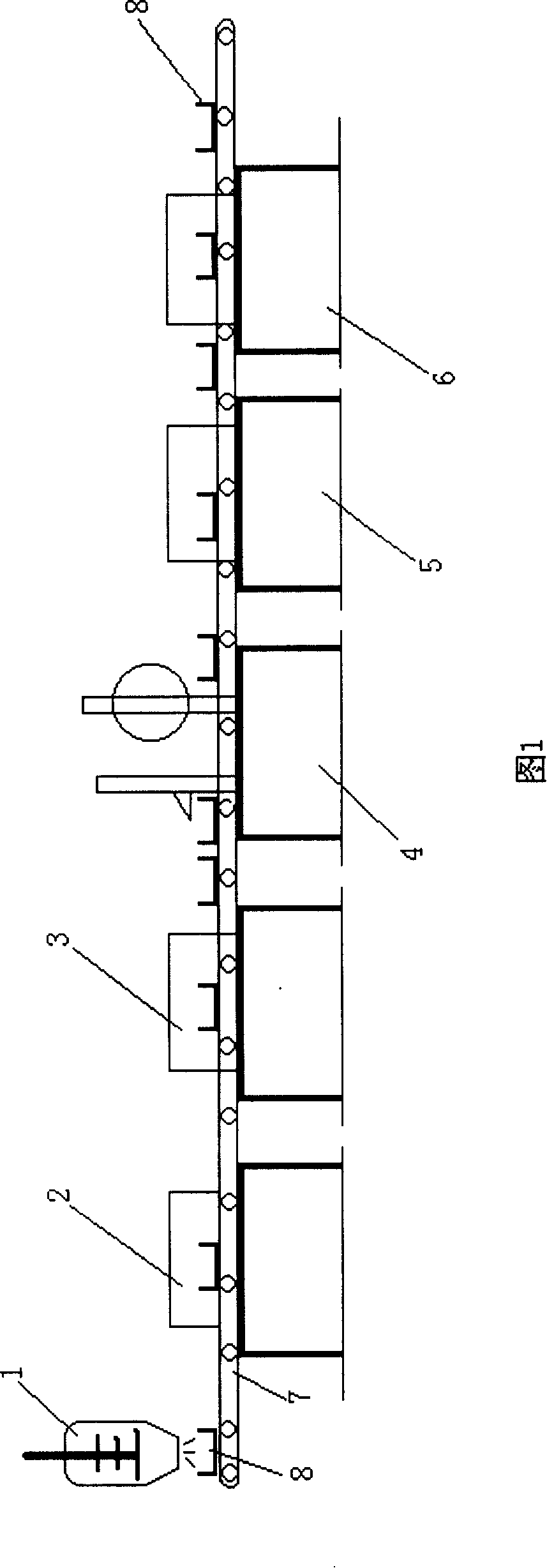

Light wall board producing process and apparatus

A light-weight wall and wall panel technology, which is applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of slow processing speed, large thermal energy loss, unstable product quality and output, etc., and shorten the production and processing cycle, improve Production and processing speed, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

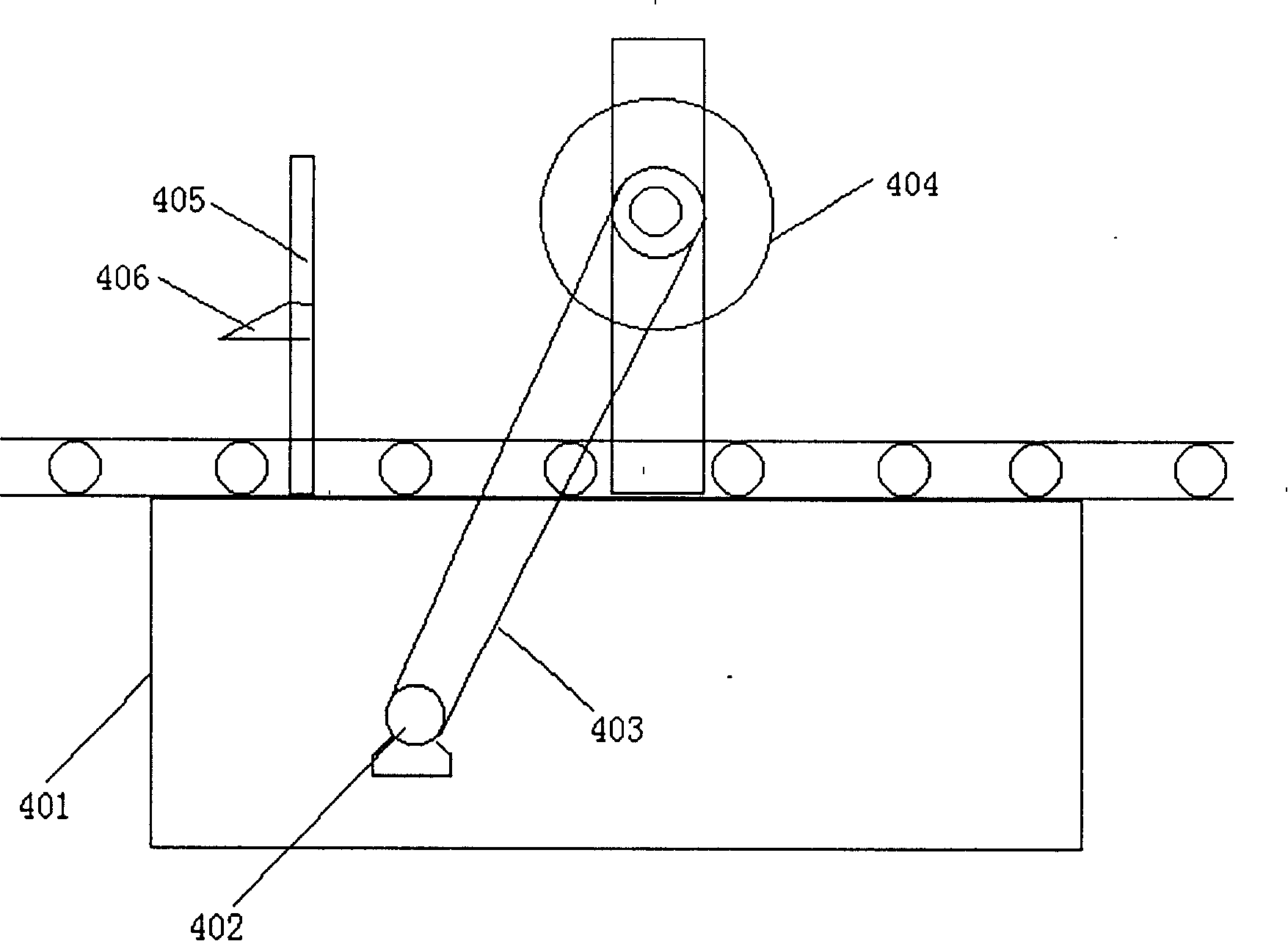

Method used

Image

Examples

Embodiment 1

[0044] (1) Stir and mix magnesium chloride, magnesium oxide, plant straw powder or sawdust, slag, adhesive, water, and glass fibers as reinforcing ribs, and inject them into the light wall panel mold; and arrange them as reinforcing ribs Glass fiber strips, shaped after vibration.

[0045] (2) Then use microwave heating to heat up the material in the mold to 45°C, crystallize as a whole, and the heating time is 10 minutes;

[0046] (3) Then place it in hot air for crystallization reaction, the crystallization reaction temperature is 60°C, and the time is 7 minutes;

[0047] (4) Before the material in the mold is cured, the surface is modified to keep it at a predetermined thickness and embossed;

[0048] (5) The corrected material is crystallized and solidified in hot air to complete the crystallization and solidification; the crystallization solidification temperature is 75°C, and the time is 12 minutes;

[0049] (6) Demoulding, taking out the cured material, and then curin...

Embodiment 2

[0052] Adopt the same method of embodiment 1, wherein adopt magnesite cement 30%, magnesium oxide 22%, fly ash 17%, sawdust 33%, gypsum 1.2%, oxalic acid 0.026%, iron trichloride 0.026%, triethanolamine 0.03 % and the balance of water to prepare a paste. All the above are percentages by weight.

[0053] Microwave heating temperature to 35 ℃, heating time is 5 minutes;

[0054] The hot air crystallization reaction temperature is 90°C, and the time is 10 minutes;

[0055] The crystallization solidification temperature is 30°C, and the time is 15 minutes;

[0056] (6) Demoulding, taking out the cured material, and then curing the cured material to obtain a finished product.

[0057] (7) Curing means that the products after demoulding from the assembly line are placed in a ventilated yard for 5 days. During this period, heavy pressure, rain, water immersion, and single-point stress are not allowed. They can be stacked so that the mixture in the finished product The whole materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com