Melt-blown non-woven fabric production line

A melt-blown non-woven fabric and production line technology, applied in the textile field, can solve the problems of unspecified melt-blown non-woven fabric production line, inability to online quality inspection of melt-blown non-woven fabric, imperfect production line, etc. Extreme effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

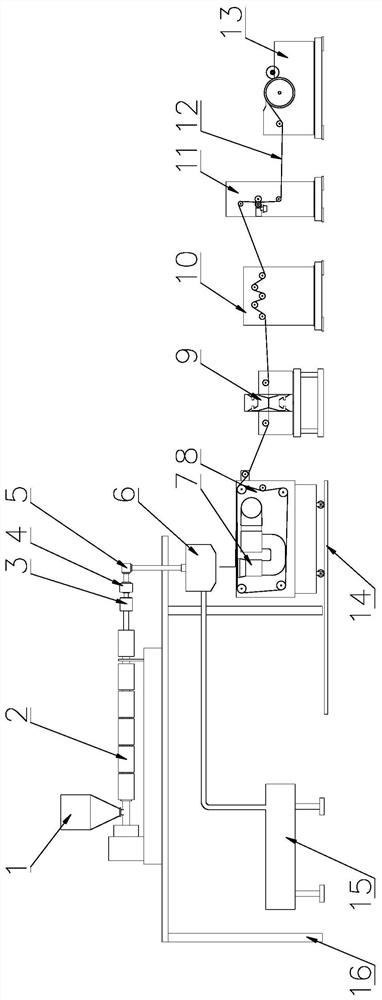

[0026] see figure 1 , a production line for melt-blown non-woven fabrics, including a material extrusion part, a web forming part, a grammage detection part 9, an electret part 10 and a winding part 13 connected in sequence, and the material extrusion part is provided with a die head 6 , a heating part 15 is connected to the die head 6 .

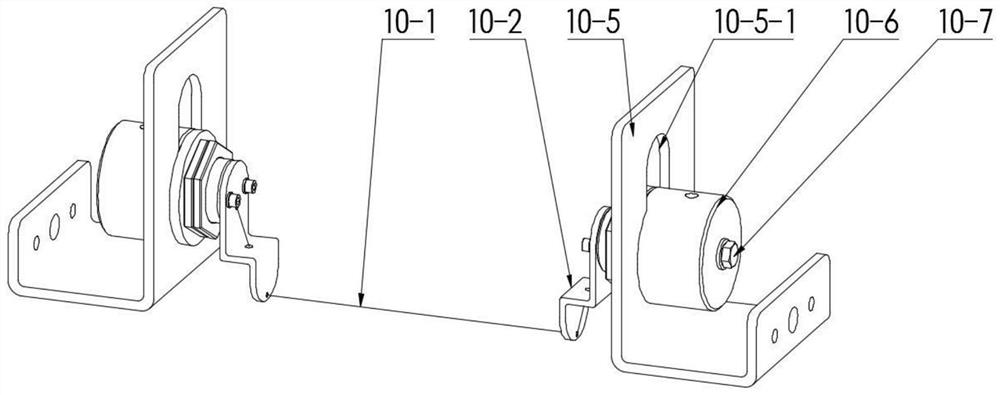

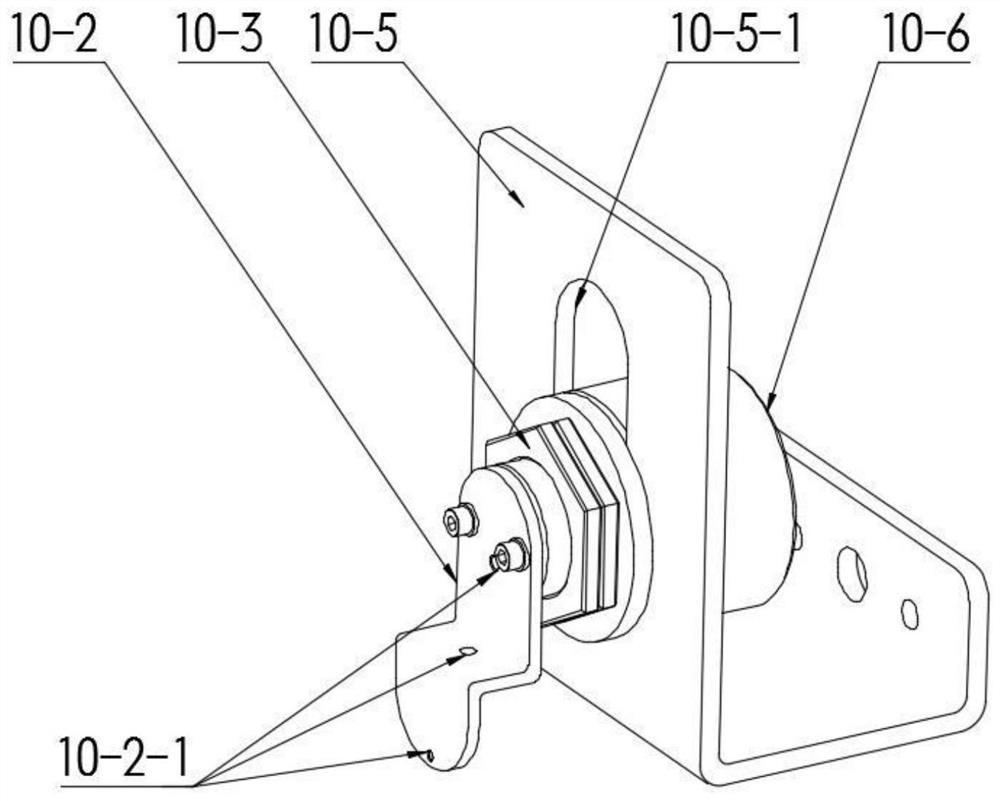

[0027] The electret part 10 includes a high-voltage electrostatic generator (not shown) and a molybdenum wire 10-1 across the surface of the melt-blown nonwoven fabric, and the two ends of the molybdenum wire 10-1 are respectively connected to two tensioned wires. The mechanism is connected, and the high-voltage electrostatic generator is arranged near any one of the tensioning mechanisms.

[0028] The tensioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com