Method for converting natural non-magnetic iron ore into magnetite

A non-magnetic, magnetite technology, applied in chemical instruments and methods, magnetic separation, filtration, etc., can solve the problems of high heating and roasting temperature, no promotion value, and difficult ore, and achieve a high degree of mechanization and continuous production Sexual production, the effect of shortening the production and processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

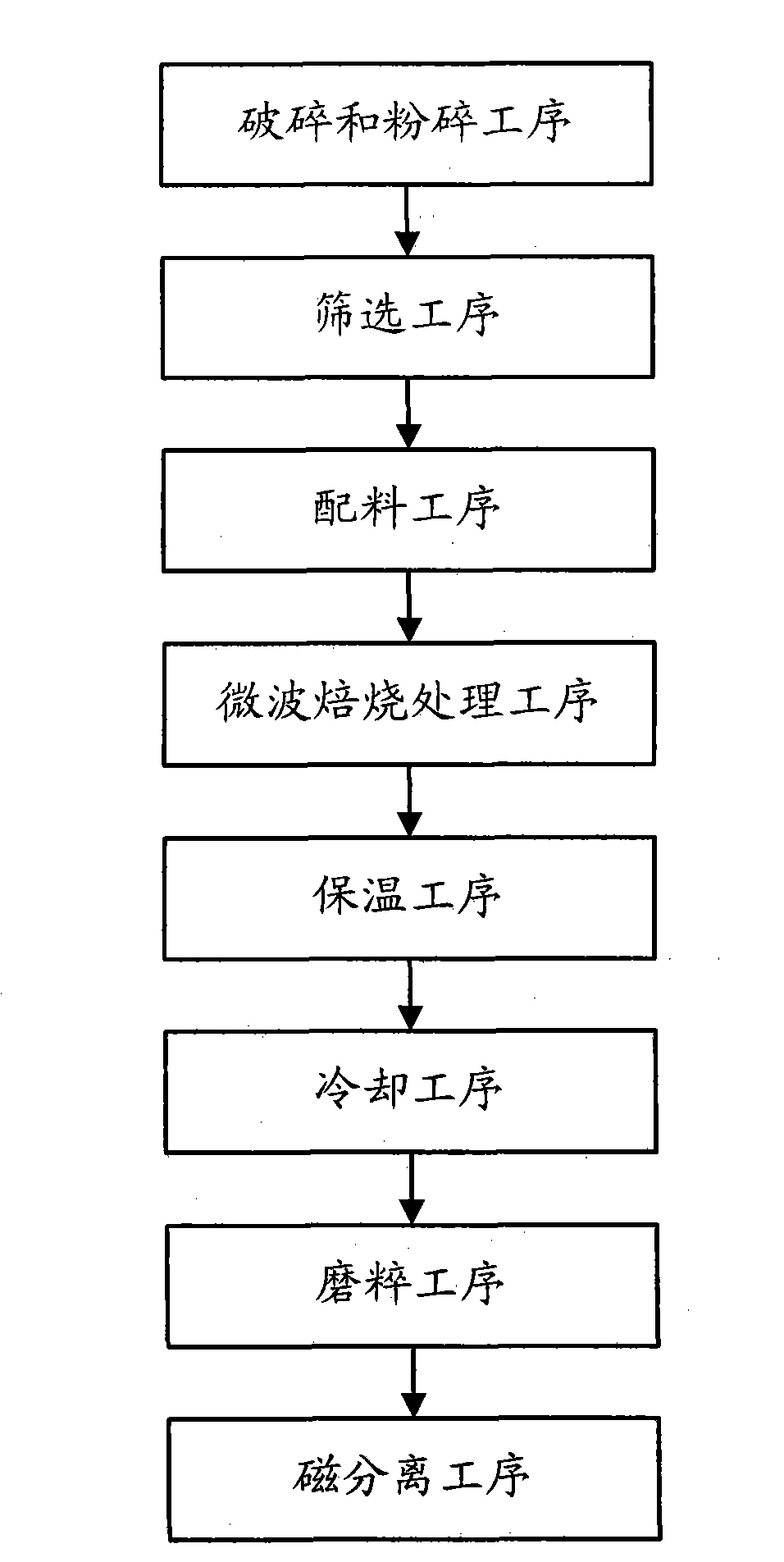

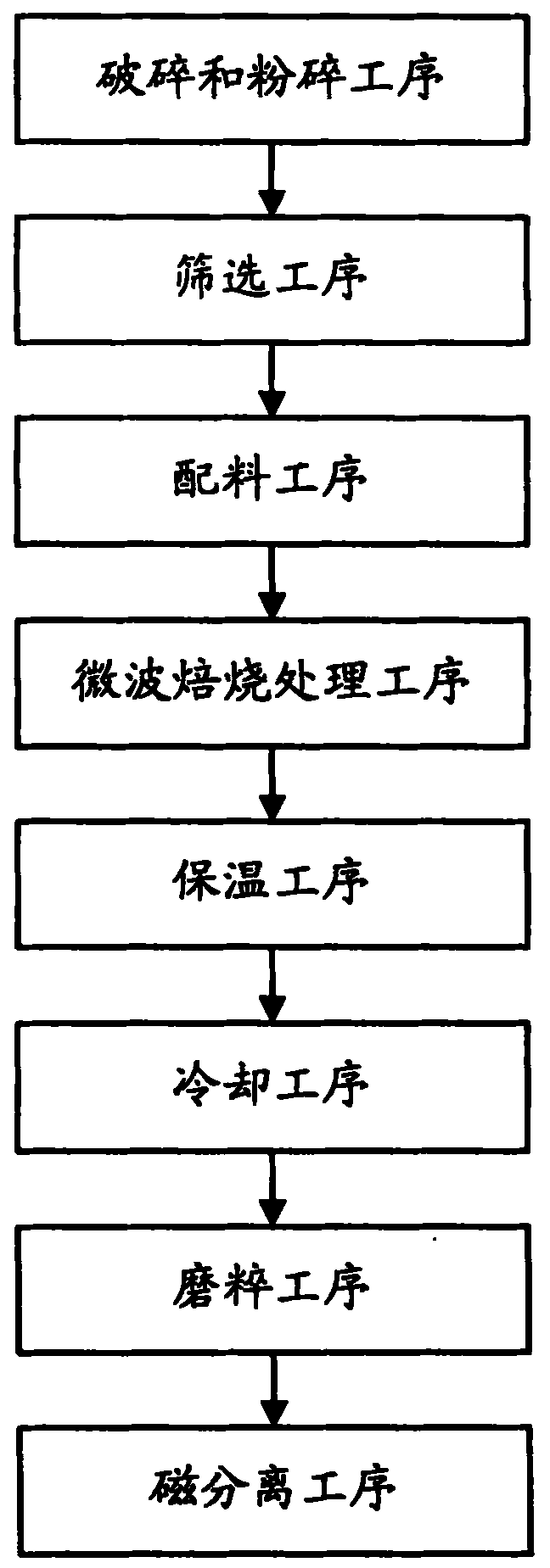

[0062] In a preferred embodiment of the present invention, the method for converting natural non-magnetic iron ores such as natural limonite, hematite, siderite, tailings after magnetic separation into magnetite includes the following steps:

[0063] (1) crushing and crushing process;

[0064] (2) Screening process; if it is a non-magnetic tailings raw material, the process (1), (2) can be omitted;

[0065] (3) Ingredients process;

[0066] (4) microwave roasting process;

[0067] (5) heat preservation process;

[0068] (6) Cooling process;

[0069] (7) Grinding process;

[0070] (8) Magnetic separation process.

[0071] Among them, the pulverization process is coarse pulverization first, and then further fine pulverization. The operating co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com