Photosensitive resin compsn., photosensitive element, prodn. method for resist pattern and prodn. method for printed circuit board

A technology of photosensitive resin and manufacturing method, applied in the field of photosensitive resin composition, can solve the problems of reduced pit reliability, reduced developing solution resistance, shortened developing time, etc., achieves excellent pit reliability, prevents Excellent effect of poor conduction and pit reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

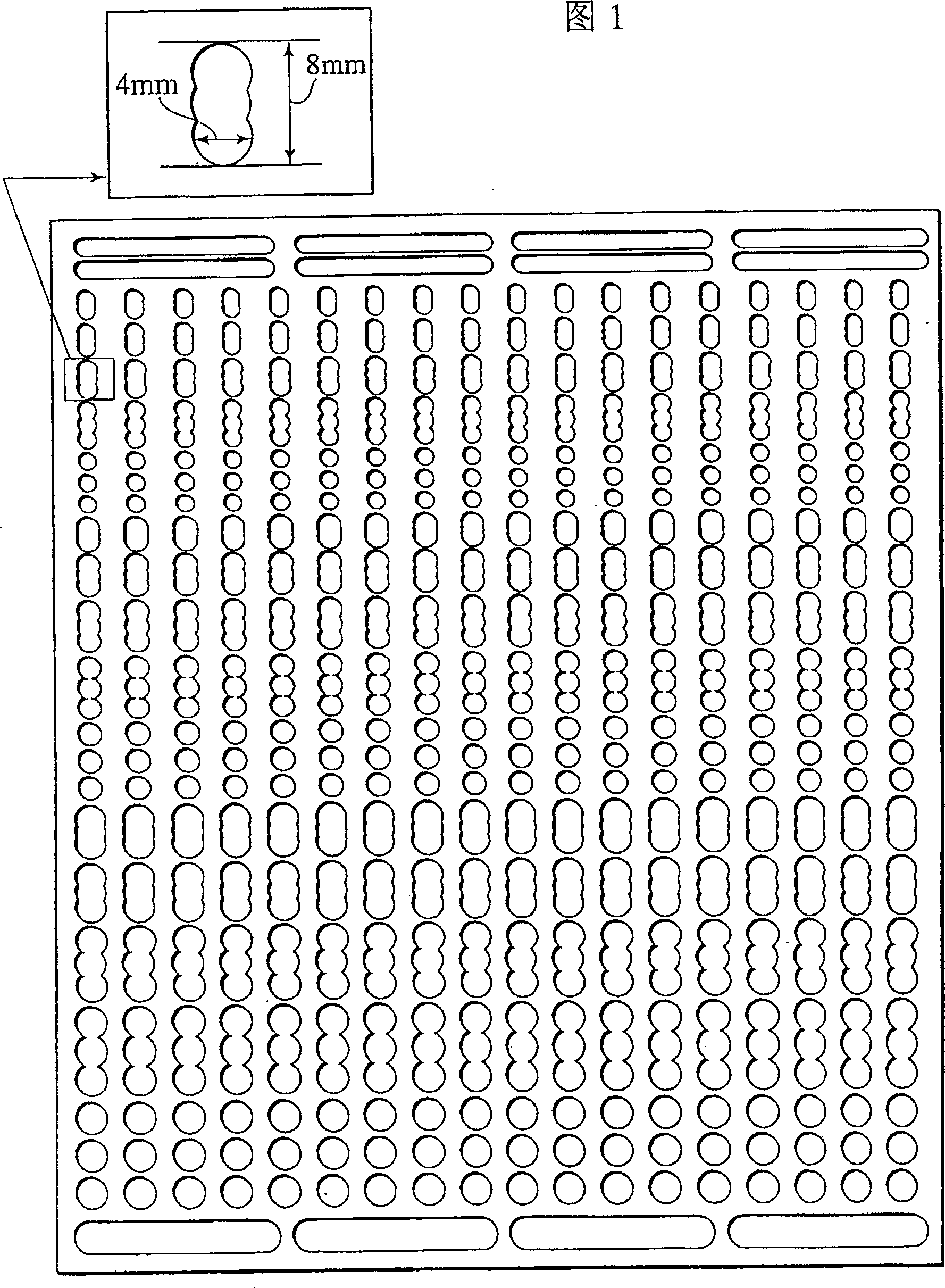

Image

Examples

example 1~8

[0101] The materials shown in Table 1 were mixed to obtain a solution. Next, the (B) component shown in Table 2 and Table 3 was dissolved in the obtained solution, and the solution of the photosensitive resin composition was obtained.

[0102] Material

Cooperate

①

②

(A)

become

Minute

Methacrylic acid / methyl methacrylate / ethyl acrylate / styrene copolymer

(20 / 57 / 21 / 2 (weight ratio)), weight average molecular weight=60000, 60% by weight

Methyl cellosolve / toluene=6 / 4 (weight ratio) solution, dispersion=2.5

89

(solid state

Composition 53)

89

(solid state

Composition 53)

Methacrylic acid / methyl methacrylate / butyl acrylate / butyl methacrylate

Copolymer (24 / 44 / 15 / 17 (weight ratio)), weight average molecular weight=30000, 60

Weight % methylcellosolve / toluene=6 / 4 (weight ratio) solution, dispersion=2.0

19

(solid state

Ingredients 11)

19

Ing...

example 10

[0130] Coordinate methacrylic acid / methyl methacrylate / ethyl acrylate copolymer (17.5 / 52.5 / 30 (weight ratio)), weight-average molecular weight=80000, 60% by weight methyl cellosolve / toluene=6 / 4 (weight ratio) solution 89g (solid content 53g), methacrylic acid / methyl methacrylate / butyl acrylate / butyl methacrylate copolymer (24 / 44 / 15 / 17), weight average molecular weight = 30000, 60 weight % methylcellosolve / toluene=6 / 4 (weight ratio) solution 19g (solid content 11g), FA-024M 36g, 1,7-bis(9-acridylheptane) 0.4g, N,N'- Tetraethyl-4,4'-diaminobenzophenone 0.04g, pale crystal violet 0.9g, tribromomethyl phenyl sulfone 1.3g, malachite green 0.05g, acetone 12.0g, toluene 5.0g and methanol 3.0g , to obtain a solution.

[0131] Then the solution of the obtained photosensitive resin composition is uniformly coated on a 16 μm thick polyethylene terephthalate film (trade name G2-16, manufactured by Teijin Co., Ltd.). After drying with a drier for 10 minutes, it was protected with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com