Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve electron emission performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacturing an electronic device containing a carbon nanotube

InactiveUS6979244B2Improve directivityImprove performanceMaterial nanotechnologyNanoinformaticsCarbon nanotubeElectron

A method of manufacturing an electronic device in which a substrate with a pair of electrodes is provided and a carbon nanotube is formed or arranged to electrically connect the electrodes.

Owner:CANON KK

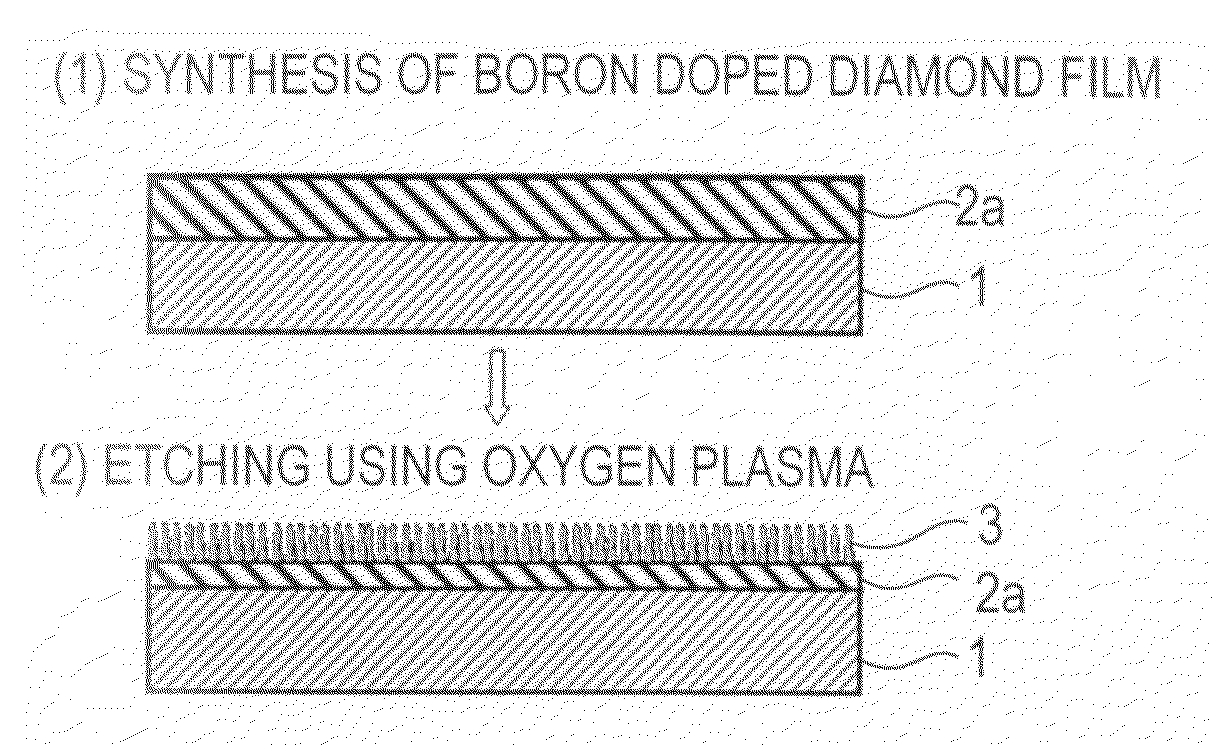

Method for Producing Diamond Having Acicular Projection Array Structure on Surface thereof, Diamond Material, Electrode and Electronic Device

InactiveUS20090258255A1Higher negative electron affinity electronImprove emission effectElectrode manufacturing processesDecorative surface effectsPt elementElectron

A method for producing a diamond having an acicular projection array structure on a surface thereof comprises the step of forming the acicular projection array structure on a surface of a diamond base material by treating the surface of the diamond base material by dry etching using oxygen gas. At least one dopant selected among boron (B), nitrogen (N), aluminum (Al), silicon (Si), phosphorus (P), sulfur (S), copper (Cu), arsenic (As), molybdenum (Mo), platinum (Pt) and gold (Au) is doped with a concentration of 1×1019 atoms / cm3 and more at least in a region near the surface of the diamond base material.

Owner:CENTRAL JAPAN RAILWAY COMPANY

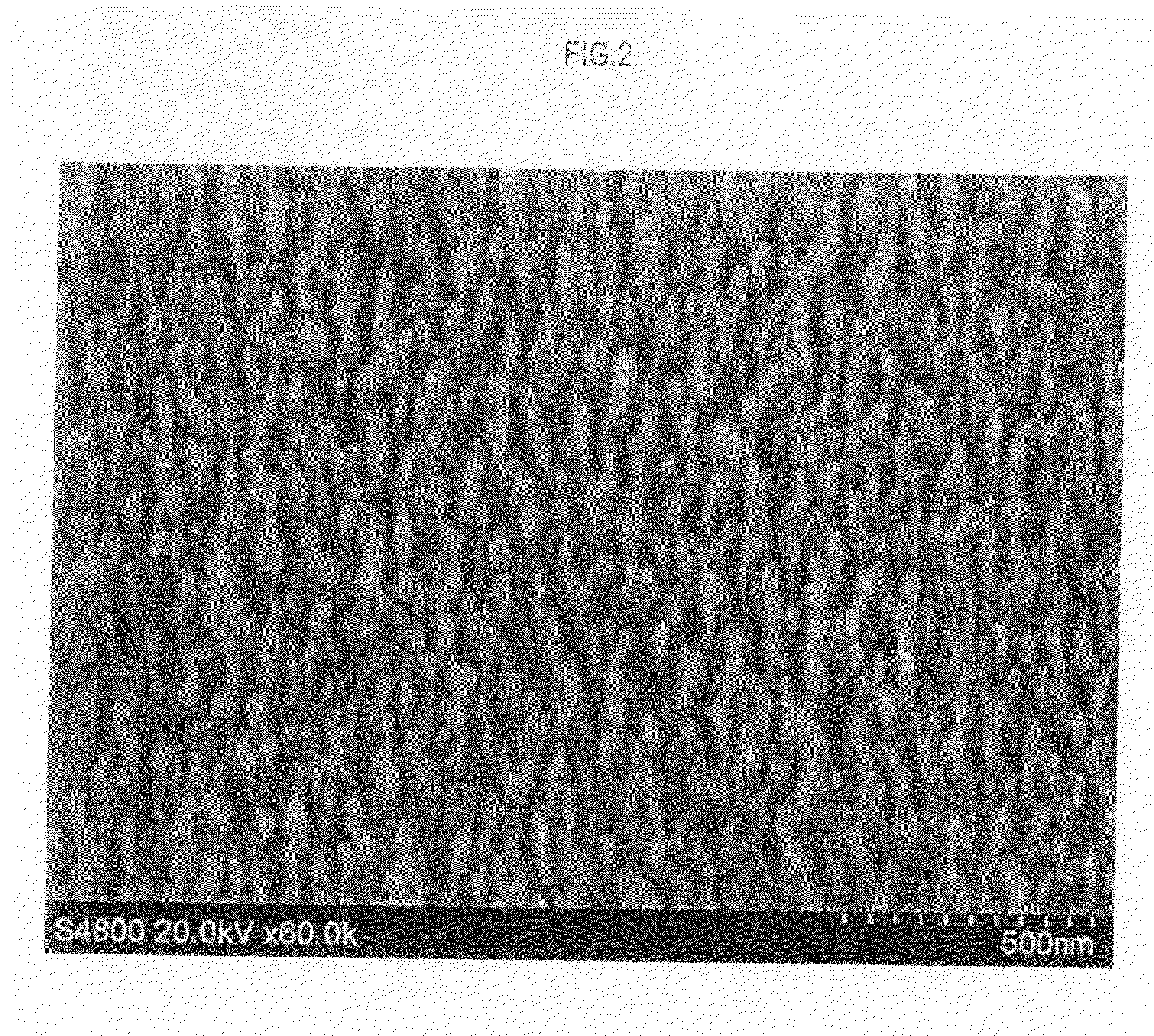

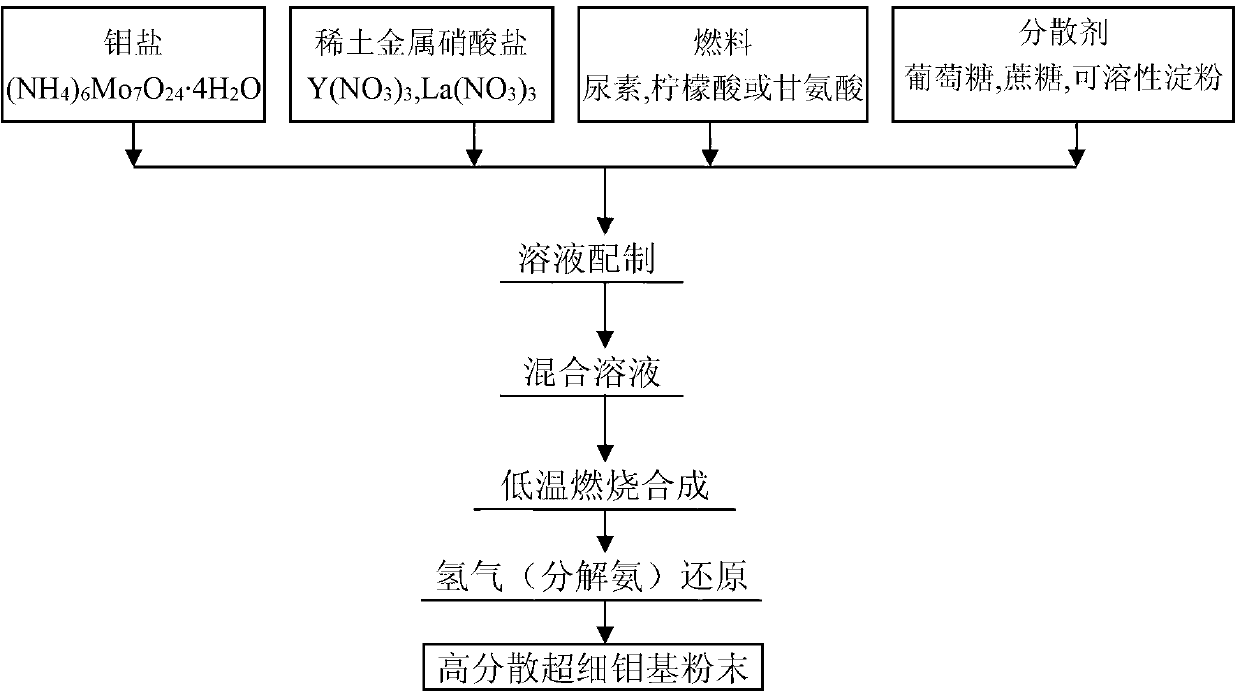

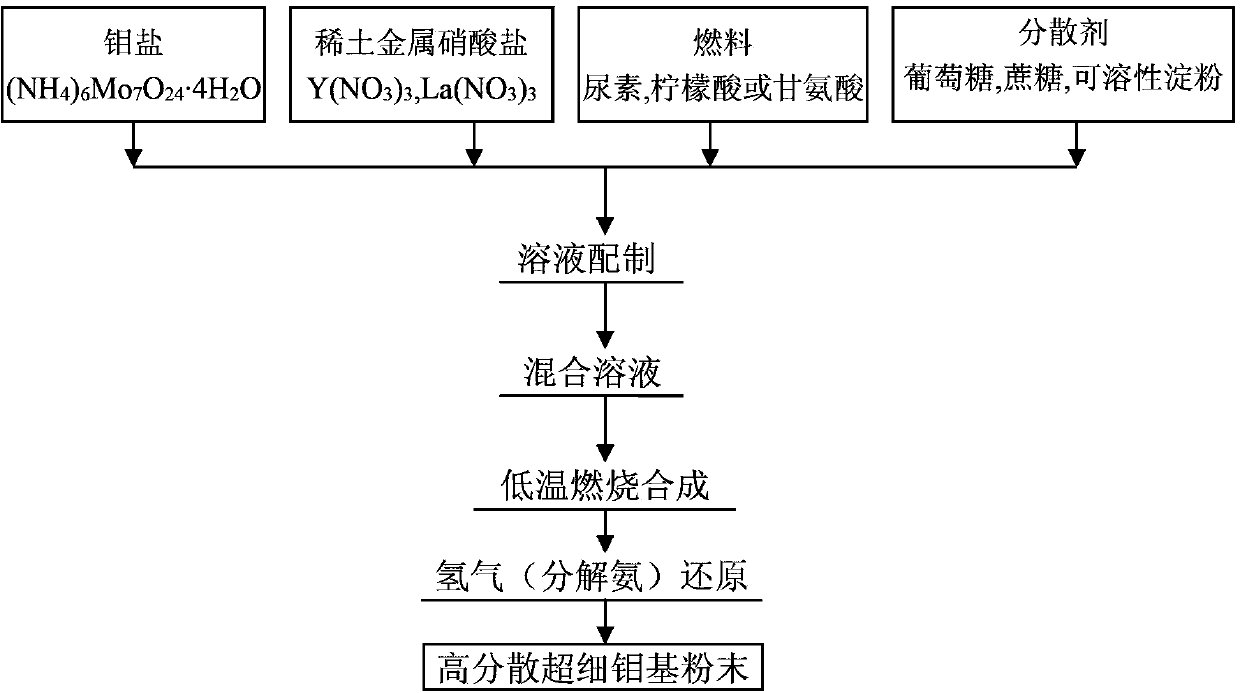

Method for manufacturing high-dispersion ultrafine molybdenum-based powder

The invention discloses a method for manufacturing high-dispersion ultrafine molybdenum-based powder, and belongs to the technical field of rare-earth refractory metal materials. A technological process includes acquiring precursor powder comprising molybdenum oxide, rare-earth oxide (one or two of Y<2>O<3> and La<2>O<3>) or copper oxide which are mixed uniformly by low-temperature combustion synthesis; and reducing the precursor powder in flowing hydrogen atmosphere. The molybdenum oxide and the copper oxide which are easy to reduce are reduced into metal molybdenum and copper, rare-earth oxide particles which cannot be reduced remain, and accordingly high-dispersion ultrafine Mo and rare-earth oxide powder or high-dispersion ultrafine Mo-Cu composite powder is obtained. The weight percent of the rare-earth oxide in the Mo and rare-earth oxide powder ranges from 0.5% to 30%, and the weight percent of the Cu in the Mo-Cu composite powder ranges from 5% to 40%. The method has the advantages that the powder particles are small in diameter and high in surface activity, a dispersion path in a sintering procedure is shortened, and the method is beneficial to acquiring high-density ultrafine-grain / nano-grain molybdenum-based alloy with uniform tissue distribution.

Owner:UNIV OF SCI & TECH BEIJING

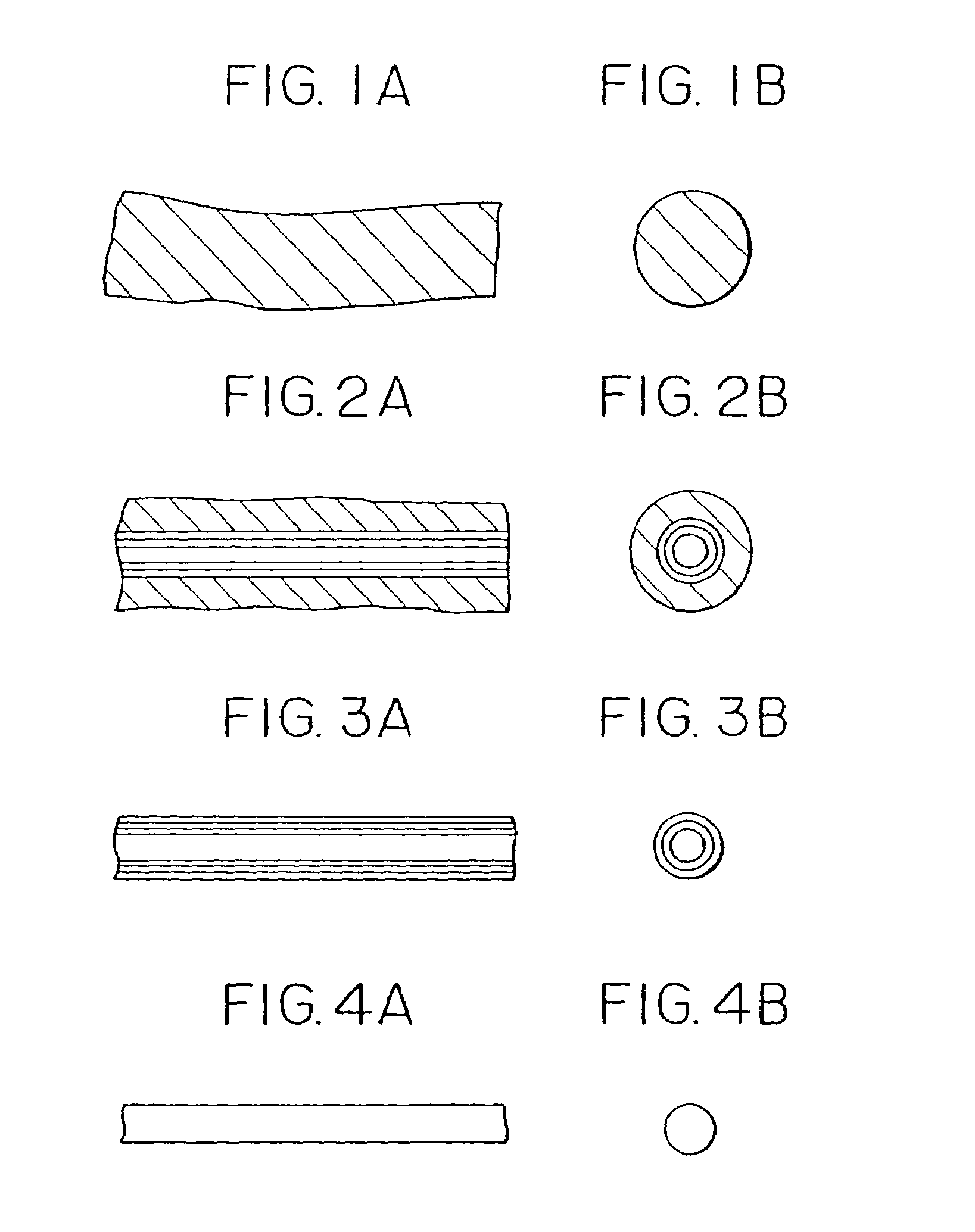

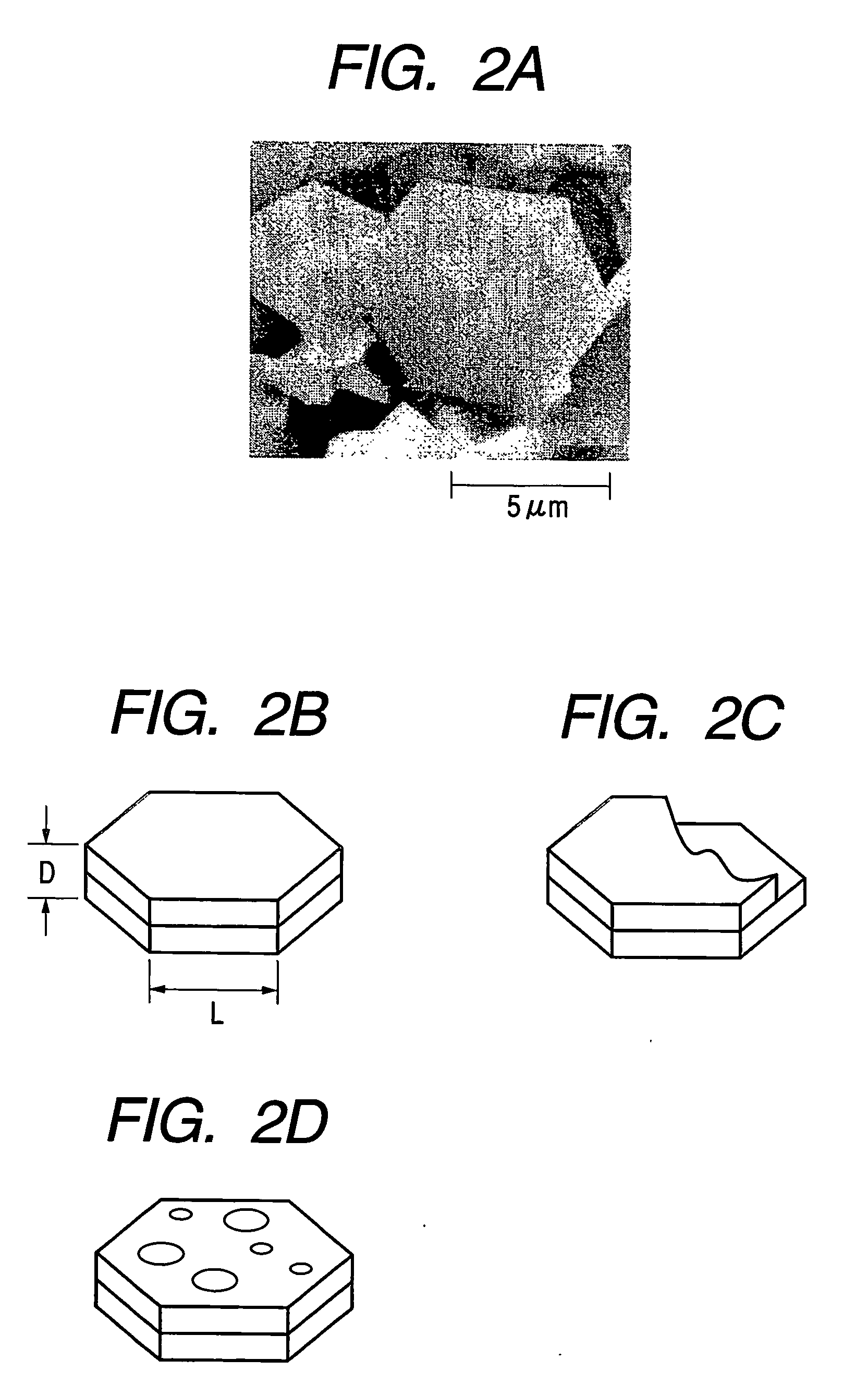

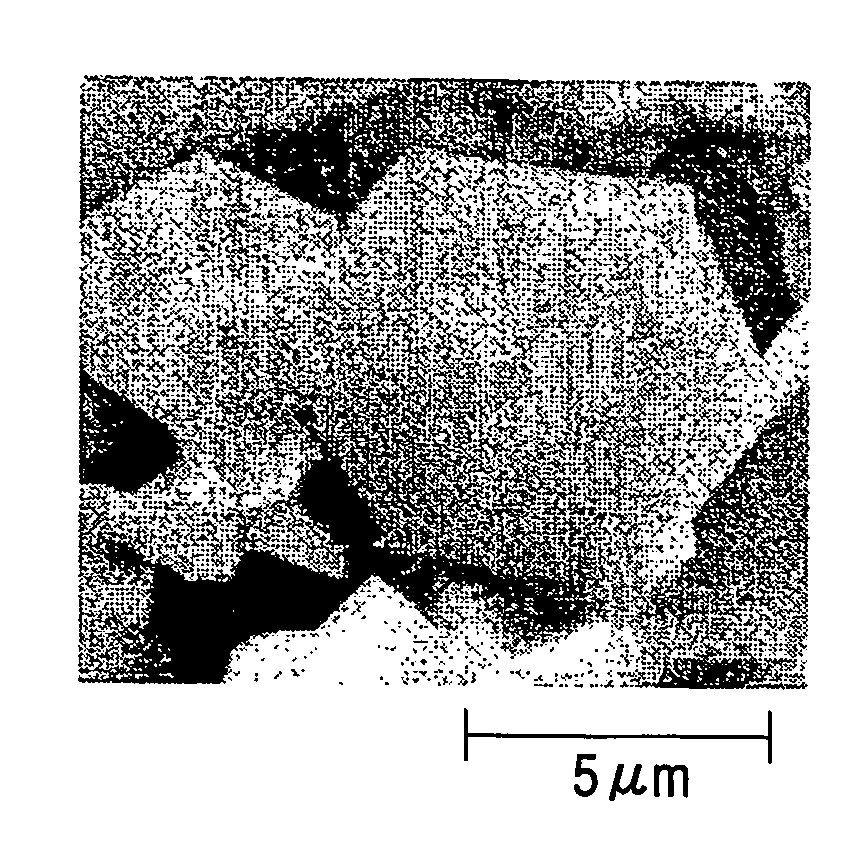

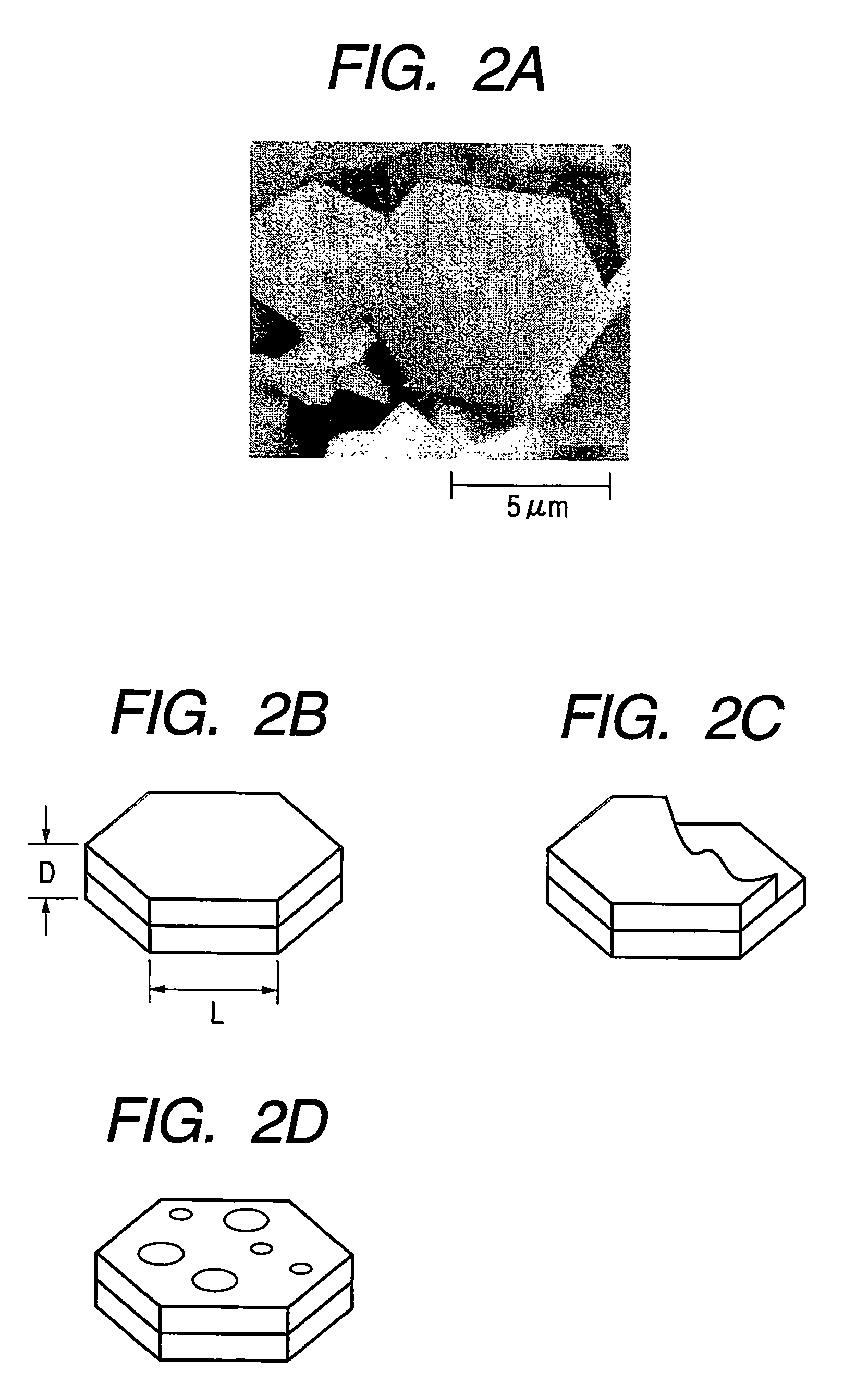

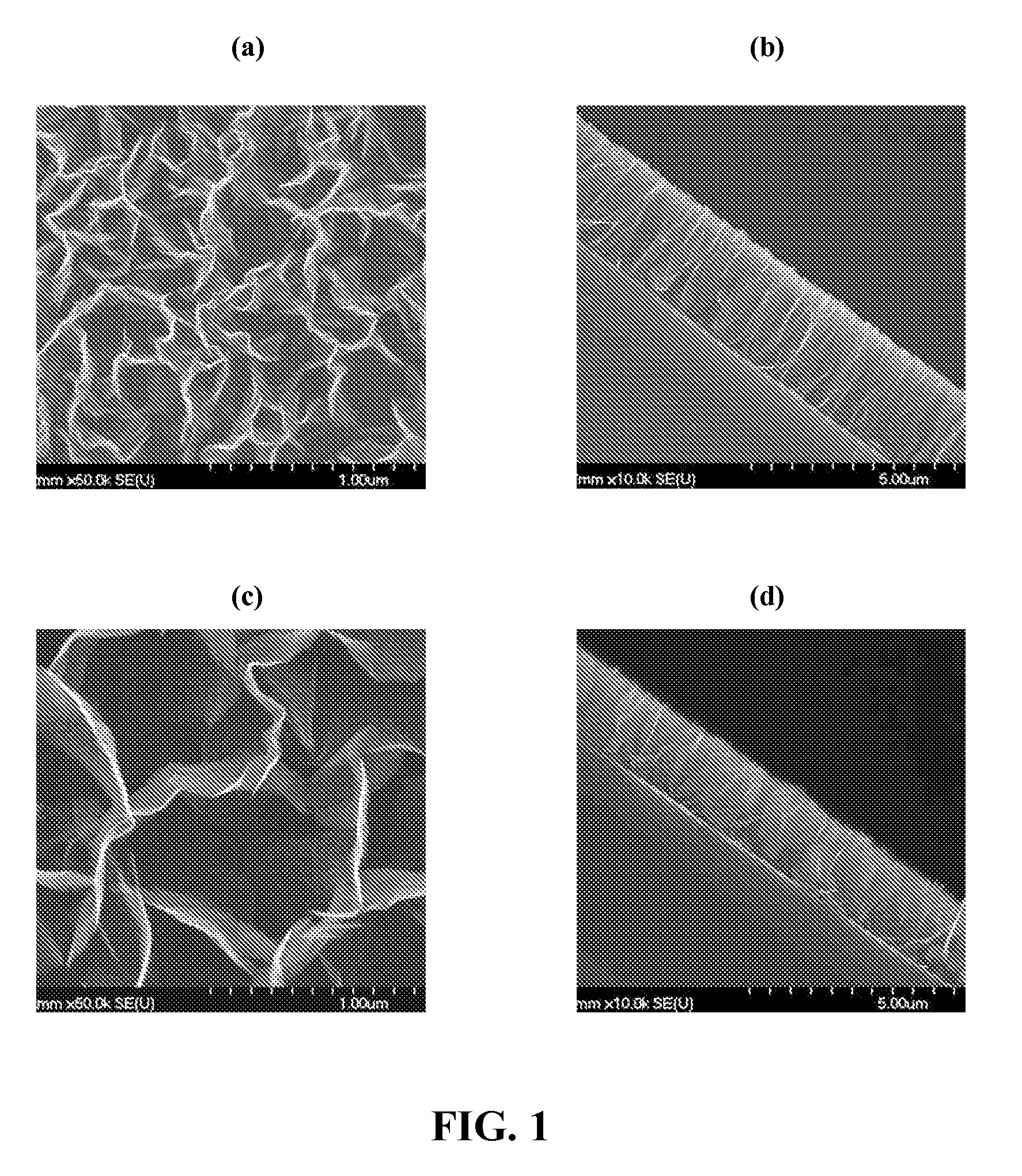

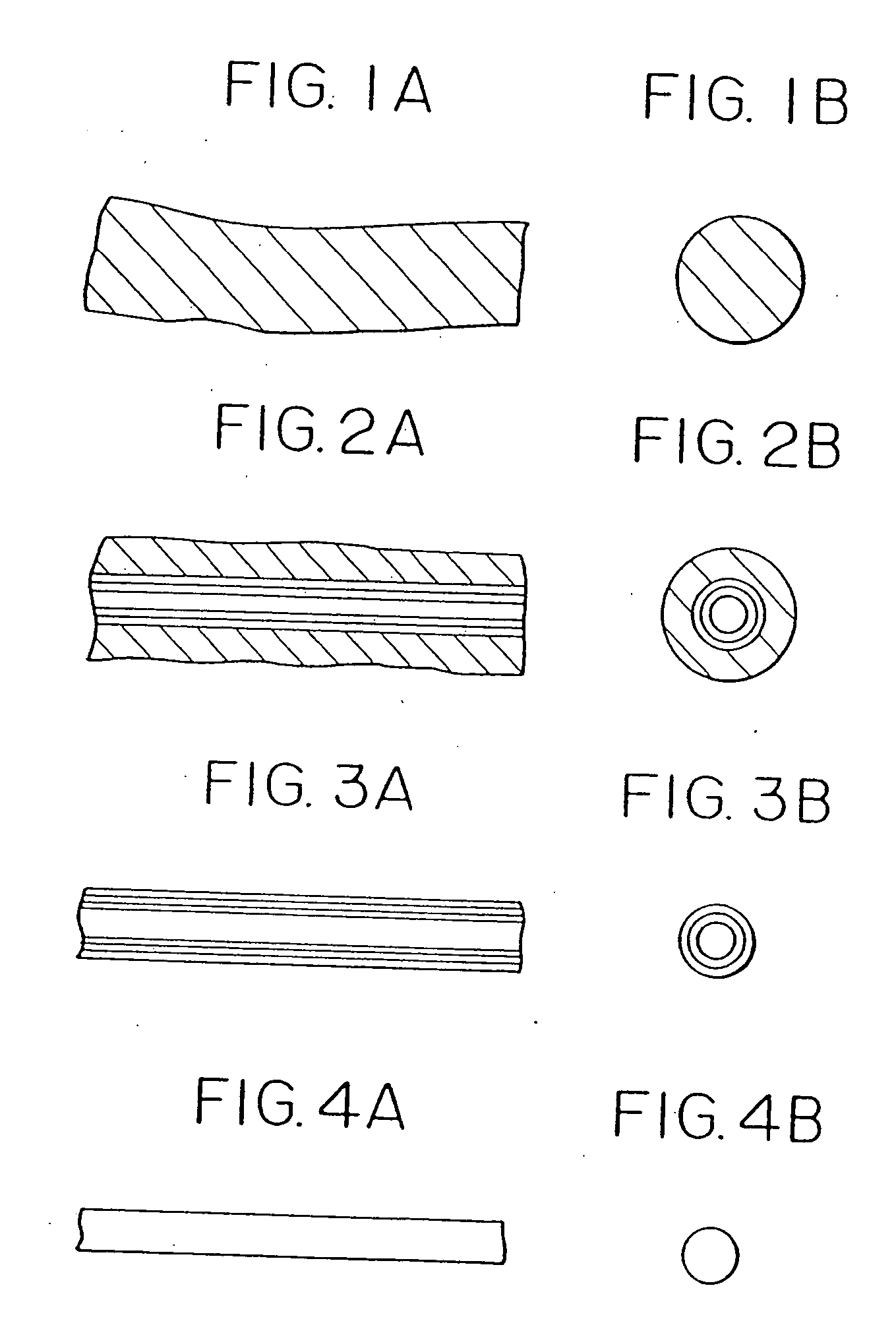

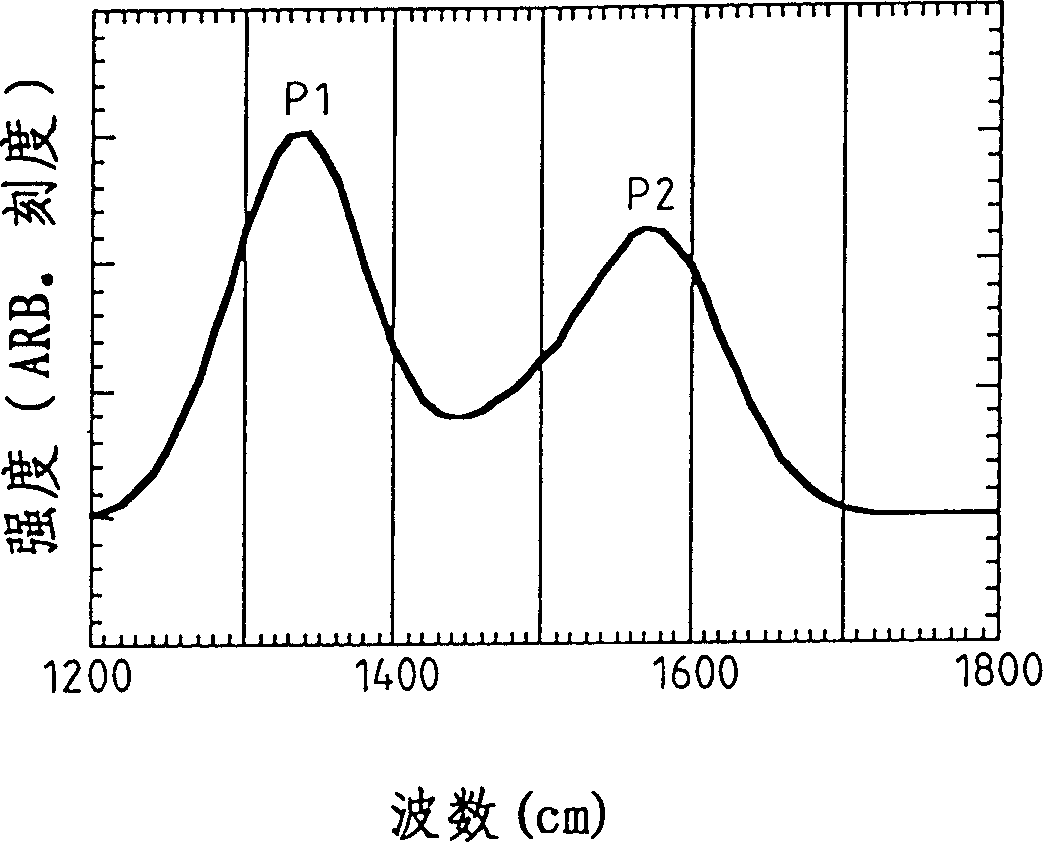

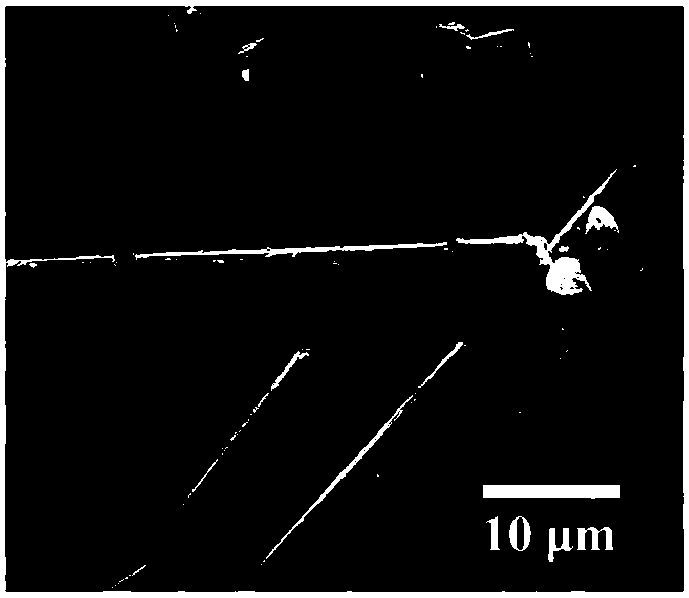

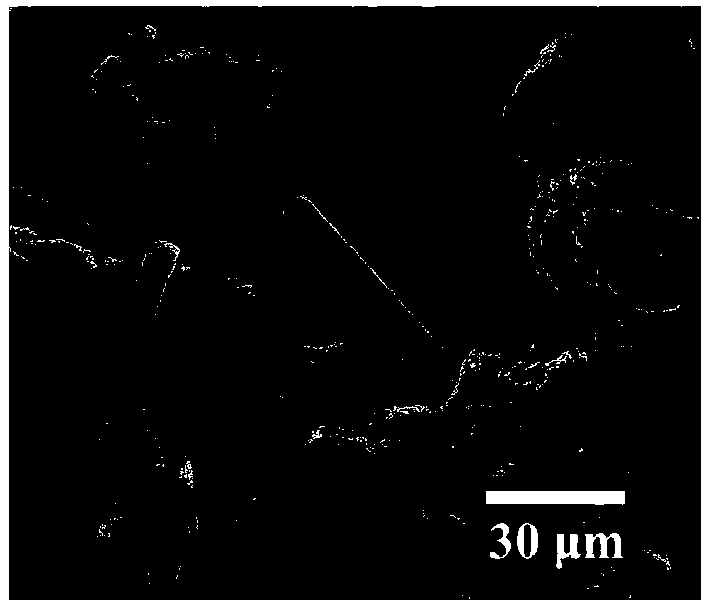

Flaky carbonaceous particle and production method thereof

InactiveUS20060062713A1Improve electron emission performanceImprove electronic conductivityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsHigh electronNanometre

A carbonaceous particle is provided which comprises a hexagonal flake formed of an aggregate of a plurality of nanocarbons and having a side length of 0.1 to 100 mm and a thickness of 10 nm to 1 mm. Thereby, a carbonaceous particle is provided which has an excellent electron emission performance, has a high electron conductivity, shows excellent characteristics particularly when used for a secondary battery, and can suitably be applied to various devices other than a secondary battery as well.

Owner:CANON KK

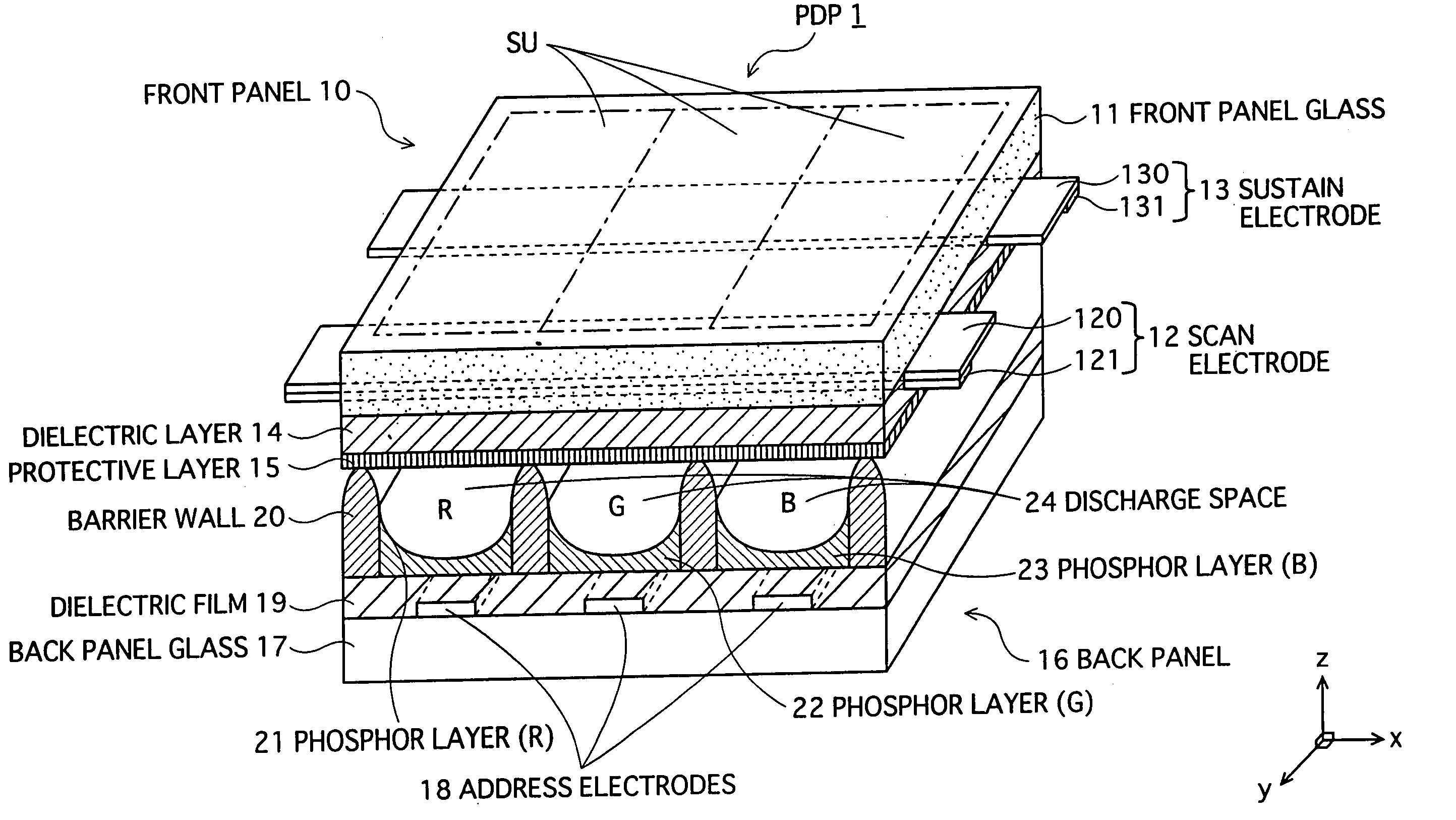

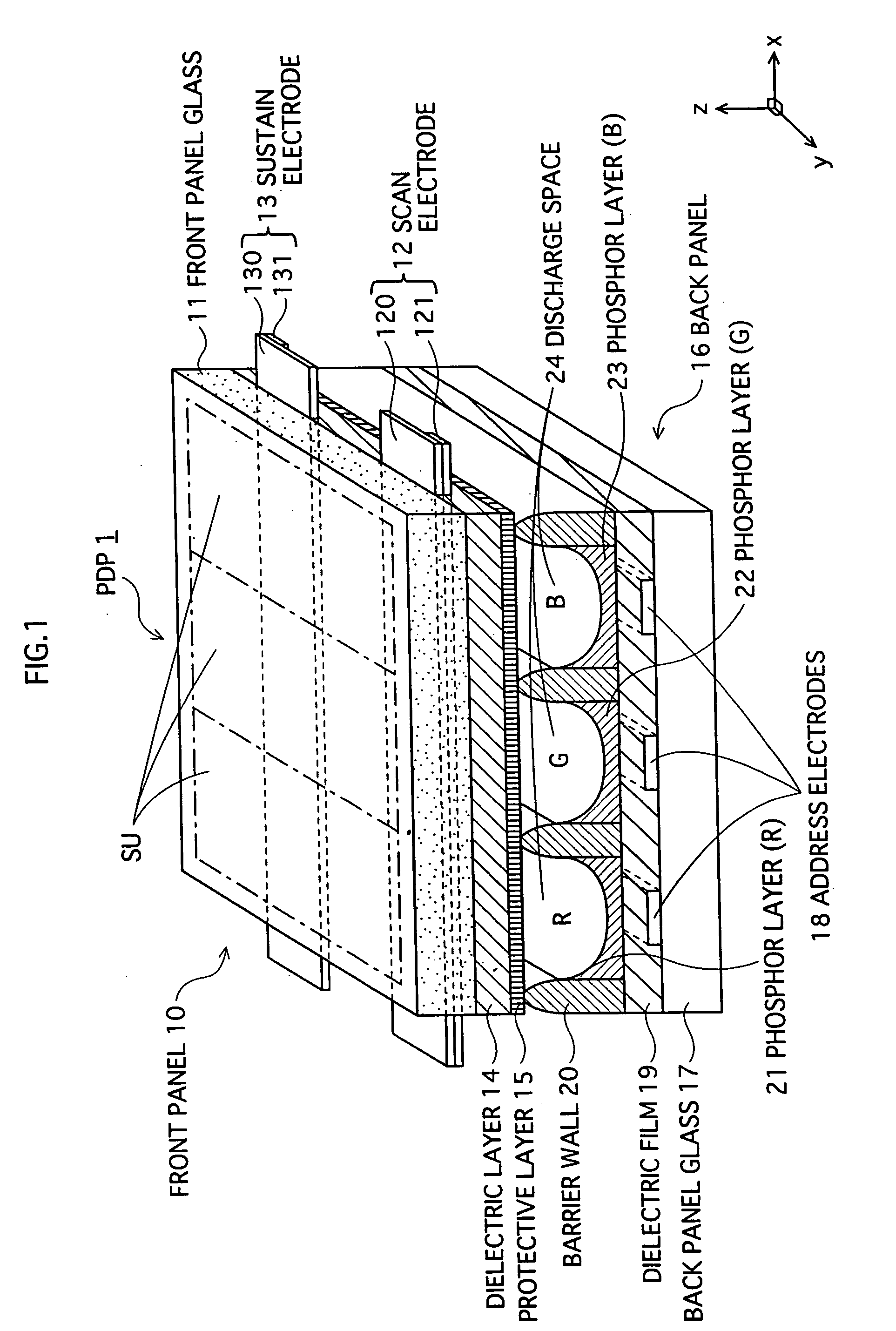

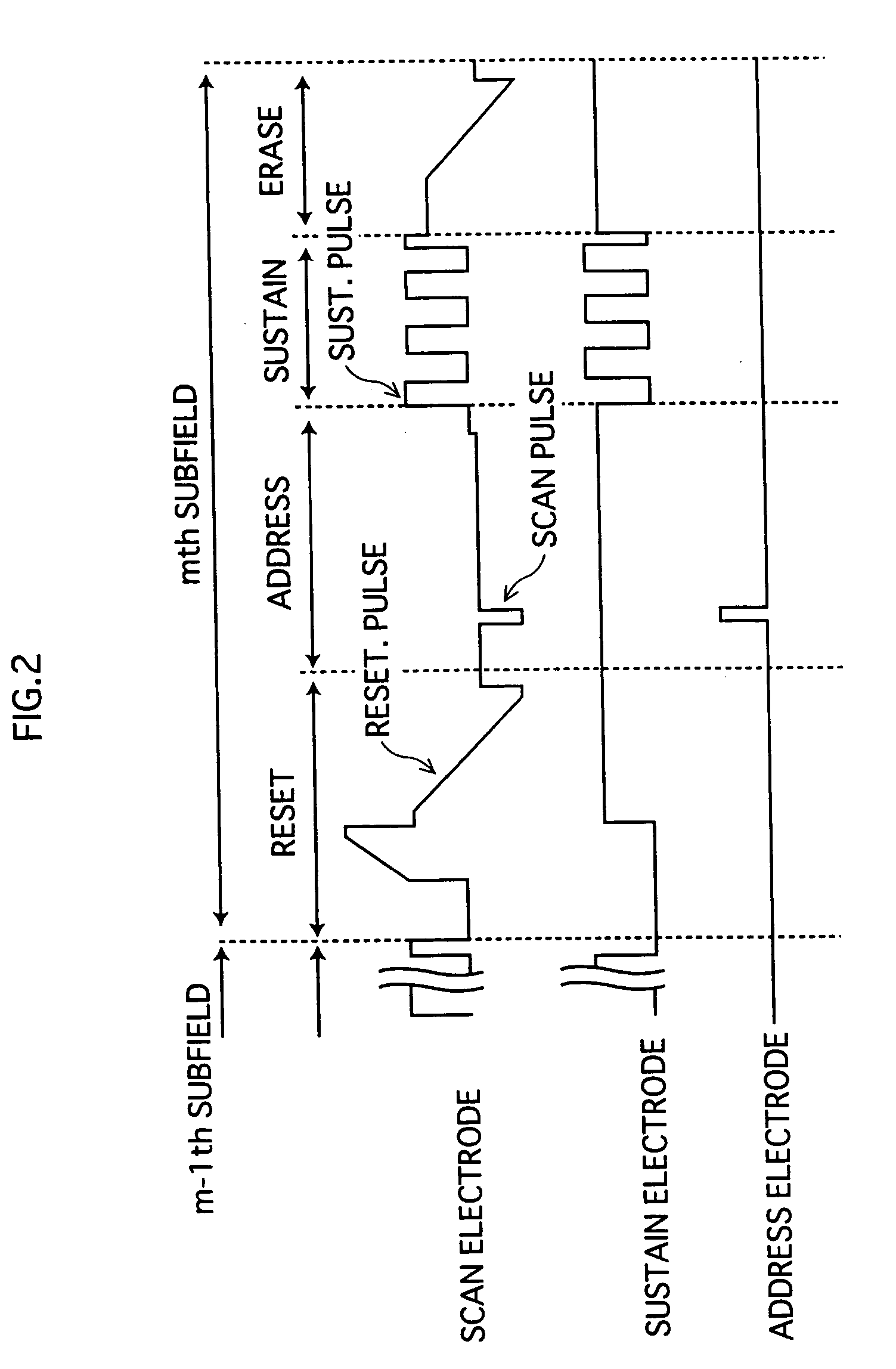

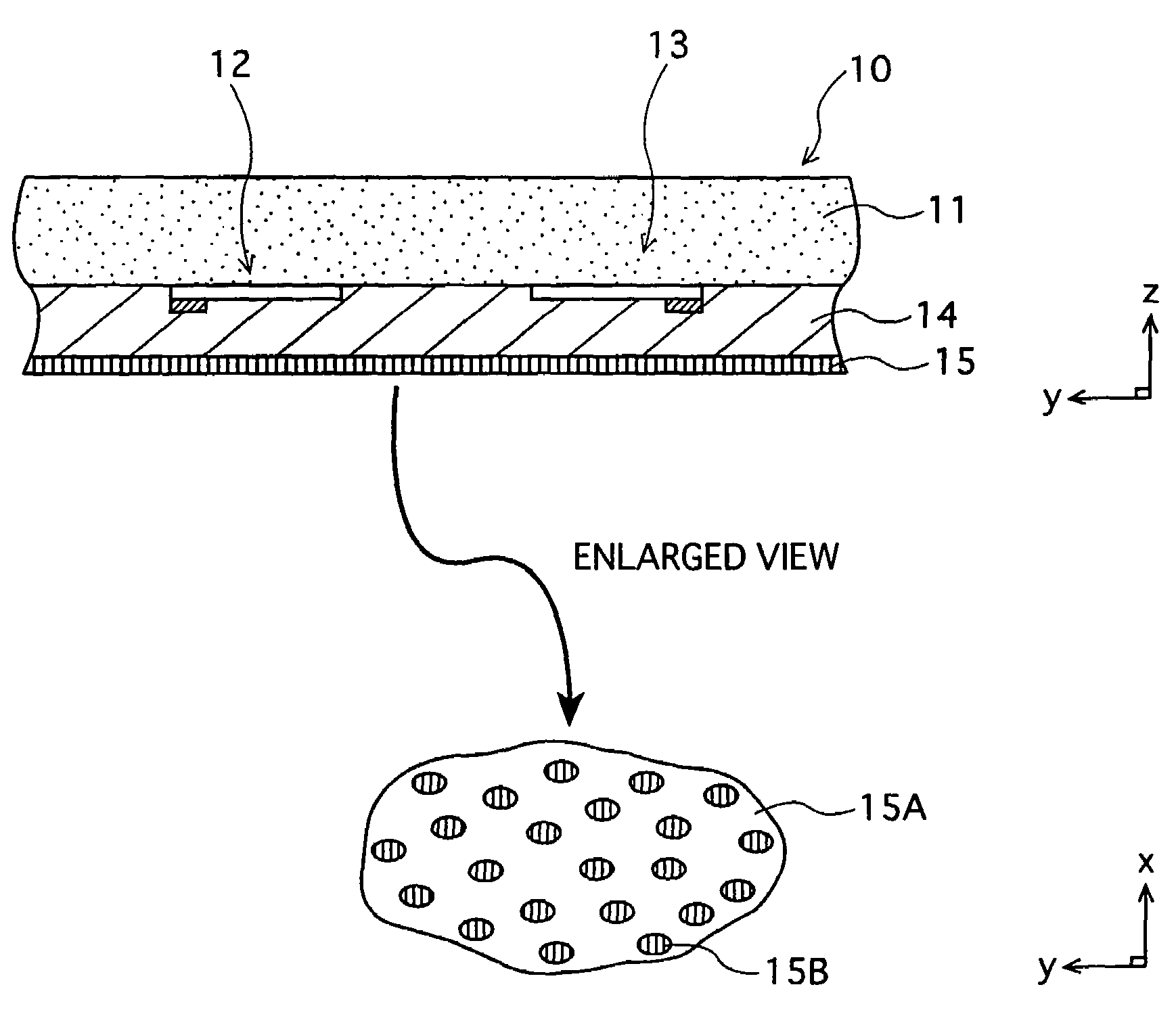

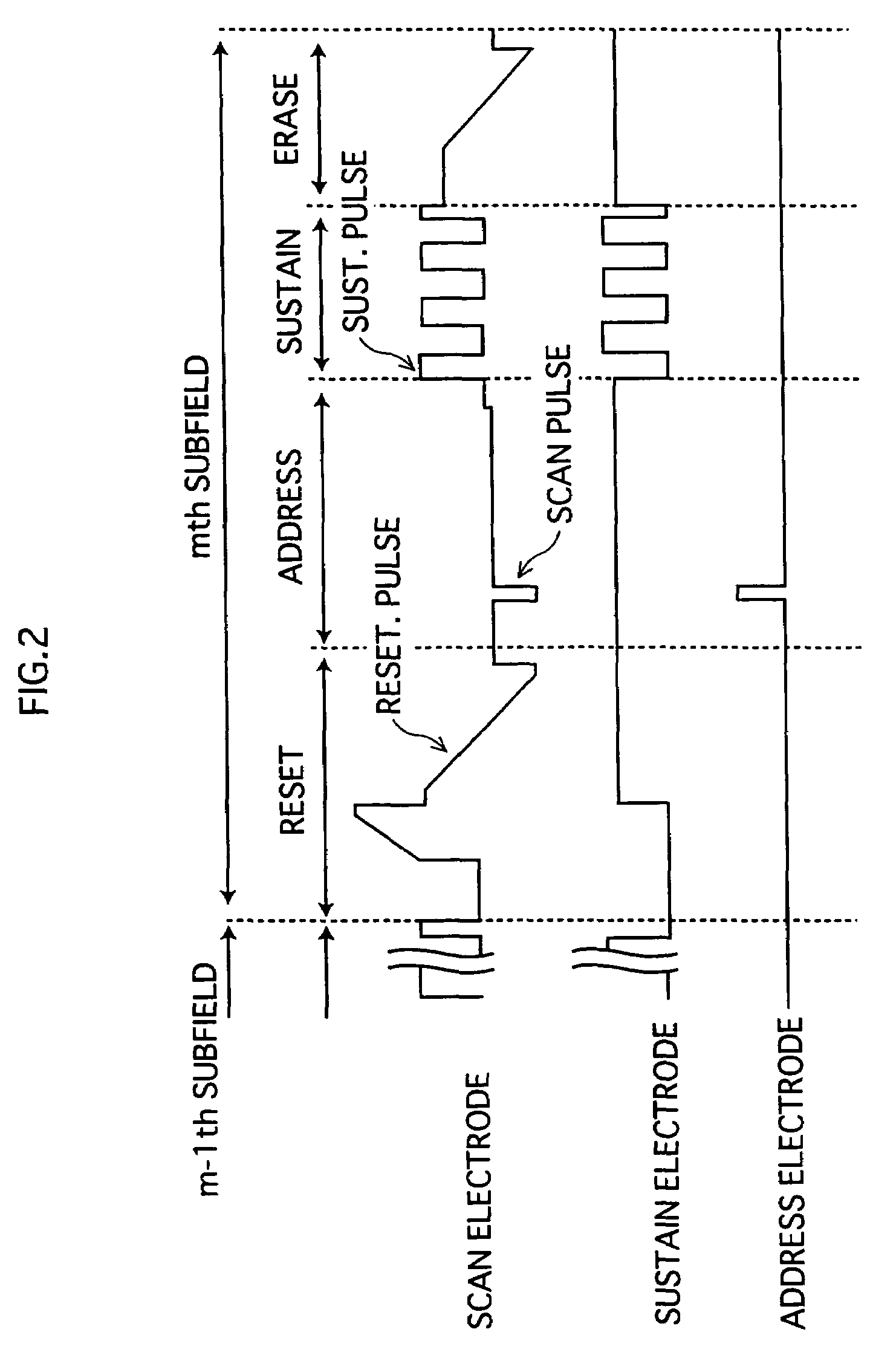

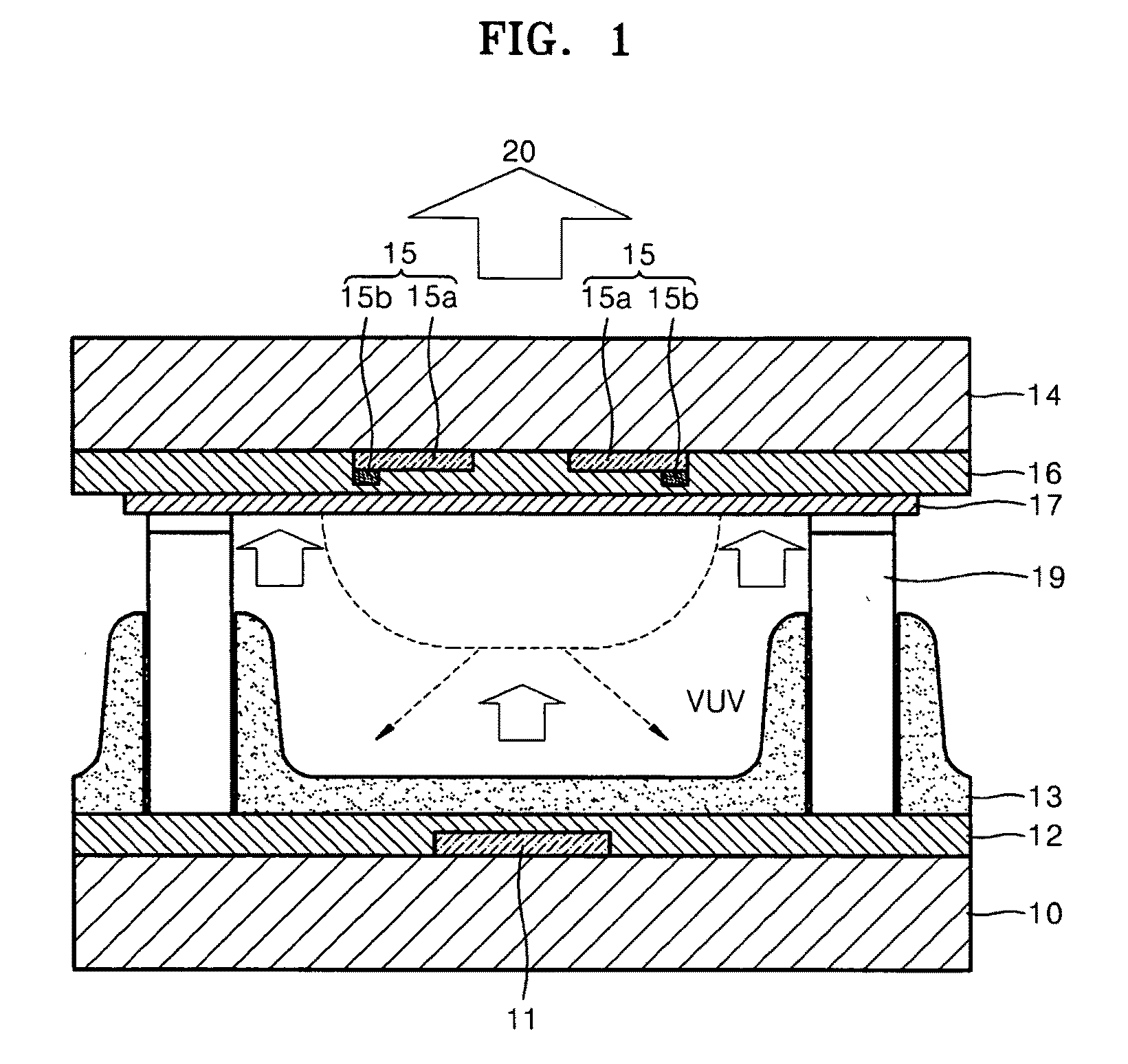

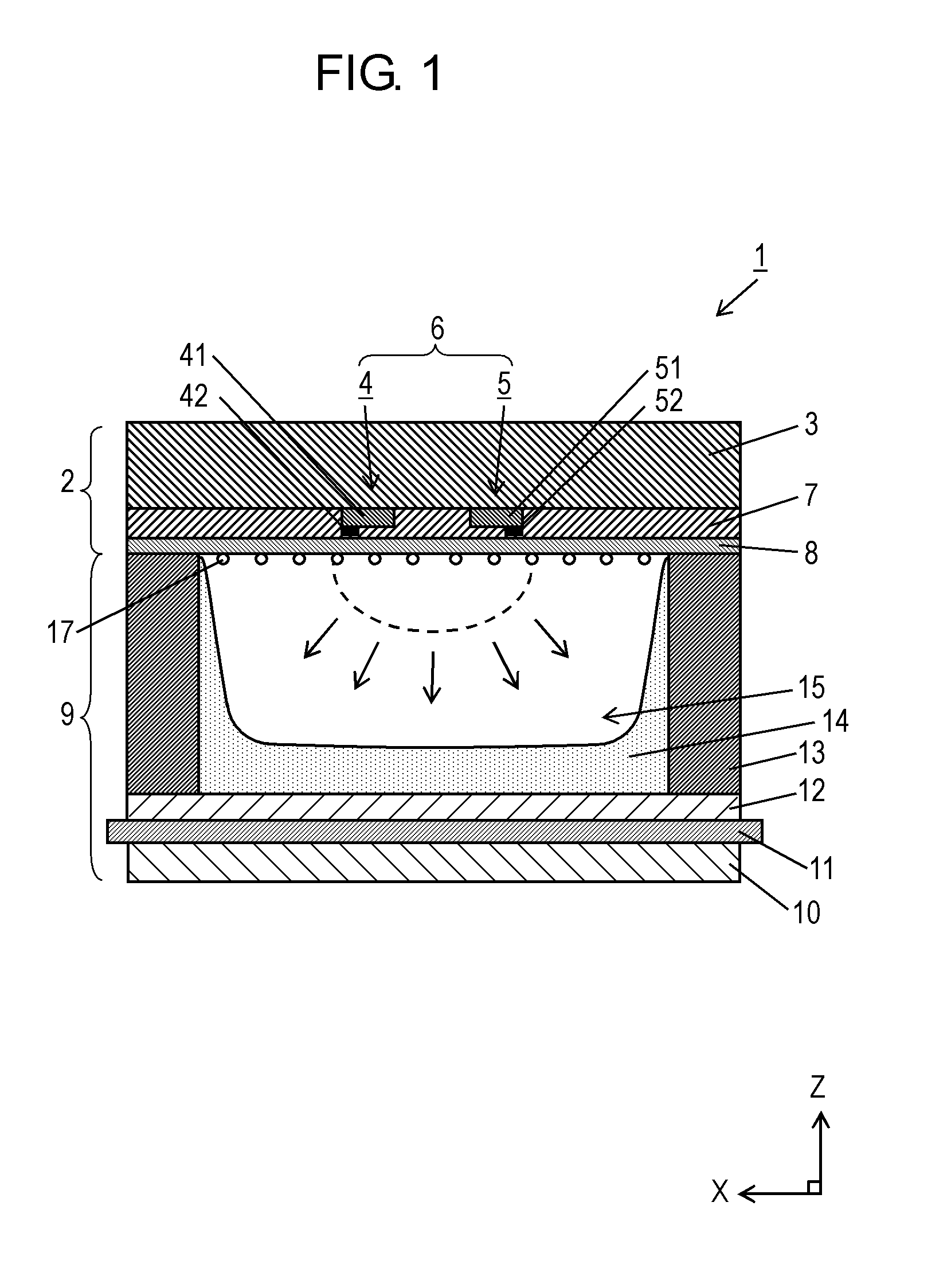

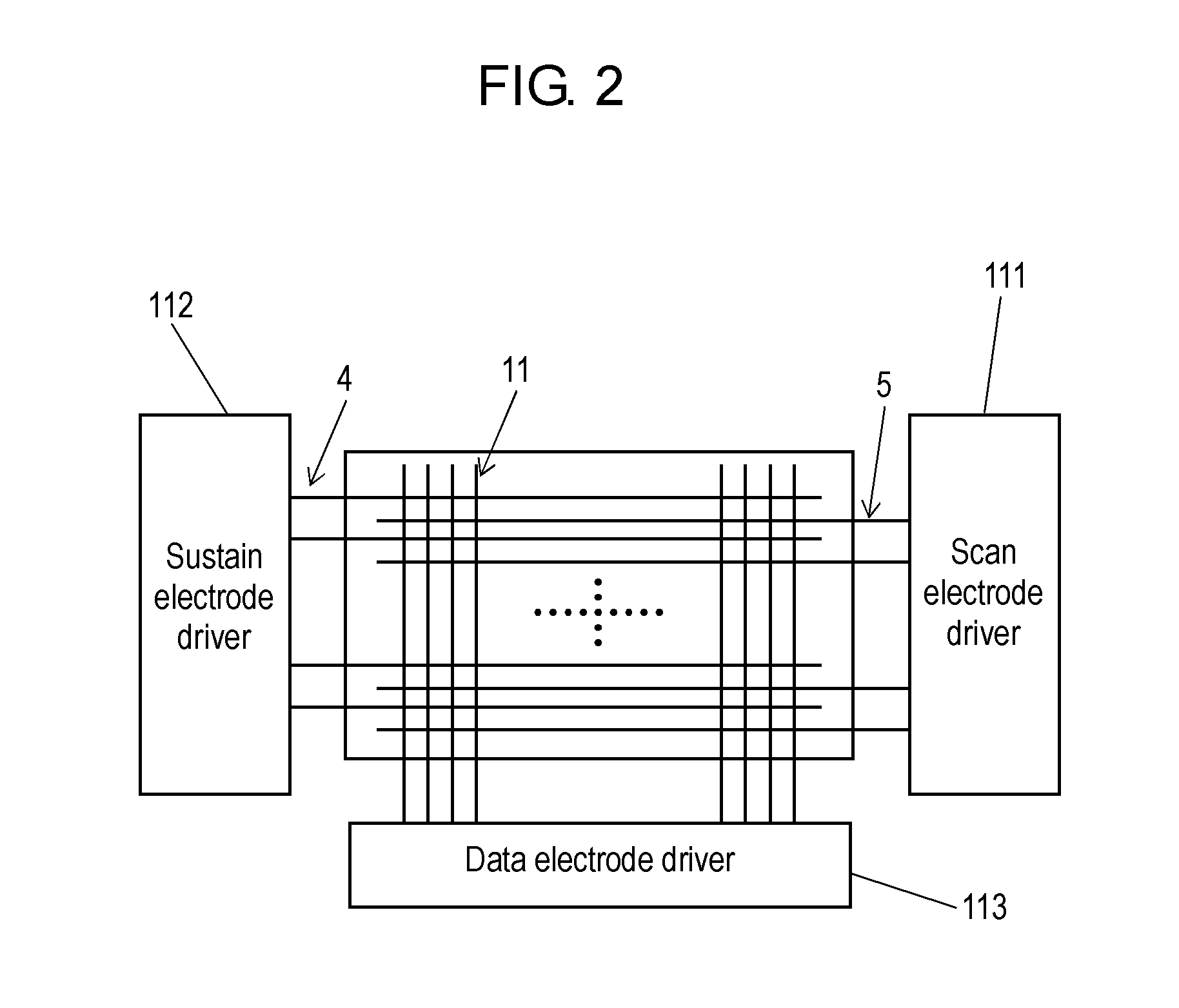

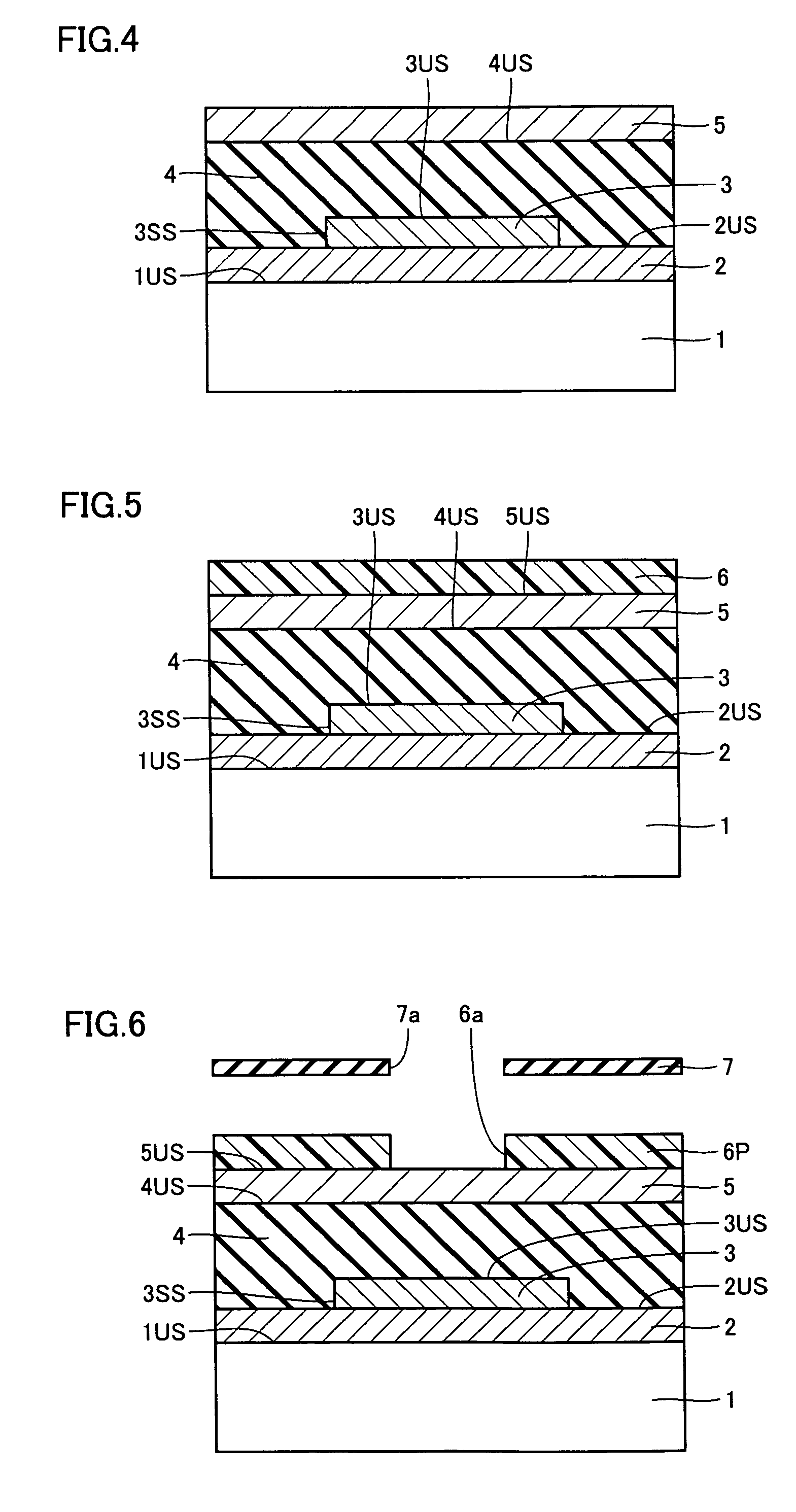

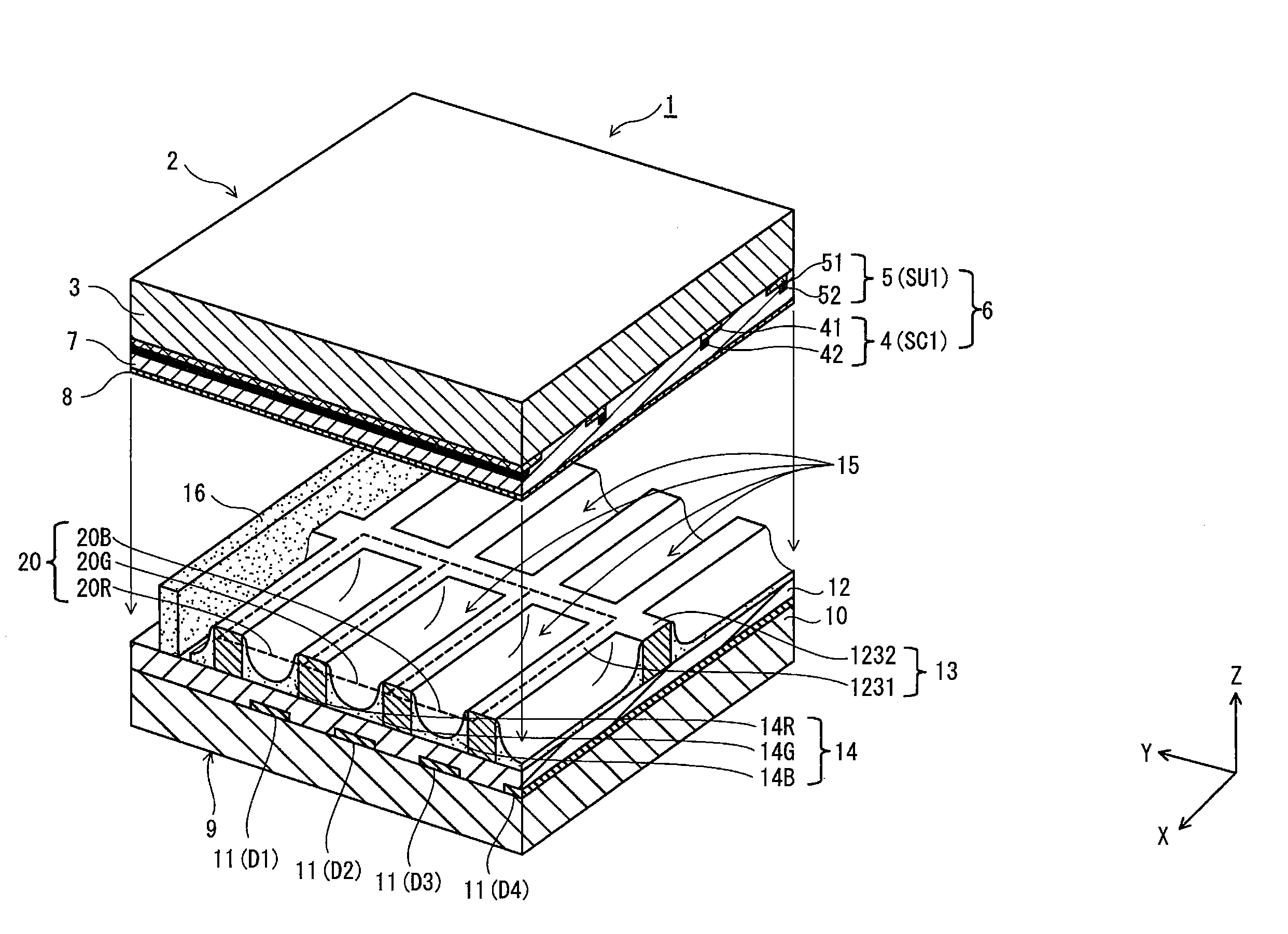

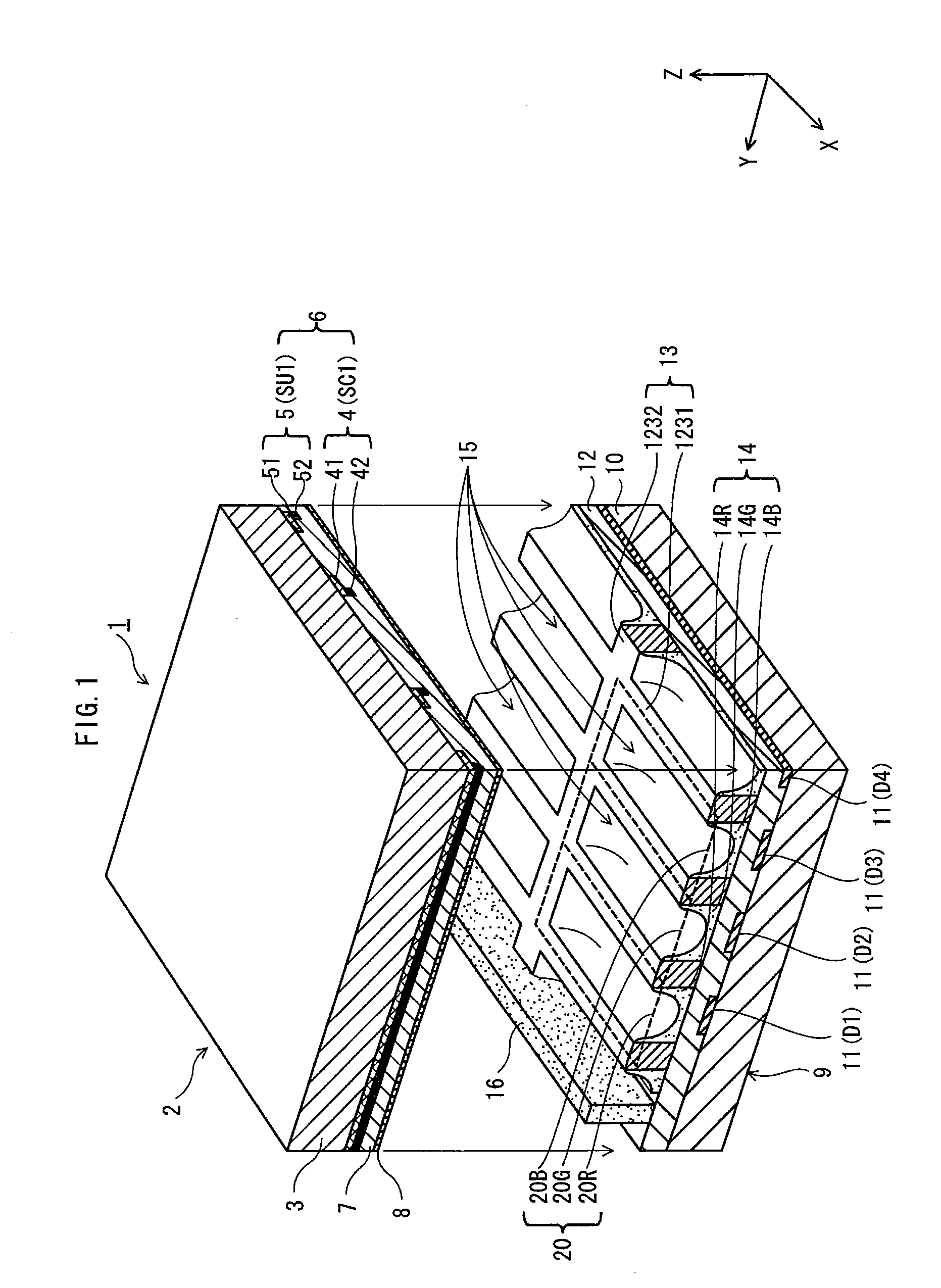

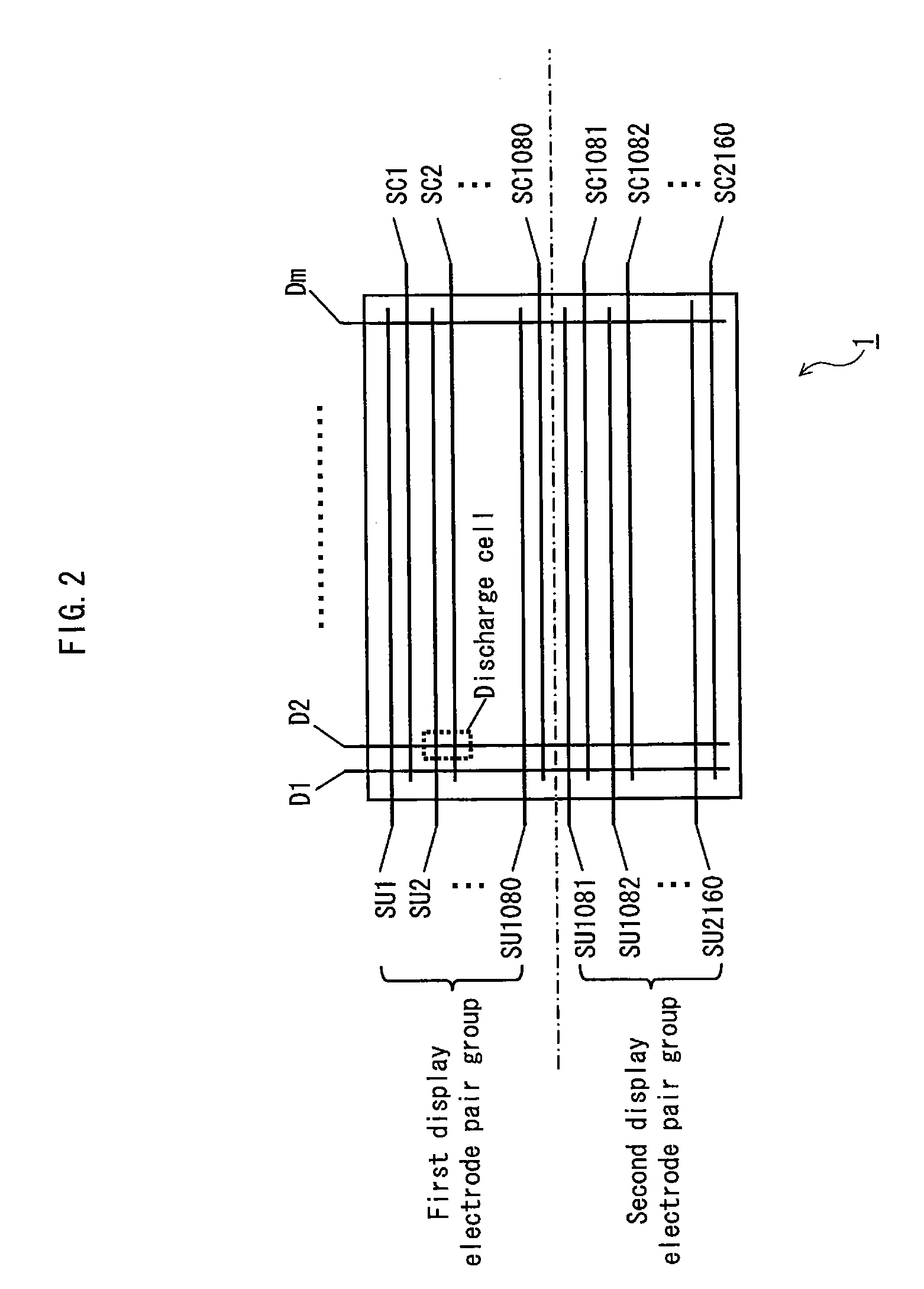

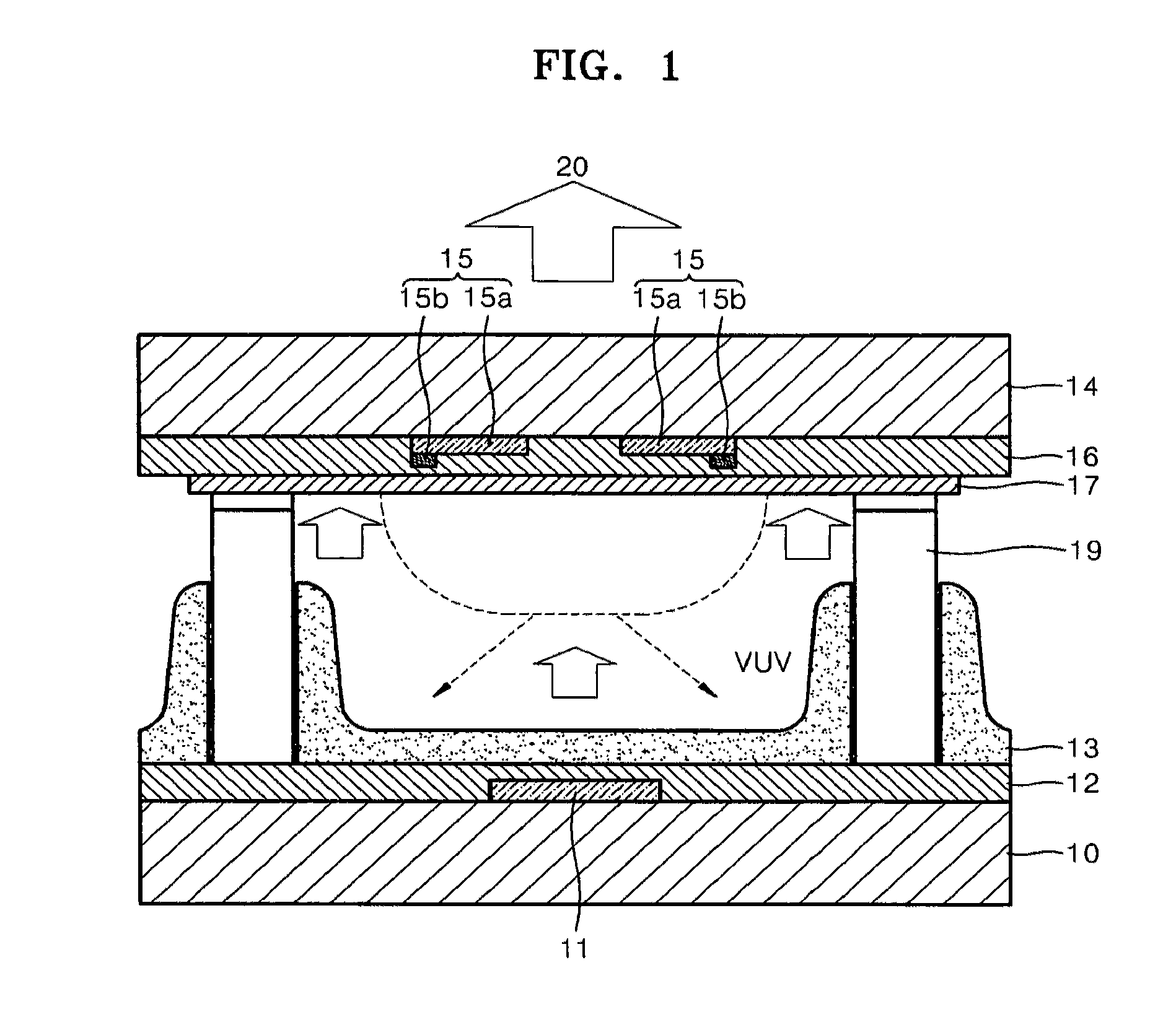

Plasma display panel and method for manaufacturing same

InactiveUS20060012721A1Good secondary electron emission propertyVoltage Vf can be reducedTelevision system detailsAddress electrodesElectronAtomic physics

A plasma display panel in which a first substrate having a protective layer formed thereon opposes a second substrate across a discharge space, with the substrates being sealed around a perimeter thereof. At a surface of the protective layer, first and second materials of different electron emission properties are exposed to the discharge space, with at least one of the materials existing in a dispersed state. The first and second materials may be first and second crystals, and the second crystal may be dispersed throughout the first crystal.

Owner:PANASONIC CORP

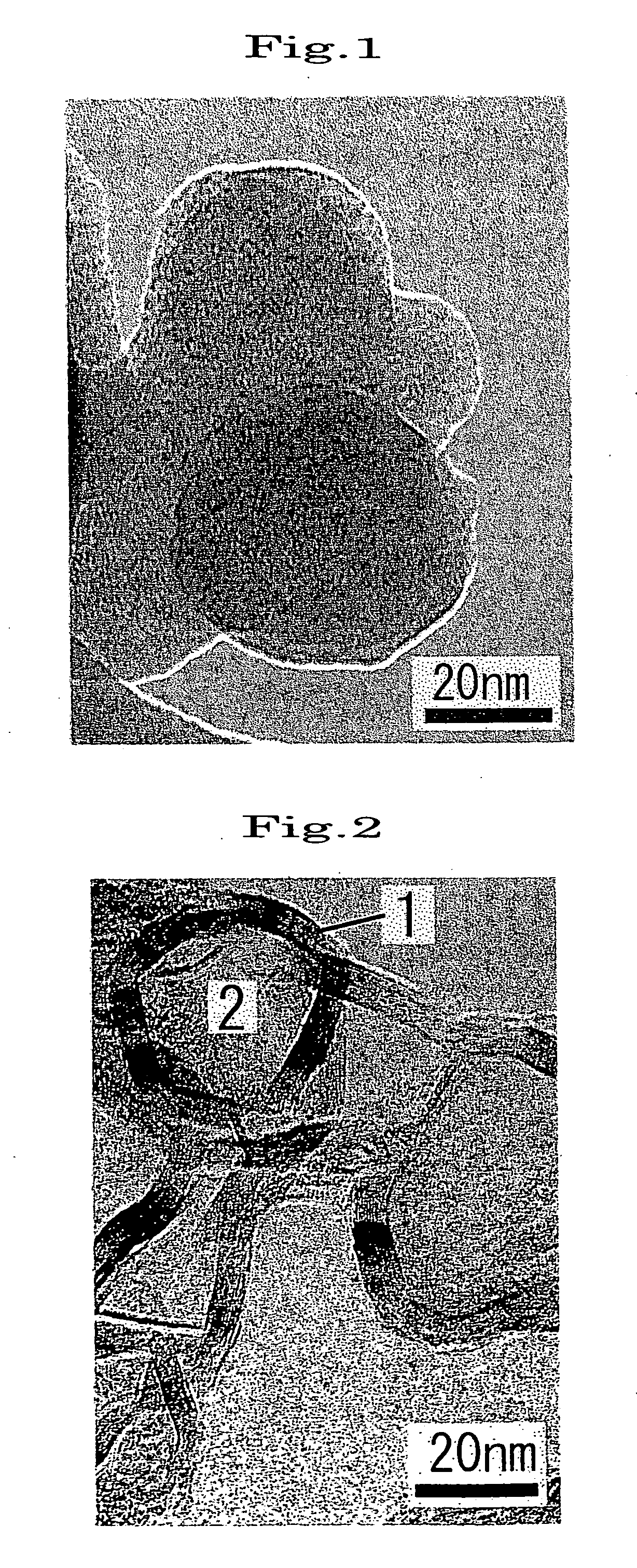

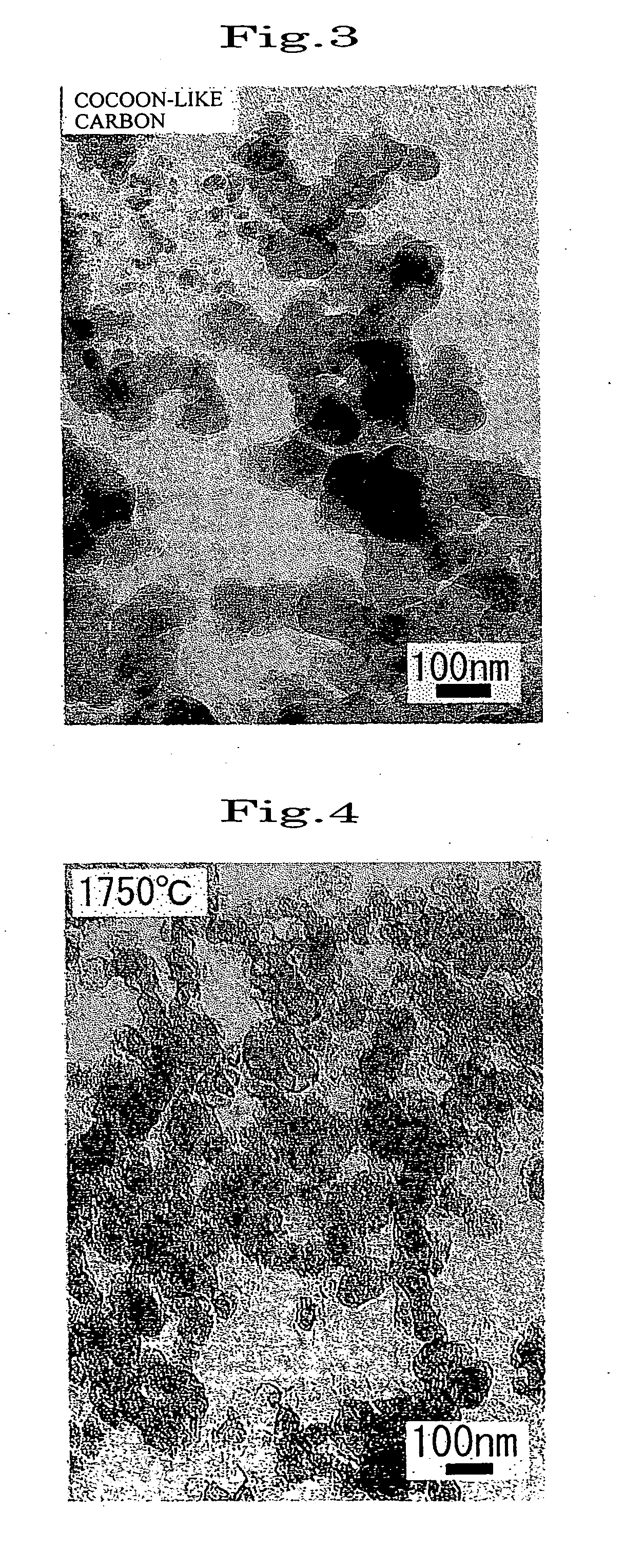

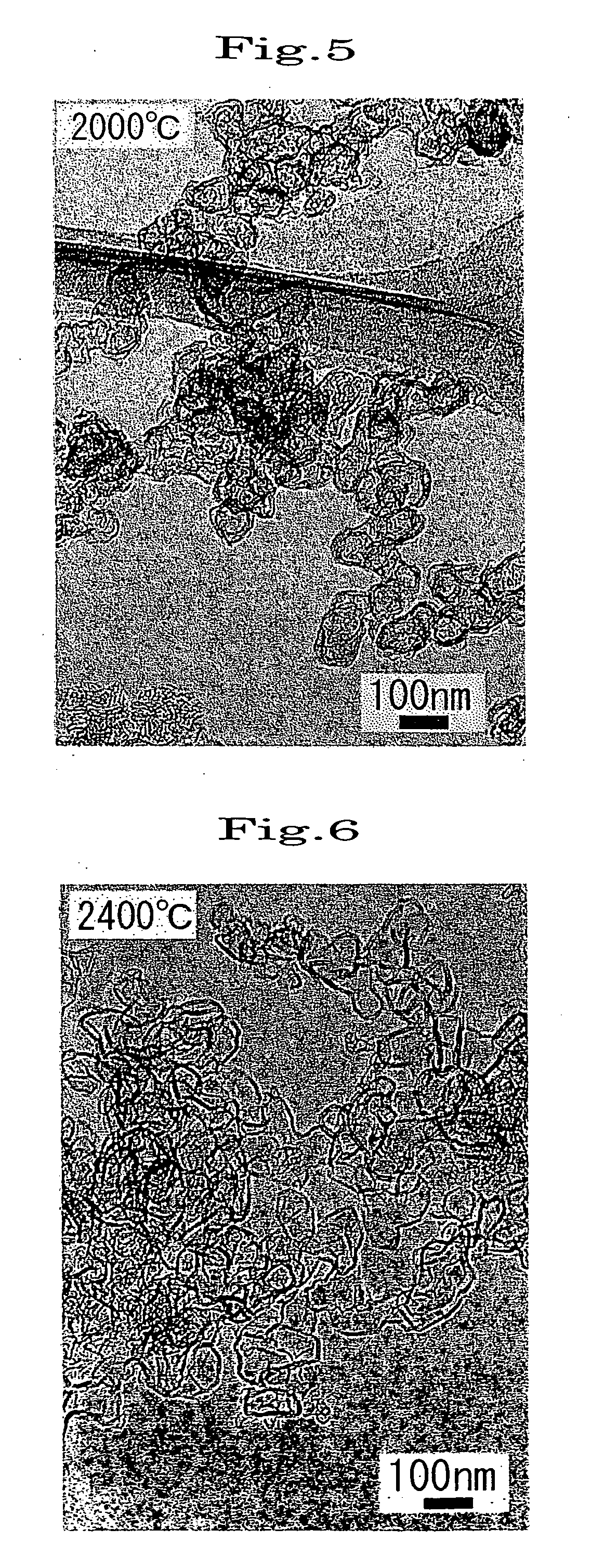

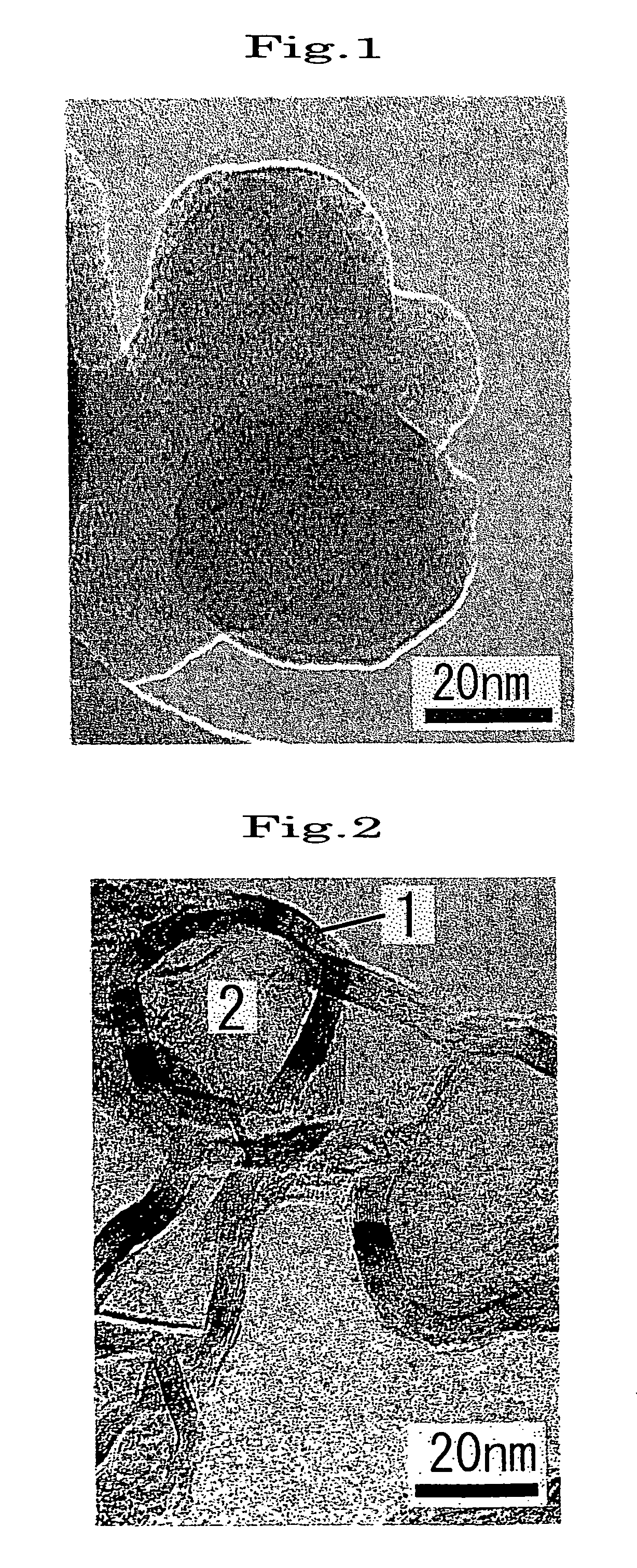

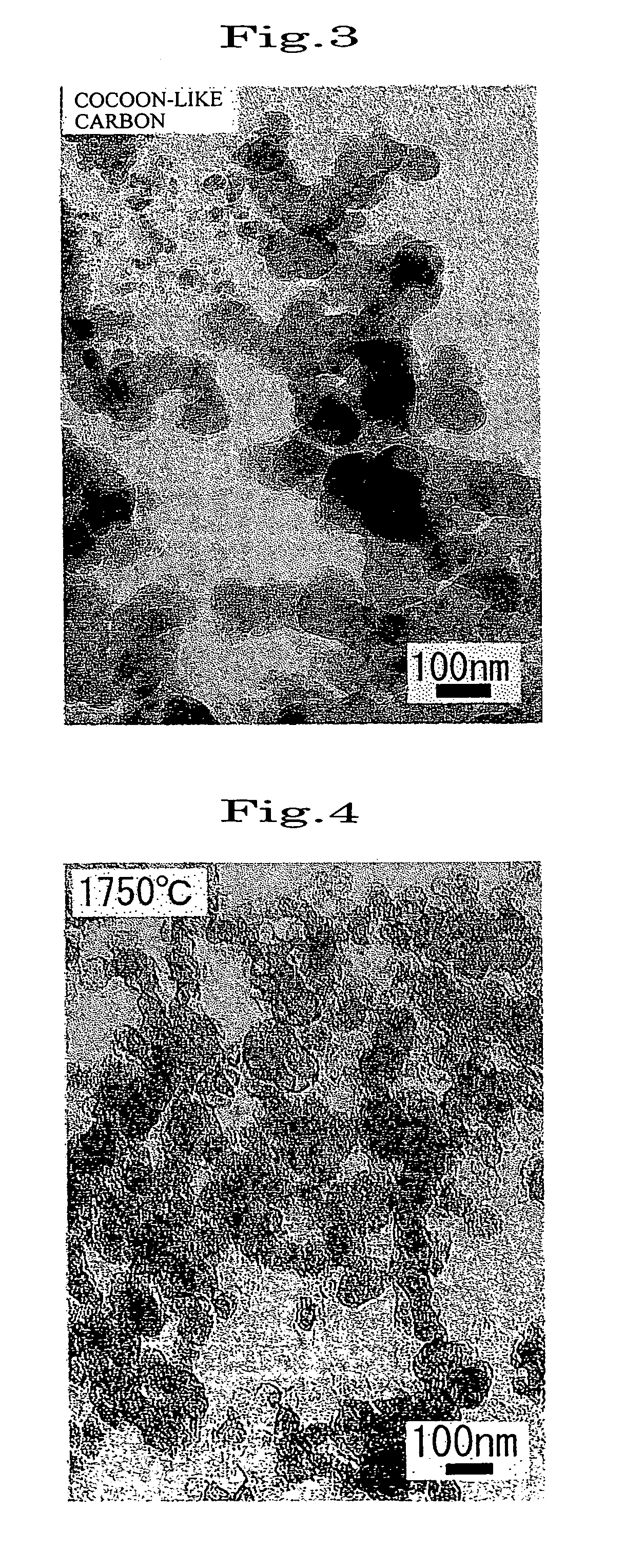

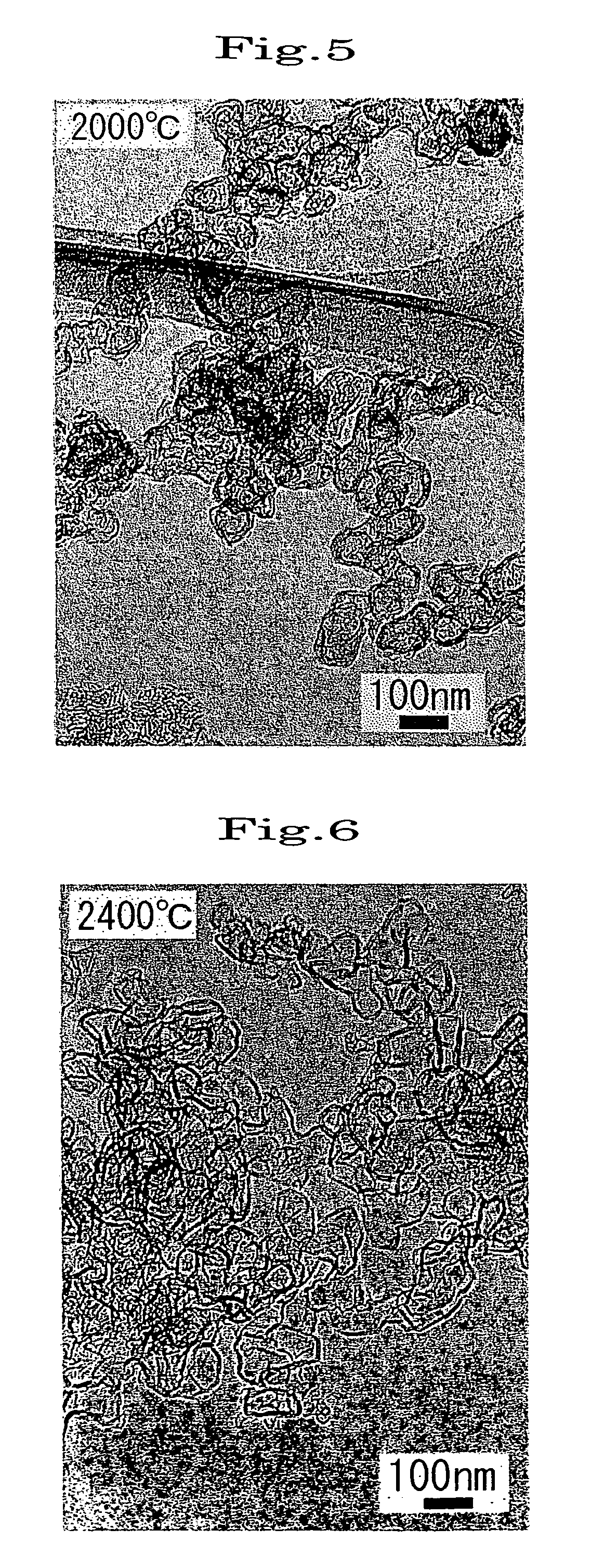

Carbon Nanoballoon Structure And Method For Preparation Thereof, And Electron Emitter

InactiveUS20070207081A1Simple structureGood chemical resistanceMaterial nanotechnologyCarbon compoundsCarbon blackElectric arc

A hollow carbon nanoballoon structure having a relatively large closed space, and a method of producing a carbon nanoballoon structure capable of easily and stably producing such a structure. The carbon nanoballoon structure is obtained by heating soot prepared by arc discharge using carbon electrodes, soot prepared by vaporizing. carbon by laser irradiation, or carbon black having a specific surface area of 1000 m2 / g or more and a primary particle diameter of 20 nm or more at a high temperature in an inert gas atmosphere, and includes graphite sheets linked to form a curved surface.

Owner:TAKIKAWA HIROFUMI +2

Flaky carbonaceous particle and production method thereof

InactiveUS7442358B2Improve electron emission performanceImprove electronic conductivityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsHigh electronNanometre

A carbonaceous particle is provided which comprises a hexagonal flake formed of an aggregate of a plurality of nanocarbons and having a side length of 0.1 to 100 mm and a thickness of 10 nm to 1 mm. Thereby, a carbonaceous particle is provided which has an excellent electron emission performance, has a high electron conductivity, shows excellent characteristics particularly when used for a secondary battery, and can suitably be applied to various devices other than a secondary battery as well.

Owner:CANON KK

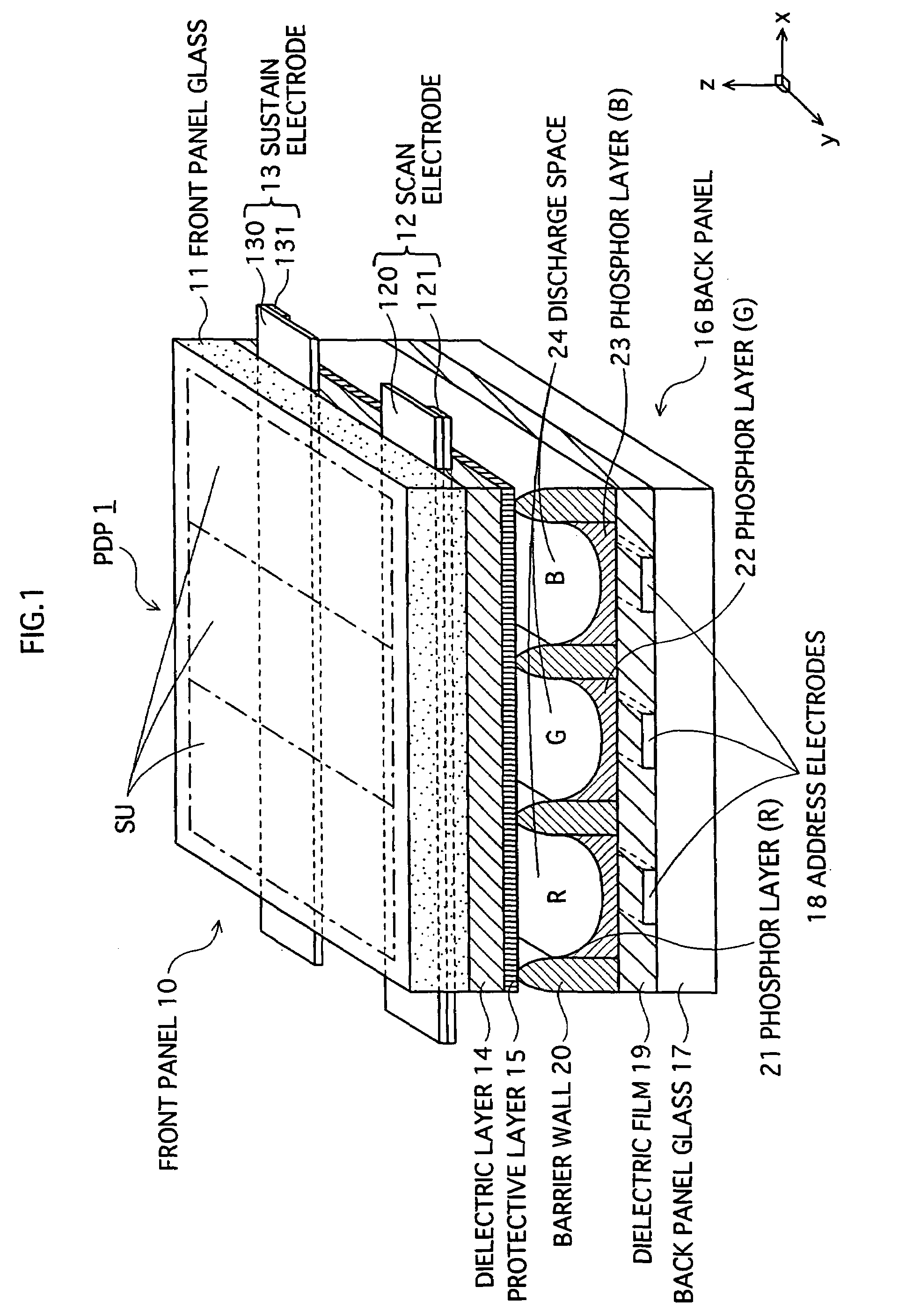

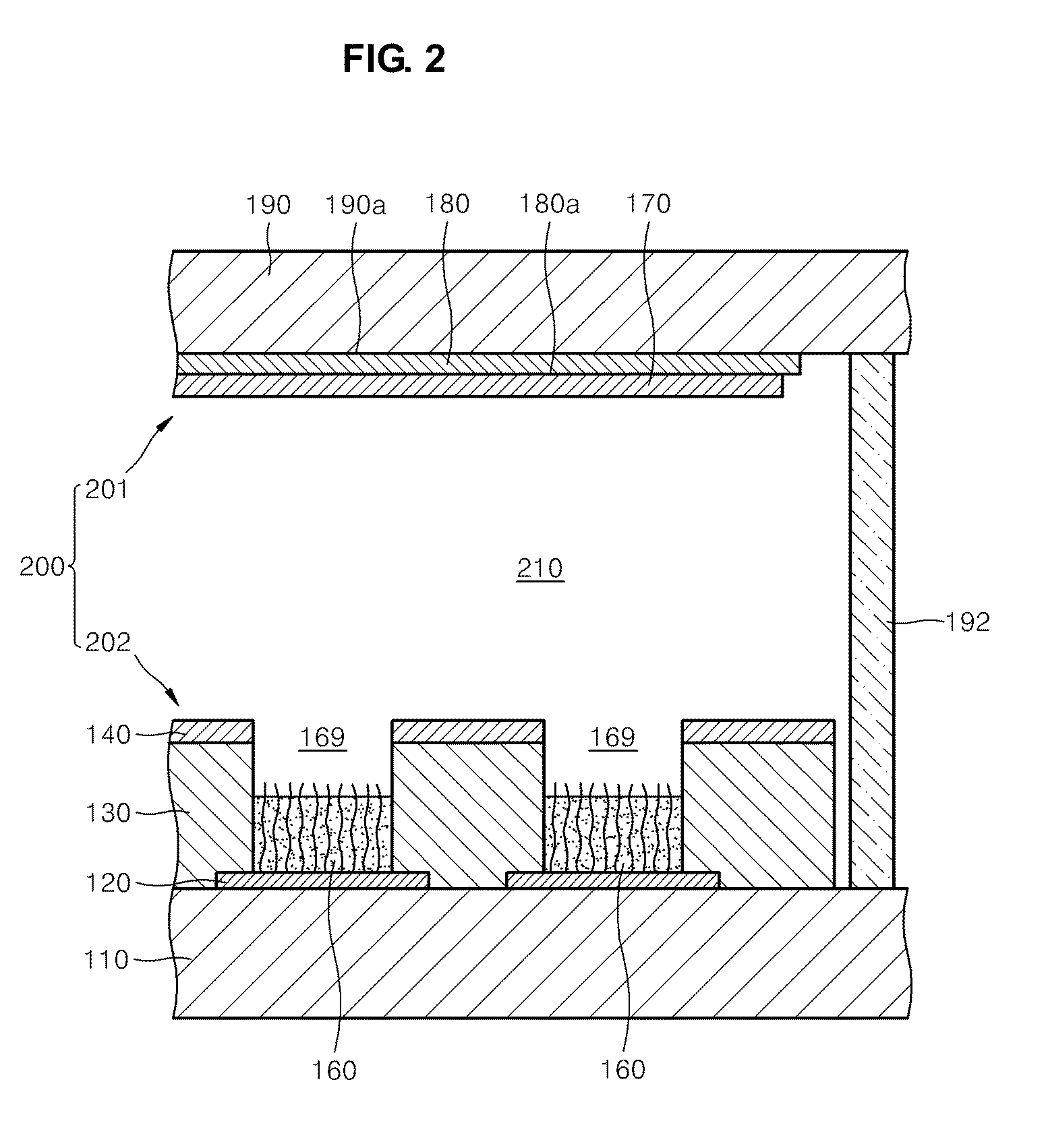

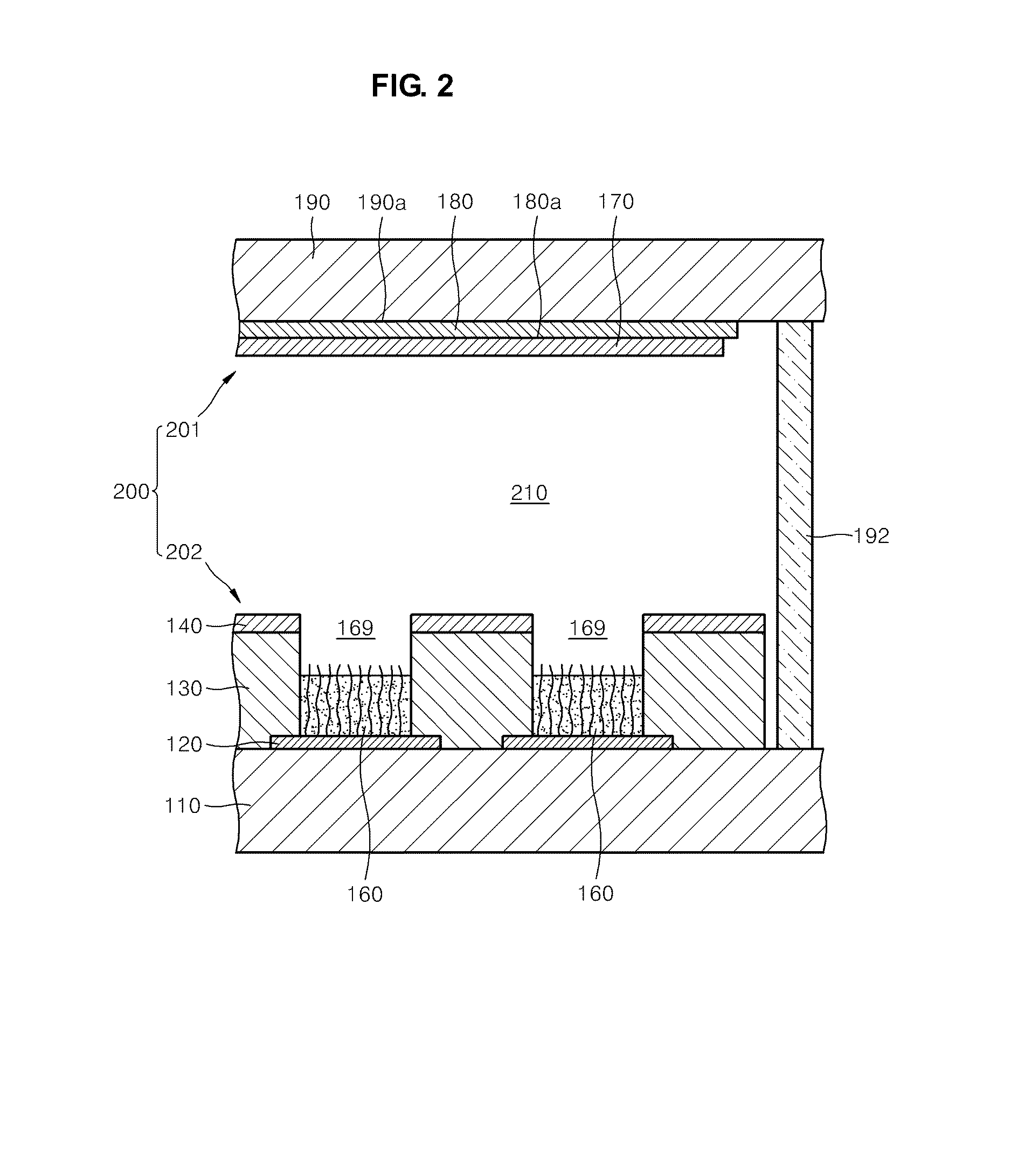

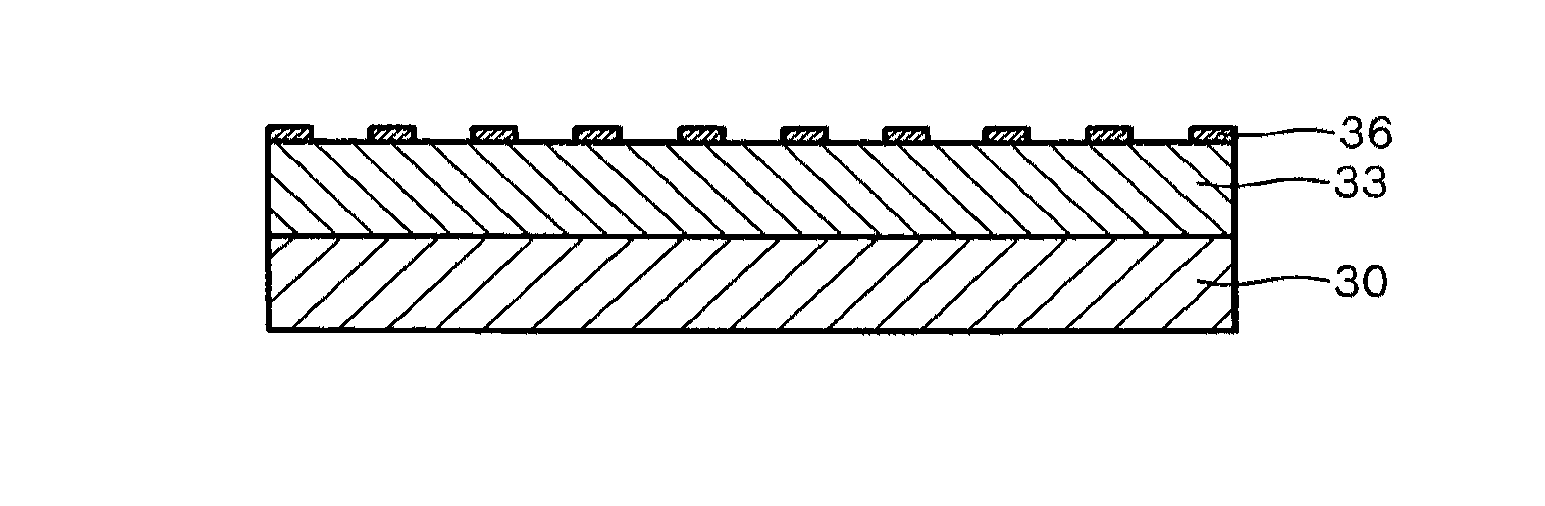

Plasma display panel and method for manufacturing same

InactiveUS7432656B2Improve electron emission performanceReduce voltageAddress electrodesSustain/scan electrodesElectronPlasma display

A plasma display panel in which a first substrate having a protective layer formed thereon opposes a second substrate across a discharge space, with the substrates being sealed around a perimeter thereof. At a surface of the protective layer, first and second materials of different electron emission properties are exposed to the discharge space, with at least one of the materials existing in a dispersed state. The first and second materials may be first and second crystals, and the second crystal may be dispersed throughout the first crystal.

Owner:PANASONIC CORP

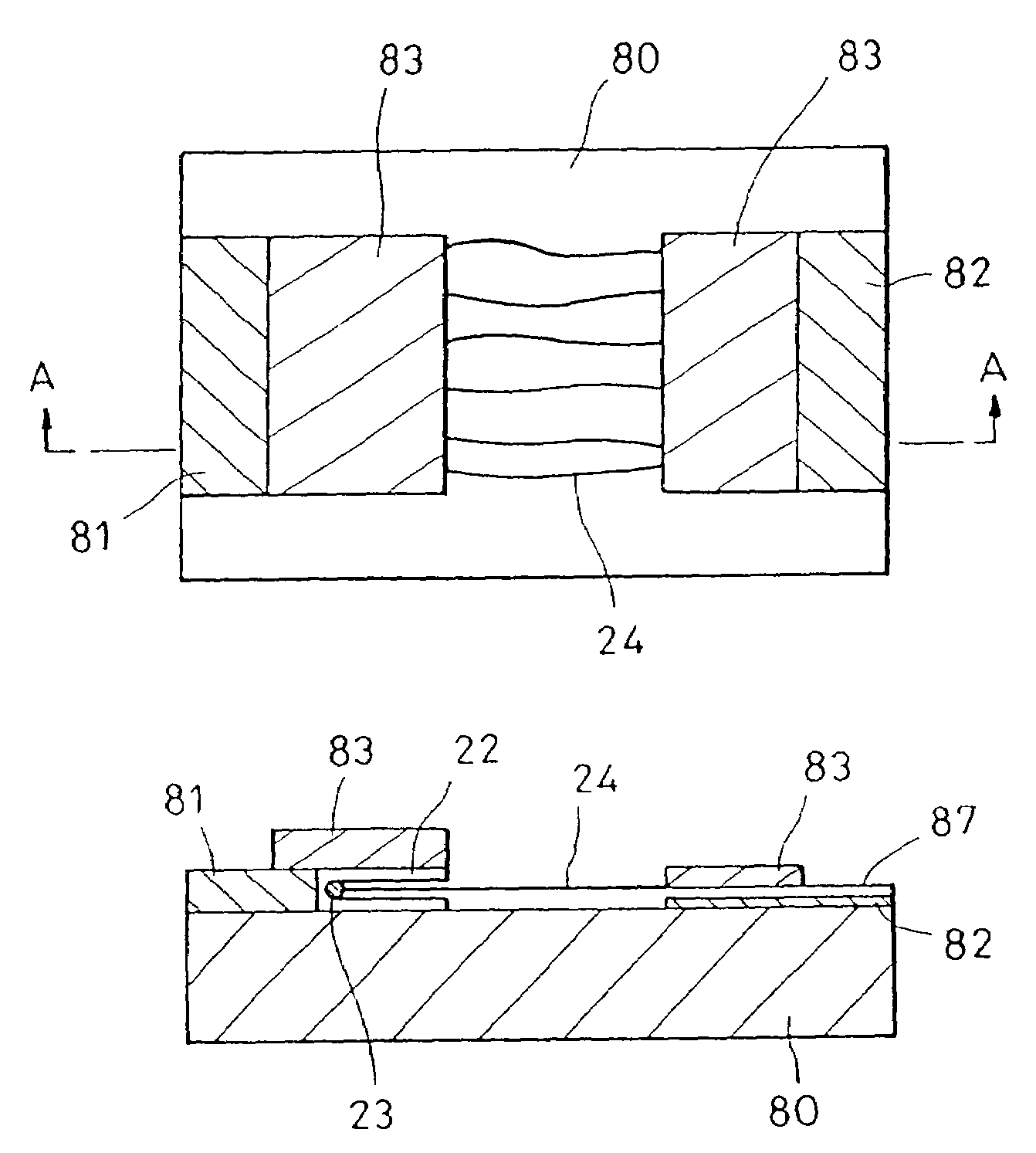

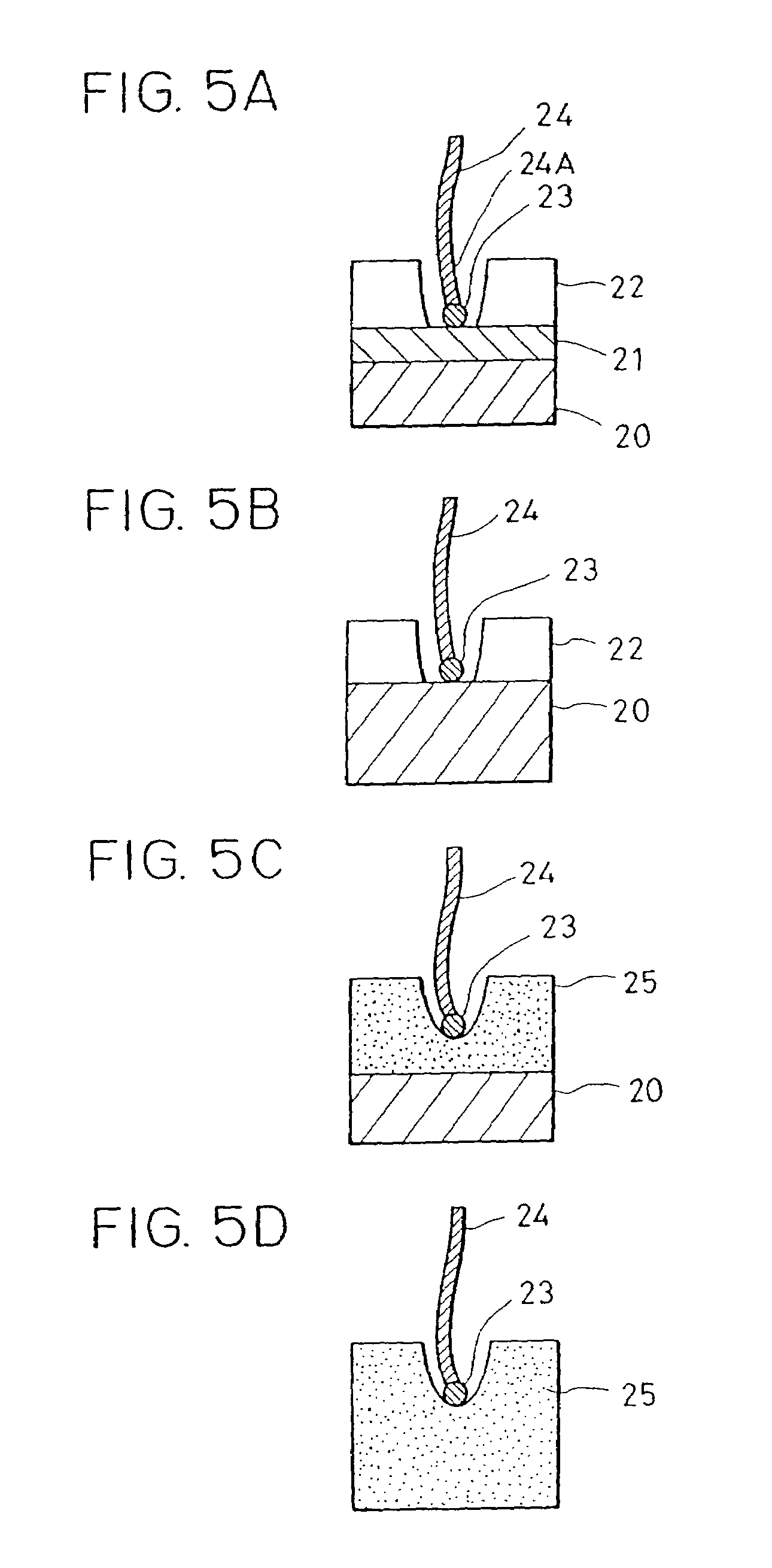

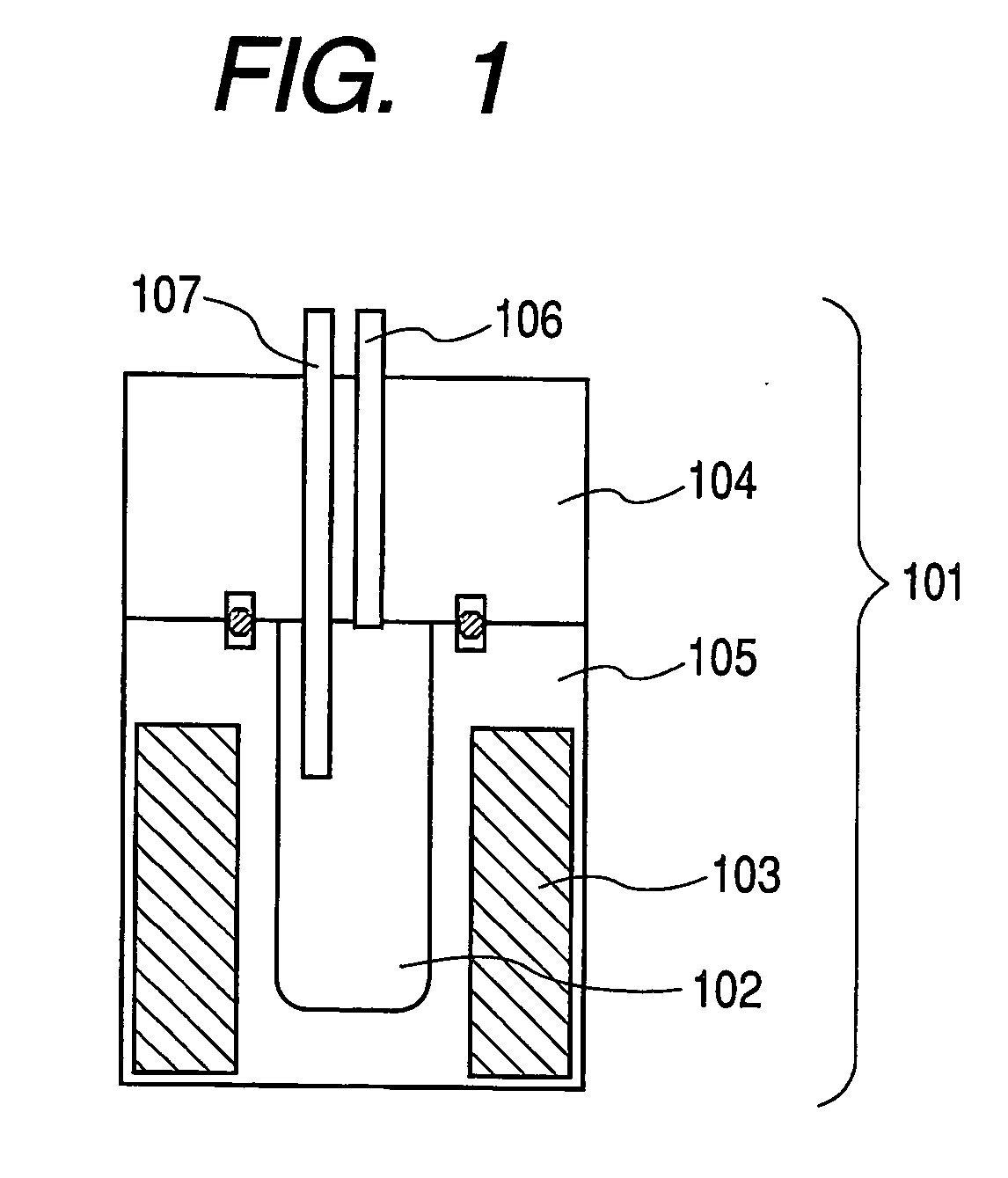

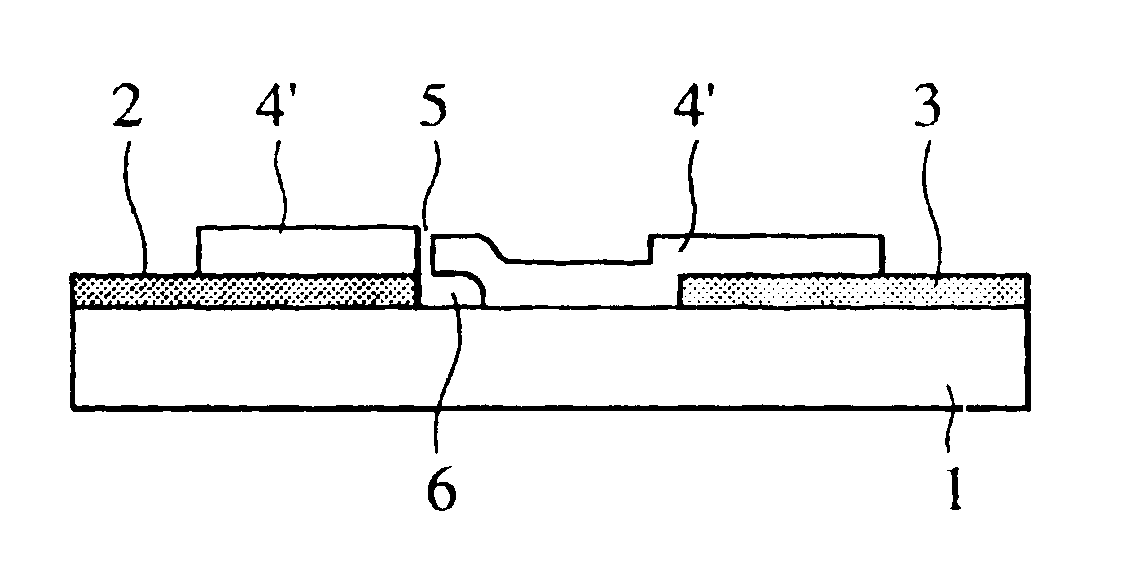

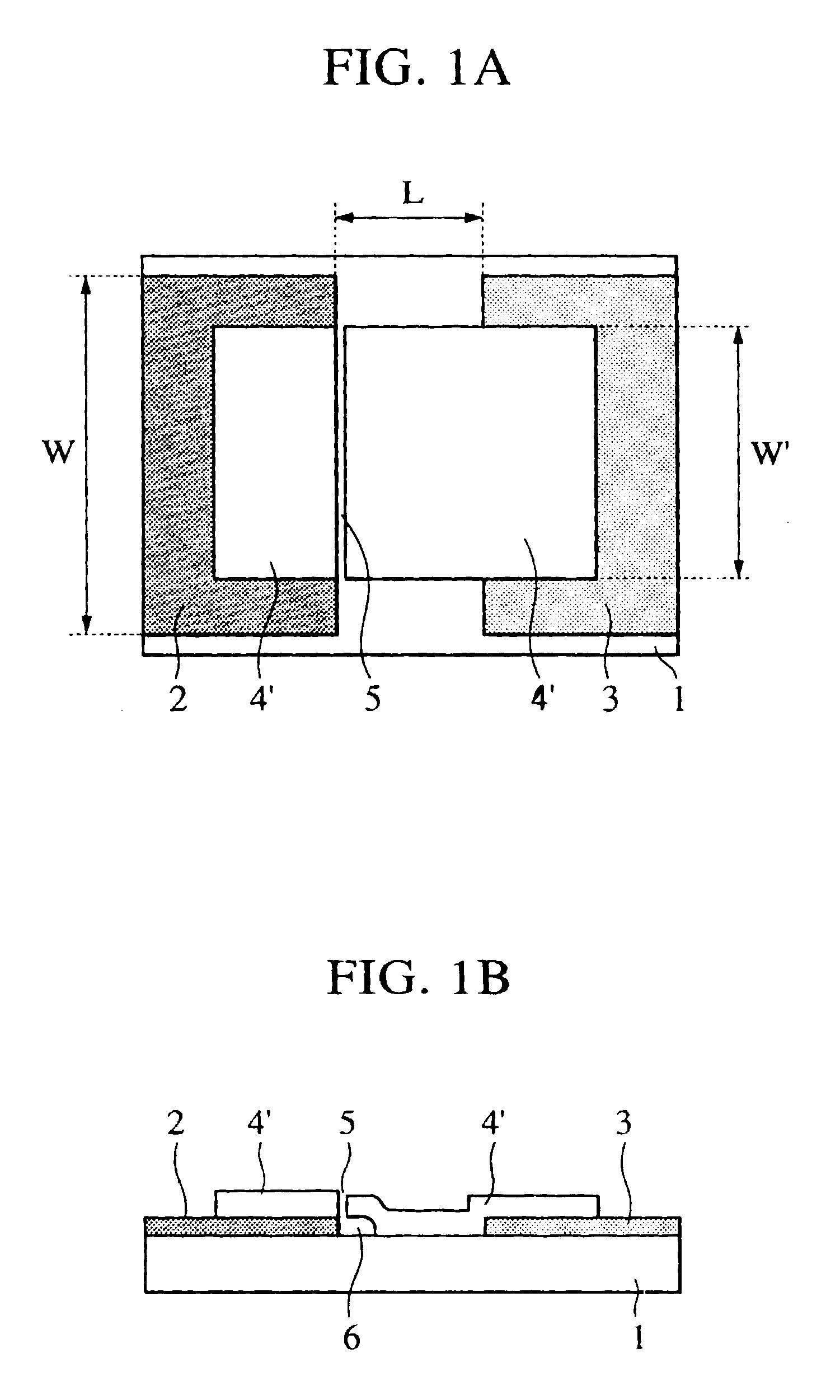

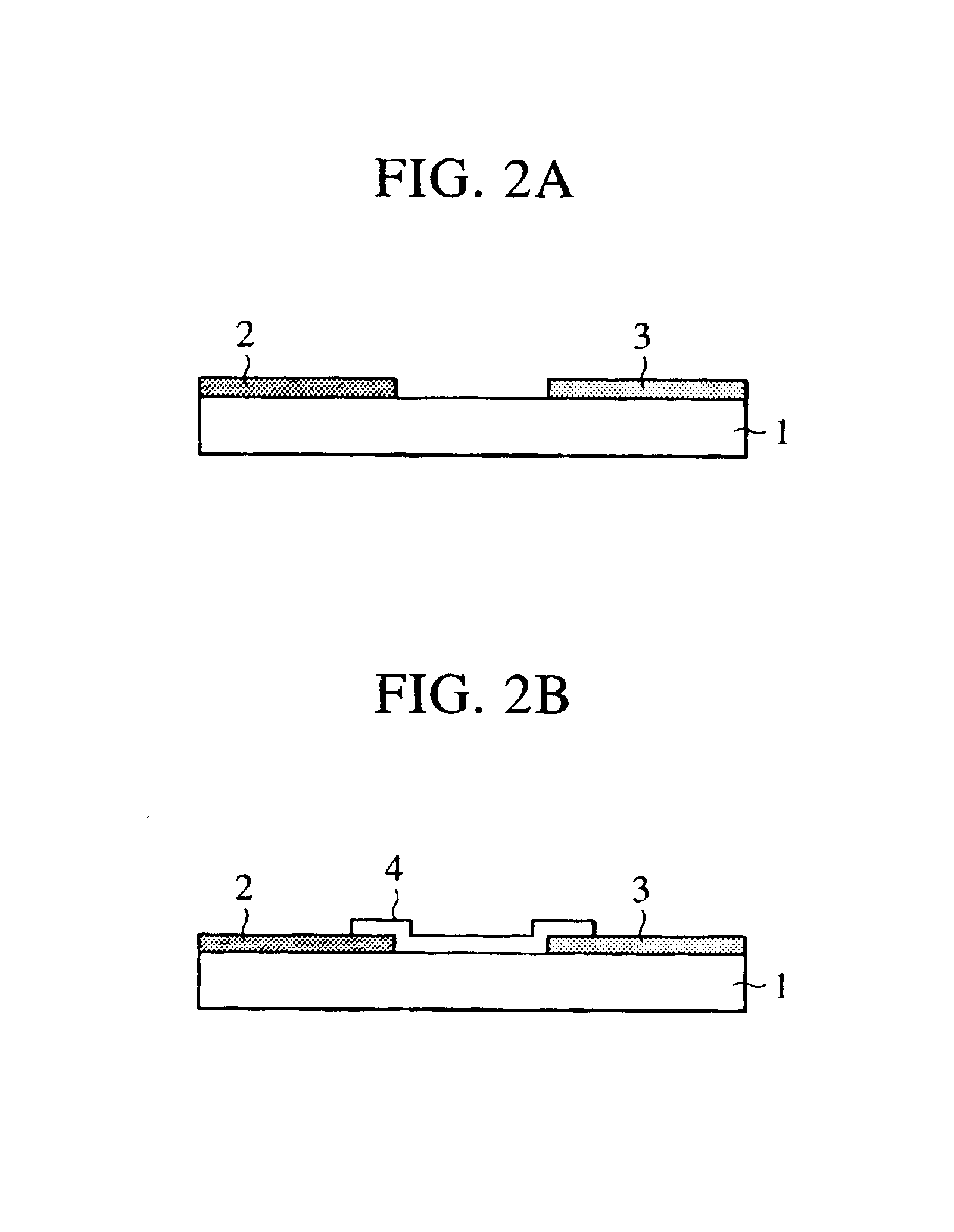

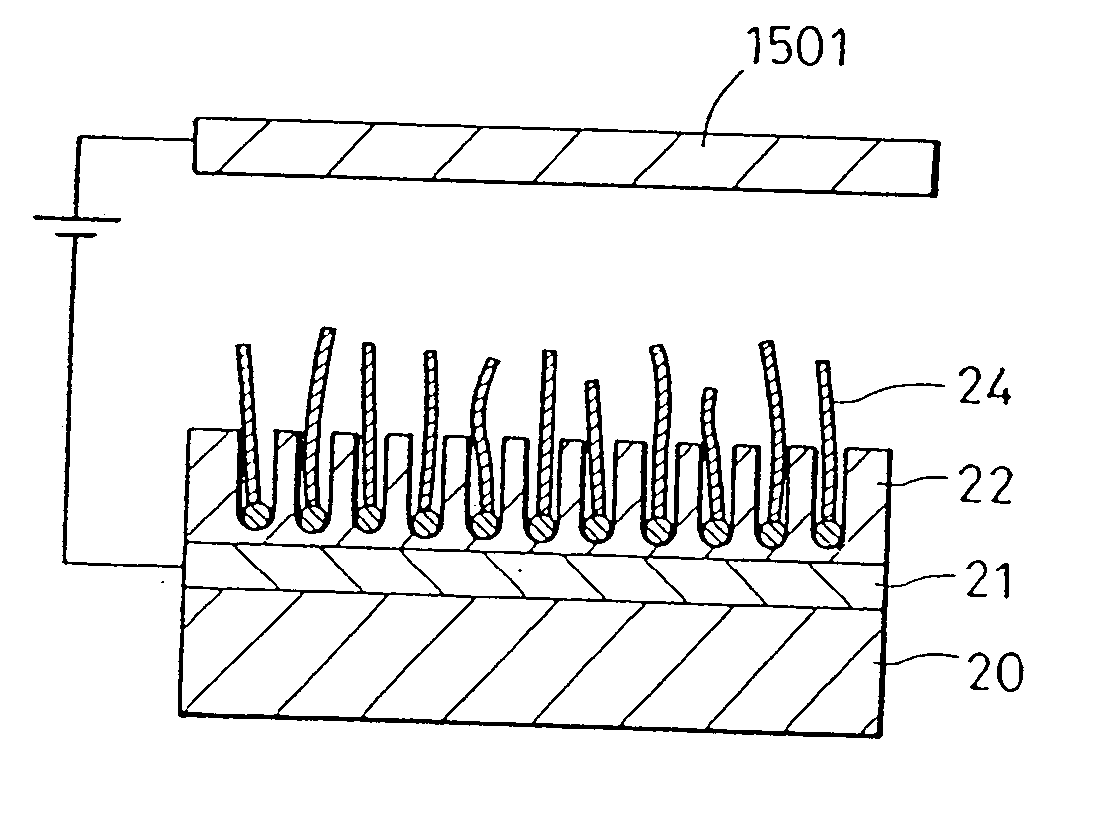

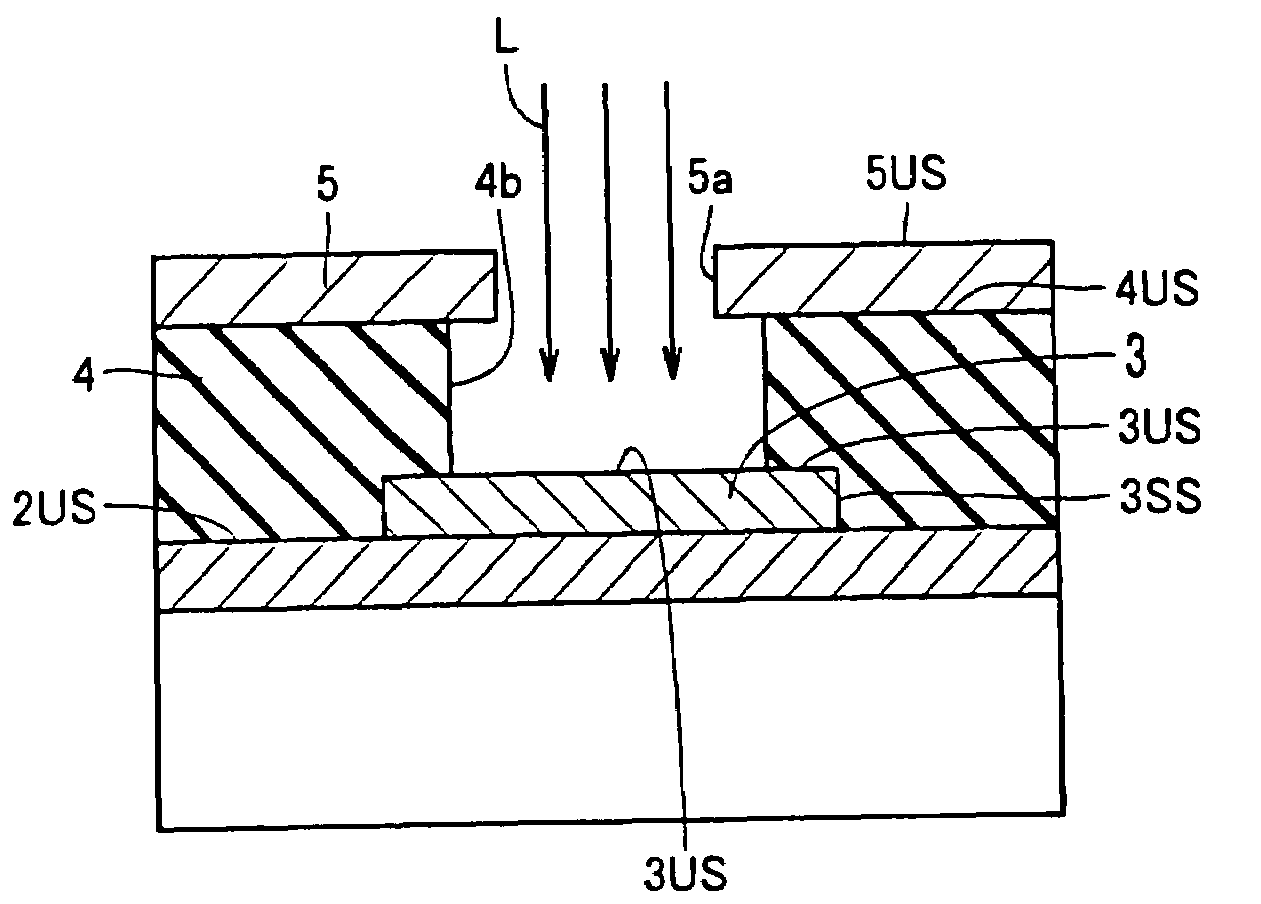

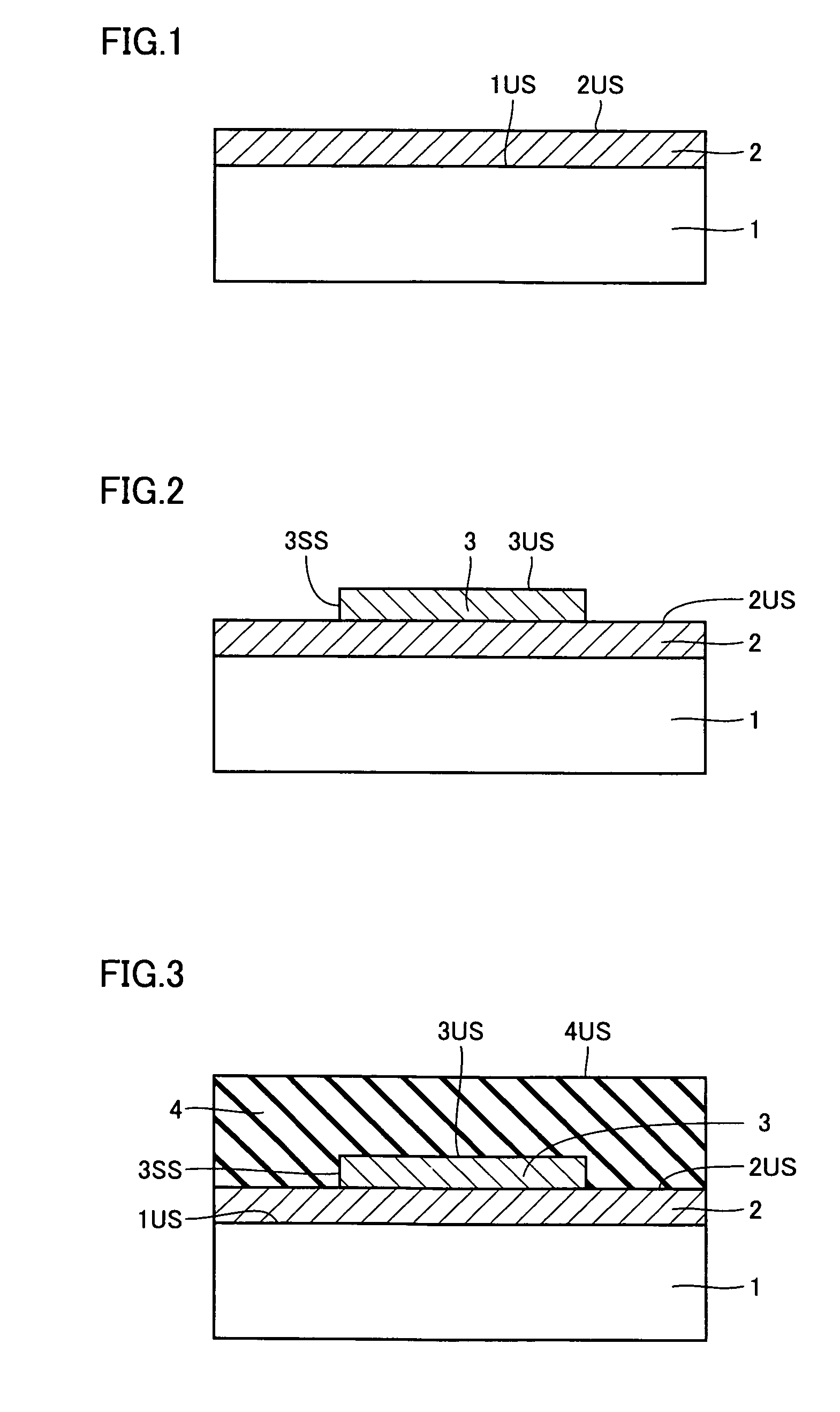

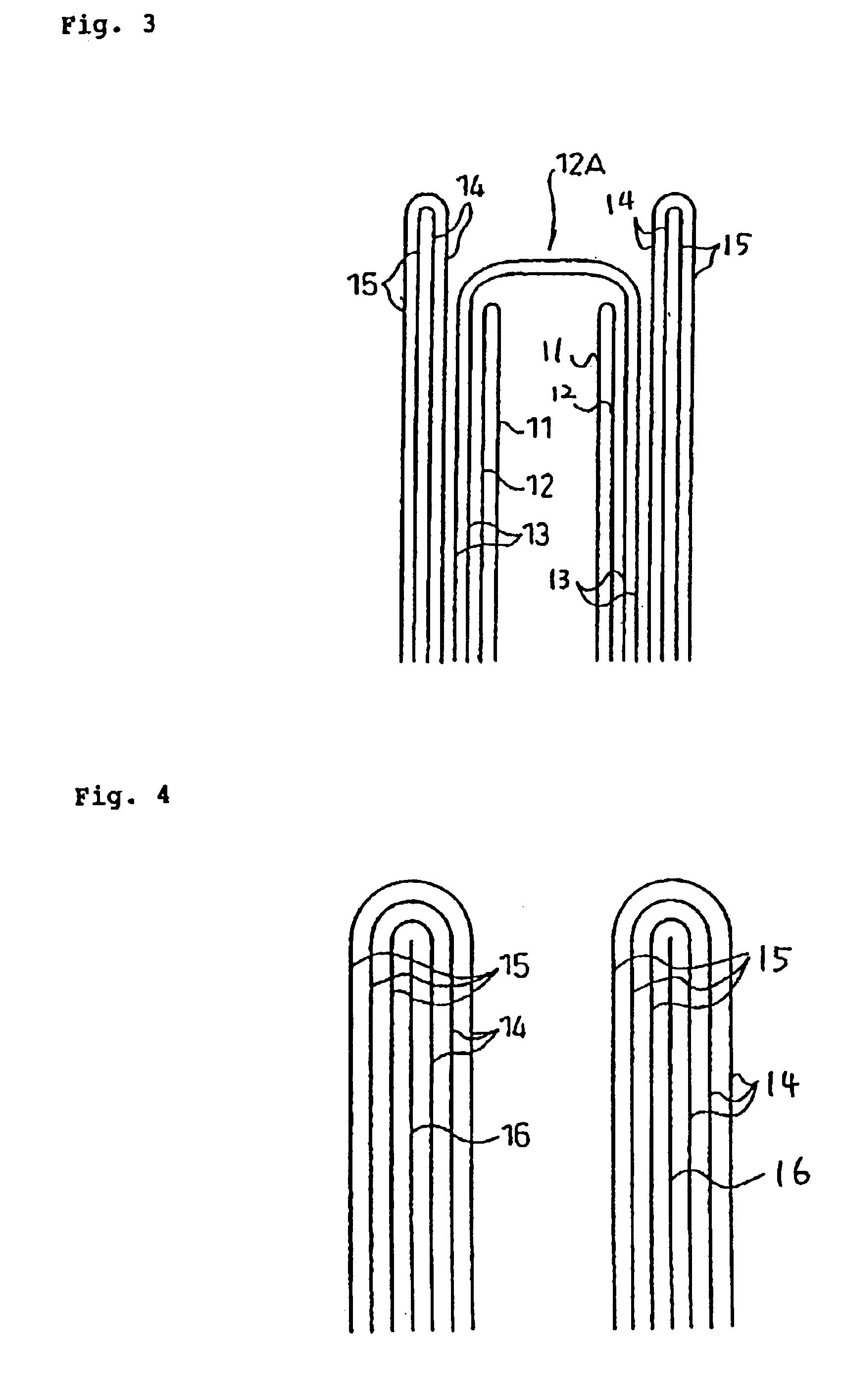

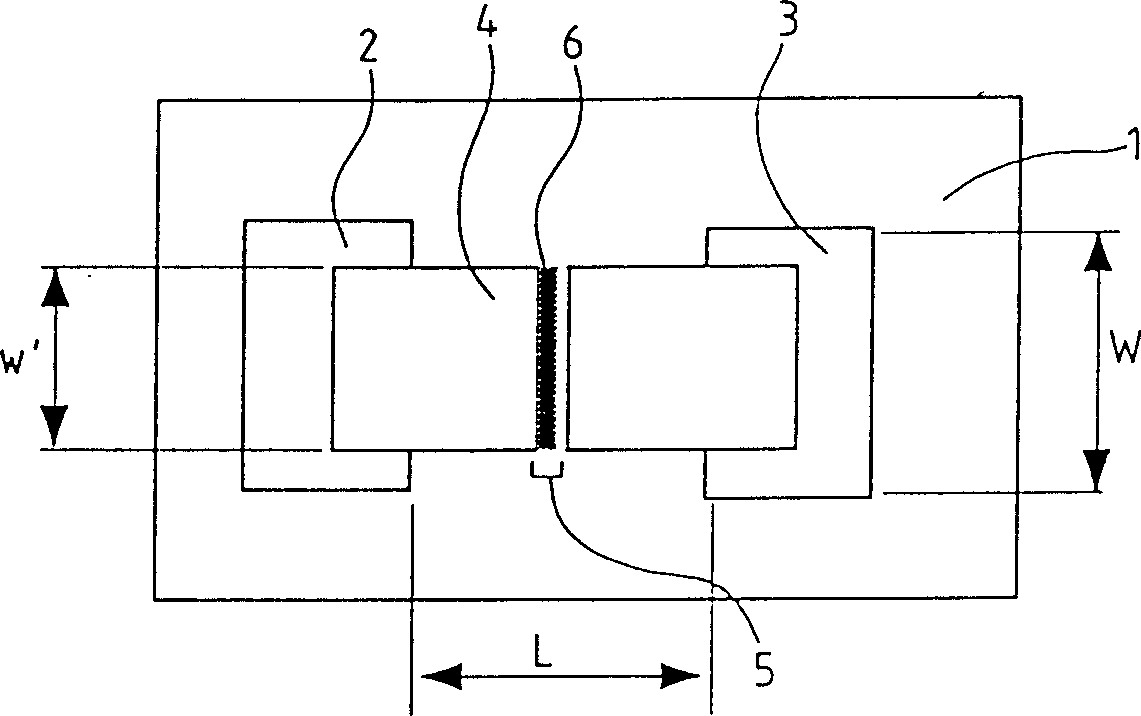

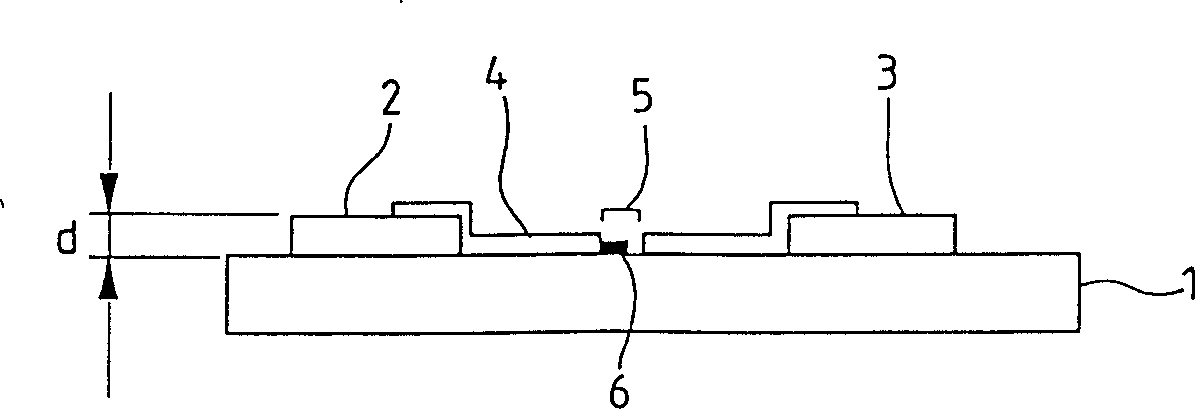

Electron emitting device, electron source and image display device and methods of manufacturing these devices

InactiveUS6992428B2Simple manufacturing methodStable production of uniformDischarge tube luminescnet screensLamp detailsCarbon filmElectron source

The present invention provides an electron emitting device including electrodes disposed with a space therebetween on a surface of a substrate, a carbon film disposed between the electrodes and connected to one of the electrodes, and a gap disposed between the carbon film and the other electrode. In the gap, the distance between the edge of the carbon film connected to one of the electrode and the edge of the other electrode at an upper position apart from the surface of the substrate is smaller than that at the surface of the substrate. The present invention also provides an electron source and an image display device each including the electron emitting device.

Owner:CANON KK

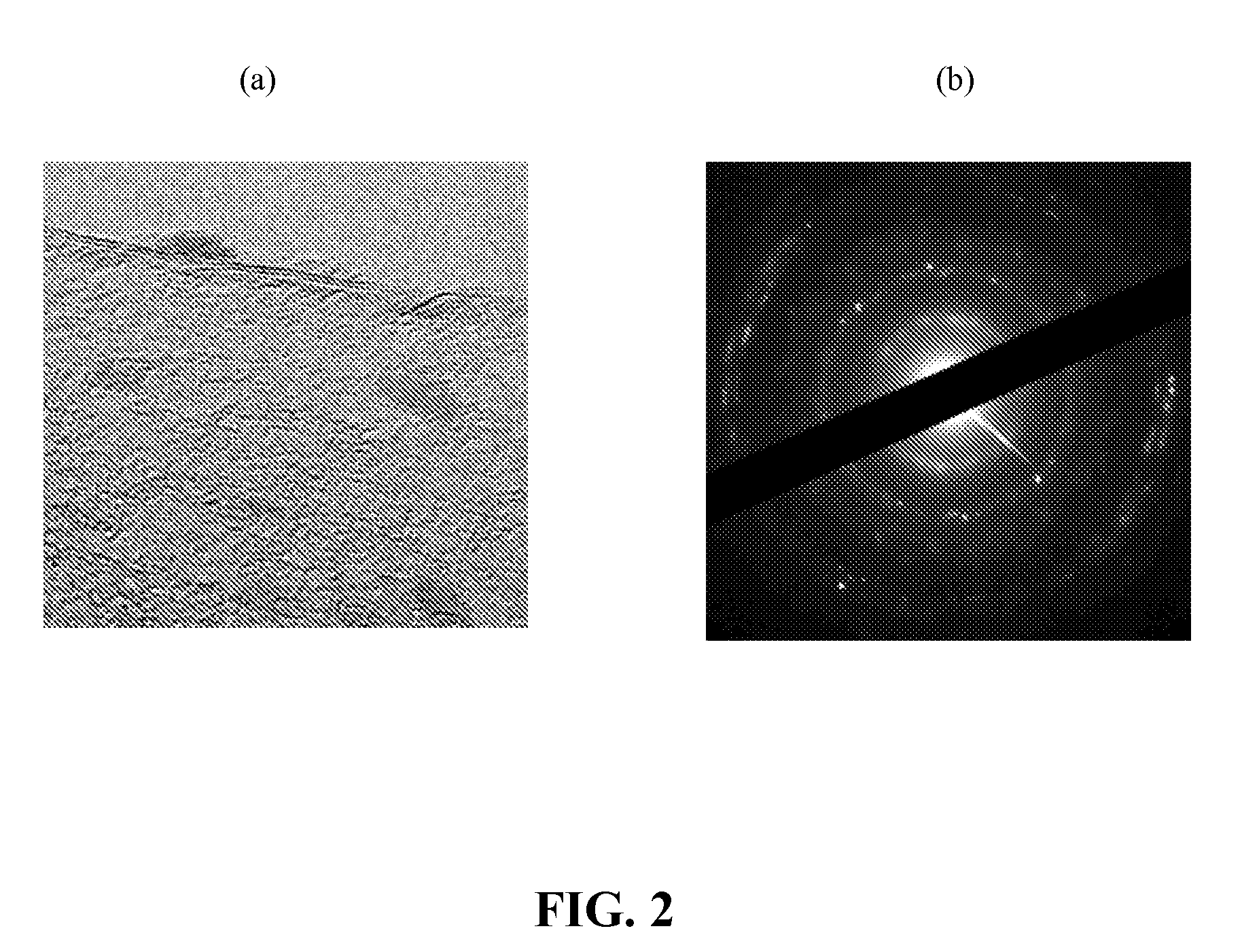

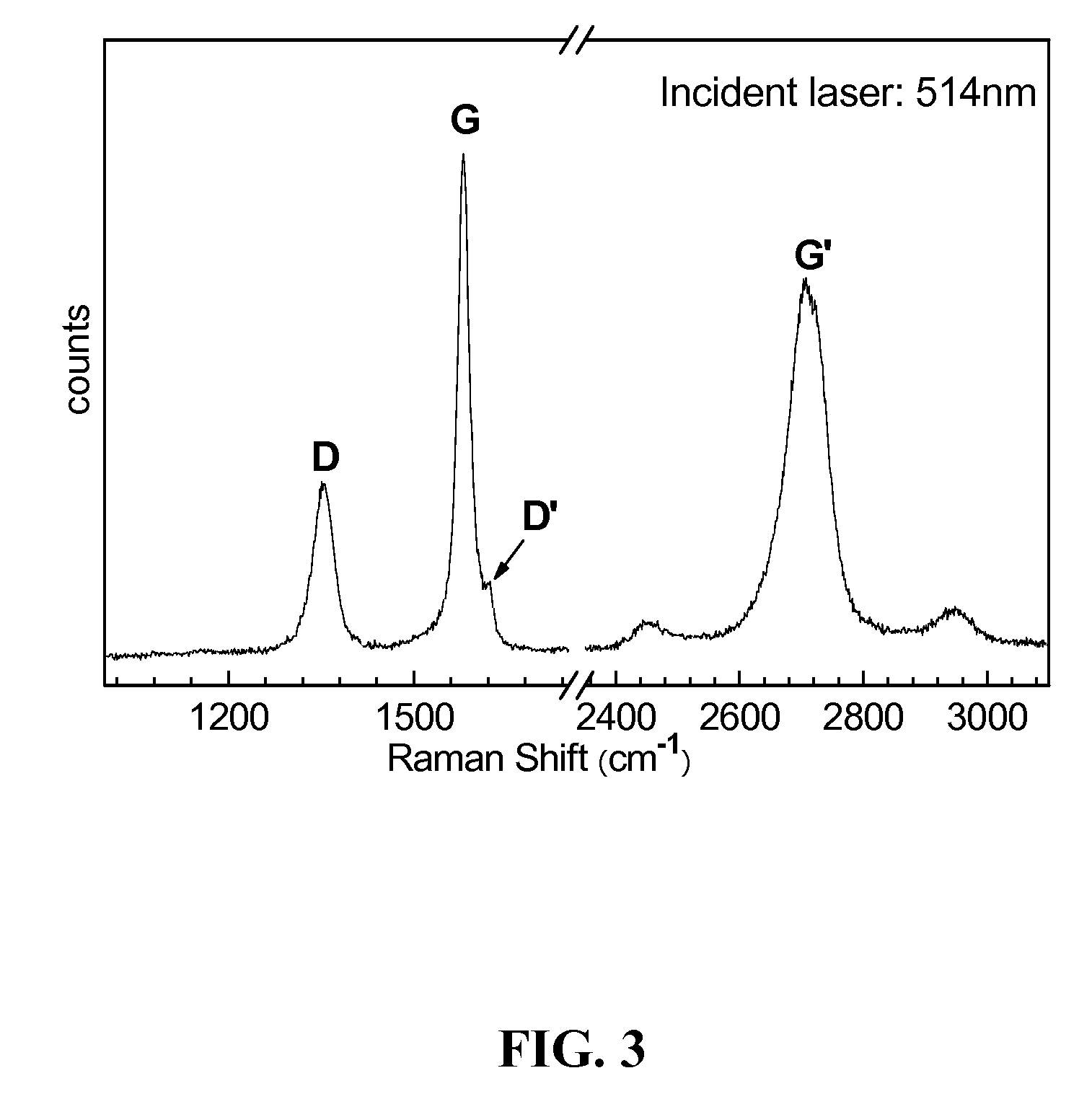

Carbon Nanoflake Compositions and Methods of Production

InactiveUS20090011241A1Enhanced vapor depositionMore vertical orientationMaterial nanotechnologySynthetic resin layered productsHigh concentrationProduct gas

Novel compositions and morphologies of carbon nanoflakes are described, as well as methods for making carbon nanoflakes using a radio frequency plasma enhanced chemical vapor deposition (RF-PECVD) process. Acetylene is used as a CVD source gas. By utilizing high concentrations of acetylene in the CVD source gas at relatively low temperatures, carbon nanoflake growth rate and robustness are improved, and the resulting carbon nanoflakes have enhanced height uniformity.

Owner:COLLEGE OF WILLIAM & MARY

Electronic device containing a carbon nanotube

InactiveUS20060033415A1Improve directivityImprove performanceMaterial nanotechnologyNanoinformaticsCarbon nanotubeMaterials science

An electronic device in which a substrate with a pair of electrodes is provided and a carbon nanotube is formed or arranged in relation to the electrodes.

Owner:CANON KK

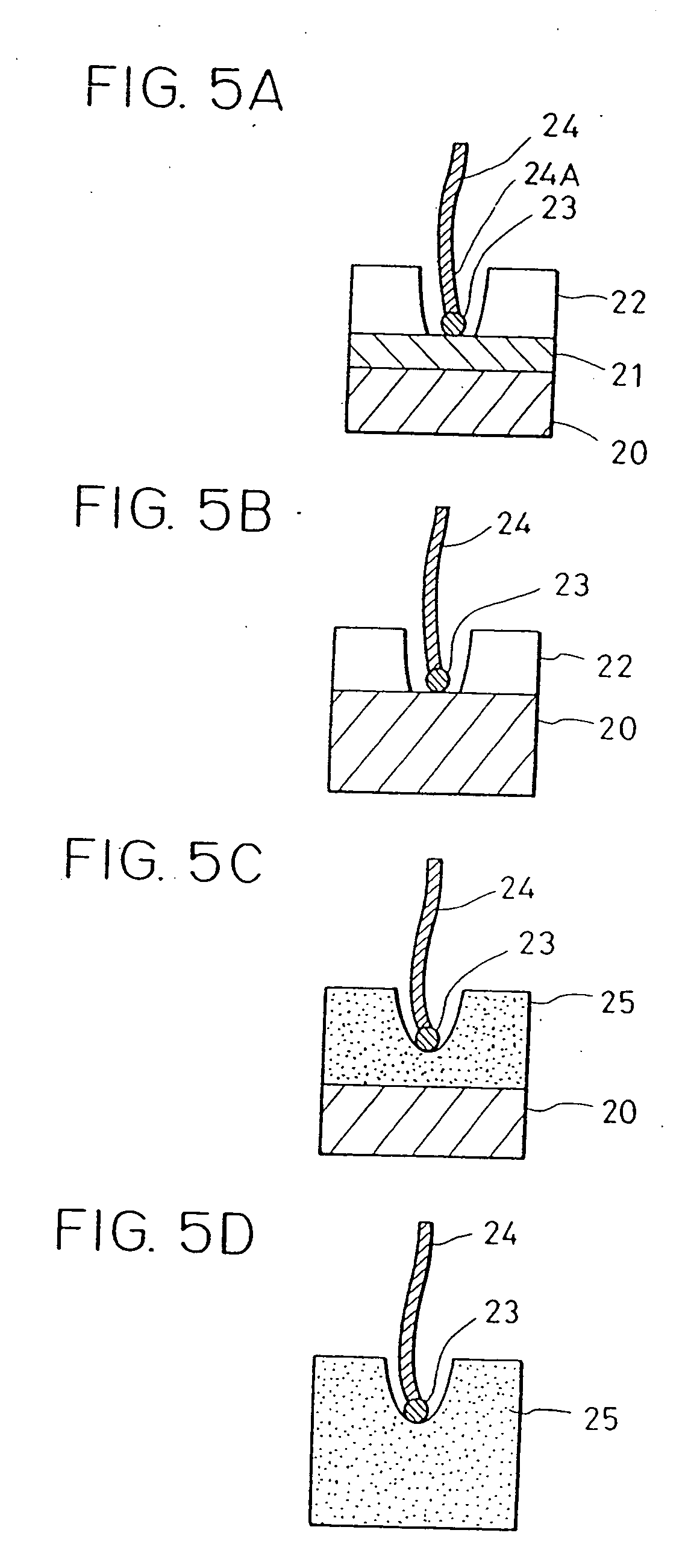

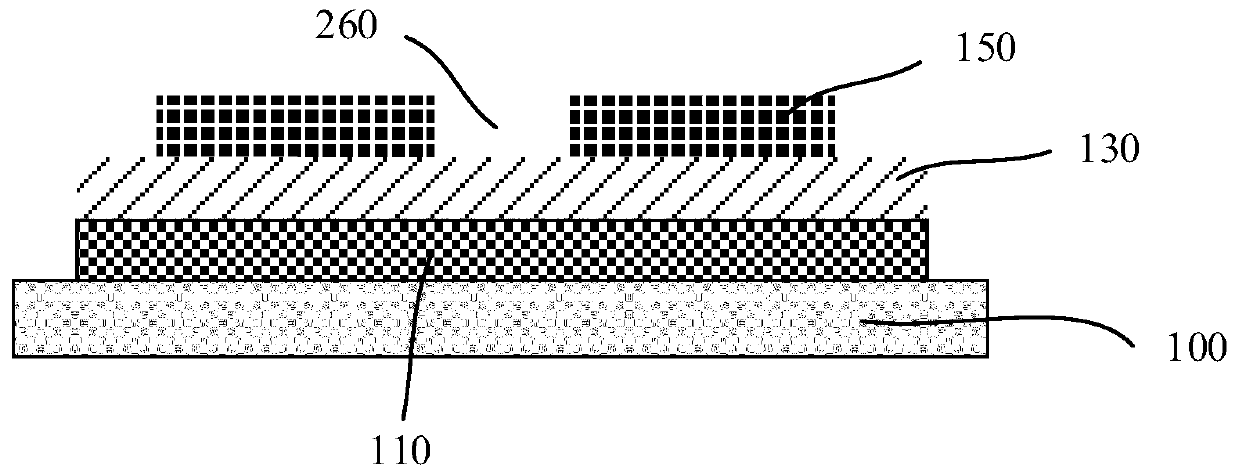

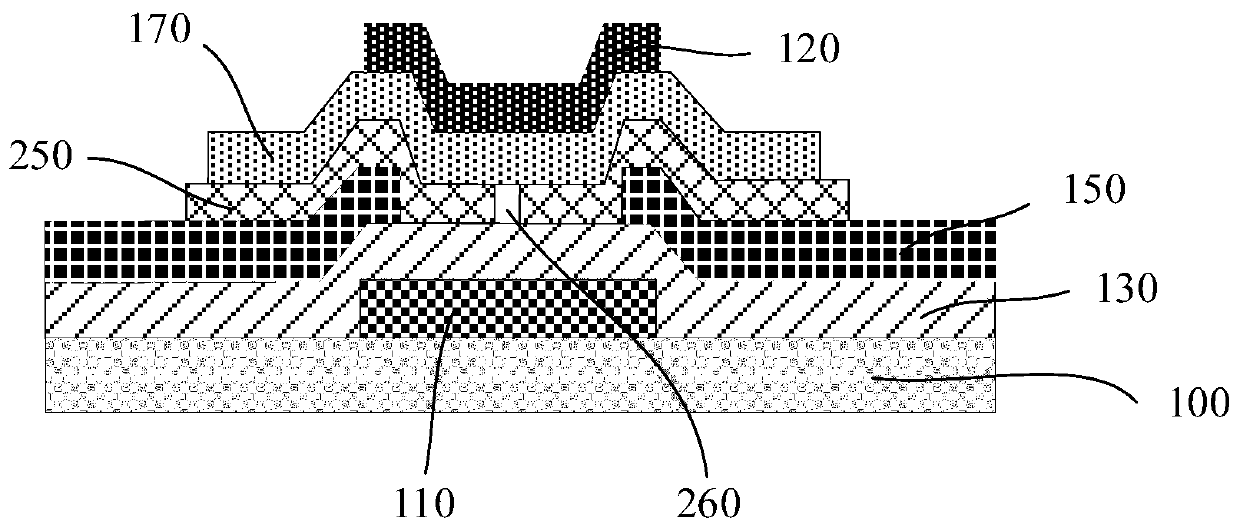

Method of manufacturing electron emission source

InactiveUS20060258254A1Enhanced electron emission capabilityIncrease surface densityCathode ray tubes/electron beam tubesNanoinformaticsCarbon nanotubeOptoelectronics

The step of forming an opening in an insulating layer to expose a carbon nanotube layer is performed using two types of dry etching different from each other in conditions. In the first-stage dry etching step, a hole is formed in the insulating layer to such a depth as not exposing the carbon nanotube layer. Thereafter, in the second-stage dry etching step, a bottom surface portion of the hole is removed, thus exposing an upper surface of the carbon nanotube layer. A method of manufacturing an electron emission source capable of improving performance of an electron emission portion is thus obtained.

Owner:MITSUBISHI ELECTRIC CORP

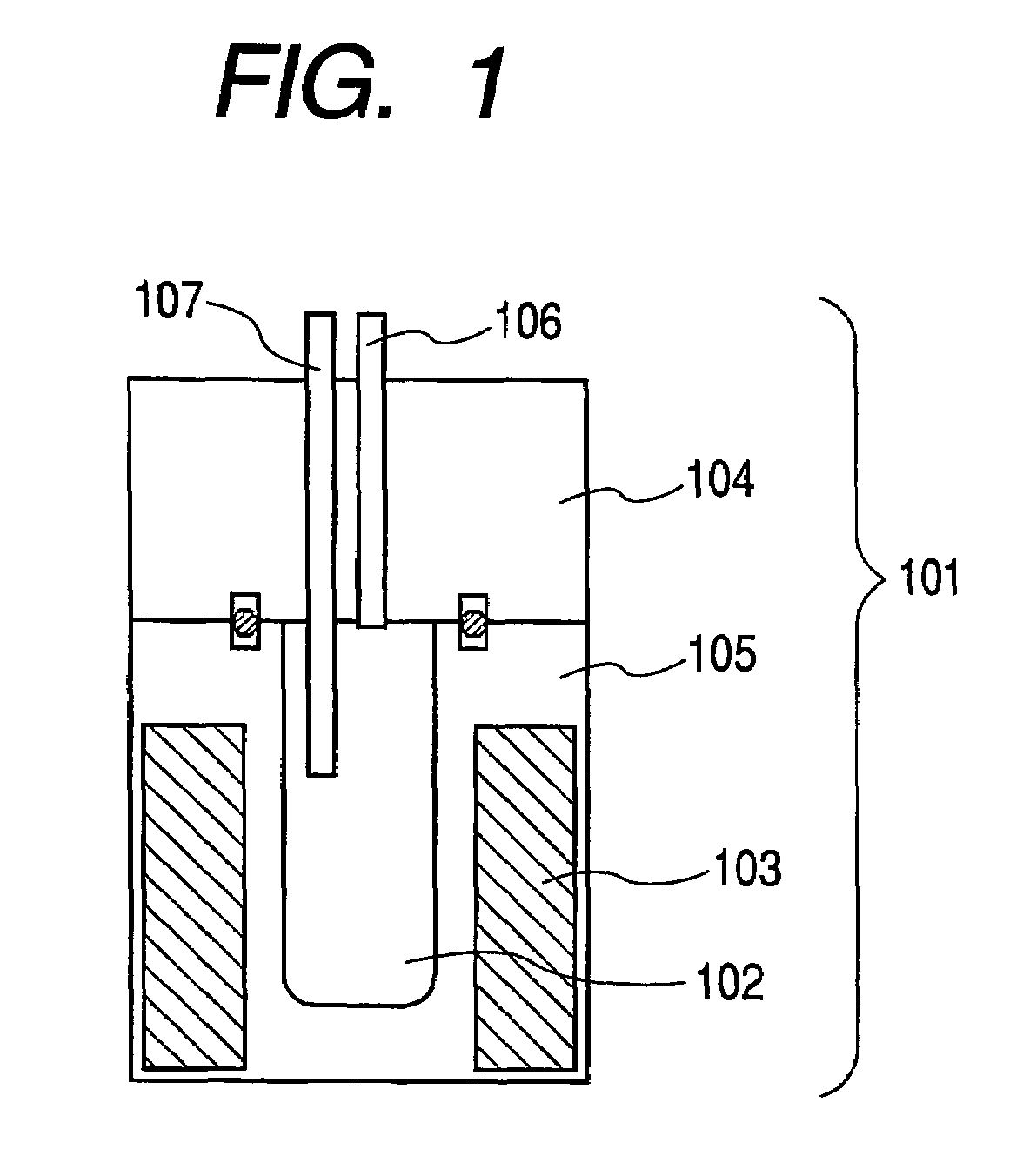

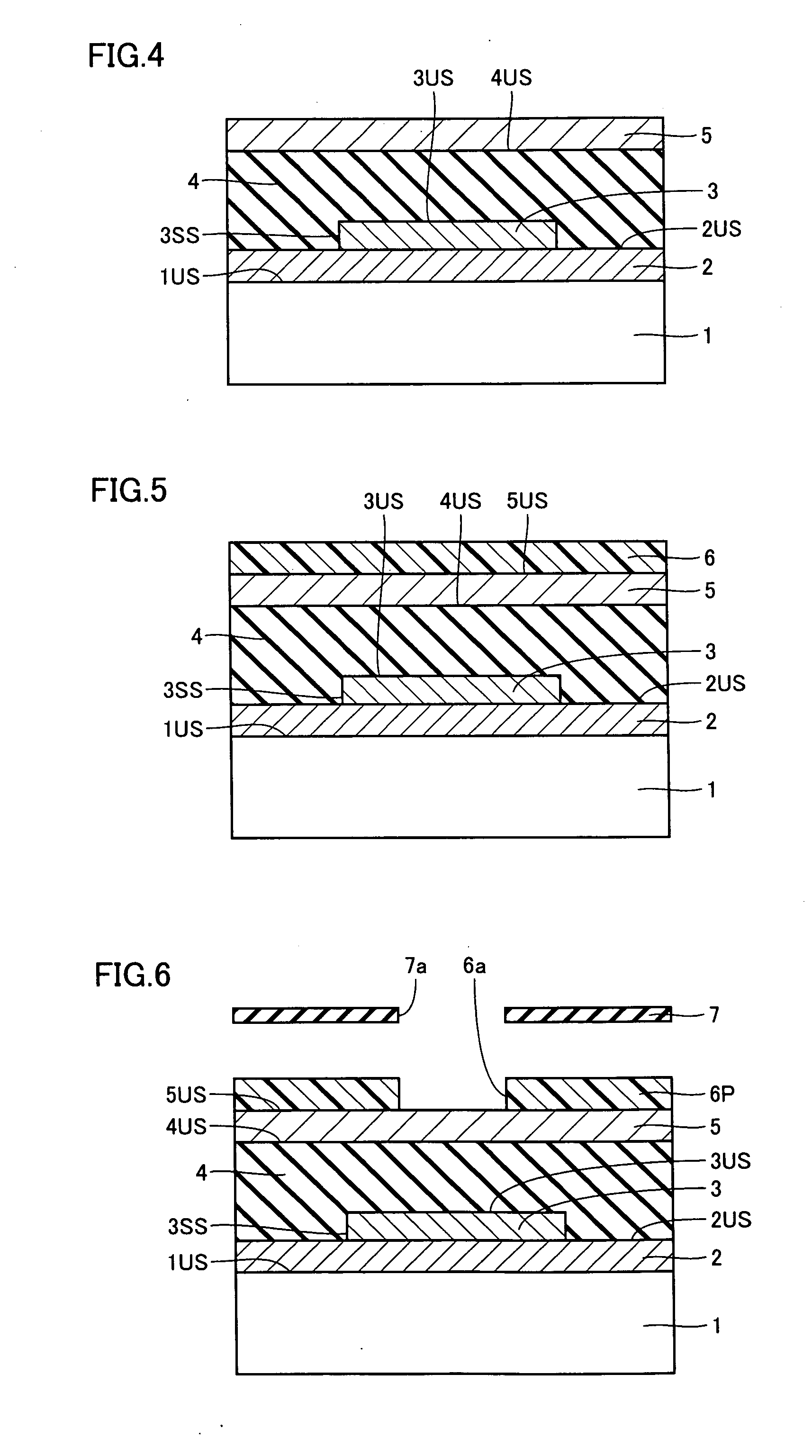

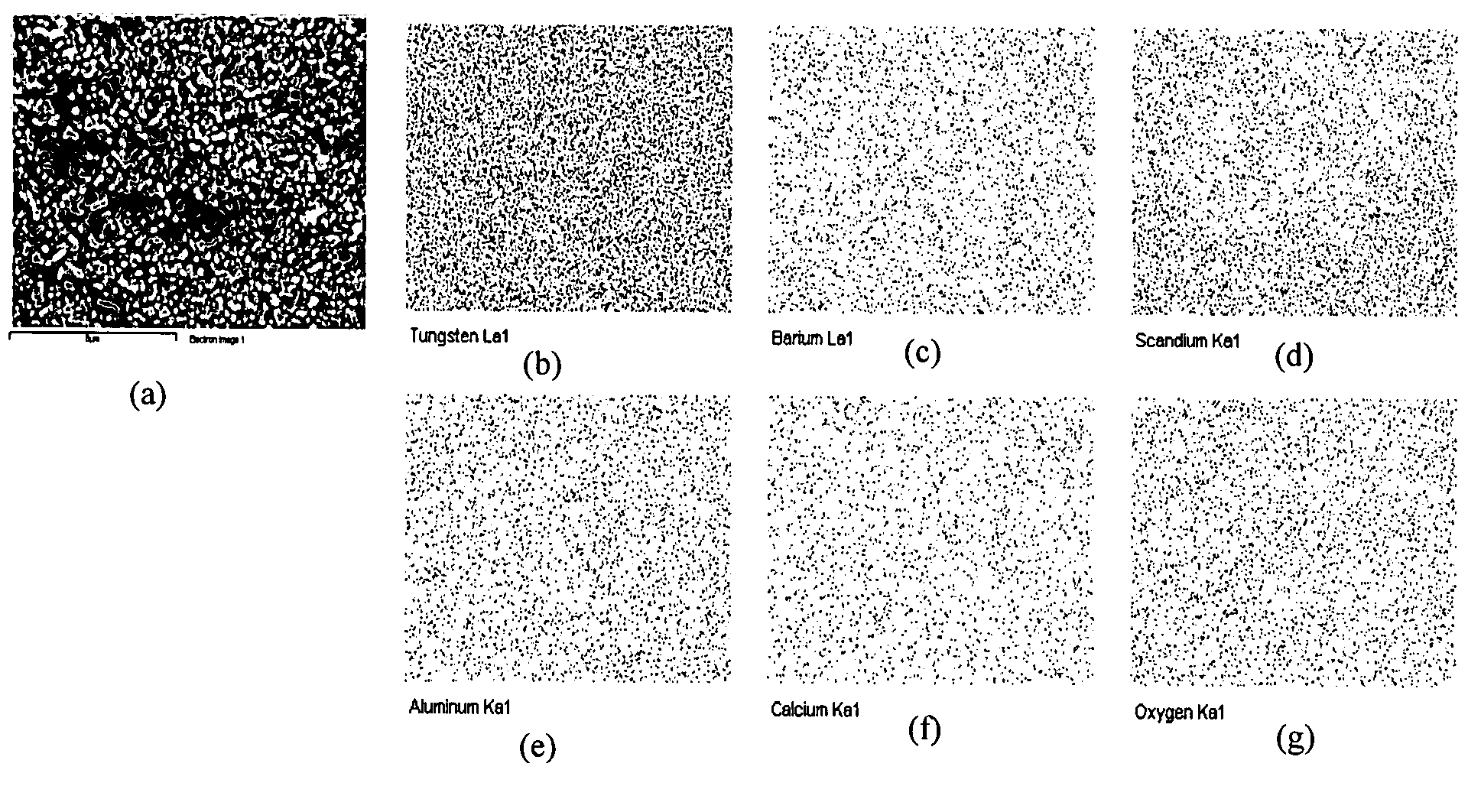

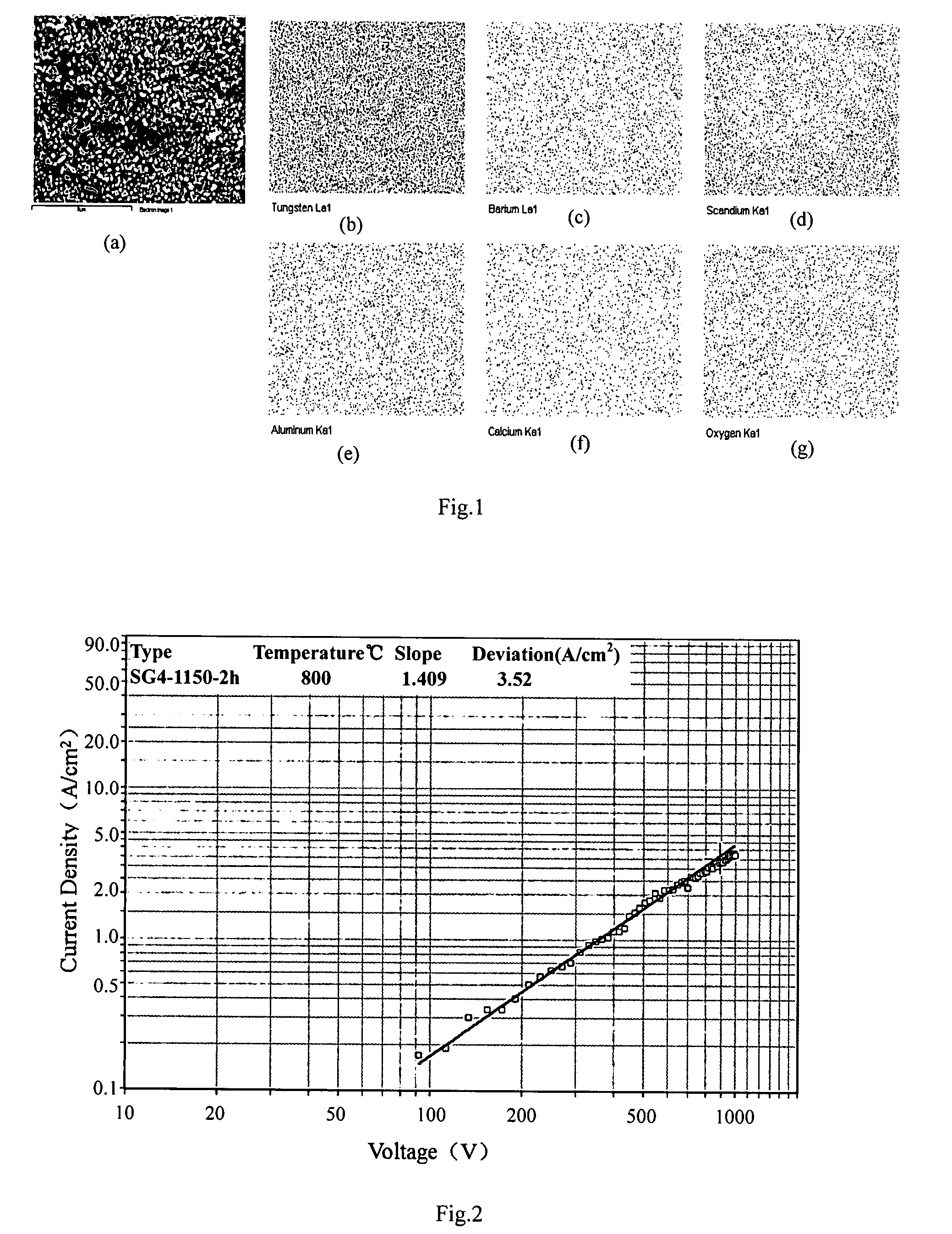

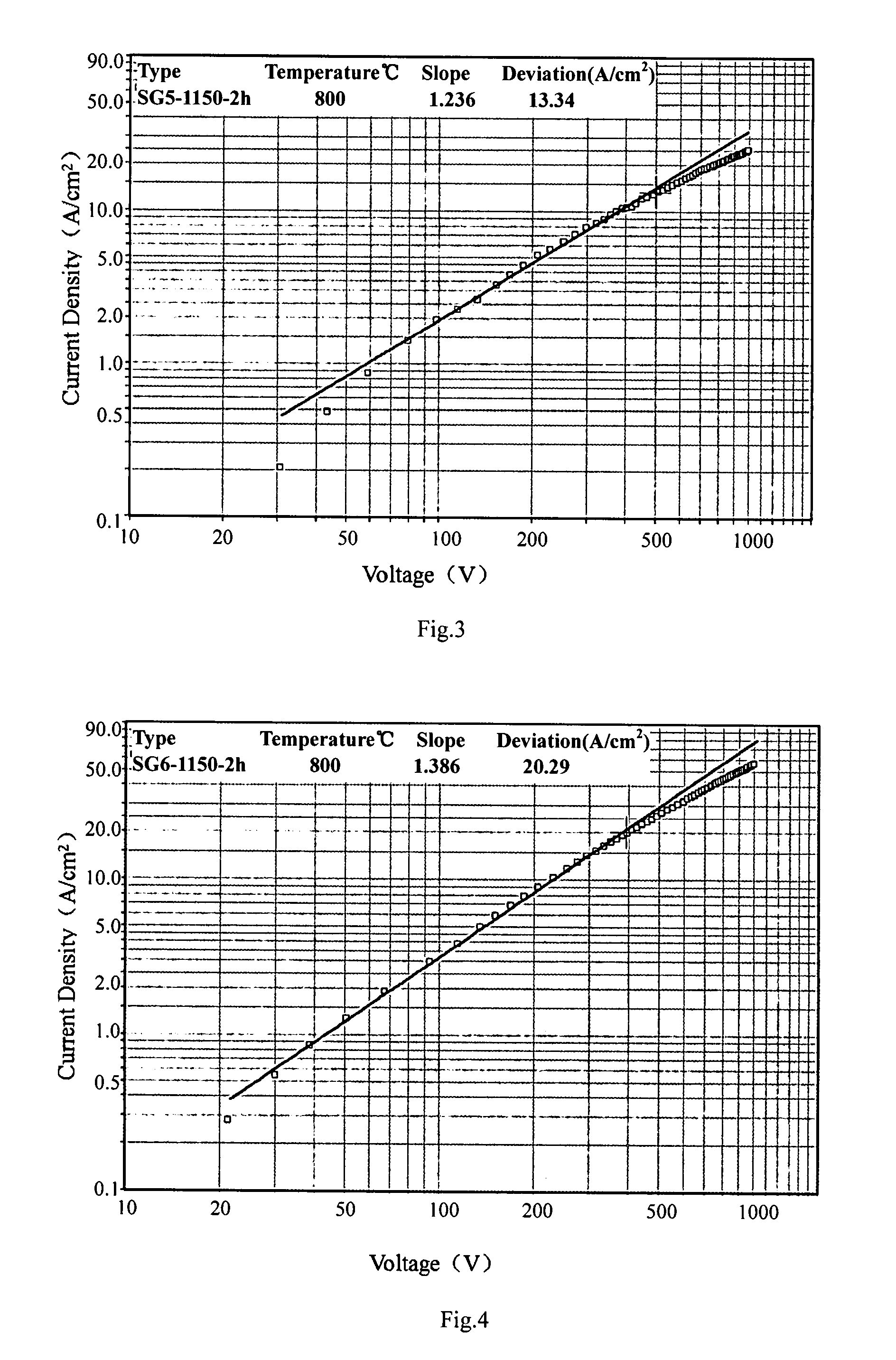

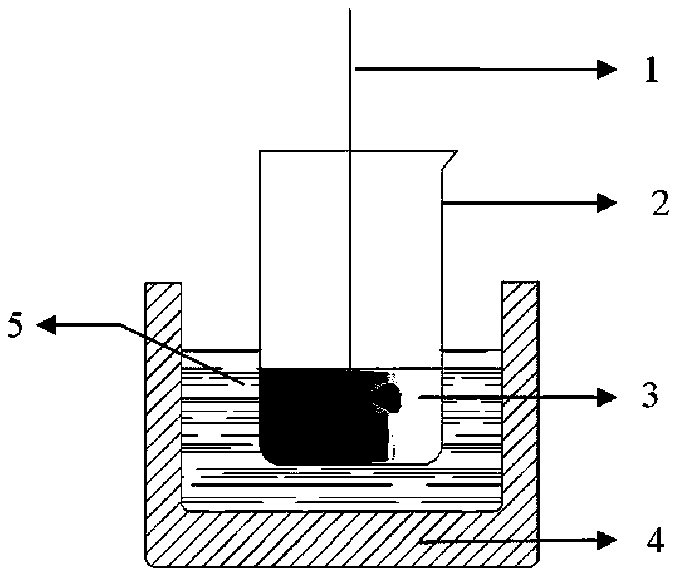

Method of manufacturing a pressed scandate dispenser cathode

InactiveUS7722804B2Improve launch performanceImprove electron emission performanceOther chemical processesMolybdeum compoundsCross-linkMetallurgy

In a method of manufacturing a pressed scandate dispenser cathode, firstly, scandium nitrate, barium nitrate, calcium nitrate, aluminum nitrate and ammonium metatungstate (AMT) are dissolved in de-ionized water, respectively, and then mixed with a solution of a cross-link agent such as citric acid and H2O2. After water bathing, the mixed aqueous solution turns into gel, and the powders are obtained after the gel calcination. Secondly, the calcined powders are reduced by hydrogen. Finally, the reduced powders are pressed into shapes and then sintered in the furnace with the atmosphere of hydrogen or by Spark Plasma Sintering (SPS 3.202-MK-V) in vacuum.

Owner:BEIJING UNIV OF TECH

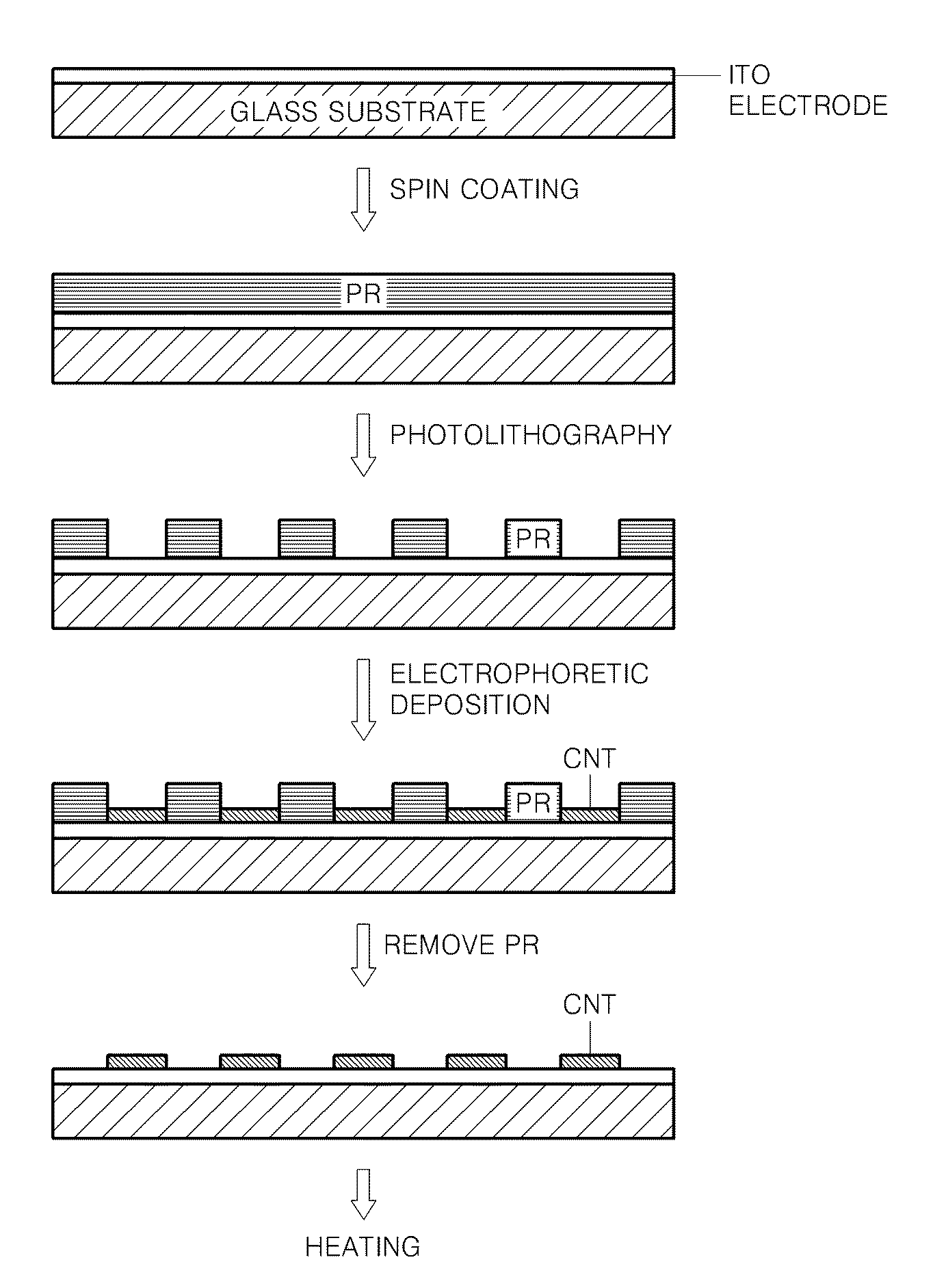

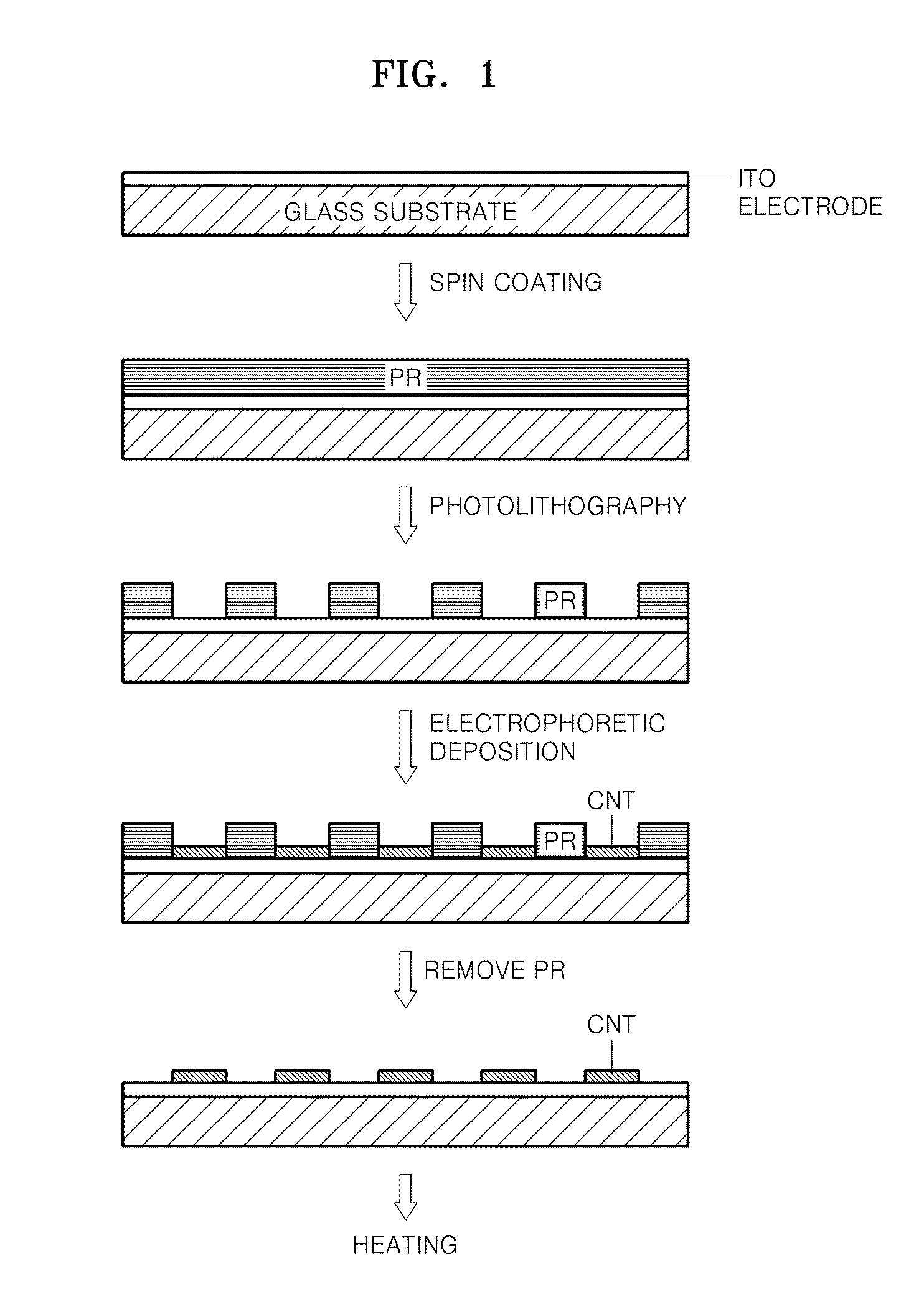

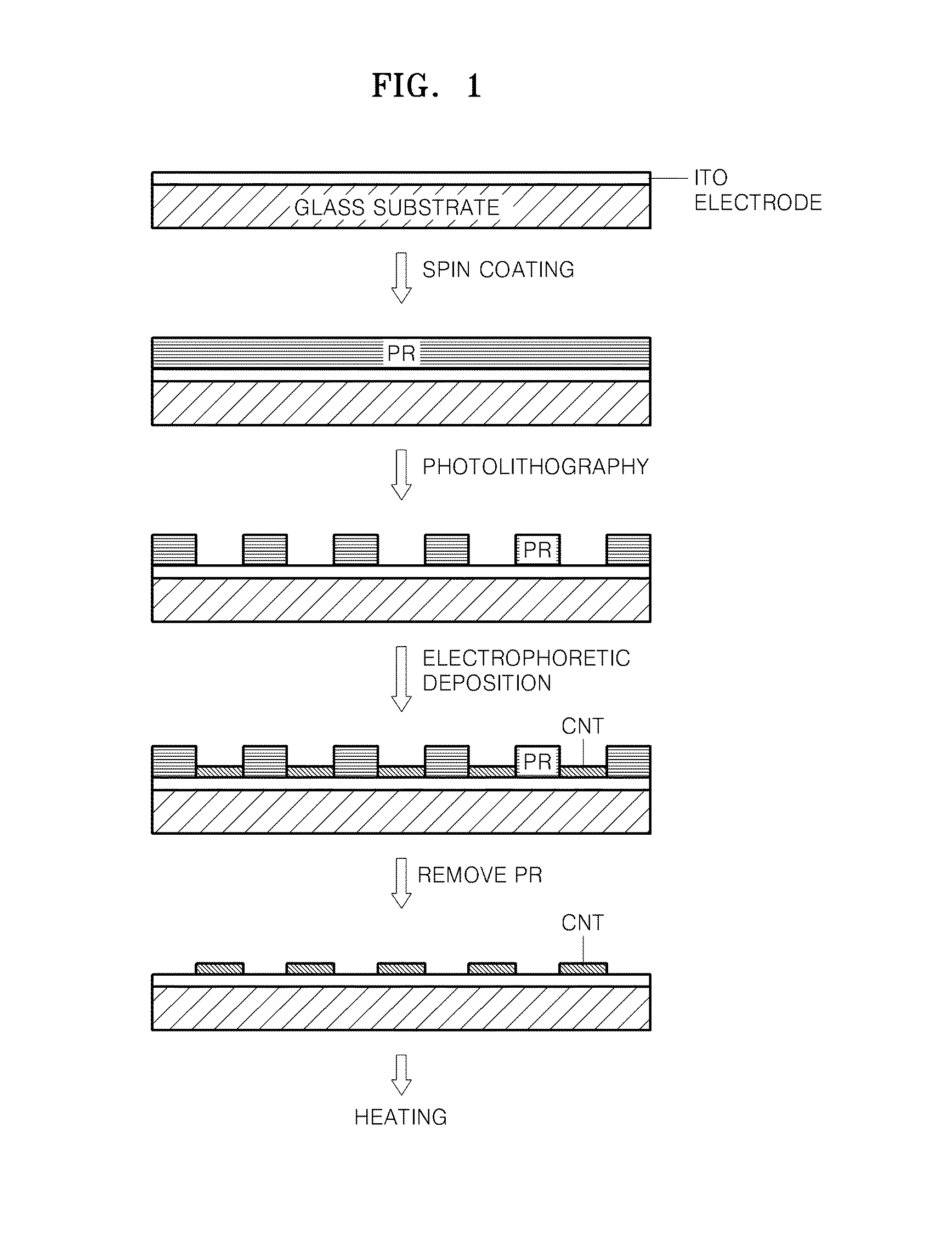

Method of preparing field electron emitter and field electron emission device including field electron emitter prepared by the method

ActiveUS20100007266A1Efficient preparationImprove electron emission performanceCathode ray/electron stream lampsVolume/mass flow measurementElectrophoresisCarbon nanotube

A method of preparing a field electron emitter includes preparing an aqueous solution including a carbon nanotube-nucleic acid composite, preparing a substrate to receive the carbon nanotube-nucleic acid composite, and electrophoresis-depositing the carbon nanotube-nucleic acid composite onto the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD +1

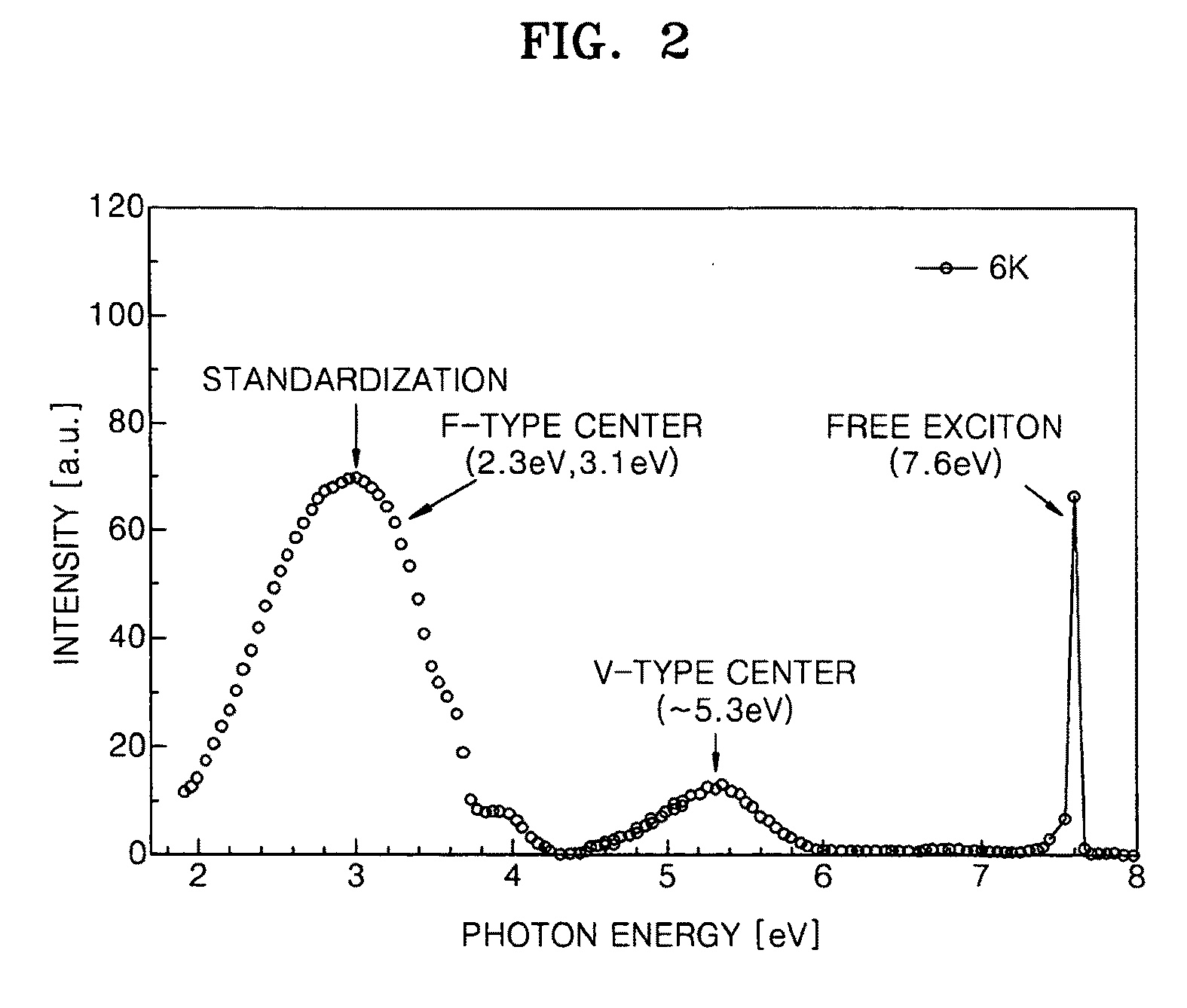

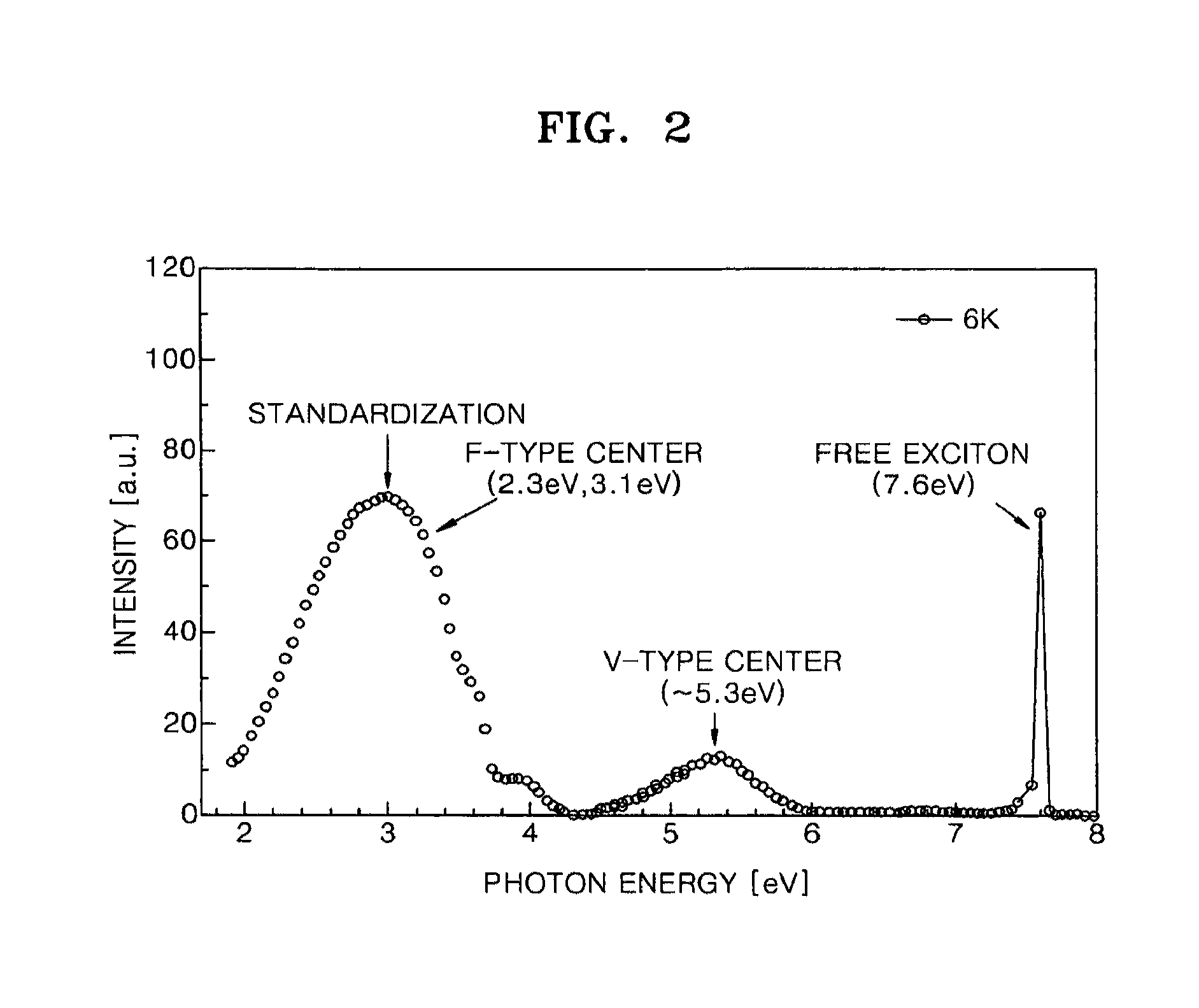

Protecting layer having magnesium oxide particles at its surface, method of preparing the same, and plasma display panel comprising the protecting layer

InactiveUS20090153019A1Improve electron emission performanceImprove reliabilityTube/lamp screens manufactureDischarge tube luminescnet screensDischarge efficiencyLow voltage

Provided are a protecting layer for a plasma display panel (PDP), a method of forming the same, and a PDP including the protecting layer. The protecting layer includes a magnesium oxide-containing layer having a surface to which magnesium oxide-containing particles having a magnesium vacancy-impurity center (VIC) are attached. The protecting layer is resistant to plasma ions and has excellent electron emission effects, and thus, a PDP including the protecting layer can be operated at low voltage with high discharge efficiency.

Owner:SAMSUNG SDI CO LTD

Method of preparing field electron emitter and field electron emission device including field electron emitter prepared by the method

ActiveUS8110976B2Efficient preparationImprove electron emission performanceCathode ray/electron stream lampsVolume/mass flow measurementElectrophoresisCarbon nanotube

A method of preparing a field electron emitter includes preparing an aqueous solution including a carbon nanotube-nucleic acid composite, preparing a substrate to receive the carbon nanotube-nucleic acid composite, and electrophoresis-depositing the carbon nanotube-nucleic acid composite onto the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Plasma display panel

InactiveUS20130015762A1High responsivityExcellent image display performanceAlternating current plasma display panelsCold-cathode tubesSecondary electronsElectricity

There is provided a PDP in which the structure of the periphery of a protective film is improved, excellent secondary electron emission property is exhibited, and improved efficiency and increased life can be expected. There is further provided a PDP in which occurrence of a discharge delay at the time of driving is prevented, and exhibition of high quality image display performance can be expected even in a high definition PDP that is driven at a high speed. Specifically, a crystalline film containing Sr in CeO2 in a concentration of 11.8 mol % to 49.4 mol % inclusive is formed on the surface of dielectric layer on the discharge space side as surface layer (protective film) having a thickness of about 1 μm. High γ fine particles having secondary electron emission property higher than those of protective film are arranged thereon.

Owner:PANASONIC CORP

Method of manufacturing electron emission source

InactiveUS7399214B2Enhanced electron emission capabilityIncrease surface densityCathode ray tubes/electron beam tubesNanoinformaticsCarbon nanotubeOptoelectronics

The step of forming an opening in an insulating layer to expose a carbon nanotube layer is performed using two types of dry etching different from each other in conditions. In the first-stage dry etching step, a hole is formed in the insulating layer to such a depth as not exposing the carbon nanotube layer. Thereafter, in the second-stage dry etching step, a bottom surface portion of the hole is removed, thus exposing an upper surface of the carbon nanotube layer. A method of manufacturing an electron emission source capable of improving performance of an electron emission portion is thus obtained.

Owner:MITSUBISHI ELECTRIC CORP

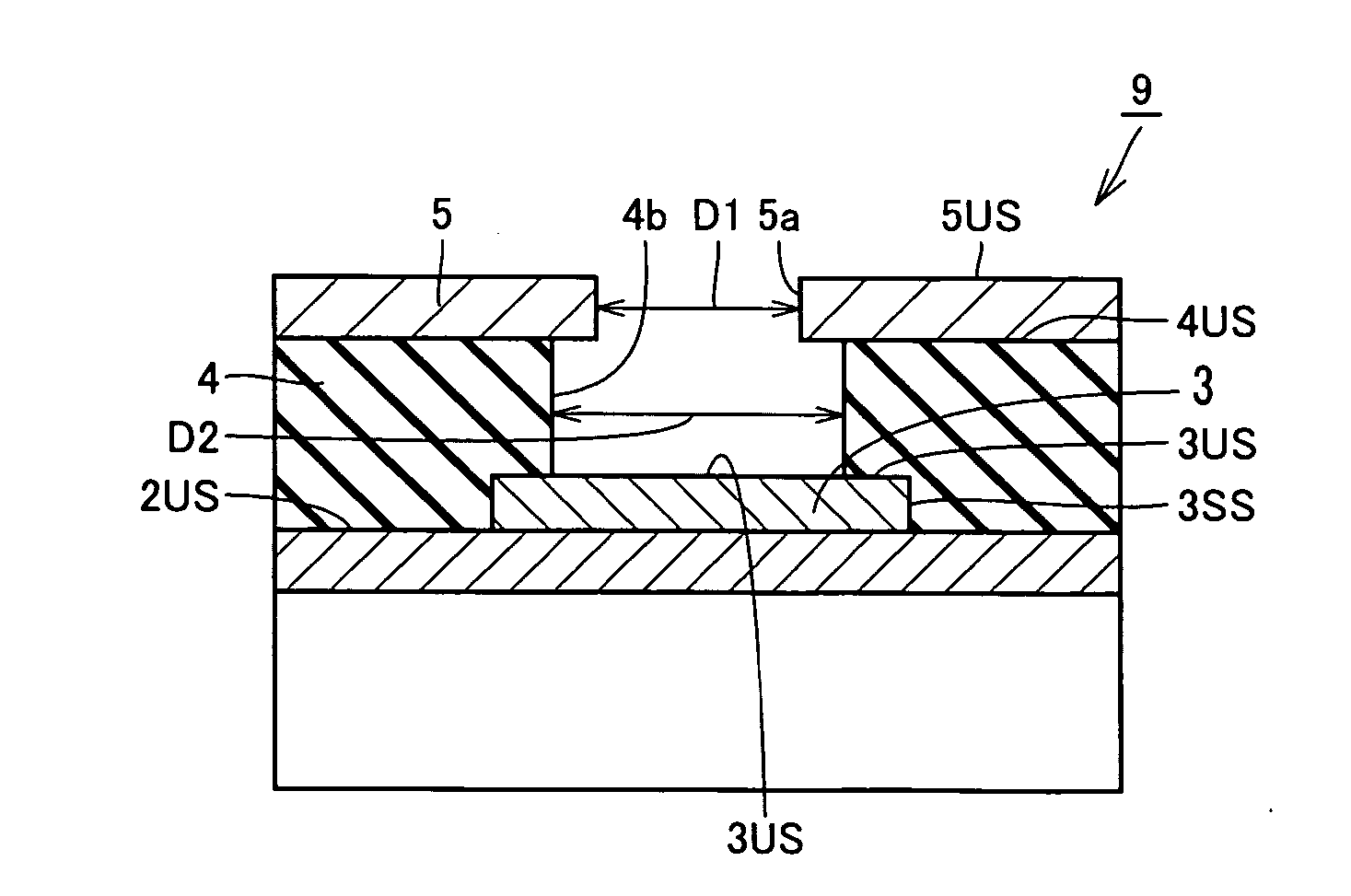

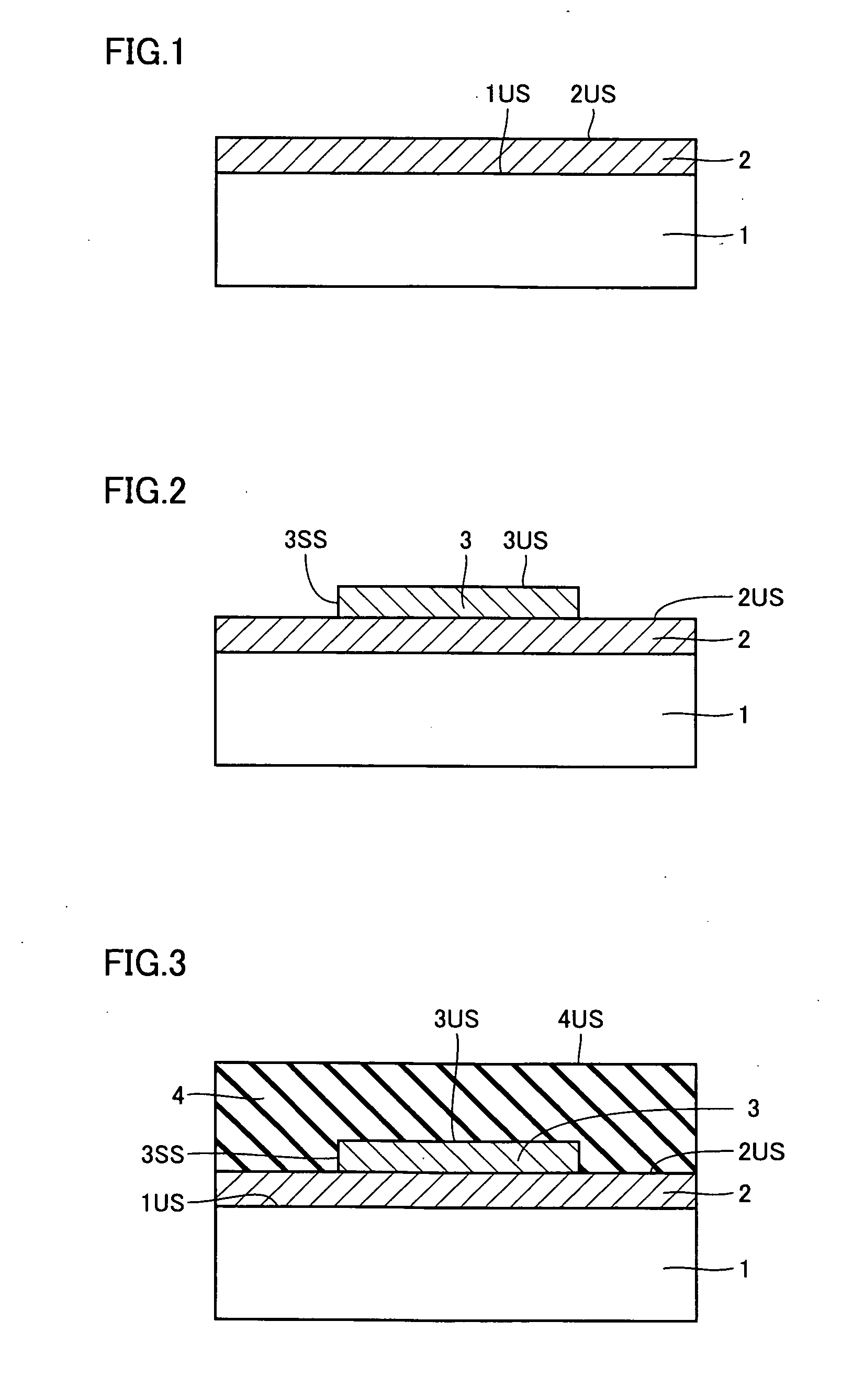

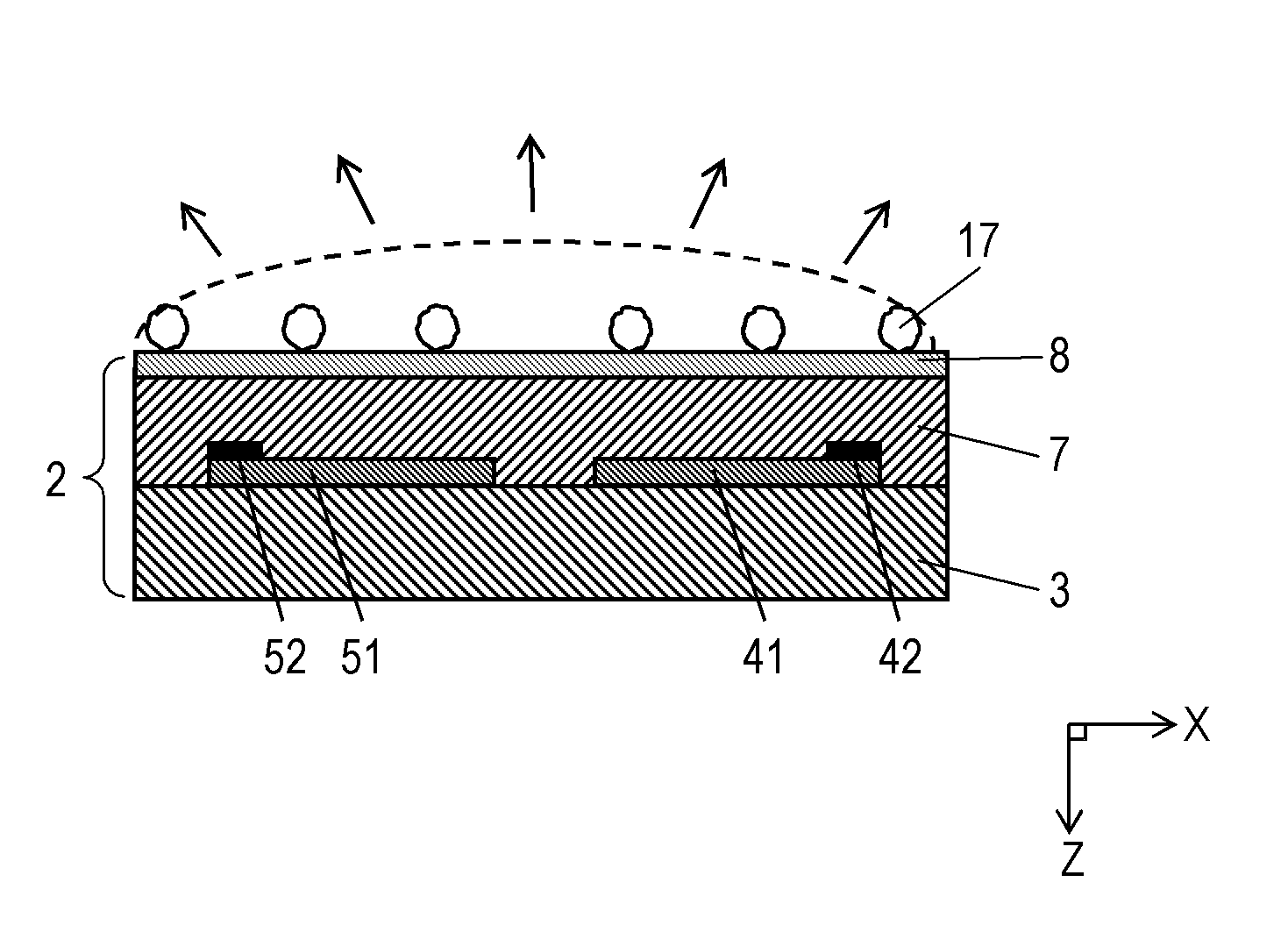

Method for producing plasma display panel

InactiveUS8317563B2Pre-baked substrate is more rapidly loweredDamage to the prebaked substrate caused by rapid cooling is preventedTube/lamp screens manufactureStatic indicating devicesCooking & bakingEngineering

Provided is a manufacturing method that allows even a PDP having high-definition cells to exhibit excellent image display performance with reduced power consumption by effectively preventing impurities from adhering to the protective layer. Specifically, in a pre-baking step, a back substrate 9 is baked at a pre-baking temperature. Here, a highest pre-baking temperature is set to be lower than a softening point of a sealing material. The back substrate 9 is superposed on a front substrate 2. Then, a sealing step is performed in a sealing atmosphere prepared by mixing a predetermined amount of a reducing gas with a non-oxidizing gas. The above enables the impurities attributed to organic components due to a sealing material paste to remain as low molecular components, whereby the impurities are evacuated and removed in an evacuating step performed after the sealing step. This prevents adherence of the impurities to the protective layer 8.

Owner:PANASONIC CORP

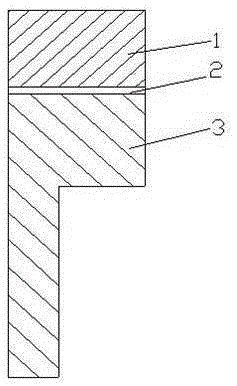

Double-gate vacuum field emission triode structure and preparation method thereof

ActiveCN110246889AEnhanced grid voltage modulation capabilityImprove electron emission performanceSemiconductor devicesAtmospheric airBottom gate

The invention discloses a double-gate vacuum field emission triode structure and a preparation method thereof, and belongs to the field of information technology and the field of vacuum microelectronic devices. The triode structure includes a bottom gate, a bottom gate insulating layer, source and drain electrodes, a conductive film, a top gate insulating layer, a top gate, and a nano-scale vacuum channel. The double-gate vacuum field emission triode can realize the double-gate control of a device current, enhances the gate voltage control capability and the modulation flexibility of the device, and achieve good electron emission performance. The top of the vacuum channel is covered with the top gate insulating layer and the top gate such that the collision scattering effect of atmospheric particles on electrons is reduced during electron transport. Thus, the device can work directly in the atmospheric environment and has good electron transport performance. The vacuum channel prepared by the method has a nano-scale size and good uniformity, and contributes to the large-scale and low-cost preparation of the device.

Owner:XI AN JIAOTONG UNIV

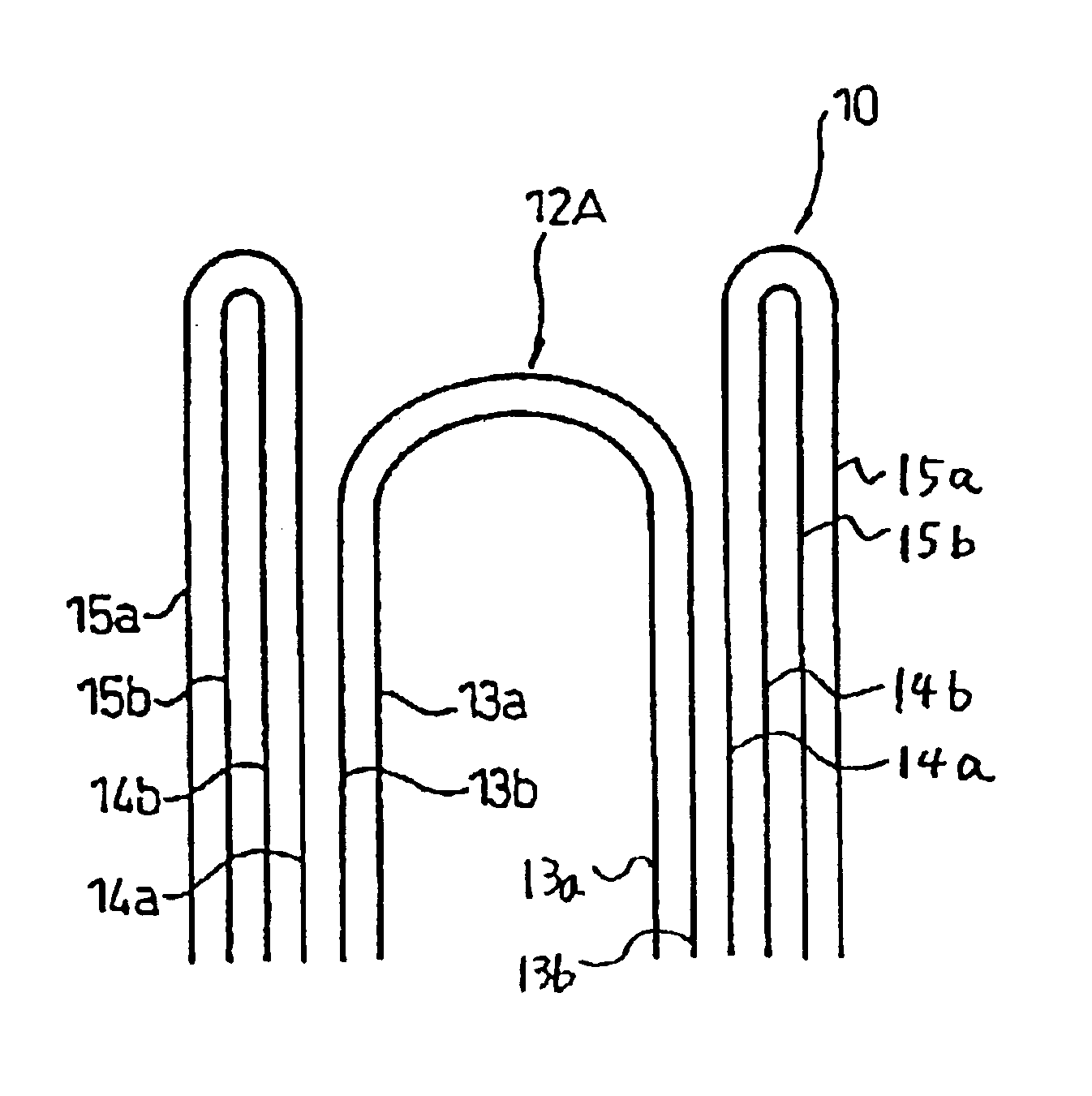

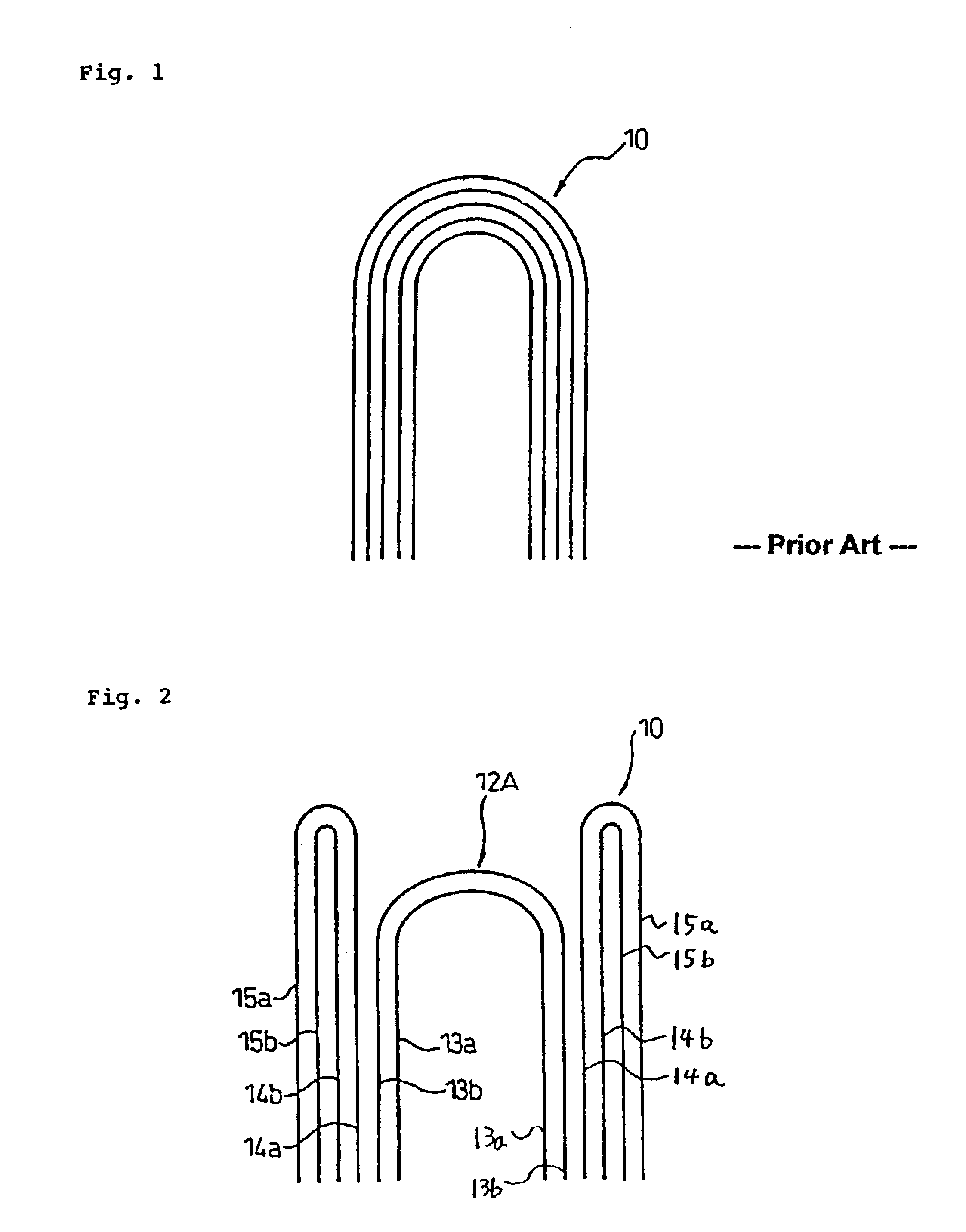

Fine carbon fiber and method for producing the same

InactiveUS6998171B2Improve conductivityImprove adhesionMaterial nanotechnologyWood working apparatusFiberCarbon fibers

A fine carbon fiber having a multilayer structure having stacked cylindrical carbon sheets and a center axis having a hollow structure. The fine carbon fiber has an outer diameter of 2 to 300 nm and an aspect ratio of 10 to 15,000, and at least one cylindrical carbon sheet layer among the multiple layers is folded at an end part of the carbon fiber and continued to another cylindrical carbon sheet. The folded and continued cylindrical carbon sheets form a cylindrical structure opened at the end part.

Owner:SHOWA DENKO KK

Method for manufacturing high-dispersion ultrafine molybdenum-based powder

Owner:UNIV OF SCI & TECH BEIJING

Electron-emitting device, electron source and image-forming apparatus as well as method of manufacturing the same

InactiveCN1165937CImprove electron emission performanceCathode ray tubes/electron beam tubesDischarge tube cold cathodesElectron sourceHydrogen atom

Owner:CANON KK

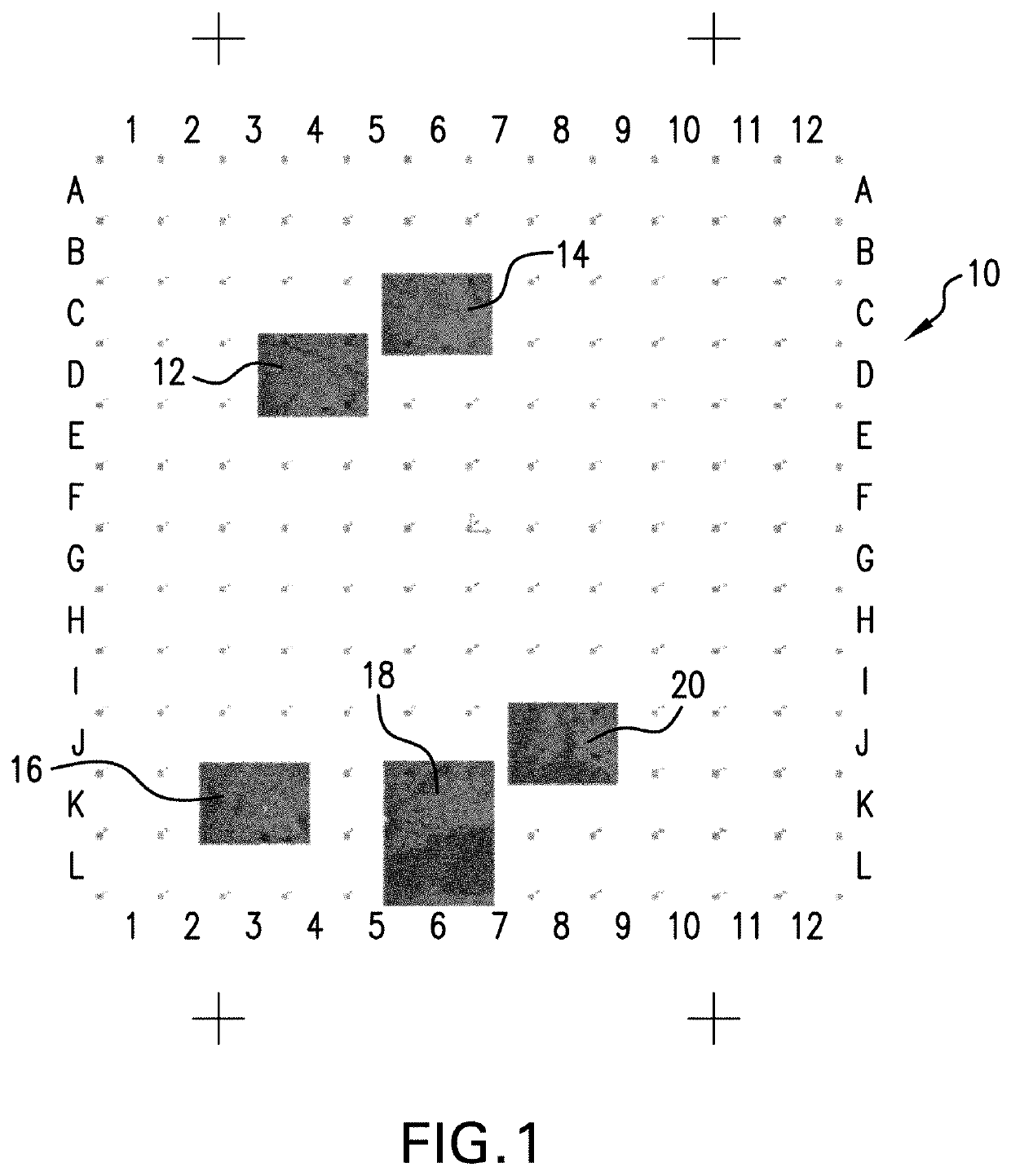

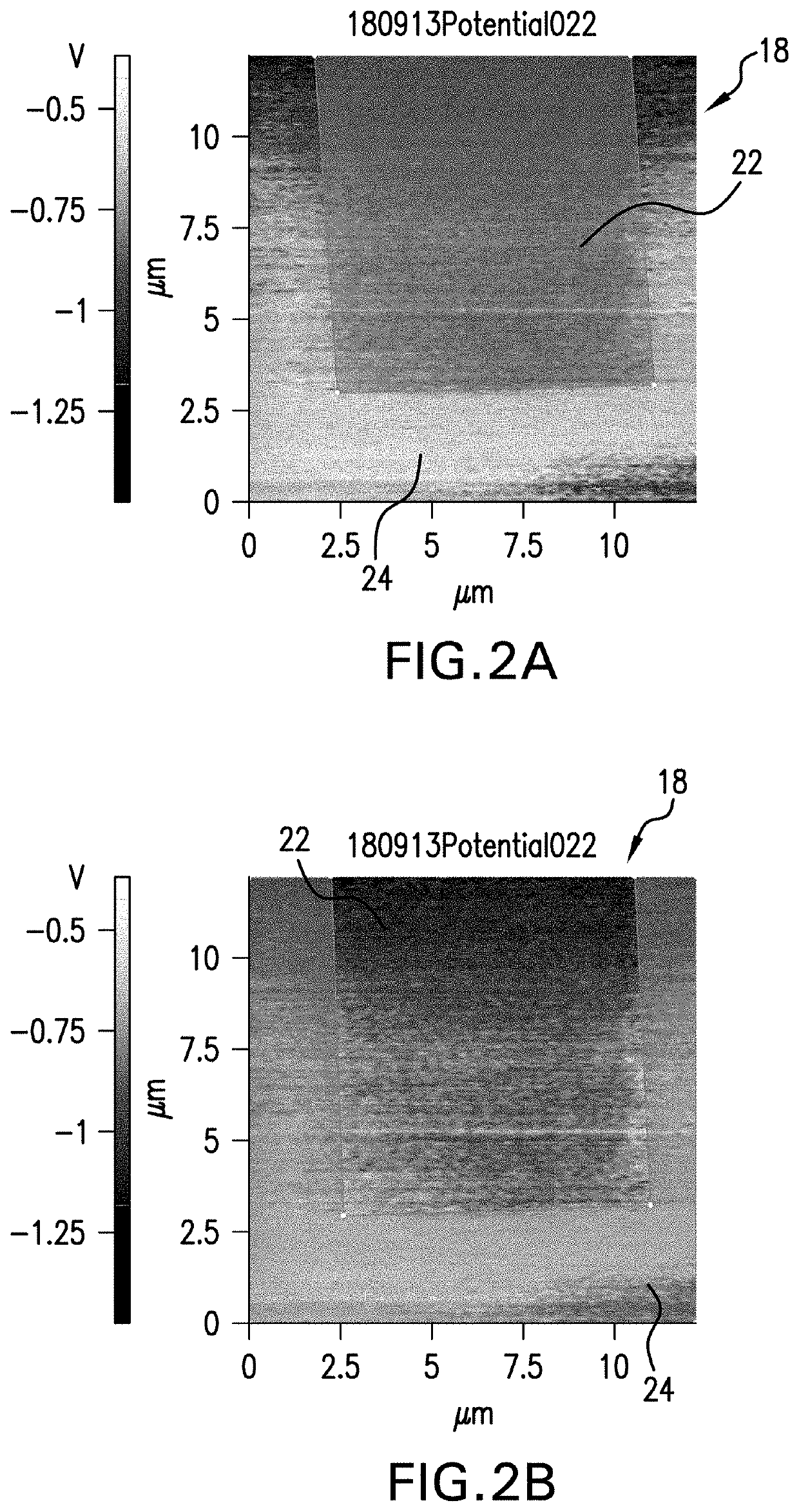

Low work function materials

ActiveUS20200263322A1Improve electron emission performanceLower work functionMaterial nanotechnologyPolycrystalline material growthMicroelectronicsElectronics

Reduced and low work function materials capable of optimizing electron emission performance in a range of vacuum and nanoscale electronic devices and processes and a method for reducing work function and producing reduced and low work function materials are described. The reduced and low work function materials advantageously may be made from single crystal materials, preferably metals, and from amorphous materials with optimal thicknesses for the materials. A surface geometry is created that may significantly reduce work function and produce a reduced or low work function for the material. It is anticipated that low and ultra-low work function materials may be produced by the present invention and that these materials will have particular utility in the optimization of electron emissions in a wide range of vacuum microelectronics and other nanoscale electronics and processes.

Owner:BOREALIS TECH LTD

Graphite composite cathode and preparation method thereof

ActiveCN105645982BImprove electron emission performanceIncrease the field enhancement factorFiberCarbon fibers

The invention discloses a graphite composite cathode and a manufacturing method thereof. The graphite composite cathode is manufactured by taking graphite powder and / or carbon black powder as a matrix material, taking carbon fibers and / or SiC crystal whiskers as a doping material, and taking mid-temperature pitch as an adhesive. The manufacturing method comprises: (1) matching of a cathode material; (2) preparation of a mixed powdery material; (3) mixing and kneading of the mixed powdery material; (4) forming of the mixed powdery material; (5) impregnating and roasting of a blank; and (6) processing of the cathode. The graphite composite cathode is large in field enhancement factor and good in electron emission performance. The manufacturing method is simple and convenient, and is low in cost.

Owner:NAT UNIV OF DEFENSE TECH

Protecting layer having magnesium oxide particles at its surface, method of preparing the same, and plasma display panel comprising the protecting layer

InactiveUS8227987B2Avoid damageImprove launch performanceTube/lamp screens manufactureDischarge tube luminescnet screensDischarge efficiencyLow voltage

Provided are a protecting layer for a plasma display panel (PDP), a method of forming the same, and a PDP including the protecting layer. The protecting layer includes a magnesium oxide-containing layer having a surface to which magnesium oxide-containing particles having a magnesium vacancy-impurity center (VIC) are attached. The protecting layer is resistant to plasma ions and has excellent electron emission effects, and thus, a PDP including the protecting layer can be operated at low voltage with high discharge efficiency.

Owner:SAMSUNG SDI CO LTD

Low work function materials

ActiveUS11486056B2Improve electron emission performanceLower work functionMaterial nanotechnologyPolycrystalline material growthSingle crystalCondensed matter physics

Owner:BOREALIS TECH LTD

Carbon nanoballoon structure and method for preparation thereof, and electron emitter

InactiveUS7754177B2Simple structureImprove electron emission performanceMaterial nanotechnologyCarbon compoundsCarbon nanosphereGraphite

A hollow carbon nanoballoon structure having a relatively large closed space, and a method of producing a carbon nanoballoon structure capable of easily and stably producing such a structure. The carbon nanoballoon structure is obtained by heating soot prepared by an arc discharge using carbon electrodes, soot prepared by vaporizing carbon by laser irradiation, or carbon black having a specific surface area of 1000 m2 / g or more and a primary particle diameter of 20 nm or more at a high temperature in an inert gas atmosphere, and includes graphite sheets linked to form a curved surface.

Owner:TAKIKAWA HIROFUMI +2

Nucleus-shell cathode emission material for fluorescent tube and its making method

InactiveCN101079363BGranularity controllableEasy to operateDischarge tube solid thermionic cathodesThermionic cathode manufacturePowder methodRare earth

The invention discloses a core-case cathode transmitting material of fluorescent lamp, which is characterized by the following: adopting (BaSrCa)CO3 powder as core and carbonic acid rare earth as casethrough solid powder method; setting the central grain size of core at 5-10um; increasing the using lift of fluorescent lamp and reducing the light decay of fluorescent lamp greatly; improving the product quality of the fluorescent lamp with little grain size for cathode transmitting material, large specific surface area and high activity.

Owner:CENT SOUTH UNIV

Distributor contact

InactiveCN105390303ASimple structureEasy to operateContact materialsContact surface shape/structureTungstenCorrosion

The invention discloses a distributor contact which is characterized in that the distributor contact is composed of three different metal layers, namely, a tungsten metal layer, a copper metal layer and an iron metal layer; the surface of the tungsten metal layer is provided with two slots which are distributed in a 'cross' shape, and the 'cross' slots are uniformly distributed on the surface of the tungsten metal layer; the metal layers are connected together through welding; and the distributor contact is coated with a layer of isolated conductive heat insulation coating. According to the invention, the 'cross' slots are arranged in the surface of the contact, and the contact has a simple structure and is easy to operate. Among metals, tungsten has the highest melting point, has good heat conduction, electrical conduction and electron emission performances and is not easy to soften, copper has excellent ductility and corrosion resistance, makes welding firmer and further enhances the conductive ability, and iron has high melting point and high thermal conductivity and facilitates heat radiation. The surface of the contact is coated with the isolated conductive heat insulation coating, which can achieve good isolation and heat insulation effects and improve the utilization rate.

Owner:苏州市大力电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com