Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Improve drying output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

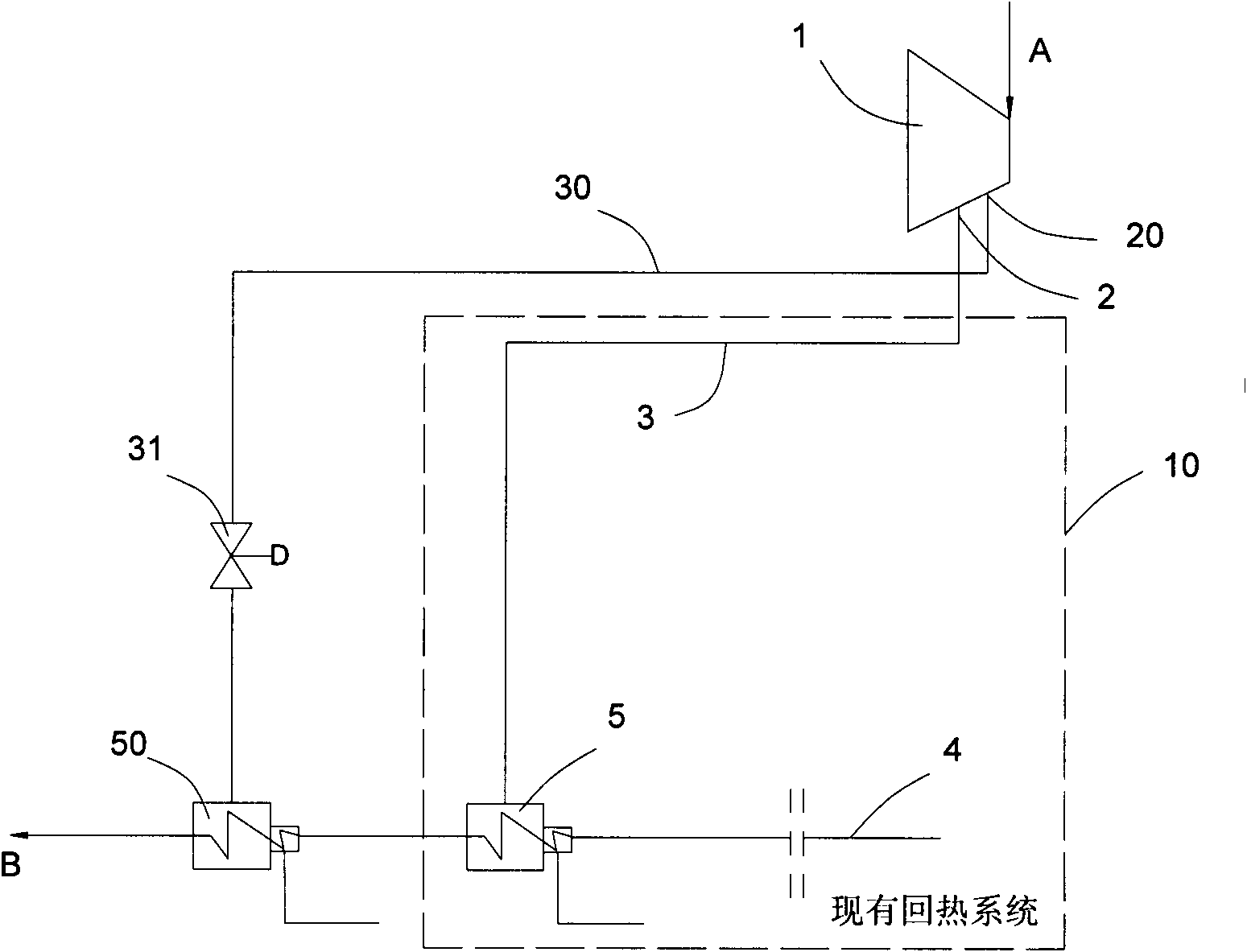

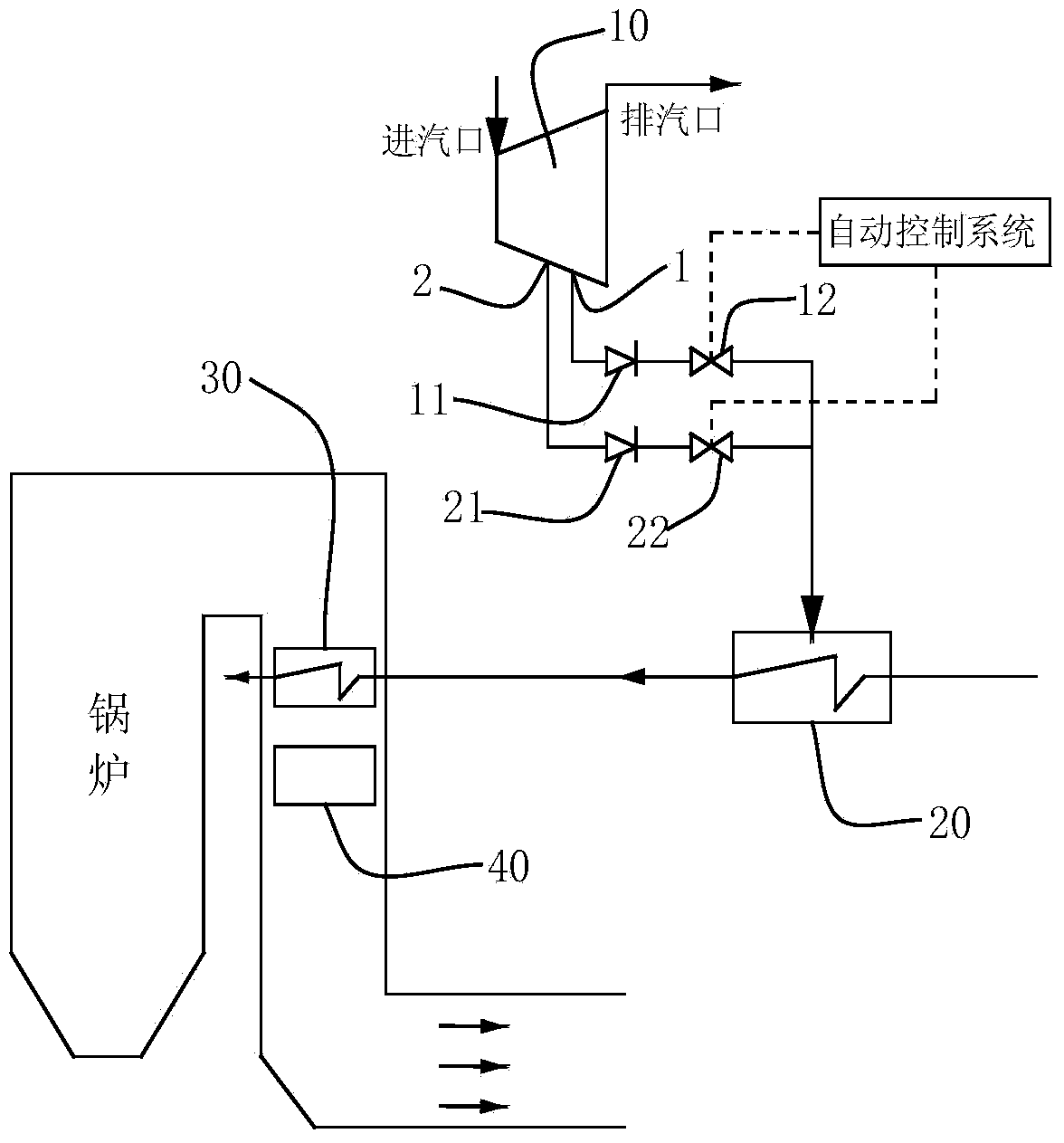

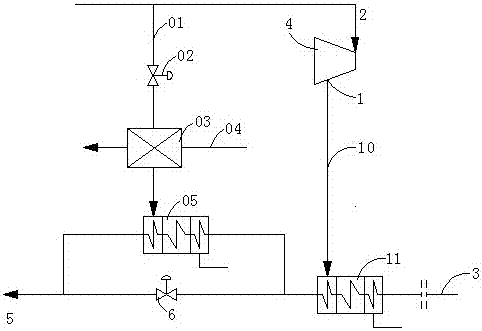

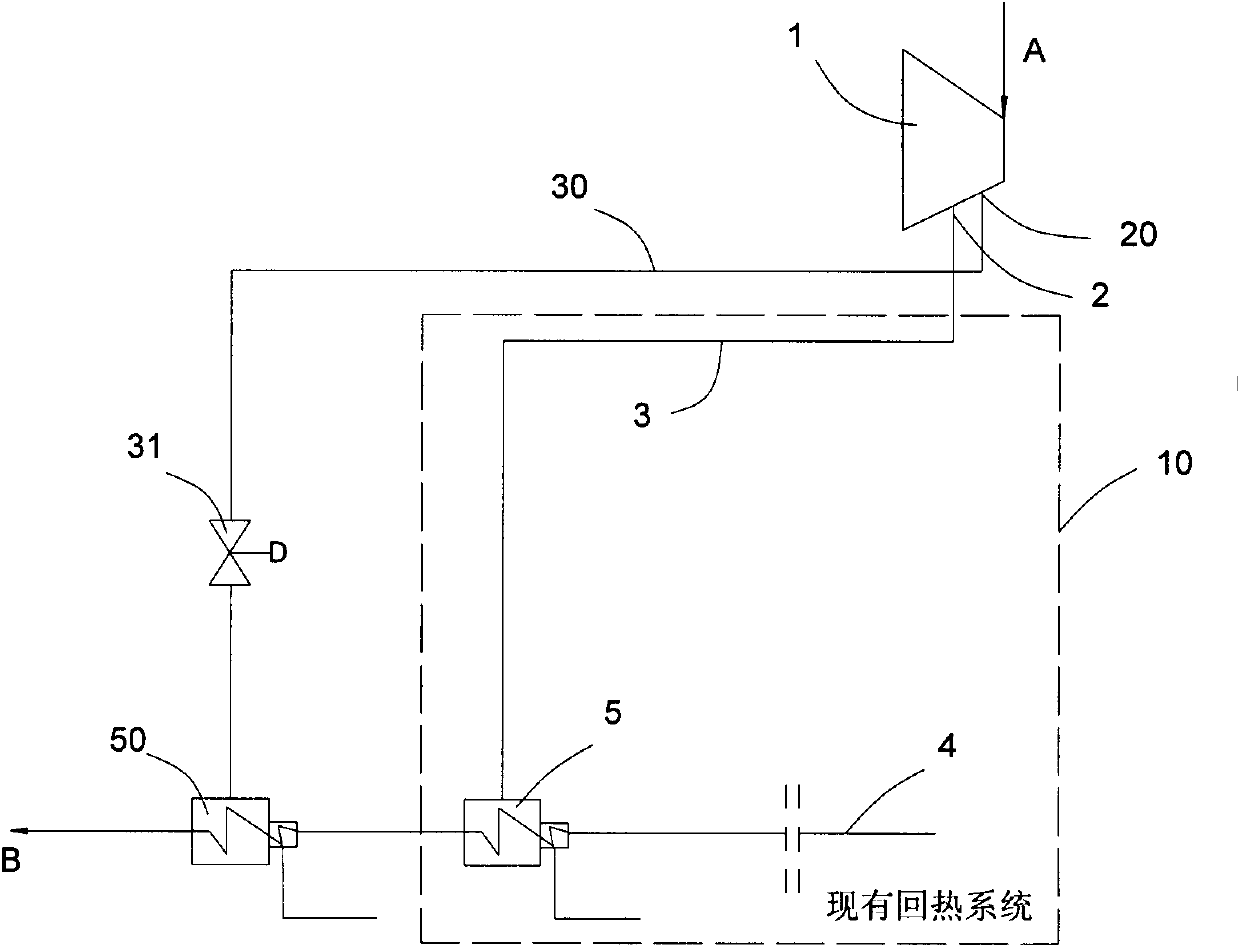

Adjustable feed water heat regenerative system for turbo generator unit

ActiveCN102537933APromote environmental protectionImprove economyMachines/enginesFeed-water heatersEngineeringHigh pressure

The invention provides an adjustable feed water heat regenerative system for a turbo generator unit, which comprises a high pressure cylinder of a steam turbine, a final-stage extraction opening, a final-stage feed water heater, a steam extraction pipe and a regulating valve, wherein the final-stage extraction opening is additionally arranged on the high pressure cylinder; the steam extraction pressure of the final-stage extraction opening is much higher than the common highest extraction pressure; additionally extracted steam is used as a heat source of the final-stage feed water heater; the steam extraction pipe is connected with the final-stage extraction opening and the final-stage feed water heater; and the regulating valve is arranged on the steam extraction pipe. Part of steam which does work is guided to the feed water heater through the final-stage steam extraction pipe so as to further heat feed water of a boiler. The heat regenerative system provided by the invention is an elastic heat regenerative system. The temperature of the feed water can be maintained or changed under the variable load condition of the unit, so that the environmental friendliness, the economy and the safety of the unit are improved and the frequency modulation characteristic is perfected.

Owner:冯伟忠

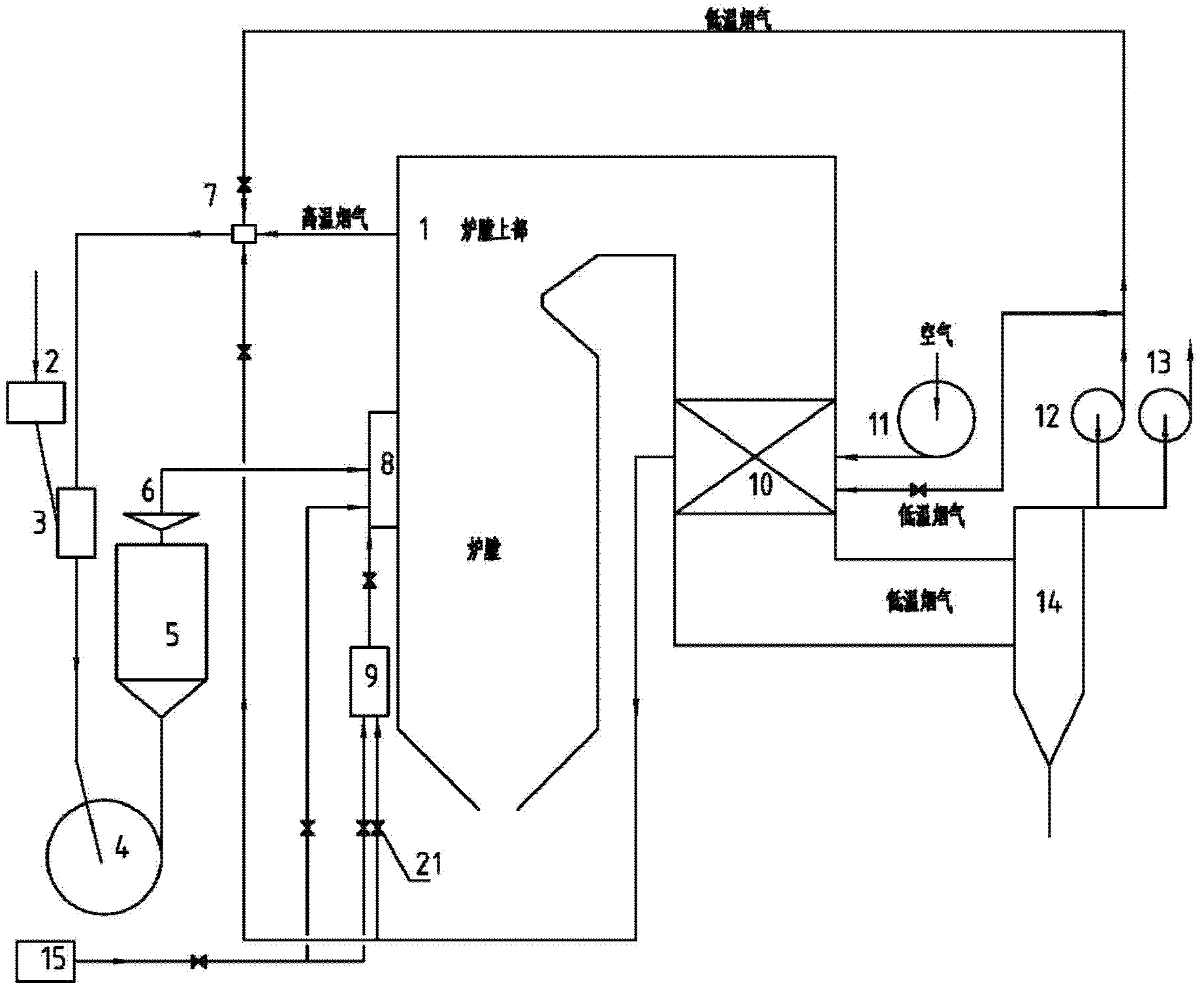

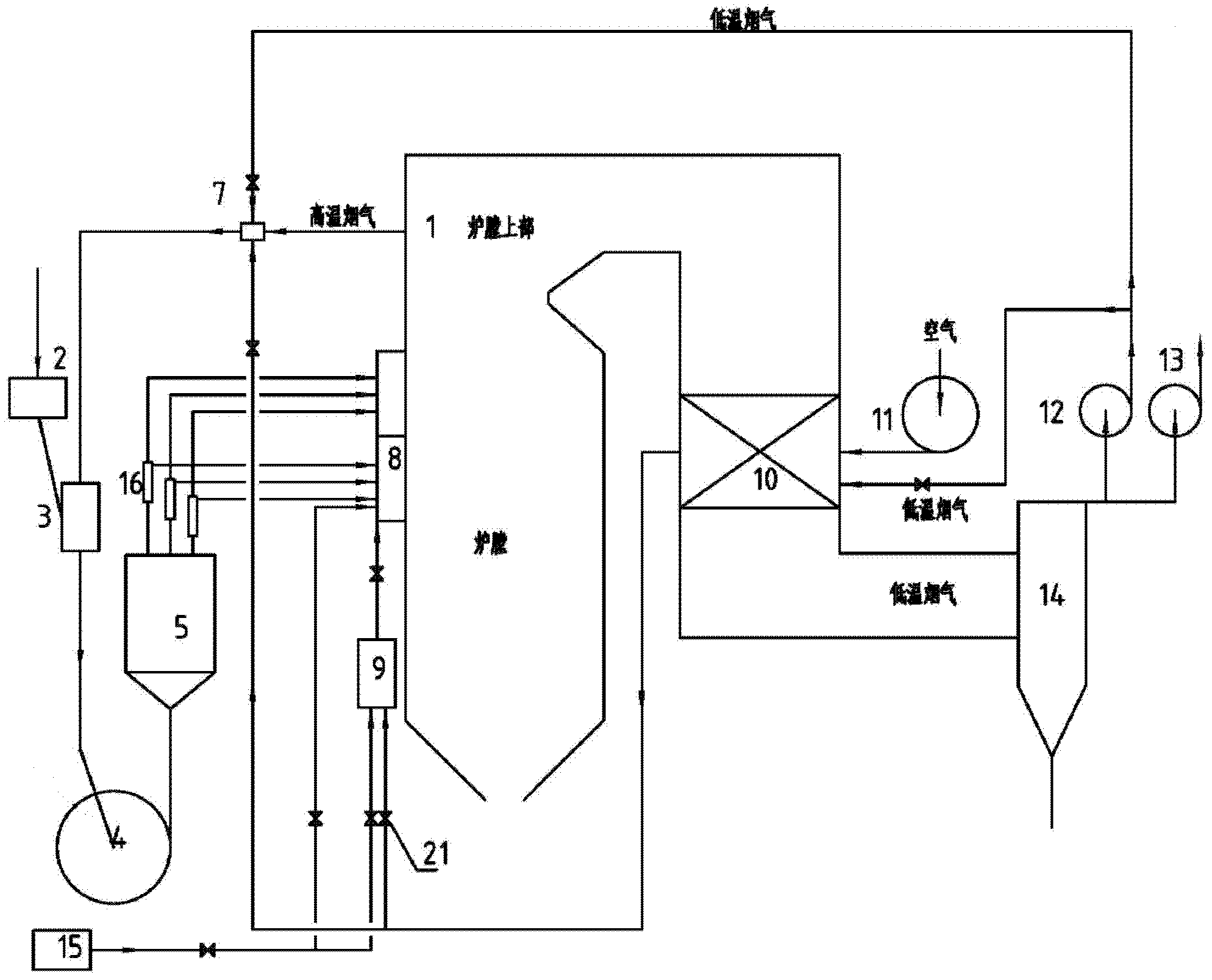

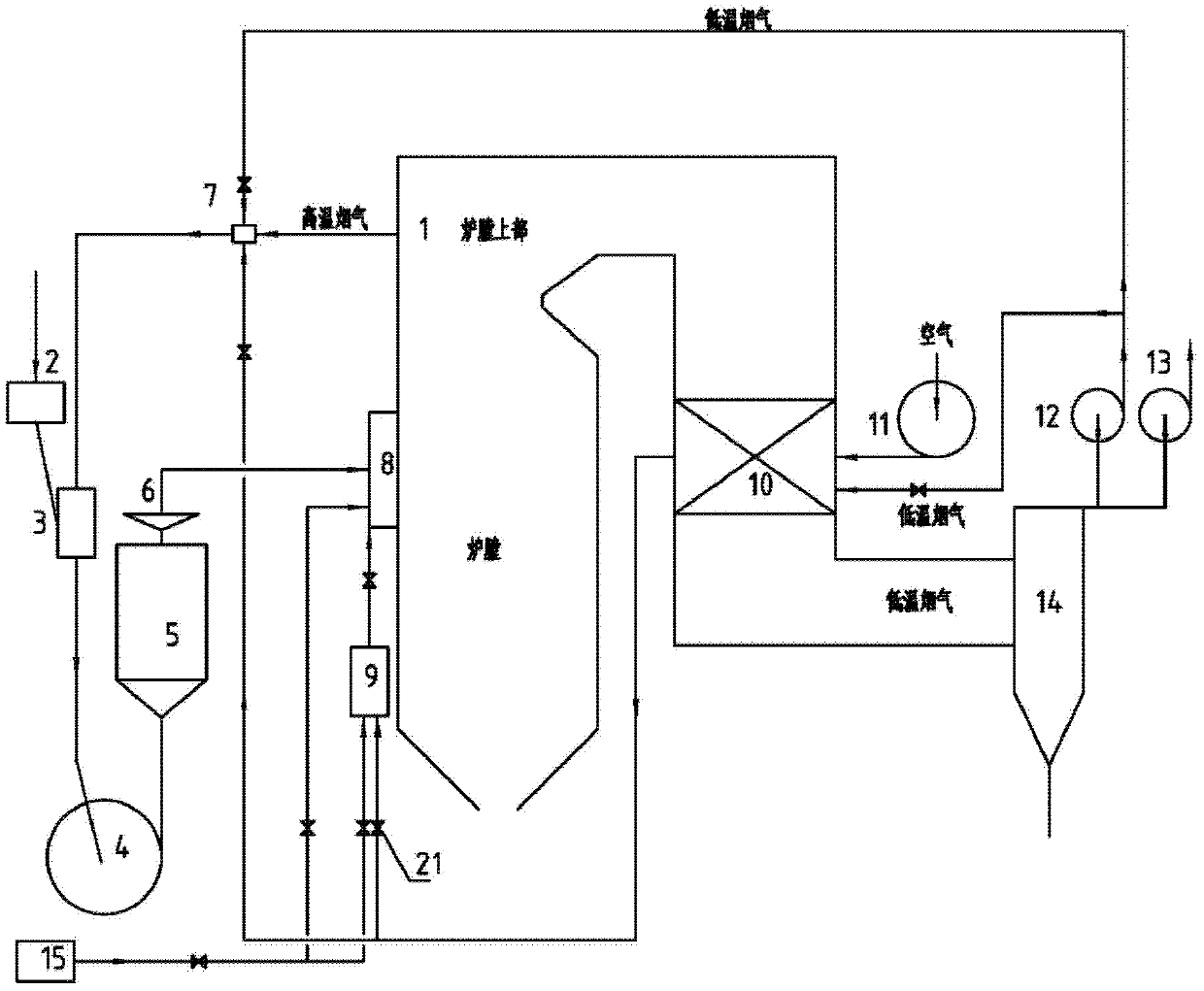

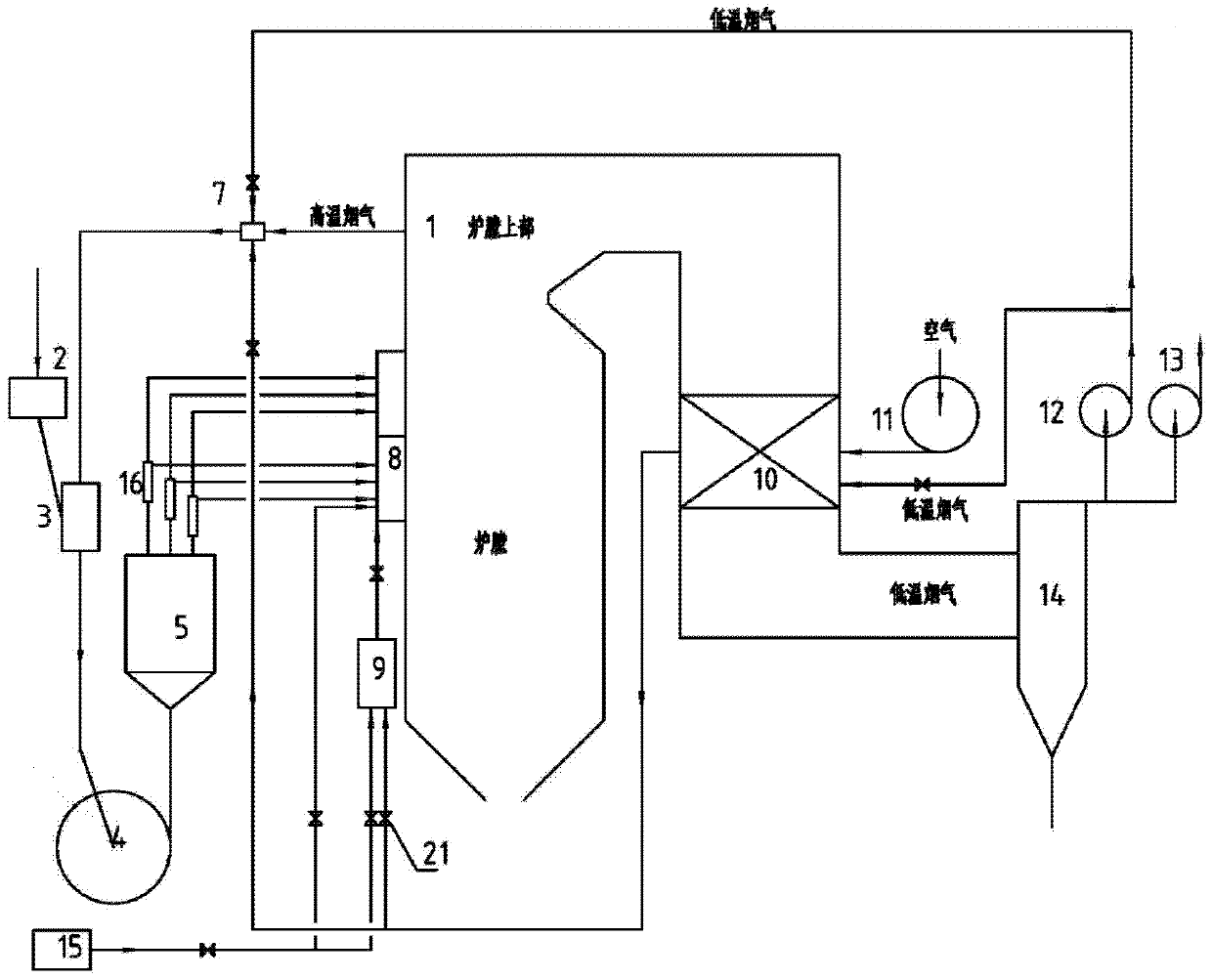

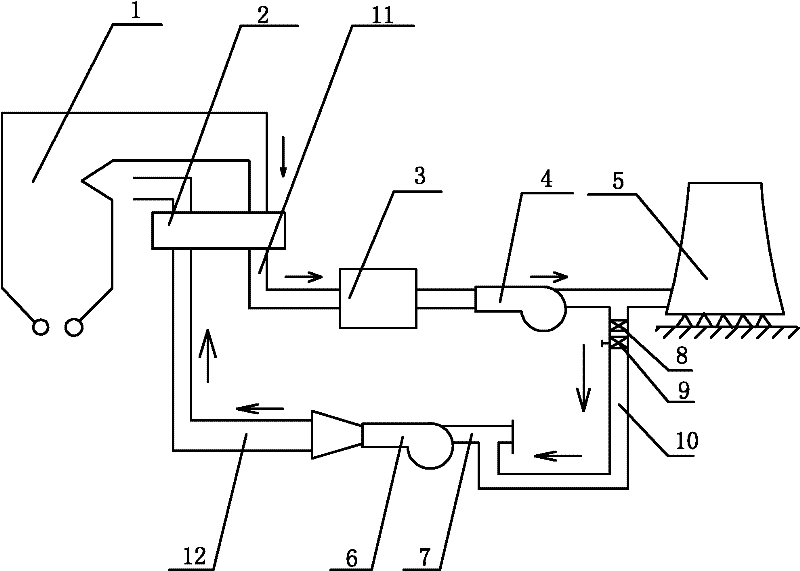

Coal powder combustion system used in high-moisture type coal oxygen-enriched combustion

ActiveCN102494334ASwitch freelyReduces the possibility of deflagrationPulverulent fuel combustion burnersDirect carbon-dioxide mitigationProcess engineeringCoal

The invention discloses a coal powder combustion system used in high-moisture type coal oxygen-enriched combustion. With the combustion system, a boiler can be switched between two modes, which are an air combustion mode and an oxygen-enriched combustion mode. According to the system, coal powder is prepared by using a fan coal-mill (4); a blower (11) is started, and the coal powder is delivered in a dry state by using a mixed gas of high-temperature flue gas, low-temperature flue gas and air, such that the combustion system is in an air combustion state. The blower (11) is stopped, and an oxygen producing apparatus (15) is started; the coal powder is delivered in a dry state by using a mixed gas of high-temperature flue gas and low-temperature flue gas, such that the combustion system is in an oxygen-enriched combustion state. Oxygen from the oxygen producing apparatus (15) is divided into two parts. One part is mixed with recycled low-temperature flue gas, and the mixed gas is delivered into a furnace as secondary gas flow. The other part with a form of pure oxygen is delivered into the furnace through a combusting apparatus. Therefore, oxygen for coal powder combustion can be supplemented.

Owner:SHANGHAI BOILER WORKS

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

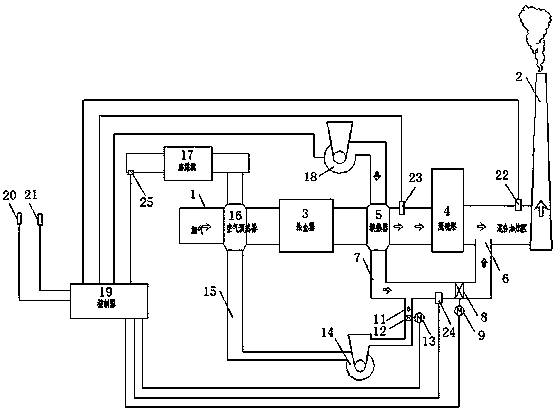

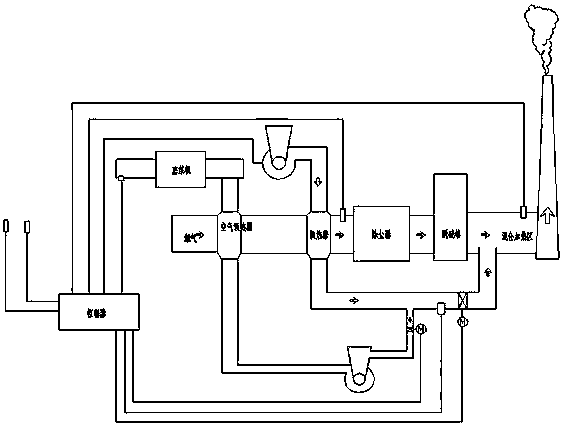

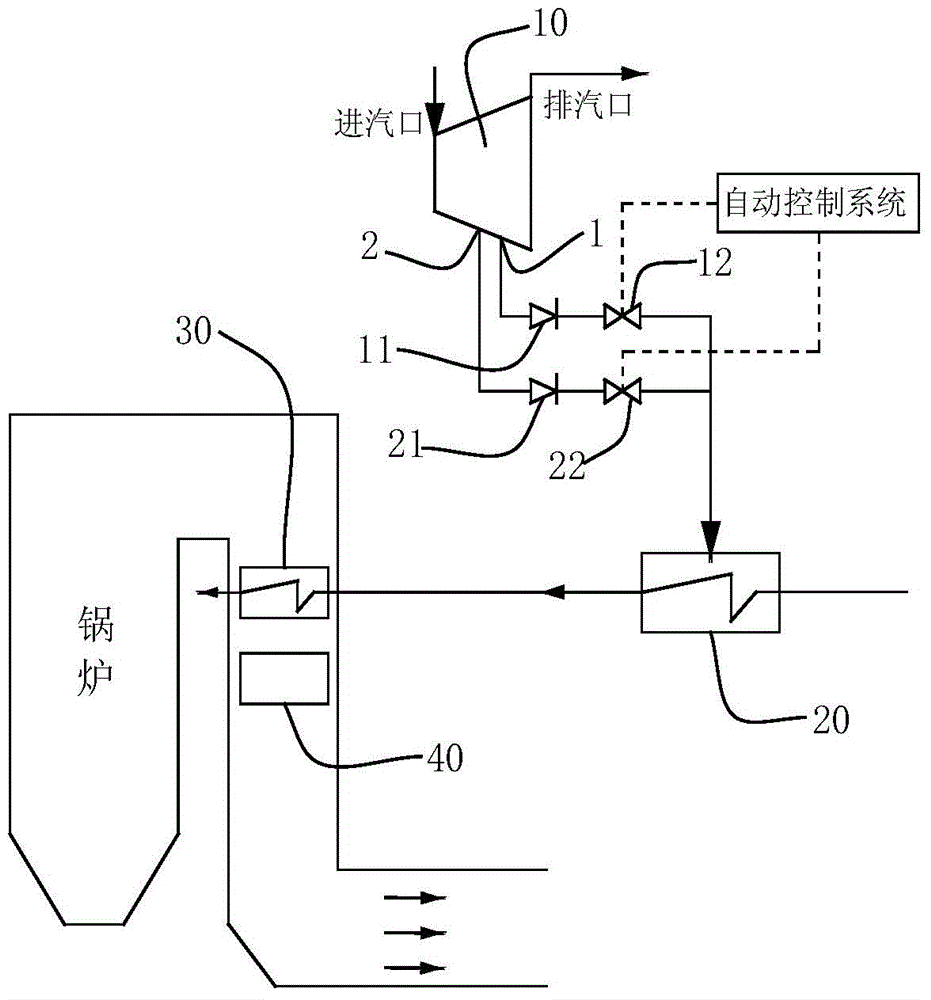

Boiler smoke and wind mixed heating adjusting system and control method thereof

PendingCN108534170AImprove protectionRealize closed-loop controlIndirect carbon-dioxide mitigationAir/fuel supply for combustionLoop controlClosed loop

The invention relates to a boiler smoke and wind mixed heating adjusting system and a control method thereof. A heat exchanger located in a flue is arranged on the inlet side or the outlet side of a dust remover, a fan is installed at an air inlet of the heat exchanger, an air outlet of the heat exchanger communicates with a hot air intake port at a flue on the outlet side of a desulfurizing towerthrough a first pipe, and a first ventilation door is arranged on the first pipe; and the air outlet of the heat exchanger communicates with an air inlet of an air feeder through a second pipe, and asecond ventilation door is arranged on the second pipe. According to the boiler smoke and wind mixed heating adjusting system and the control method thereof, the smoke temperature of the dust removeror an inlet of the desulfurizing tower is reduced, protection of the dust remover is promoted, the loss of desulfurization water and discharge of waste water are reduced, hot air is fed into a primary fan, and the drying capacity of a coal mill can be greatly improved; the hot air is mixed and enters a chimney, and white smoke plume visual pollution can be effectively eliminated; temperature measuring points and a controller are installed, so that closed-loop control of the temperature is achieved, an expected effect can be effectively achieved, and the economic efficiency and environmental protection property of the device are adjusted to an optimal balancing state.

Owner:ZHUHAI HUAYUAN AUTOMATION TECH

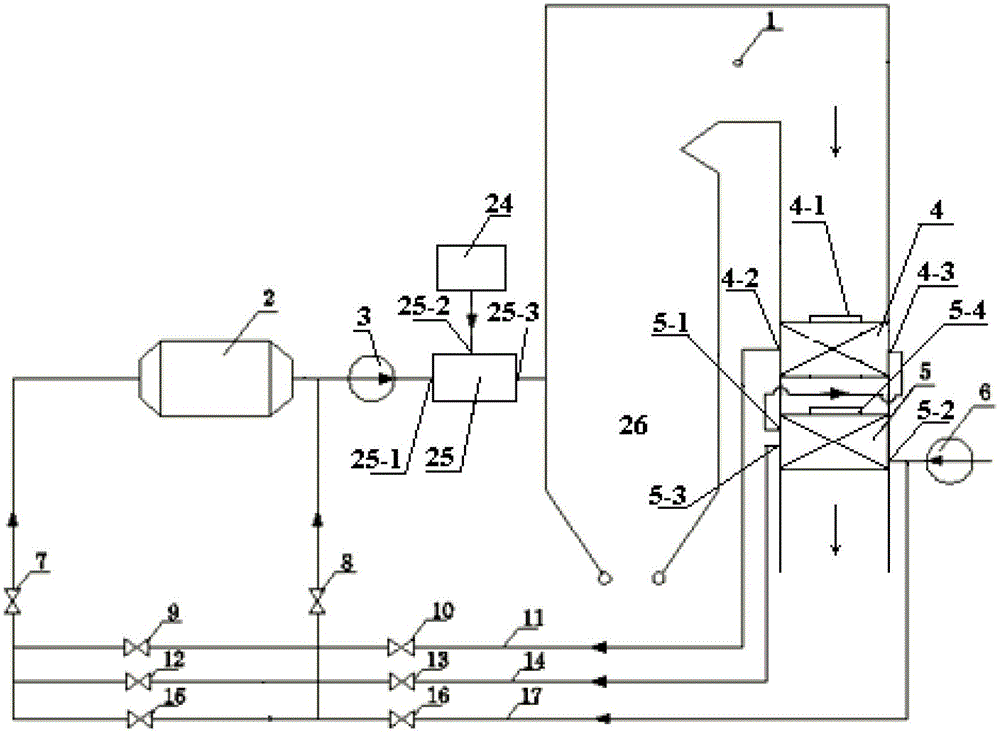

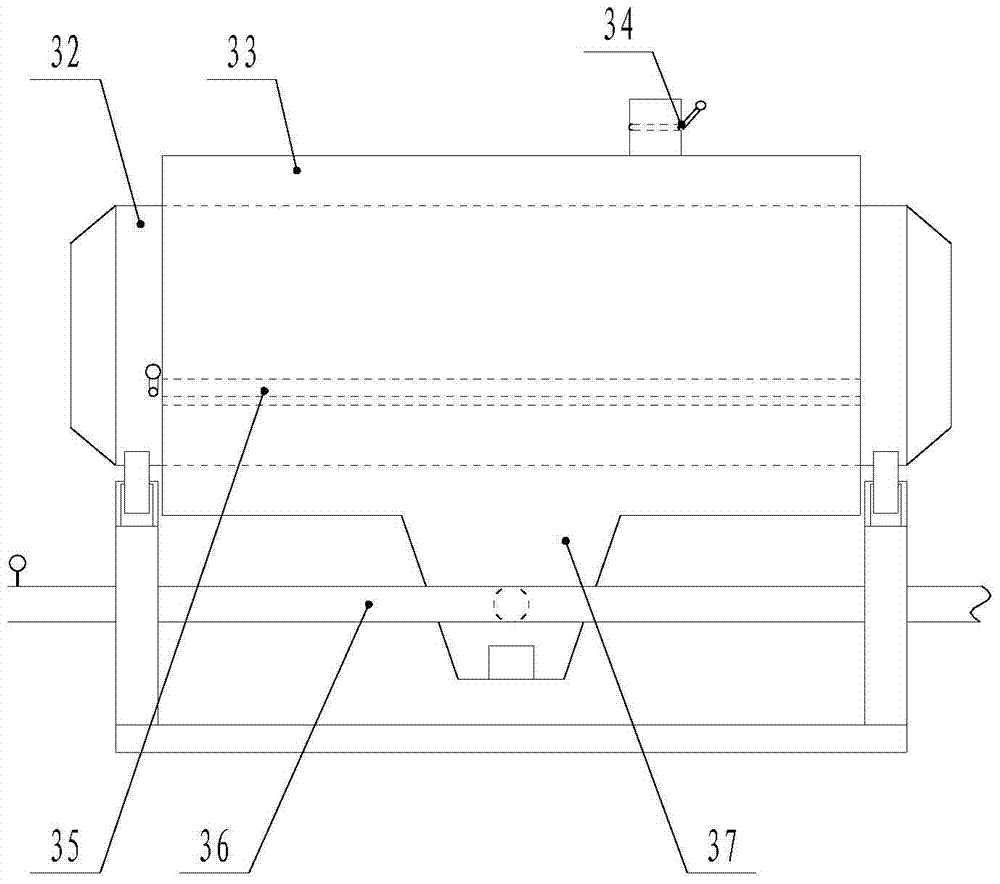

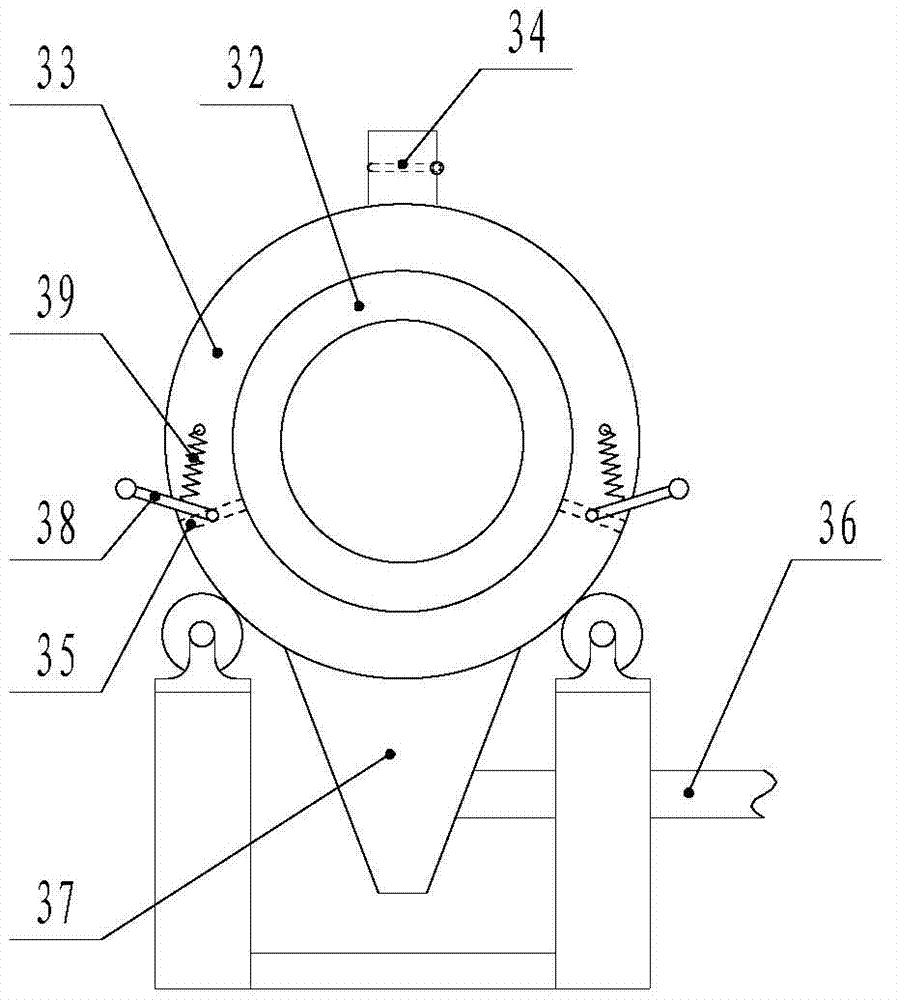

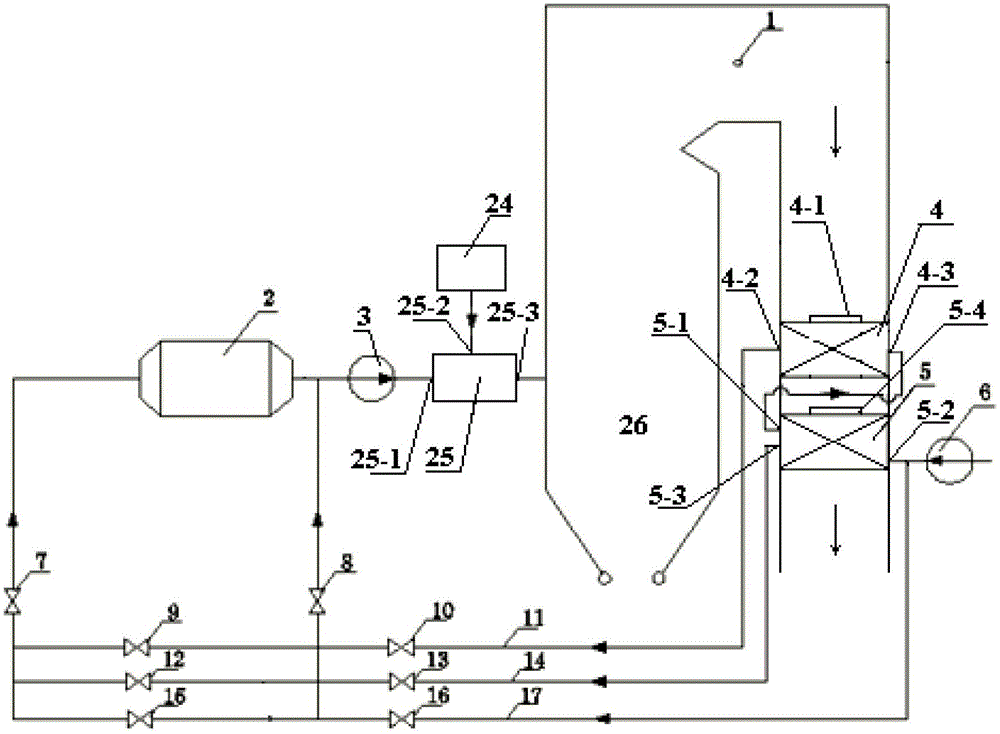

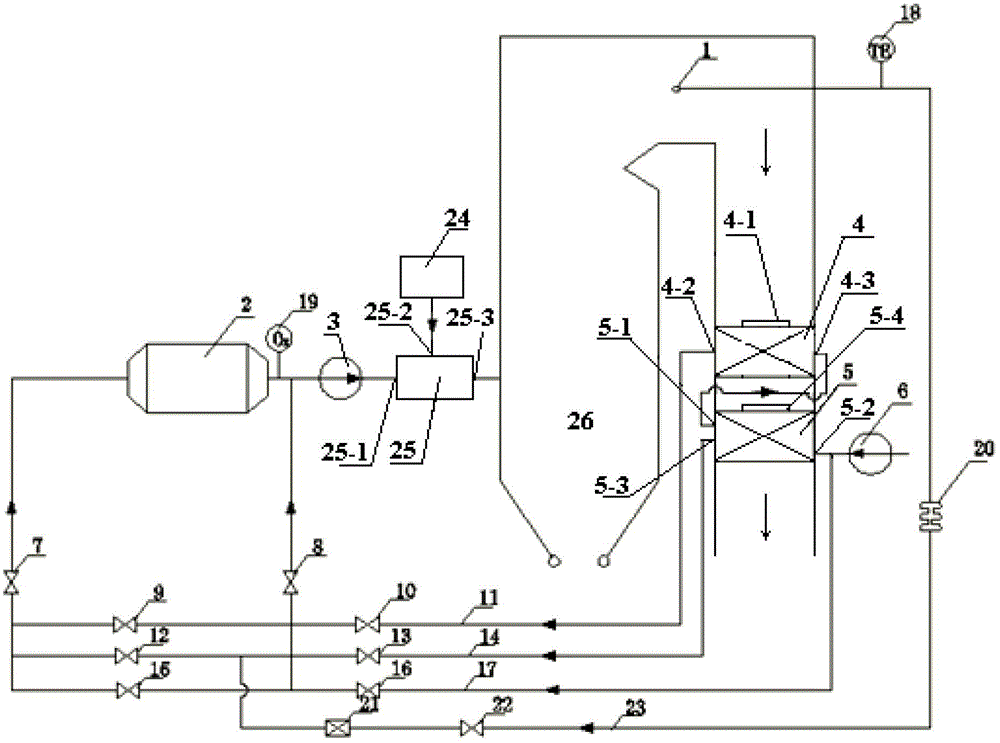

System for improving drying capacity of bin and feeder coal pulverizing system when boiler changes coal types

ActiveCN103148496AImprove qualityImprove drying outputDrying gas arrangementsLump/pulverulent fuel preparationBrown coalFlue gas

The invention discloses a system for improving the drying capacity of a bin and feeder coal pulverizing system when a boiler changes coal types and relates to a system for improving the drying capacity of a coal pulverizing system. The invention aims at solving the problem that boilers adopting the bin and feeder coal pulverizing system change the coal types in thermal power enterprises, in particular to the problems of safety and economy of boiler operation in the lignite-bleeding burning process. A high-temperature coal economizer manhole is communicated with a first warm air isolating door air inlet and a second warm air isolating door air outlet by a flue gas pipeline of the system; and a flue gas isolating door and a flue gas adjusting door are sequentially arranged on the flue gas pipeline according to the flowing direction of mediums. The system disclosed by the invention has the advantages of low reforming cost, low operation and maintenance cost, reliability in operation and capability of operating for a long time. The system is used for reforming the coal pulverizing system when the boiler adopting the bin and feeder coal pulverizing system changes the coal types.

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

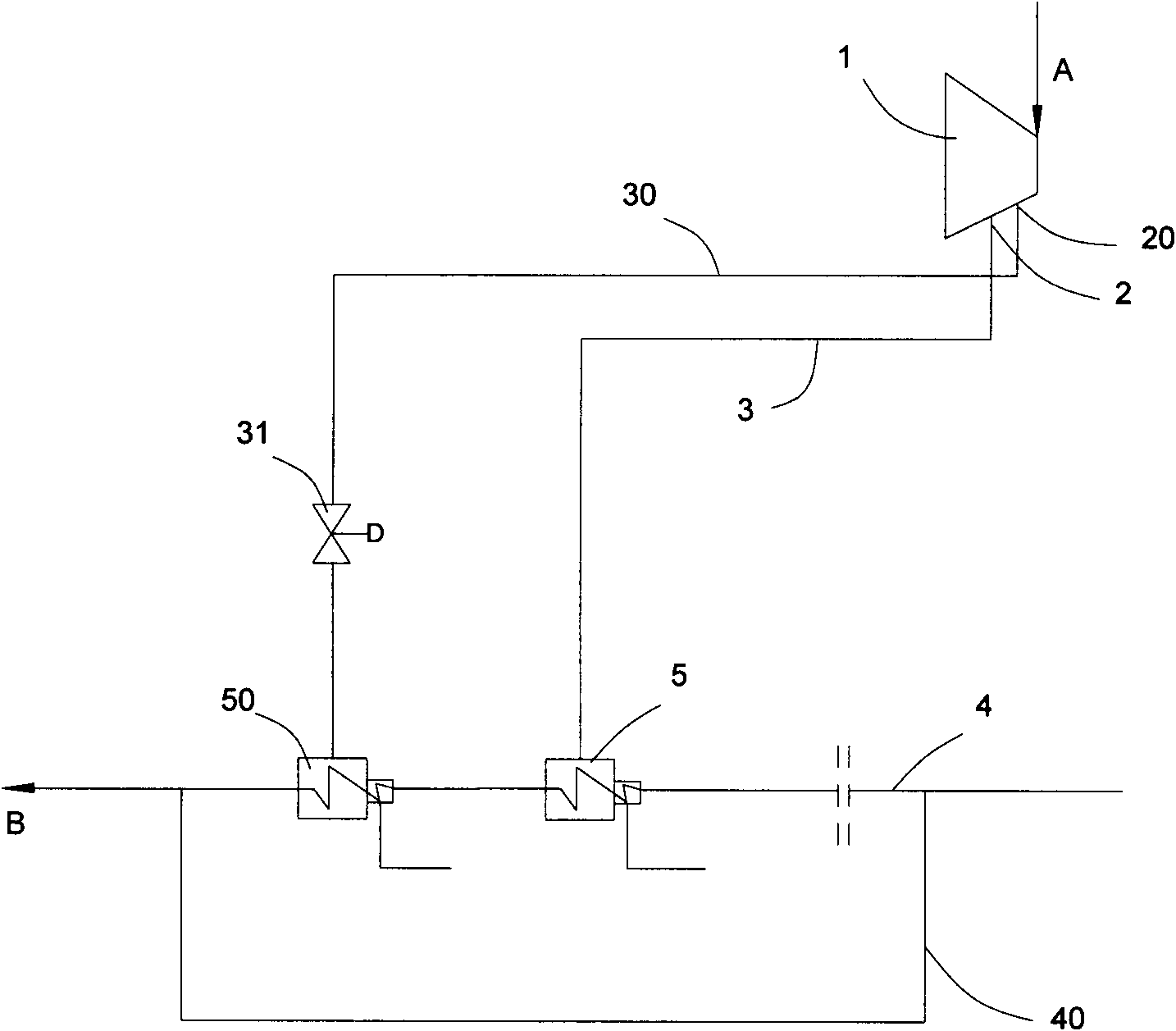

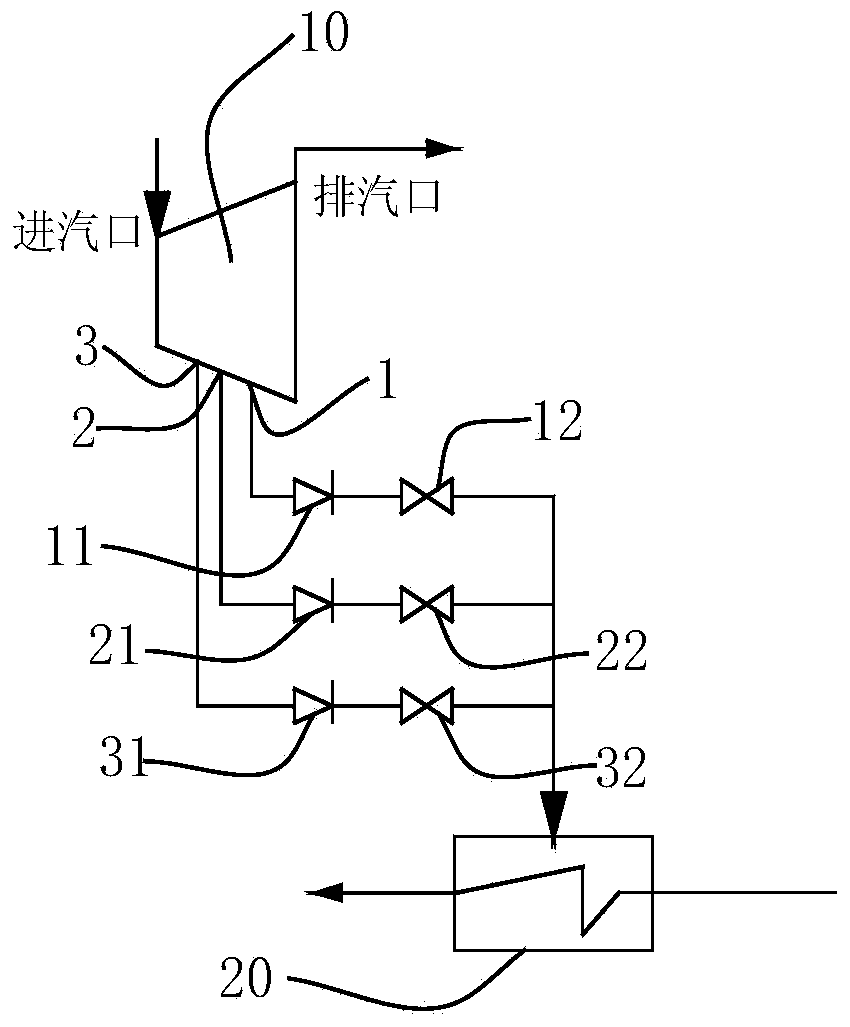

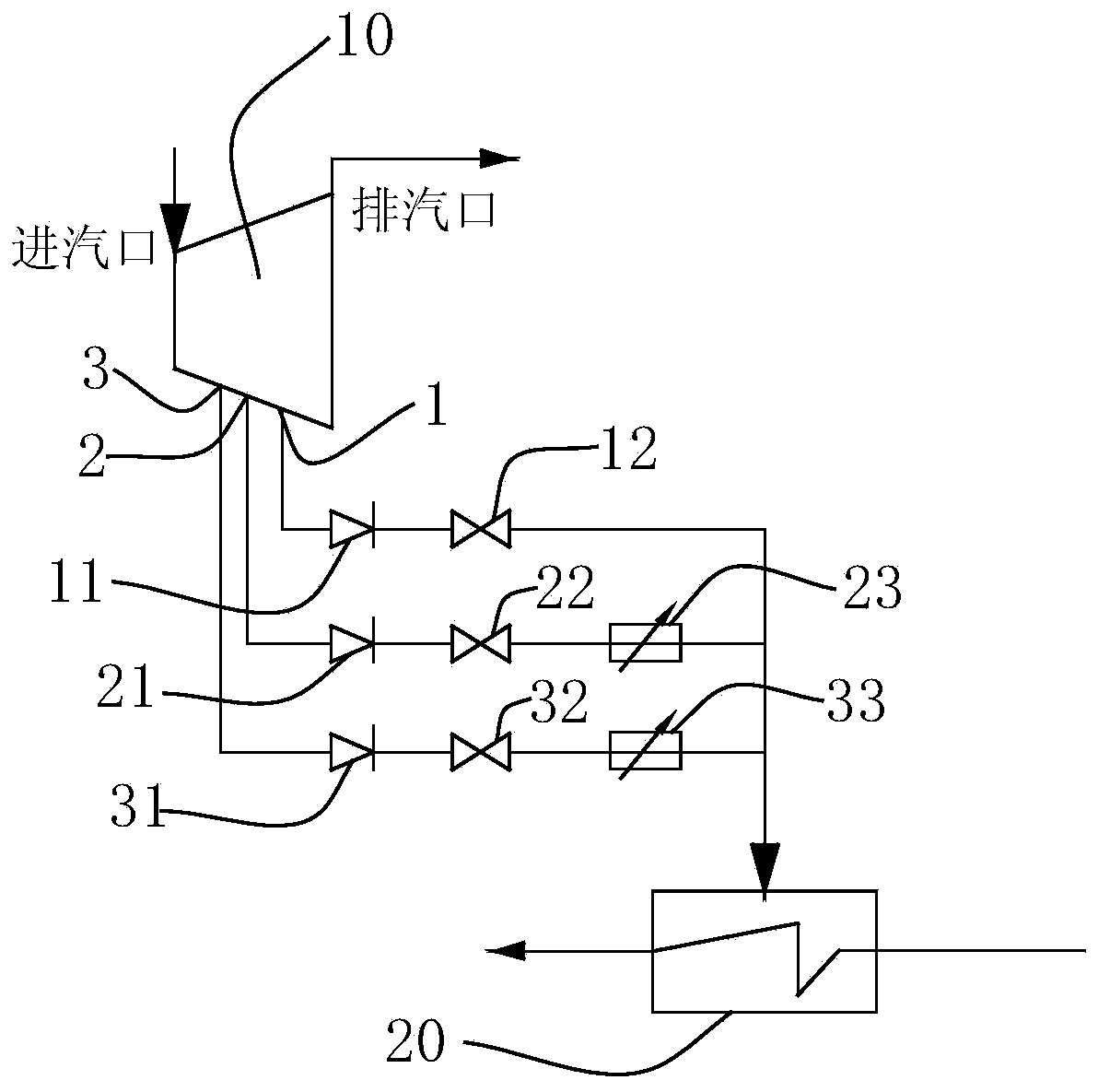

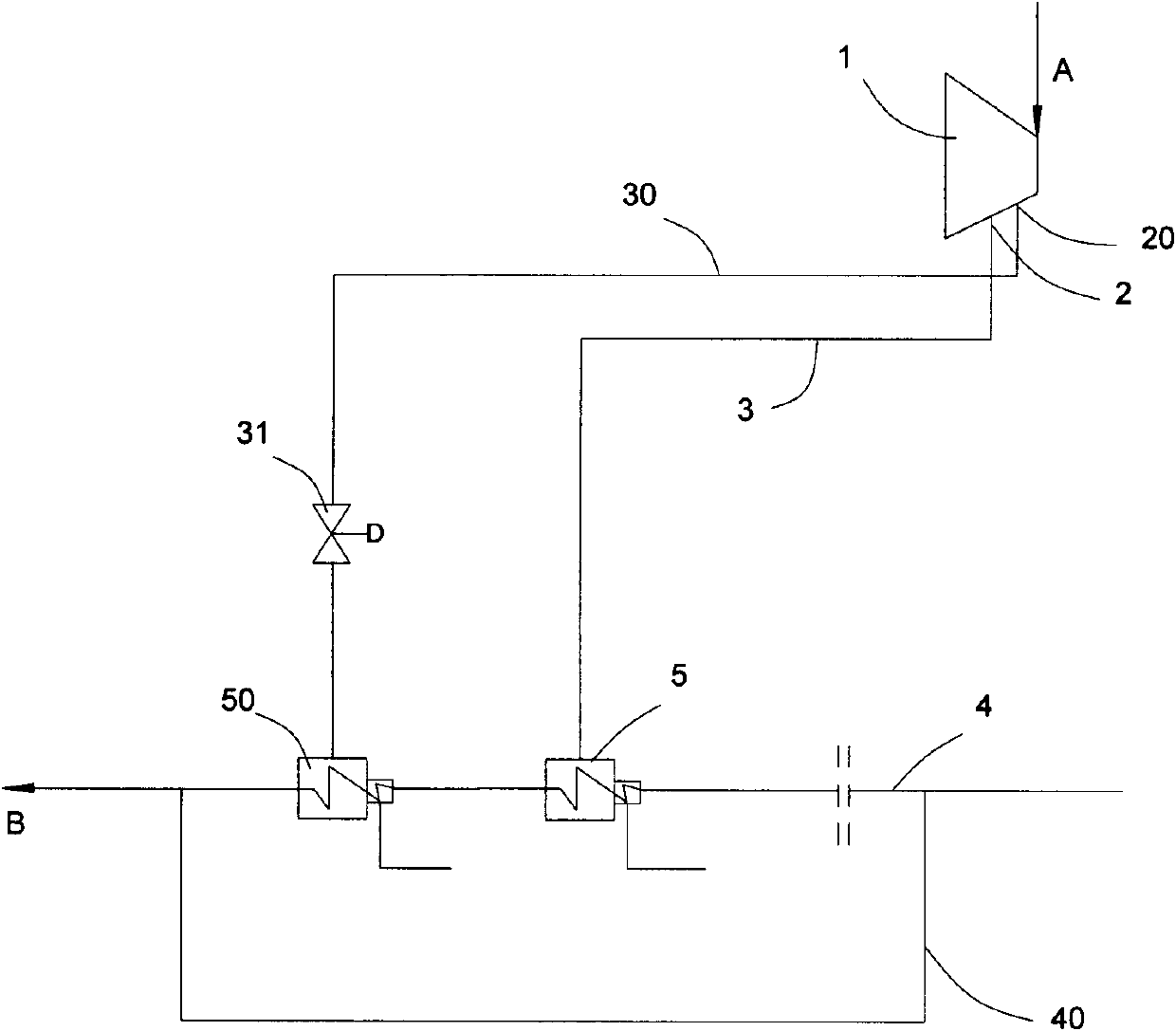

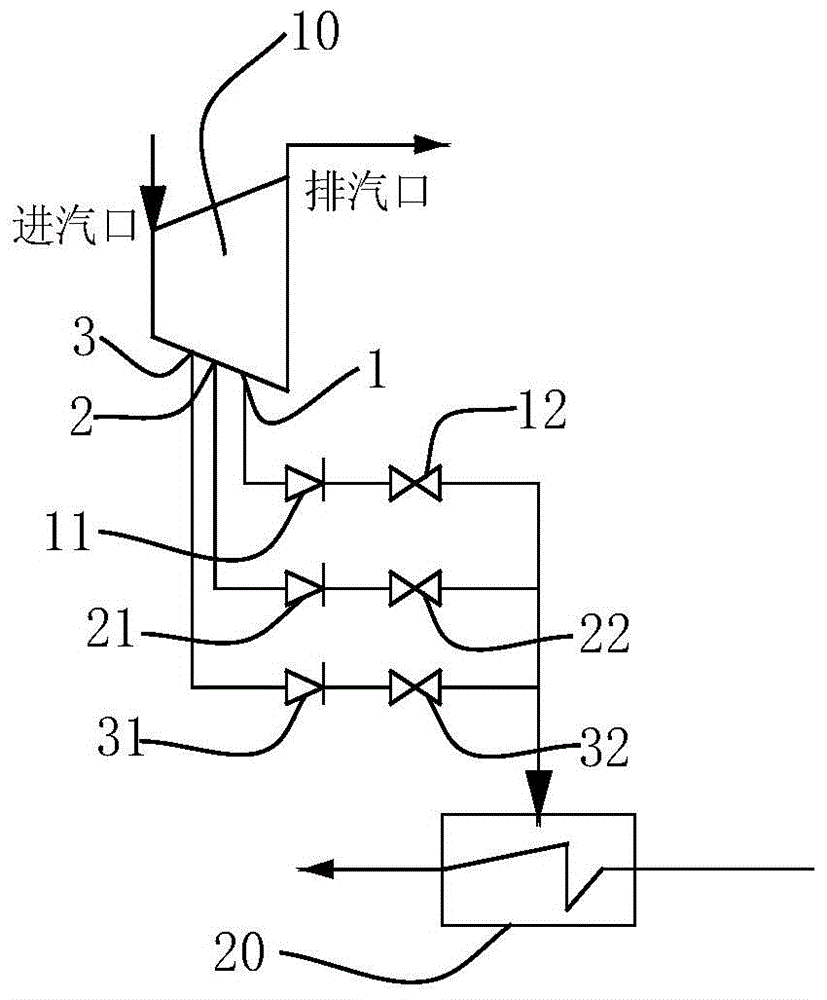

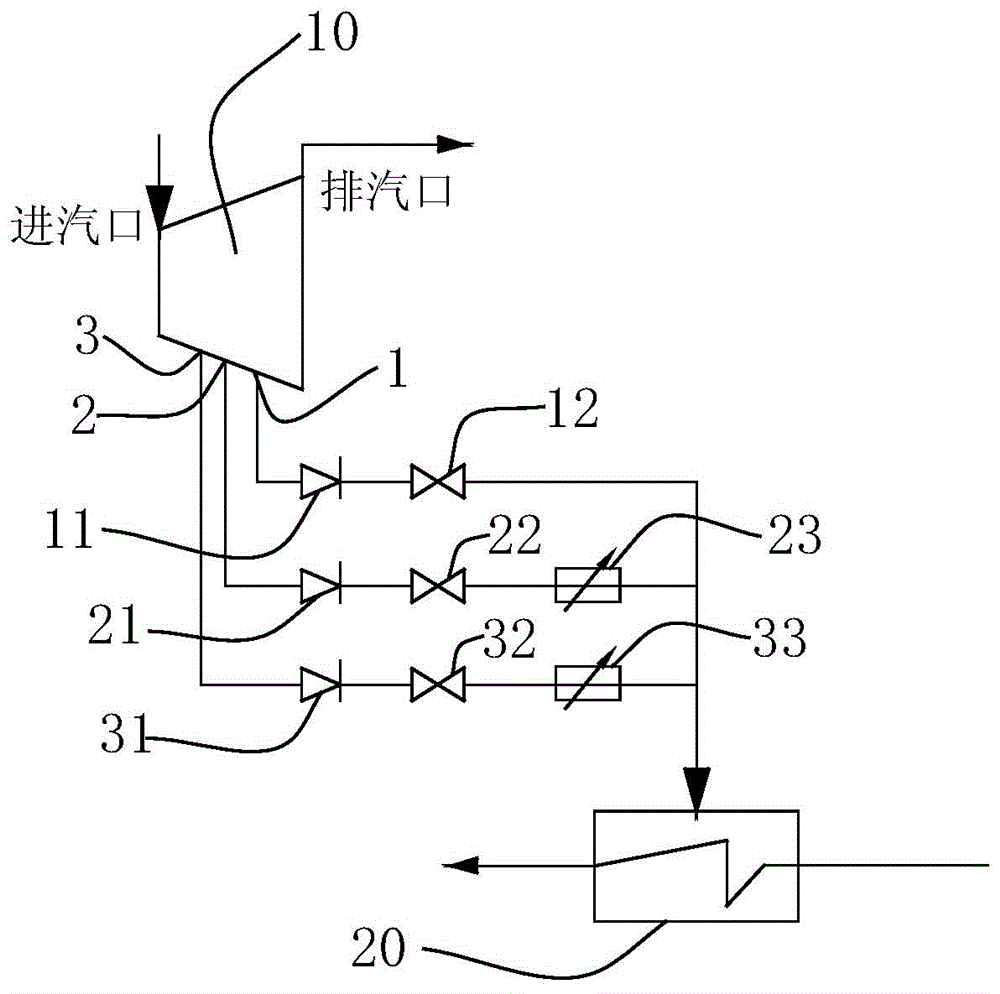

Regenerative system of turbogenerator unit and operation method thereof

ActiveCN103644005ASolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

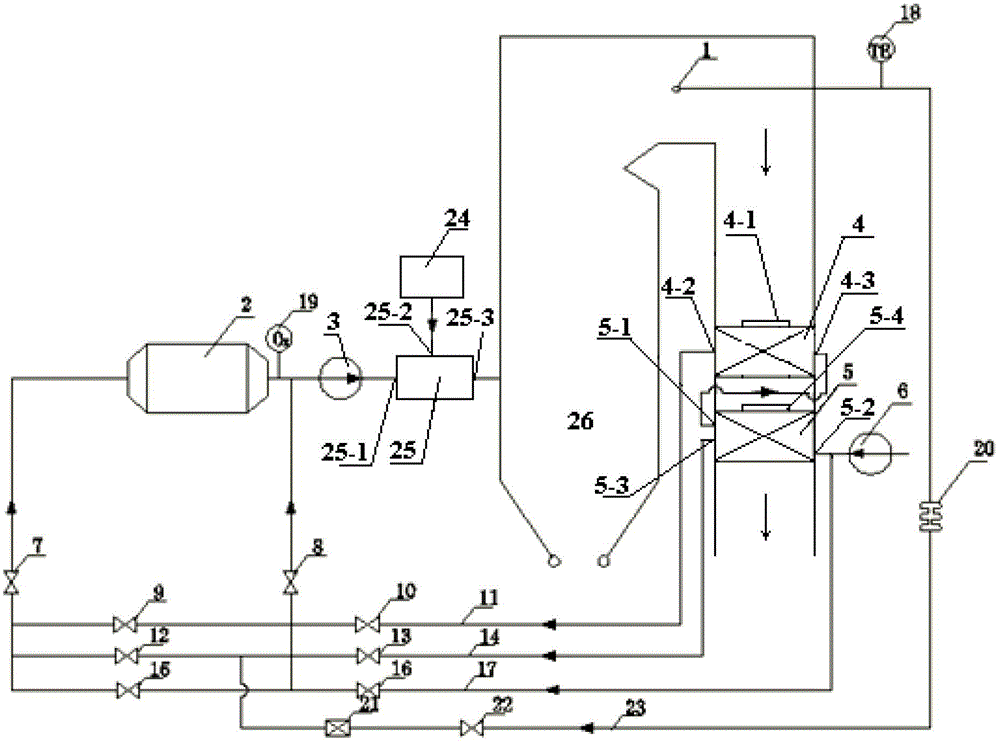

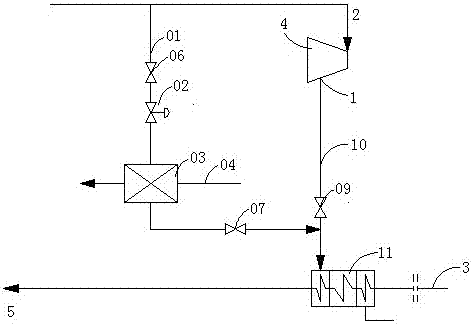

Direct blowing type coal pulverizing system and method taking flue gas as drying medium

PendingCN109959023AImprove adaptabilityImprove drying outputSolid fuel pretreatmentDrying gas arrangementsBoiler furnaceFlue gas

The invention provides a direct blowing type coal pulverizing system and method taking flue gas as a drying medium. The structure is simple, arrangement is reasonable, the boiler flue gas is fully utilized, and the requirement of milling high-moisture coal can be met. The system comprises a coal pulverizing device and a flue gas extracting device; the coal pulverizing device comprises a coal feeder, a coal mill and a coarse pulverized coal separator which are sequentially connected; a pulverized coal outlet of the coarse pulverized coal separator is connected with a pulverized coal inlet of aboiler; a coal economizer is arranged in a flue of the boiler, and an induced draft fan is arranged at a flue outlet; and the flue gas extracting device comprises a high-temperature flue gas way connected with an inlet flue of the coal economizer, a middle-temperature flue gas way connected with an outlet flue of the coal economizer and a low-temperature flue gas way connected with an outlet flueof the induced draft fan, the three flue gas ways are connected to the mixed pipeline input end separately, the mixed pipeline output end is connected with the coal mill through a flue gas fan sequentially, and mixed flue gas is introduced to serve as a drying and explosion preventing medium.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

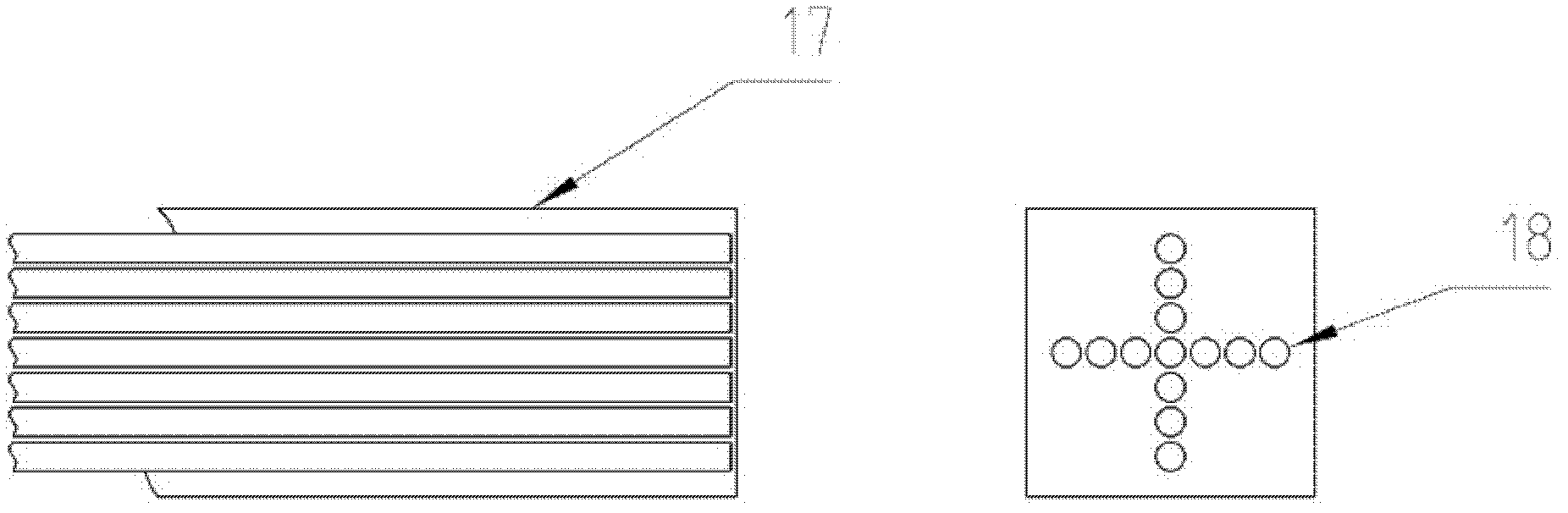

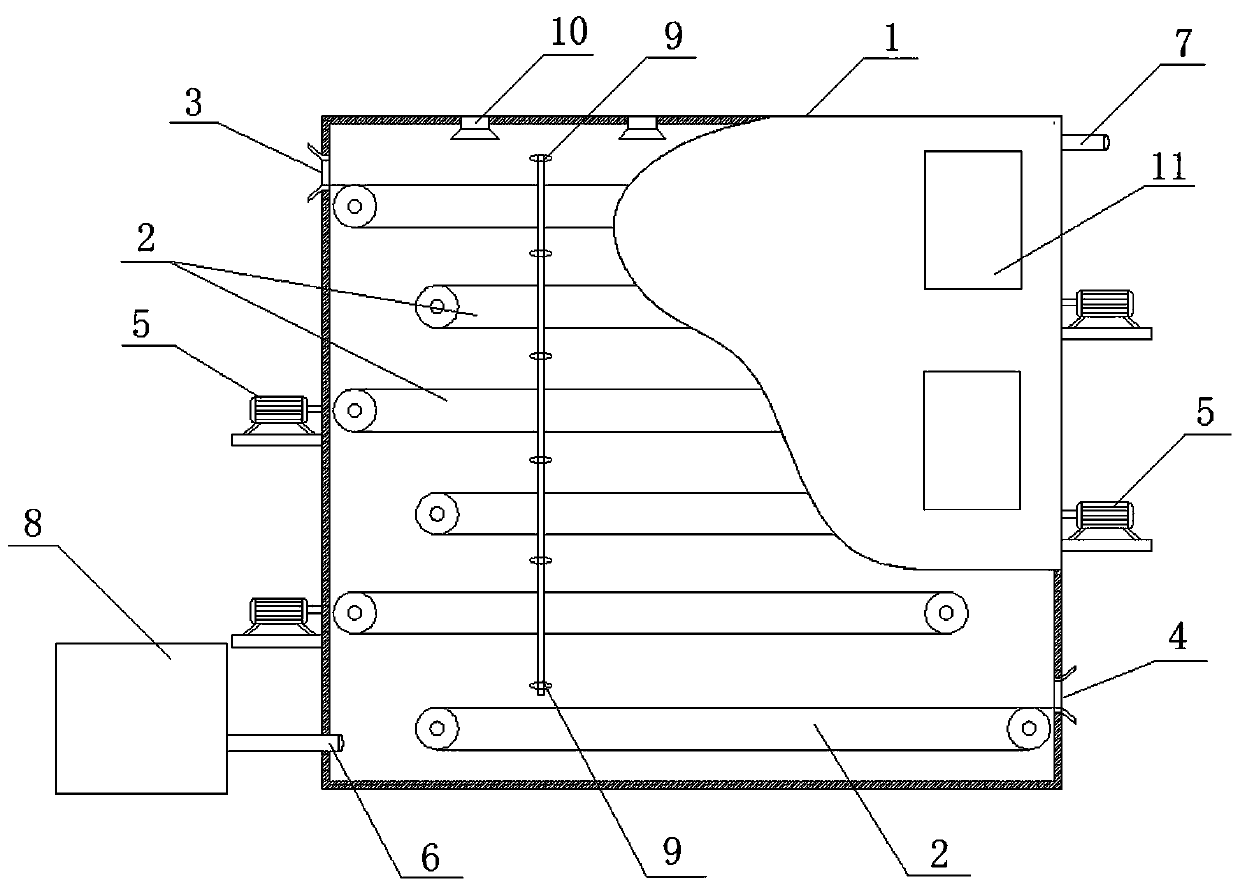

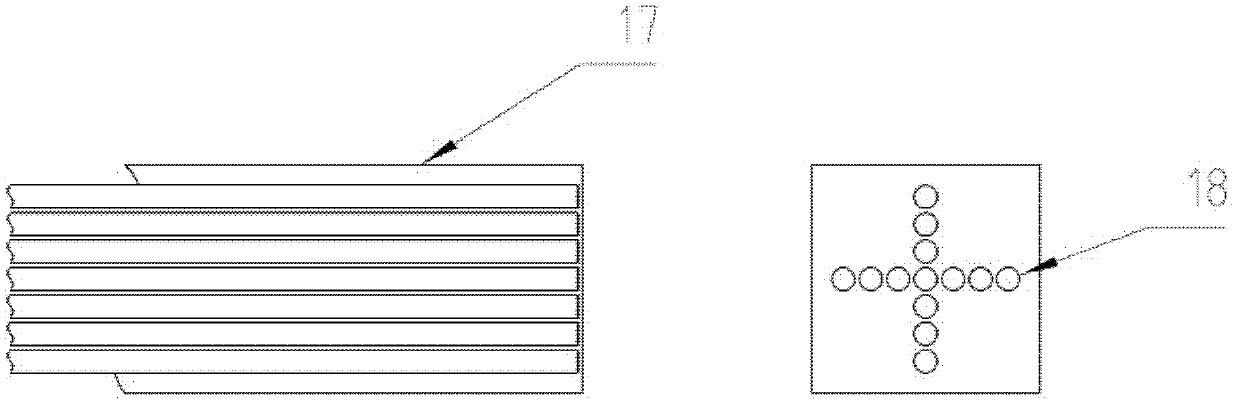

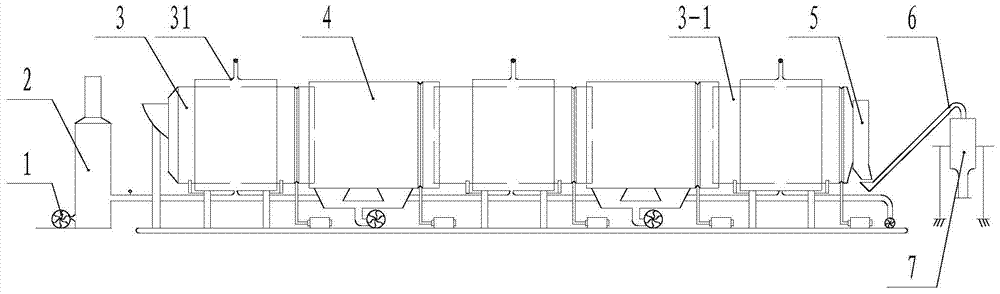

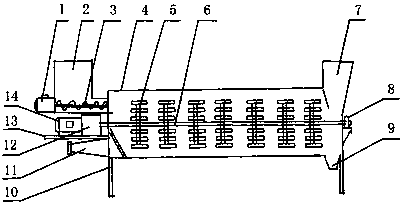

Continuously running layered grass drying device

PendingCN107764022AFully dryDry thoroughlyDrying gas arrangementsDrying chambers/containersHot air ovenAgricultural engineering

The invention discloses a continuously running layered grass drying device which comprises a shell. The shell is provided with a grass inlet and a grass outlet. Multiple layers of belt conveyors usedfor conveying grass are horizontally arranged in the shell. Conveying belts of the conveyors are of ventilating grid type structures, and the conveyors are sequentially arranged in a staggered mannerfrom top to bottom. The conveying directions of every two adjacent conveyors are opposite. The conveyor on the topmost layer is connected with the grass inlet in the upper end, and the conveyor on thelowermost layer is connected with the grass outlet in the lower end. Grass of the conveyors of the upper layers can downwards fall into the conveying belts of the lower layers of conveyors when conveyed to the tail ends in the conveying directions of the conveyors, and the conveyors on different layers are independently driven by motors which are arranged on the outer wall of the shell correspondingly. The bottom of the shell is provided with a hot air inlet externally connected with a hot blast heater, and a hot air outlet is formed in the top of the shell. Continuous and sufficient drying of grass can be achieved through the layered structure, and the technical problems that drying is not even and not thorough and the drying efficiency is low of an existing drying device are solved, wherein the technical problems are caused by structural defects.

Owner:山丹县天泽农牧科技开发有限责任公司

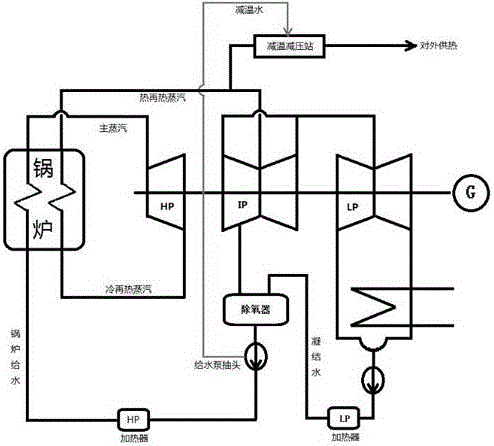

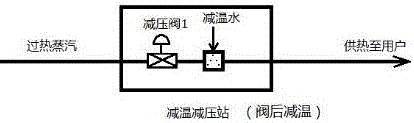

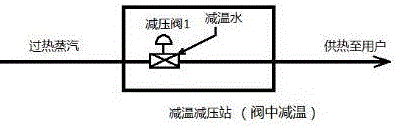

Matching device and method for heating parameters of thermal power generating unit

InactiveCN106194295AImprove combustionCombustion adaptationFeed water supplySteam useEngineeringSuperheated steam

The invention discloses a matching device for heating parameters of a thermal power generating unit. A steam pipeline for conveying superheated steam is arranged in the thermal power generating unit; the steam pipeline is connected to a heating user port through a branch pipeline; a matching device for the heating parameters is further arranged on the branch pipeline; the matching device comprises a pressure reducing valve and a heat exchanger which are in tandem connection on the branch pipeline; the heat exchanger is arranged in a to-be-heated area of the thermal power generating unit for returning excessive heating heat to a boiler thermodynamic system; and the to-be-heated area comprises an air flue, a gas flue, a water feeding pipeline and a steam pipeline in the thermal power generating unit. The invention further discloses a matching method for the heating parameters of the thermal power generating unit. The matching device and the matching method has the advantages of improving thermal cycle efficiency, reducing energy consumption and reducing production cost.

Owner:上海量朝能源科技有限公司

Coal powder combustion system used in high-moisture type coal oxygen-enriched combustion

ActiveCN102494334BImprove drying outputDry enoughPulverulent fuel combustion burnersDirect carbon-dioxide mitigationCombustion systemFlue gas

Owner:SHANGHAI BOILER WORKS

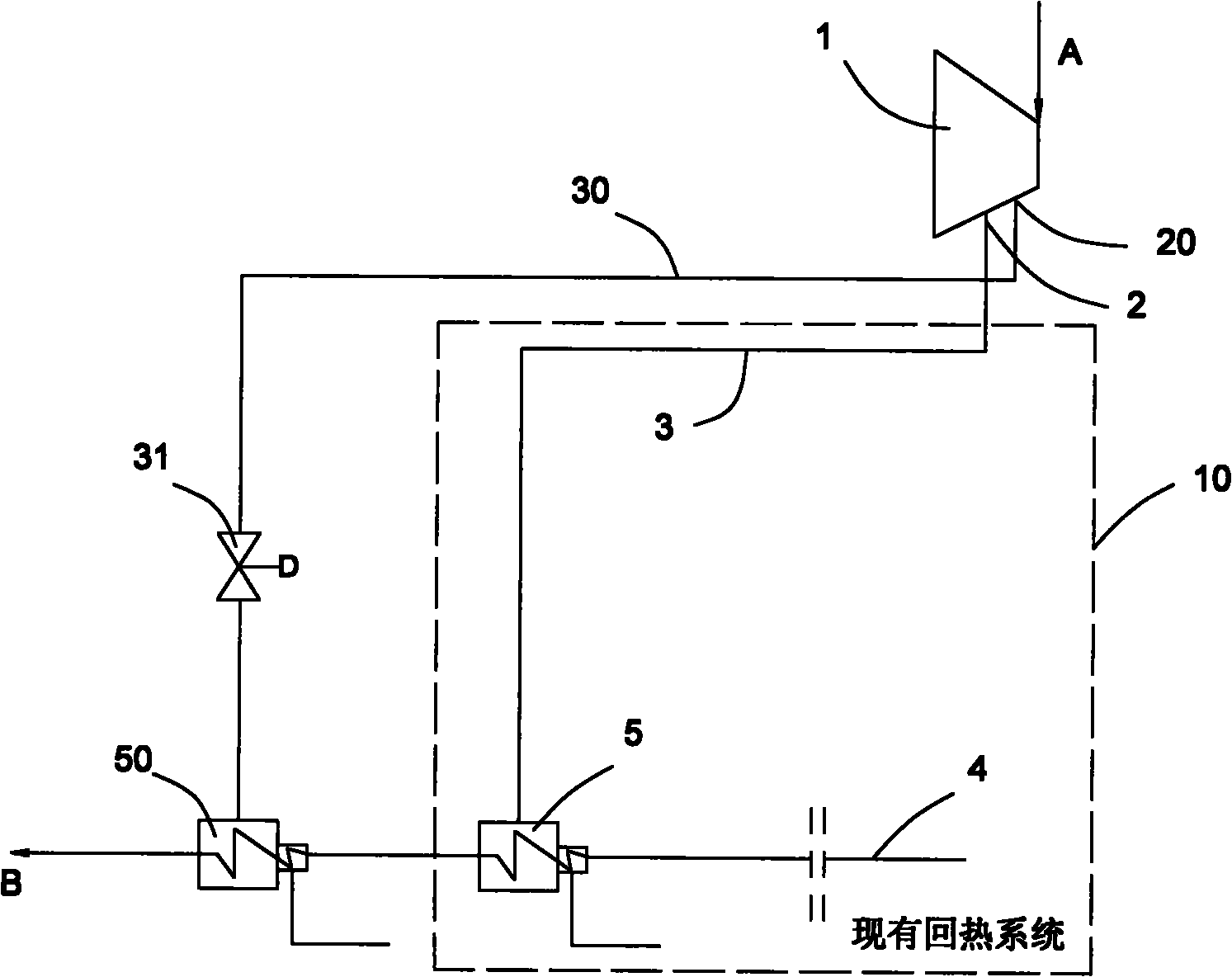

Joint heat regenerative system

PendingCN107388230AImprove combustion effectImprove drying outputSteam engine plantsFeed-water heatersAir preheaterJoint heat

The invention discloses a joint heat regenerative system which comprises a high-pressure cylinder of a steam turbine, a main steam pipeline, a conventional last-stage steam extraction pipeline, an additional pipeline, heat exchangers, a feed water heater and a steam-side adjusting valve. The additional pipeline is additionally arranged on the main steam pipeline, main steam in the main steam pipeline is used as a heat source for the heat exchangers, exhausted steam of the heat exchangers is used as a heat source for the feed water heater, and the steam-side adjusting valve is arranged on the additional pipeline and is used for adjusting main steam in the additional pipeline, so that steam extraction pressures adjusted by the steam-side adjusting valve can be controlled, outlet temperatures of the feed water heater can be controlled, and requirements on ultimate feed water temperatures can be met. The joint heat regenerative system has the advantages that heat of steam of boilers can be recycled at starting phases of units by the aid of the joint heat regenerative system, and the problems of low pulverized coal burnout rates, black smoke of fuel oil and easiness in low-temperature moisture condensation, ash clogging, corrosion and the like of equipment such as air preheaters of tail flues in starting phases can be solved by the aid of the joint heat regenerative system.

Owner:冯煜珵

Method for selecting rotating direction of trisector regenerative air preheater of large power station boiler

ActiveCN101922727AChange the temperature riseLarge temperature riseCombustion processIndirect carbon-dioxide mitigationAir preheaterPower station

The invention discloses a method for selecting the rotating direction of a trisector regenerative air preheater of a large power station boiler, aiming to solve the problems that the present rotating direction of the air preheater always causes the moisture condensation of the air preheater or the insufficient drying output power of a pulverization system. The invention is characterized in that when the problems of air preheater moisture condensation caused by season changes or insufficient output power of the pulverization system appear, a motor is reversely rotated to drive a rotor to reversely rotate; and when a heat transfer element rotates, the heat transfer element sequentially passes through a smoke flowing area, a primary air flowing area and a secondary air flowing area for raising the temperature of primary air, thereby the problems of moisture condensation of the air preheater or drying output power of the pulverization system, and the like are solved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY

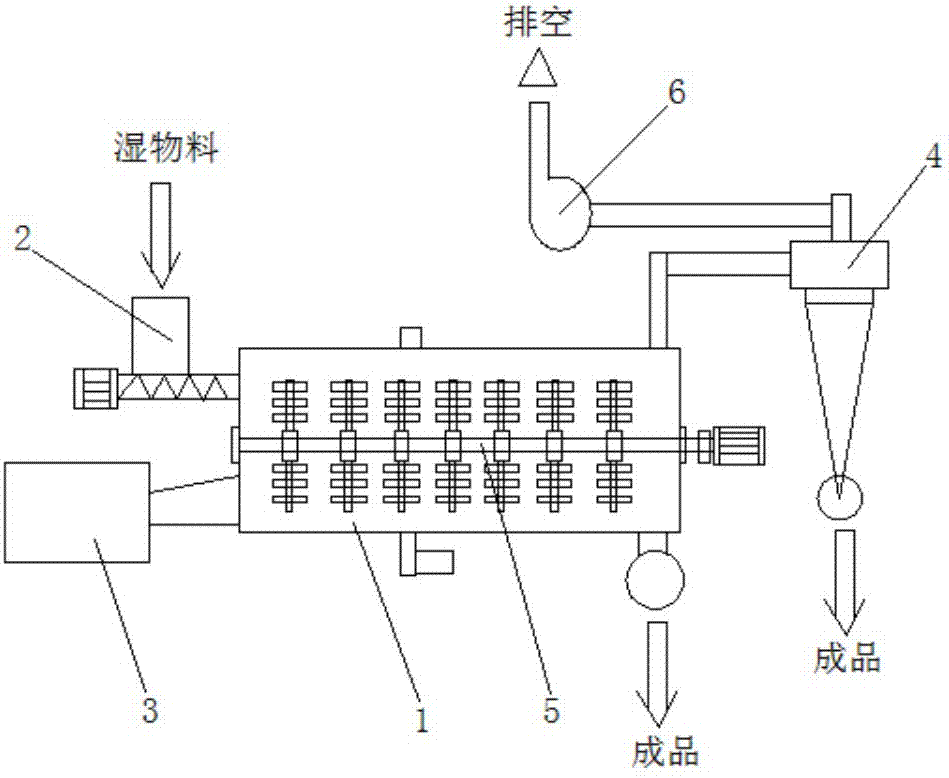

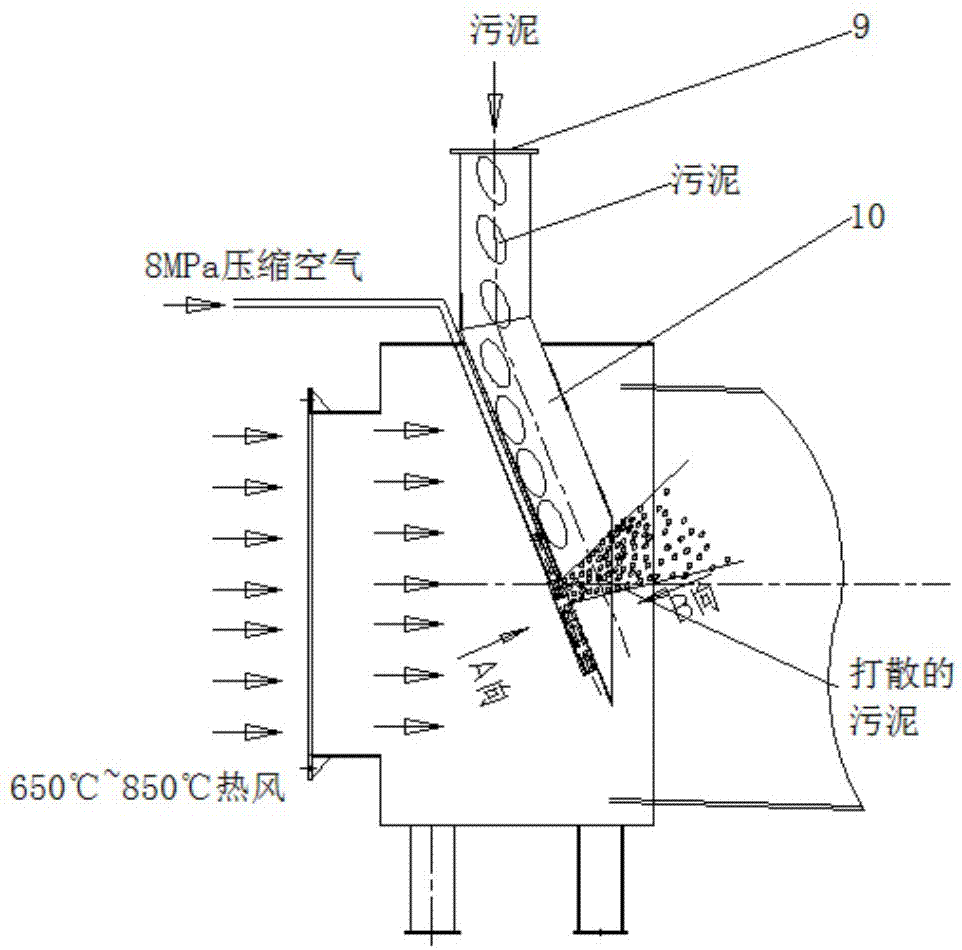

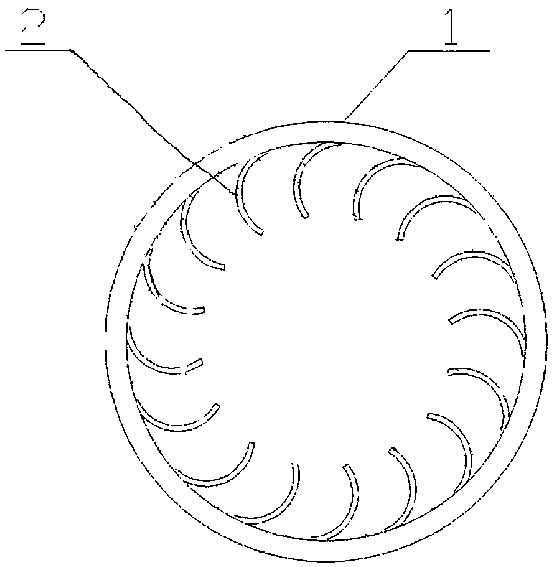

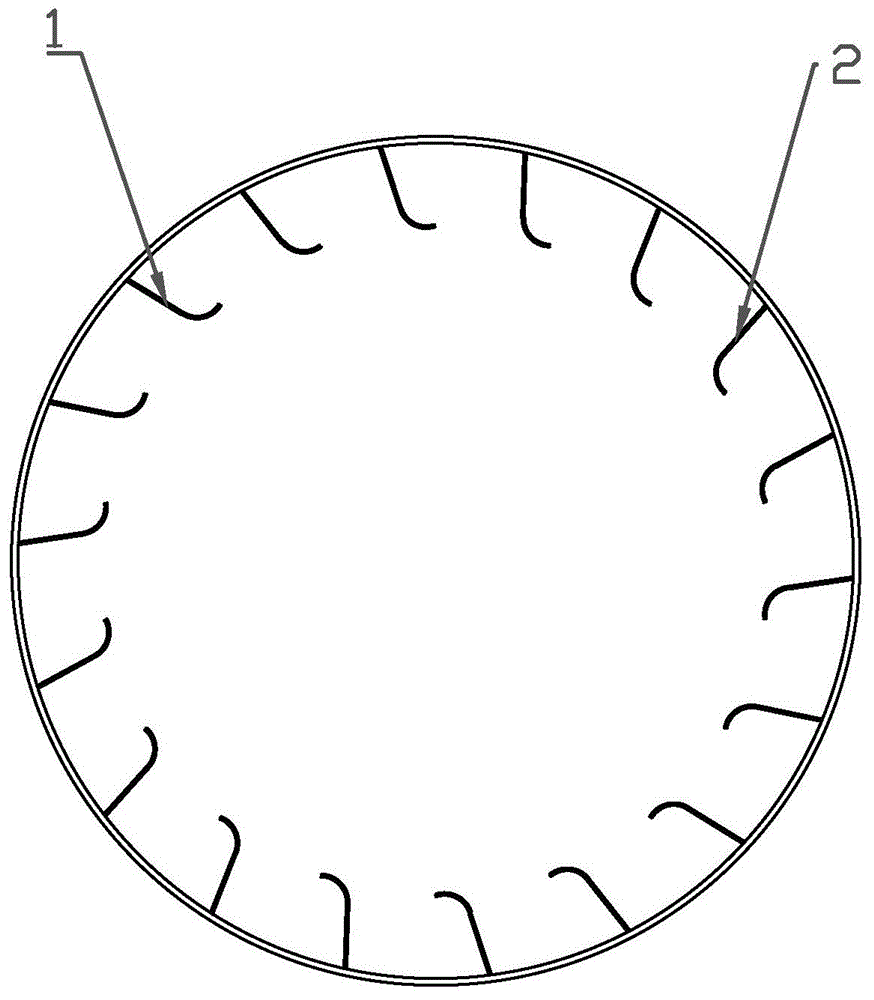

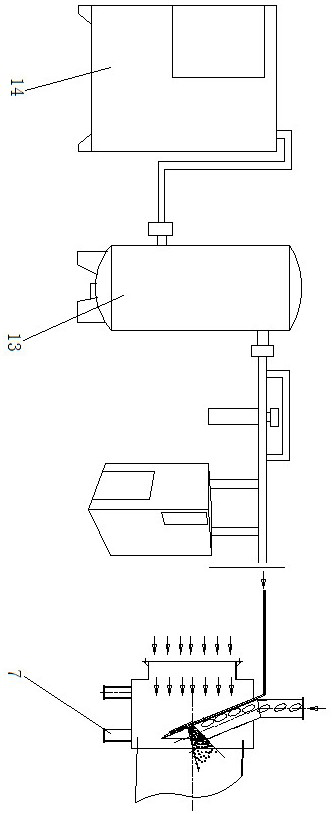

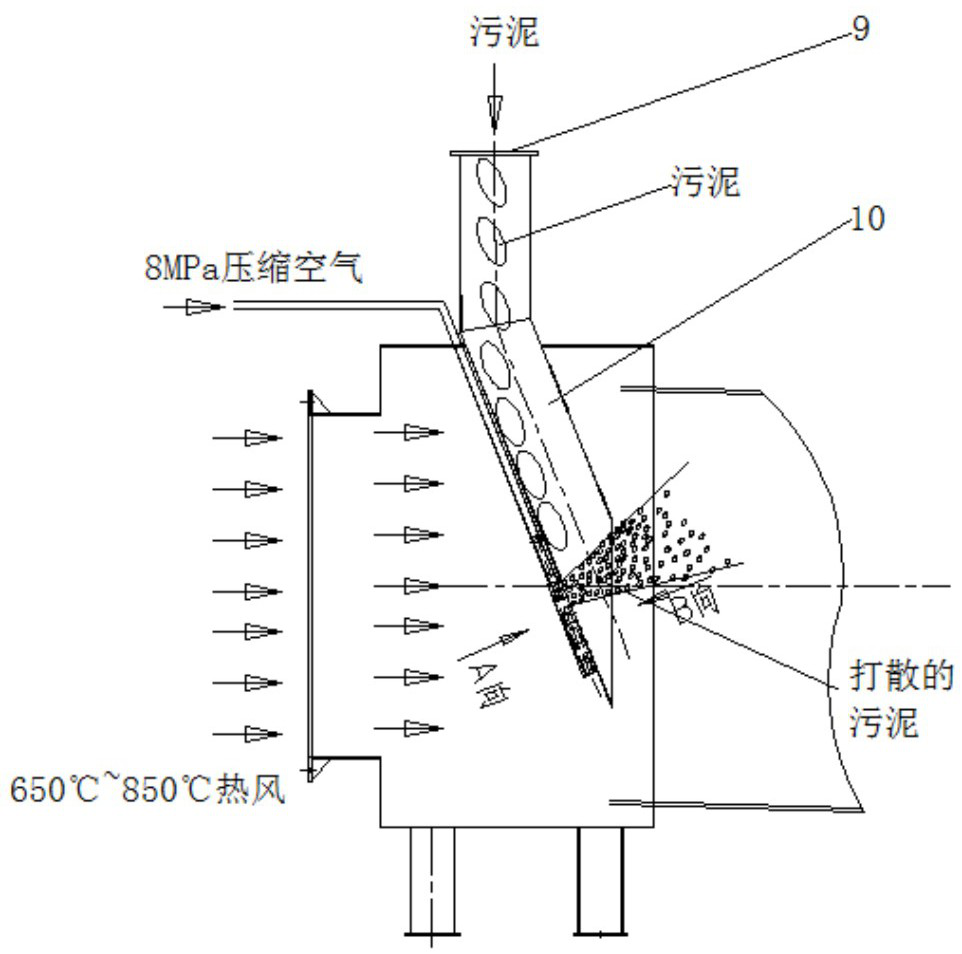

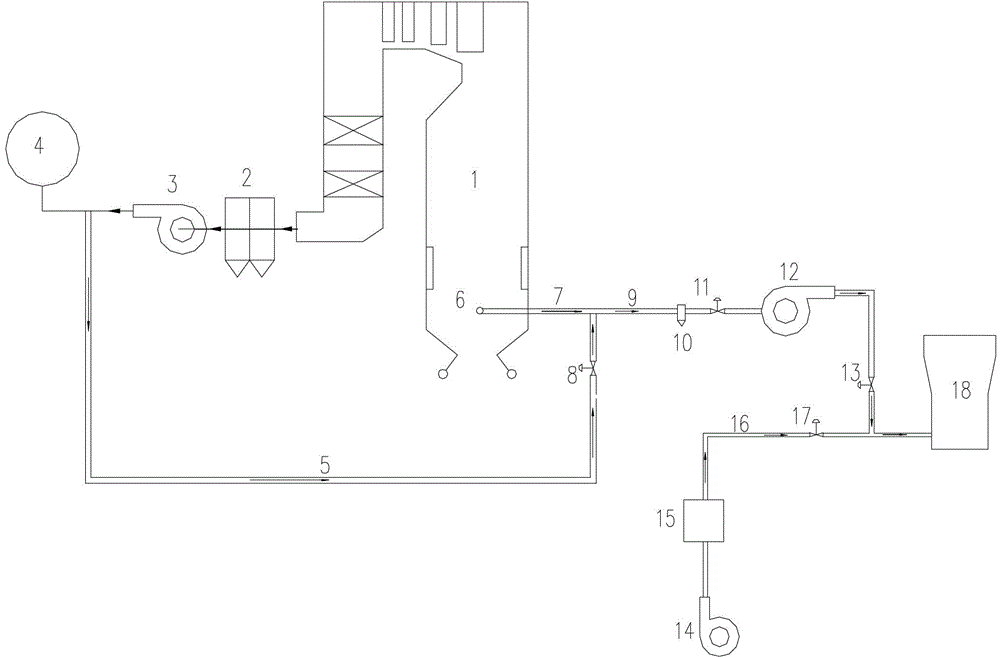

Rotary cylinder dryer for high-pressure airflow sludge scattering device with sprouted bed

ActiveCN106904809AImprove the breaking effectImprove drying outputSludge treatment by de-watering/drying/thickeningGrain treatmentsSludgePulp and paper industry

The invention discloses a rotary cylinder dryer for a high-pressure airflow sludge scattering device with a sprouted bed. The rotary cylinder dryer comprises a dryer body, the dryer body comprises a rotary cylinder, a sludge inlet is formed in the top of the rotary cylinder and extends into the rotary cylinder through a sludge chute, the sprouted bed is arranged at the bottom of the sludge chute, a high-pressure air chamber is formed in the rear side of the sprouted bed, air is supplied for the high-pressure air chamber through a high-pressure air pipe, the high-pressure air pipe comprises a high-pressure air main pipe and a plurality of high-pressure air branch pipes connected with the high-pressure air main pipe, the high-pressure air main pipe is connected with an air compressor through an air storage bag, the sprouted bed sequentially includes a first sprouted bed, a second sprouted bed and a third sprouted bed from top to bottom, and the high-pressure air branch pipes are connected with the first sprouted bed, the second sprouted bed and the third sprouted bed. The rotary cylinder dryer is good in scattering effect, and test operations show that the drying yield of an original rotary cylinder can be doubled.

Owner:FOSHAN FENGHUI MACHINERY

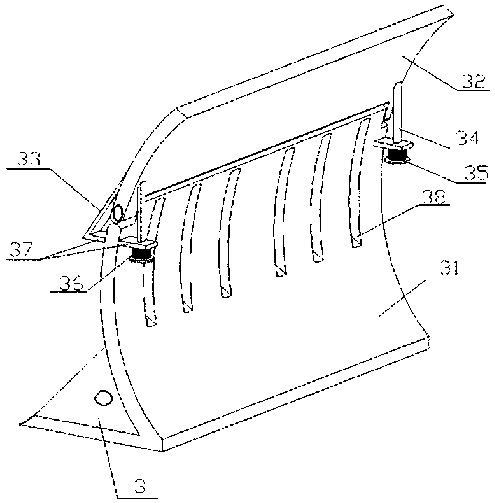

Dryer material lifting mechanism

InactiveCN108826956ALarge scattering areaEvenly distributedDrying solid materialsEngineeringMechanical engineering

The invention relates to a dryer material lifting mechanism. Aiming at the design of a material lifting plate in the prior art, the structure and the position distribution are improved; based on no influence on the material lifting operation, lifted material blocks are effectively prevented from falling and rupturing; and meanwhile, the drying efficiency is improved.

Owner:李晓

grain dryer

ActiveCN105004155BImprove qualityDiffuse fullyDrying gas arrangementsSeed preservation by dryingAgricultural engineeringBreakage rate

The invention discloses a grain dryer, which belongs to the technical field of agricultural food preservation and processing. It mainly includes a drying device; the drying device includes more than one set of drying and slowing devices and a terminal drying cylinder, and the drying and slowing device includes a drying cylinder and a slowing cylinder connected in sequence, and the slowing cylinder and the drying cylinder are connected in sequence. The terminal drying cylinder is connected; the drying cylinder and the terminal drying cylinder are respectively connected to the pipeline; the drying device is connected to the conveying equipment through a cleaning device, and the cleaning device includes a material inlet and an air inlet. A primary deflector is provided, a secondary deflector is provided obliquely below the primary deflector, and a discharge port is provided directly below the primary deflector. The invention has the advantages of simple structure, convenient use, easy repair and maintenance, large drying capacity, good performance of dried grain products, and greatly reduced waist burst rate and broken rate. The invention is mainly used for grain drying.

Owner:LINYI JIHONG MACHINERY MFR

Dust-removing dryer for grain

InactiveCN106804699AFast and efficient dryingImprove qualityUsing liquid separation agentSeed preservation by dryingPulp and paper industryAir blower

The invention relates to a dust-removing dryer for grain and belongs to the field of agricultural drying machinery. The dryer comprises a box, an air heater and a purification tank, wherein water is contained in the purification tank, an air blower is arranged at the top of the box, an air outlet of the air blower is connected with an air inlet of the box, and an air inlet of the air blower is connected with the air heater through a pipeline; drying pipes are arranged in the box, a plurality of through holes are formed in the side wall of each drying pipe, and exhaust ports are formed in one side wall of the box and extend into the liquid level of the purification tank. The dust-removing dryer for the grain dries the grain in an up-ventilation and down-exhaust manner, the grain is ensured to be dried quickly and effectively, and the workload of farmers can be reduced; moisture in the grain is fully diffused, the quality of the dried grain is higher, the exhaust ports are placed in water, impurities and dust in exhaust air are adsorbed by water, pollution can be prevented, the exhaust air is purified, and the dryer is simple in structure and has very high practicability.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

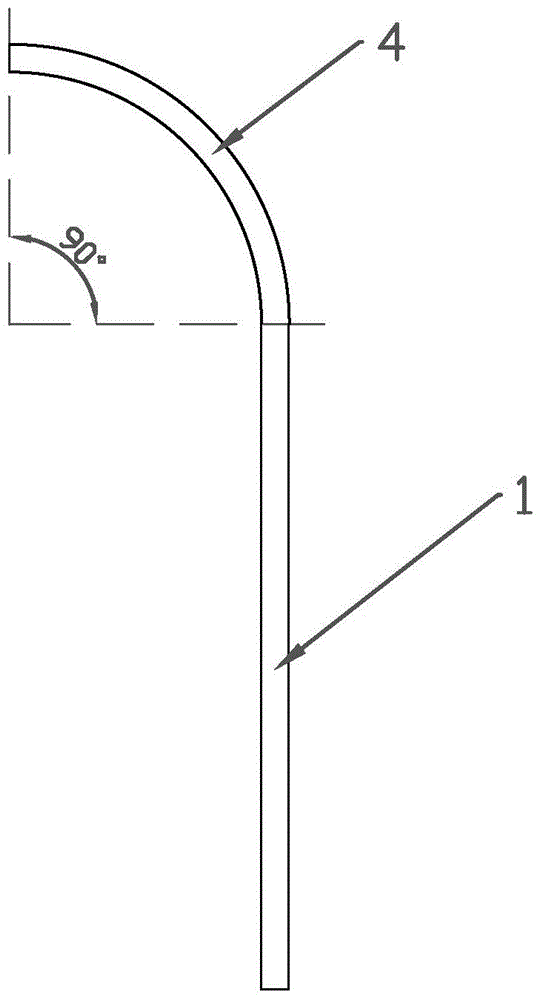

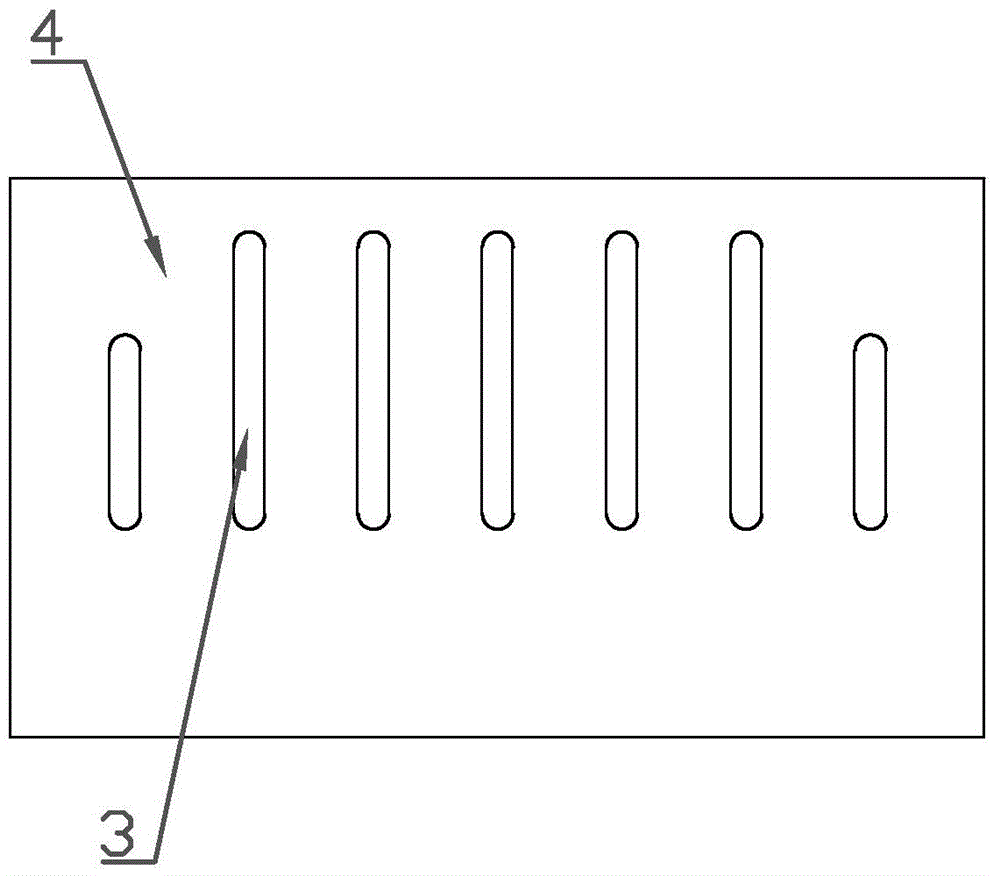

Lifting board device of drying machine

InactiveCN104019656AIncrease the scattered areaReduce thermal voidingDrying solid materialsEngineeringMechanical engineering

The invention discloses a lifting board device of a drying machine. The lifting board device comprises a plurality of lifting boards and a drying barrel body for installing the lifting boards, wherein the lifting boards are uniformly arranged in the drying barrel body and are welded on the drying barrel body. The lifting board device is characterized in that seven or eight grid gaps are formed in each lifting board; the upper end of each lifting board is bent and is in an arc shape; the grid gaps are distributed in the arc-shaped part of each lifting board; the length of each grid gap is 120-180 mm and the width of each grid gap is 10-15 mm; the lifting boards comprise forward lifting boards, backward lifting boards and horizontal lifting boards which are distributed in a staggered manner in the drying barrel body. The lifting board device of the drying machine has the characteristics of small size, light weight, simple structure and convenience in installing and maintenance, and the technical problem in a traditional inner structure of a drying machine is effectively solved.

Owner:SHANDONG ZHANGQIU BLOWER

Biomass gas coupled coal-fired unit power generation device

PendingCN109705920AEfficient use ofIncrease power generation timeEnergy inputGranular/pulverulent flues gasificationAir preheaterOne pass

The invention provides a biomass gas coupled coal-fired unit power generation device, which mainly solves the problems that under an ultralow load situation, SCR inlet temperature is lower than effective working temperature of a catalyst, which causes that denitration cannot be put in use. A circulating fluidized bed gasifier, a cyclone dust collector, a fuel gas heat exchanger are successively connected via pipelines. The outlet of the fuel gas heat exchanger is divided into two paths: one passes through a fuel gas combustor A via a path-A fuel gas pipeline and is connected to the hearth of aboiler furnace, the other passes through a fuel gas combustor B via a path-B fuel gas pipeline and is connected to a horizontal flue in the front of a SCR denitration device. The SCR denitration device is connected to the outlet of a coal-firing boiler economizer through the horizontal flue. The fuel gas combustion chamber of the fuel gas combustor B is connected to a tail secondary air duct of the coal-firing boiler. The tail secondary air duct of the coal-firing boiler and the outlet flue of the SCR denitration device are respectively to a revolving air preheater. The device achieves coupled power generation of the biomass flue gas and the coal-fired unit under an ultralow load situation of the coal-fired unit.

Owner:HARBIN BOILER

Adjustable feed water heat regenerative system for turbo generator unit

ActiveCN102537933BIncrease temperatureIncrease profitMachines/enginesFeed-water heatersEngineeringHigh pressure

The invention provides an adjustable feed water heat regenerative system for a turbo generator unit, which comprises a high pressure cylinder of a steam turbine, a final-stage extraction opening, a final-stage feed water heater, a steam extraction pipe and a regulating valve, wherein the final-stage extraction opening is additionally arranged on the high pressure cylinder; the steam extraction pressure of the final-stage extraction opening is much higher than the common highest extraction pressure; additionally extracted steam is used as a heat source of the final-stage feed water heater; the steam extraction pipe is connected with the final-stage extraction opening and the final-stage feed water heater; and the regulating valve is arranged on the steam extraction pipe. Part of steam which does work is guided to the feed water heater through the final-stage steam extraction pipe so as to further heat feed water of a boiler. The heat regenerative system provided by the invention is an elastic heat regenerative system. The temperature of the feed water can be maintained or changed under the variable load condition of the unit, so that the environmental friendliness, the economy and the safety of the unit are improved and the frequency modulation characteristic is perfected.

Owner:冯伟忠

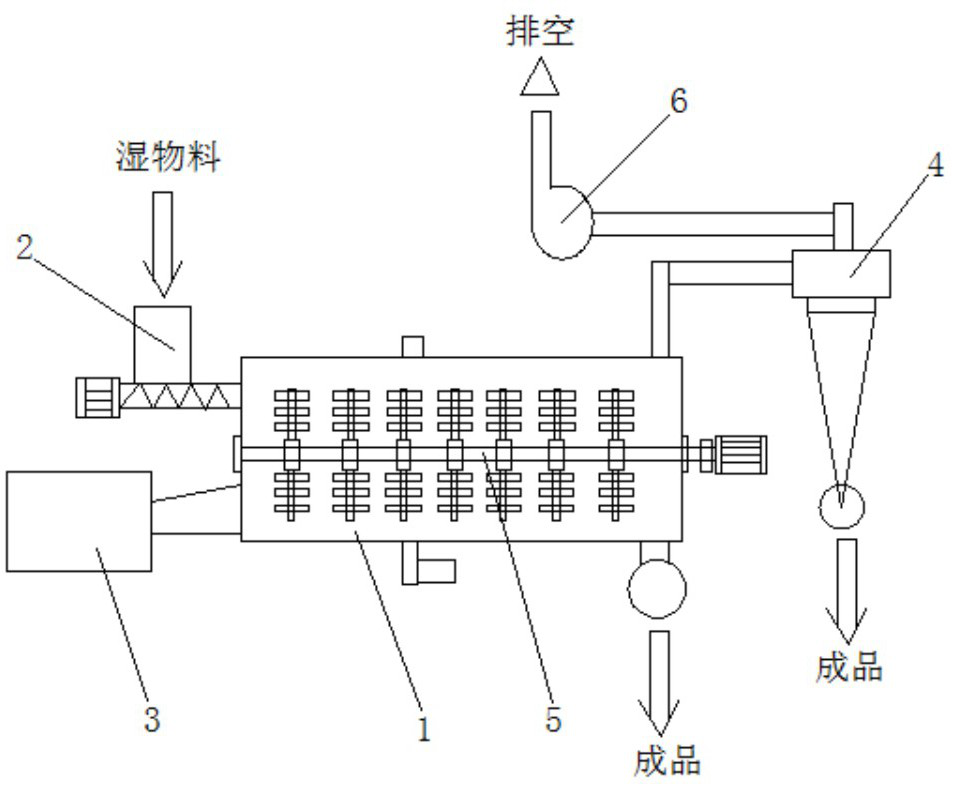

Rake type pulverizing hot air stirring sludge drying device

InactiveCN108168250AGood breaking effectOvercome feed agglomerationDrying gas arrangementsDrying chambers/containersSludgeSolid fuel

The invention discloses a rake type pulverizing hot air stirring sludge drying device. The rake type pulverizing hot air stirring sludge drying device is composed of a speed changing motor, a feedinggroove, a spiral material guiding and feeding shaft, a machine body, grid section wing plate scattering teeth, a stirring shaft, an air outlet, a bearing fixing sleeve, a discharging port, machine legs, a hot air inlet pipe, a speed reducer, a supporting platform and a stirring motor. The hot air inlet pipe is adopted for drying sludge biological organic fertilizer and biological solid fuel entering the machine body, the stirring shaft with the grid section wing plate scattering teeth arranged at equal intervals is used for stirring and pulverizing the sludge biological organic fertilizer andthe biological solid fuel entering the machine body, and the defects that feeding is caked, pulverizing is difficult and the drying effect in blocks is not good are overcome. The beneficial effects that the drying yield is high, the treating capability is high, the material body pulverizing, colliding and scattering effects are good, and the processing cost is low are achieved; and the rake type pulverizing hot air stirring sludge drying device is ideal equipment for sludge biological organic fertilizer and biological solid fuel drying production.

Owner:党庆风

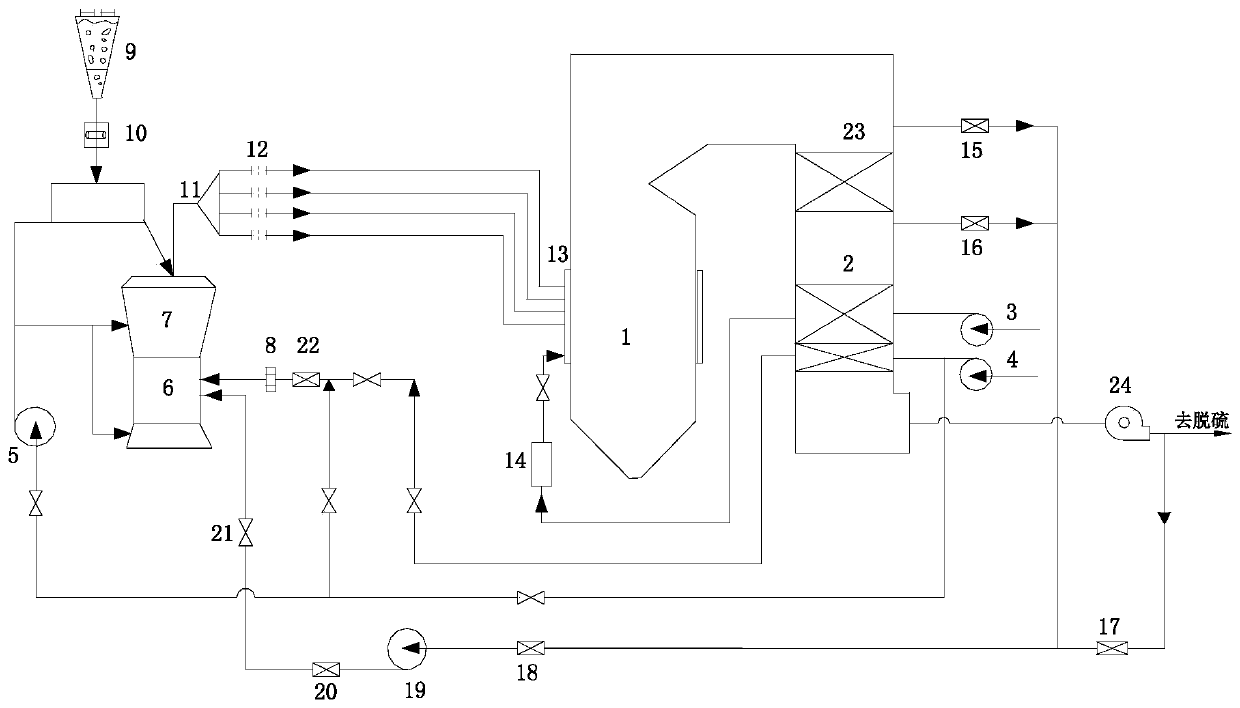

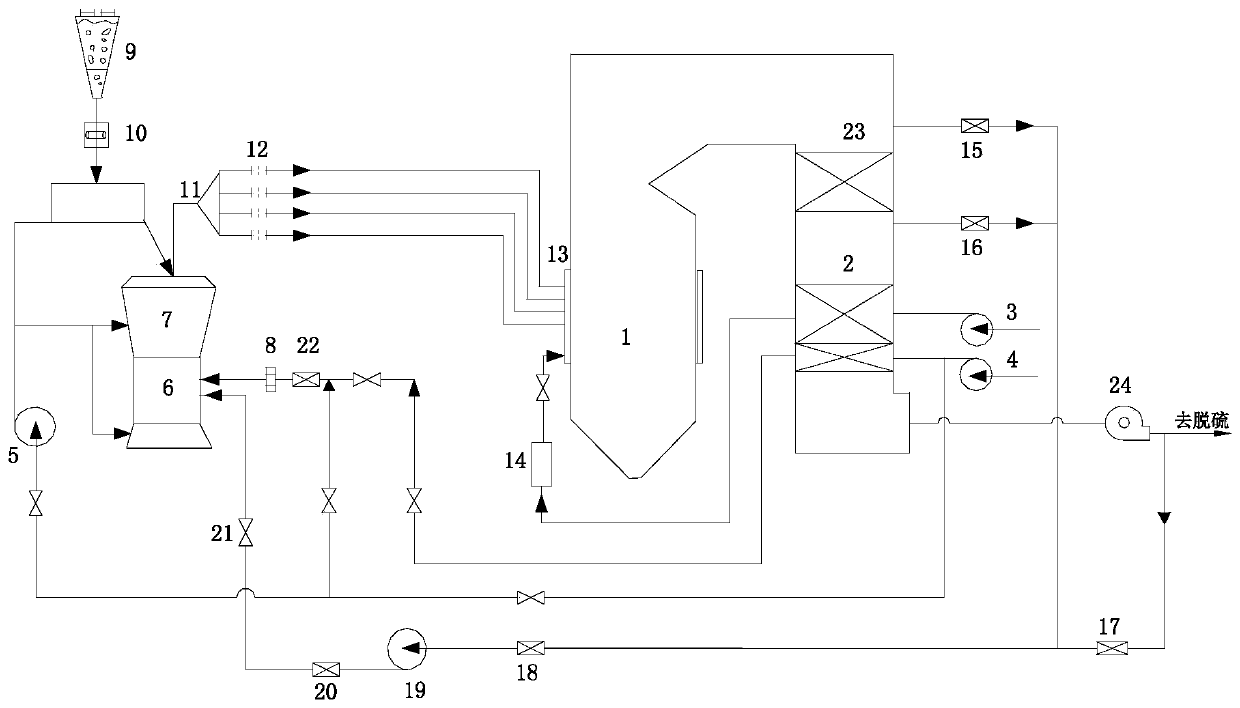

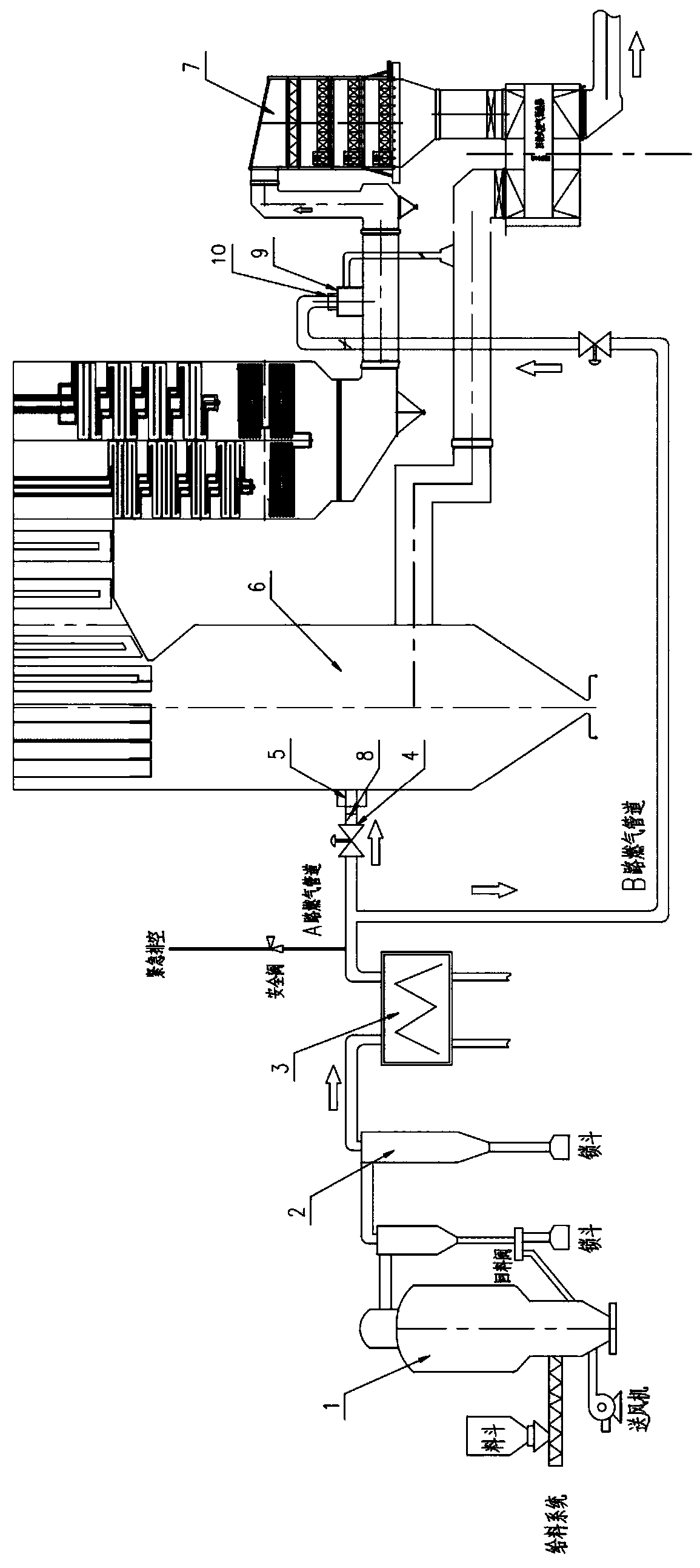

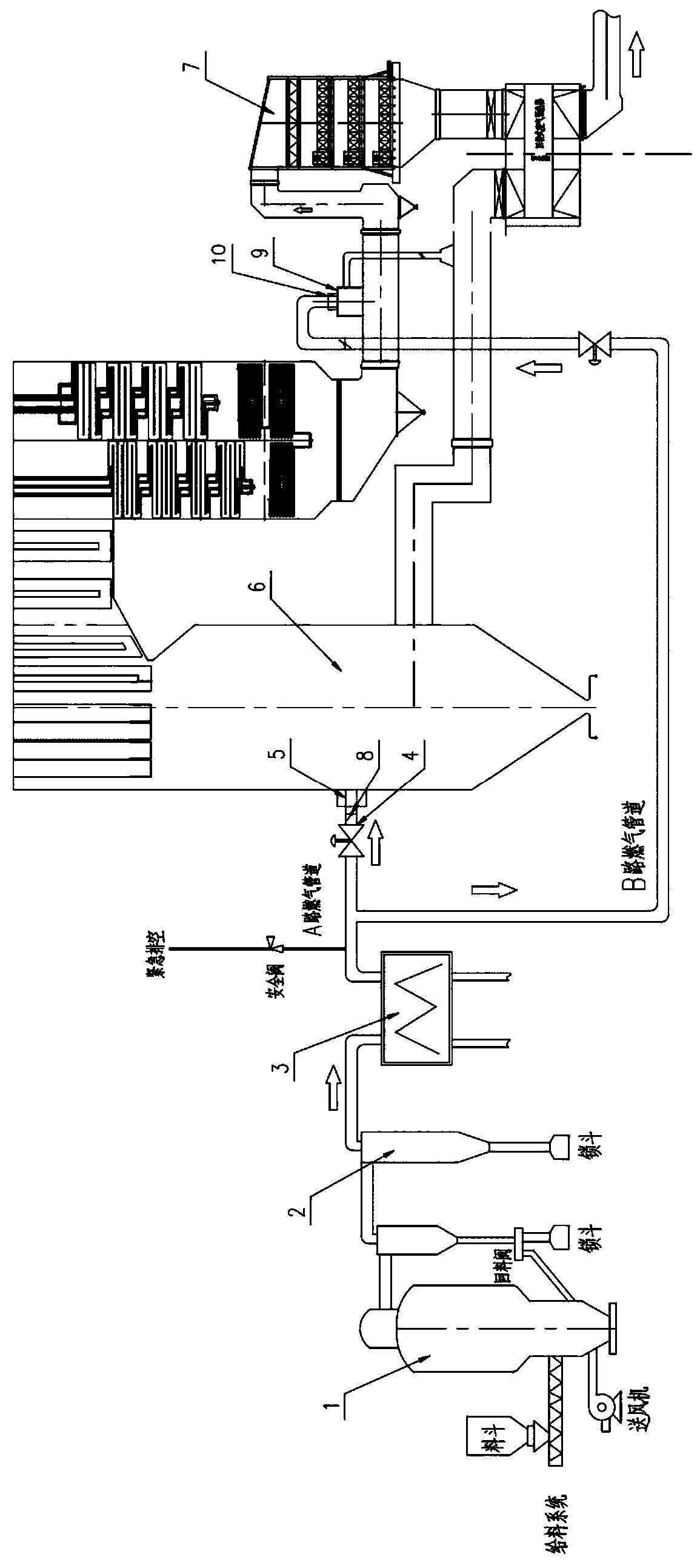

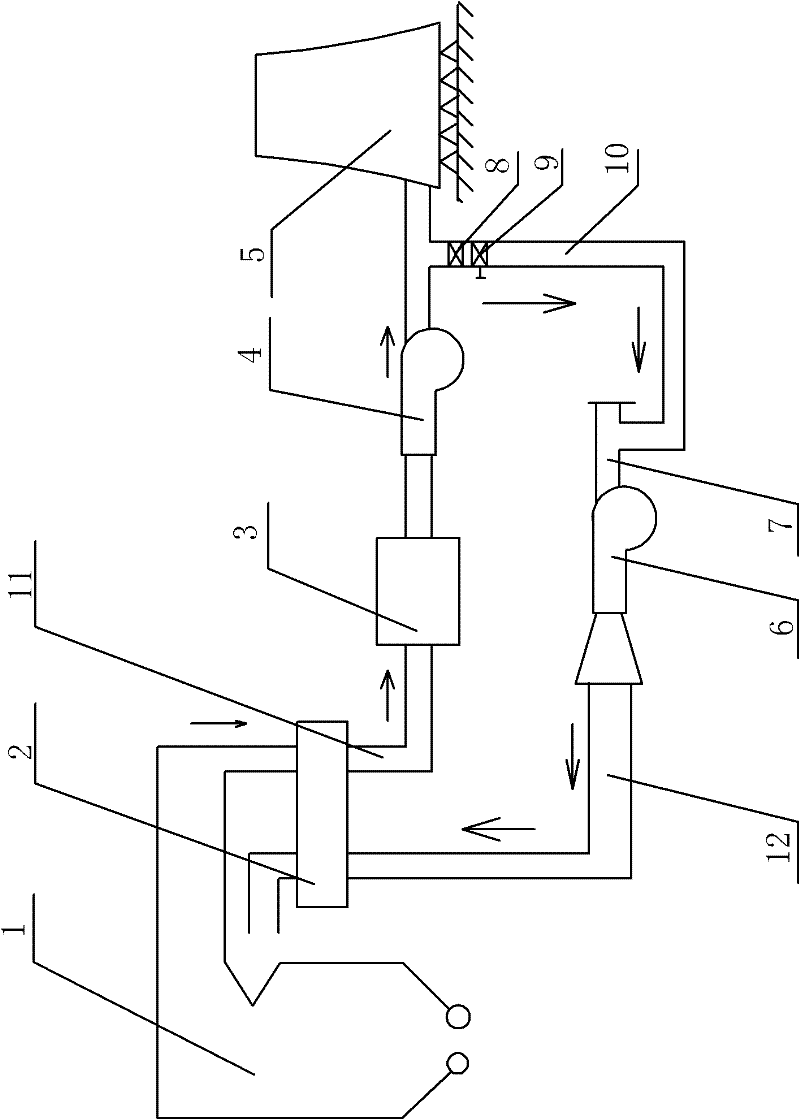

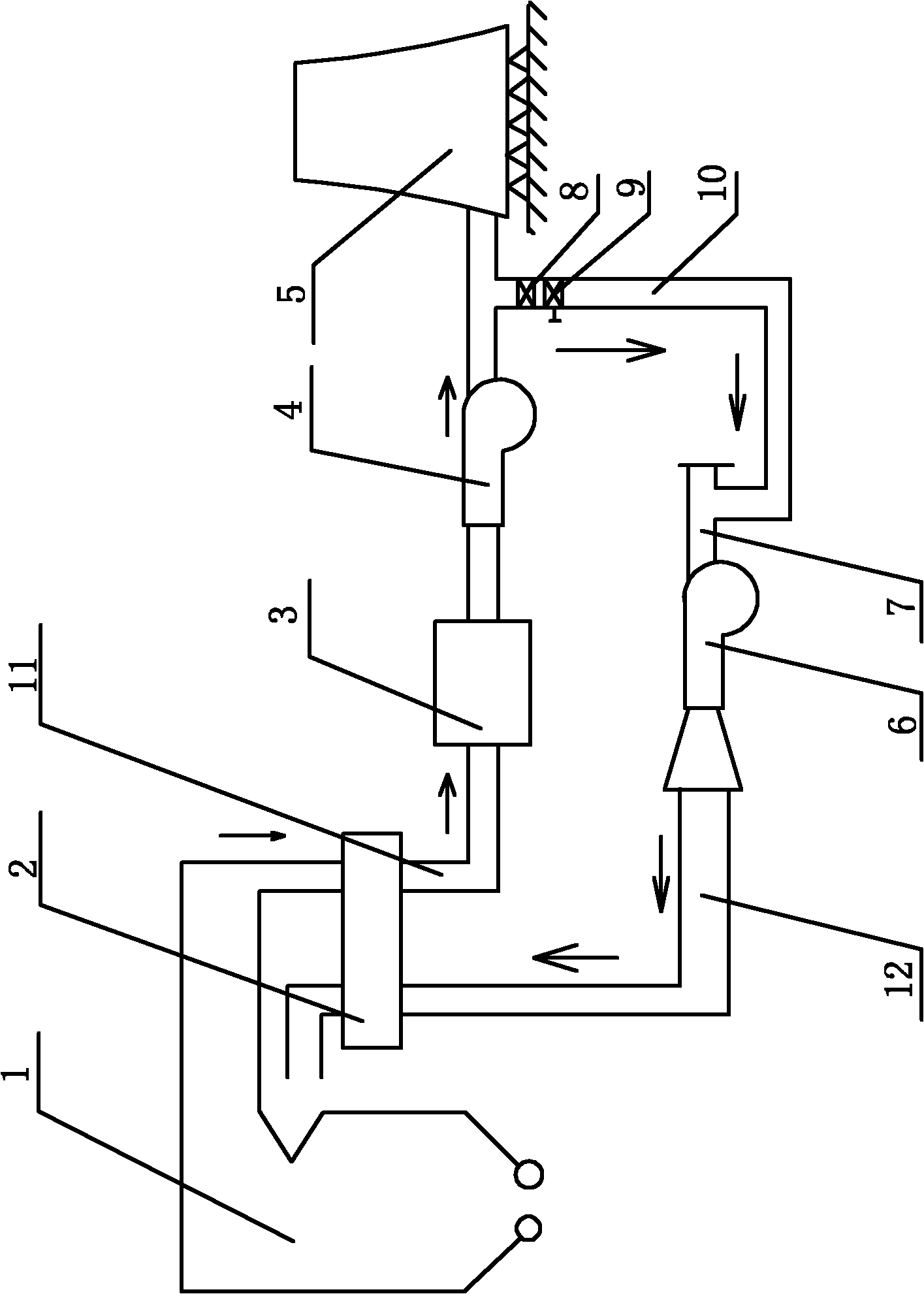

Boiler powder generation system for burning lignite in power station gas duct and cooling tower machine

InactiveCN101936537BImprove drying outputImprove operational safetyLump/pulverulent fuel preparationAir preheaterCooling tower

The invention discloses a boiler powder generation system for burning lignite in a power station gas duct and cooling tower machine, which relates to a boiler powder generation system. The aim of the invention is to solve the problem that lignite in a bitumite-combusting boiler in the conventional thermal power generation causes a great safety hazards. An outlet end of a first pipe is communicated with a gas duct and cooling tower through a dust collector for electrical appliances and a draught fan in turn; the inlet end of a cold boiler gas duct is communicated with the first pipe; the communication part of the cold boiler gas duct and the first pipe is positioned between the draught fan and the gas duct and cooling tower; a cold boiler gas insulating baffle plate and a cold boiler gas regulating baffle plate are arranged from the inlet end of the cold boiler gas duct to the outlet of the cold boiler gas duct in turn; the outlet end of the cold boiler gas duct is communicated with an inlet air duct; the outlet end of the inlet air duct is communicated with the inlet end of a primary fan; the outlet end of the primary fan is communicated with the inlet end of a second pipe; and the outlet end of the second pipe is communicated with the cold end of an air preheater. The invention is used in technology for burning lignite in the power station gas duct and cooling tower machine.

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

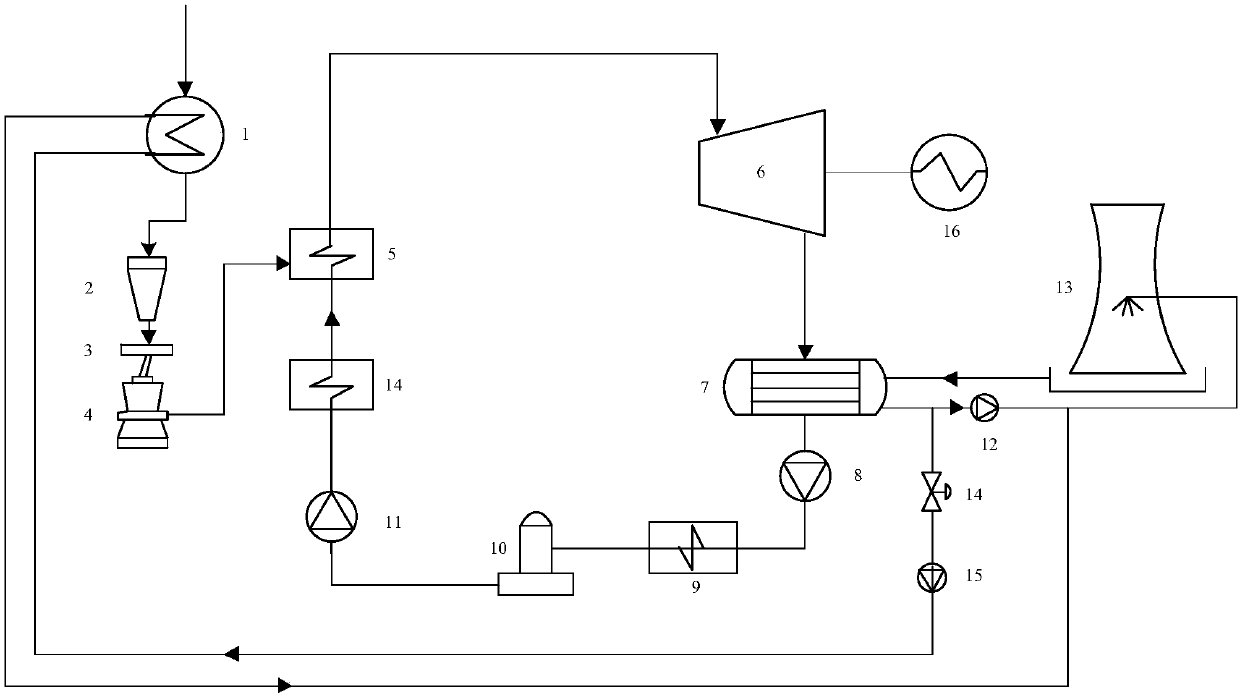

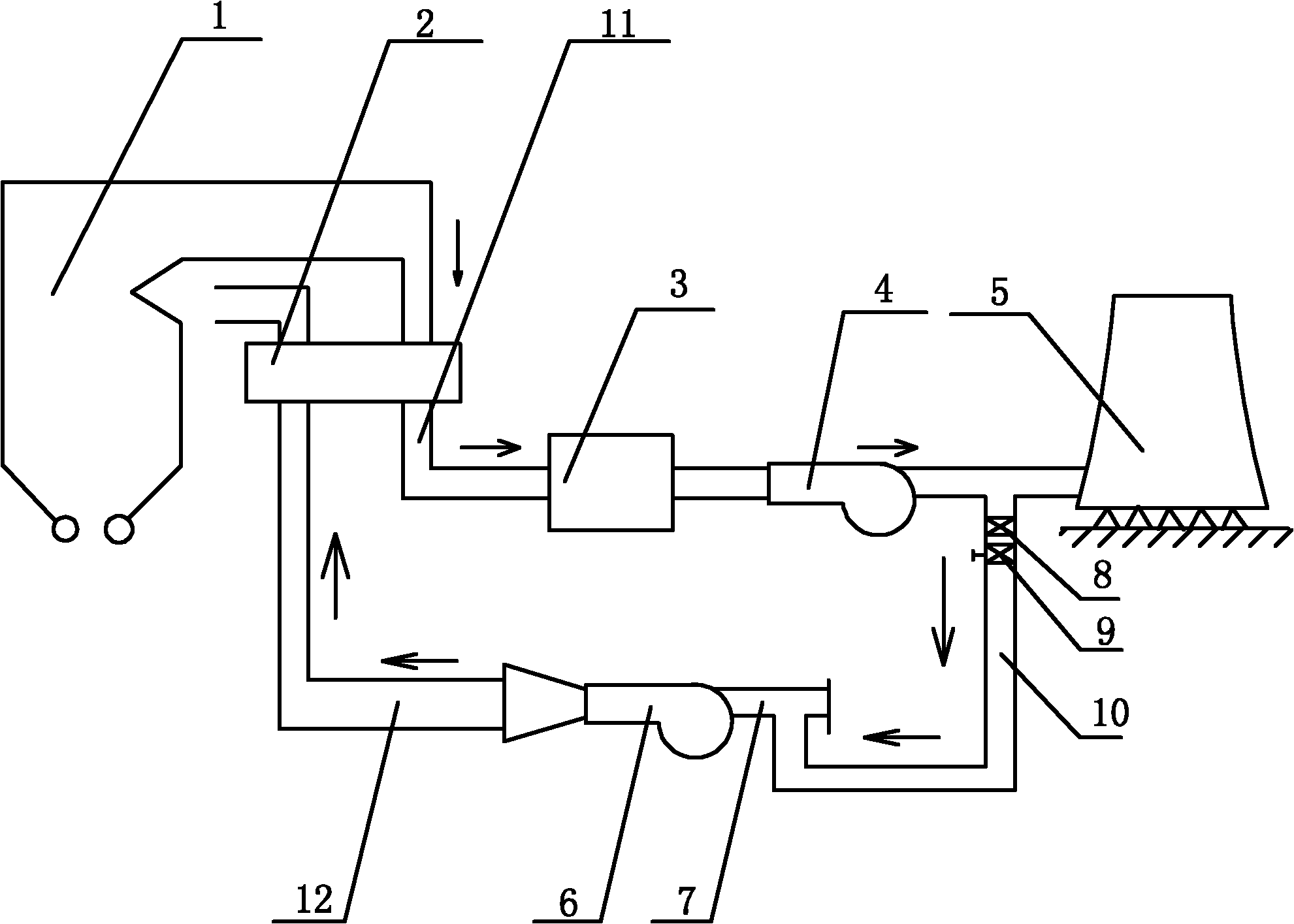

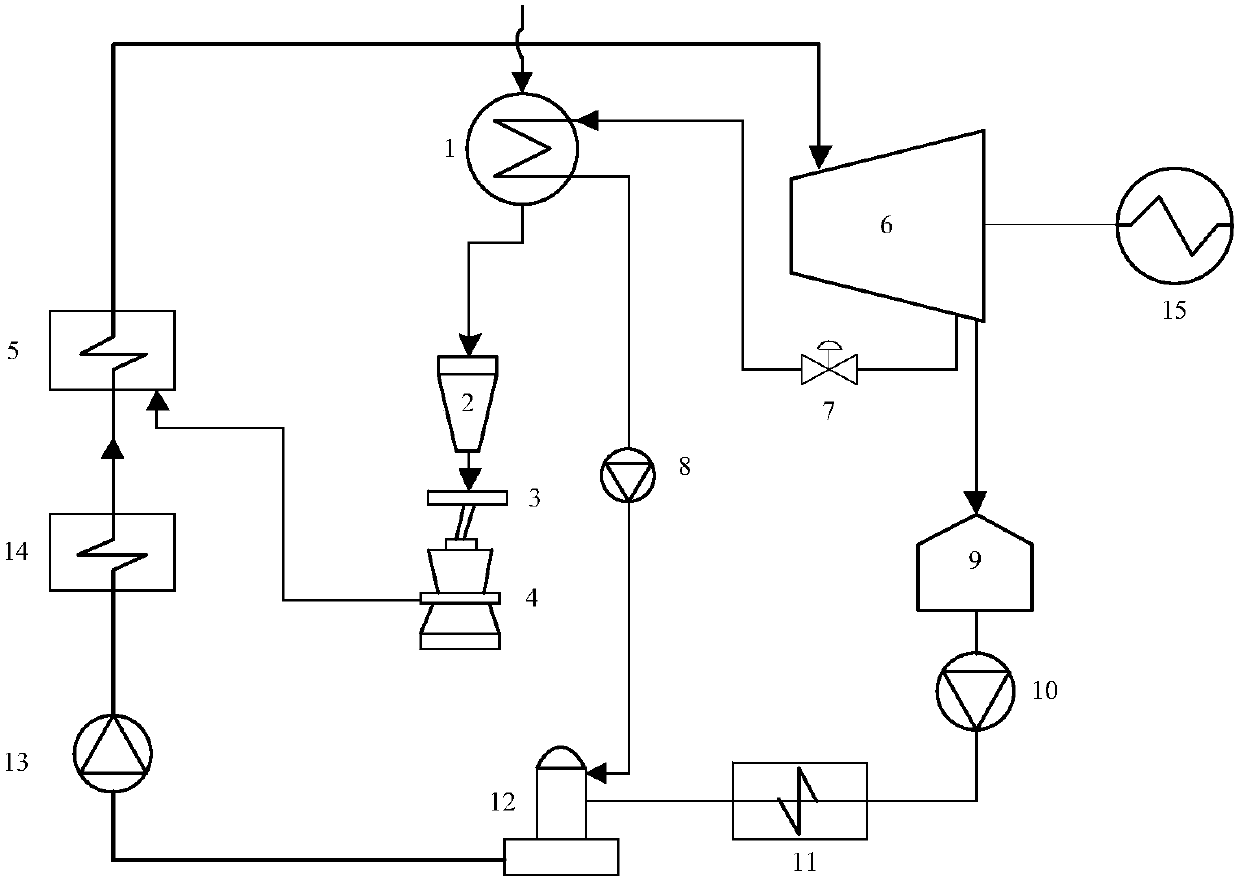

Power generating system utilizing circulating cooling water to heat raw coal

PendingCN107620975AEfficient use ofIncrease temperatureSteam useLump/pulverulent fuel preparationCoalElectric generator

The invention provides a power generating system utilizing circulating cooling water to heat raw coal. Raw coal in a coal field enters a coal cabin after being heated and unfrozen by a heat exchangerarranged under the ground of the coal field, and then the raw coal is fed into a coal mill through a coal feeder so as to be pulverized; qualified pulverized coal is carried into a boiler through primary air so as to be burned; exhausted steam of a steam turbine enters a steam condenser to release heat, then the exhausted steam is fed into a low-pressure heater through a condensate water pump, isheated and then enters a deaerator, generated steam is fed into a high-pressure heater through a feed pump and then enters the boiler to absorb heat, steam with the corresponding parameters returns tothe steam turbine to act, and the steam turbine drives a power generator to generate power; and exhausted steam of the steam turbine exchanges heat with circulating cooling water in the steam condenser, part of heated circulating cooling water is fed into a raw coal heater through a water pump, after raw coal heating, the part of heated circulating cooling water is converged with the other part of circulating cooling water which passes through a circulating water pump and then fed into a cooling tower to be cooled, and cooled circulating cooling water is fed into the steam condenser again toachieve circulation. The power generating system has important significance to efficient utilization of a thermal power generation unit which fires high-moisture coal.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

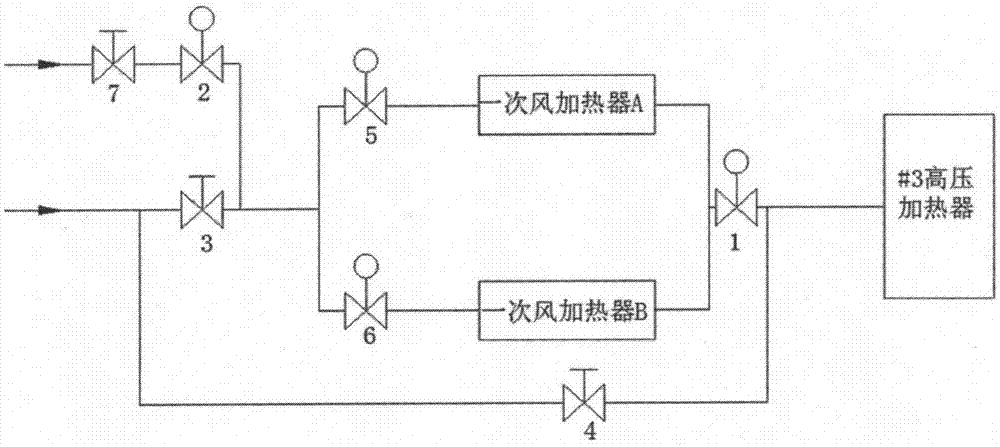

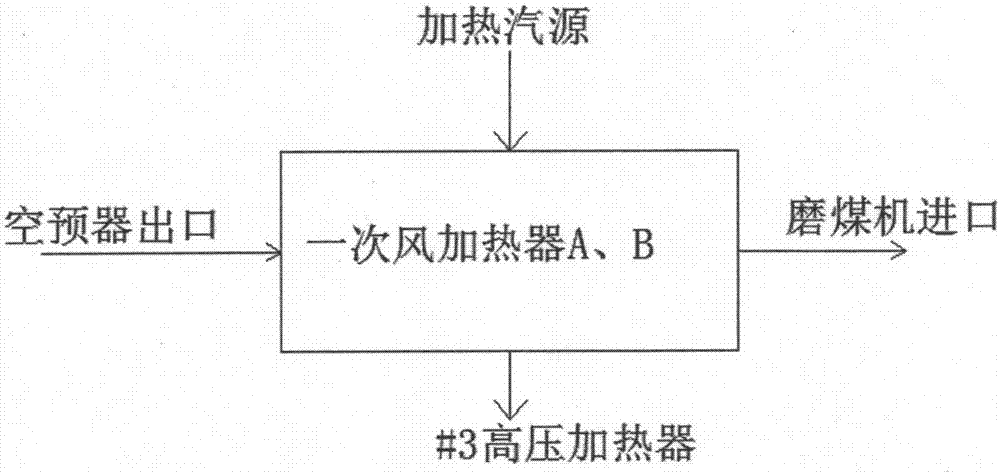

Hot primary air heating system for dry coal pulverizing system

InactiveCN107504512AAchieve energy saving effectLow running costHeating arrangementLump/pulverulent fuel preparationEngineeringHigh pressure

The invention provides a hot primary air heating system for a dry coal pulverizing system. The hot primary air heating system comprises a steam extraction pipeline, wherein the steam extraction pipeline is connected to the steam extraction end of a steam turbine, and the steam extraction pipeline communicates with a high-pressure heater. The hot primary air heating system is characterized in that a stop valve I is arranged on a pipeline between the steam extraction pipeline and the high-pressure heater, the hot primary air heating system further comprises a primary air heater I, a primary air heater II and a reheat steam pipeline, the steam extraction pipeline is connected to the inlet ends of the primary air heater I and the primary air heater II by virtue of a stop valve II at the same time, the outlet ends of the primary air heater I and the primary air heater II communicate with the high-pressure heater, the reheat steam pipeline communicates with a reheater, and the reheat steam pipeline is connected to the inlet ends of the primary air heater I and the primary air heater II by virtue of a stop valve III at the same time. According to the hot primary air heating system, the degree of superheat of high-temperature steam is fully used, so that the effect of energy conservation of a whole thermal cycle unit is achieved, the drying capacity of the coal pulverizing system is increased, and the operating cost of the unit is reduced.

Owner:SHANGHAI POWER EQUIP RES INST

A system to improve the drying output of the intermediate storage pulverizing system when the boiler changes the coal type

ActiveCN103148496BImprove qualityImprove drying outputDrying gas arrangementsLump/pulverulent fuel preparationFlue gasProcess engineering

The invention discloses a system for improving the drying capacity of a bin and feeder coal pulverizing system when a boiler changes coal types and relates to a system for improving the drying capacity of a coal pulverizing system. The invention aims at solving the problem that boilers adopting the bin and feeder coal pulverizing system change the coal types in thermal power enterprises, in particular to the problems of safety and economy of boiler operation in the lignite-bleeding burning process. A high-temperature coal economizer manhole is communicated with a first warm air isolating door air inlet and a second warm air isolating door air outlet by a flue gas pipeline of the system; and a flue gas isolating door and a flue gas adjusting door are sequentially arranged on the flue gas pipeline according to the flowing direction of mediums. The system disclosed by the invention has the advantages of low reforming cost, low operation and maintenance cost, reliability in operation and capability of operating for a long time. The system is used for reforming the coal pulverizing system when the boiler adopting the bin and feeder coal pulverizing system changes the coal types.

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

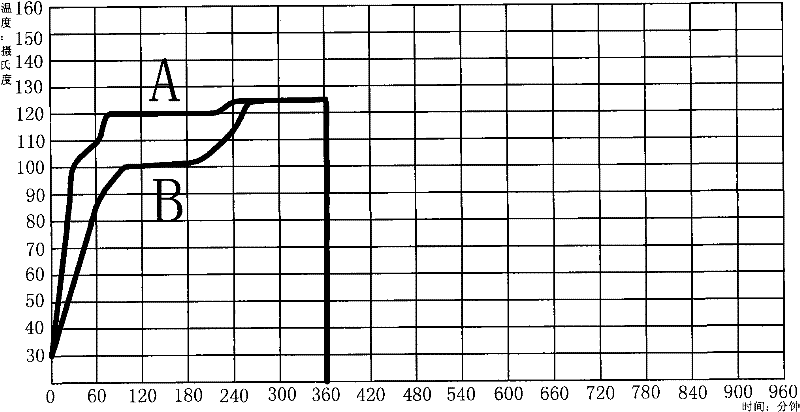

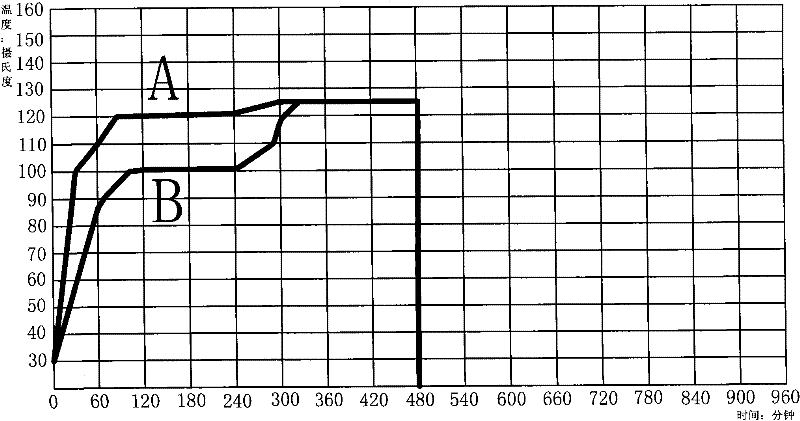

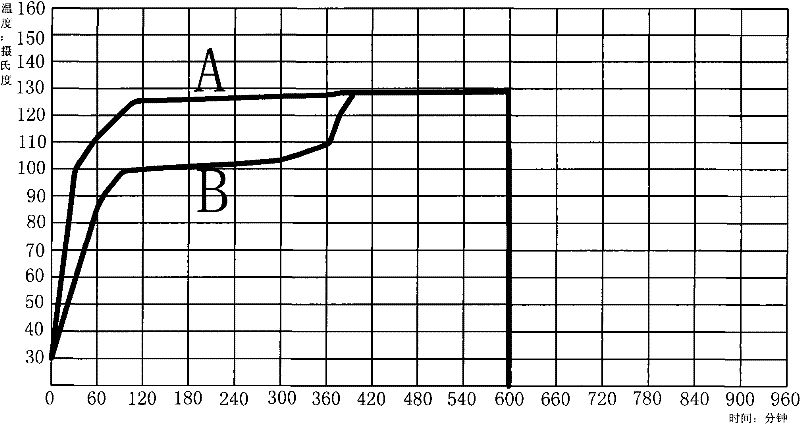

Process for drying glass fiber filament by using hot blast air and microwave

The invention relates to a process for drying a glass fiber strand by using hot blast air and microwave, which comprises the following steps: (a) temperature-raising time period: the setting temperature of a drying oven during the temperature-raising time period is 85-115DEG C, the time is 1-2.5hours and the microwave power density is 0-4kW / m<3>; (b) water-pumping time period: the setting temperature of the drying oven during the water-pumping time period is 100-125DEG C, the time is 2-10 hours and the microwave power density is 0-4kW / m<3>;and (c) film-forming time period: the setting temperature of the drying oven during the film-forming time period is 115-130DEG C, the time is 1-4.5 hours and the microwave power density is 0-2kW / m<3>. The invention can overcome the technical defects in the prior art that nonuniform drying inside and outside a spool bobbin or a spinning cake, poor film-forming property by drying, easy yarn burst, long drying time, poor stiffness and instable production quality in the process of drying the glass fiber strand and an oversized glass fiber spool bobbin cannot be effectively dried.

Owner:YANTAI NORTH MICROWAVE TECH

Boiler powder generation system for burning lignite in power station gas duct and cooling tower machine

ActiveCN101936537AImprove drying outputImprove operational safetyLump/pulverulent fuel preparationAir preheaterCooling tower

The invention discloses a boiler powder generation system for burning lignite in a power station gas duct and cooling tower machine, which relates to a boiler powder generation system. The aim of the invention is to solve the problem that lignite in a bitumite-combusting boiler in the conventional thermal power generation causes a great safety hazards. An outlet end of a first pipe is communicated with a gas duct and cooling tower through a dust collector for electrical appliances and a draught fan in turn; the inlet end of a cold boiler gas duct is communicated with the first pipe; the communication part of the cold boiler gas duct and the first pipe is positioned between the draught fan and the gas duct and cooling tower; a cold boiler gas insulating baffle plate and a cold boiler gas regulating baffle plate are arranged from the inlet end of the cold boiler gas duct to the outlet of the cold boiler gas duct in turn; the outlet end of the cold boiler gas duct is communicated with an inlet air duct; the outlet end of the inlet air duct is communicated with the inlet end of a primary fan; the outlet end of the primary fan is communicated with the inlet end of a second pipe; and the outlet end of the second pipe is communicated with the cold end of an air preheater. The invention is used in technology for burning lignite in the power station gas duct and cooling tower machine.

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

Regenerative system of turbogenerator unit and operation method thereof

ActiveCN103644005BSolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

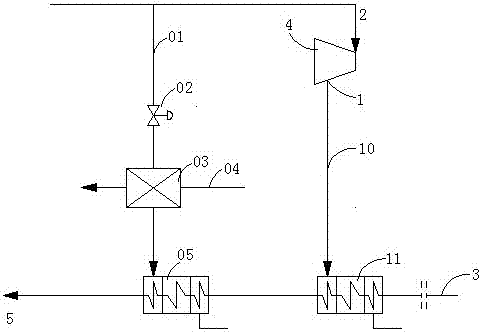

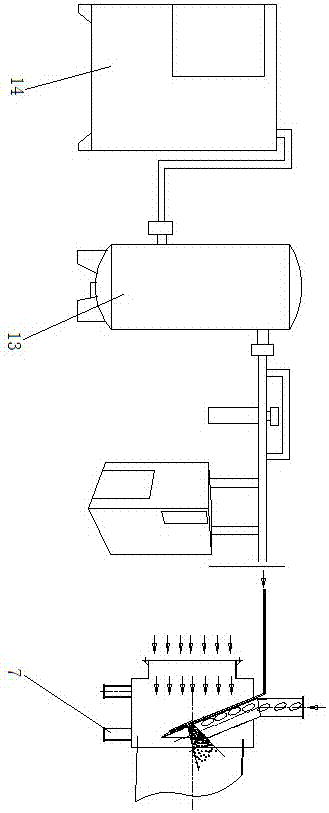

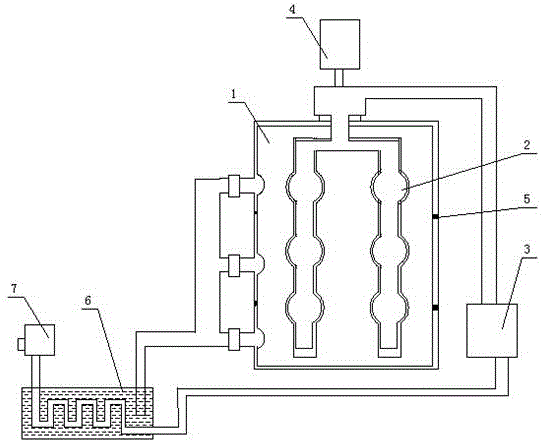

System using low-pressure steam extraction of steam turbine to heat raw coal for power generation

The invention discloses a system using low-pressure steam extraction of a steam turbine to heat raw coal for power generation. The system comprises a heat exchanger (1), a coal bin (2), a coal feedingmachine (3), a coal mill (4) and a boiler (5), wherein the heat exchanger (1), the coal bin (2), the coal feeding machine (3), the coal mill (4) and the boiler (5) are connected in sequence. After being heated to be unfrozen through the heat exchanger (1) arranged below the ground of a coal yard, the raw coal in the coal yard enters the coal bin (2); then, the raw coal is delivered into the coalmill (4) to be made into powder through the coal feeding machine (3); and qualified coal powder is carried by primary air and enters the boiler (5) to be burnt. By means of the system, great significance is achieved for efficient utilization of thermal power generation units which burn high-moisture coal for use in cold areas of northern China.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

A rotary drum dryer with a spouted bed high-pressure airflow sludge dispersing device

ActiveCN106904809BImprove the breaking effectImprove drying outputSludge treatment by de-watering/drying/thickeningGrain treatmentsSludgeProcess engineering

The invention discloses a rotary cylinder dryer for a high-pressure airflow sludge scattering device with a sprouted bed. The rotary cylinder dryer comprises a dryer body, the dryer body comprises a rotary cylinder, a sludge inlet is formed in the top of the rotary cylinder and extends into the rotary cylinder through a sludge chute, the sprouted bed is arranged at the bottom of the sludge chute, a high-pressure air chamber is formed in the rear side of the sprouted bed, air is supplied for the high-pressure air chamber through a high-pressure air pipe, the high-pressure air pipe comprises a high-pressure air main pipe and a plurality of high-pressure air branch pipes connected with the high-pressure air main pipe, the high-pressure air main pipe is connected with an air compressor through an air storage bag, the sprouted bed sequentially includes a first sprouted bed, a second sprouted bed and a third sprouted bed from top to bottom, and the high-pressure air branch pipes are connected with the first sprouted bed, the second sprouted bed and the third sprouted bed. The rotary cylinder dryer is good in scattering effect, and test operations show that the drying yield of an original rotary cylinder can be doubled.

Owner:FOSHAN FENGHUI MACHINERY

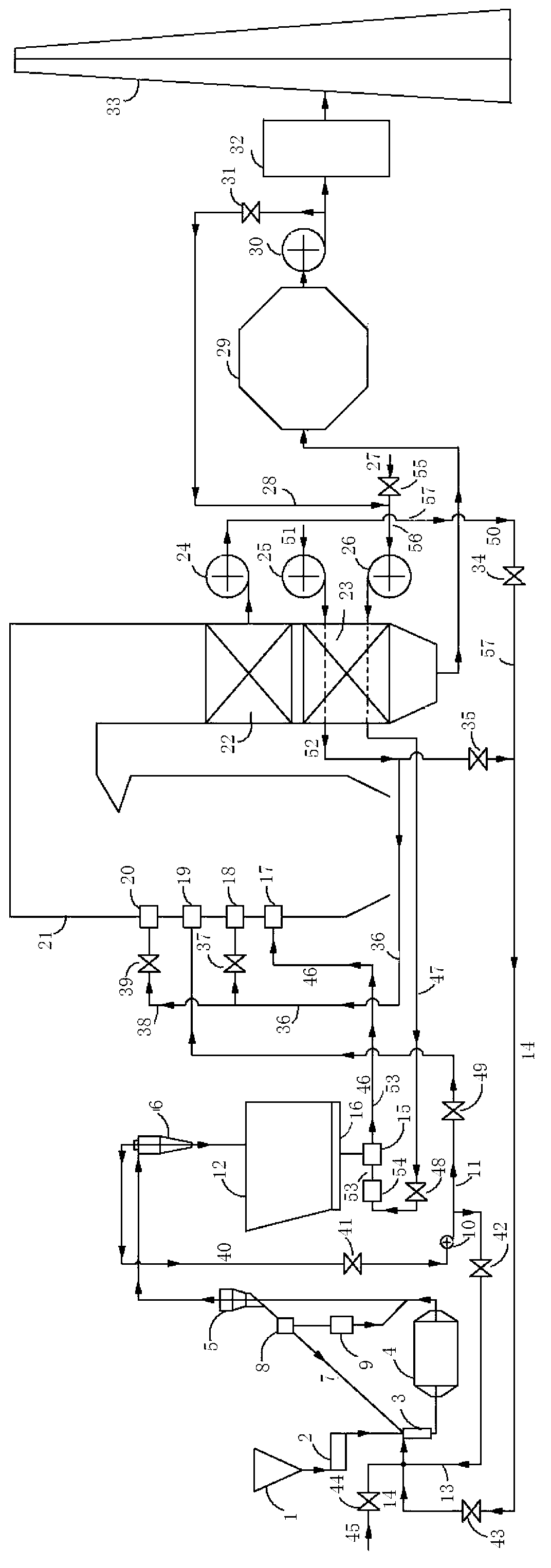

Cold and hot flue gas drying lignite medium speed pulverization system

ActiveCN103206717BLow oxygenImprove adaptabilityDrying gas arrangementsLump/pulverulent fuel preparationCombustorProcess engineering

The invention discloses an intermediate-speed powder milling system capable of drying lignite by using cold and hot smoke, and relates to a power making system capable of drying lignite by using smoke. The system solves the problems of the existing powder making system that a gas recirculation flow path is large, a principal parameter of a boiler is seriously influenced, the abrasion of a heated face of the boiler is also aggravated, a coking trend is aggravated, the boiler efficiency is affected, and the serious potential safety hazards are generated. According to the system provided by the invention, a hot furnace smoke pumping port is arranged between a combustor of a boiler and a furnace hopper, one end of a hot furnace smoke pipeline is communicated with the hot furnace smoke pumping port, the other end of an induced draft fan of the boiler is communicated with one end of a cold smoke pipeline, the other end of the cold smoke pipeline and the other end of the hot furnace smoke pipeline are both communicated with one end of a mixing pressurization pipeline, the other end of the mixing pressurization pipeline is communicated one end of a hot smoke fan through an ash removing deslagging device, and the other end of the hot smoke fan and the other end of a hot air pipeline are both communicated with a primary air inlet of an intermediate-speed coal milling machine. The intermediate-speed powder milling system provided by the invention is used for dried lignite.

Owner:HULUDAO HUANENG IND CERAMIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com