Boiler powder generation system for burning lignite in power station gas duct and cooling tower machine

A technology for smoke towers and units, which is applied in the direction of combustion methods, combustion equipment, block/powder fuel preparation, etc., can solve problems such as potential safety hazards, and achieve the effects of increasing safety, improving drying output, and reducing the possibility of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

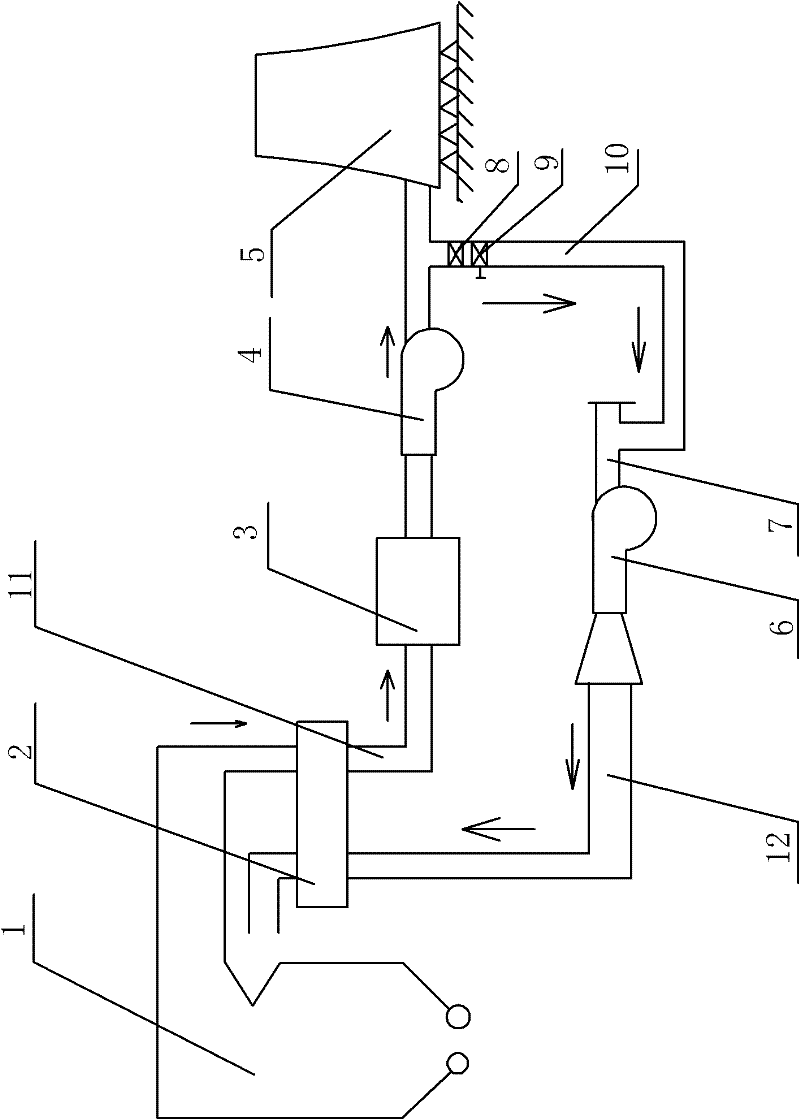

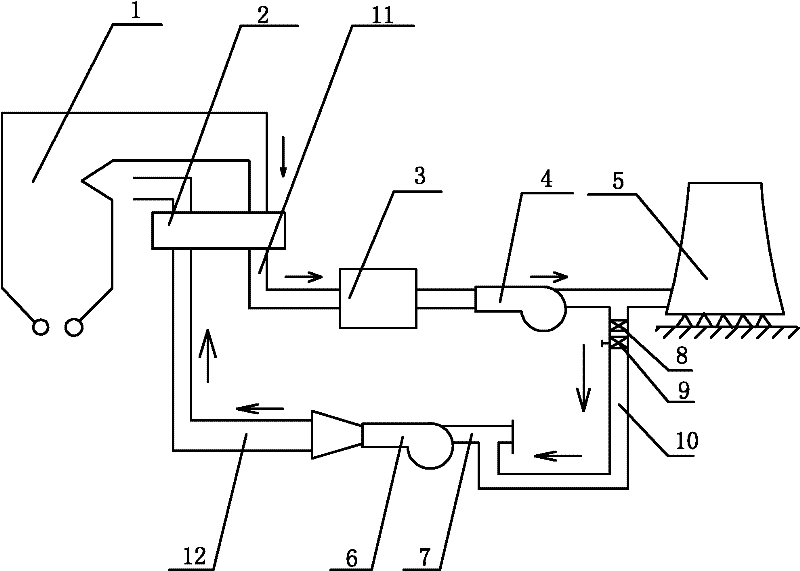

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment. The system of this embodiment includes an air preheater 2, an electrical dust removal device 3, an induced draft fan 4, a smoke tower 5, a primary fan 6, a primary fan inlet duct 7, a first pipeline 11 and a second pipe Road 12, the outlet end of the cold furnace flue gas of the boiler 1 communicates with the inlet end of the first pipeline 11 through the hot end of the air preheater 2, and the outlet end of the first pipeline 11 passes through the electrical dust removal device 3 and the induced draft fan in turn 4 communicates with the smoke tower 5, and the system also includes a cold furnace smoke isolation baffle 8, a cold furnace smoke regulating baffle 9 and a cold furnace smoke pipeline 10, the inlet end of the cold furnace smoke pipeline 10 communicates with the first pipeline 11, The connection between the cold furnace smoke pipeline 10 and the first pipeline 11 is located between the...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the cold furnace smoke pipe 10 of this embodiment is a carbon steel pipe; Other components and connections are the same as those in the first embodiment.

[0010] Working principle: the cold furnace smoke gas discharged from the boiler 1 enters the first pipeline 11, and a part of the cold furnace smoke is sent into the cold furnace smoke pipe 10 by taking advantage of the high pressure head at the outlet of the induced draft fan 4, and the other part enters the smoke tower 5 Among them, the cold furnace flue gas entering the cold furnace flue pipe 10 is mixed with the cold air entering from the inlet duct 7 and then enters the primary fan 6, enters the second pipeline 12 from the outlet end of the primary fan 6, and passes through the air preheater 2 Enter the coal mill. The cold furnace smoke isolation baffle 8 and the cold furnace smoke adjustment baffle 9 are set in the cold furnace s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com