Cold and hot flue gas drying lignite medium speed pulverization system

A flue gas and drying technology, which is applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of large flue gas recirculation process, aggravated coking tendency, and hidden safety hazards, so as to improve the adaptability of coal types and reduce the Oxygen content, safety improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

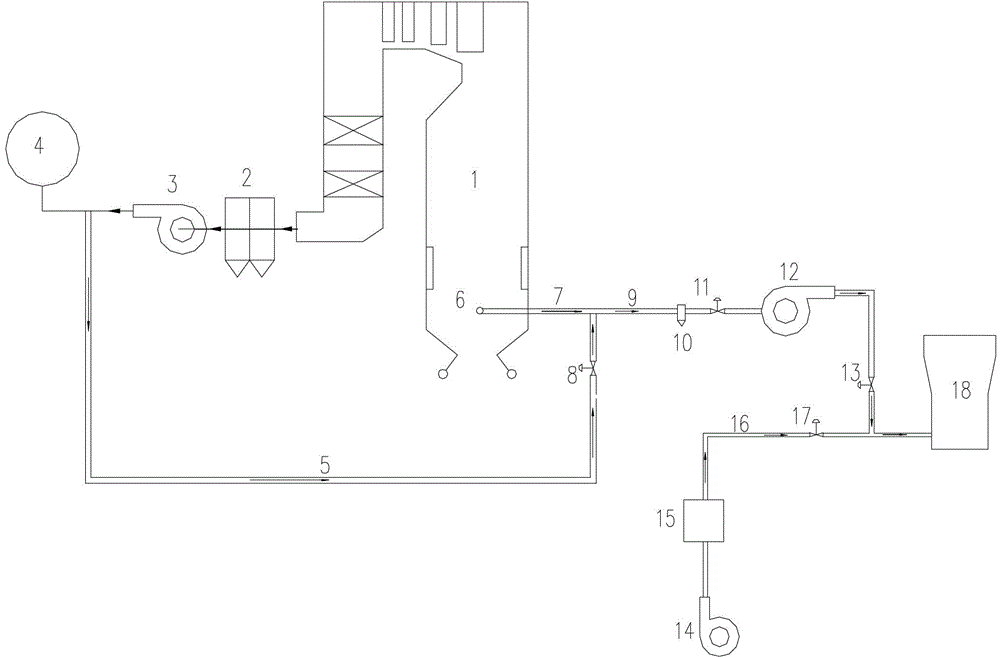

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, the system of this embodiment comprises boiler 1, electric precipitator 2, boiler induced draft fan 3, chimney 4, primary fan 14, air preheater 15 and hot blast pipeline 16, one end of electric precipitator 2 and The tail flue of the boiler 1 is connected, the electrostatic precipitator 2 is connected with the inlet end of the boiler induced draft fan 3, the outlet end of the boiler induced draft fan 3 is connected with the chimney 4, and the primary fan 14 is connected with the hot air pipeline 16 through the air preheater 15 One end is connected, and the system also includes a cold smoke pipeline 5, a hot furnace smoke exhaust port 6, a hot furnace smoke pipeline 7, a mixing and boosting pipeline 9, an ash and slag removal device 10, a hot smoke blower 12 and a medium-speed mill The coal machine 18 is provided with a hot furnace smoke exhaust port 6 between the burner of the boiler 1 and the ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 Describe this embodiment, the system of this embodiment also includes a first electric control valve 8, the cold smoke pipeline 5 is provided with a first electric control valve 8, the advantage of this structure is to regulate the cold smoke entering the mixing increase pipeline 9 amount. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 Describe this embodiment, the system of this embodiment also includes a second electric regulating valve 11, a second electric regulating valve 11 is arranged between the ash and slag removal device 10 and the hot smoke blower 12, the advantage of this structure is to adjust the mixing The amount of flue gas entering the hot air hood 12. Other implementation modes are the same as the specific implementation mode 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com