Rake type pulverizing hot air stirring sludge drying device

A drying device and hot air technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of not being easily broken, agglomerated, affecting the production efficiency and production volume of enterprises, and achieve low processing cost and processing capacity. The effect of large, high drying output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

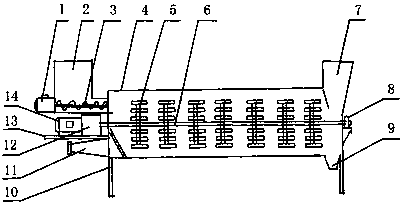

[0012] As shown in the drawings, the rake crushing hot air stirring sludge drying device consists of a variable speed motor 1, a feeding trough 2, a screw guide feeding shaft 3, a body 4, a grate wing plate breaking teeth 5, a stirring shaft 6, It is composed of exhaust port 7, bearing fixing sleeve 8, discharge port 9, machine legs 10, hot air inlet pipe 11, reducer 12, support platform 13, and stirring motor 14; Groove 2, a support platform 13 is set in the middle of one side of the body 4, a hot air inlet pipe 11 is set in the lower part of one side of the body 4, an exhaust port 7 is set in the upper part of the other side of the body 2, a bearing fixing sleeve 8 is set in the middle of the other side of the body 2, and the body 4 The lower part of the other side is provided with a discharge port 9, and machine legs 10 are provided around the bottom of the body 4.

[0013] The inner bottom of the feed tank 2 is provided with a spiral guide feed shaft 3, the outer end of wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com