A system to improve the drying output of the intermediate storage pulverizing system when the boiler changes the coal type

A pulverizing system and middle-storage technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., to achieve the effect of improving quality, low operation and maintenance cost, and improving drying output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

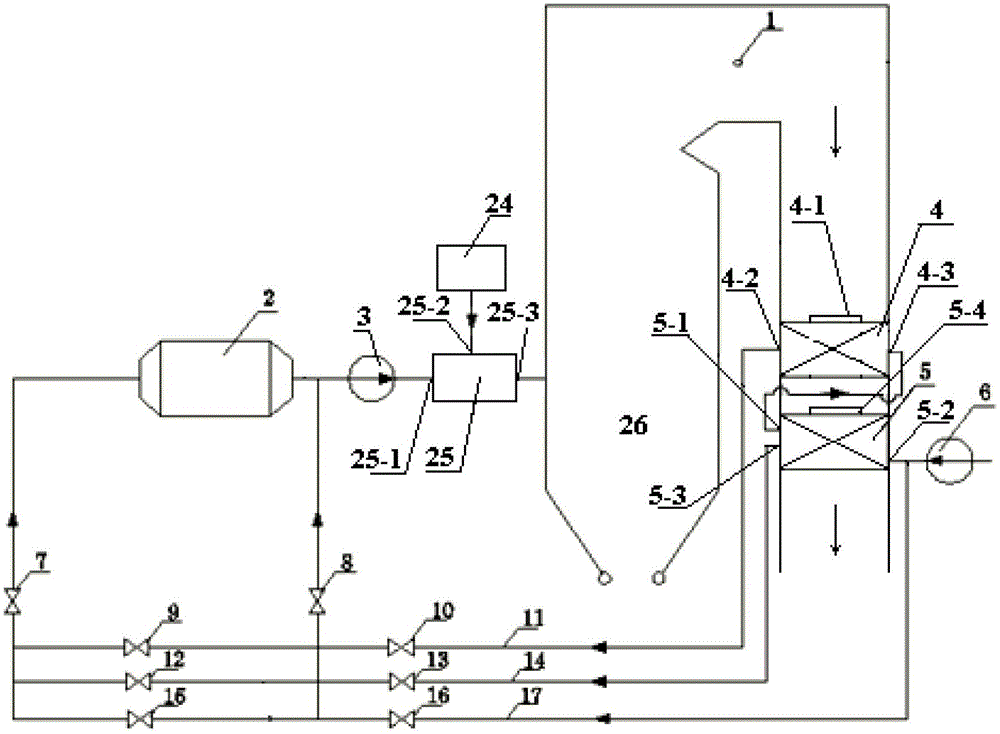

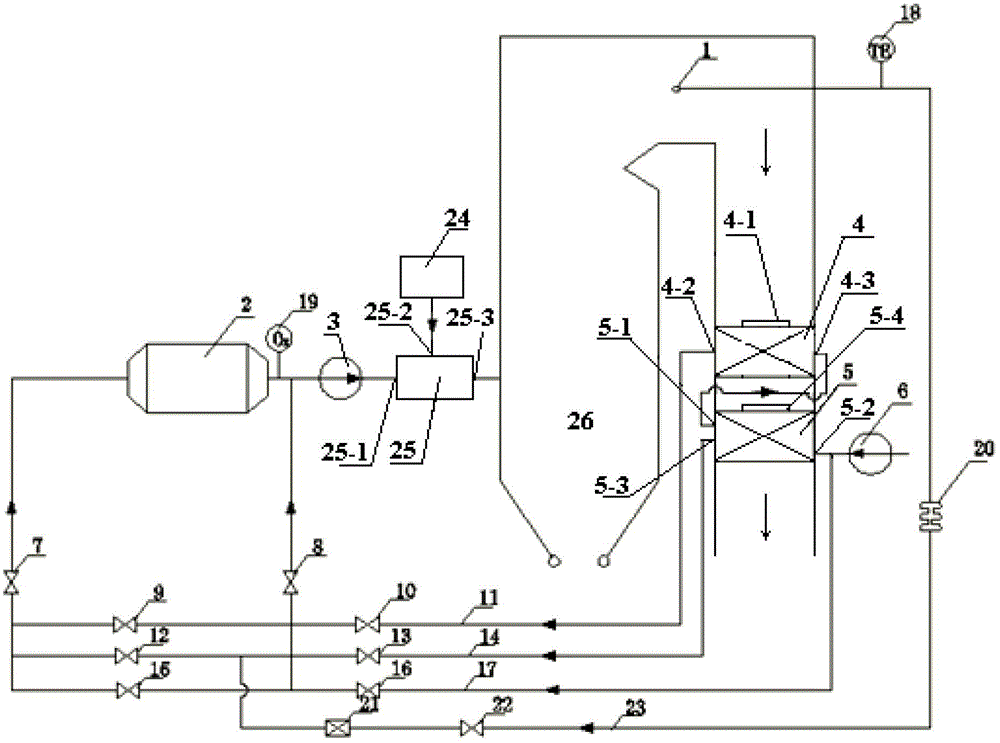

[0015] Specific implementation mode 1: This implementation mode is a system for improving the drying output of the intermediate storage pulverizing system when the boiler changes coal types. Air preheater 4, primary air preheater 5, blower 6, first mixed air isolation door 7, second mixed air isolation door 8, first hot air isolation door 9, second hot air isolation door 10, hot air duct 11, first A warm air isolation door 12, a second warm air isolation door 13, a warm air duct 14, a first cold air isolation door 15, a second cold air isolation door 16, a cold air duct 17, a powder bin 24, an air powder mixer 25 and a furnace 26 Composition; wherein, the furnace 26 communicates with the smoke side inlet 4-1 of the secondary air preheater 4, the hot blast outlet 4-2 of the secondary air preheater 4 communicates with the air inlet of the hot blast duct 11, and the inlet air duct 4 of the secondary air preheater 4 -3 communicates with the air outlet 5-1 of the primary air prehea...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that: the material of the flue gas pipeline 23 is a low-alloy heat-resistant steel pipe. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the pipe diameter of the flue gas pipeline 23 is 950mm-1000mm. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com