Power generating system utilizing circulating cooling water to heat raw coal

A technology for circulating cooling water and power generation systems, applied in lighting and heating equipment, steam applications, machines/engines, etc., can solve problems such as low power generation and low system power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

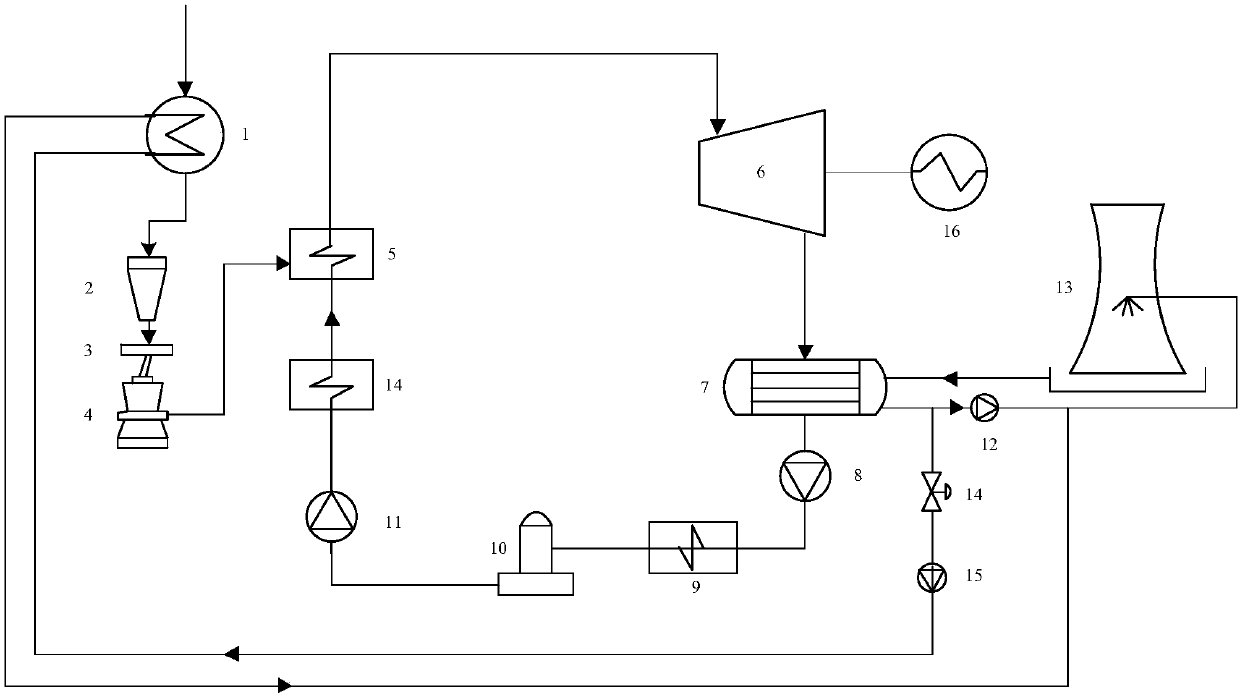

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] A schematic diagram of a power generation system that utilizes circulating cooling water to heat raw coal proposed by the present invention is as follows figure 1 As shown, the technical key is as follows:

[0019] The raw coal in the coal yard is heated and thawed by the heat exchanger 1 arranged below the ground of the coal yard, and then enters the coal bunker 2, and then is sent to the coal mill 4 through the coal feeder 3 for pulverization, and the qualified coal powder is carried by the primary wind Enter boiler 5 to burn. The heat exchanger 1 can be divided into one or more independent units according to the planning of the coal yard and the habit of stacking coal.

[0020] The exhaust steam from the steam turbine 6 enters the condenser 7 to release heat, and then is sent to the low-pressure heater 9 through the condensate pump 8. After being heated, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com