grain dryer

A grain dryer and drying cylinder technology, applied in dryers, drying, non-progressive dryers and other directions, can solve the problems of complex drying methods, high energy consumption of equipment, single equipment, etc., to reduce explosion Waist rate and broken rate, good slowing effect, high grain quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

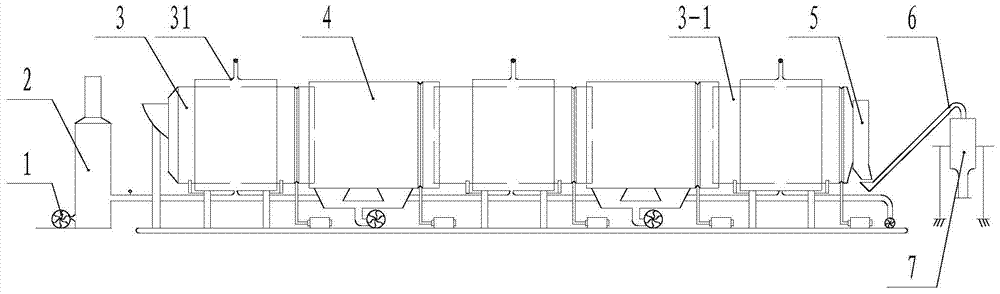

[0026] Such as figure 1 As shown, the grain dryer includes a drying device, a conveying device 6 and a filling device 7 connected in sequence, and the drying device includes more than one set of drying slowing device and a terminal drying cylinder 3-1. The drying and slowing device includes a drying cylinder 3 and a slowing cylinder 4 connected in sequence, and the slowing cylinder 4 is connected with the end drying cylinder 3-1; the bottom of the drying cylinder 3 is provided with an ash falling device 37, and the drying cylinder 3 and the The end drying cylinder 3-1 is connected to the hot blast stove 2 through the pipeline 36 respectively, the hot blast stove 2 is connected to the hot air blower 1, and the bottom of the slow drying cylinder 4 is connected to the blowing device through the slow cooling pipeline 44.

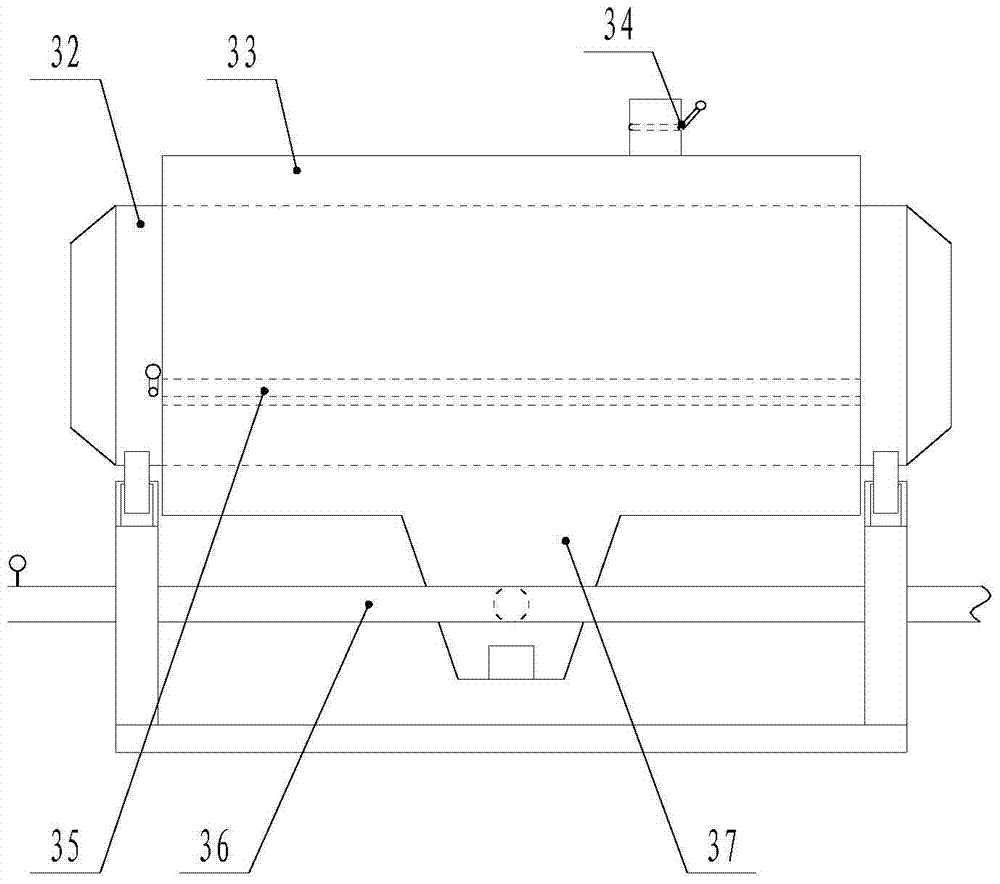

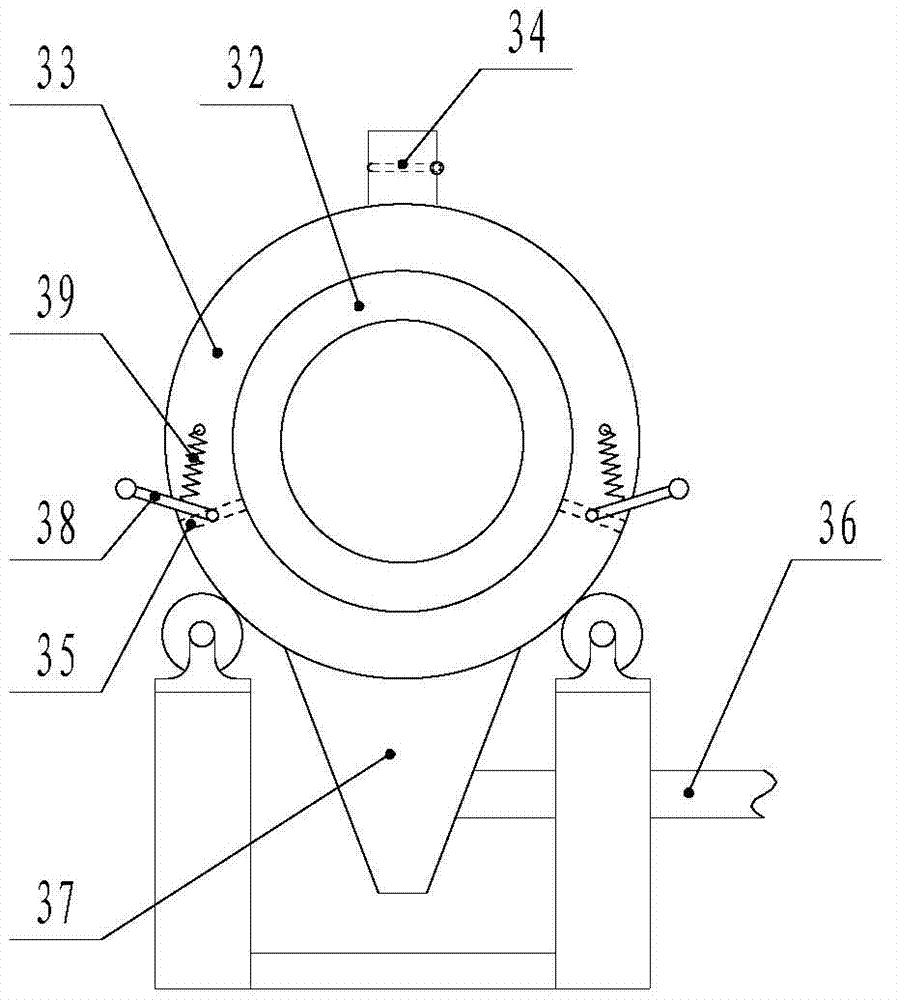

[0027] Such as figure 2 and image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com