Process for drying glass fiber filament by using hot blast air and microwave

A technology of glass fiber and microwave, which is applied in the field of glass fiber precursor drying technology, can solve the problems of effective drying of super-large glass fiber yarn clusters, unstable product quality, poor drying film formation, etc., to reduce drying Low cost, overcoming poor film formation during drying, and high drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

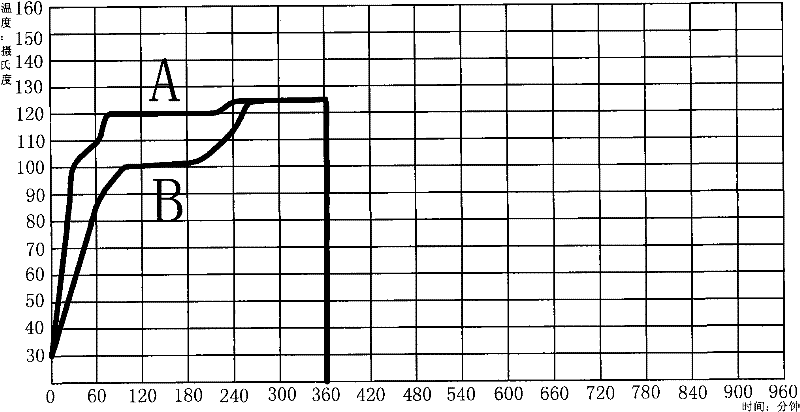

[0028] In this embodiment, the present invention uses hot air and microwaves to dry glass fiber precursors for 6 hours, including the following steps: (a) heating period: the temperature of the drying oven is set at 105° C., and the time is 1 hour. Microwave power density is 2.5kw / m 3 ; (b) Water-lifting period: the temperature is set at 120°C, the time is 3 hours, and the microwave power density is 2kw / m2 during the water-lifting period of the drying furnace 3 ; (c) Film-forming period: the drying furnace film-forming period is set at a temperature of 125°C, a time of 2 hours, and a microwave power density of 1kw / m 3 . A microwave energy feed port is arranged in the drying furnace, and the microwave energy feed port corresponds to the gap between the glass fiber precursor yarn balls or the glass fiber precursor silk cakes. The output power of each microwave energy feed port is equal to 0.25kw. The surface temperature curve of glass fiber precursor yarn or glass fiber precu...

Embodiment 2

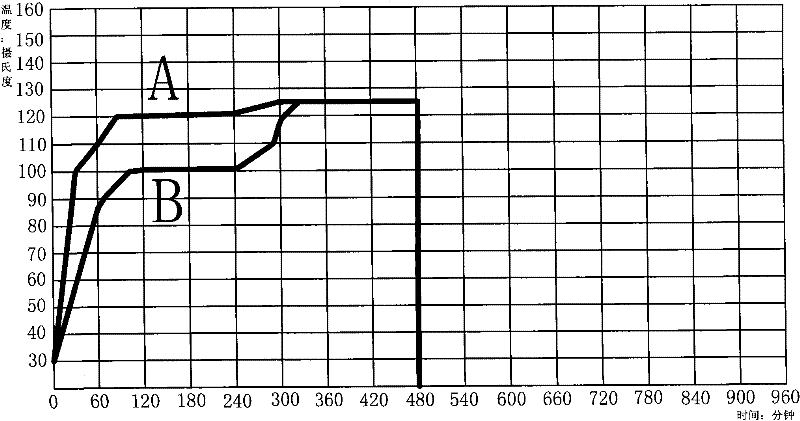

[0030] In this embodiment, the present invention uses hot air and microwaves to dry glass fiber precursors for 8 hours, including the following steps: (a) The heating period of the drying furnace is set at 105°C for 1 hour, and the microwave power density 2kw / m 3 ; (b) The temperature is set at 120°C during the water extraction period of the drying furnace, the time is 4 hours, and the microwave power density is 2kw / m 3 ; (c) The film forming period of the drying oven is set at 125°C for 3 hours, and the microwave power density is 1kw / m 3 . A microwave energy feed port is arranged in the drying furnace, and the microwave energy feed port corresponds to the center position of the glass fiber precursor yarn ball or the glass fiber precursor yarn cake. The output power of each microwave energy feed port is equal to 0.25kw. The surface temperature curve of glass fiber precursor yarn or glass fiber precursor cake and the internal temperature curve of glass fiber precursor yarn o...

Embodiment 3

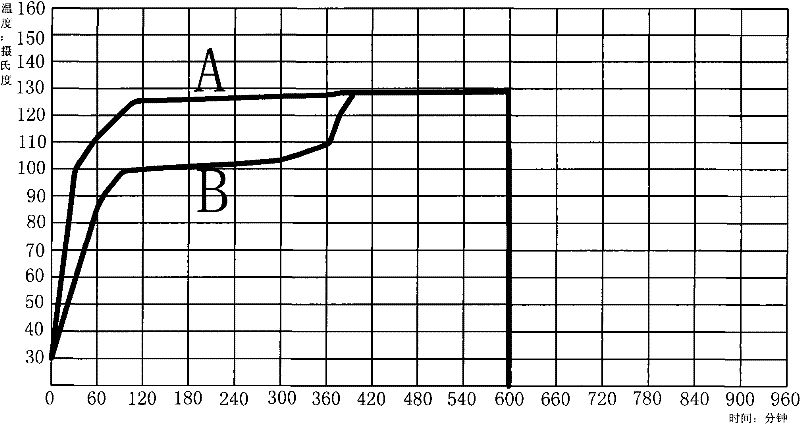

[0032] In this embodiment, the present invention utilizes hot air and microwaves to dry glass fiber precursors for 10 hours, including the following steps: (a) The heating period of the drying oven is set at 105°C for 1 hour, and the microwave power density 3kw / m 3 ; (b) The temperature is set at 125°C during the water extraction period of the drying furnace, the time is 5 hours, and the microwave power density is 2kw / m 3 ; (c) The film forming period of the drying furnace is set at a temperature of 128°C, a time of 4 hours, and a microwave power density of 1kw / m 3 . A microwave feed port is provided in the drying furnace, a part of the microwave feed port corresponds to the gap between the glass fiber precursor yarn ball or a glass fiber precursor cake, and the other part of the microwave feed port corresponds to the glass fiber precursor The center position of the bobbin or fiberglass strand cake. The output power of each microwave energy feed port is equal to 0.3kw. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com