Dust-removing dryer for grain

A dryer and grain technology, applied in chemical instruments and methods, preservation of seeds by drying, separation of dispersed particles, etc., can solve the problems of unsatisfactory drying effect, low automation level, complicated drying methods, etc. The effect of grain drying quality, pollution prevention, and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

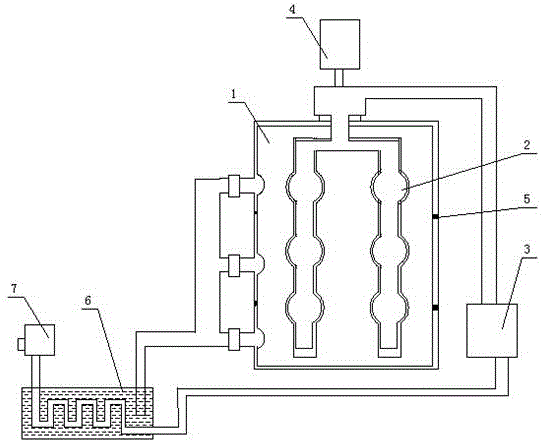

[0023] Such as figure 1 Shown, grain dedusting dryer of the present invention comprises box body 1, air heater 3 and purification pool 6; Water is housed in the purification pool 6, and box body 1 top is provided with air blower 4, and the air outlet of this air blower 4 It is connected with the air inlet of the box body 1, and the air inlet of the blower 4 is connected with the air heater 3 through a pipeline; a drying pipe 2 is arranged inside the box body 1, and a plurality of through holes are arranged on the side wall of the drying pipe 2, An exhaust port is provided on the side wall of the box body 1 , and the exhaust port extends below the liquid surface of the purification tank 6 . The upper, middle, and lower parts of the side wall of the box body 1 are respectively provided with exhaust branch pipes, and each exhaust branch pipe is provided with a solenoid valve; the exhaust branch pipes are connected to the same exhaust main pipe, and the outlet of the exhaust main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com