Integrated drying equipment for polyester staple fiber production

A technology of polyester staple fiber and drying equipment, applied in drying, dryer, non-progressive dryer and other directions, can solve the problems of inconvenient drying of PET slices, large volume, inconvenient drying of PET slices, etc. The effect of convenient drying treatment, convenient operation and convenient drying treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

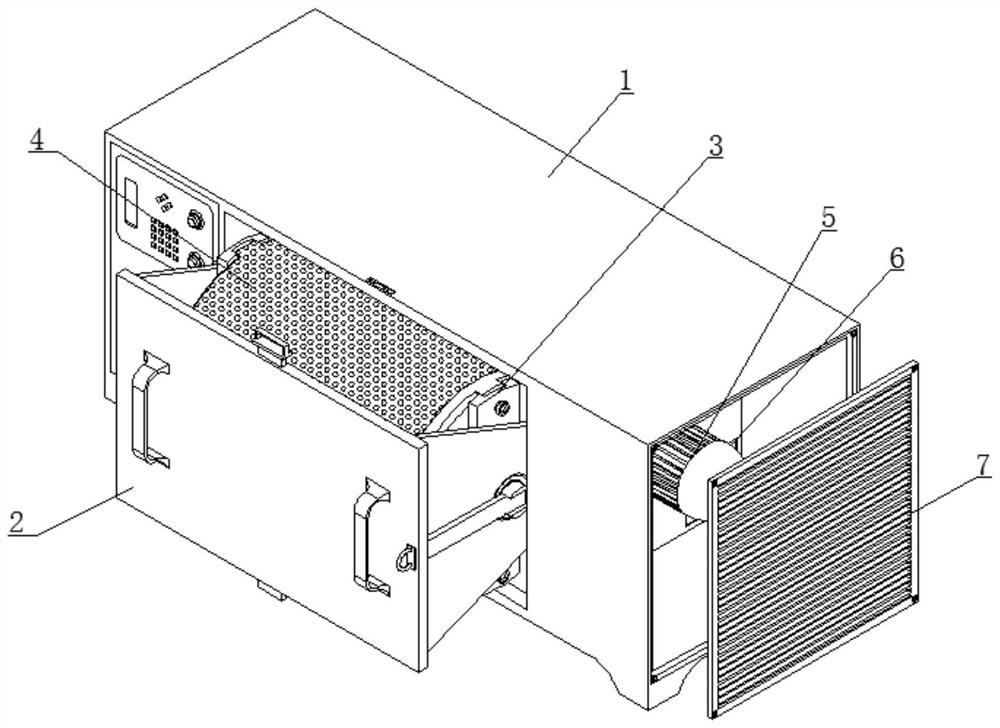

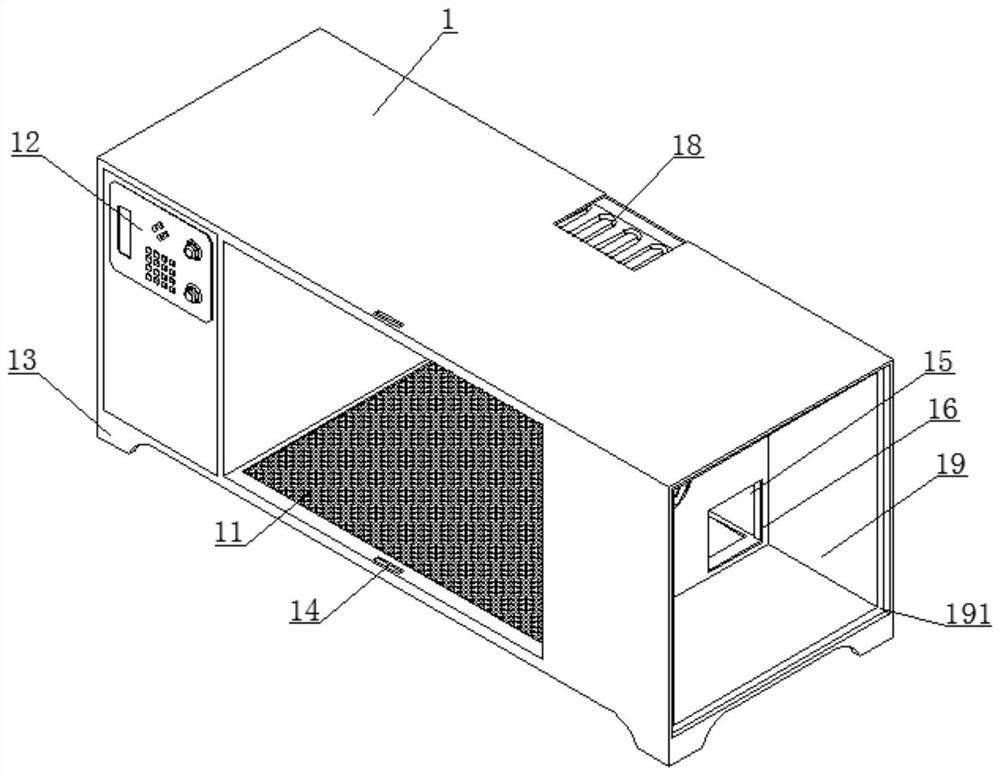

[0026] Example: refer to figure 1 with figure 2Shown: an integrated drying equipment for polyester staple fiber production, including a body 1, an installation cavity 19 is provided in the middle of the body 1, and a drawing head 2 is installed inside the installation cavity 19, and the two sides of the drawing head 2 are rotatably connected with cards. head 3, and a roller 4 is provided between the two chucks 3, the roller 4 is clamped between the two chucks 3, a motor 5 is provided inside one side of the body 1, and the output end of the motor 5 is inserted into the installation cavity 19 and connected with the The chucks 3 are clamped together, and the fan 6 is installed at one corner of the installation cavity 19 of the body 1 through screws, and the side of the body 1 aligned with the motor 5 is installed with an access panel 7 through screws; the body 1 is convenient for the operation of the entire device, and is convenient The use of the whole equipment, the pull head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com