Cable surface washing and baking device for communication engineering

A surface cleaning and drying device technology, which is applied in the field of communication, can solve the problems of poor cleaning quality of equipment and the inability to ensure complete cleaning of impurities on the cable surface, etc., and achieve the effect of convenient cleaning and drying treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

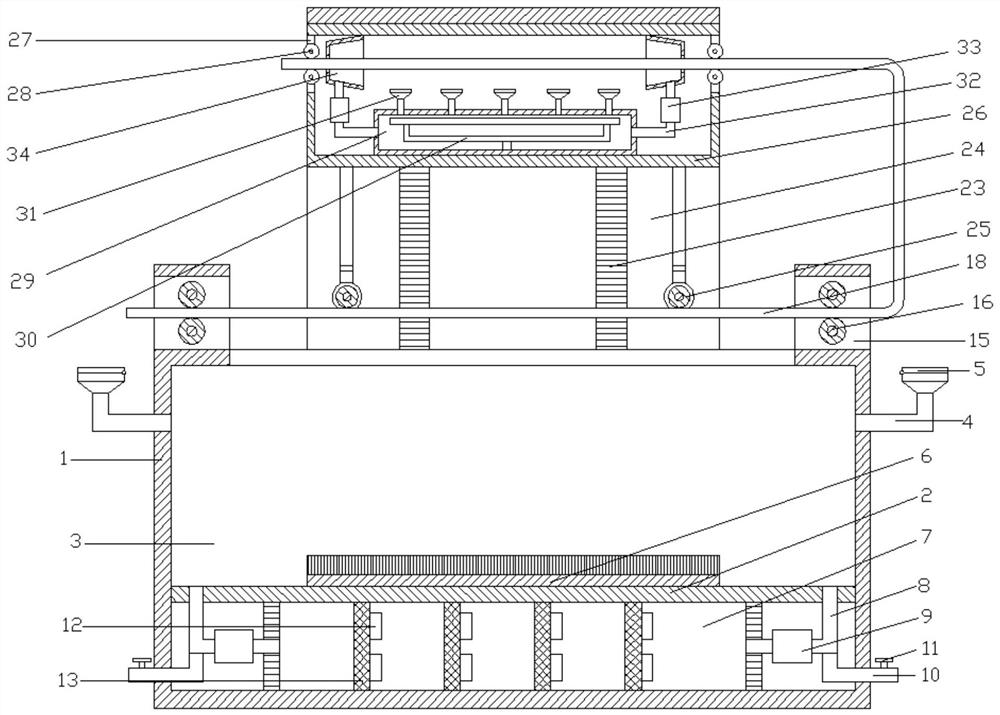

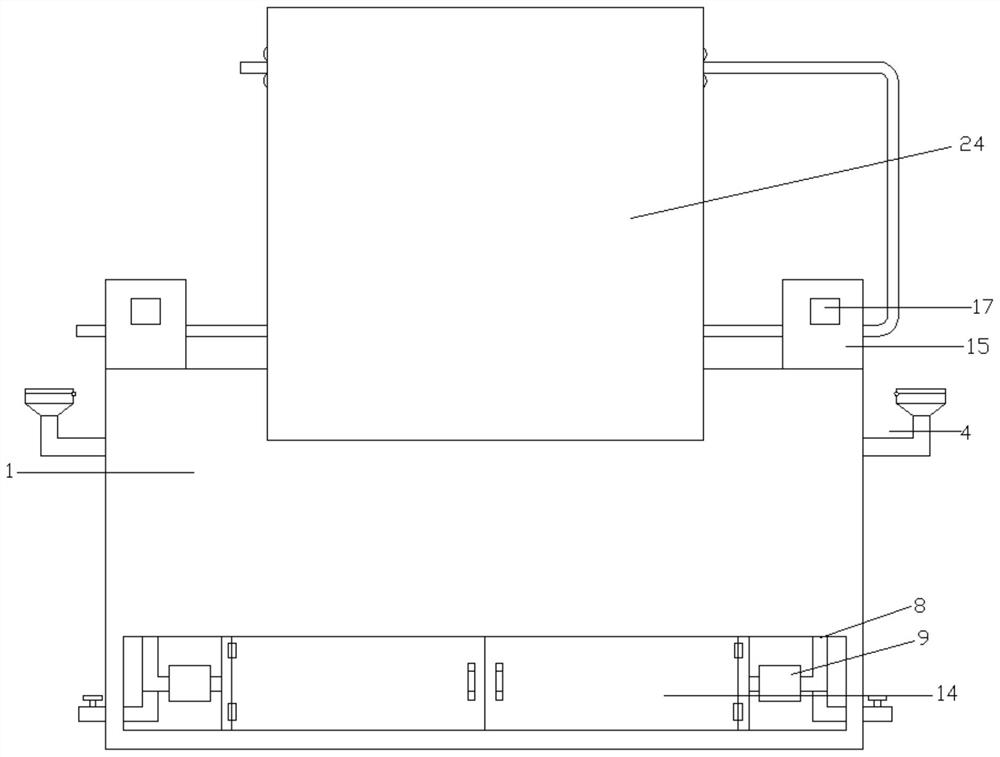

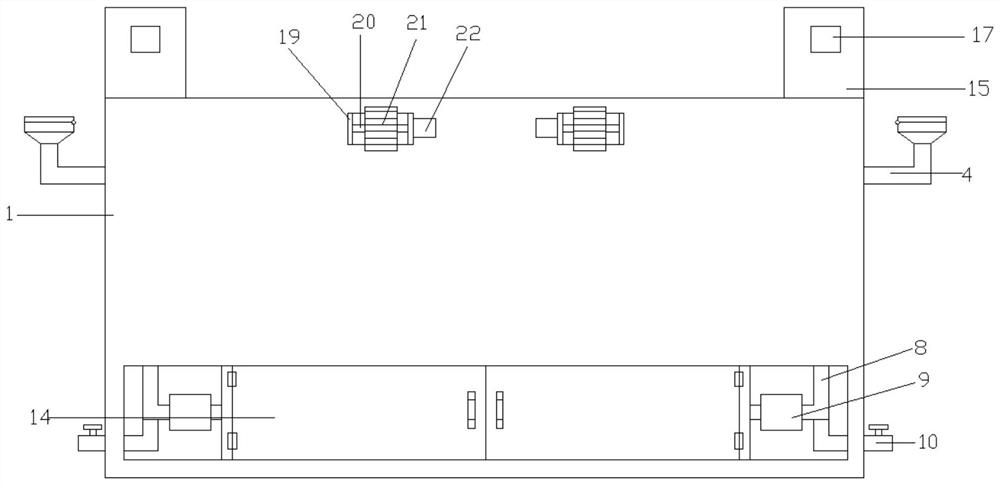

[0026] refer to Figure 1~4 , in an embodiment of the present invention, a cable surface cleaning and drying device for communication engineering, including a box body 1, the lower end of the box body 1 is provided with a partition 2, and the partition board 2 divides the upper end of the box body 1 into a cleaning chamber 3. There are water inlets 4 on the left and right sides of the upper end of the cleaning chamber 3, and the upper side of the water inlet 4 is connected with a sealing plate 5 through a hinge, which can facilitate the addition of cleaning solution to the inside of the cleaning chamber 3. The middle end of the bottom of the cleaning chamber 3 A cleaning brush 6 is fixedly installed to scrub the surface of the cable.

[0027] The middle part of the lower side of the dividing plate 2 is provided with a filter chamber 7, the left and right sides of the filtering chamber 7 are connected with the bottom dividing plate 2 of the cleaning chamber 3 through a connecti...

Embodiment 2

[0033] The difference from Embodiment 1 is that a drain pipe 10 is installed at the outer end of the lower side of the connecting pipe 8, and a control valve 11 is installed on the drain pipe 10 outside the box body 1, which can facilitate the discharge of the cleaning solution, which can facilitate the equipment Proceed to replace the cleaning solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com