Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve deformation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

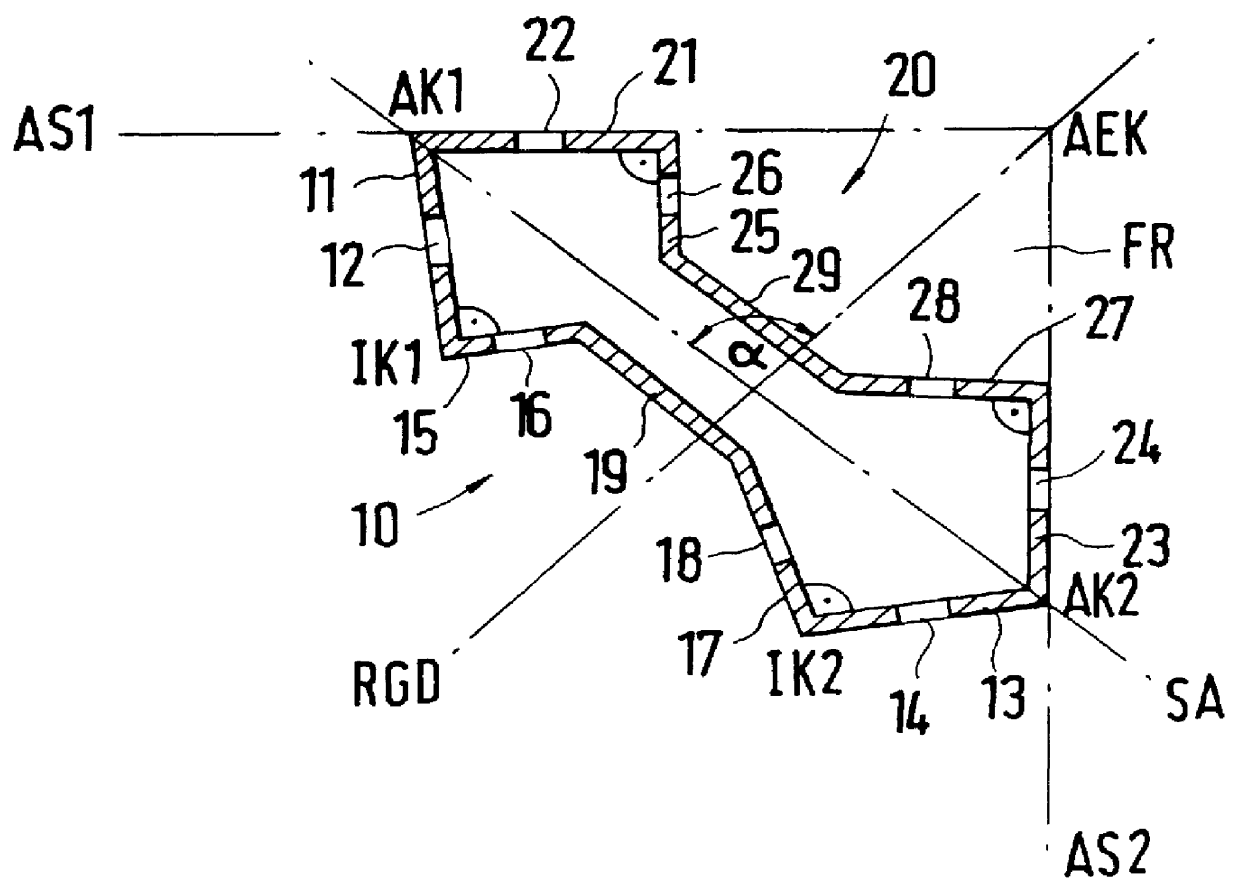

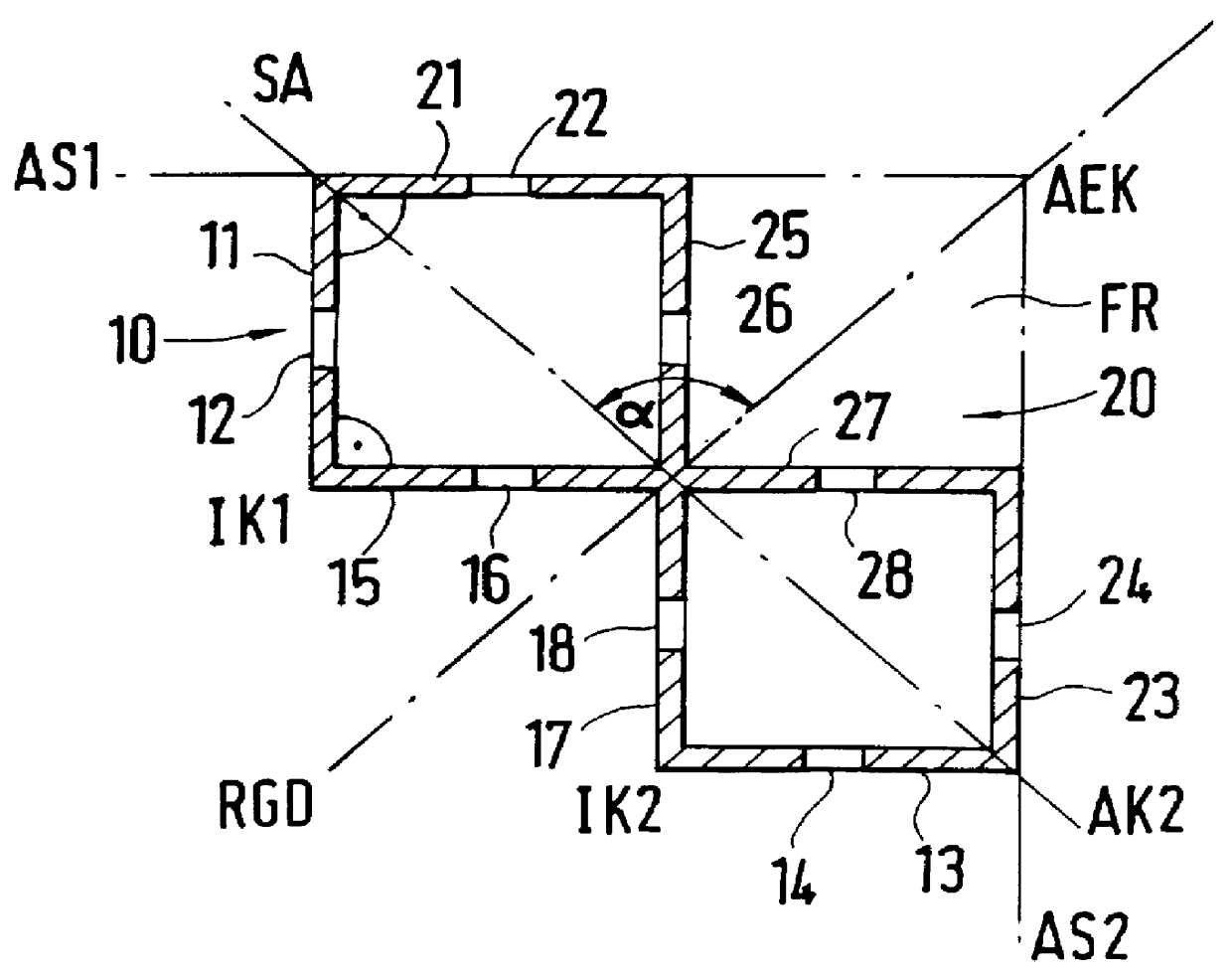

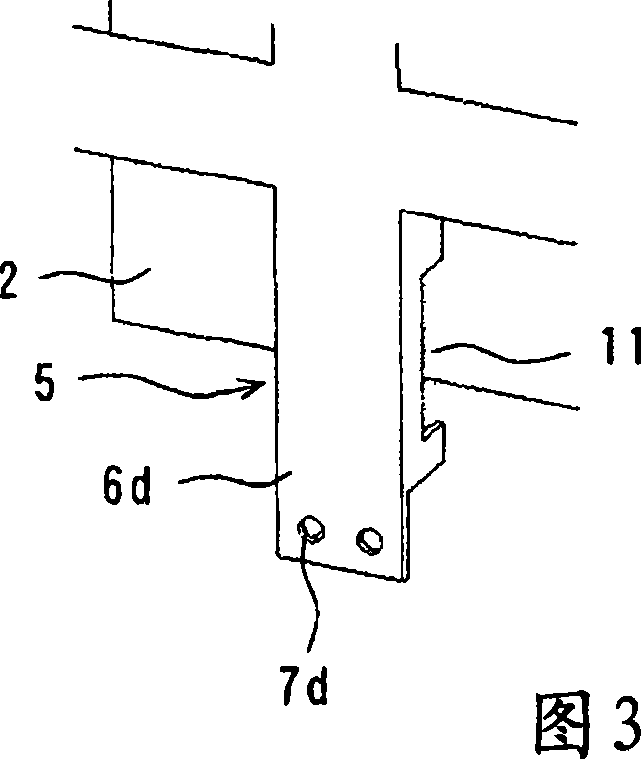

Frame piece for a rack of a switching cabinet

InactiveUS6138843AEasy to manufactureImprove deformation strengthSubstation/switching arrangement detailsMetal casingsAxis of symmetryDiagonal

A frame piece for a rack of a switching cabinet, which has a profile outside and a profile inside, the transitions of which lie at a distance from an outside corner edge of the rack and form a free space with the profile outside to the outside corner edge, for swinging a cabinet door and introducing edges of abutting paneling elements. A frame piece with many possibilities of variation with respect to fastening planes, fastening directions and stability is created according to this invention, because the frame piece is designed as having mirror image symmetry in cross-section with respect to an axis of symmetry which is at an angle of inclination to the rack diagonal. On both sides of the rack diagonal with the profile inside and profile outside, there are at least two profile sections that are at an angle with respect to one another, at least a part of which has fastening seats.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

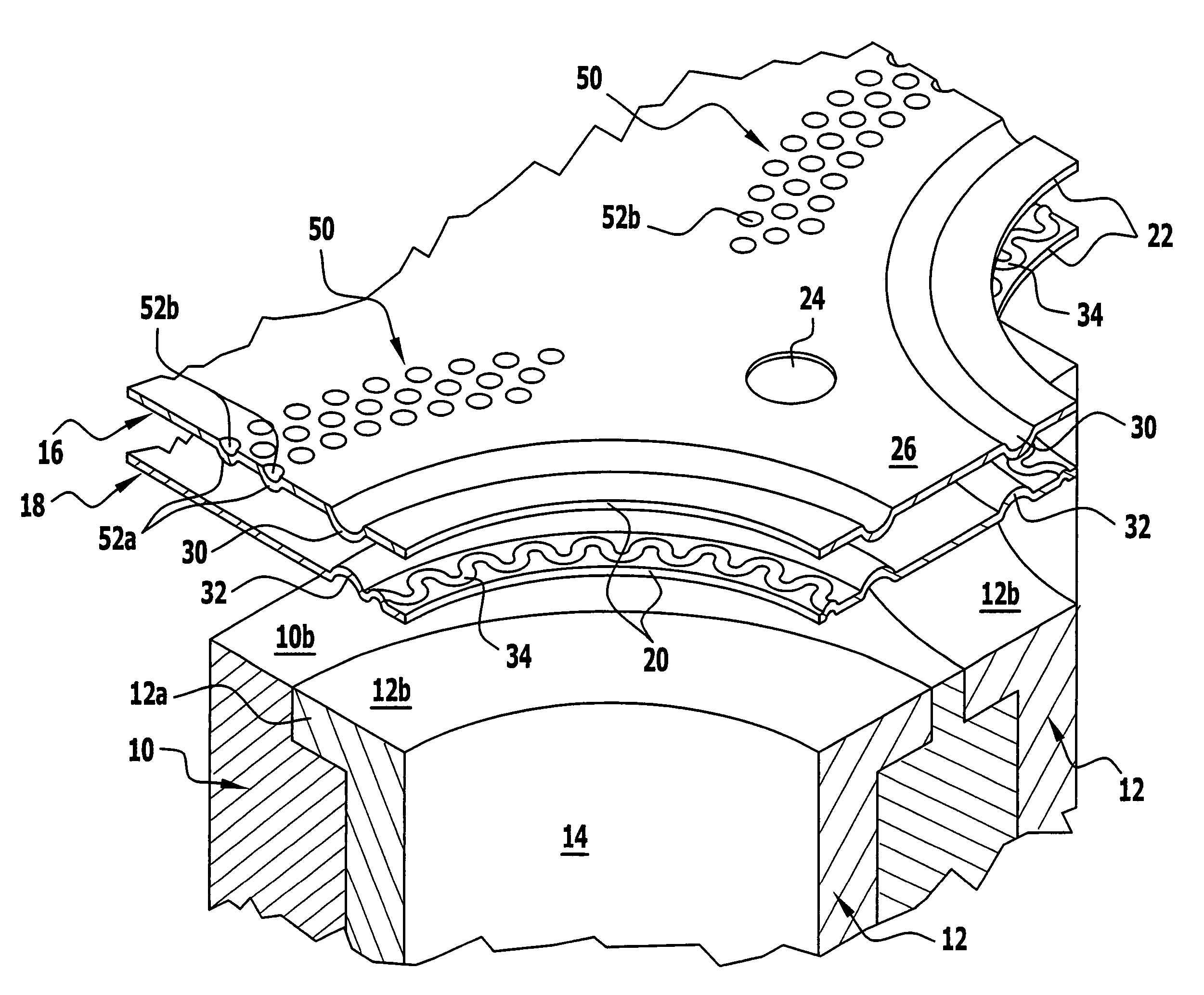

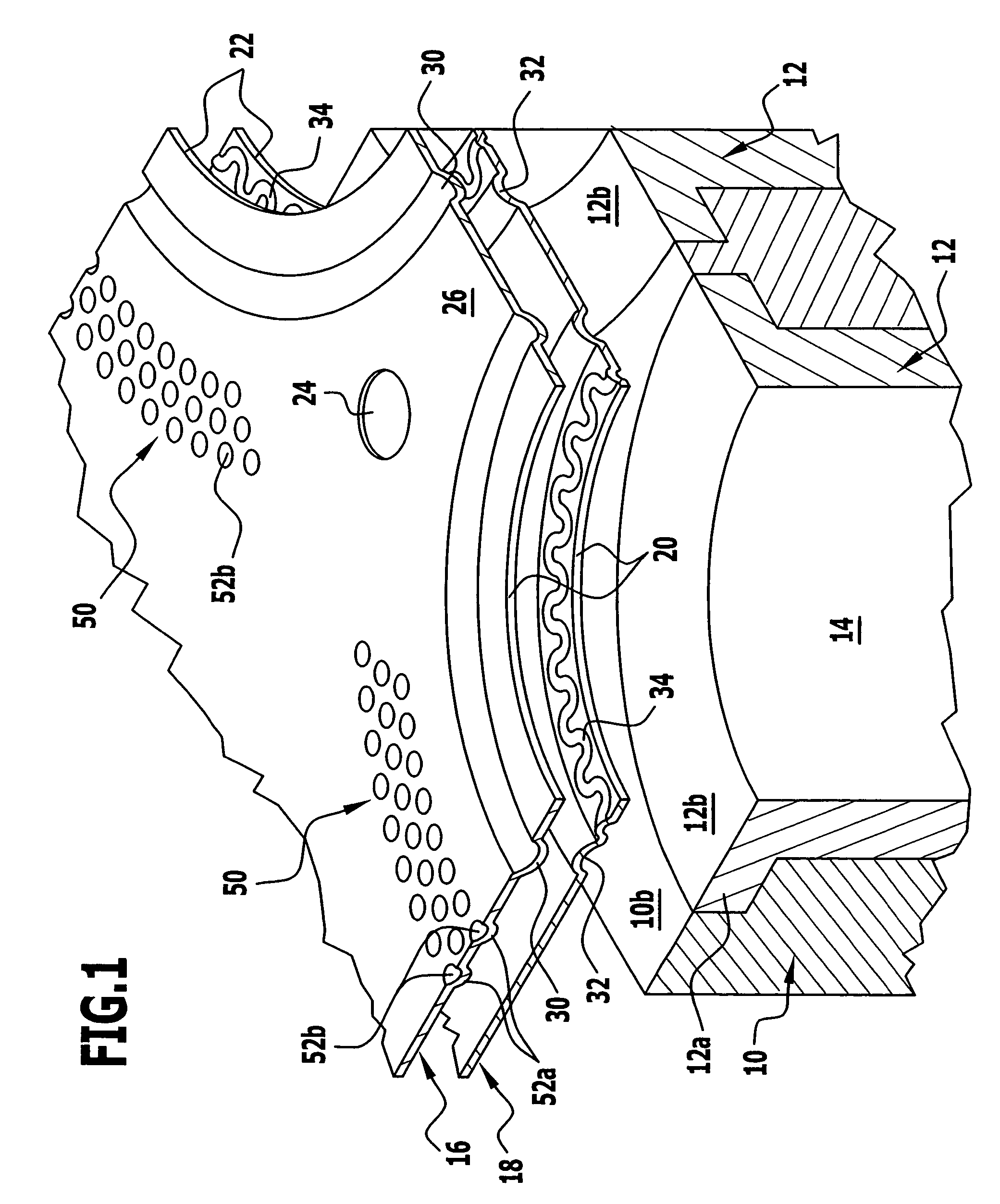

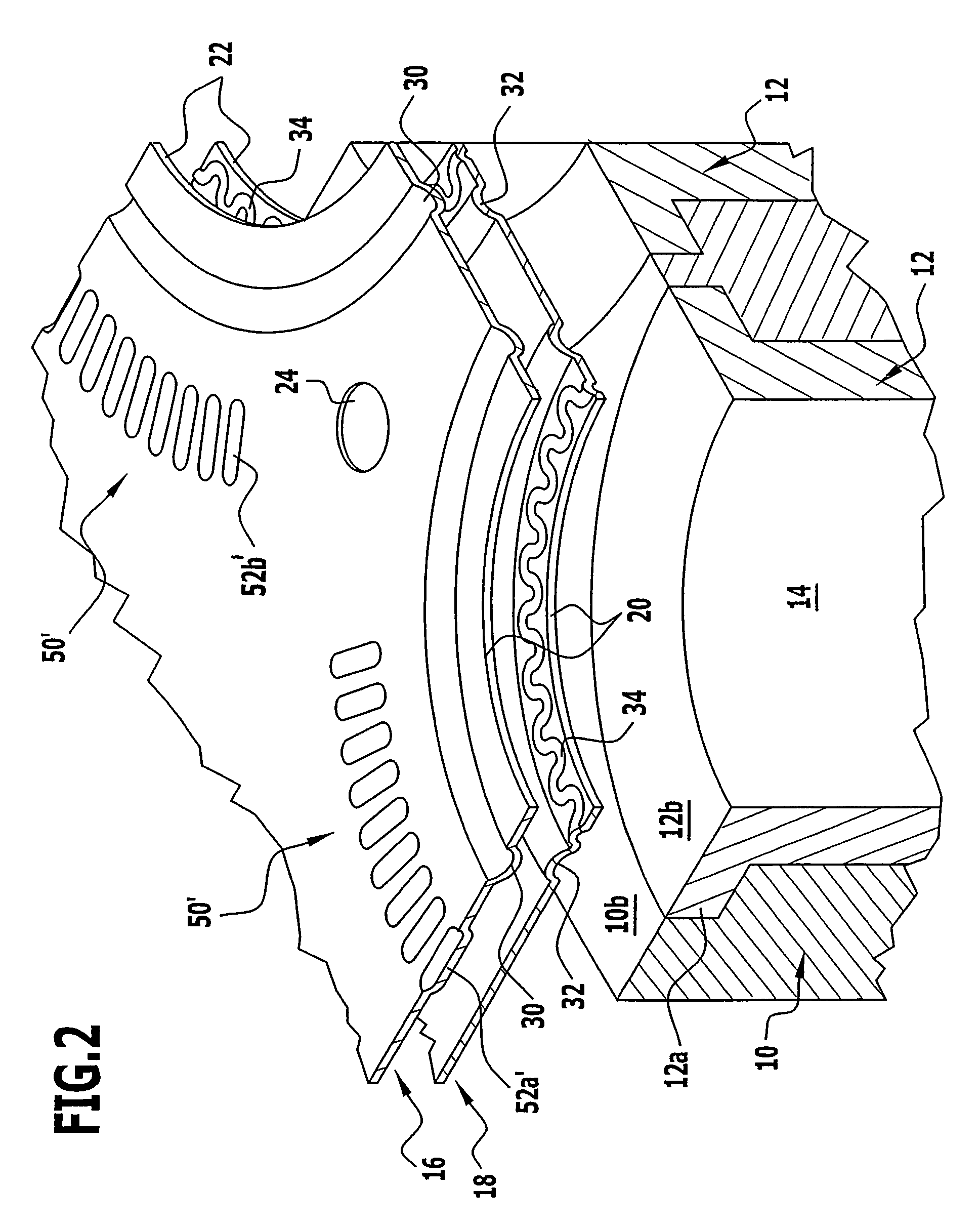

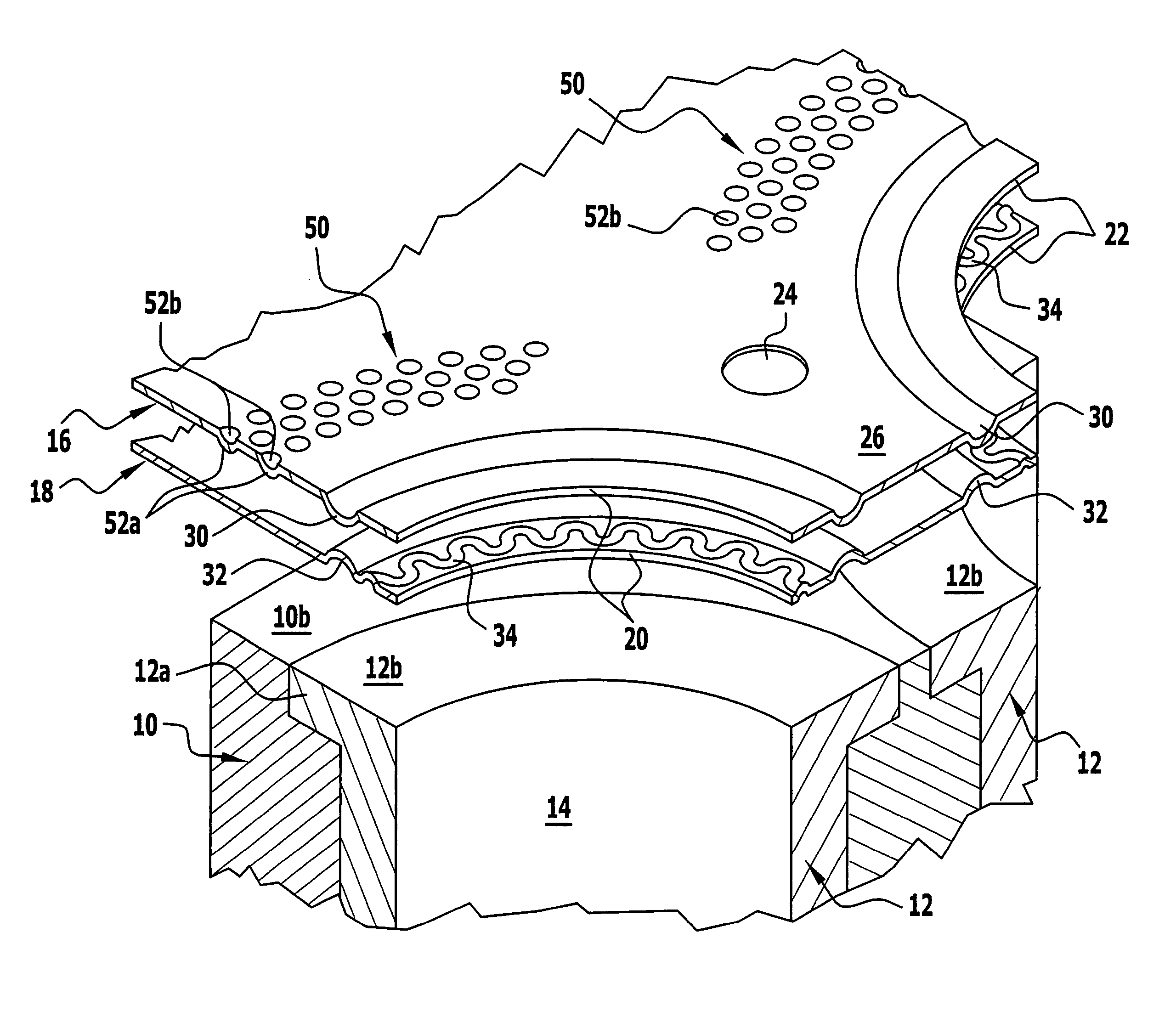

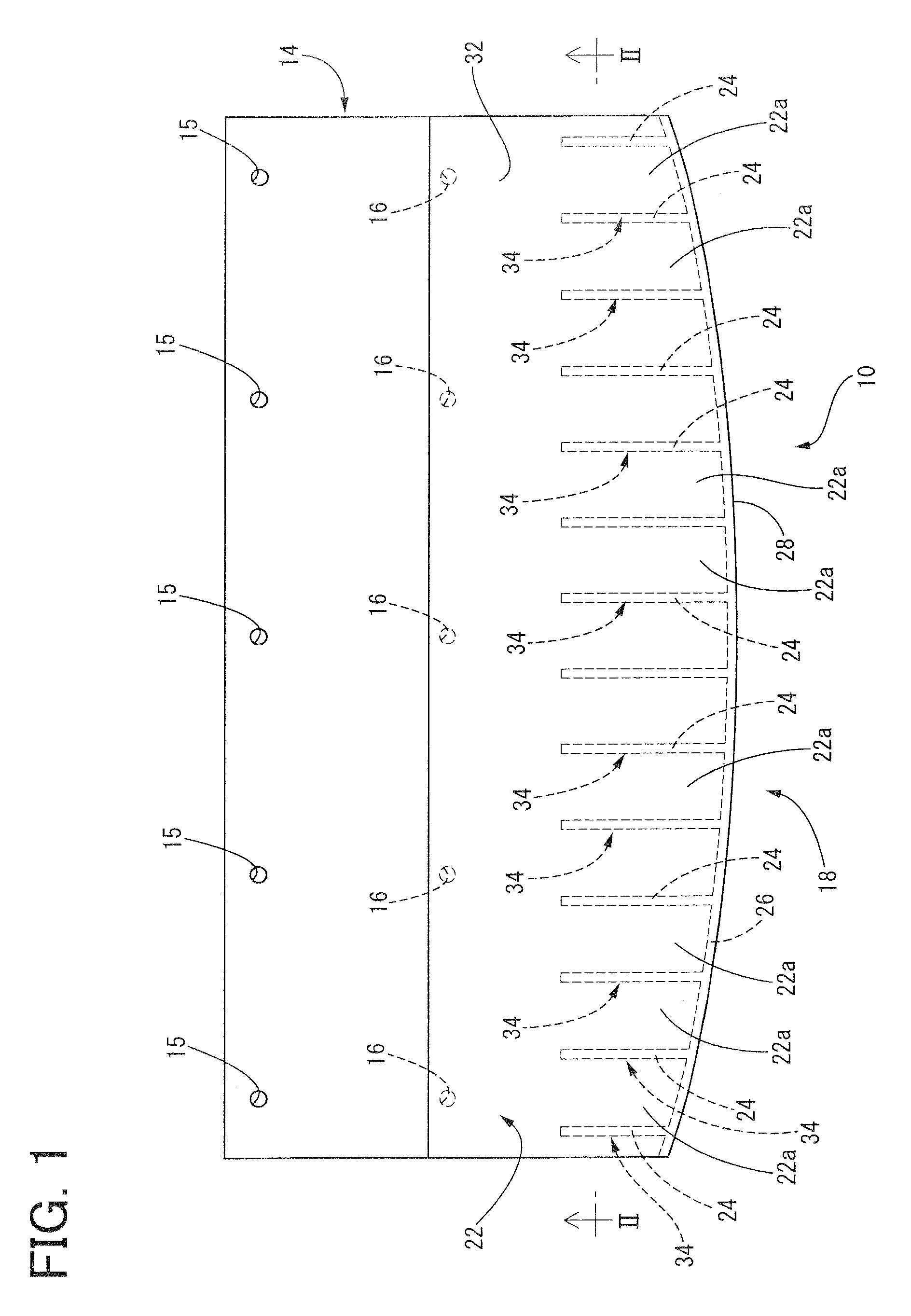

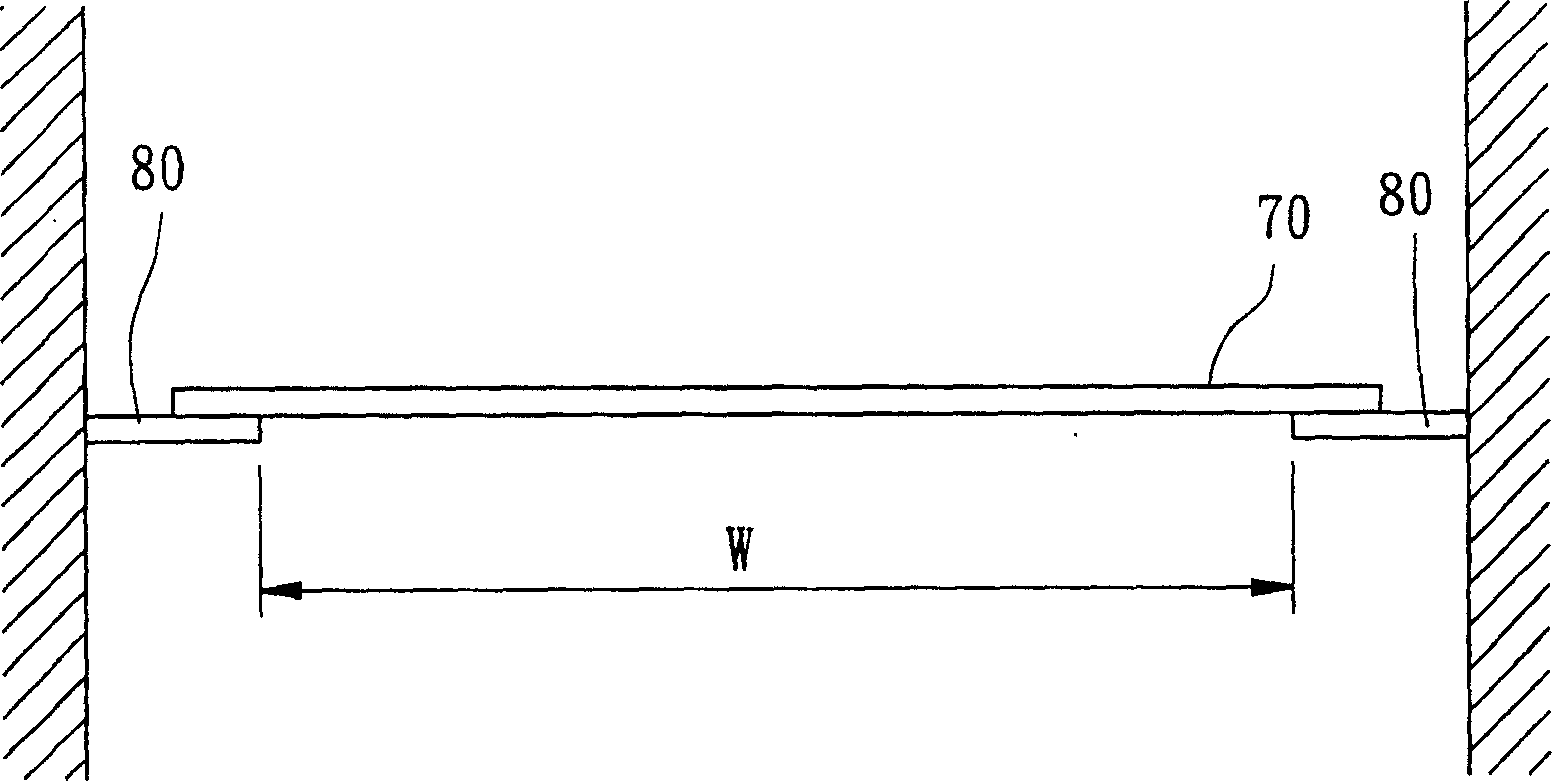

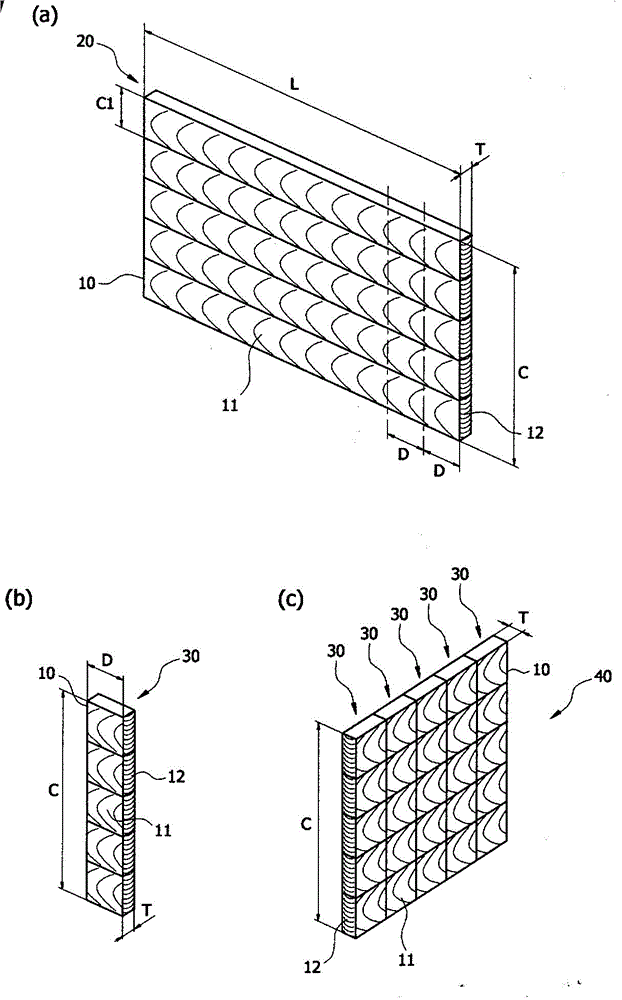

Cylinder head gasket having deformation delimiting devices radially inside and outside sealing bead

InactiveUS7527269B2Improve deformation strengthLess expensiveEngine sealsSealing arrangements for enginesEngineeringHead gasket

Cylinder head gasket is provided having a single-layered or multilayered metallic gasket plate with sealing beads in at least one metal layer, which are elastically deformable in height and surround the combustion chamber through-openings, and deformation delimiting devices which delimit the flattening of the sealing beads. In order to achieve as good a sealing function as possible in the long term and as good a protection as possible of the sealing beads against inadmissibly high deformations during operation of the engine, the deformation delimiting devices, one of which is formed by a meandering bead stamped into a metal layer, and the other by a plurality of elevations stamped out of a metal layer, are provided radially inside and radially outside of the sealing beads.

Owner:ELRINGKLINGER AG

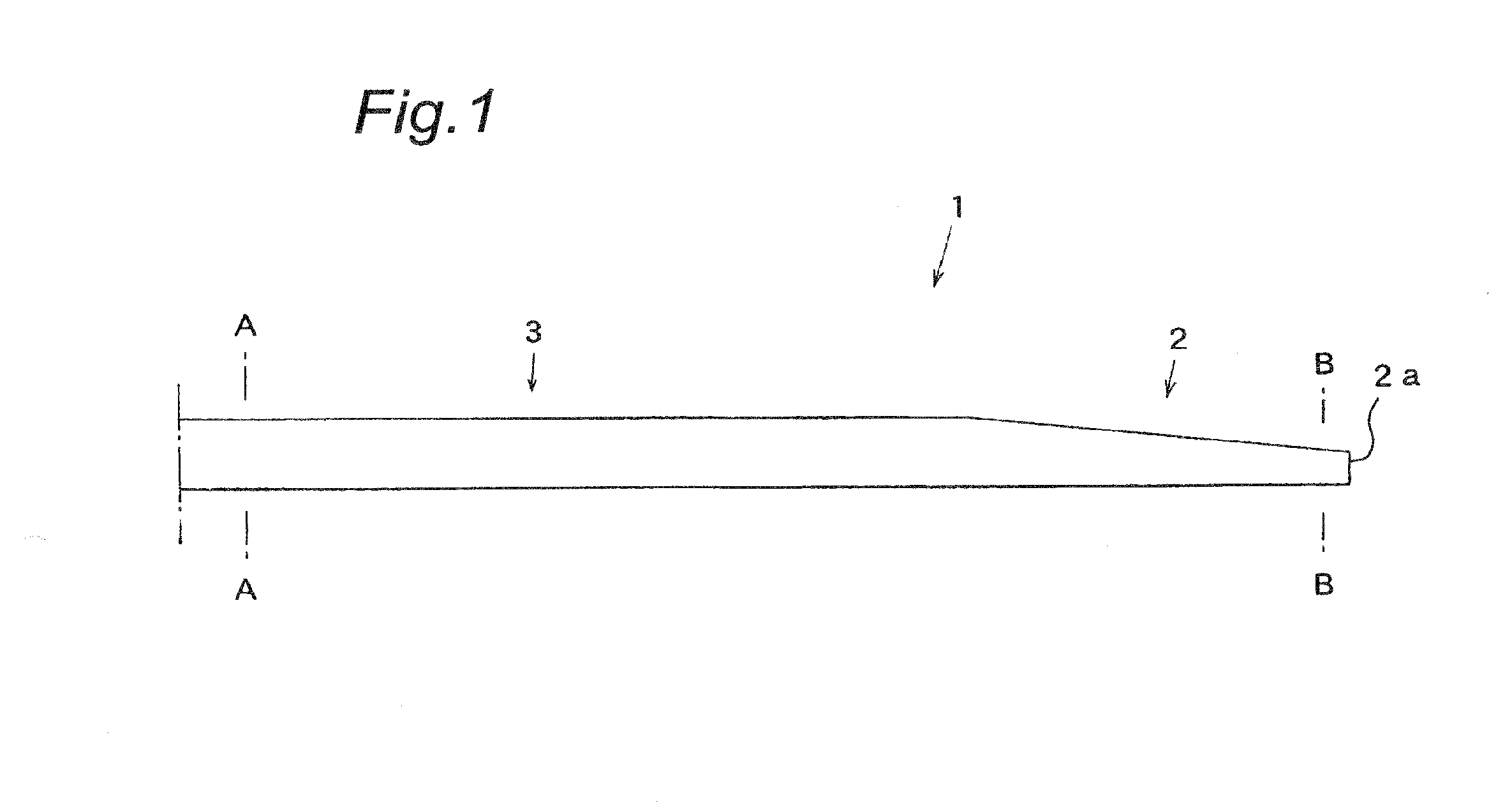

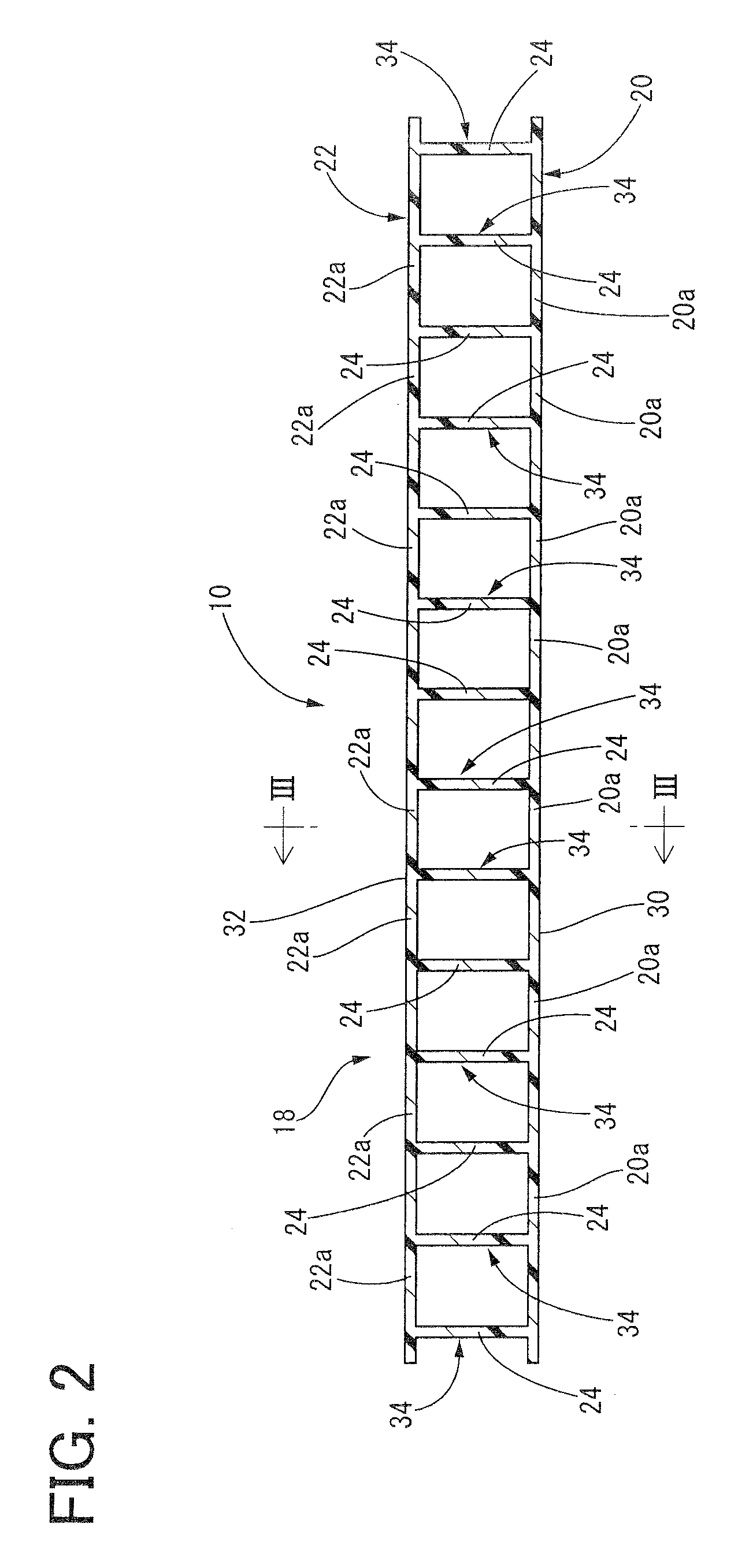

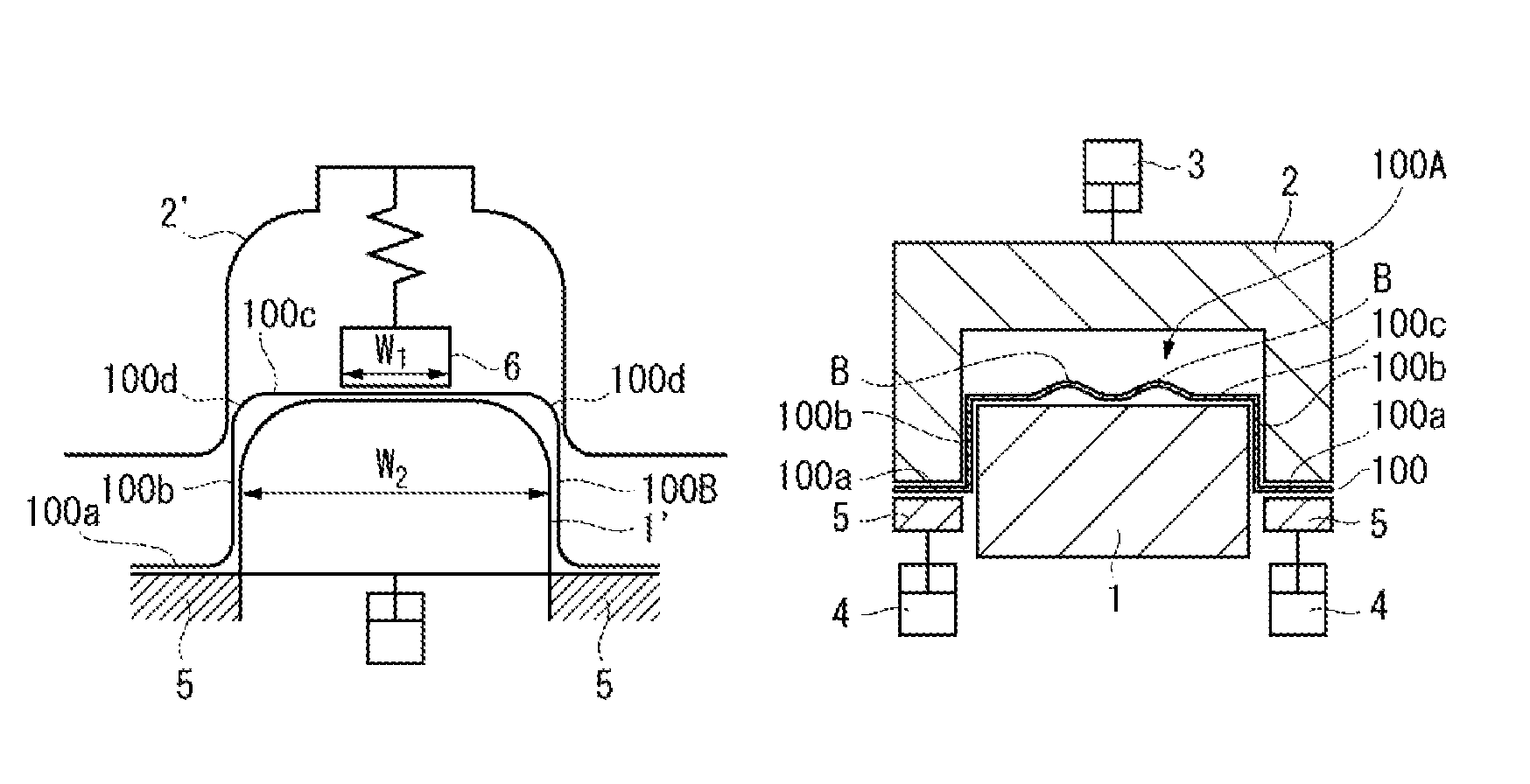

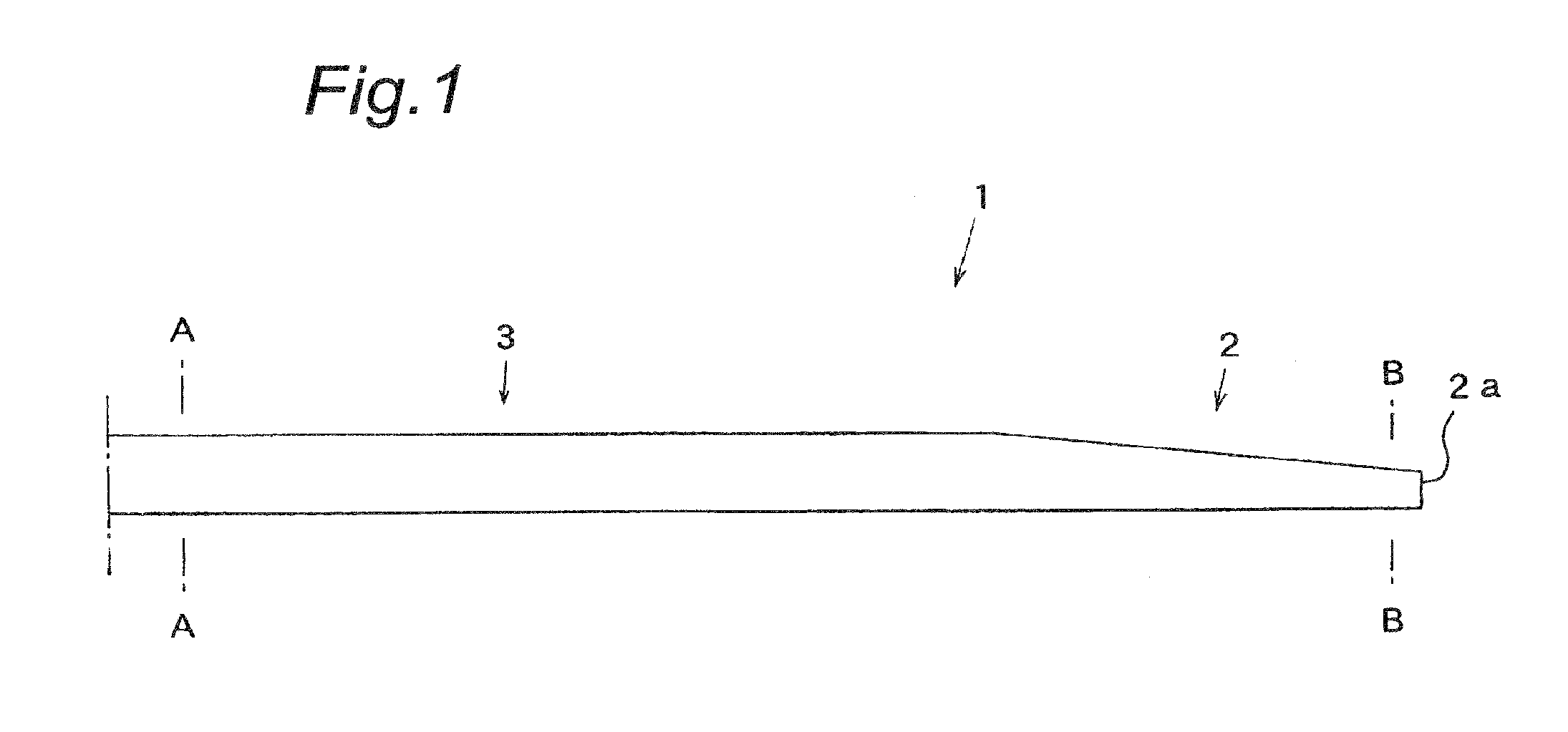

Press forming method and vehicle component

ActiveUS20140182349A1Enhance absorption rateImprove deformation strengthVehicle componentsEngineeringWork hardening

Disclosed is a press forming method press forming a workpiece between a die and a punch, while pushing the punch into the die by means of a relative motion of the die and the punch, the method includes: producing an intermediate molding (100B) having ridges (100d) formed in predetermined parts of the workpiece, and then press forming the intermediate molding (100B) into a final shape, to thereby substantially thicken and work-harden the predetermined parts of the workpiece.

Owner:NIPPON STEEL CORP

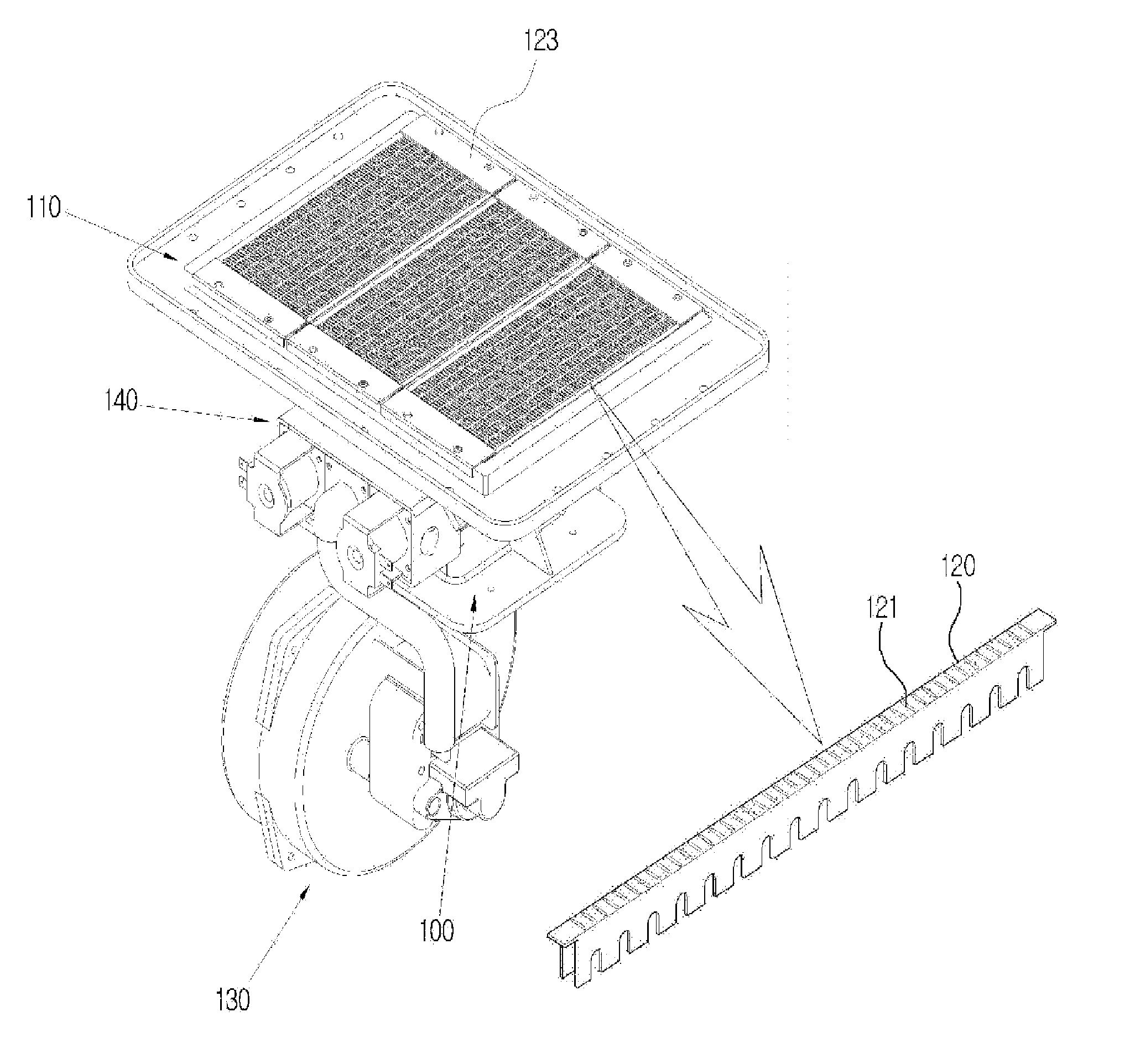

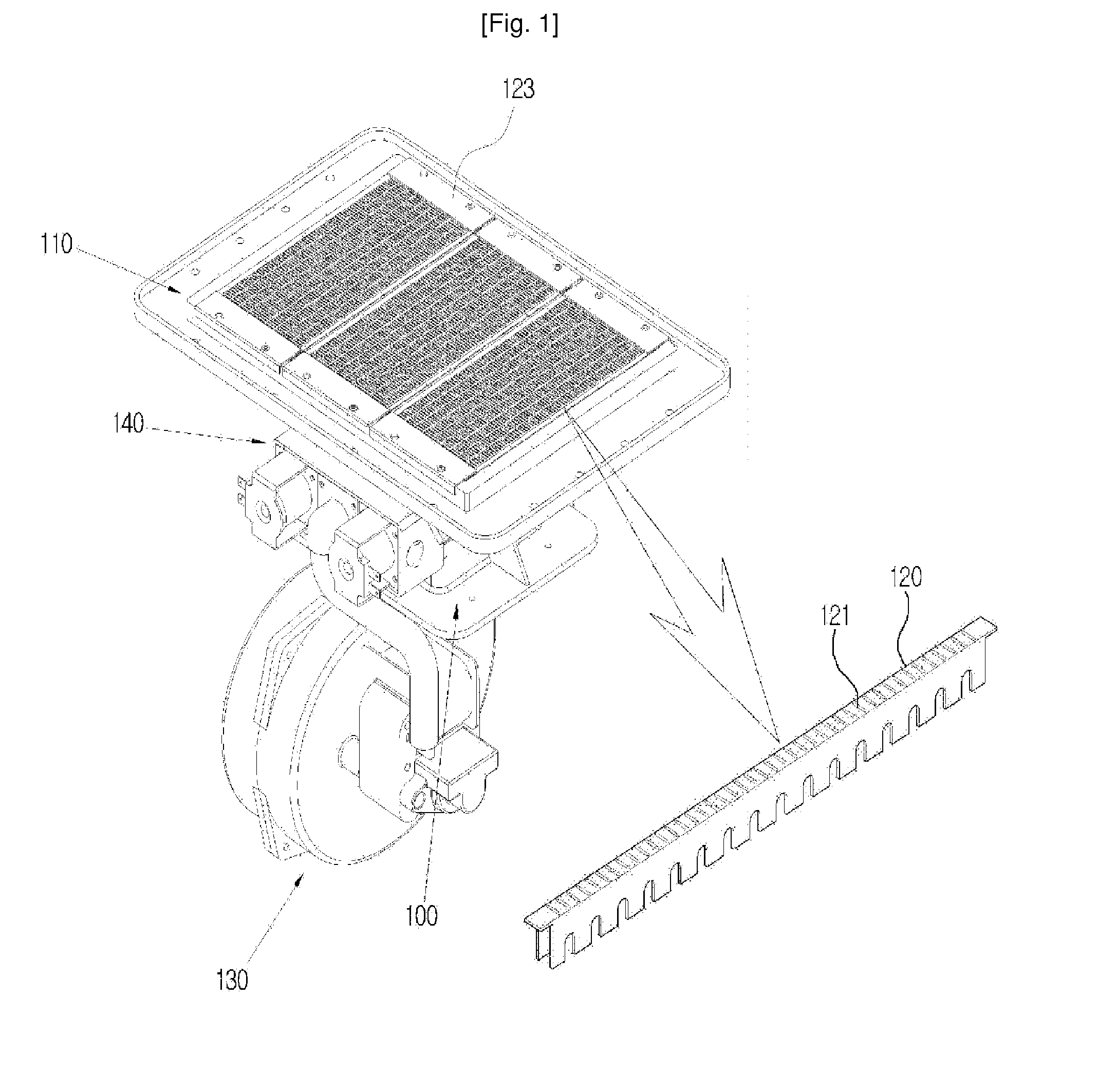

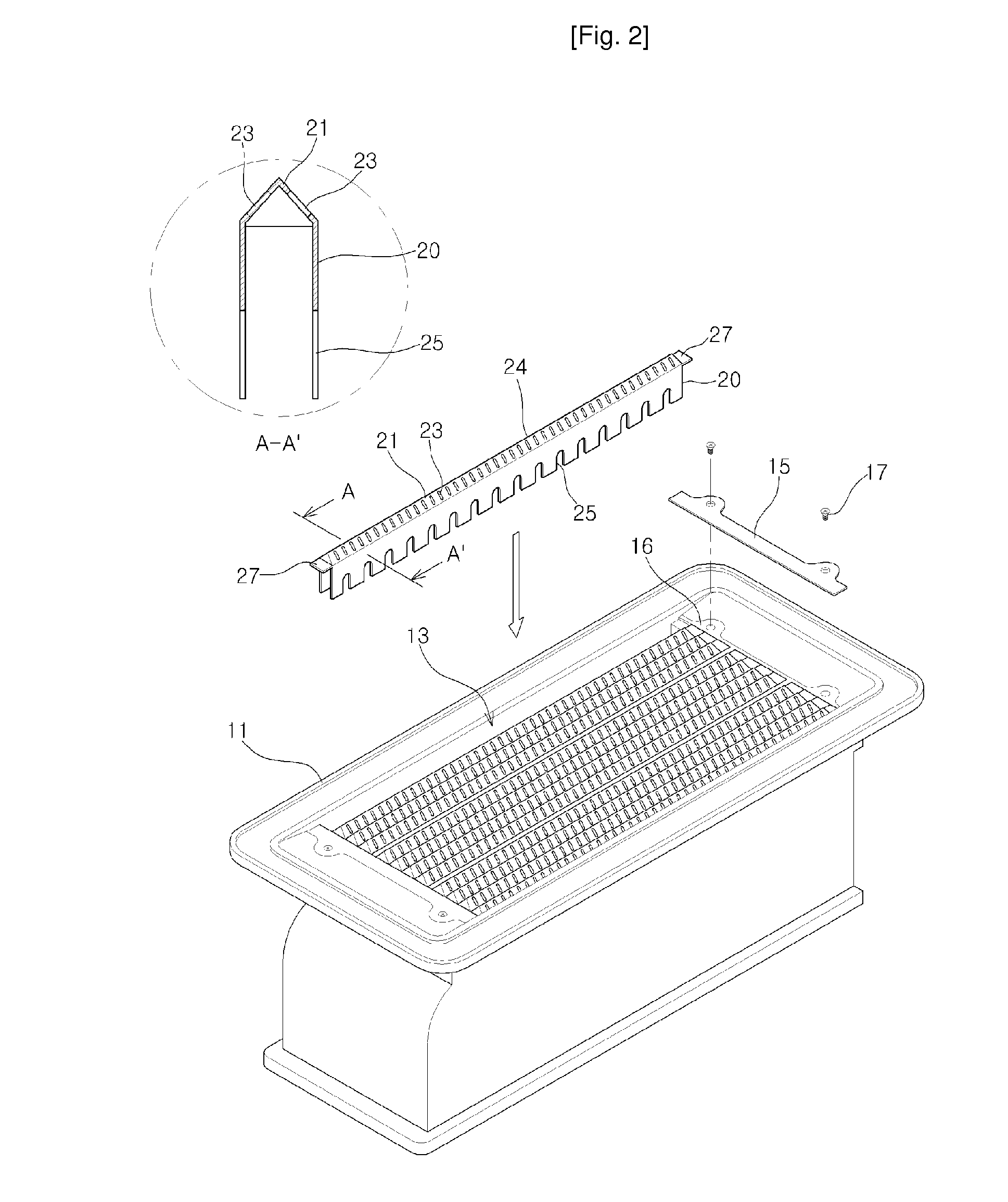

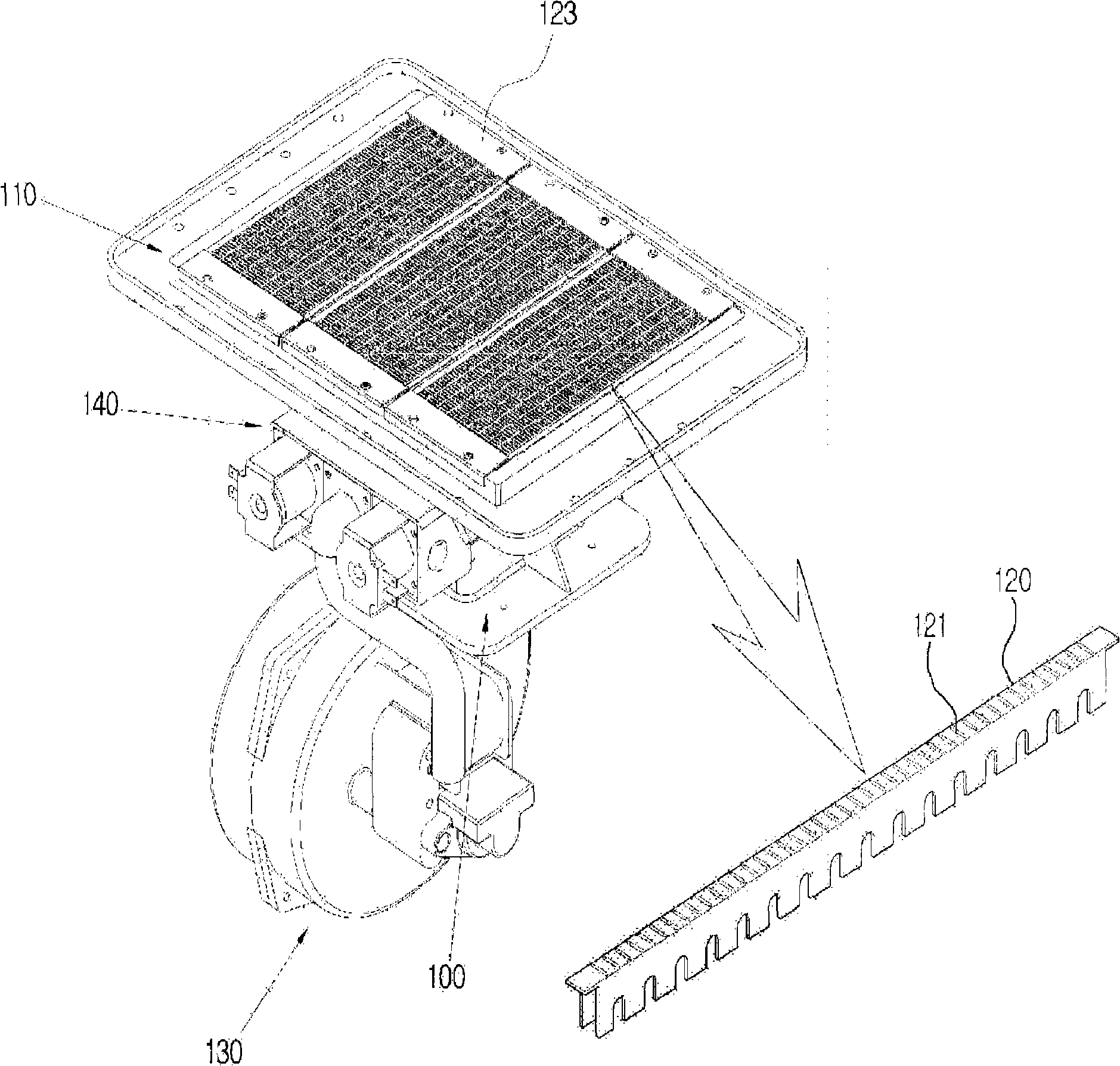

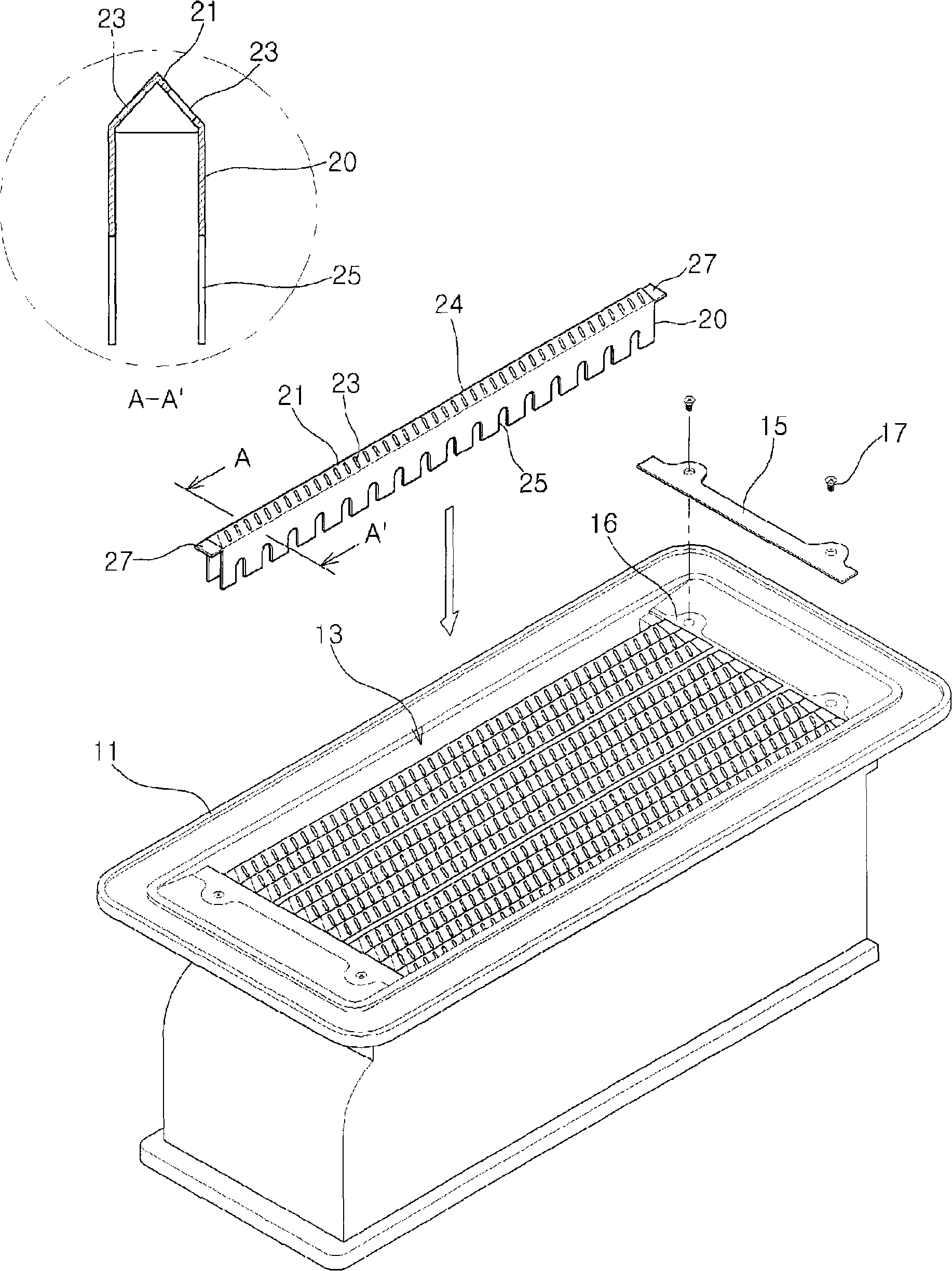

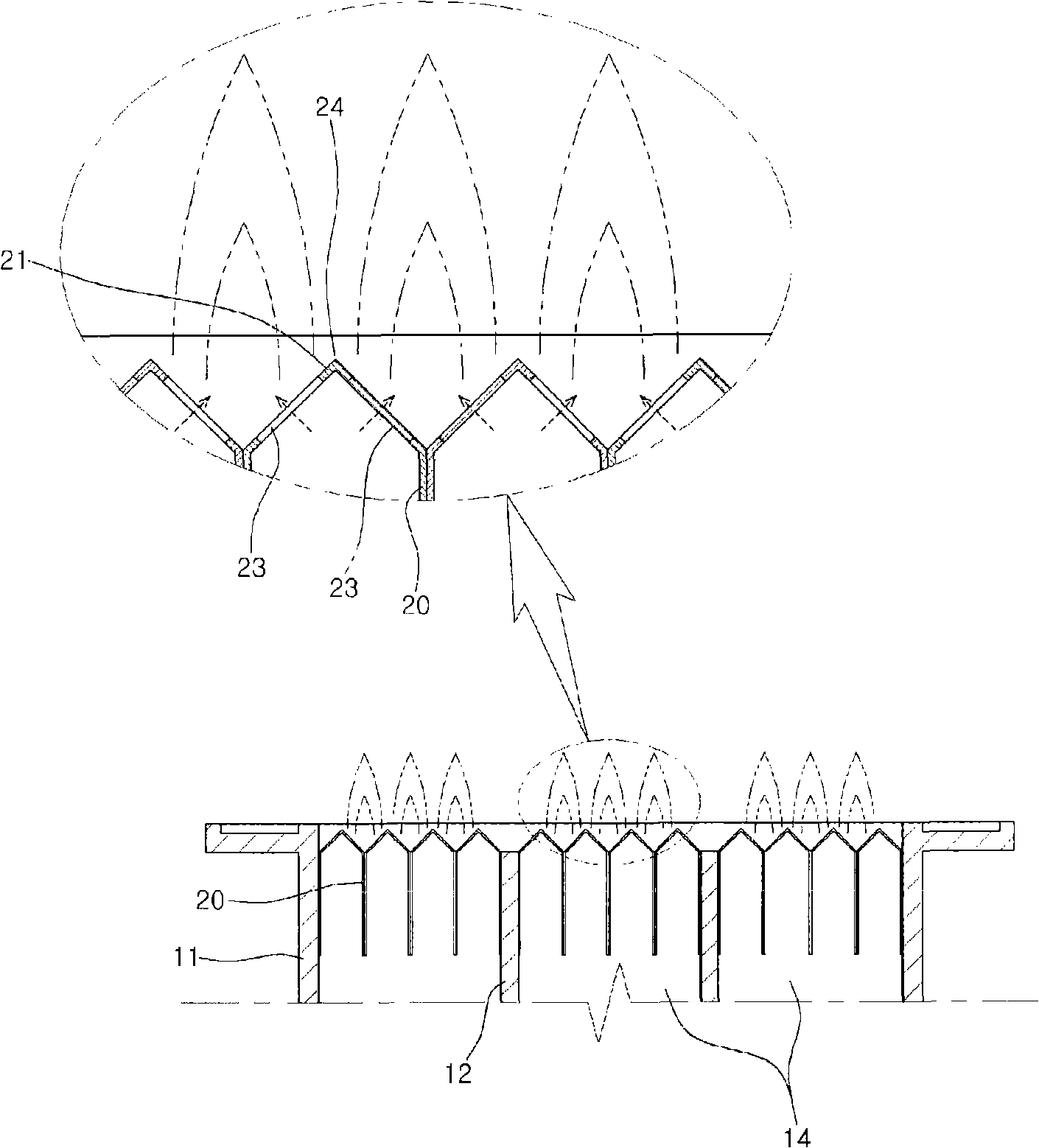

Flame structure of gas burner

InactiveUS20090291402A1Reduce in sizeCombustion load be increasePilot flame ignitersGaseous fuel burnerGas burnerFlame structure

A fire hole part structure of a gas burner, which is constructed to be manufactured at a low cost, can improve flame stability, and can prevent incomplete combustion due to the length of flame. The structure is provided to a premixing ignition burner, which is installed to apply heat to a heat exchanger of a boiler, and includes fire hole pieces which are installed parallel to one another in mounting openings of a burner body, and each of which is defined with fire holes at regular intervals. An upper wall of at least one of the fire hole pieces is bent or curved to extend in at least two directions, and the fire holes are defined through respective surface portions of the upper wall, which extend in different directions, to face different directions.

Owner:KYUNGDONG NAVIEN

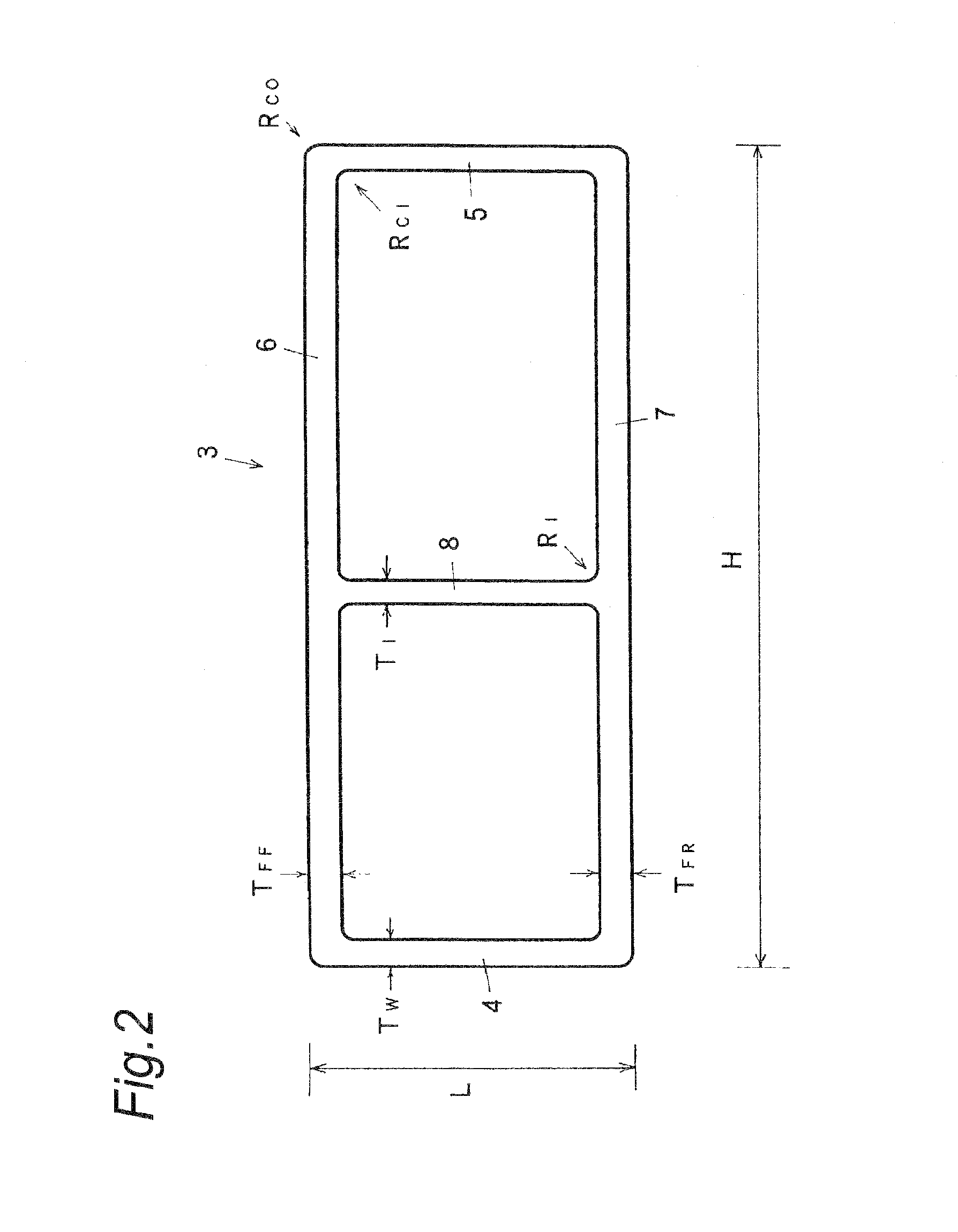

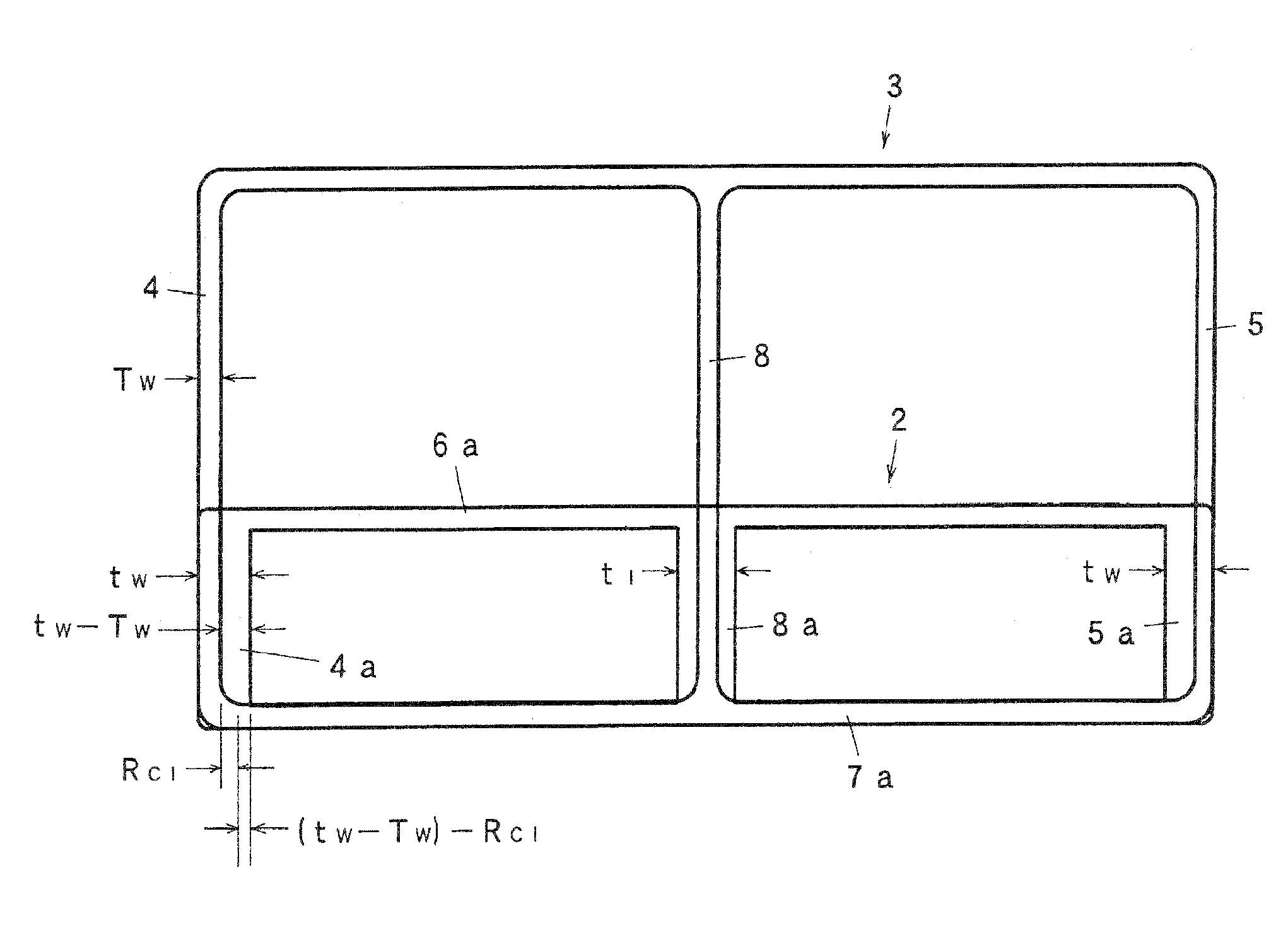

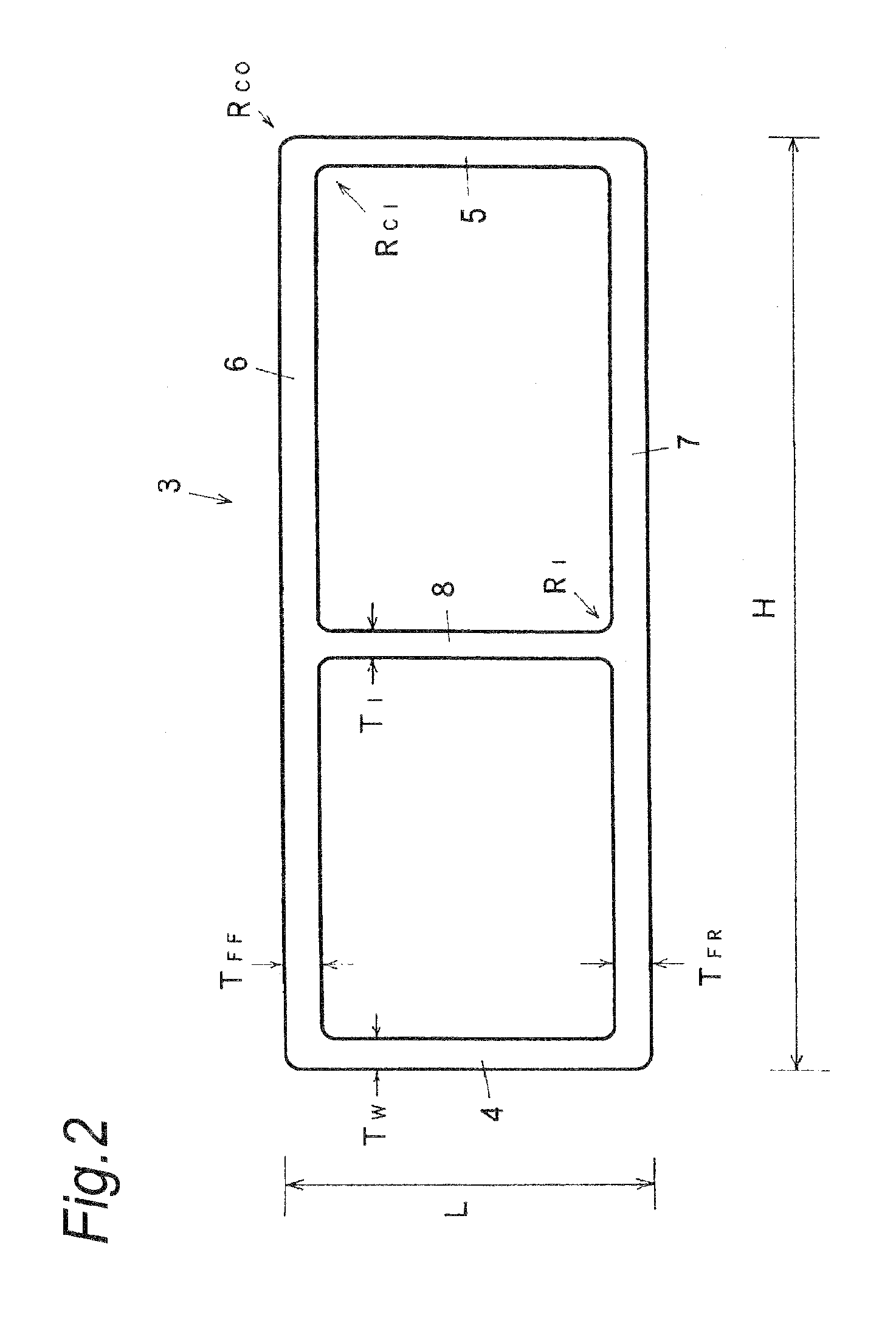

Anti-collision component

ActiveUS20160114747A1Reduce overall form factorImprove deformation strengthBumpersDoorsEngineeringCorner radius

An anti-collision component consisting of a metal hollow profile for automobiles includes a collision side flange, a body side flange, and a web connected to the flanges. The hollow profile has a longitudinal end at which a cross-sectional configuration is deformed by swaging to reduce a dimension between the flanges. The following relations are established:tW>TW RCI≧(tW-TW)where tW is a wall thickness of the web at the end, TW is a wall thickness of the web at a portion where the cross-sectional configuration is not deformed, and RCI is an inside corner radius of a corner formed of the web and each flange at the portion.

Owner:KOBE STEEL LTD +1

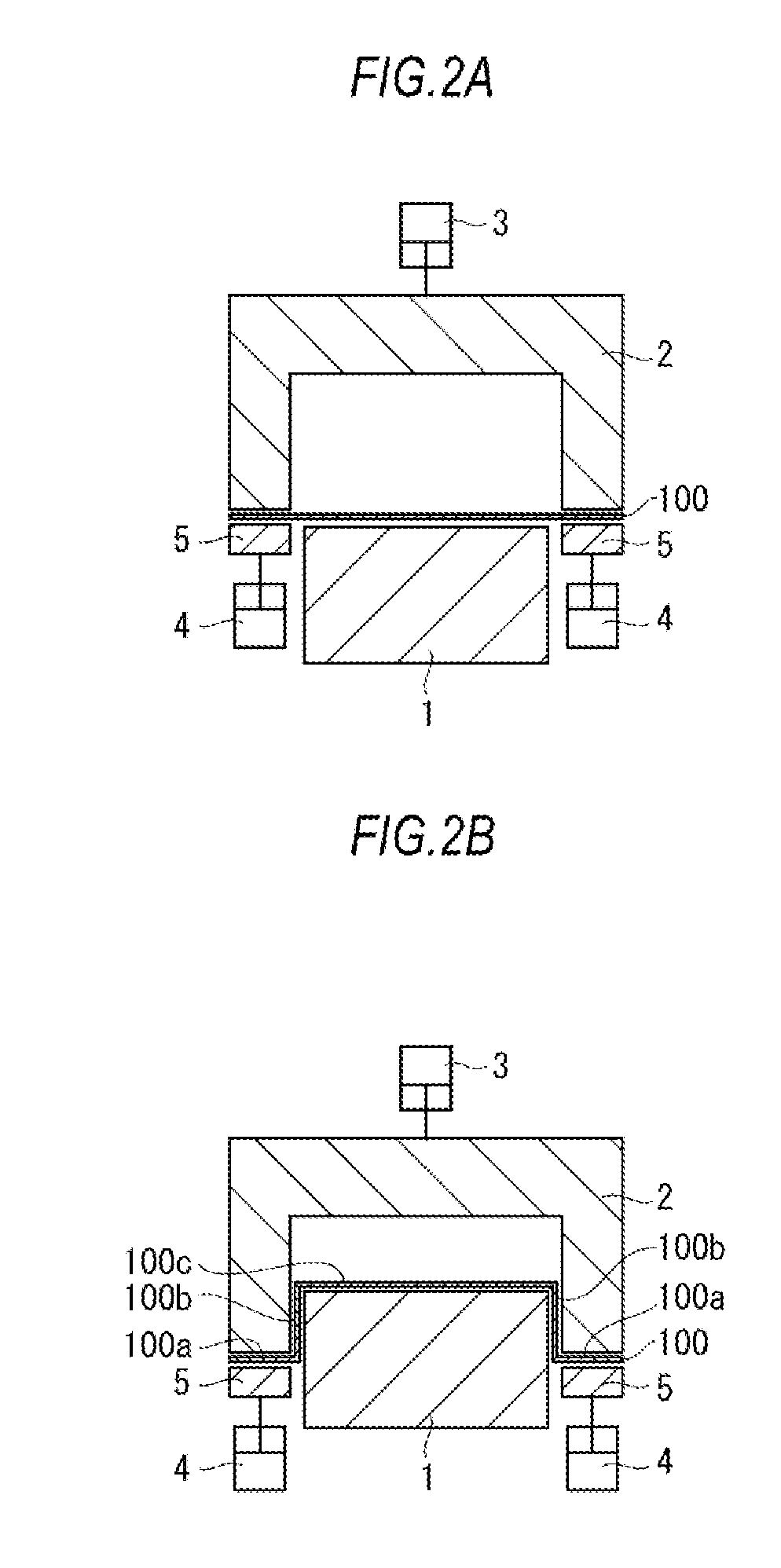

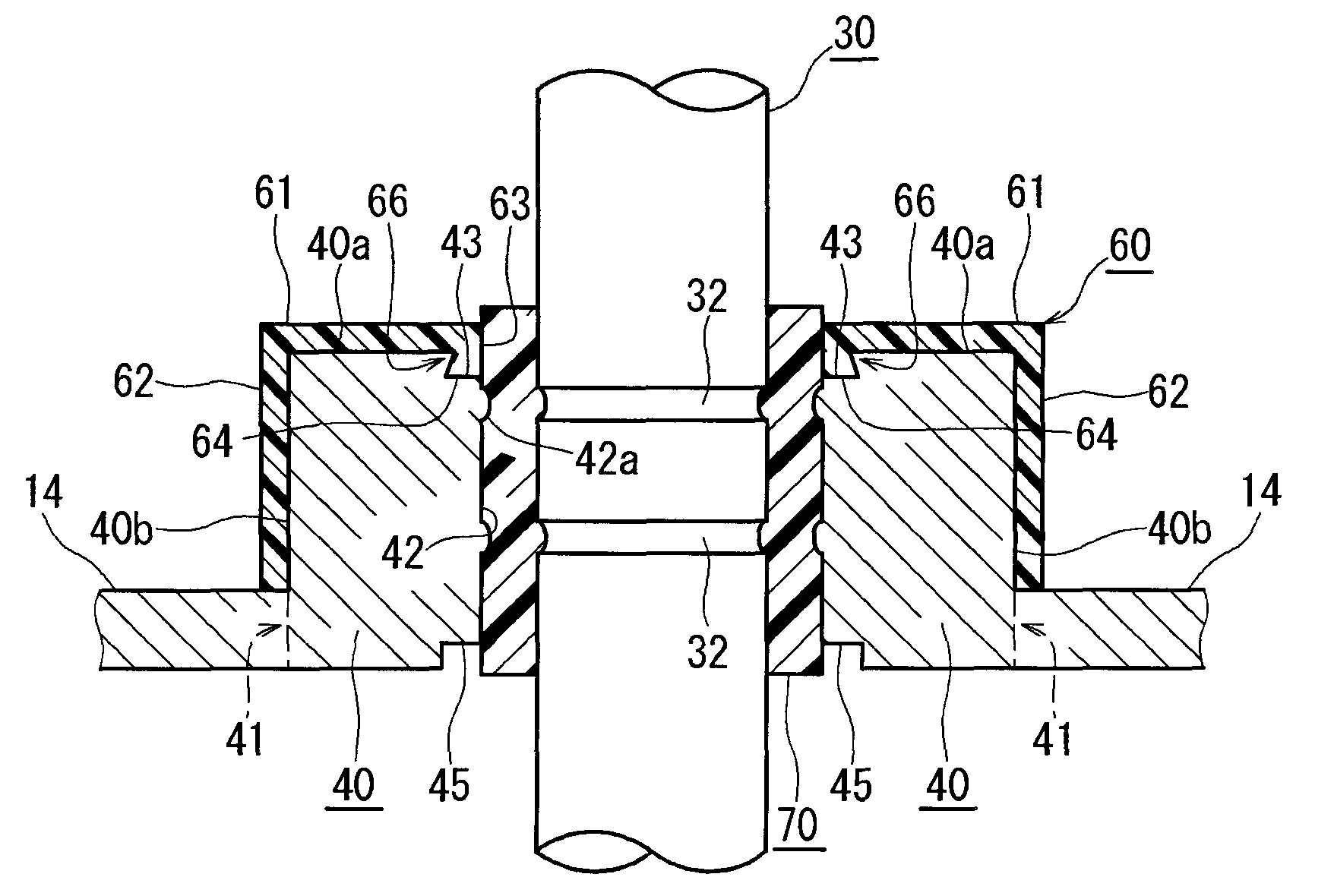

Battery having an electrode terminal fixed to a battery case

ActiveUS8795880B2More sealReliable deformationSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical and Electronics engineeringElectrode

A battery (100) includes a terminal fixing portion (40) projecting outwardly from a lid body (14), and an outer cover member (60) covering the terminal fixing portion (40). The terminal fixing portion (40) includes a hole (42) into which an electrode terminal (30) is inserted. The outer cover member (60) includes a cylindrical portion (62) (deformation restricting portion) covering an outer peripheral surface (40b) of the terminal fixing portion (40) and restrict deformation of the outer peripheral surface (40b) of the terminal fixing portion (40), and a pressure application portion (64) that compresses against a top end portion (40a) of the terminal fixing portion (40) and causes the terminal fixing portion (40) to deform.

Owner:TOYOTA JIDOSHA KK

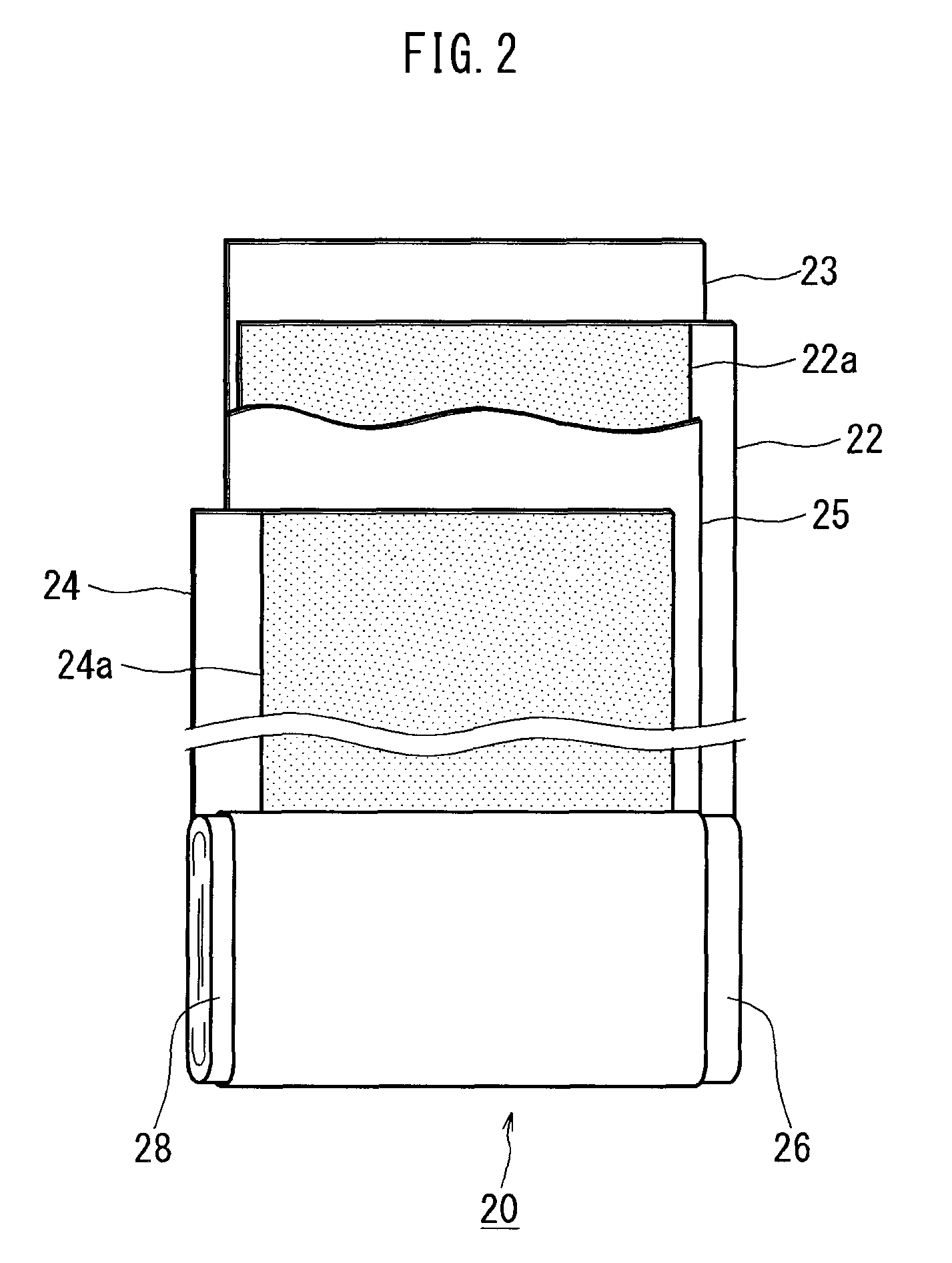

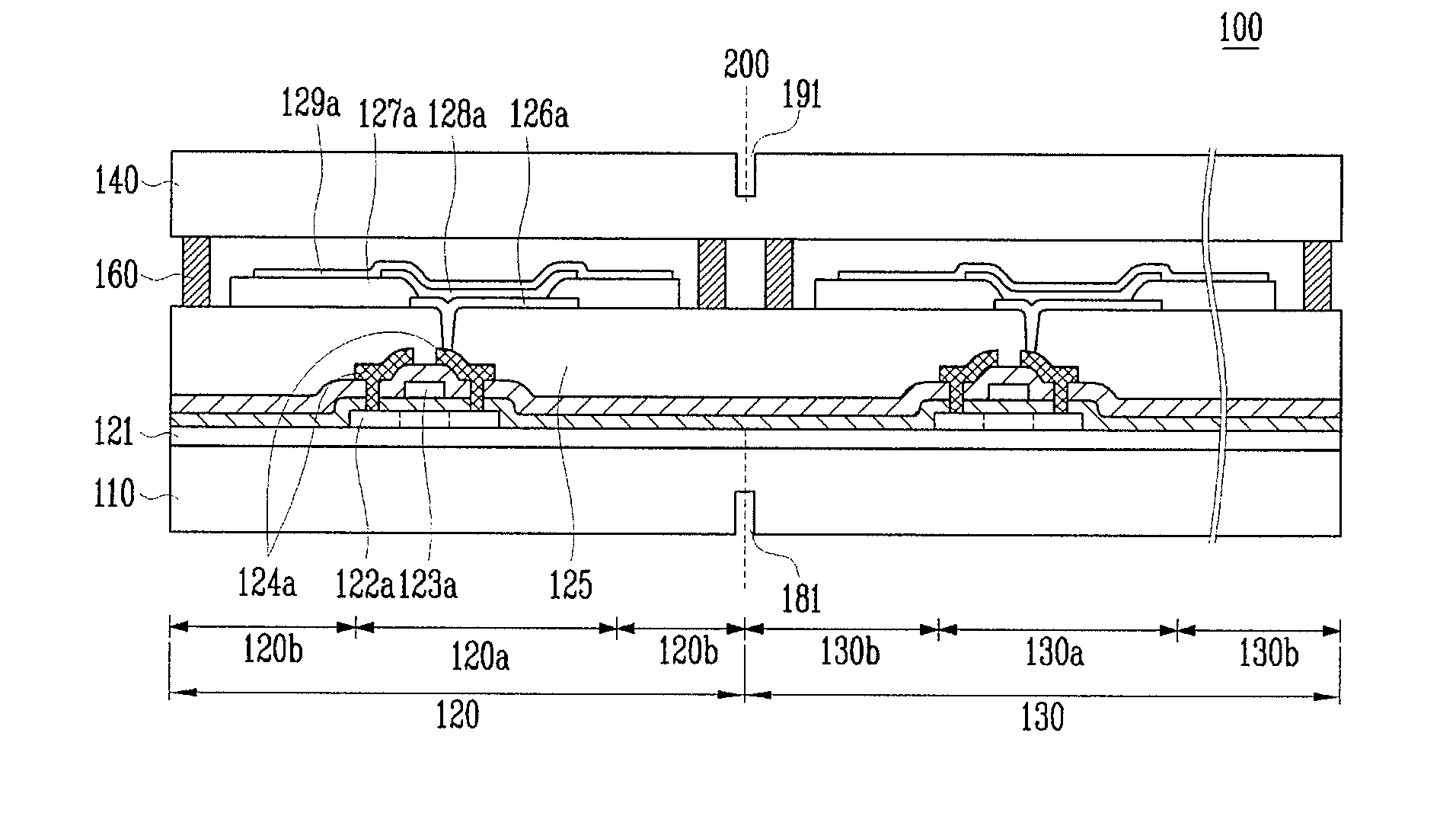

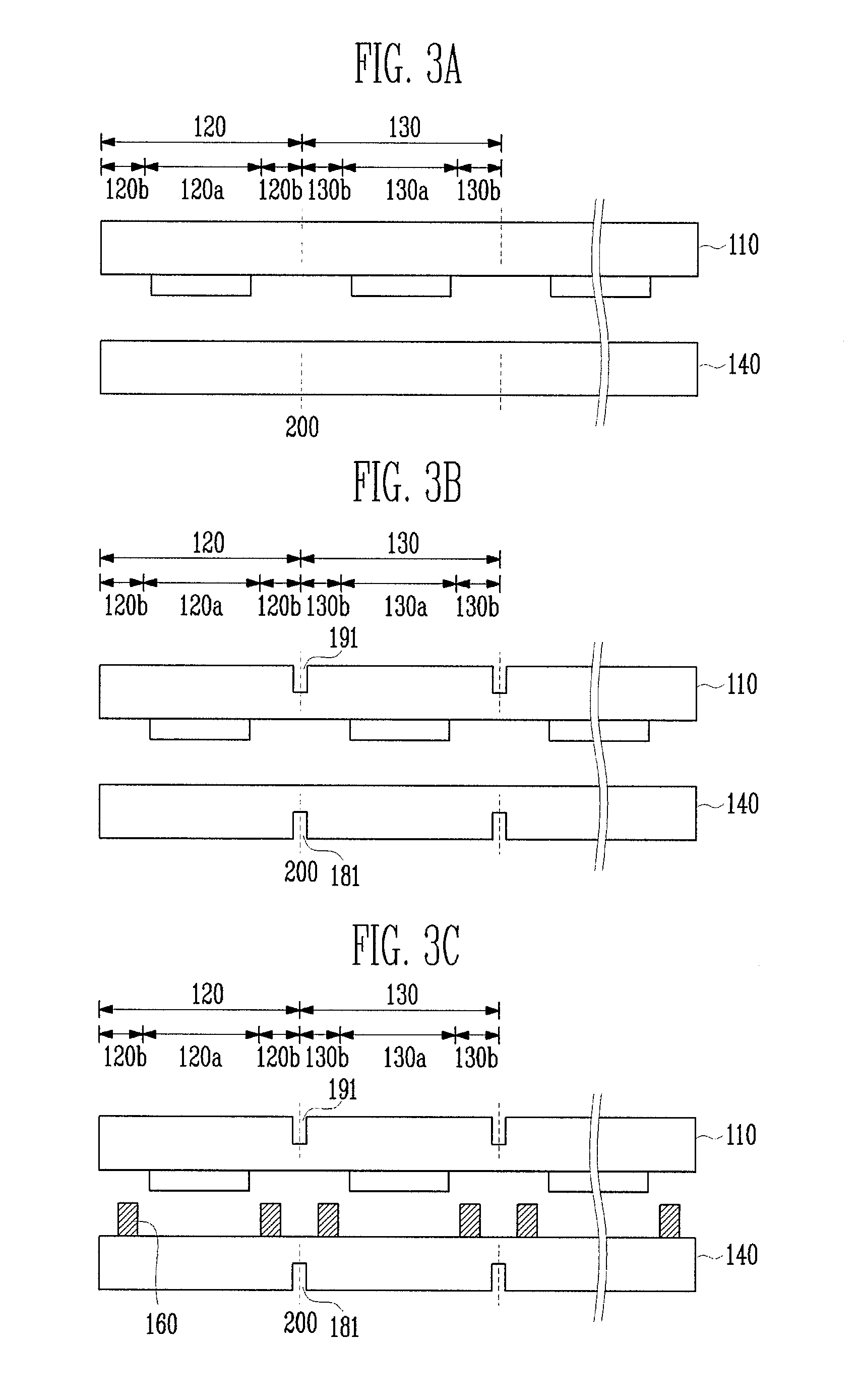

Organic light emitting display and fabricating method thereof

ActiveUS20110006671A1Improve deformation strengthInhibition strengthTube/lamp screens manufactureDischarge tube luminescnet screensEngineeringSurface plate

An organic light emitting display is formed with a plurality of display panels that are cut and separated from a mother substrate to form a unit display panel. Here, the substrate has a groove on its outer surface to improve the deformation strength of the cutting surface and to protect the strength of the panel from being degraded by improving the quality of the cutting cross-section. The organic light emitting display includes: a first substrate formed with a plurality of display panels partitioned by a cutting line and having a first groove on its outer surface corresponding to the cutting line; and a second substrate overlapped with an upper part of the first substrate and having a second groove on its outer surface corresponding to the cutting line, wherein the first and second grooves are formed with cutting positions lower than that of the outer surfaces of the respective substrates.

Owner:SAMSUNG DISPLAY CO LTD

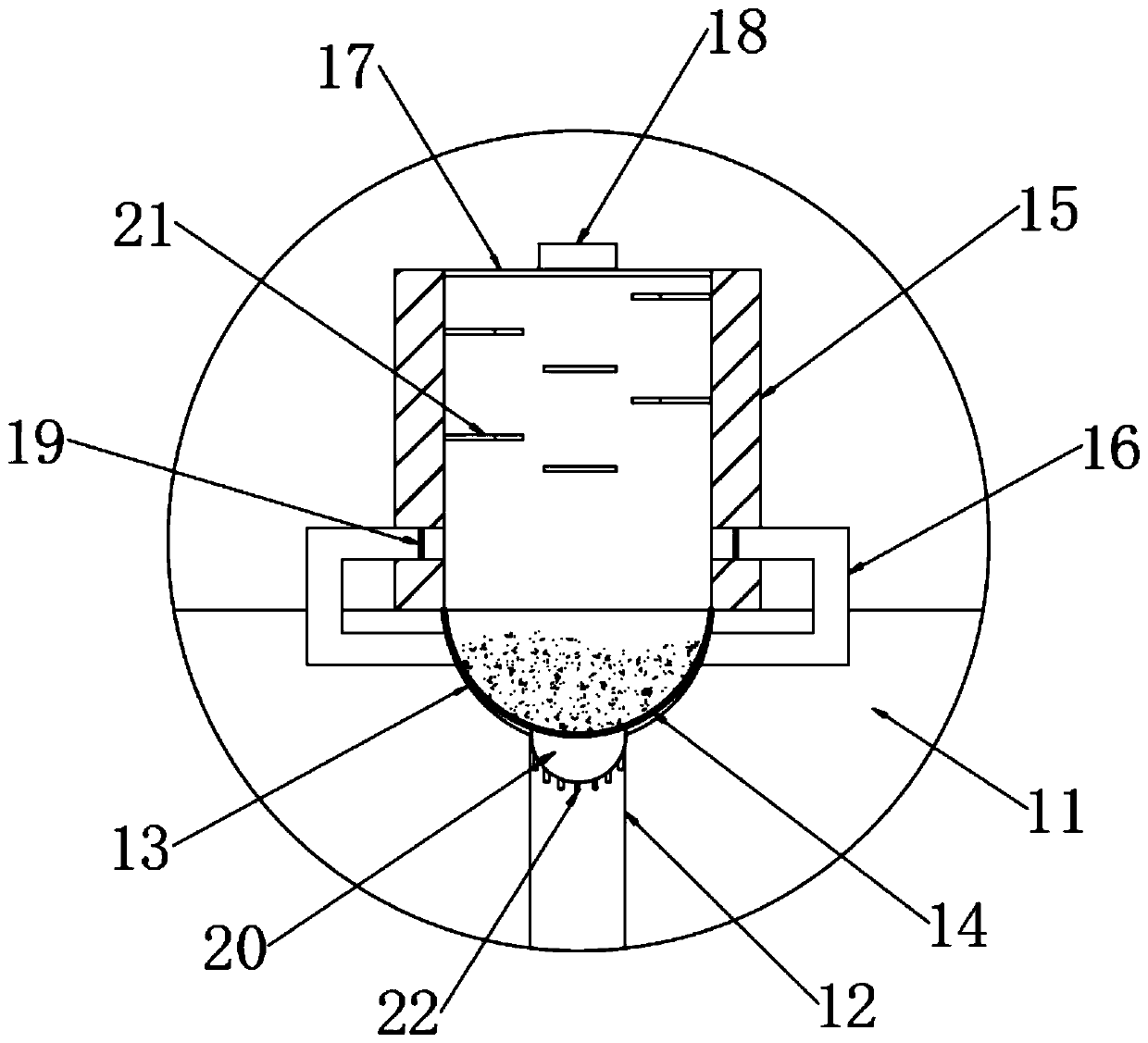

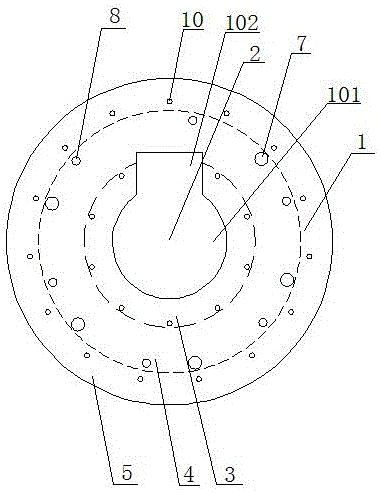

Suspension point contact type supercritical extraction device

PendingCN111282309AImprove extraction rateImprove dispersion effectSolid solvent extractionComposite materialSupercritical fluid

The invention discloses a suspension point contact type supercritical extraction device. The invention belongs to the technical field of supercritical extraction. A hanging basket static extraction mode in a traditional extraction kettle can be abandoned; the deformation characteristic of an empty throwing material receiving film is utilized; contained materials are shaken and thrown in the air; apowdery material is promoted to keep a dispersed suspended state; then, supercritical fluid sequentially passes through a limited space to be in full contact with the materials; the extraction rate of effective substances is obviously improved; through the characteristics of the empty throwing material receiving film and the assisting action of an assisting hanging piece, on one hand, the material dispersion effect is improved, meanwhile, the posture can be changed by overturning, the material is in contact with the supercritical fluid, the materials are fully extracted, and extraction dead corners are not prone to occurring; on the other hand, the situation that the extraction effect is affected due to the static adhesion phenomenon of the powdery materials can be avoided; the one-way extraction rate of the materials can be greatly increased, and the extraction efficiency is greatly improved.

Owner:NANTONG HUAAN SUPER CRITICAL EXTRACTION

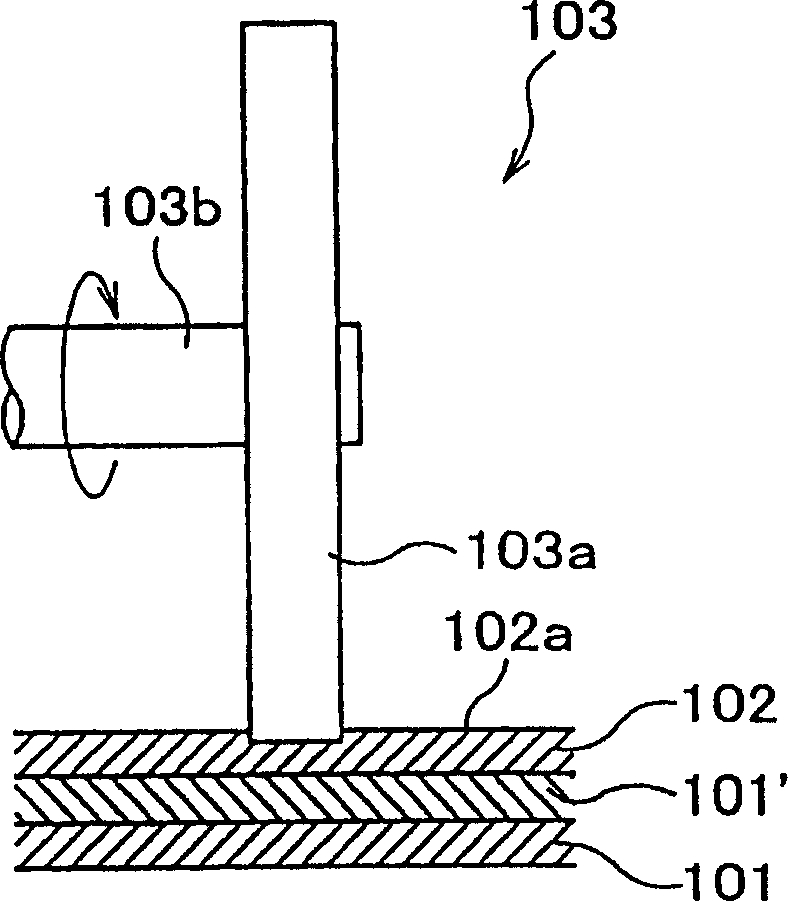

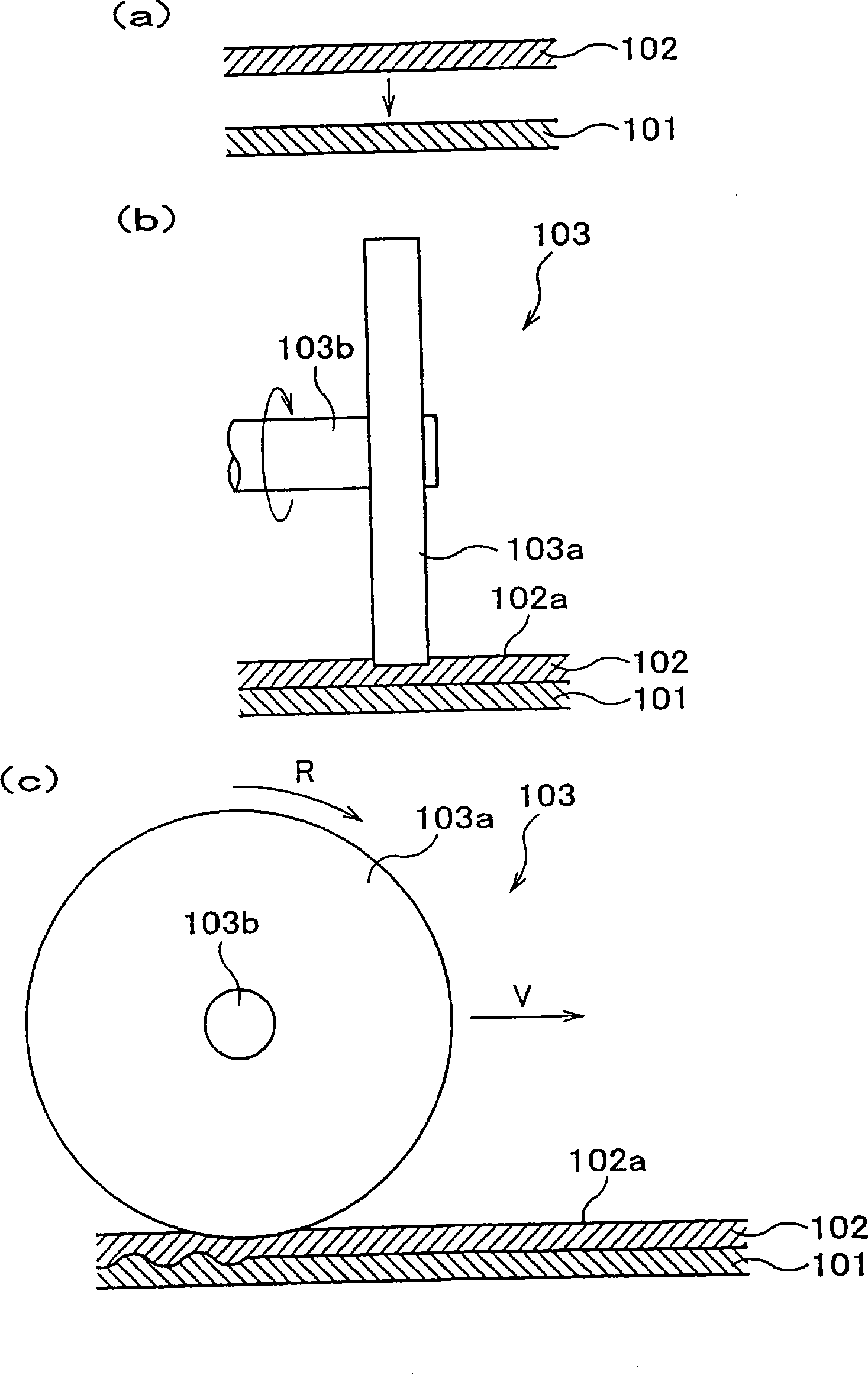

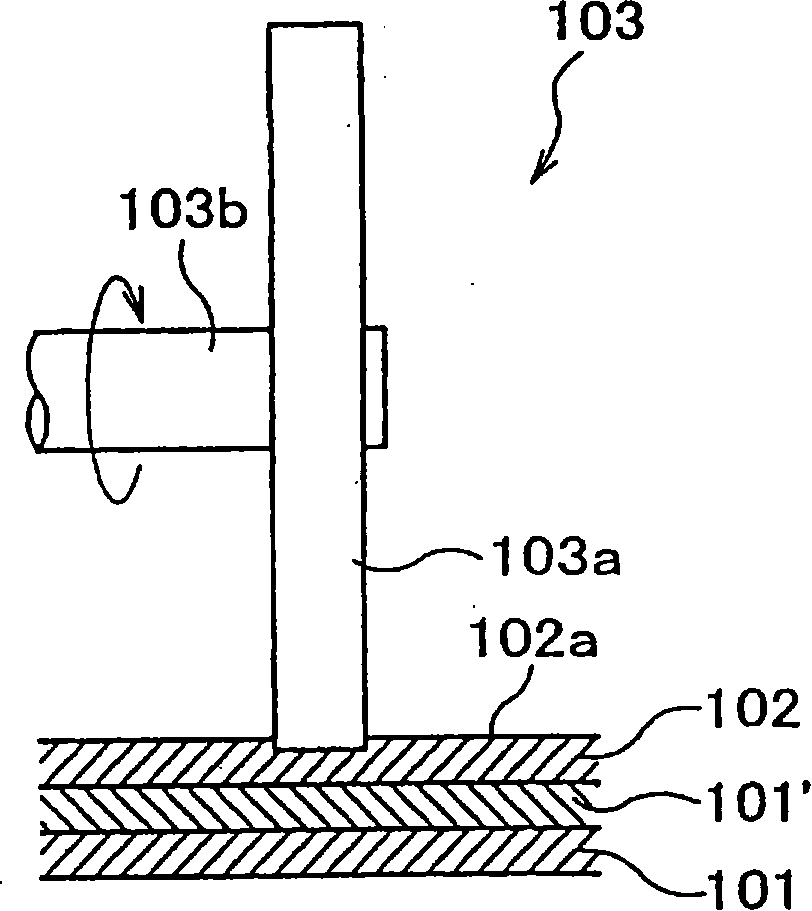

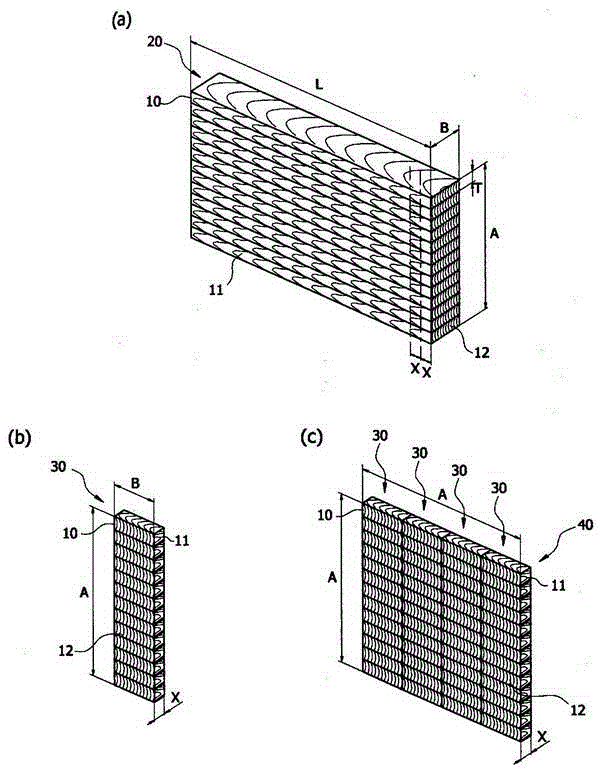

Method of joining members, method of joining metallic members, radiation member, process for manufacturing the same, jig for the manufacturing and heat sink

InactiveCN1678425AImprove deformation strengthImprove joint strengthNon-electric welding apparatusAluminiumRadiation

A method of joining two metallic members of different melting points piled on each other, which enables obtaining stable joined part quality and enables junction of large metallic members of complex configuration. Two or more metallic members (aluminum member (101) and copper member (102)) are joined to each other through a process comprising arranging two or more metallic members (aluminum member (101) and copper member (102)) so that these are piled on each other in the order of highness of melting point and moving the circumferential face of tool main body (103a) of disk-shaped junction tool (103) capable of rotating in the circumferential direction, while in the piling portion pressing the same in the surface (102a) of metallic member (copper member (102)) having the highest melting point among those of the metallic members, along the surface (102a) of metallic member (copper member (102)).

Owner:NIPPON LIGHT METAL CO LTD

Cylinder head gasket

InactiveUS20060055121A1Improve deformation strengthLess expensiveEngine sealsSealing arrangements for enginesCombustion chamberCylinder head

Cylinder head gasket having a single-layered or multilayered metallic gasket plate with sealing beads in at least one metal layer, which are elastically deformable in height and surround the combustion chamber through-openings, and deformation delimiting devices which delimit the flattening of the sealing beads; in order to achieve as good a sealing function as possible in the long term and as good a protection as possible of the sealing beads against inadmissibly high deformations during operation of the engine, deformation delimiting devices, one of which is formed by a meandering bead stamped into a metal layer, and the other by a plurality of elevations stamped out of a metal layer, are provided radially inside and radially outside the sealing beads.

Owner:ELRINGKLINGER AG

Method of joining metallic members and process for manufacturing radiation member

InactiveCN101161395AImprove deformation strengthImprove joint strengthSemiconductor/solid-state device detailsSolid-state devicesCopperMetal

A method of joining two metallic members of different melting points piled on each other, which enables obtaining stable joined part quality and enables junction of large metallic members of complex configuration. Two or more metallic members (aluminum member (101) and copper member (102)) are joined to each other through a process comprising arranging two or more metallic members (aluminum member (101) and copper member (102)) so that these are piled on each other in the order of highness of melting point and moving the circumferential face of tool main body (103a) of disk-shaped junction tool (103) capable of rotating in the circumferential direction, while in the piling portion pressing the same in the surface (102a) of metallic member (copper member (102)) having the highest melting point among those of the metallic members, along the surface (102a) of metallic member (copper member (102)).

Owner:NIPPON LIGHT METAL CO LTD

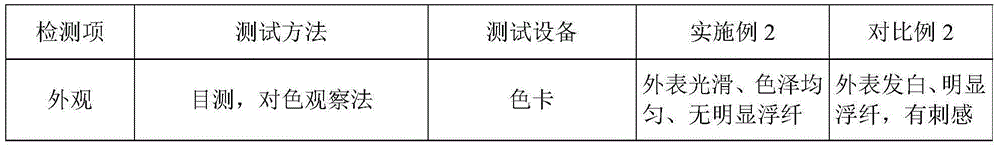

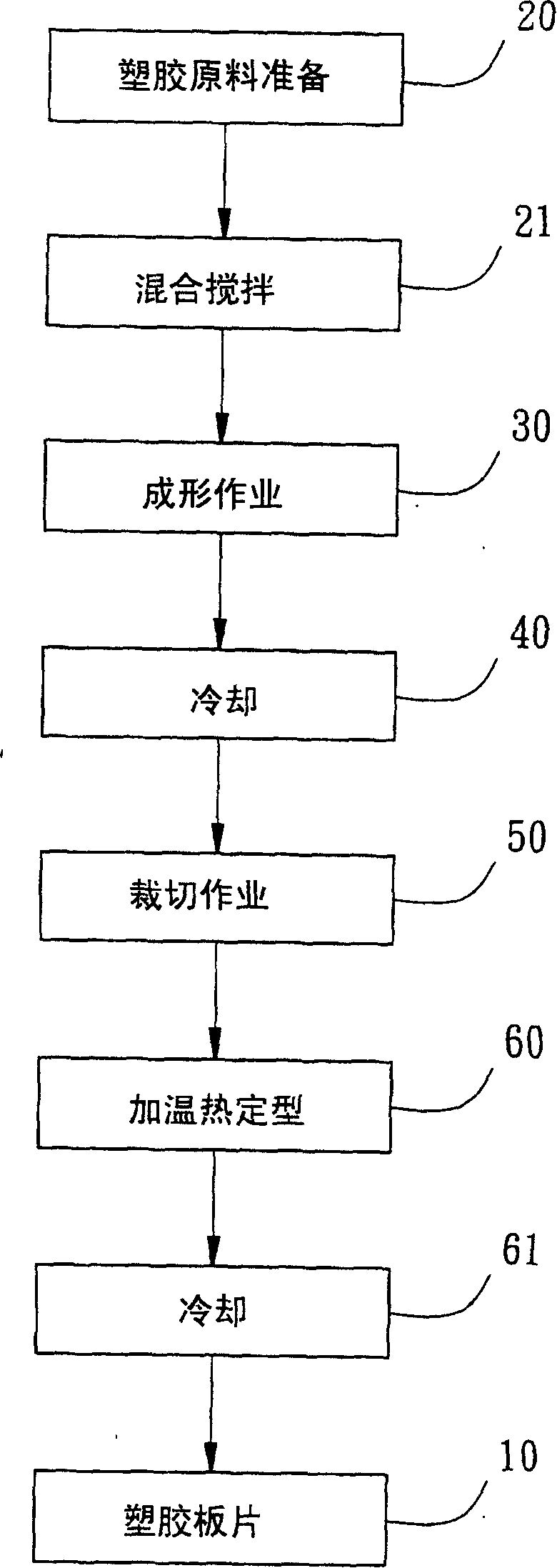

Lithium ion battery plastic casing, lithium ion battery, and manufacturing method of lithium ion battery plastic casing and lithium ion battery

InactiveCN106543551AReduce manufacturing costImprove deformation strengthJackets/cases materialsFiberGlass fiber

The invention discloses a lithium ion battery plastic casing, a lithium ion battery, and a manufacturing method of the lithium ion battery plastic casing and the lithium ion battery. The lithium ion battery plastic casing comprises a main body and a cover plate; the main body and the cover plate are prepared via injection moulding of a modified polypropylene material comprising 35 to 76.9% of polypropylene, 3 to 7.5% of a mineral filler, 15 to 20% of glass fiber, 5% of grafted polypropylene, and 0.1 to 2.5% of a processing accessory ingredient. The lithium ion battery comprises the lithium ion battery plastic casing. The manufacturing method of the lithium ion battery comprises following steps: 1, the modified polypropylene material is subjected to injection moulding so as to obtain the main body and the cover plate; 2, a battery cell is packaged with the main body, the cover plate is arranged at an opening of the main body, and sealing is carried out via heat melting welding. The lithium ion battery plastic casing is simple in structure, low in production cost, smooth in appearance, uniform in color, high in strength, low in weight loss, excellent in aging resistance, and long in service life; no obvious fiber exposure is observed; and deformation is not easily caused.

Owner:TIANJIN SINOPOLY NEW ENERGY TECH

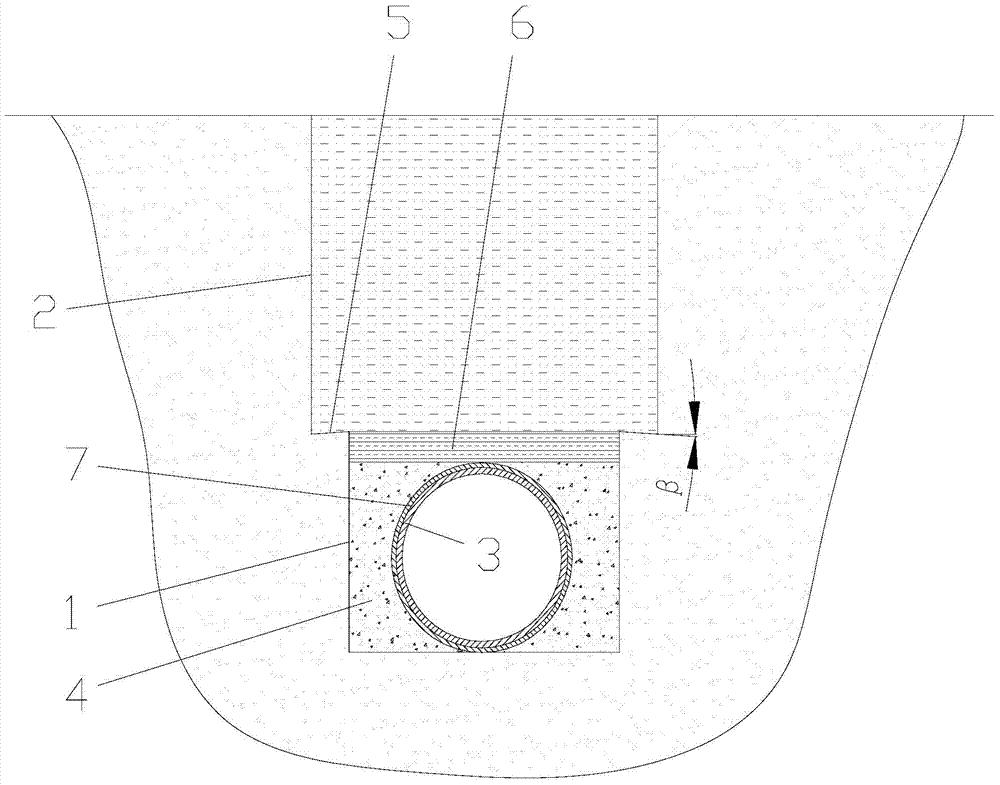

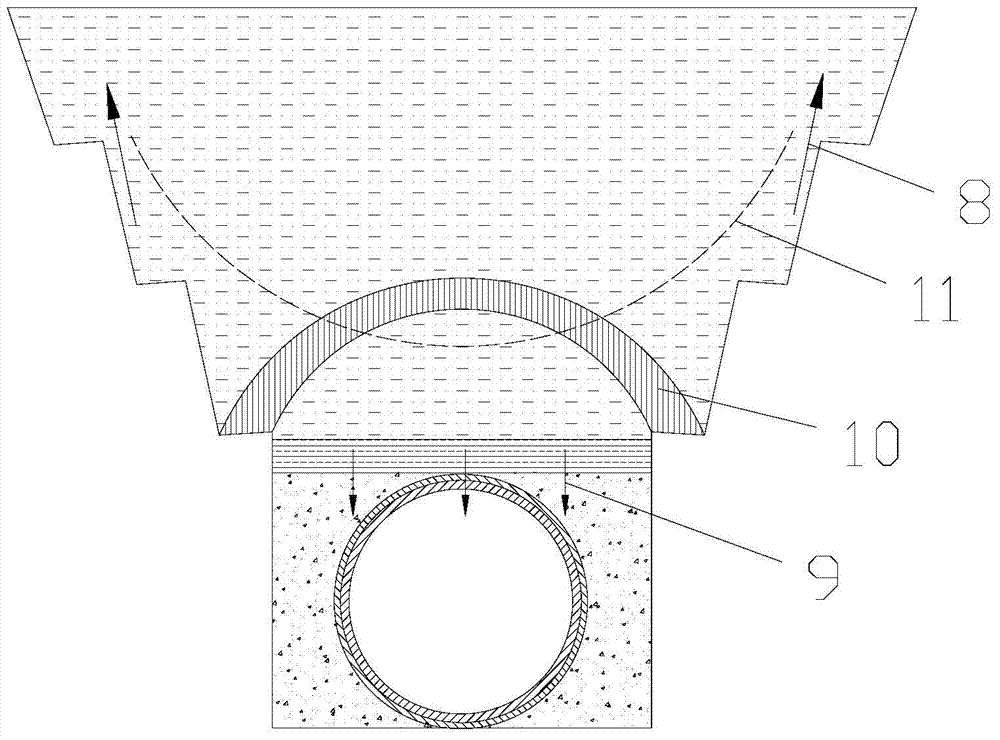

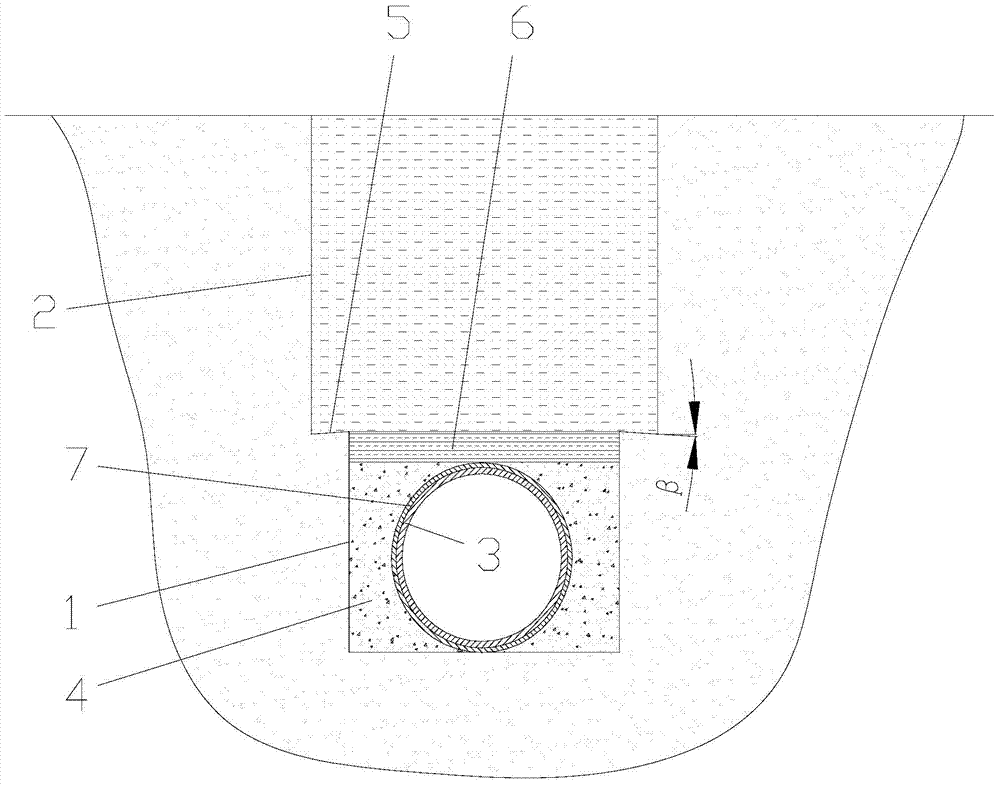

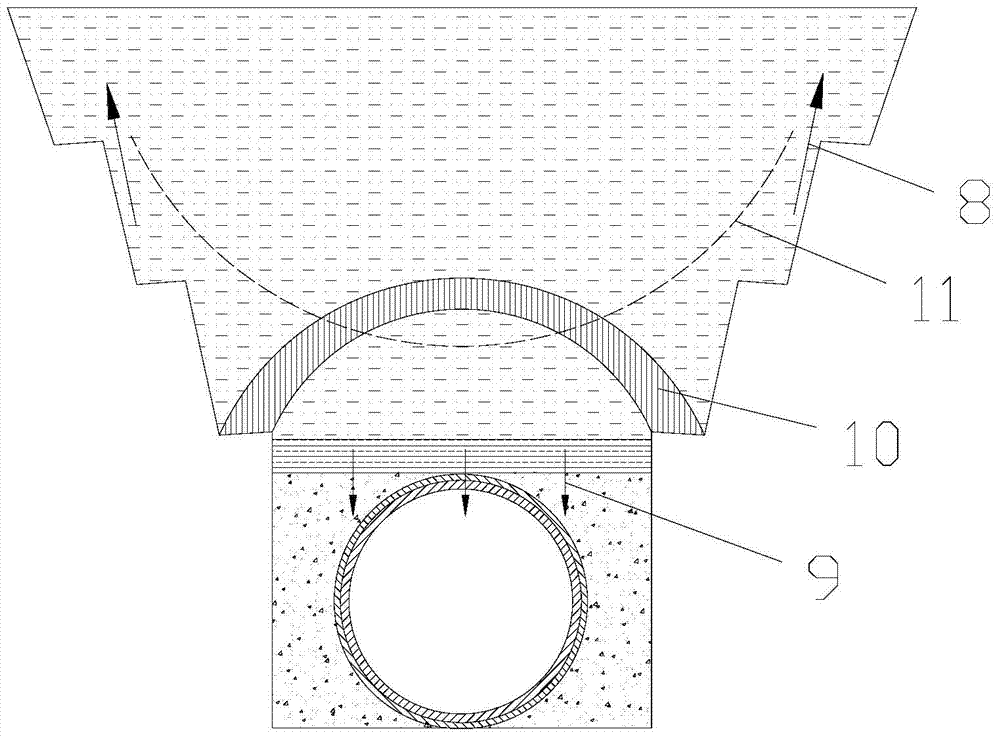

Pipe burying structure capable of reducing pipe top vertical loads and construction method for pipe burying structure

ActiveCN103527847AReduce vertical loadImprove compactness and strengthPipe laying and repairThermal insulationVertical loadCut and fill

The invention discloses a pipe burying structure capable of reducing pipe top vertical loads and a construction method for the pipe burying structure. The construction method comprises the steps of S1, digging a pipe groove and a backfill groove above the pipe groove and digging at least one step on two side walls of the backfill groove; S2, laying pipes in the pipe groove and completing port welding of the pipes; S3, filling earth in the pipe groove, and compacting and flattening the filled earth to the pipe top elevation; S4, laying a degradable material interlayer above the top of the pipe, wherein the degradable material interlayer is disposed below a transverse step plane of the lowest layer of steps; S5, filling earth into the backfill groove and compacting the earth. According to the pipe burying structure and the construction method for the pipe burying structure, an soil arch effect and backfill groove side wall friction can be used for obviously reducing the top pressure of the pipes, and the pipes are protected from being fractured and damaged. The construction process is simple, costs of used materials are low, and the construction method has a good application prospect and a wide generalization performance and applicable to open digging burying of underground shallow buried pipes.

Owner:哈尔滨市政建设有限公司

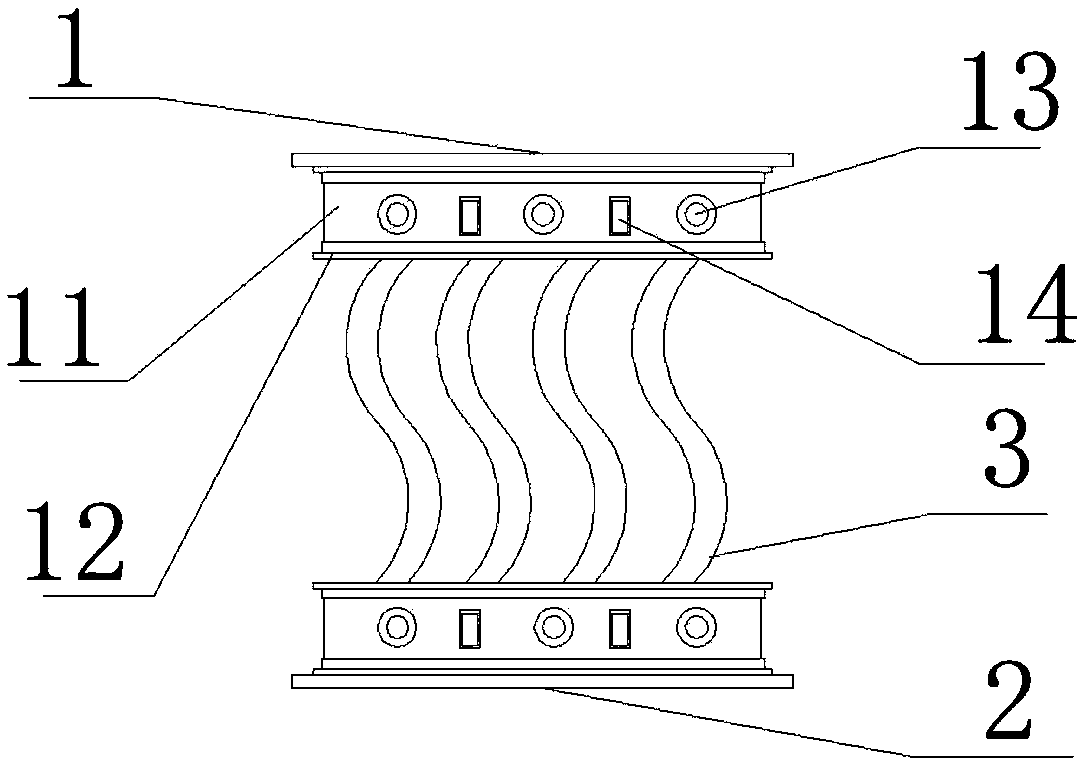

Earthquake-resistance shock-absorption damping device for building

InactiveCN105369931AObtain real-time displacement changesSimple structureSatellite radio beaconingShock proofingEarthquake resistanceEarthquake intensity

The invention discloses an earthquake-resistance shock-absorption damping device for a building. The earthquake-resistance shock-absorption damping device is characterized by comprising an upper connecting part, a buffer part and a lower connecting part, wherein the upper connecting part comprises a plurality of layers of steel plates, channel steel, an earthquake monitoring alarm device and expansion bolts; the plurality of layers of steel plates are connected with the channel steel by welding; the earthquake monitoring alarm device is mounted on the channel steel; the upper connecting part is fixed with the building by connecting through the expansion bolts; the buffer part is mounted between the upper connecting part and the lower connecting part by welding; the lower connecting part is fixed with the building by connecting through the expansion bolts; the earthquake monitoring alarm device can be used for timely finding occurrence of an earthquake and earthquake intensity; and the buffer part is great in deformation strength and is clear in stress. The earthquake-resistance shock-absorption damping device is creative design scheme, and is beneficial to popularization and application.

Owner:ANHUI UNIV OF SCI & TECH

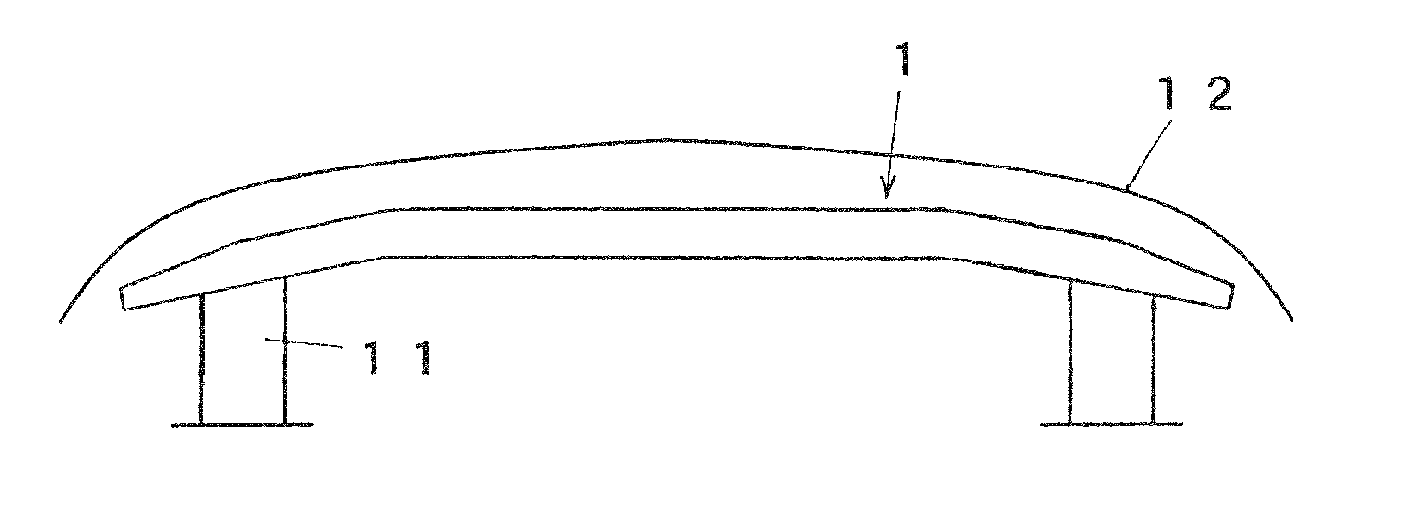

Pedestrian protection apparatus for vehicle

ActiveUS8714294B2Improve aerodynamic performanceReduce air resistanceVehicle seatsPedestrian/occupant safety arrangementStructural engineeringMechanical engineering

A pedestrian protection apparatus for a vehicle is provided that can sufficiently protect a pedestrian and can advantageously improve aerodynamic performance at a lower region of the vehicle. The apparatus includes a reinforcing portion at a front section thereof. The reinforcing portion includes a plurality of cylindrical structures that extend in a front to back direction of the vehicle and are arranged in a line in a vehicle width direction. The cylindrical structures include: vertical ribs that are opposed to each other in the vehicle width direction and extend in the front to back direction of the vehicle; an upper connecting plate that extends across upper ends of all of the vertical ribs so as to integrally connect the upper ends; and a lower connecting plate that extends across lower ends of all of the vertical ribs so as to integrally connect the lower ends.

Owner:KOJIMA PRESS IND CO LTD

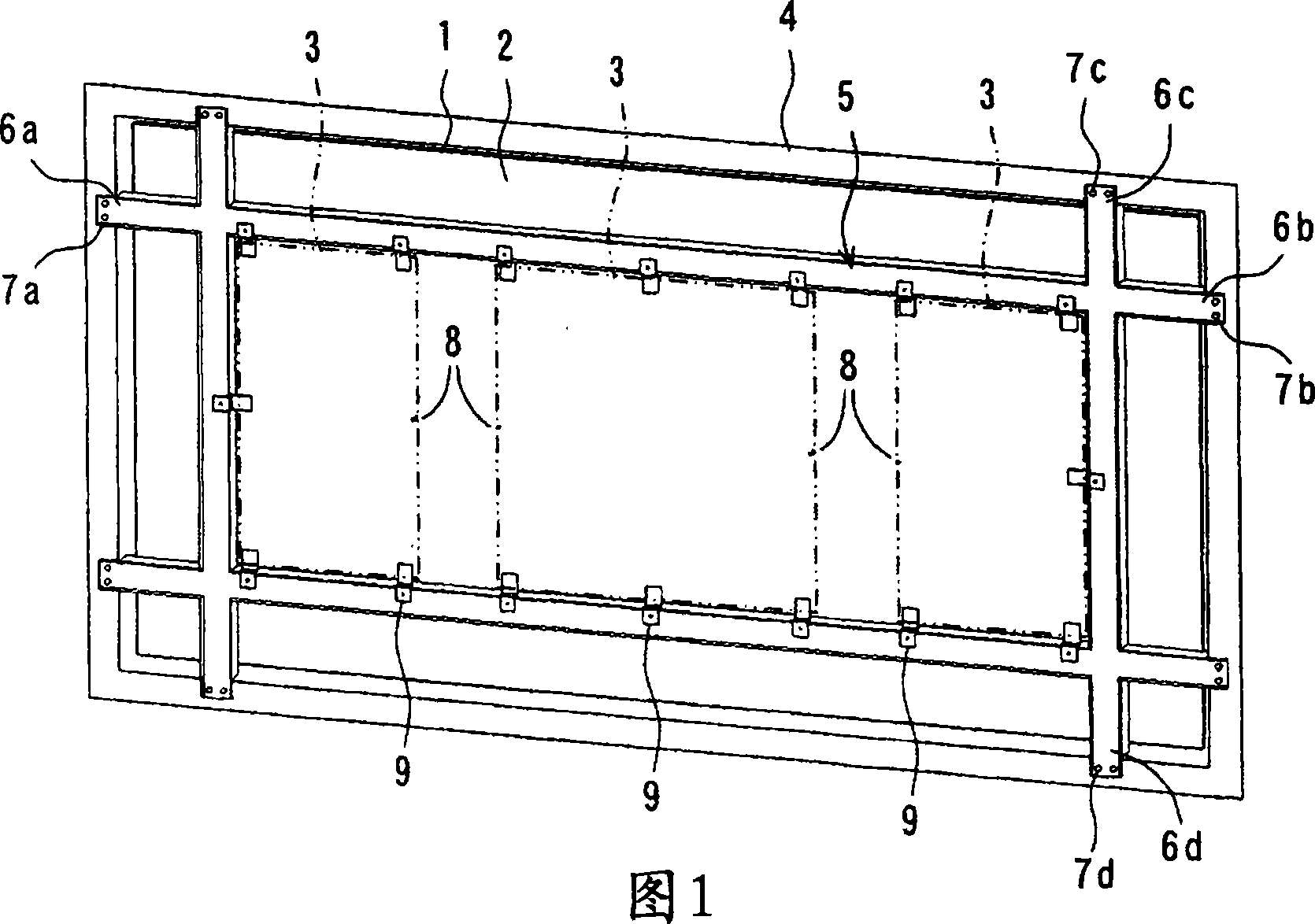

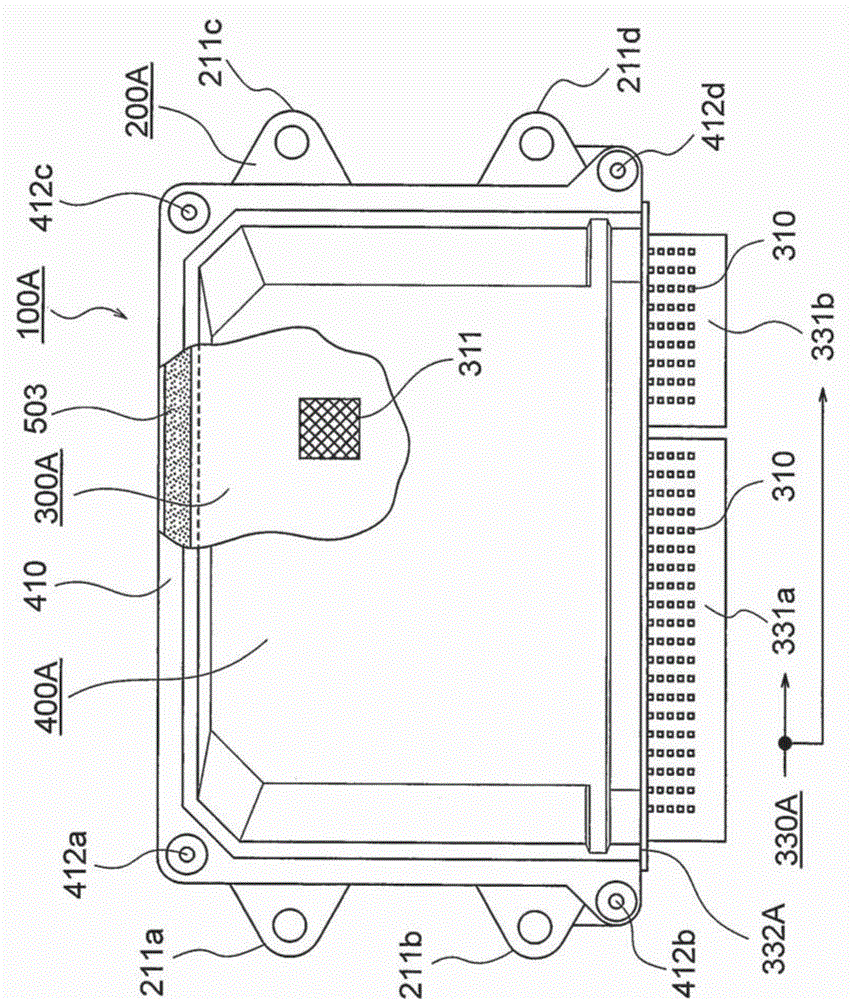

Plasma display system

InactiveCN101377895AImprove deformation strengthTelevision system detailsGas discharge vessels/containersEngineeringUltimate tensile strength

Owner:HITACHI LTD

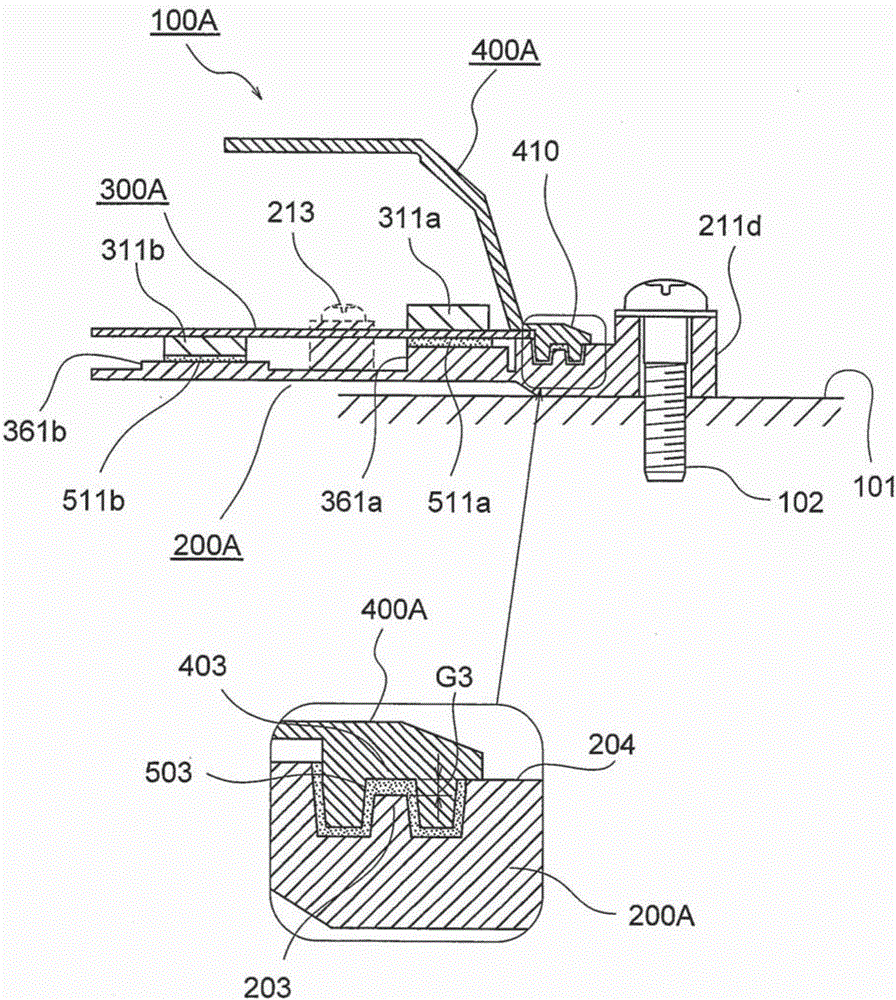

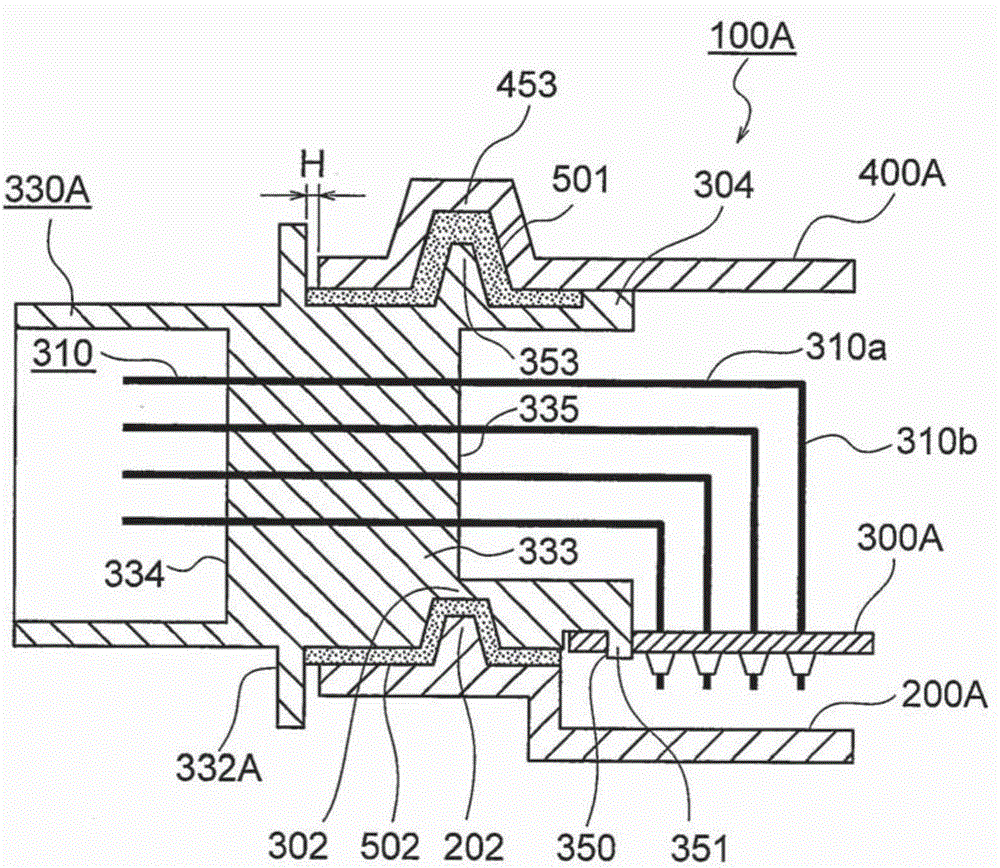

Waterproof control unit and method of assembling the same

ActiveCN105530792AReduce the burden onWide extension widthCoupling device detailsElectrical apparatus contructional detailsMechanical engineeringControl unit

In a waterproof control unit in which a part of a connector housing mounted on a circuit board is exposed and the circuit board is hermetically housed in a casing including a base and a cover, a sealing gap between the cover and the connector housing is defined between fitting surfaces of a first concave thread and a first convex thread, and a waterproof sealing material is applied to the sealing gap. A waterproof sealing material is applied to the latter sealing gap. Each of the sealing gaps extends inward and outward across an inner boundary surface of a partition wall of the connector housing. Plane movement of each of the sealing gaps is restricted by side-surface convex threads and side-surface concave threads.

Owner:MITSUBISHI ELECTRIC CORP

Press forming method and vehicle component

ActiveUS9511403B2Improve deformation strengthImprove absorption rateVehicle componentsEngineeringRelative motion

Disclosed is a press forming method press forming a workpiece between a die and a punch, while pushing the punch into the die by means of a relative motion of the die and the punch, the method includes: producing an intermediate molding (100B) having ridges (100d) formed in predetermined parts of the workpiece, and then press forming the intermediate molding (100B) into a final shape, to thereby substantially thicken and work-harden the predetermined parts of the workpiece.

Owner:NIPPON STEEL CORP

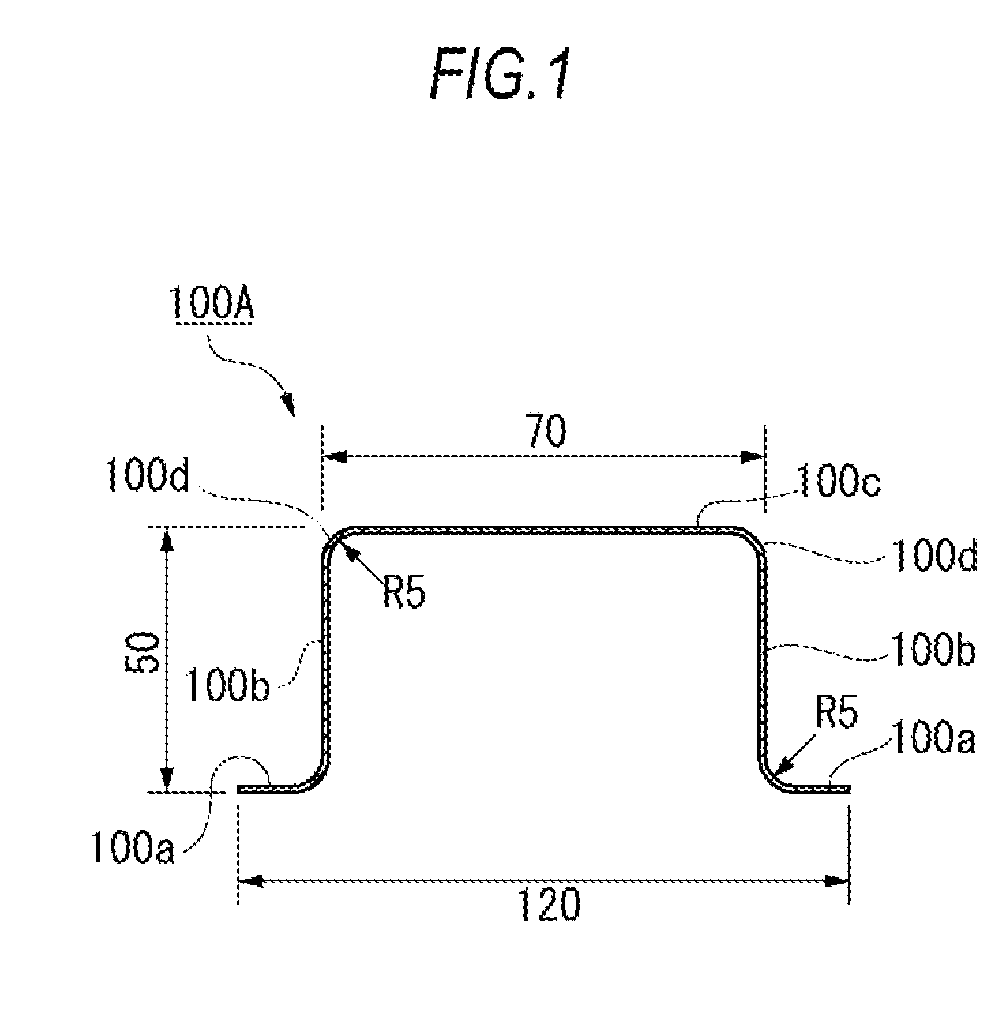

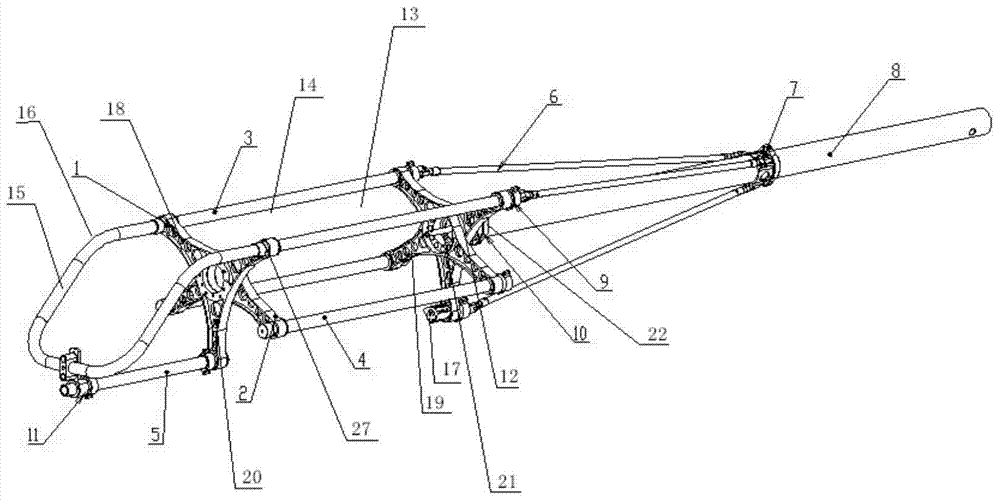

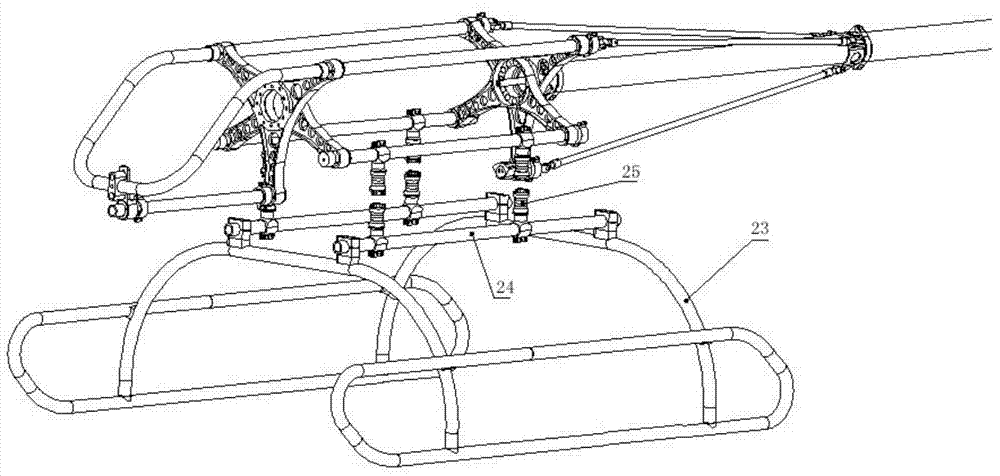

Upper beam, helicopter airframe adopting same and helicopter

InactiveCN104554700AImproved mobility and shock resistanceSimple structureFuselage framesWeight reductionCost savingsAirframe

The invention discloses an upper beam, a helicopter airframe adopting the upper beam and a helicopter. The upper beam is a U-shaped component formed by two straight rod parts which are parallel to each other and a bridge joint part for connecting one ends of the two straight rod parts. The airframe is of a damping structure formed by mutual connection of an upper frame and a tripod through an engine assembly and a damper, the upper frame is of a rigid structure formed by the upper beam, a front beam, an upper bearing beam, supporting rods and a tail pipe through two pairs of middle beams with five connecting supporting arms, and three of the supporting rods are connected with three of the middle beams. A gearbox is positioned on the upper bearing beam. The airframe has the beneficial effects of being simple in structure, easy to manufacture, cost-saving, light in weight, good in rigidity, excellent in damping performance, easy for disassembling, assembling and maintenance, and the like.

Owner:张伟

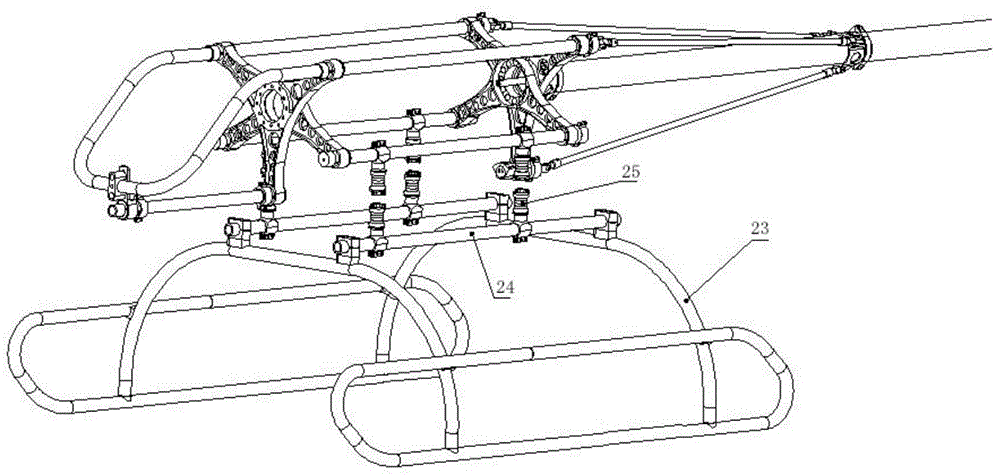

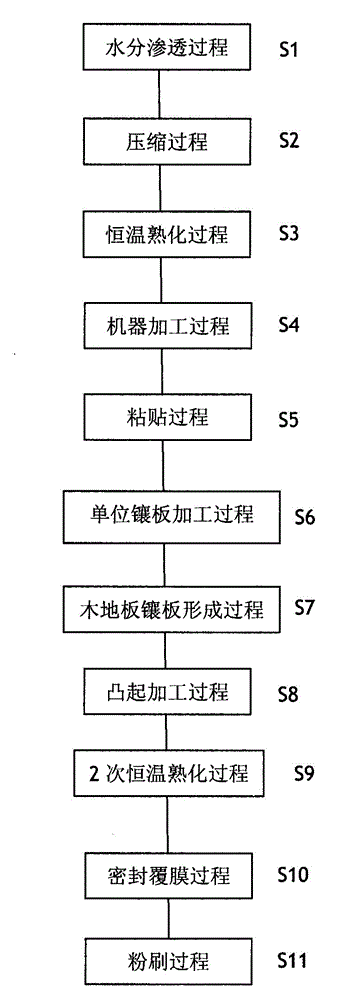

Plastic rubber sheet forming and shaping processing method

The plastic plate forming and setting process includes extrusion plastic plate, cooling to form, and post heating and setting treatment. In the post heating and setting treatment, the plastic plate is heated to certain temperature and maintained for one period, and this makes the plastic molecule arrangement formed in the extrusion altered, eliminates the residual stress caused in the heating extrusion and strengthens the molecular structure of the plastic plate. The present invention raises the heat resistance and reduces the deformation caused by ambient temperature change of the plastic plate.

Owner:NIEN MADE ENTERPRISE CO LTD

Flame hole structure of gas burner

The present invention is directed to a fire hole part structure of a gas burner, which is constructed to be manufactured at a low cost, can improve flame stability, and can prevent incomplete combustion due to the length of flame. The structure is provided to a premixing ignition burner, which is installed to apply heat to a heat exchanger of a boiler, and includes fire hole pieces (20) which are installed parallel to one another in mounting openings (13) of a burner body (11), and each of which is defined with fire holes (23) at regular intervals. An upper wall (21) of at least one of the fire hole pieces (20) is bent or curved to extend in at least two directions, and the fire holes (23) are defined through respective surface portions of the upper wall (21), which extend in different directions, to face different directions.

Owner:KYUNGDONG NAVIEN

Compression and compression integrated floor by floor

InactiveCN102873735AHigh strengthHigh densityWood compressionWood dampingLongitudinal planePulp and paper industry

The invention relates to a compression floor and a producing method of the compression integrated floor. According to the properties of the wood, the processed wood is cut; after the paste in the outer layer coated layer to prevent the external show of wooden floor, to prevent deformation, can be use for a long time, and keep good quality. Each wood floor blocks combined with other wood block of cross-sectional or longitudinal plane way, multiple wood blocks on the deformation of the steel together play the role of complement each other, therefore, increases the stiffness, especially in wood cutting surface is not connected, but independent existence, so, no direction for deformation, can reduce the overall degree of deformation of wooden floor, and can form a variety of compressed wood texture style and integrating compression wood floor production method.

Owner:金奇豪

High-performance anti-deformation cable filling material

InactiveCN108219436AImprove tensile propertiesEnvironmentally friendlyFlexible cablesFlexible conductorsPliabilityTemperature resistance

The invention discloses a high-performance anti-deformation cable filling material which is prepared from the following ingredients in parts by weight: 55 to 75 parts of polycarbamate, 35 to 55 partsof phenolic resin, 10 to 18 parts of calcium stearate, 13 to 20 parts of titanium dioxide nanopowder, 15 to 25 parts of polyethylene, 7 to 12 parts of lithium-based enhancing powder, 10 to 15 parts ofquartz powder, 2 to 6 parts of epoxypropane glycerinum, 5 to 11 parts of aluminum hydroxide, 6 to 12 parts of magnesium hydroxide, 3 to 8 parts of antimonous oxide and 10 to 15 parts of compound filler. The cable filling material disclosed by the invention has the advantages of environmental friendliness, good flame retardation, high temperature resistance, low smoke, easiness in being peeledeasypeel, good compatibility, high strength, bending resistance, high anti-deformation strength and excellent corrosion resistance and flexibility. The cable filling material not only has an effective protecting effect on cables, but also can enhance tensile resistance of the whole cable.

Owner:ANHUI GUOHUA CABLE GROUP

Anti-collision component

ActiveUS9352710B2Reduce overall form factorEasily damagedBumpersDoorsEngineeringMechanical engineering

An anti-collision component consisting of a metal hollow profile for automobiles includes a collision side flange, a body side flange, and a web connected to the flanges. The hollow profile has a longitudinal end at which a cross-sectional configuration is deformed by swaging to reduce a dimension between the flanges. The following relations are established:tW>TW RCI≧(tW−TW)where tW is a wall thickness of the web at the end, TW is a wall thickness of the web at a portion where the cross-sectional configuration is not deformed, and RCI is an inside corner radius of a corner formed of the web and each flange at the portion.

Owner:KOBE STEEL LTD +1

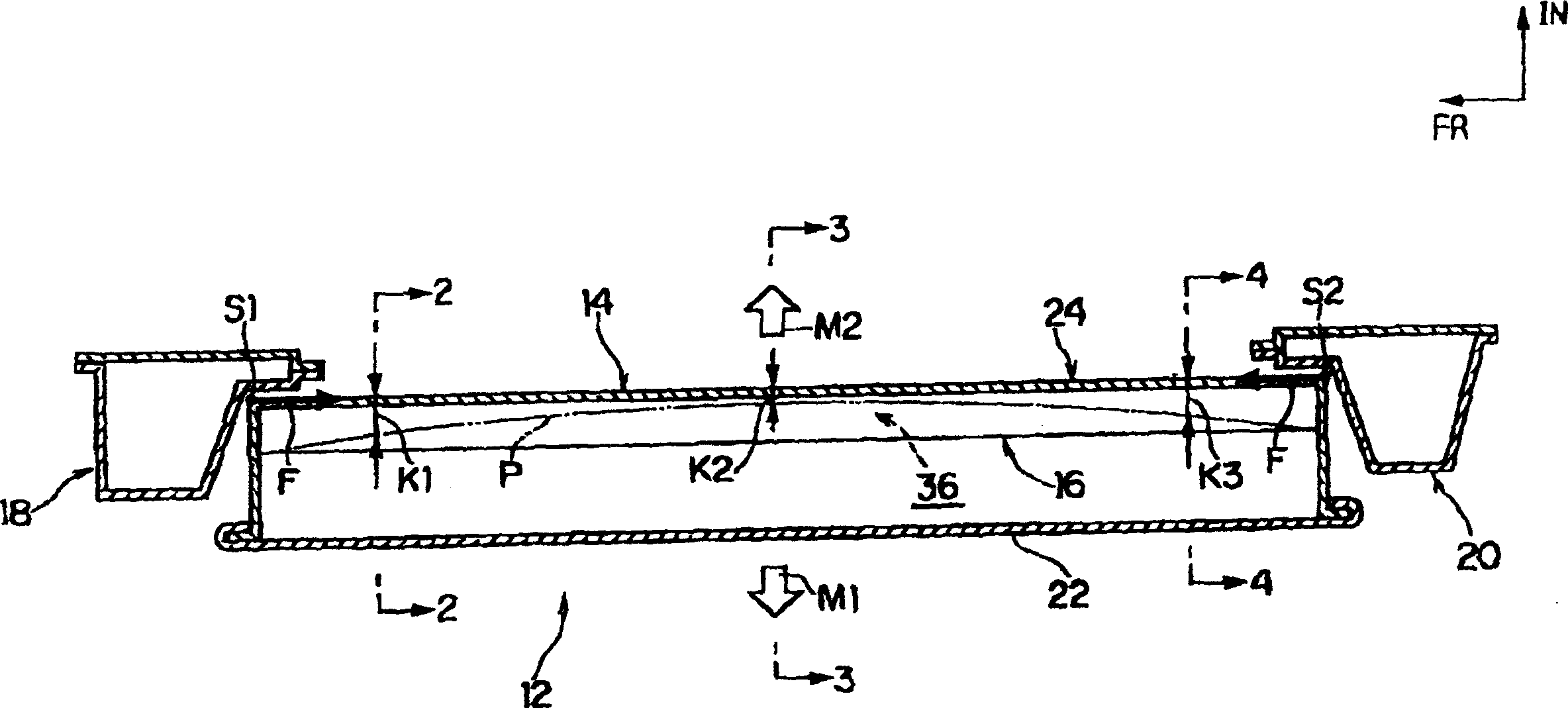

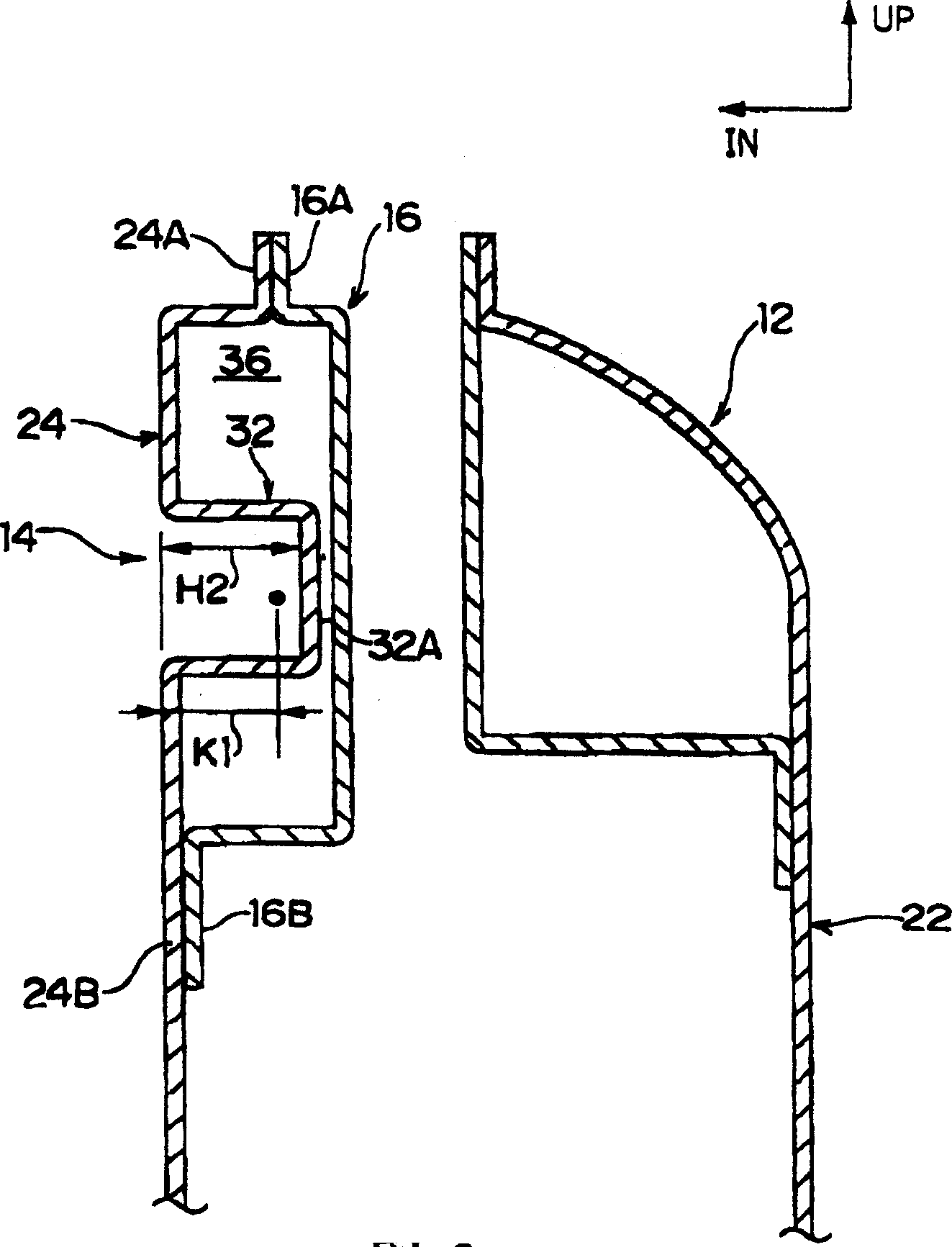

Door frieze structure

Owner:TOYOTA JIDOSHA KK

Upper beam, helicopter body and helicopter using the upper beam

InactiveCN104554700BWith structural strengthRigidFuselage framesWeight reductionAirframeRigid structure

The invention discloses an upper beam, a helicopter airframe adopting the upper beam and a helicopter. The upper beam is a U-shaped component formed by two straight rod parts which are parallel to each other and a bridge joint part for connecting one ends of the two straight rod parts. The airframe is of a damping structure formed by mutual connection of an upper frame and a tripod through an engine assembly and a damper, the upper frame is of a rigid structure formed by the upper beam, a front beam, an upper bearing beam, supporting rods and a tail pipe through two pairs of middle beams with five connecting supporting arms, and three of the supporting rods are connected with three of the middle beams. A gearbox is positioned on the upper bearing beam. The airframe has the beneficial effects of being simple in structure, easy to manufacture, cost-saving, light in weight, good in rigidity, excellent in damping performance, easy for disassembling, assembling and maintenance, and the like.

Owner:张伟

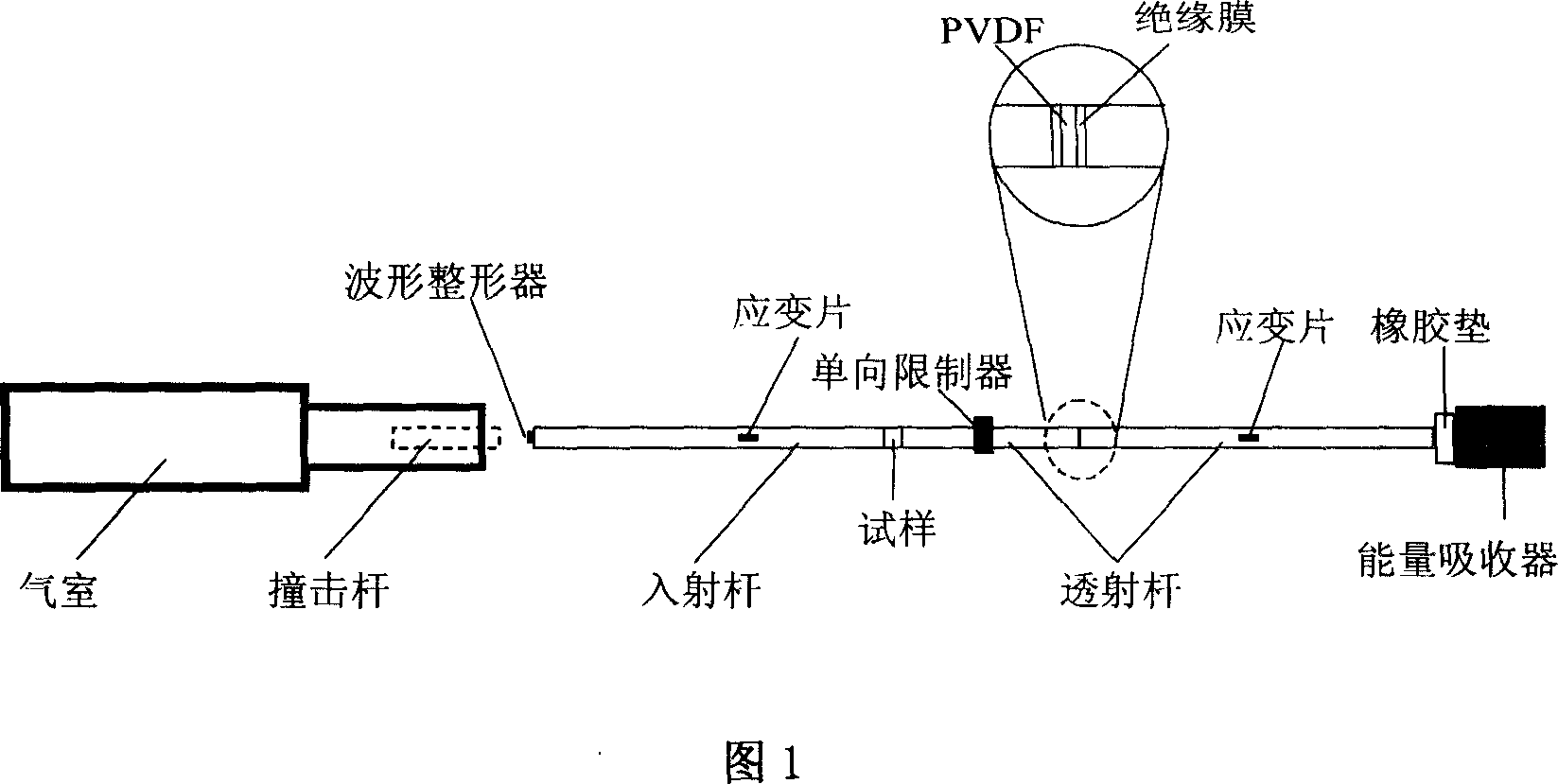

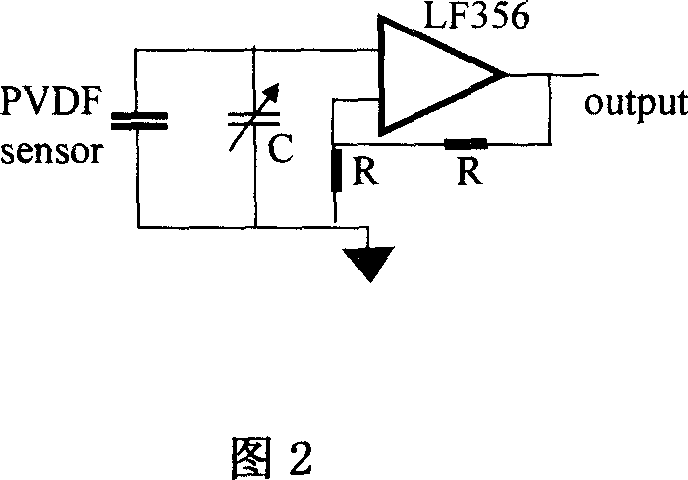

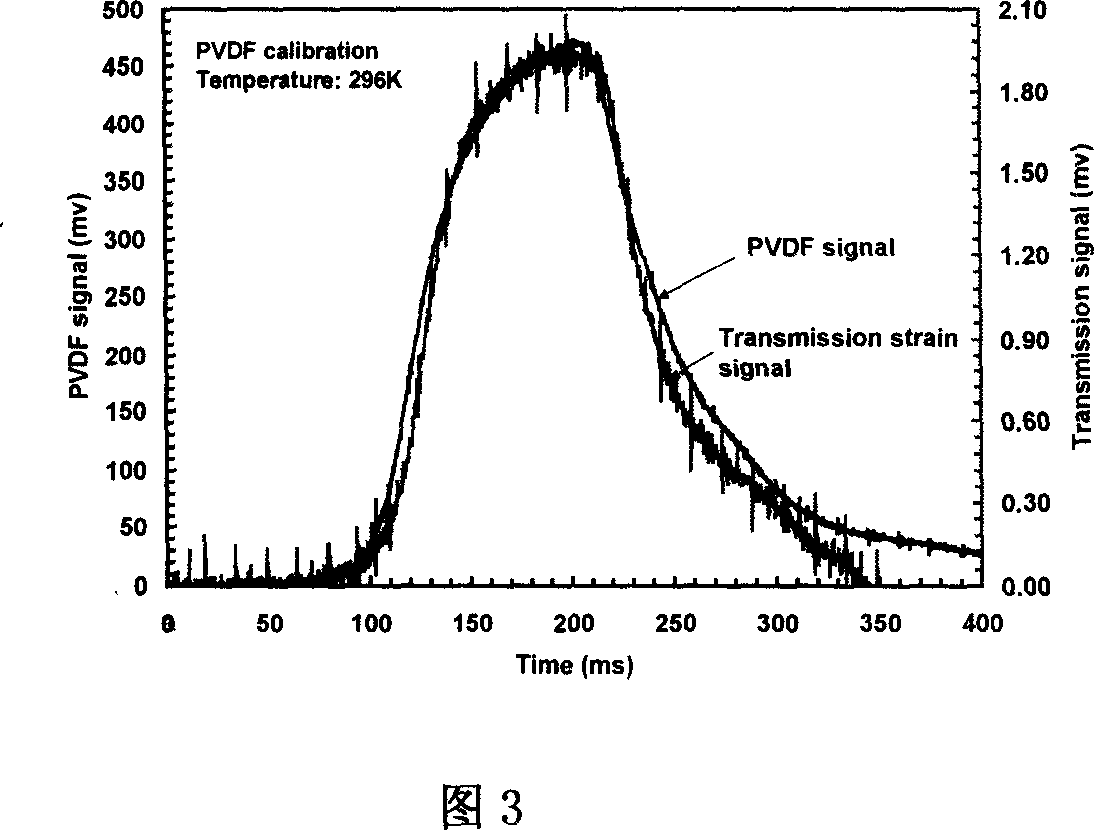

Dynamic performance detection method for foam materials or soft materials

InactiveCN1967206ALight weightTough and highForce measurement using piezo-resistive materialsUsing mechanical meansElectricityImpedance Converter

The invention discloses a foam material or soft material dynamic performance measurement method, for the foam material or soft material dynamic performance measurement. First, divide the transmission pole of the Hepuxinsen strut into two sections, and then take a thickness of 10-60 mum piezoelectric film, and affix the micron-level insulation membrane on its both sides, and then paste the piezoelectric film with insulation membrane sandwiched between two transmission poles, and the section of the transmission pole near the specimen is equipped with a one-way limiter in the center, and the one-way limiter is fastened with the transmission pole by the clip fixture; put another section of the transmission pole close to fixed stationary energy absorber through the rubber pad, and the rubber pad modulates the pre-tension through the piezoelectric film; electrical connect the piezoelectric film output electrode and the impedance converter; add sample loading, and through the output of impedance converter to obtain foam material or soft material dynamic force or stress force value. The invention uses the piezoelectric film, making dynamic performance measurement of foam or soft material simple and easy, and with high measurement sensitivity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pipe burying structure capable of reducing pipe top vertical loads and construction method for pipe burying structure

ActiveCN103527847BRelieve pressureIncrease frictionPipe laying and repairThermal insulationCut and fillVertical load

The invention discloses a pipe burying structure capable of reducing pipe top vertical loads and a construction method for the pipe burying structure. The construction method comprises the steps of S1, digging a pipe groove and a backfill groove above the pipe groove and digging at least one step on two side walls of the backfill groove; S2, laying pipes in the pipe groove and completing port welding of the pipes; S3, filling earth in the pipe groove, and compacting and flattening the filled earth to the pipe top elevation; S4, laying a degradable material interlayer above the top of the pipe, wherein the degradable material interlayer is disposed below a transverse step plane of the lowest layer of steps; S5, filling earth into the backfill groove and compacting the earth. According to the pipe burying structure and the construction method for the pipe burying structure, an soil arch effect and backfill groove side wall friction can be used for obviously reducing the top pressure of the pipes, and the pipes are protected from being fractured and damaged. The construction process is simple, costs of used materials are low, and the construction method has a good application prospect and a wide generalization performance and applicable to open digging burying of underground shallow buried pipes.

Owner:哈尔滨市政建设有限公司

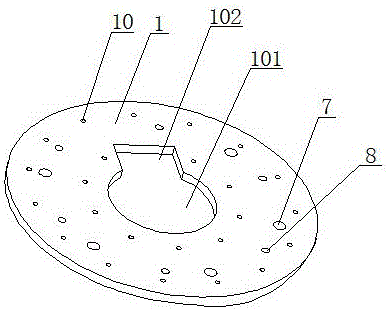

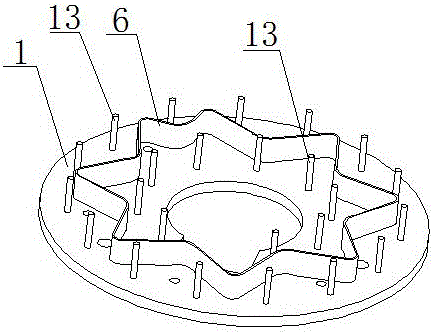

Assembly structure and assembly method for improving service life of molybdenum sheet heat preservation screen

PendingCN106637420AImprove deformation strengthExtended service lifeAfter-treatment apparatusCrucibleEngineering

The invention discloses an assembly structure for improving the service life of a molybdenum sheet heat preservation screen, which comprises a plurality of mutually overlapped molybdenum sheets; each single molybdenum sheet is divided into a hollow zone, an inner zone, a middle zone and an outer zone sequentially from the center to the outside, wherein a reinforcing crossers is arranged at the middle zone, a plurality of inner support roller mounting holes and outer support roller mounting holes are respectively and annularly distributed in the inner zone and the outer zone of the molybdenum sheet, and inner reinforcing crossers and outer reinforcing crossers are respectively arranged at the inner support roller mounting holes and the outer support roller mounting holes. By changing the existing assembly manner, the deformation strength of each single molybdenum sheet is improved, the deformation strength of the original clearance zone between every two adjacent molybdenum sheets is enhanced, the possibility of deformation is low when a crucible and the molybdenum sheet heat preservation screen are attached at a high temperature state, the service life of the molybdenum sheet heat preservation screen is effectively improved, and the production cost is reduced.

Owner:成都新源汇博光电科技有限公司

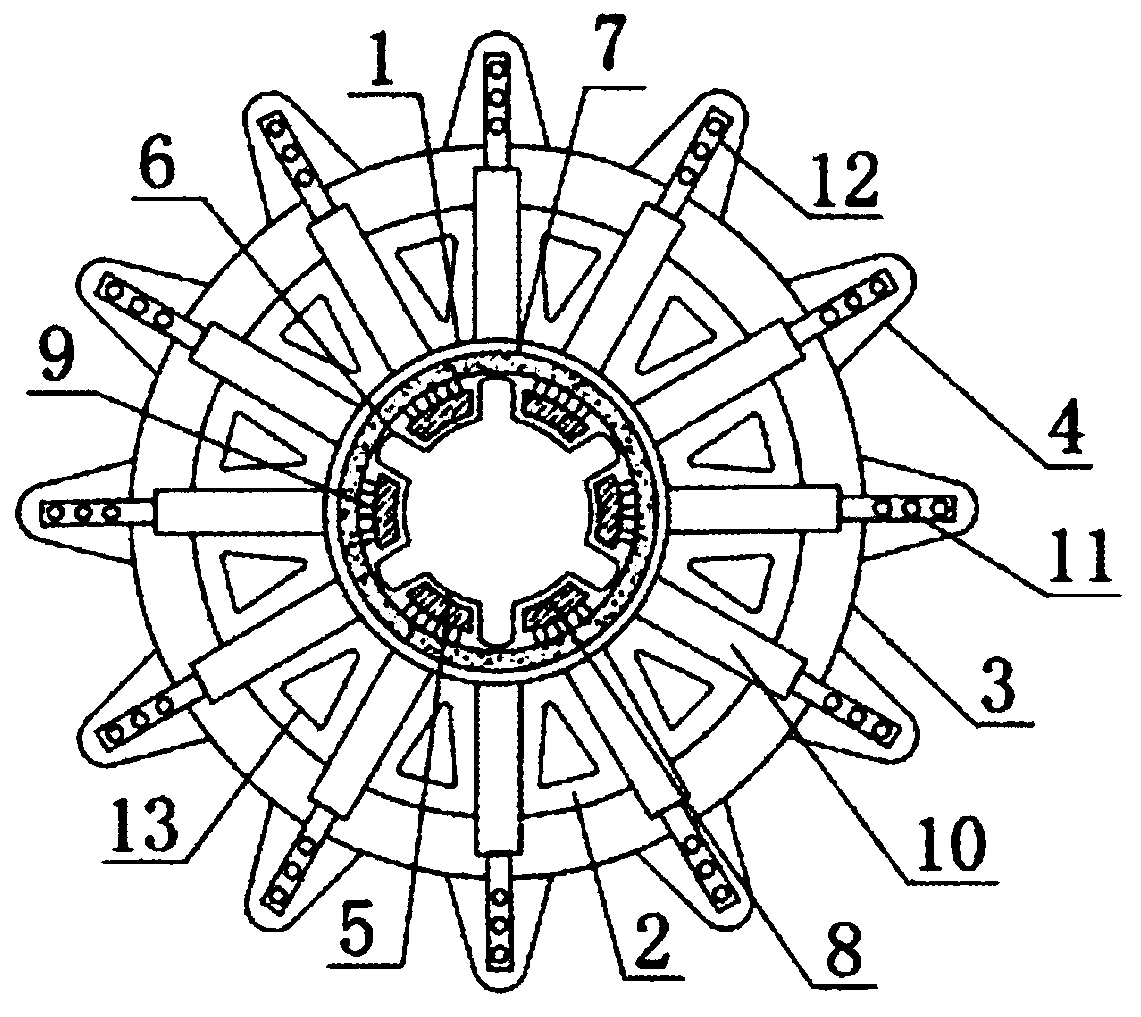

Reinforcing gear

InactiveCN109185425AImprove the strength of forceImprove deformation strengthPortable liftingGear lubrication/coolingStress strengthFlange

The invention relates to a reinforcing gear. The reinforcing gear comprises a connecting sleeve ring, a flange is arranged on the outer side of the connecting sleeve ring, a connecting block is arranged on the outer side of the flange, wheel teeth are arranged on the outer side of the connecting block, a through hole is formed in the middle of the connecting sleeve ring, limiting grooves are formed in the inner wall of the through hole, an annular reinforcing rib and a reinforcing block are arranged in the connecting sleeve ring, a fixing rod is arranged in the flange, the fixing rod is inserted into the connecting block and is fixedly connected with a reinforcing column, the reinforcing column is located in the wheel teeth, an extending rod is arranged on the side wall of the reinforcingcolumn, the extension rod is located in the wheel teeth, and a heat dissipation opening is formed in the flange. According to the reinforcing gear, the reinforcing block is arranged between every twoadjacent limiting grooves, the stress strength of the connecting sleeve ring is improved, and meanwhile, the deformation resistance of the limiting grooves is also improved; an annular reinforcing ribis arranged in the connecting sleeve ring, the annular reinforcing rib is connected with the reinforcing block through a connecting rib, and the stress intensity of the connecting sleeve ring is improved.

Owner:扬州市轩煌铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com