Lithium ion battery plastic casing, lithium ion battery, and manufacturing method of lithium ion battery plastic casing and lithium ion battery

A technology for lithium-ion batteries and plastic casings, applied to battery box/case materials, battery pack components, battery boxes/coatings, etc., can solve problems such as surface cracks, poor appearance, and reduced casing service life, and achieve Improve compressive strength and deformation resistance, improve bad appearance, and improve aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A lithium-ion battery plastic case, comprising a body and a cover plate, wherein the upper end of the body is open, the cover plate is arranged at the opening of the upper end of the body, and a safety valve installation hole is arranged on the cover plate; both the body and the cover plate are modified Injection molded polypropylene material.

[0042] The raw material components of the modified polypropylene material are shown in Table 1, wherein the polypropylene is a mixture of high crystalline polypropylene, homopolypropylene and random copolymerized polypropylene in a mass ratio of 1:1:1, and its melt The bulk flow rate is 1-3g / 10min (230℃, 2.16kg); the glass fiber is chopped glass fiber with a length of 0.2-10mm and a diameter of 8-20μm; the compatibilizer is polypropylene grafted with maleic acid, and its grafted The rate is 0.3-1.2%, and the melt flow rate is 50-120g / 10min (230°C, 2.16kg); the antioxidant is Ciba IRGAFOS38. The preparation method of the modifie...

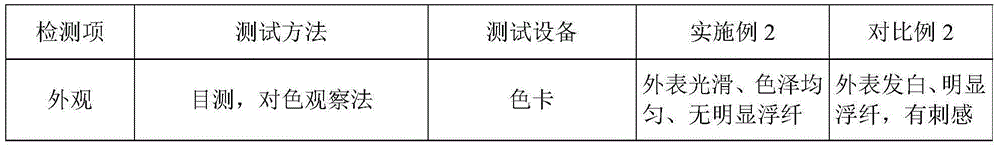

Embodiment 2

[0048] A lithium-ion battery plastic case, comprising a body and a cover plate, wherein the lower end of the body is open, the cover plate is arranged at the opening of the lower end of the body, and a safety valve installation hole is provided on the upper end of the body; both the body and the cover plate are modified Injection molded from non-toxic polypropylene material.

[0049] The raw material components of the modified polypropylene material are shown in Table 1, wherein the polypropylene is a mixture of high crystalline polypropylene, homopolypropylene and random copolymerized polypropylene in a mass ratio of 1:1:1, and its melt The bulk flow rate is 1-3g / 10min (230℃, 2.16kg); the glass fiber is chopped glass fiber with a length of 0.2-10mm and a diameter of 8-20μm; the compatibilizer is polypropylene grafted with maleic acid, and its grafted The rate is 0.3-1.2%, and the melt flow rate is 50-120g / 10min (230°C, 2.16kg); the antioxidant is Ciba IRGAFOS38; the lubricant...

Embodiment 3

[0055] A lithium-ion battery plastic case, comprising a body and a cover plate, wherein the upper end of the body is open, the cover plate is arranged at the opening of the upper end of the body, and a safety valve installation hole is arranged on the cover plate; both the body and the cover plate are modified Injection molded polypropylene material.

[0056] The raw material components of the modified polypropylene material are shown in Table 1, wherein the polypropylene is a mixture of high crystalline polypropylene, homopolypropylene and random copolymerized polypropylene in a mass ratio of 1:1:1, and its melt The bulk flow rate is 1-3g / 10min (230℃, 2.16kg); the glass fiber is chopped glass fiber with a length of 0.2-10mm and a diameter of 8-20μm; the compatibilizer is polypropylene grafted with maleic acid, and its grafted The rate is 0.3-1.2%, and the melt flow rate is 50-120g / 10min (230°C, 2.16kg); the antioxidant is antioxidant 1010; the lubricant is amide grease; the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com