Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve chlorination efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for processing low-content non-ferrous metal materials to extract non-ferrous metals

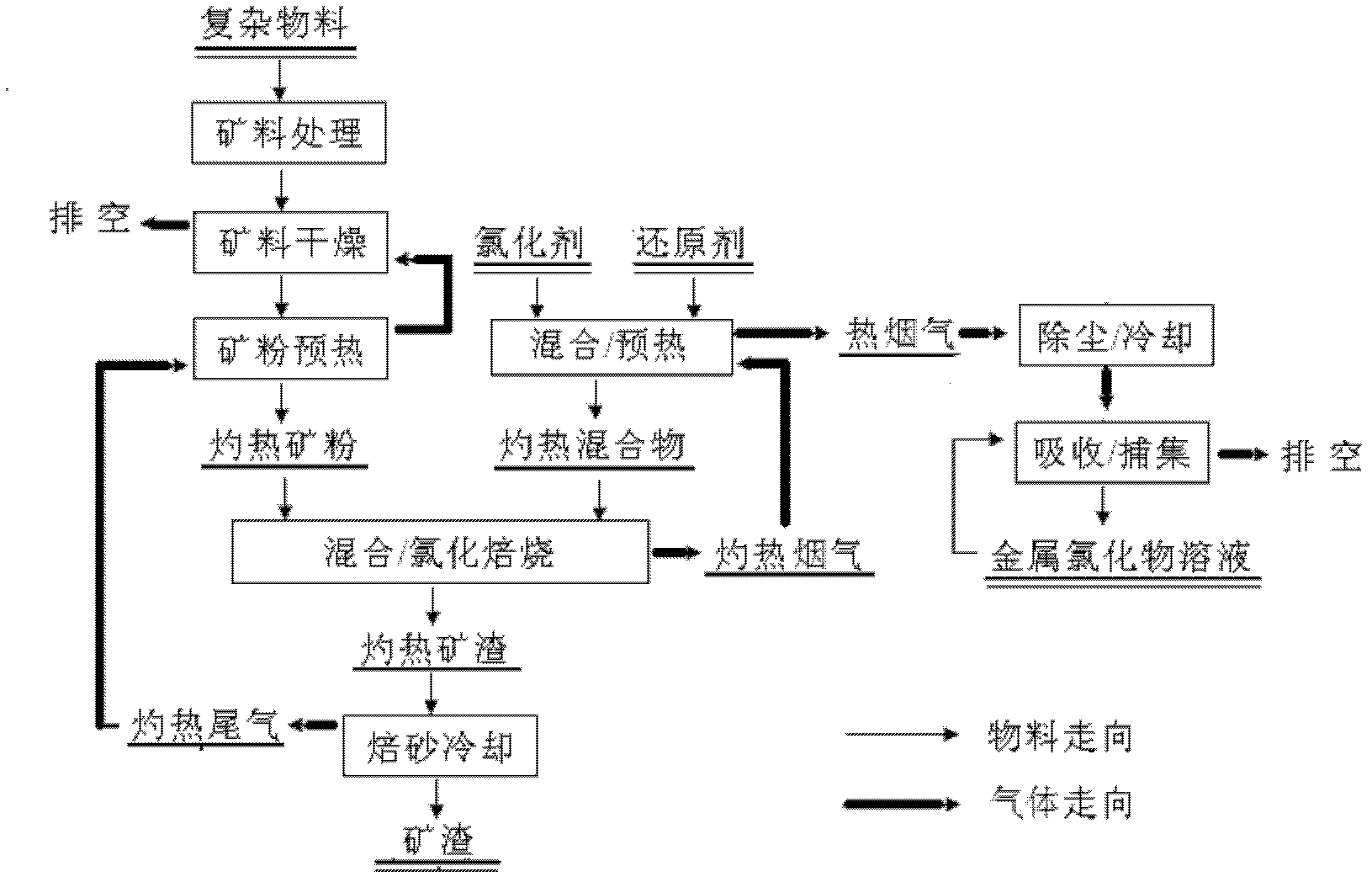

InactiveCN102277485ALow melting pointIncrease relative volatilityProcess efficiency improvementMetal chlorideFlue gas

The invention discloses a method for processing low-content non-ferrous metal materials to extract non-ferrous metals: (1) pretreatment: processing the low-content non-ferrous metal materials into powder materials with a water content not higher than 10% and a particle size of -60 mesh; ( 2) Preheating: Preheat the mixture of reducing agent and chlorinating agent and low-content non-ferrous metal materials to 500-800°C respectively; (3) High-temperature chlorination roasting: add to the preheated low-content non-ferrous metal materials 0~6wt% reducing agent and 4~10wt% chlorinating agent, carry out the chlorination roasting of valuable metals; roasting temperature 800~1100 ℃, roasting time 30~60min; (4) Valuable metal chloride capture recovery: chlorine After the high-temperature flue gas from chemical roasting is collected to remove mineral dust, it is cooled and wet-type collected to recover valuable metal chlorides. The economical and efficient extraction of valuable metals in low-content nonferrous metal materials is realized.

Owner:CENT SOUTH UNIV

Synthetic process of ethyl maltol

The invention belongs to the technical fields of spices and in particular relates to a synthetic process of ethyl maltol. The process comprises a chlorination reaction step, a hydrolysis rearrangement step and a sublimating and purifying step, wherein the chlorination reaction is realized by reacting alpha-ethylfuran methanol with chlorine at the flow ratio of (1.8 to 2.3L):1kg to generate a hydroxy chlorovinylketone intermediate; the hydrolysis rearrangement means that the hydroxy chlorovinylketone intermediate is hydrolyzed at the temperature of 90 to 105DEG C for 3 to 4.5 hours to obtain an ethyl maltol coarse crystal; the coarse crystal is sublimated and purified under the conditions that the temperature is 200 to 225DEG C and the pressure is 0.080 to 0.090MPa to obtain an ethyl maltol product. The synthetic process disclosed by the invention is detailed and specific in operation and is stable; the chlorinating efficiency is improved and the generation of foamed yellow crystals is controlled; meanwhile, sublimating and purifying conditions are controlled, thereby effectively improving the yield and the purity of the ethyl maltol.

Owner:广东省肇庆香料厂有限公司

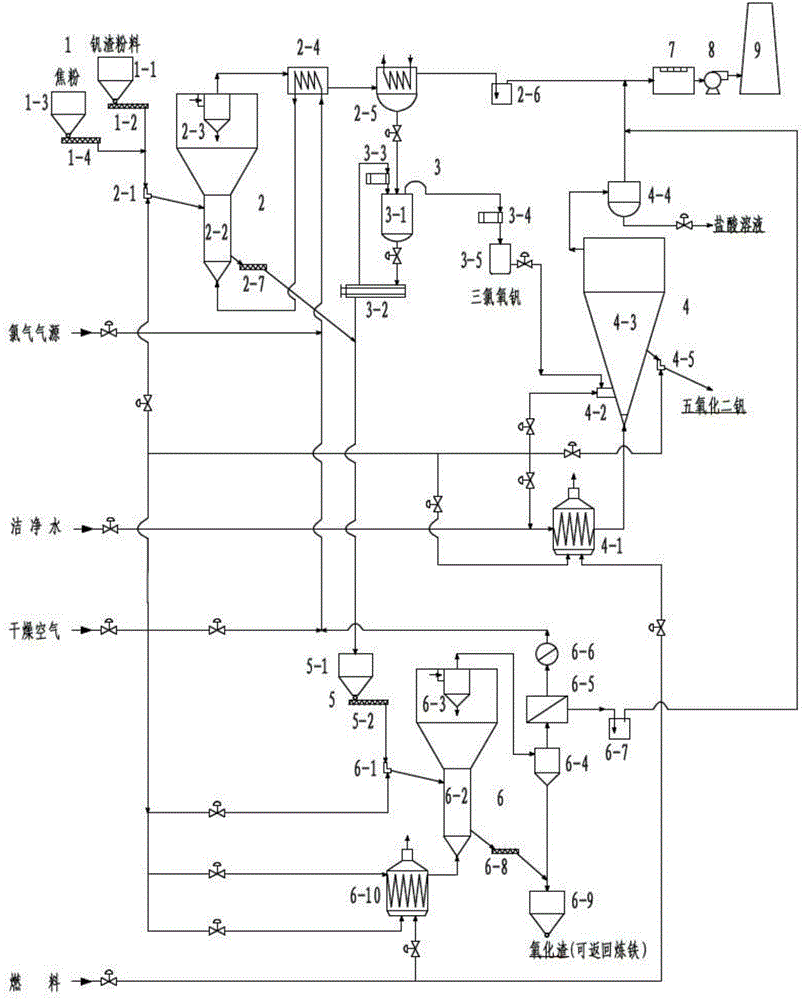

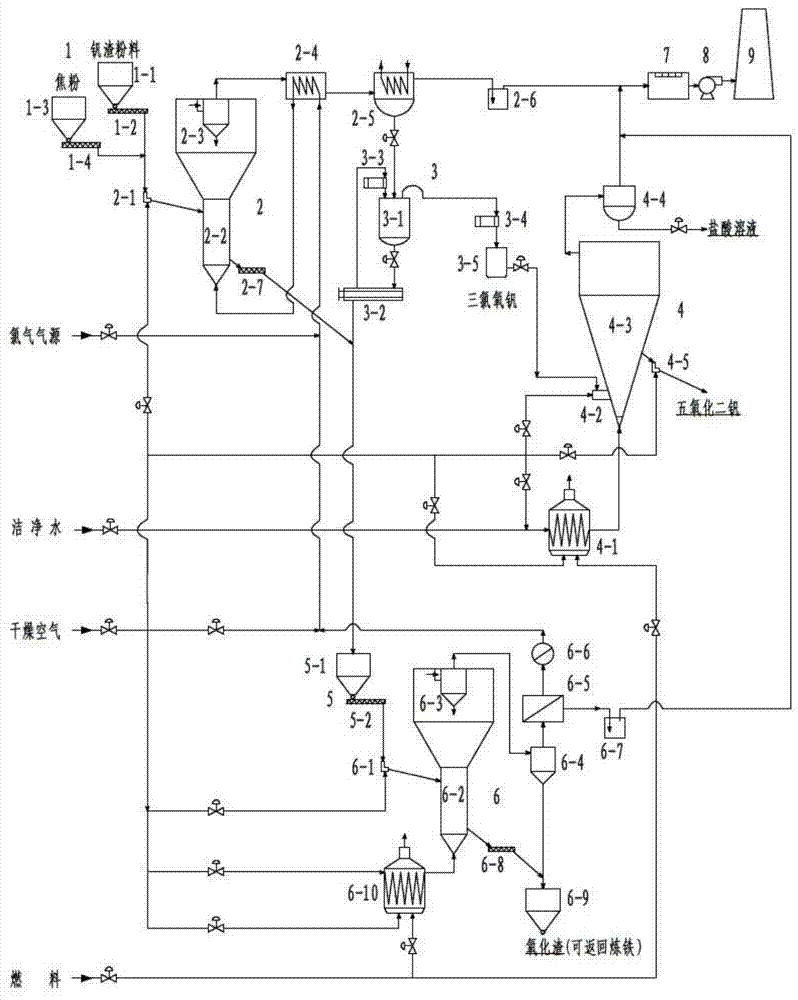

System and method for high-efficiency extraction of vanadium from vanadium slag through chlorination

ActiveCN105986126AAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementFlue gasPrecipitation

The invention specifically discloses a system and method for high-efficiency extraction of vanadium from vanadium slag through chlorination, belonging to the fields of chemical engineering and metallurgy. By means of heat exchange between chlorination gas and chlorination flue gas, the chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination; by means of high-temperature fluidization oxidation of chlorinated slag, the chlorinated slag is treated in a comprehensive manner, and the chlorine gas is recycled; furthermore, by means of vapor-phase hydrolysis of the chlorination product vanadium oxytrichloride, a powdered vanadium pentoxide product and a hydrochloric acid byproduct are obtained; so the efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of the chlorinated slag is eliminated, and the problem of ammonia-nitrogen pollution caused by conventional ammonium salt precipitation is prevented. The system and method provided by the invention are applicable to extraction of vanadium from vanadium slag containing 10 to 28 wt% of V2O5 through chlorination and have the advantages of high efficiency, low energy consumption, no pollution, good economic performance, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A system and method for efficiently chlorinating vanadium from vanadium slag

ActiveCN105986126BAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementSlagGas phase

Provided are a system and method for highly effective chlorination and vanadium extraction from vanadium slag. By means of heat exchange between a chlorination gas and a chlorination flue gas, a chlorination gas is preheated and an appropriate amount of air is added, which causes coke powder to partially combust, thus providing a balanced supply of heat during the process of chlorination; also, by means of high-temperature fluidization oxidation of the chlorinated slag, the chlorinated slag is used in a comprehensive manner, and the chlorine gas is recycled; further, by means of vapor-phase hydrolysis of the vanadium oxytrichloride product of chlorination, a powdered divanadium pentoxide product is obtained; the reaction efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of chlorinated slag is eliminated, and the pollution problem caused by conventional ammonium salt precipitation is prevented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

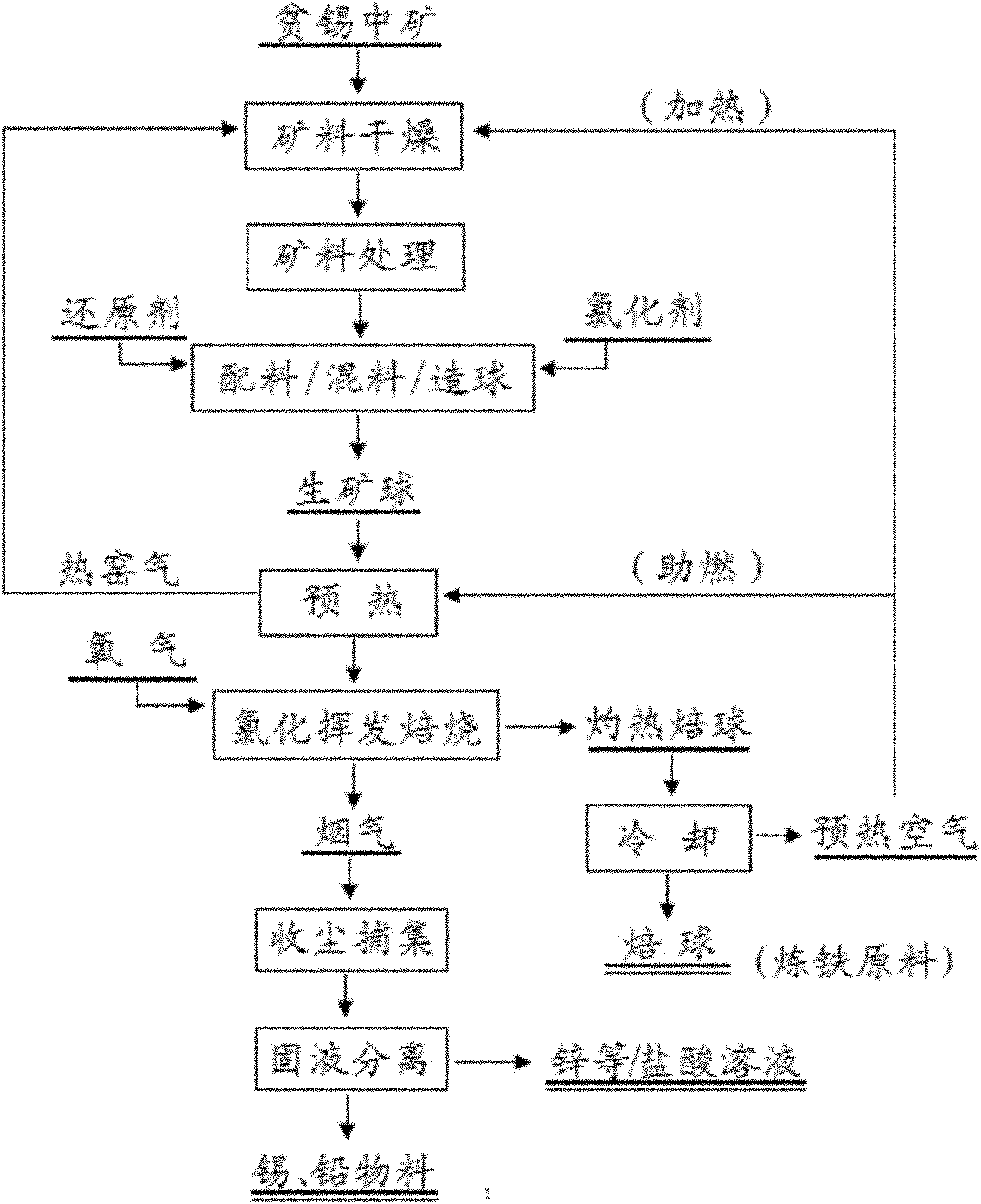

Method for treating enrichment set in poor pin and extracting tin and other color metals

InactiveCN102051472AIncrease the chlorine body chlorination doseReduce consumptionProcess efficiency improvementMetal chlorideChemical reaction

The invention relates to a method for treating an enrichment set in poor pin and extracting tin and other color metals. The method comprises the following steps of: drying and treating mineral aggregate; proportioning, mixing and pelletizing; adding a chlorinating agent and a reducing agent to the treated mineral powder in the poor tin and uniformly mixing; pelletizing; adding chlorinating agent 4-8 percent by weight of the powder and reducing agent which is 3-5 percent by weight of the powder; preheating and heating mineral aggregate pellets, heating the mixed mineral aggregate pellets in a preheated heater to rise the temperature within the limit that the collected heat of the mineral aggregate pellets is ensured to avoid causing a chemical reaction; chlorinating; volatilizing, roasting and putting the obtained hot mineral aggregate pellets in a chlorinated reactor for carrying out a chlorinating, volatilizing and roasting reaction of valuable metals at a roasting temperature of 800-1100 DEG C for a roasting time of 40-100 min; trapping and recovering valuable metal chloride; collecting and removing the mineral smoke generated in the volatilizing, roasting and putting step, cooling, trapping in a wetting mode and recovering the valuable metal chloride; circularly absorbing trapping liquid and improving the valuable metal content in a solution; and cooling the hot roasted pellets.

Owner:CENT SOUTH UNIV

High-temperature activation purifying method for quartz sand

ActiveCN108910897AReduce dosageImprove chlorination efficiencySilicaAlkaline earth metalBiological activation

The invention relates to a high-temperature activation purifying method for quartz sand and belongs to the technical field of production of quartz glass. According to the activation purifying method disclosed by the invention, the quartz sand reacts with chlorination gas for 15 to 120 minutes in a sealed furnace hearth at the temperature of 950 DEG C to 1,450 DEG C under the condition of shaft-around swinging, so as to remove alkali-metal and alkaline-earth metal element impurities from the quartz sand. The quartz sand continuously turns over and flows in the sealed furnace hearth, so that theefficiency of chlorination is greatly increased, meanwhile, the consumption of the chlorination gas is reduced, and the production cost and environmental stress are reduced effectively. The problemsin the existing processes that a high-temperature gasified purification reaction of the quartz sand is insufficient and is low in yield, a large number of toxic chlorating agent is used, and severe hazards are caused to environments and human bodies are solved. According to the method, materials can be in full reaction, problems of hardening and caking do not occur easily, and thus, the method hasthe characteristics of high reaction efficiency, low environmental load and high coefficient of safety and has a positive popularization significance in improving product quality.

Owner:HUBEI FEILIHUA QUARTZ GLASS

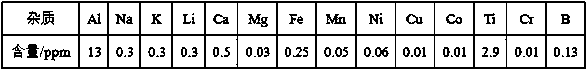

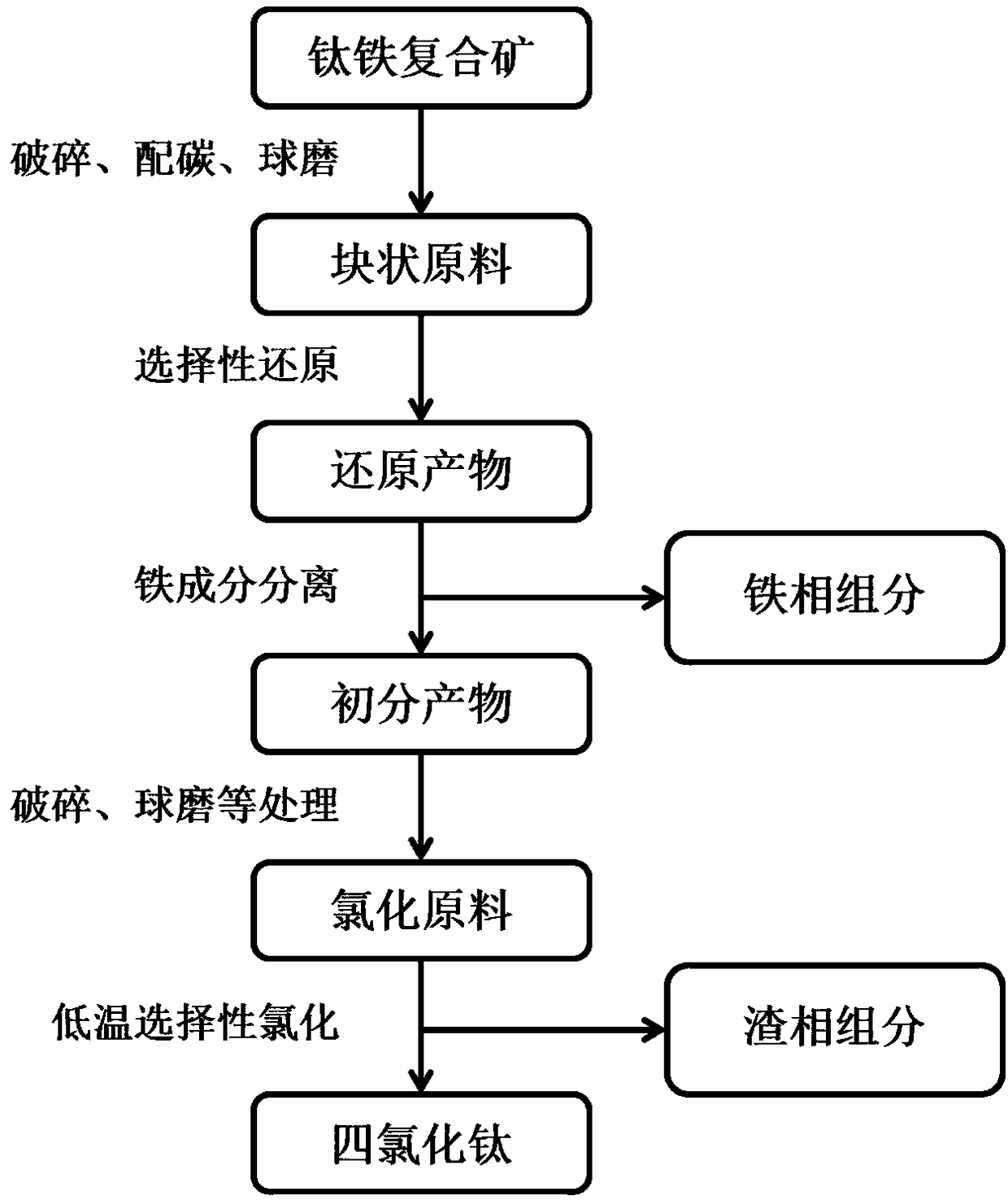

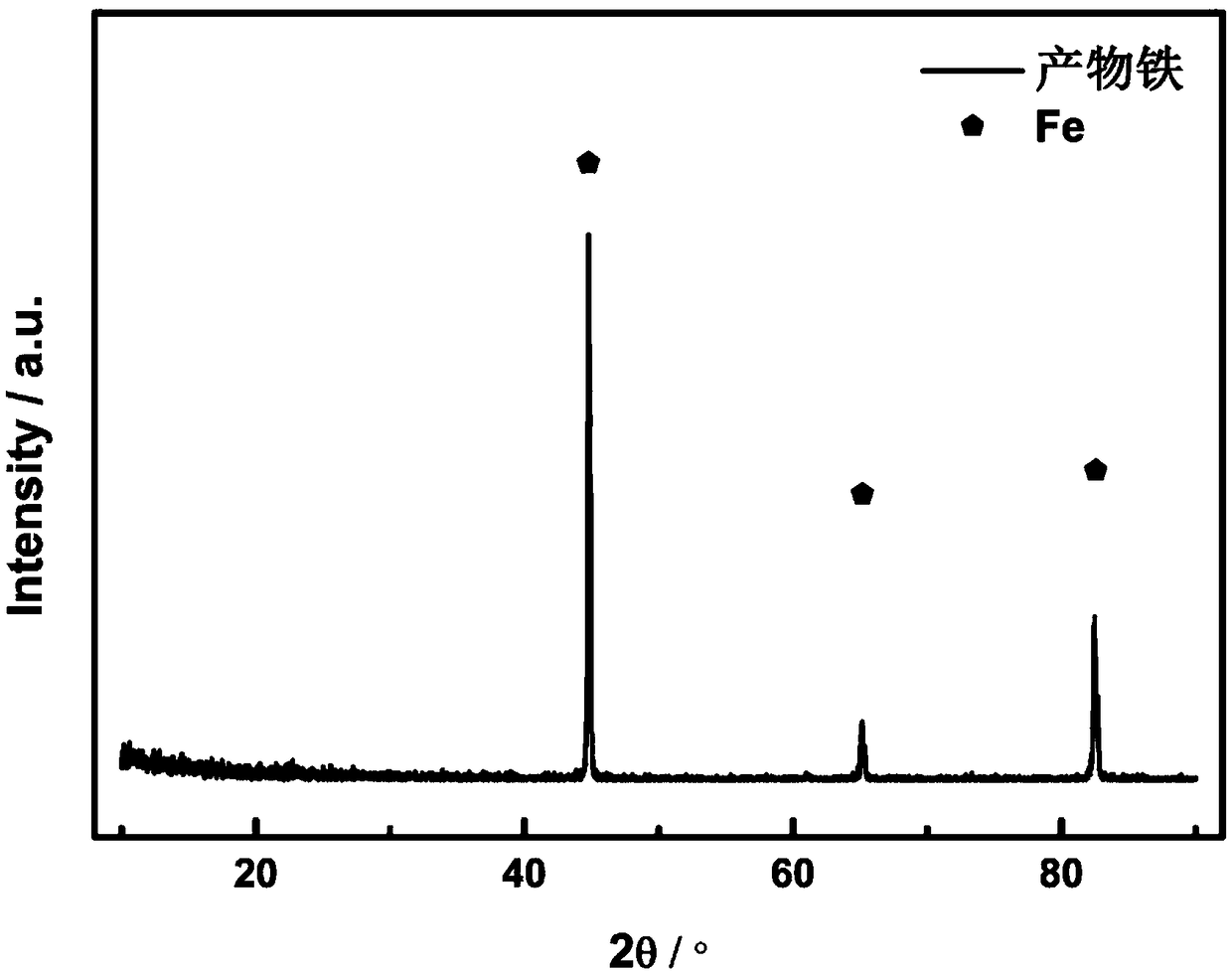

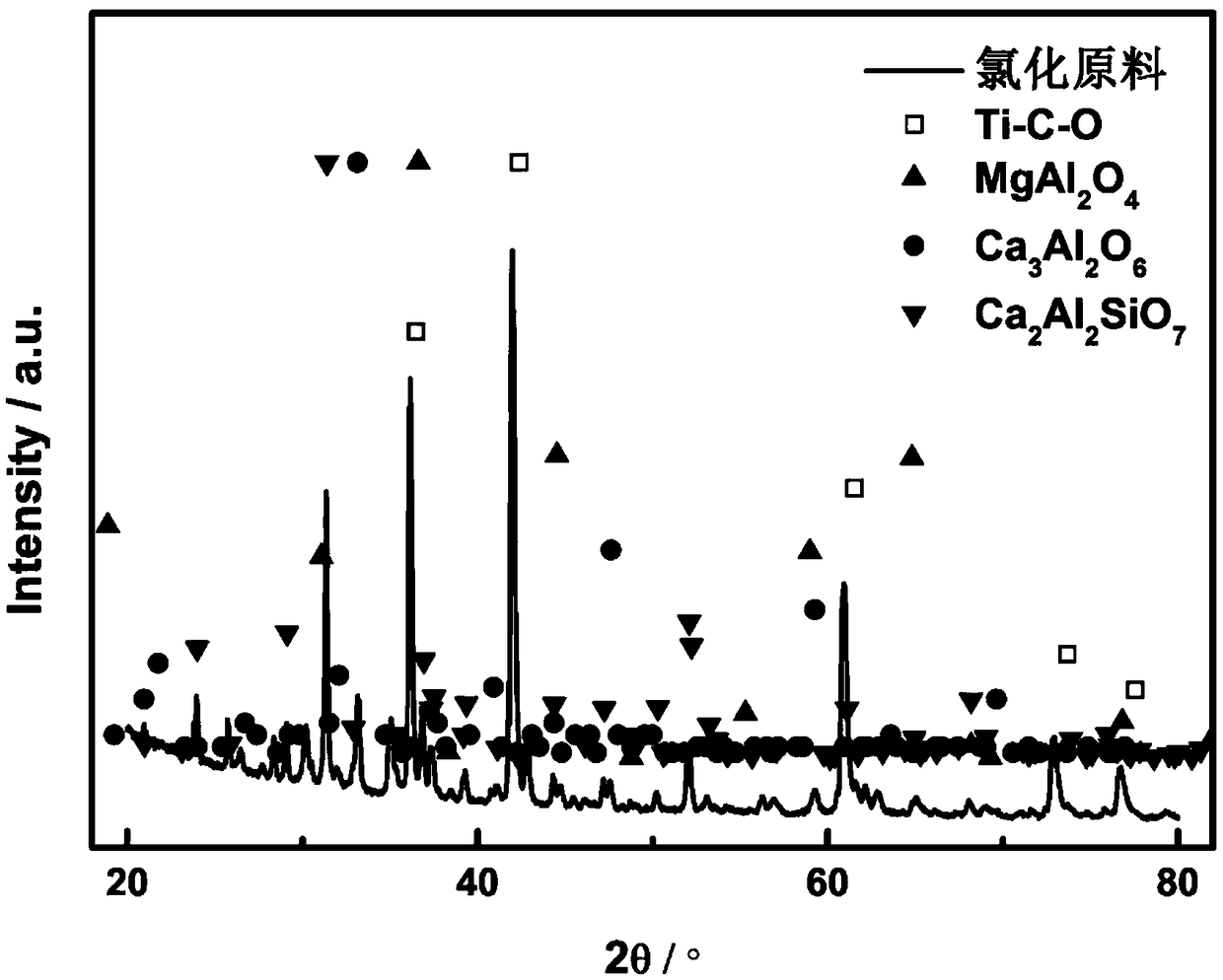

Method for preparing titanium products with ferrotitanium composite ores as raw materials

The invention relates to a method for preparing titanium products with ferrotitanium composite ores as raw materials, and belongs to the field of chemical engineering. The preparation method comprisesthe following steps: ferrotitanium composite ore raw materials are fed in carbon raw materials according to a certain chemical ratio for uniform mixing, and then, are heated and reduced under a certain atmosphere, so that iron components are reduced as metal iron, titanium components are reduced as carton titanium oxide, carton nitrogen titanium oxide, and other components (aluminum, magnesium, calcium, silicon) are maintained in an oxide state. After iron components are separated, slag phases are selectively chloridized at low temperature to directly obtain titanium tetrachloride with the grade of higher than 99%. The method can effectively reduce the cost in traditional iron and titanium extracting methods, effectively solves the problem of synchronous chloridization of other oxides inthe traditional chloridization method process, prominently improves the selectivity of chloridization procedures in the production process of titanium tetrachloride, improves the chloridization efficiency of titanium, can directly obtain high-purified titanium products, needs no subsequent refining and purification, and greatly simplifies the iron and titanium element extracting method flow of theferrotitanium composite ores.

Owner:朱鸿民

Method for promoting growth of TiC in molten slag

InactiveCN109279606AReduce chlorine consumption and residueImprove chlorination efficiencyTitanium carbideProcess efficiency improvementTitanium metalEnvironmental pressure

The invention relates to a method for promoting growth of TiC in molten slag and belongs to the field of titanium metal smelting. The method is used for solving the technical problem that subsequent purification and enrichment of the TiC are high in difficulty due to the fact that the TiC prepared from titaniferous furnace slag through carbothermic reduction is relatively small in particle size. The method for promoting growth of the TiC in titanium slag smelting, disclosed by the invention, comprises the steps of adding electric furnace dedusted dust produced during smelting into an electricfurnace during the preparation of titanium carbide slag from titaniferous feedstocks through carbothermic reduction, and carrying out smelting together with the titaniferous feedstocks and a reducer,thereby obtaining the titanium carbide slag. According to the method, the particle size of titanium carbide particles prepared by the method can reach 7 to 30 microns, a titanium carbide product withrelatively high grade can be obtained through wet magnetic separation, the dedusted dust produced during smelting can be effectively recycled, and thus, the environmental pressure is alleviated.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

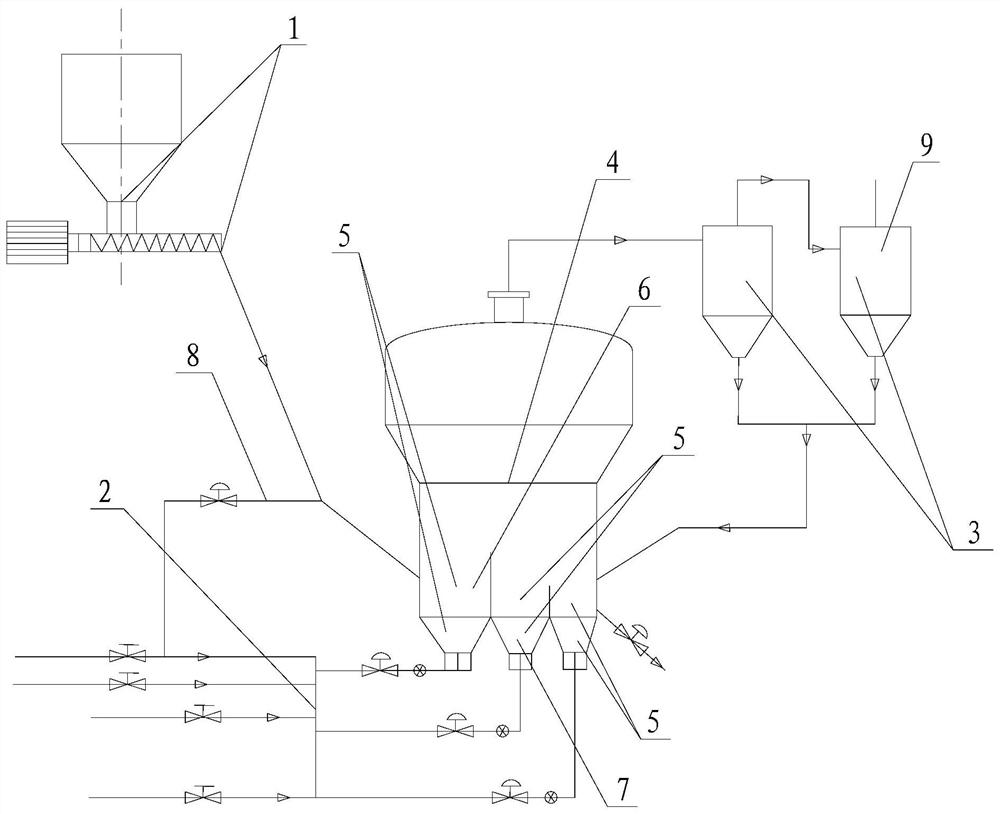

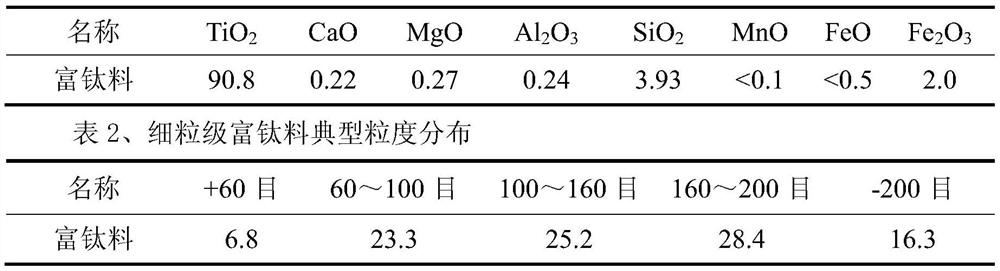

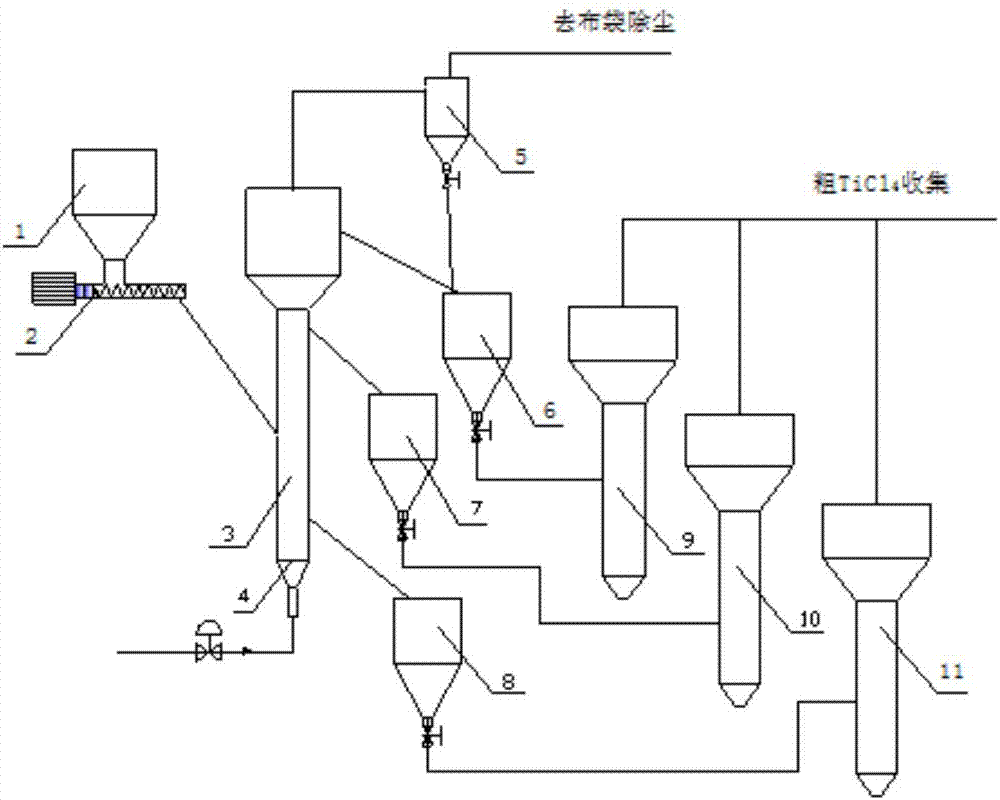

Chlorination furnace for fine-fraction titanium-rich material and fluidizing chlorination process thereof

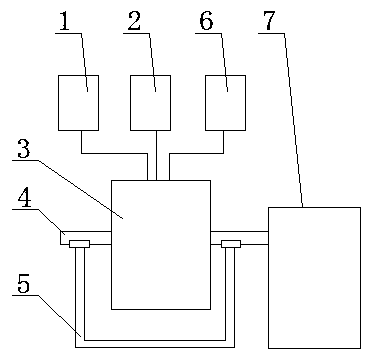

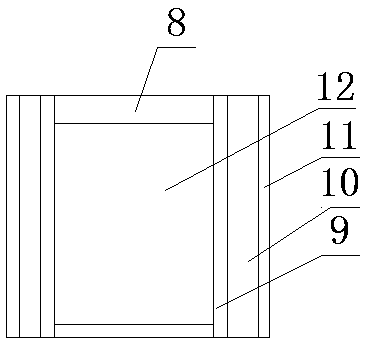

ActiveCN111908501AIncrease the chlorination rateHigh product yieldTitanium tetrachlorideTitanium chlorideWater chlorination

The invention discloses a chlorination furnace for a fine-fraction titanium-rich material and a fluidizing chlorination process thereof, and belongs to the technical field of design and manufacturingof metallurgical production equipment. Provided are a chlorination furnace for the fine-fraction titanium-rich material and the fluidizing chlorination process thereof that can effectively increase chlorination efficiency and greatly reduce chlorination loss. The chlorination furnace comprises a feeding system, a gas supply system, a titanium tetrachloride collecting system and a chlorination furnace body, and further comprises at least two groups of fluidizing chlorination reaction units with gradually deepened chlorination depth, the fluidizing chlorination reaction units sequentially arranged at the lower part of the chlorination furnace body along the chlorination direction communicate with each other by respective upper openings in an overflowing manner; the fluidizing chlorination process enables a fine-grained titanium-rich material entering the chlorination furnace body to be deepened along with the chlorination depth; and the chlorination rate of the titanium-rich material andthe product yield are improved by gradually chlorinating each group of adjacent fluidizing chlorination reaction units of which the chlorination parameters can be independently controlled in an overflow manner.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

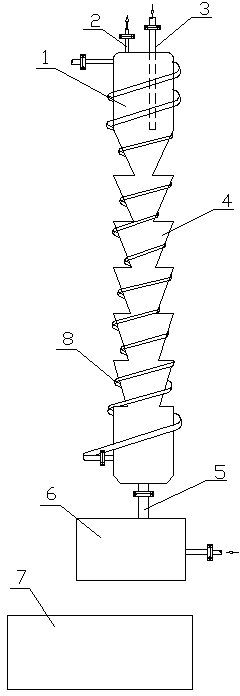

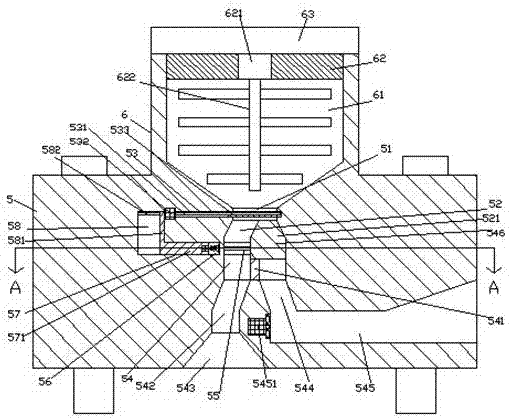

Silica oxygen-free chlorination and acid extraction treatment method and device

ActiveCN104843718AImprove the effect of chlorination reactionImprove chlorination efficiencySilicaOxygenSilicon dioxide

The invention discloses a silica oxygen-free chlorination acid extraction treatment method and device. The device comprises a vertical chlorination reaction furnace, an acid extraction tank and a specific gravity separation tank. The acid extraction tank is connected to a discharge outlet of the vertical chlorination reaction furnace by a discharge pipe. The specific gravity separation tank is arranged below the acid extraction tank. The wall of the middle of the vertical chlorination reaction furnace along the furnace axial direction forms inward concaves so that multiple cone frustums with large upper ends and small lower ends are formed, the cone frustums are connected in a way that the small end of the upper cone frustum is connected to the large end of the lower cone frustum, and the bottom diameters of the cone frustums are gradually decreased from bottom to top. The wall of the middle of the vertical chlorination reaction furnace forms the multiple cone frustums connected in a way that the small end of the upper cone frustum is connected to the large end of the lower cone frustum so that when chlorinated gas enters into the furnace from the furnace bottom and is discharged by the furnace top, eddy is formed in the furnace and thus chlorination reaction effects are improved. In chlorination treatment, SiO2 particles are pre-heated and then the chlorinated gas at a temperature of 500-1500 DEG C is fed into the chlorination reaction furnace from the furnace bottom so that chlorination efficiency is high and effects are good.

Owner:连云港神汇硅材料科技有限公司

Method for extracting nonferrous metal from waste circuit board

InactiveCN107716105AEconomic extractionEfficient extractionMagnetic separationNonferrous metalPrinted circuit board

The invention discloses a method for extracting nonferrous metal from a waste circuit board. The method comprises the following steps that 1, the waste circuit board is pretreated so as to obtain fine-particle materials; 2, the fine-particle materials are subjected to gravity separation so as to obtain a heavy product; 3, a reducing agent, a chlorinating agent and the heavy product are subjected to heat treatment correspondingly; 4, valuable metal is subjected to a chlorination reaction; and 5, ferromagnetic materials are removed, and a concentrate of the nonferrous metal is obtained. According to the extracting method, the circuit board is crushed and heated, a mixture containing the nonferrous metal is obtained, emission of a large amount of harmful gas and solid waste is reduced, and thus the environment is protected; a wet-type shaking-table sorting method is adopted, and thus dust is avoided; and a combination of reaction material preheating and high-temperature chlorination is adopted, the chlorine retention capacity and the chlorination efficiency of the valuable metal are improved, the dosage of the chlorinating agent is decreased, the extracting process is simplified, andthe recycling cost is reduced.

Owner:宝鸡市铭坤有色金属有限公司

System and method for high-value comprehensive utilization of high-chromium vanadium slag

ActiveCN109837395AReduce overflowImprove chlorination efficiencyProcess efficiency improvementSlagManganese

The invention discloses a system and method for high-value comprehensive utilization of a high-chromium vanadium slag. Vanadium, chromium and iron in the high-chromium vanadium slag are converted through selective chlorination by a circulating fluidized bed to corresponding gaseous chlorides, and most impurities such as manganese, titanium, and silicon are remained in the chlorinated residue, so that valuable elements are separated from other impurities. The gaseous chlorides separates crude chromium trichloride by high temperature dust collection, separates crude ferric chloride by medium temperature dust collection, and separates crude vanadium oxychloride from low temperature elution. The crude chromium trichloride is dissolved and stirred to obtain an aqueous solution to recover the chromium salt; the crude ferric chloride and chlorinated residue are hydrolyzed and dechlorinated by high temperature to obtain an oxidized slag for iron production; and the crude vanadium oxychloride vanadium is subjected to sedimented purification, rectification and refinement, and catalytic oxidation to obtain high-purity vanadium pentoxide powder. By means of the system and the method, the high-value comprehensive utilization of the high-chromium vanadium slag is achieved, and the chromium chloride solution and high purity vanadium pentoxide powder are produced by the method of one-step of chlorination with multi-step recovery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

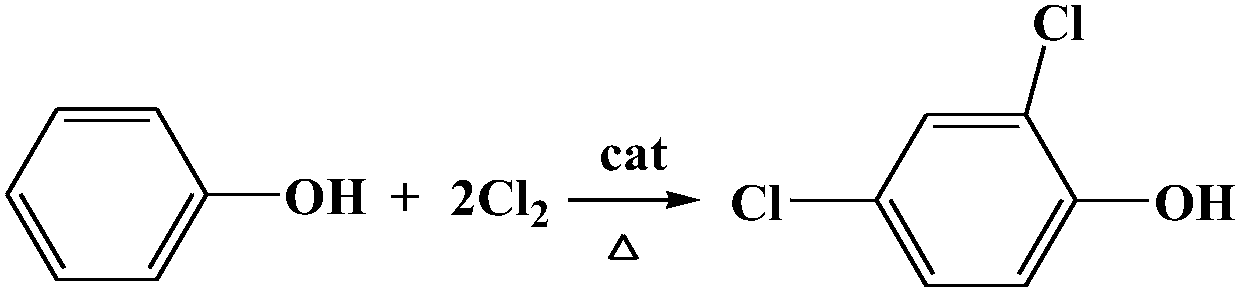

Production method and production system for 2,4-dichlorophenol

InactiveCN108424355ALess impuritiesEasy to separate and purifyOrganic chemistryOrganic compound preparationContinuous useMetal catalyst

The invention provides a production system for 2,4-dichlorophenol. The production system comprises a fixed-bed reactor, which comprises a phenol feeding port, a sulfuryl chloride feeding port and a discharge outlet, and is provided with a supported metal salt catalyst; a deacidification tower, which comprises a feed inlet, a gas discharge outlet and a liquid discharge outlet, wherein the feed inlet of the deacidification tower communicates with the discharge outlet of the fixed-bed reactor; and a rectifying tower, wherein the feed inlet of the rectifying tower communicates with the liquid discharge outlet of the deacidification tower. Compared with the prior art, the production system provided by the invention has the following advantages: the supported metal salt catalyst is fixed in thefixed-bed reactor for continuous usage and is not in a same system with phenol and a metal catalyst, so impurities in a reaction solution used in a chlorination reaction are reduced, the reaction solution can be easily separated and purified, a finally rectified substance has no solid residue, and a reaction route is clean and environment-friendly.

Owner:SHANDONG RUNBO BIOTECH CO LTD

Preparation process for magnetic chlorinated rubber

The invention discloses a preparation process for magnetic chlorinated rubber, relating to the technical field of rubber processing. The process comprises the following steps of 1) raw material preparation; 2) sizing material plastication; 3) magnetic oriented mixing; 4) sizing material molding and magnetizing; and 5) sizing material vulcanization. The magnetic chlorinated rubber prepared by using the preparation process has good fire resistance, high strength, excellent mechanical property and good abrasive resistance, can be adapted to rubbing for a long time, can not be damaged, and has high magnetic property and good elasticity; an environment-friendly fire retardant is added in the mixing process, so that the flame retardant property is further improved; plenty of energy sources can be saved in the production process, and the preparation process is simple and is easy to master.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

Method for extracting valuable metal from low-content nonferrous metal

InactiveCN103725868AImprove chlorine retentionReduce usageProcess efficiency improvementProcessing typeMetal chloride

The invention discloses a method for extracting valuable metal from low-content nonferrous metal. The method comprises the following steps: (1) pretreatment, (2) preheating, (3), high-temperature chloridizing roasting, and (4), trapping and recovery of valuable metal chloride. According to the chloridizing metallurgy method for which metal chloride is used for metal extraction, great advantages are provided when low-grade metal materials which are difficult to process are processed, and valuable metal can be extracted economically and efficiently, and the method is a universal technical scheme aiming at complex low-content nonferrous metal materials with various processing types, large resource quantities and complex ore types.

Owner:ANHUI HUAIHUA

Method for preparing high-purity vanadium oxychloride from ferrovanadium fine powder

InactiveCN111410228AImprove chlorination efficiencyHigh purityVanadium compoundsNitrogen gasWater chlorination

The invention belongs to the technical field of chemical metallurgy, and particularly relates to a method for preparing high-purity vanadium oxychloride from ferrovanadium fine powder. The technical problem to be solved by the invention is to provide a method for preparing high-purity vanadium oxytrichloride by effectively utilizing ferrovanadium fine powder. The method comprises the following steps: a, putting ferrovanadium fine powder into a chlorination reactor, introducing nitrogen, performing heating to 300-600 DEG C, introducing chlorine and oxygen, adjusting the total flow rate of nitrogen, chlorine and oxygen, carrying out chlorination reaction, and condensing volatile components in the reactor in the reaction process to obtain a vanadium oxytrichloride crude product; b, after thechlorination reaction is finished, stopping introducing the chlorine and the oxygen, adjusting the flow rate of the nitrogen again, and stopping introducing the nitrogen after the reactor is cooled toroom temperature; and c, distilling and condensing the vanadium oxytrichloride crude product to obtain high-purity vanadium oxytrichloride. By means of the method, the high-purity vanadium oxychloride product can be prepared, the purity can reach 99.9% or above, and meanwhile the chlorination efficiency of vanadium in ferrovanadium fine powder can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for enriching titanium carbide in carbide slag

The invention discloses a method for enriching titanium carbide in carbide slag, relates to the technical field of metallurgical chemical, and solves the problem that the chlorination rate is low due to the fact that the grade of titanium carbide in high blast furnace slag titanium extraction industrialization process is low. The adopted technical scheme is that a blast furnace is opened for deslagging after titanium-bearing blast furnace slag reaches a smelting finish point, a slag pan is used for receiving slag and is rotated after the slag is received so that TiC particles can sink, gather and grow constantly, after the titanium-bearing blast furnace slag is cooled, the titanium-bearing blast furnace slag on the upper layer in the slag pan is reacted with acid after smashed, most CaO, MgO and Al2O3 are removed, and a finished product rich in titanium carbide is obtained after filtering and drying; the titanium-bearing blast furnace slag on the lower layer in the slag pan is directly taken as a finished product rich in titanium carbide. With the method for enriching the titanium carbide in the carbide slag, TiC grade in the titanium-bearing carbide slag is improved, the contact opportunity of titanium carbide and chlorine is increased during lower temperature chlorination, generation of chlorination reaction can be promoted, and the chlorination efficiency is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

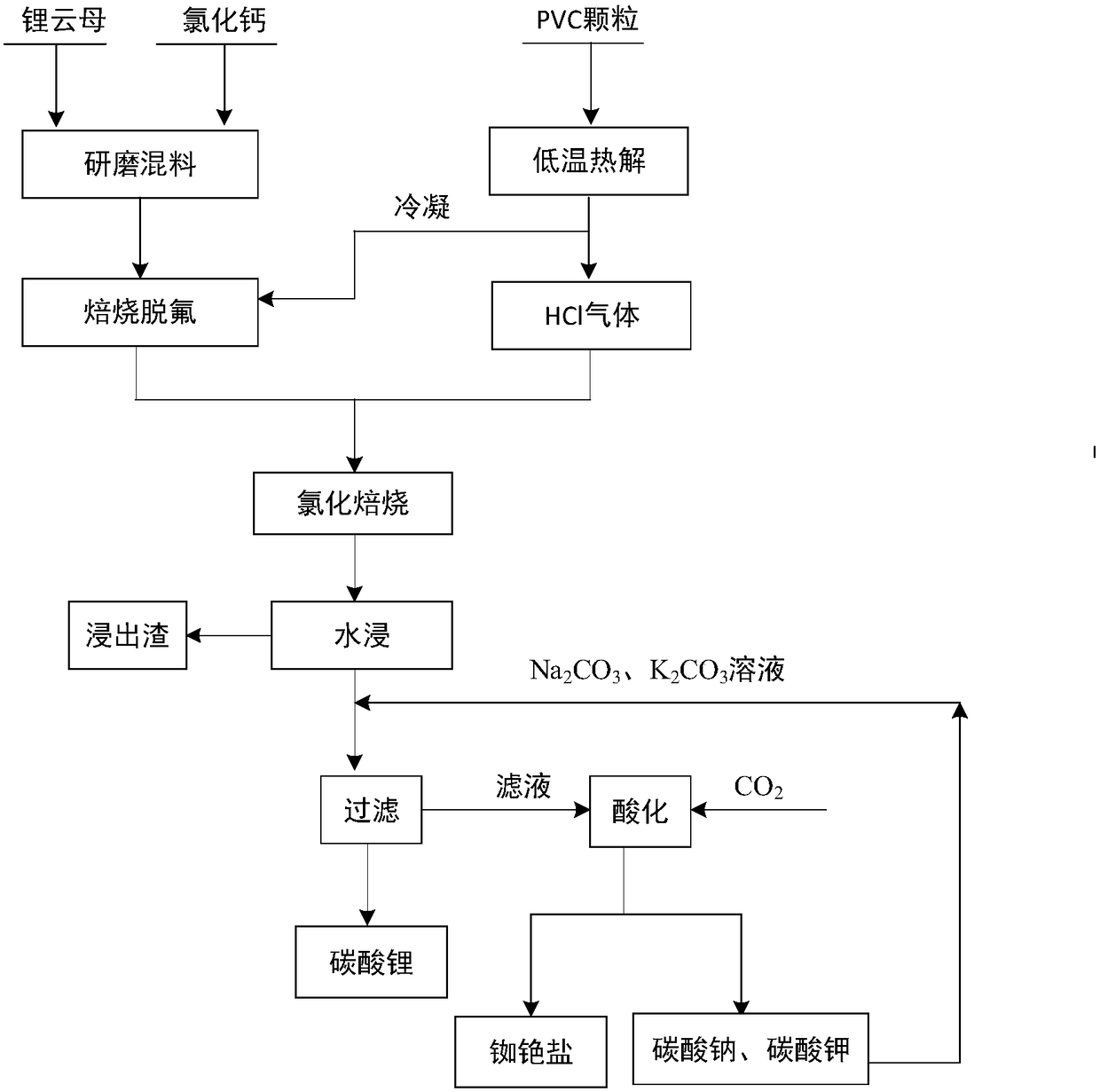

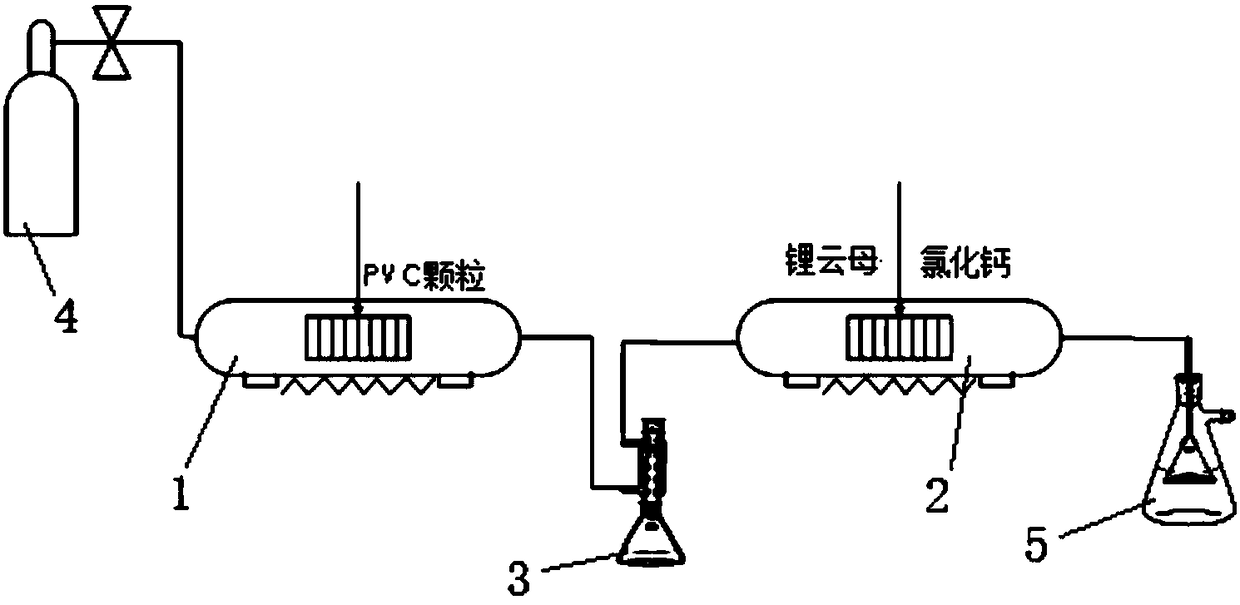

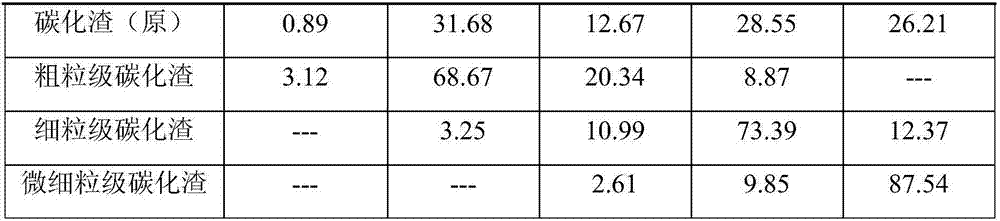

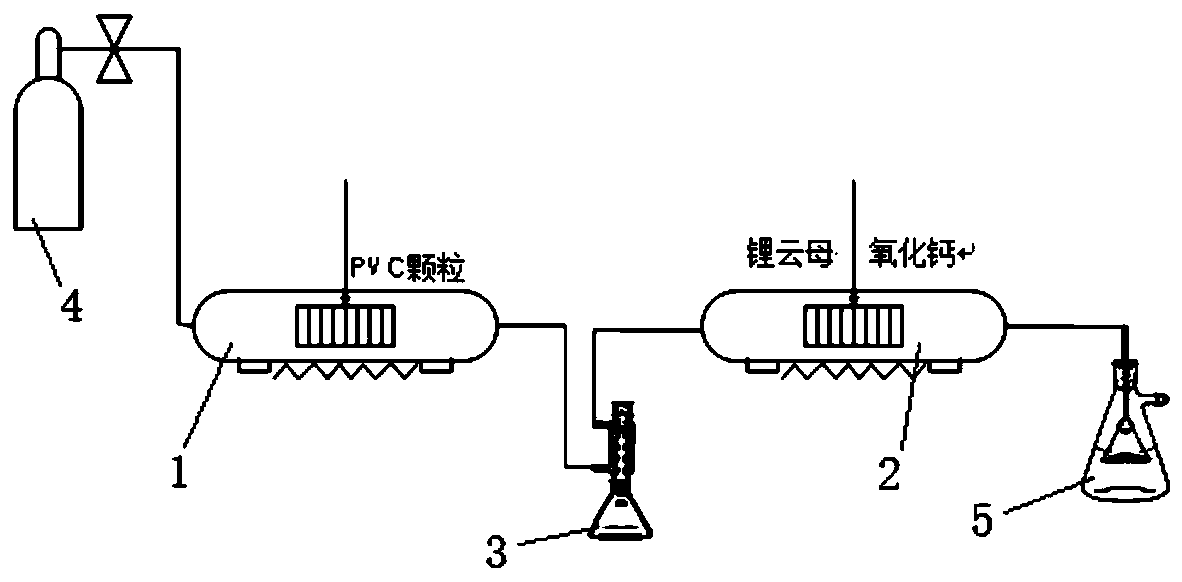

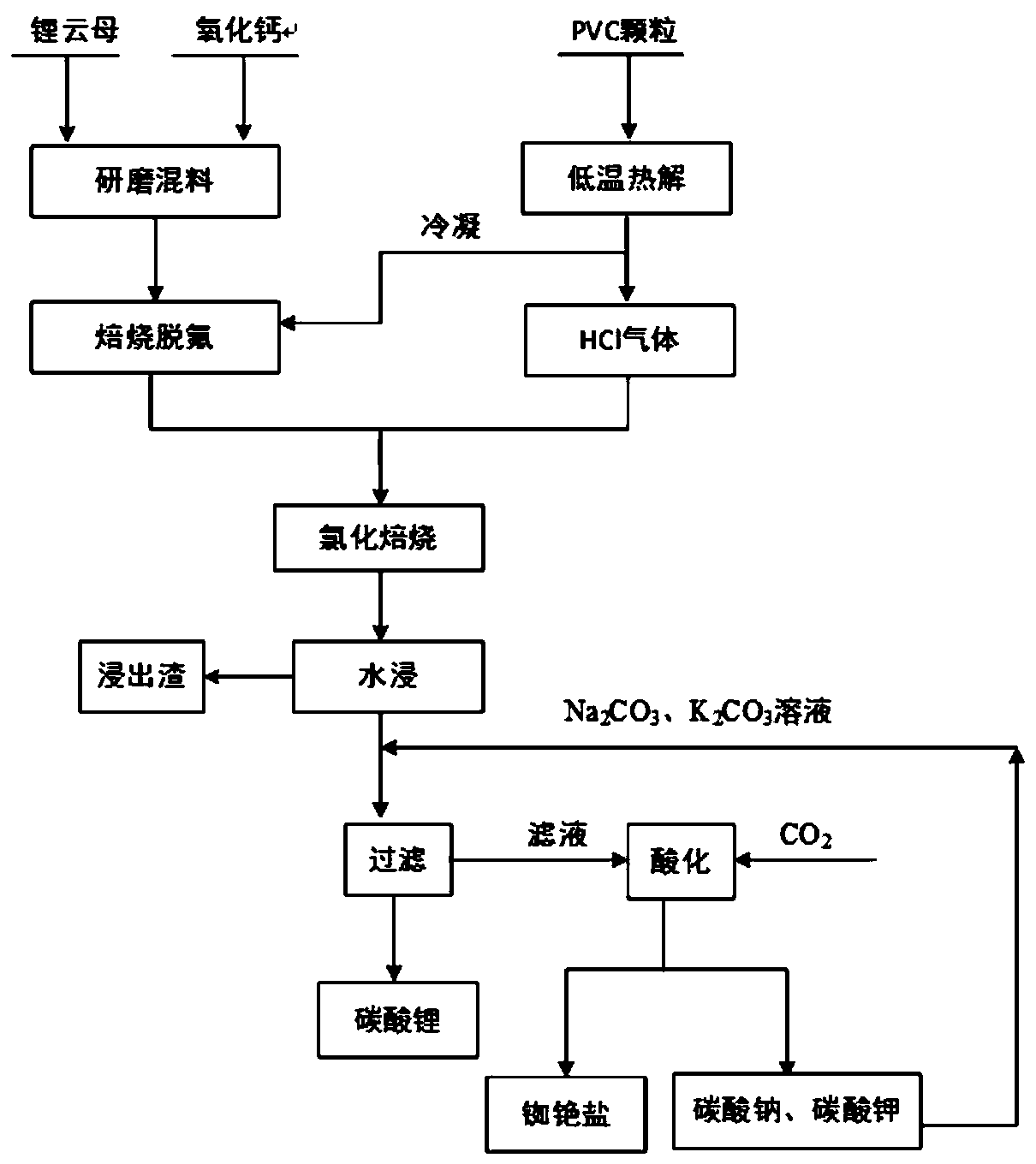

Method for extracting lithium from lepidolite through PVC pyrolysis

ActiveCN108285975ARealize comprehensive utilizationReduce manufacturing costProcess efficiency improvementLithium carbonateEconomic benefits

The invention provides a method for extracting lithium from lepidolite through PVC pyrolysis. The method comprises the following steps of: (1) performing low-temperature pyrolysis on cleaned and driedPVC plastic under inert atmosphere to obtain HCl gas and tar; (2) mixing lepidolite ores with calcium oxide, and performing defluorination roasting after uniformly grinding to obtain defluorinated lepidolite ores; (3) leading HCl gas obtained in the step (1) into the defluorinated lepidolite ores obtained in step (2), and performing chlorination roasting to obtain clinker; (4) leaching the clinker obtained in step (3) with water, and performing solid-liquid separation to obtain leach liquor; and (5) adding an alkali precipitator into the leach liquor obtained in step (4), and filtering afterreacting to obtain lithium carbonate solid and filtrate. The method provides a novel idea for comprehensive utilization of PVC waste, reduces pollution, on environment, of PVC waste, reduces production cost of lithium carbonate, realizes comprehensive utilization of PVC, and generates great economic benefits.

Owner:CENT SOUTH UNIV

Preparation process of chlorinated butadiene-nitrile rubber

The invention discloses a preparation process of chlorinated butadiene-nitrile rubber and relates to the technical field of rubber materials. The preparation process comprises the following steps: (1) preparing raw materials; (2) plastifying a rubber material; (3) mixing the rubber material; (4) forming the rubber material; and (5) vulcanizing the rubber material. The chlorinated butadiene-nitrile rubber material prepared by the process is good in fire resistance, capable of delaying ignition, high in strength, excellent in mechanical property, and good in wear resistance, and magnetic powder, a reinforcing filler and an anti-aging agent are added into the rubber material to ensure a better heat-resistant effect; and the preparation process is simple and easy to master.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

A kind of synthesis technique of ethyl maltol

The invention belongs to the technical fields of spices and in particular relates to a synthetic process of ethyl maltol. The process comprises a chlorination reaction step, a hydrolysis rearrangement step and a sublimating and purifying step, wherein the chlorination reaction is realized by reacting alpha-ethylfuran methanol with chlorine at the flow ratio of (1.8 to 2.3L):1kg to generate a hydroxy chlorovinylketone intermediate; the hydrolysis rearrangement means that the hydroxy chlorovinylketone intermediate is hydrolyzed at the temperature of 90 to 105DEG C for 3 to 4.5 hours to obtain an ethyl maltol coarse crystal; the coarse crystal is sublimated and purified under the conditions that the temperature is 200 to 225DEG C and the pressure is 0.080 to 0.090MPa to obtain an ethyl maltol product. The synthetic process disclosed by the invention is detailed and specific in operation and is stable; the chlorinating efficiency is improved and the generation of foamed yellow crystals is controlled; meanwhile, sublimating and purifying conditions are controlled, thereby effectively improving the yield and the purity of the ethyl maltol.

Owner:广东省肇庆香料厂有限公司

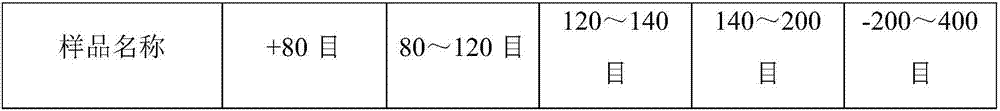

Method for Improving Chlorination Efficiency of Titanium-Containing Blast Furnace Slag

ActiveCN105819500BImprove chlorination efficiencyImprove recycling efficiencyTitanium tetrachlorideReduction treatmentSlag

The invention belongs to the field of chemical engineering, particularly relates to a method for improving the chlorinating efficiency of titanium-bearing blast furnace slag, and aims at solving the technical problems that at present, due to the fact that the low-temperature chlorination rate of carbide slag is low, the recycling efficiency of Ti is seriously affected, and the economical efficiency of the whole process is affected. The method for improving the chlorinating efficiency of the titanium-bearing blast furnace slag comprises the following steps that 1, the carbide slag which is subjected to high-temperature thermal reduction treatment and smashed into 80-400 meshes is divided into coarse fraction carbide slag, fine fraction carbide slag and micro-fine fraction carbide slag; 2, the coarse fraction carbide slag, the fine fraction carbide slag and the micro-fine fraction carbide slag are added into three boiling chlorination reactors for boiling chlorination respectively. According to the method, the chlorinating efficiency of blast furnace slag is effectively improved, and the recycling efficiency of Ti is greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Manufacturing process of chlorinated rubber

The invention discloses a manufacturing process of chlorinated rubber and relates to the technical field of rubber materials. The manufacturing process comprises the following steps: 1) preparing raw materials; 2) plasticating a rubber material; 3) mixing the rubber material; 4) molding the rubber material; and 5) vulcanizing the rubber material. The chlorinated rubber material prepared by the method disclosed by the invention has good flame retardance, capability of delaying ignition, high strength, excellent mechanical properties and good wear resistance, can be suitable for long-term friction and can prevent damages; and furthermore, an environment-friendly flame retardant is added in the mixing process, so that the flame retardance is further improved, and the preparation process is simple and easy to grasp.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

Method for enriching titanium carbide in carbide slag

The invention discloses a method for enriching titanium carbide in carbide slag, relates to the technical field of metallurgical chemical, and solves the problem that the chlorination rate is low due to the fact that the grade of titanium carbide in high blast furnace slag titanium extraction industrialization process is low. The adopted technical scheme is that a blast furnace is opened for deslagging after titanium-bearing blast furnace slag reaches a smelting finish point, a slag pan is used for receiving slag and is rotated after the slag is received so that TiC particles can sink, gather and grow constantly, after the titanium-bearing blast furnace slag is cooled, the titanium-bearing blast furnace slag on the upper layer in the slag pan is reacted with acid after smashed, most CaO, MgO and Al2O3 are removed, and a finished product rich in titanium carbide is obtained after filtering and drying; the titanium-bearing blast furnace slag on the lower layer in the slag pan is directly taken as a finished product rich in titanium carbide. With the method for enriching the titanium carbide in the carbide slag, TiC grade in the titanium-bearing carbide slag is improved, the contact opportunity of titanium carbide and chlorine is increased during lower temperature chlorination, generation of chlorination reaction can be promoted, and the chlorination efficiency is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of method utilizing pvc pyrolysis to extract lithium from lepidolite

ActiveCN108285975BRealize comprehensive utilizationReduce manufacturing costProcess efficiency improvementLithium carbonateEconomic benefits

The invention provides a method for extracting lithium from lepidolite through PVC pyrolysis. The method comprises the following steps of: (1) performing low-temperature pyrolysis on cleaned and driedPVC plastic under inert atmosphere to obtain HCl gas and tar; (2) mixing lepidolite ores with calcium oxide, and performing defluorination roasting after uniformly grinding to obtain defluorinated lepidolite ores; (3) leading HCl gas obtained in the step (1) into the defluorinated lepidolite ores obtained in step (2), and performing chlorination roasting to obtain clinker; (4) leaching the clinker obtained in step (3) with water, and performing solid-liquid separation to obtain leach liquor; and (5) adding an alkali precipitator into the leach liquor obtained in step (4), and filtering afterreacting to obtain lithium carbonate solid and filtrate. The method provides a novel idea for comprehensive utilization of PVC waste, reduces pollution, on environment, of PVC waste, reduces production cost of lithium carbonate, realizes comprehensive utilization of PVC, and generates great economic benefits.

Owner:CENT SOUTH UNIV

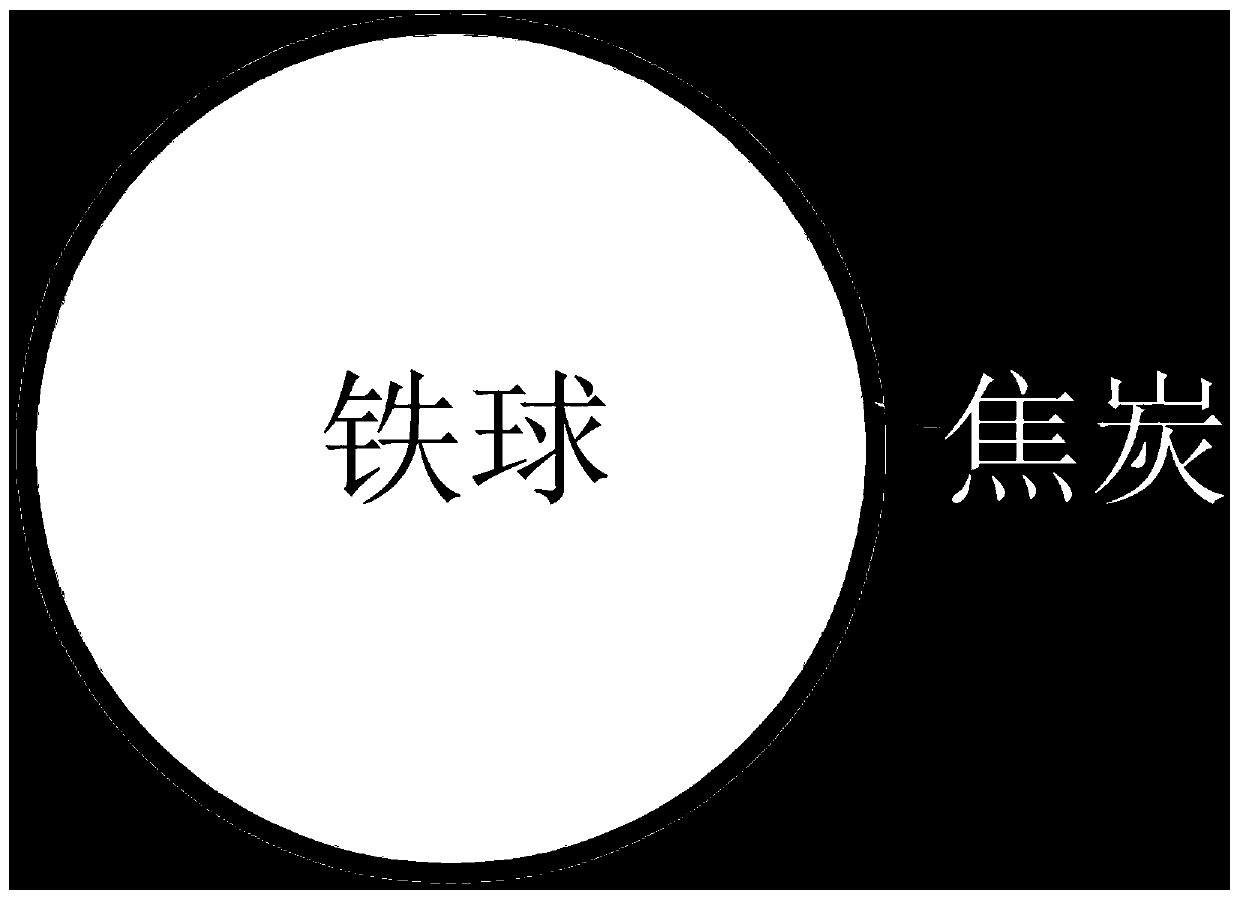

Process method for preparing TiC crystal grains by reducing and carbonizing titanium-containing blast furnace slag

InactiveCN110817877AOvercoming technical problems of lightness and buoyancyLarge particle sizeTitanium carbideTitanium tetrachlorideSlagCoke

The invention discloses a process method, particularly discloses a process method for preparing TiC crystal grains by reducing and carbonizing titanium-containing blast furnace slag, and belongs to the technical field of metallurgical tailing recycling production processes. The process method is capable of increasing TiC crystal grain aggregate particle size effectively, and comprises the following steps of: spherical iron-containing coke particles with the density matched with the density of titanium-containing blast furnace slag melt are fired firstly, then the spherical iron-containing cokeparticles and the titanium-containing blast furnace slag melt are uniformly mixed and subjected to high-temperature carbonization to prepare the Fe-TiC combination with the diameter ranging from 220micrometers to 280 micrometers, wherein average radial length of the TiC grains ranges from 20 micrometers to 30 micrometers.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

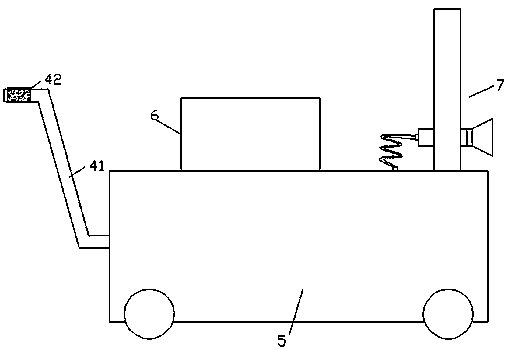

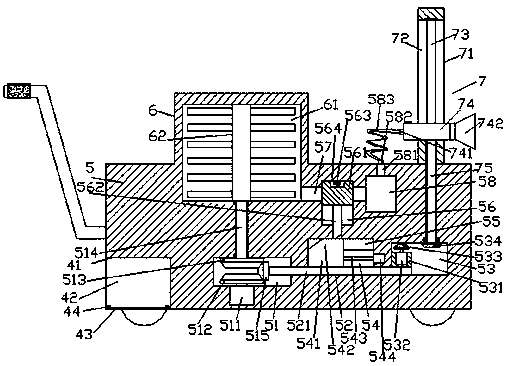

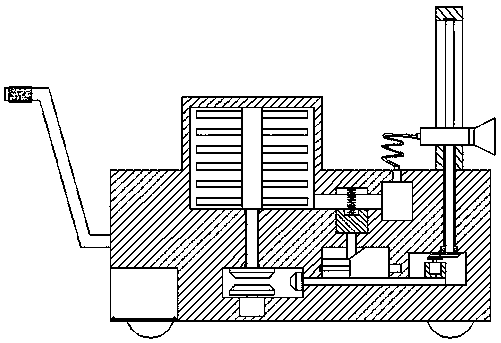

Novel sewage treatment device

InactiveCN107840439ARealize opening and closing controlRealize automatic control on and off controlWater/sewage treatment by oxidationAutomatic controlEngineering

The invention discloses a novel sewage processor, which comprises a fuselage, a liquid chlorine tank arranged on the top left side of the fuselage, and a chlorine adding device arranged on the top right side of the fuselage. Liquid chlorine chamber, the extension section at the bottom of the liquid chlorine chamber protrudes into the fuselage, the liquid chlorine chamber is connected with a mixing component, the fuselage below the liquid chlorine chamber is provided with a first chamber, and a conversion device is installed in the first chamber , the body above the right side of the first chamber is provided with a guide cavity, and the fuselage on the right side of the guide cavity is provided with a second chamber. The left extension tail tip passes through the right inner wall of the first chamber and is set through, and the right extension tail tip of the sliding joint groove passes through the left inner wall of the second chamber and is arranged through; the invention has simple structure, convenient operation and improved The service life and chlorination efficiency reduce the workload and can automatically control the height adjustment.

Owner:佛山启辰环保资源再生有限公司

Sewage treatment apparatus

ActiveCN107215945AMeet different chlorination work needsImprove work efficiencySpecific water treatment objectivesWater/sewage treatment using germicide/oligodynamic-processConical cavitySewage treatment

The invention discloses a sewage treatment apparatus. The sewage treatment apparatus comprises a base and a storage box installed at the top of the base, wherein a storage cavity extending downwards is arranged in the storage box, an extension section of the bottom of the storage cavity stretches into the base, a conveying opening with the top being communicated with the storage cavity is arranged in the base at the tail end of the bottom of the storage cavity, a slide cavity extending in the lateral direction is arranged in the conveying opening in a penetrating manner, an opening-closing management apparatus is arranged in the slide cavity, a conical cavity is arranged at the bottom of the conveying opening in a penetrating manner, the bottom of the conical cavity is provided with a conveying cavity in a penetrating manner, the middle end in the bottom of the conveying cavity is provided with a baffle plate fixedly connected with a front inner wall and a rear inner wall of the conveying cavity, a slide block is connected into the conveying cavity at the top of the baffle plate in a sliding and matching manner, and the top of the slide block is fixedly provided with a conical slide block stretching into the conical cavity and connected in a sliding and matching manner. The sewage treatment apparatus is simple in structure, convenient in operation, capable of improving the chlorine addition efficiency, good in chlorine addition effect, capable of alleviating the labor intensity, time-saving and labor-saving in use, and capable of meeting various chlorine addition requirements.

Owner:ANHUI DEQI ENVIRONMENTAL PROTECTION TECH CO LTD

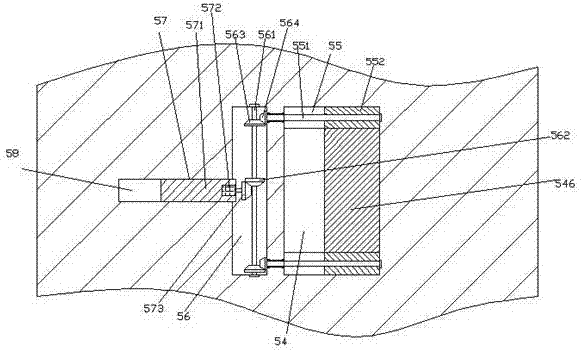

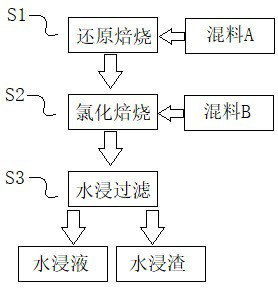

A kind of manganese slag collaborative calcium chloride waste slag recycling treatment method

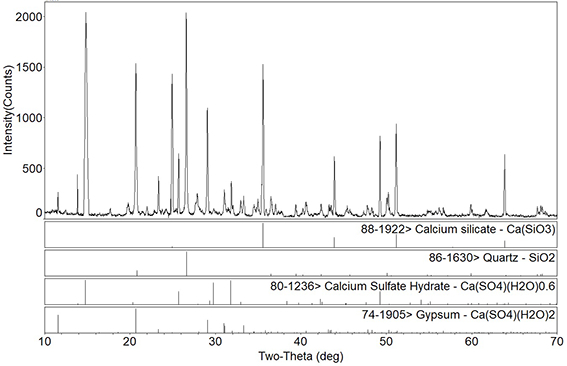

ActiveCN113387390BEasy to implementControls are responsiveCement productionManganese halidesCalcium silicateSulfate

The invention discloses a manganese slag and calcium chloride waste slag recycling treatment method. The manganese slag and calcium chloride waste slag are roasted in two stages to realize the synergistic recycling method. Calcium chloride, silicon dioxide and water vapor in the air are utilized. The reaction characteristics of calcium silicate and hydrogen chloride are formed at high temperature. The manganese slag containing the low-valent manganese phase formed by reduction roasting is mixed with the above materials to carry out high-temperature chlorination roasting, and the roasted product is separated by water leaching to obtain manganese chloride, and obtain The water leaching residue composed of calcium silicate, calcium sulfate and silica mixture realizes the synergistic utilization of manganese residue and calcium chloride waste residue, improves the resource value of the above solid waste, has high economic benefits, and reduces the For the environmental pollution caused by the separate treatment of the corresponding solid waste, the entire treatment process is simple and easy to implement, and the energy consumption is low, which can be widely used in the electrolytic manganese industry.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

A kind of preparation method of titanium carbide slag

ActiveCN106517202BHigh content of titanium carbideRefine the grain sizeTitanium carbideSlagTitanium nitride

Relating to the field of metallurgy, the invention discloses a preparation method of titanium carbide slag. The method includes: subjecting a titanium-containing raw material and a reducing agent to carbonation reaction in the presence of a nucleating agent, wherein the nucleating agent is selected from a titanium carbide-containing substance and / or an iron-containing substance. The method provided by the invention can make titanium carbide particles in the carbonization reaction gather and grow up, is conducive to further separation and purification for preparation of high-grade titanium carbide slag, achieves efficient utilization of titanium carbide slag, and improves the comprehensive utilization rate of titanium resources.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

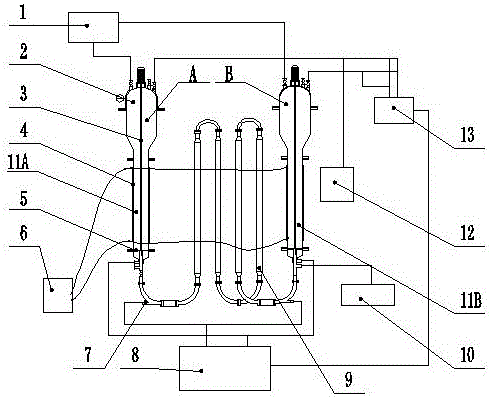

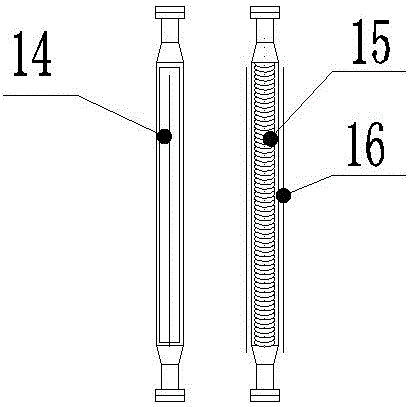

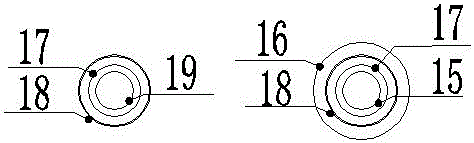

A device and process for producing chlorinated high polymer

ActiveCN104607114BImprove chlorination efficiencyPromote environmental protectionEnergy based chemical/physical/physico-chemical processesPolymer scienceUltraviolet lights

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com