Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Improve anti-reflection ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

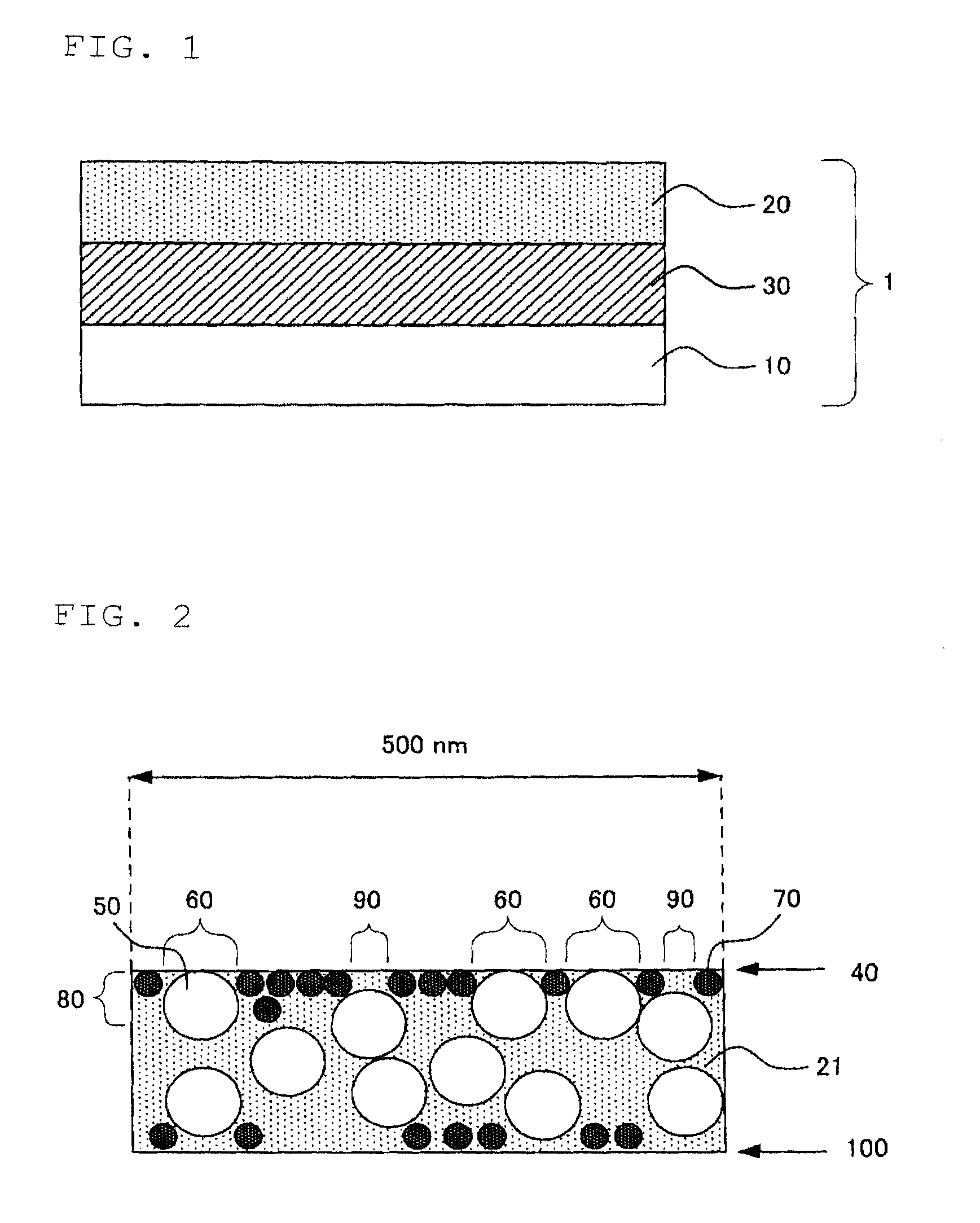

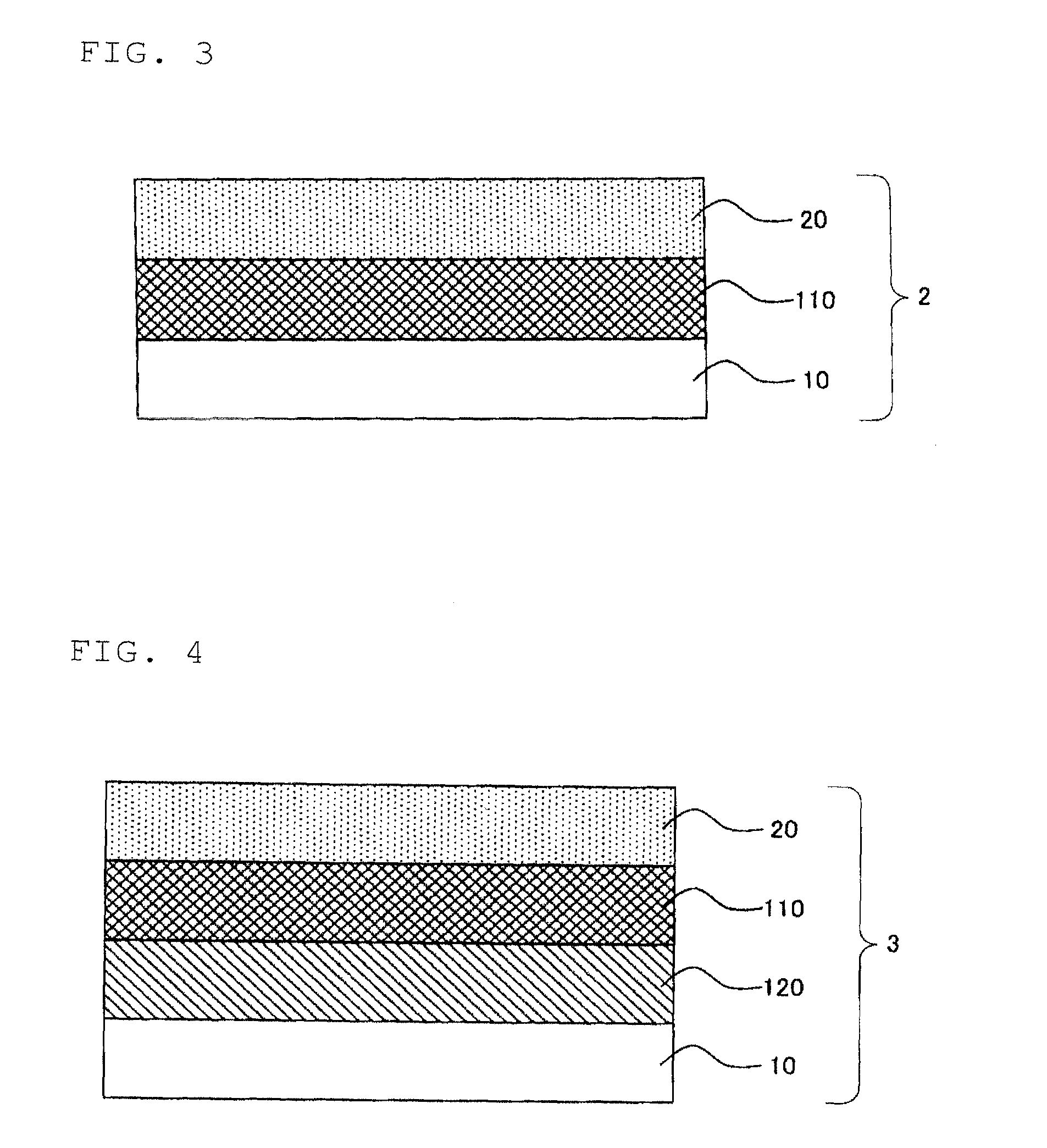

Optical film and display panel

ActiveUS20120200933A1Improve wear resistanceImprove anti-reflection abilityCoatingsNon-linear opticsRefractive indexDisplay device

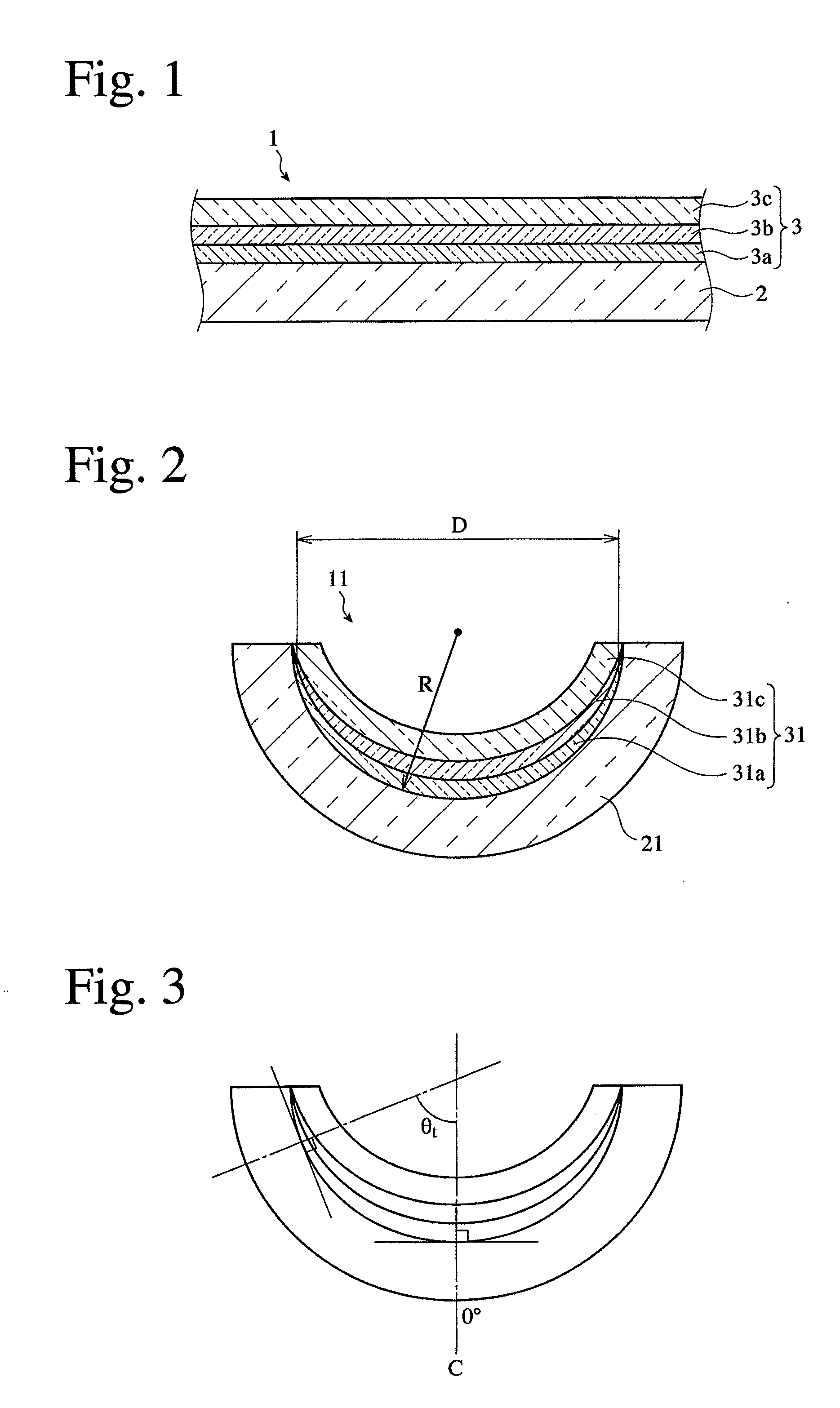

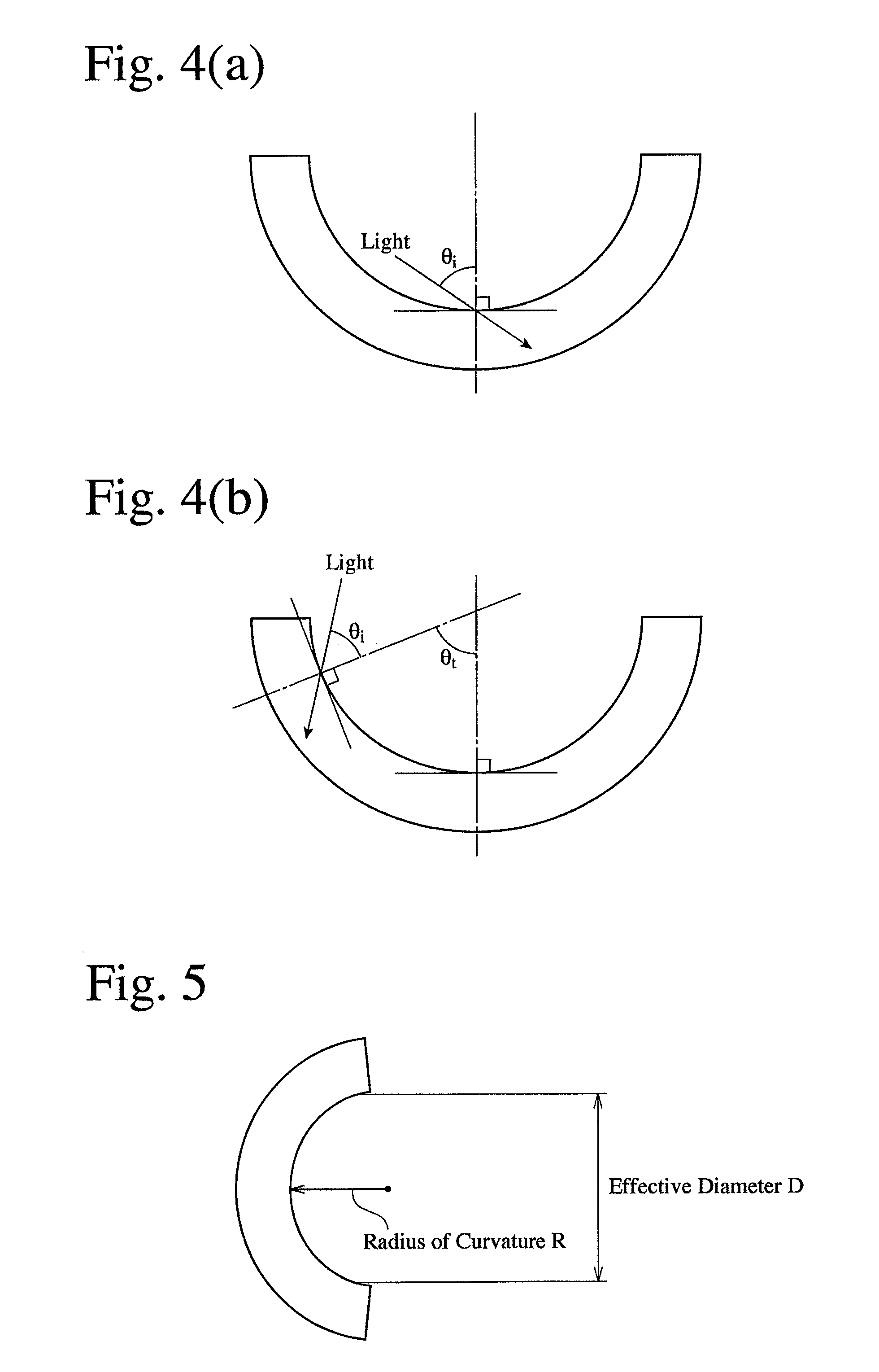

An optical film having an optically-transparent substrate, and a low refractive index layer having a thickness d on one side of the optically-transparent substrate, a polarizing plate and a display panel provided with the same, and a display provided with the same.

Owner:DAI NIPPON PRINTING CO LTD

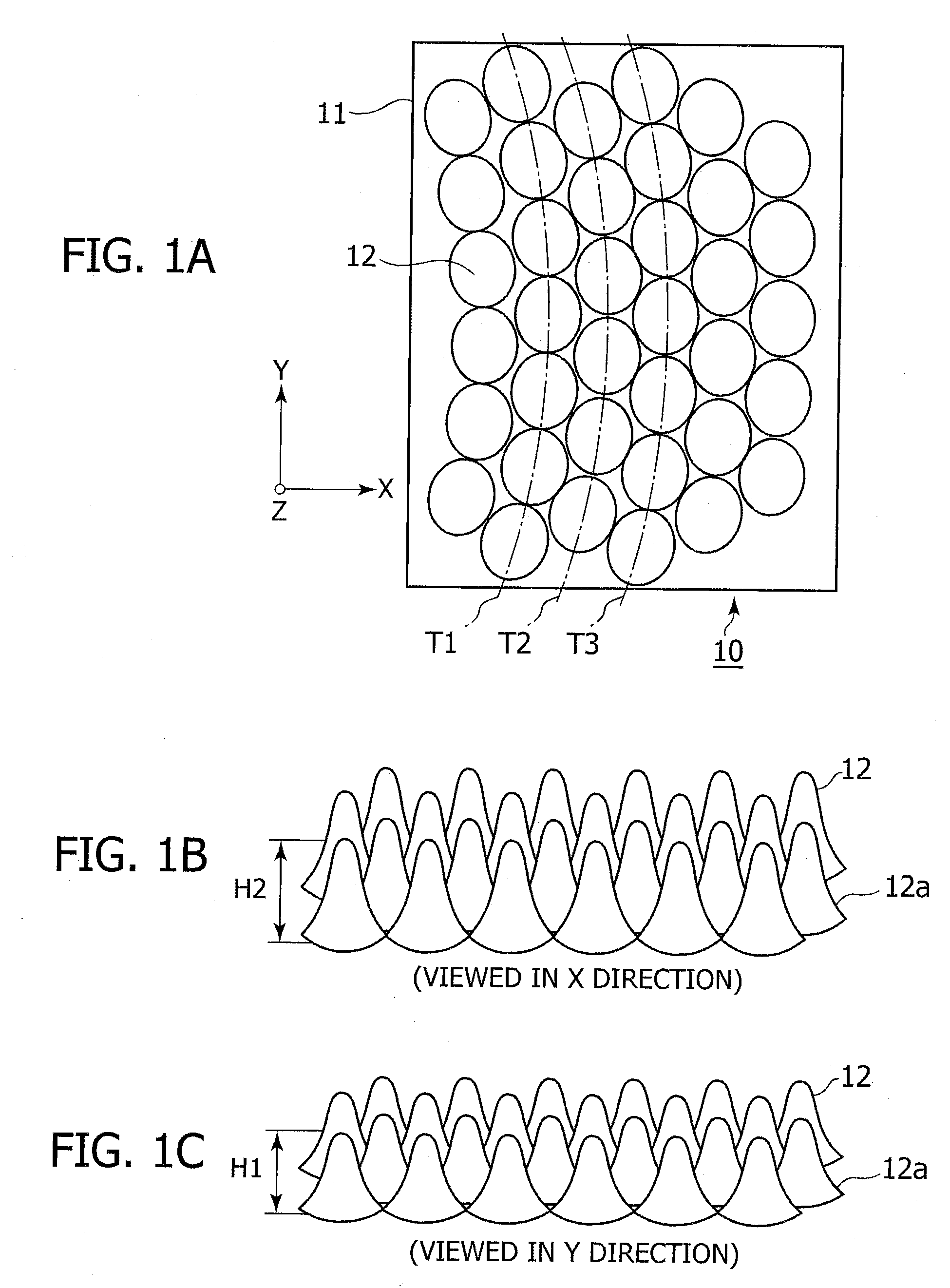

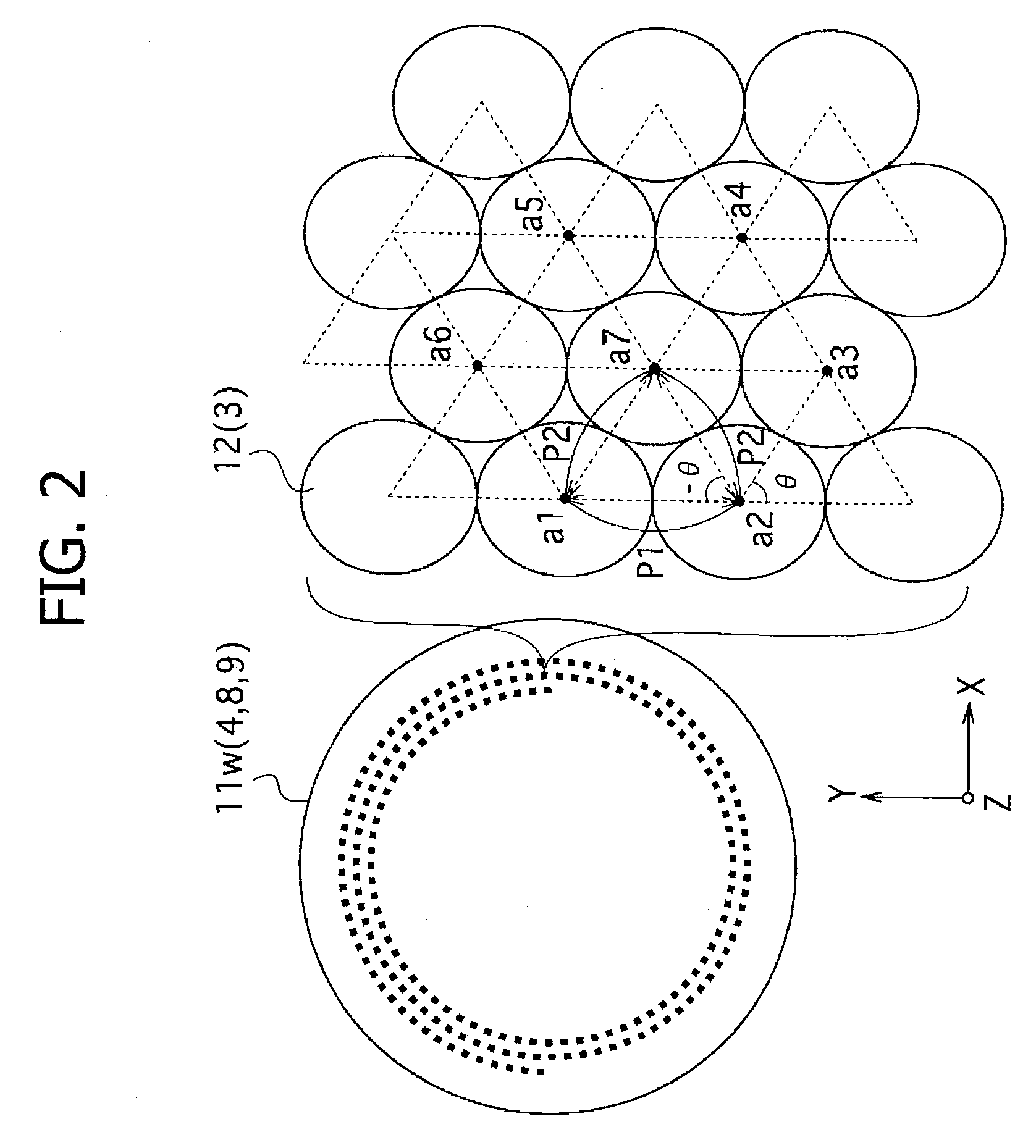

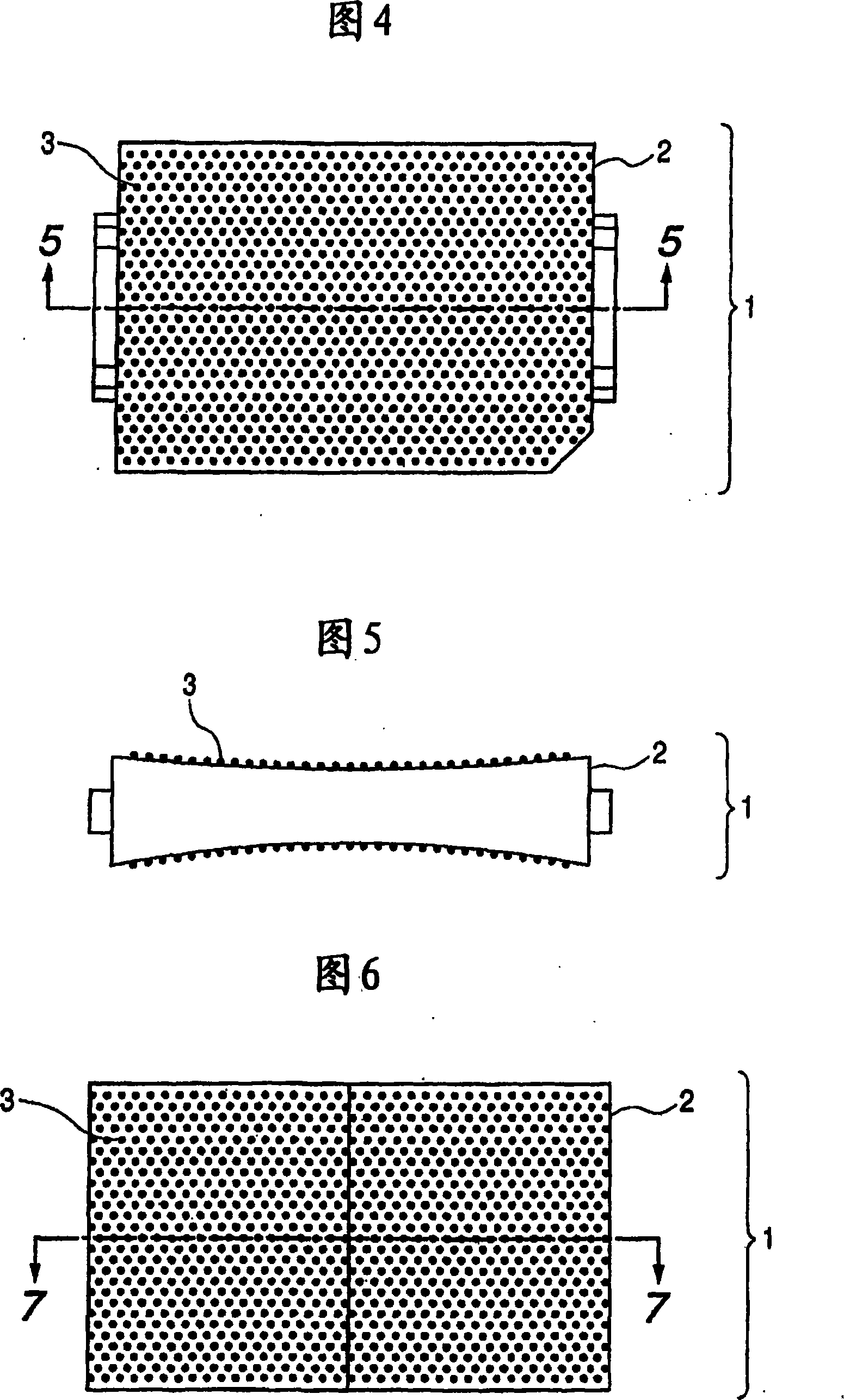

Optical Device, Method for Producing Master for Use in Producing Optical Device, and Photoelectric Conversion Apparatus

InactiveUS20080265149A1Good light transmissionLight utilization efficiencyDecorative surface effectsFinal product manufactureEllipsePhotoelectric conversion

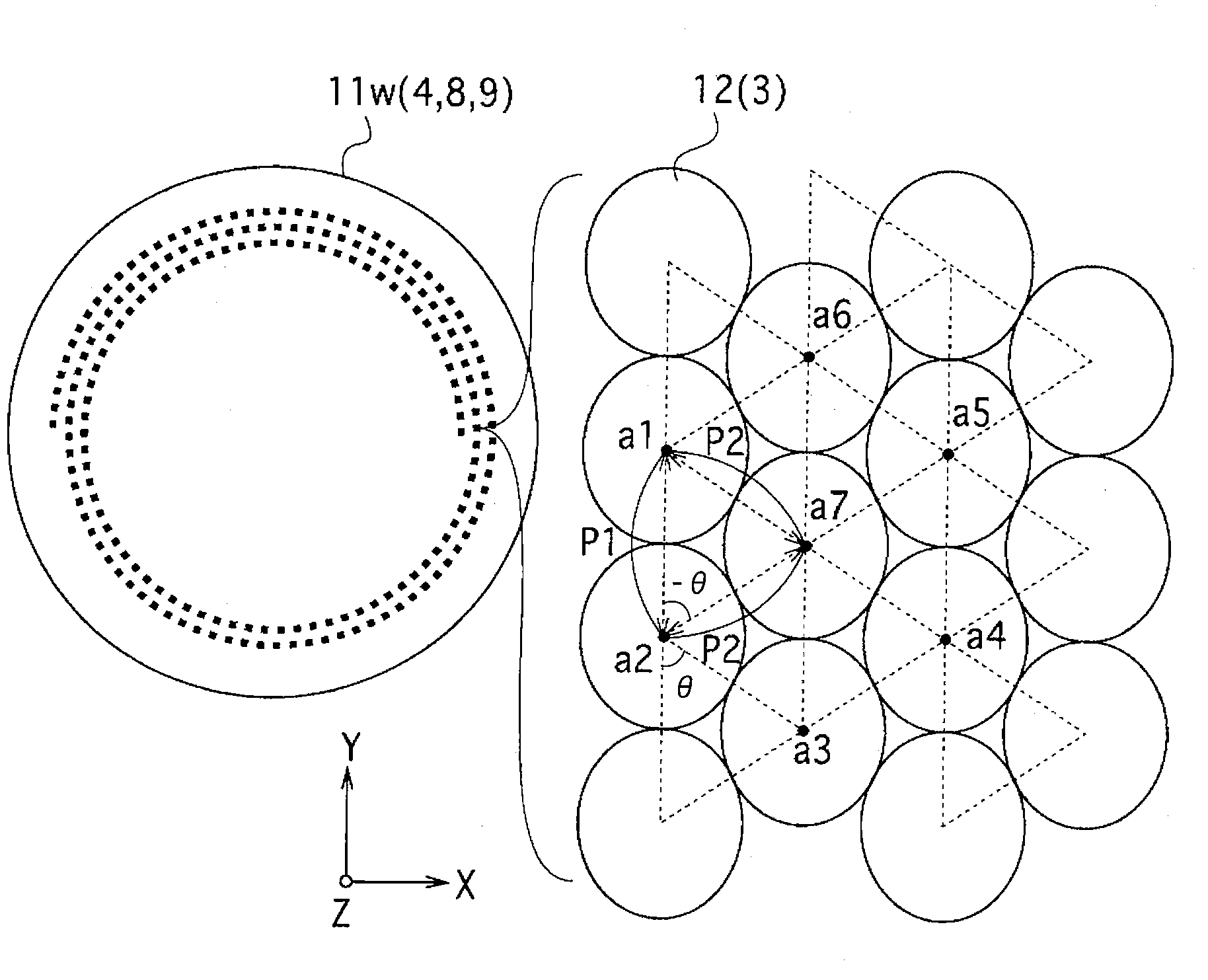

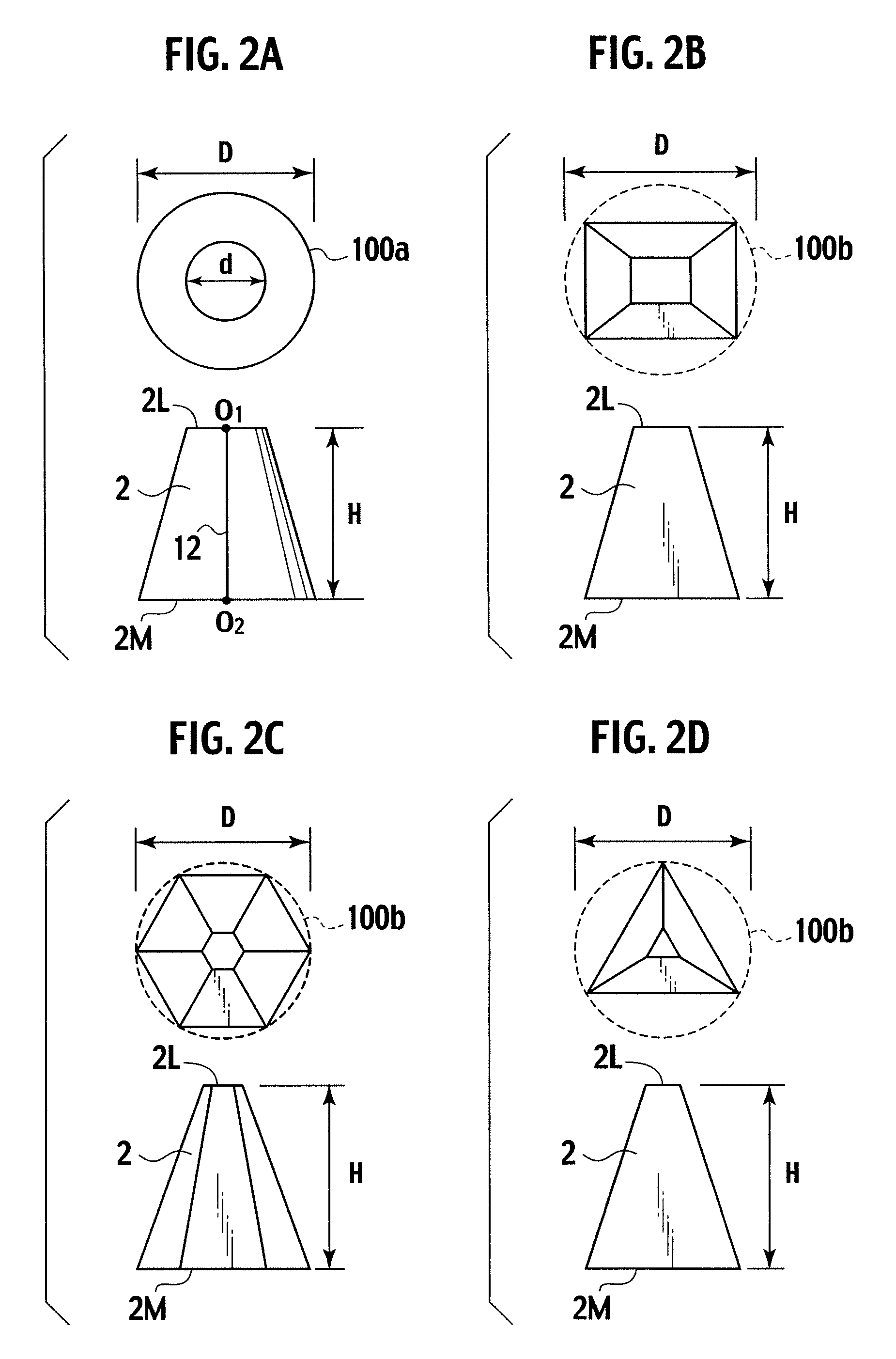

In an optical device, a number of structures having higher portions or lower portions are arranged at a fine pitch equal to or shorter than a wavelength of visible light on a surface of a base. Each of the structures is arranged to form a plurality of arc track rows on the surface of the base, and to form a quasi-hexagonal lattice pattern, and the structure has an elliptical cone or truncated elliptical cone shape having a major axis in a circumferential direction of the arc tracks.

Owner:SONY CORP +1

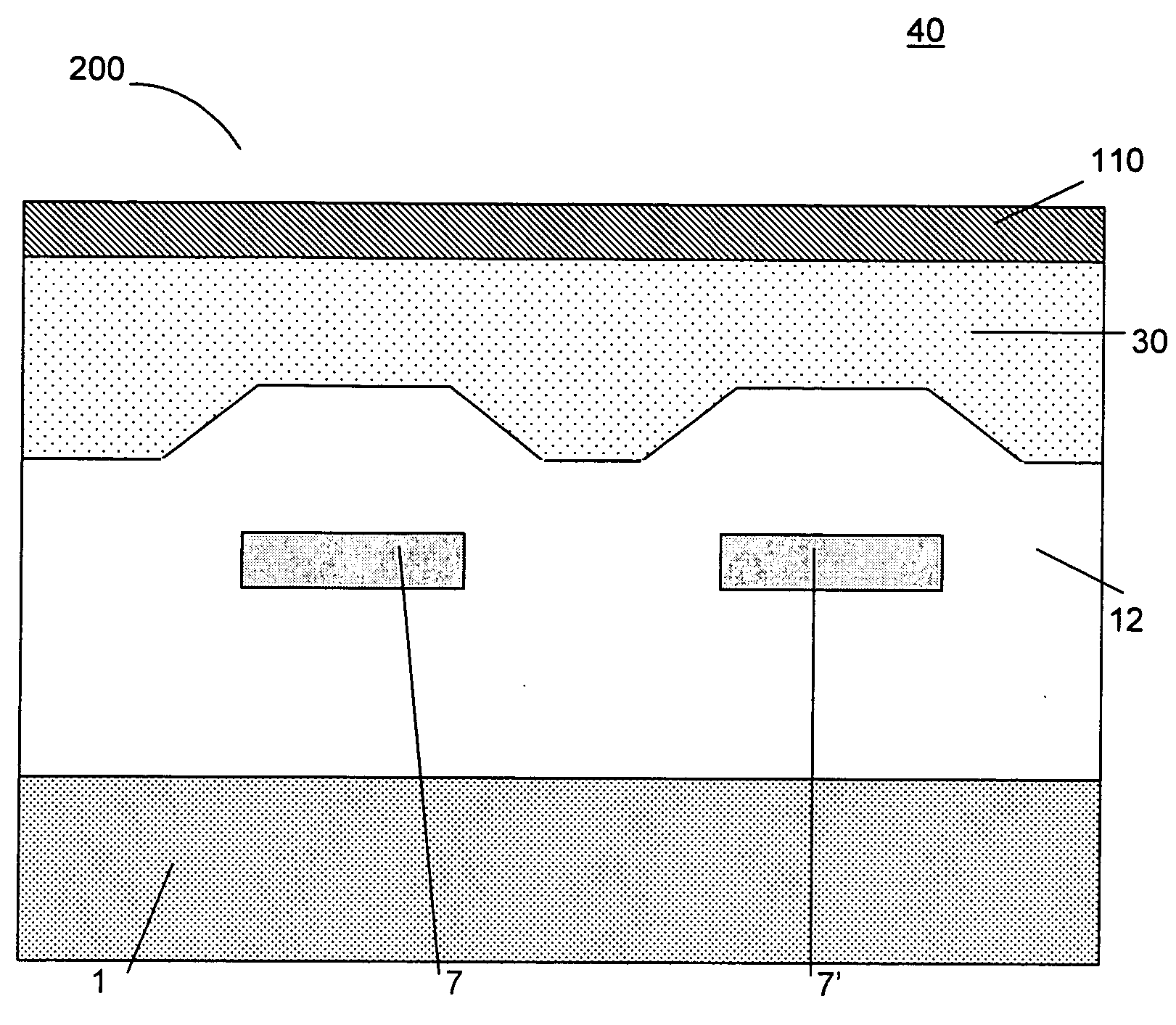

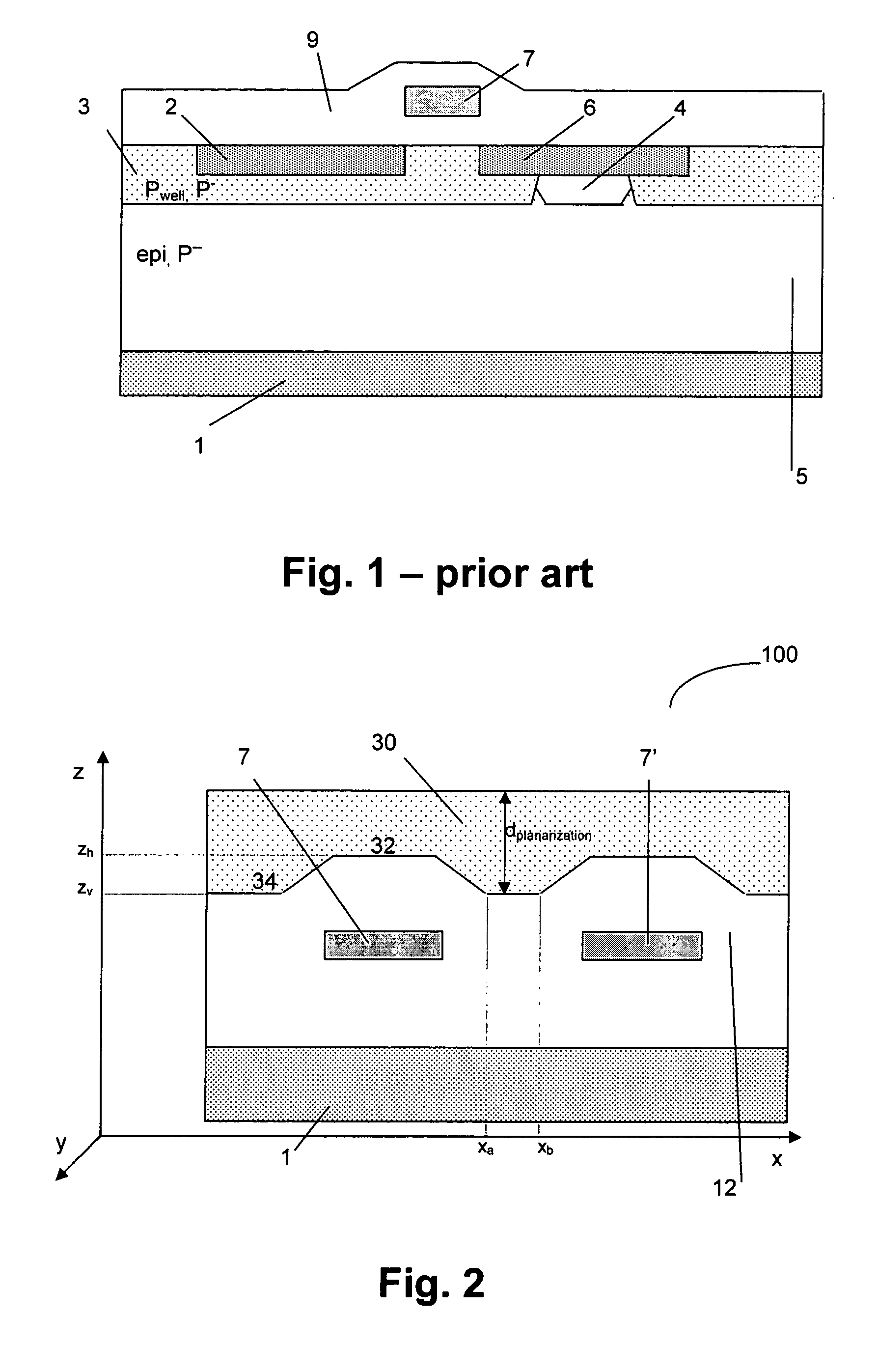

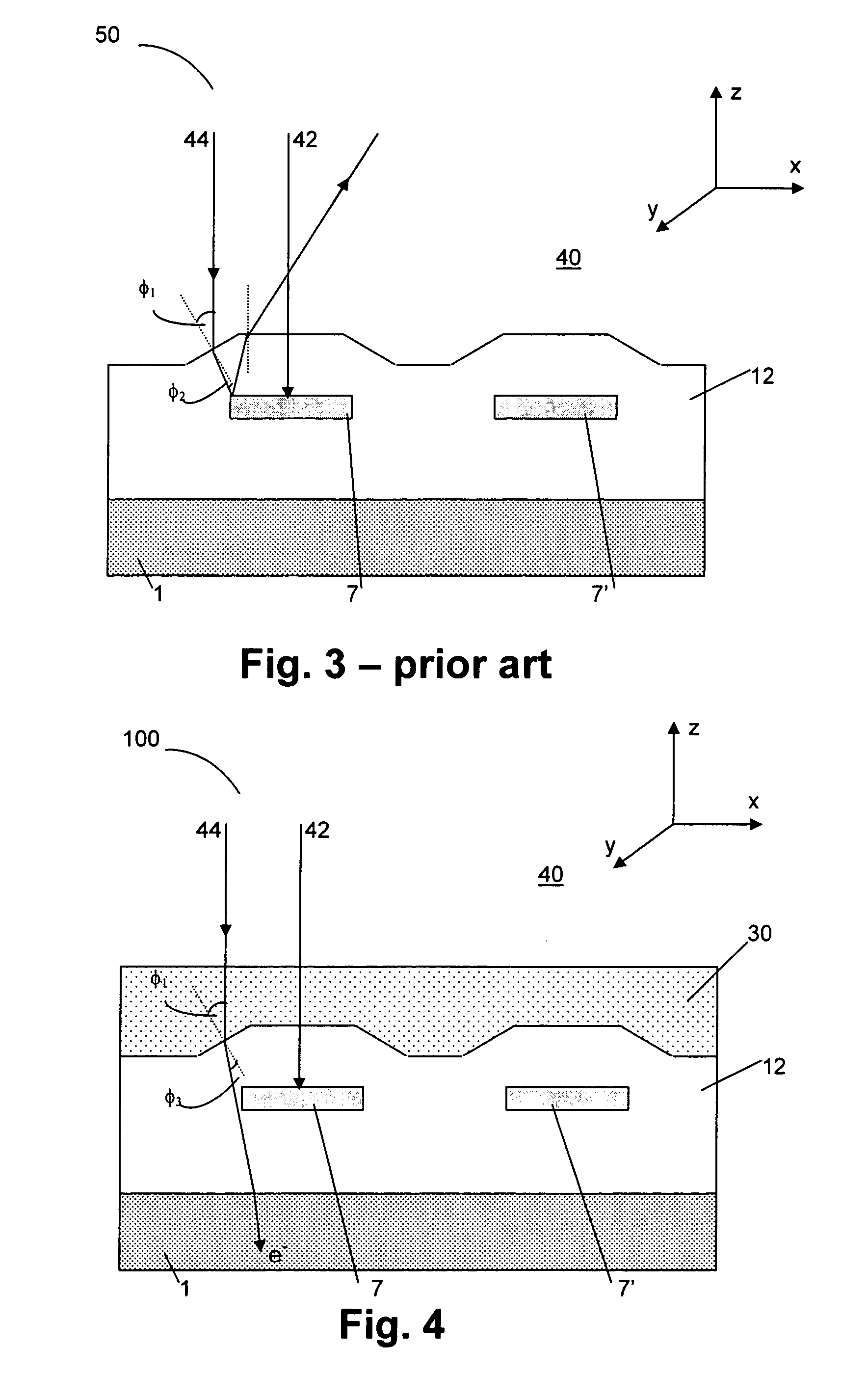

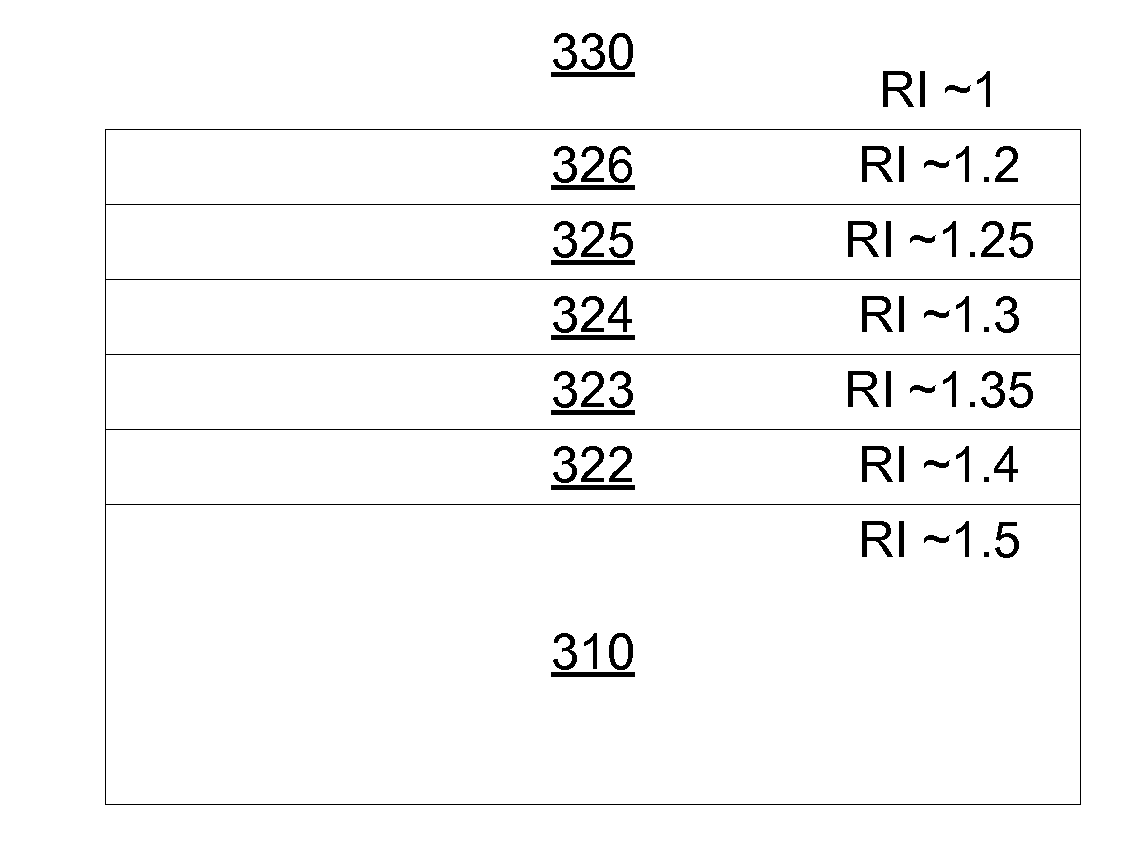

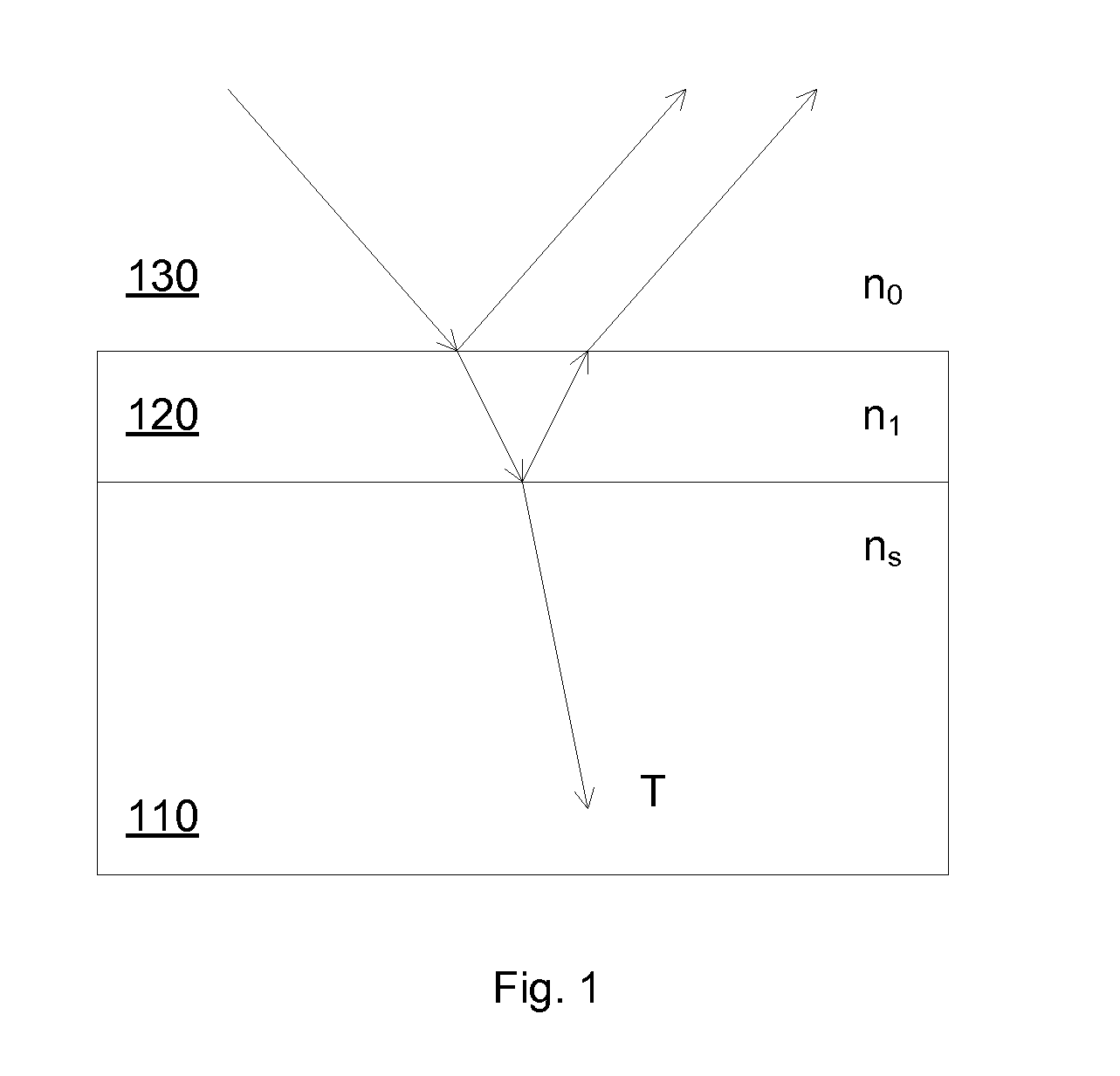

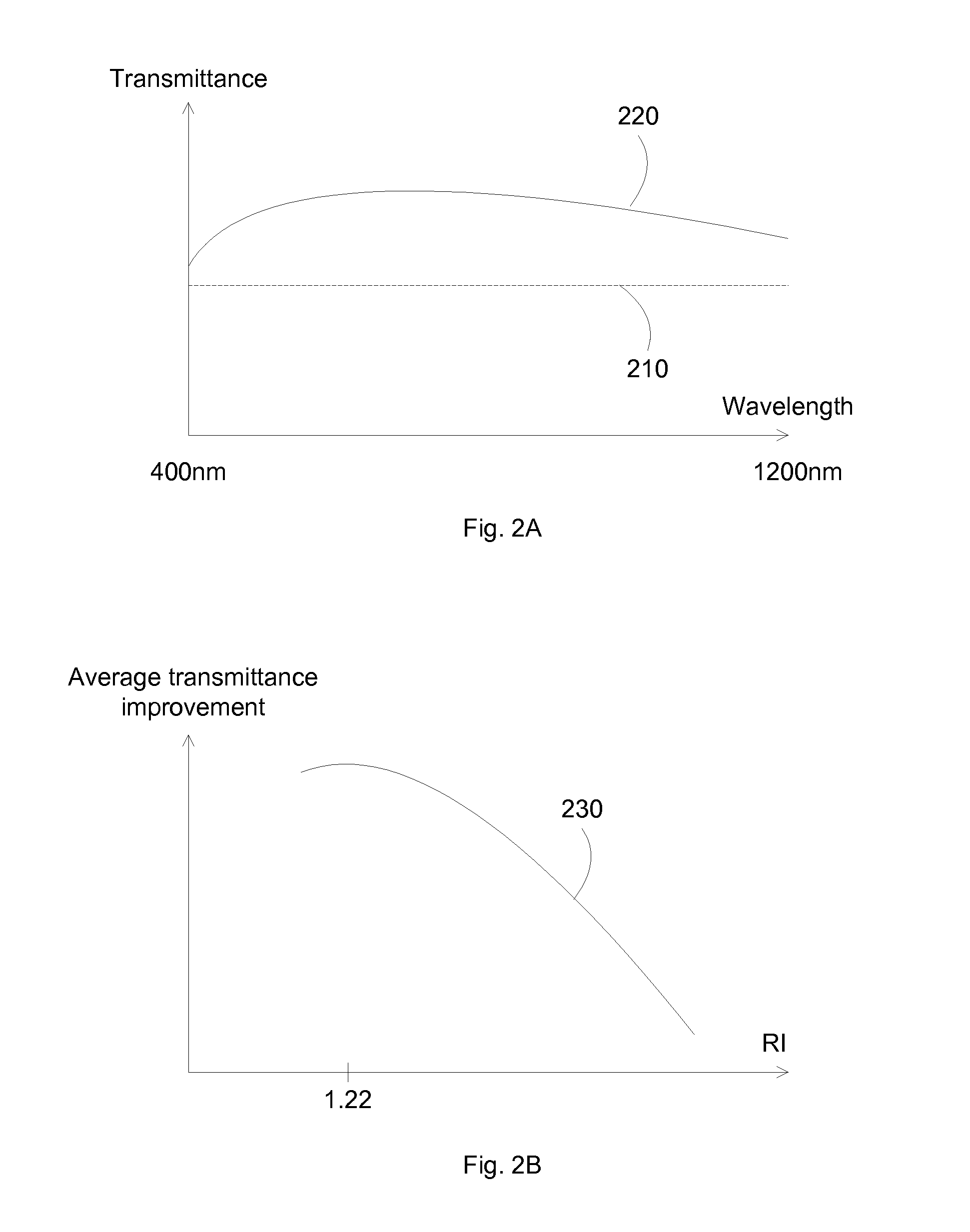

Planarization of an image detector device for improved spectral response

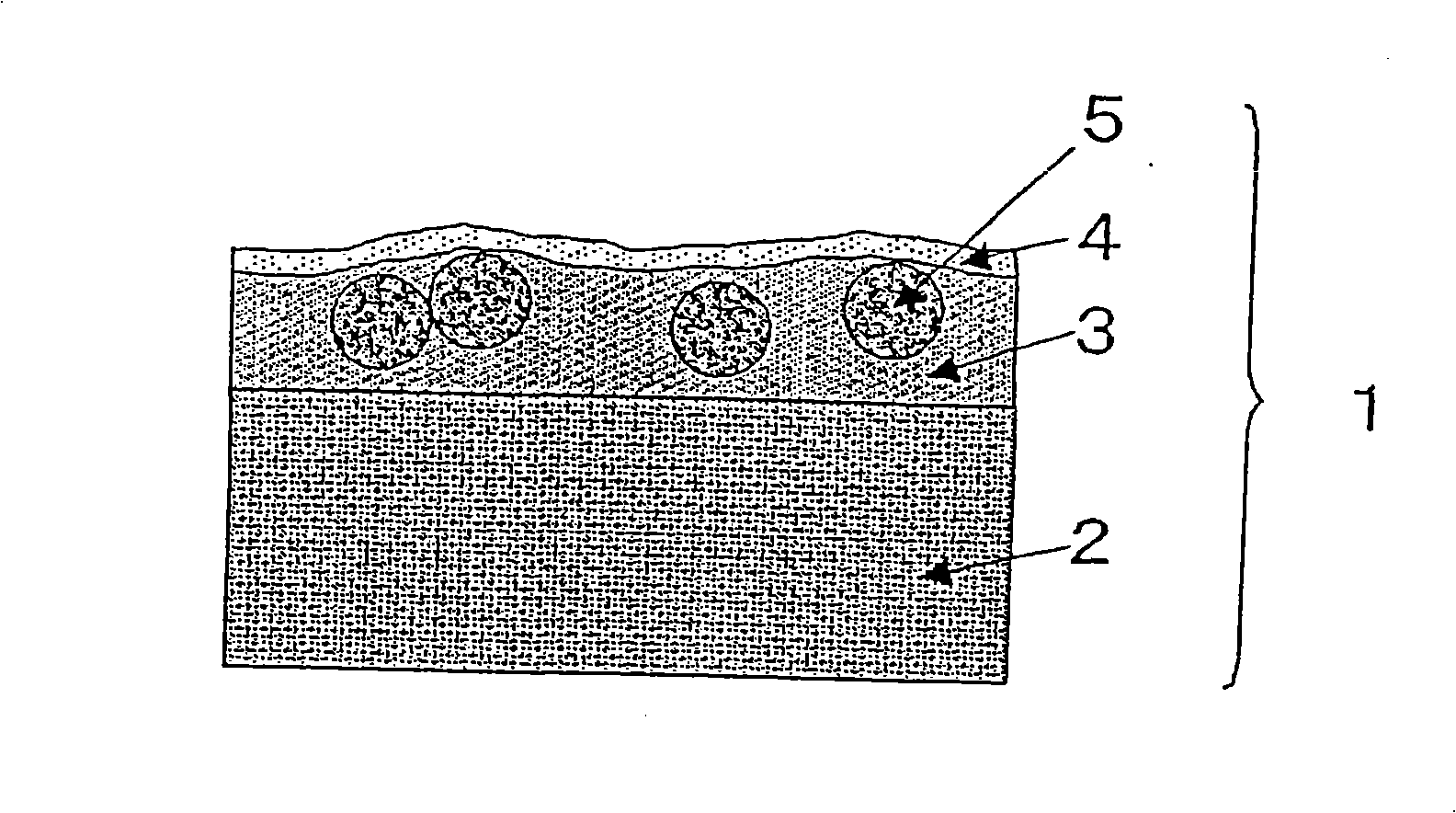

InactiveUS20050110050A1Improve quantum efficiencyImprove response efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyAnti-reflective coating

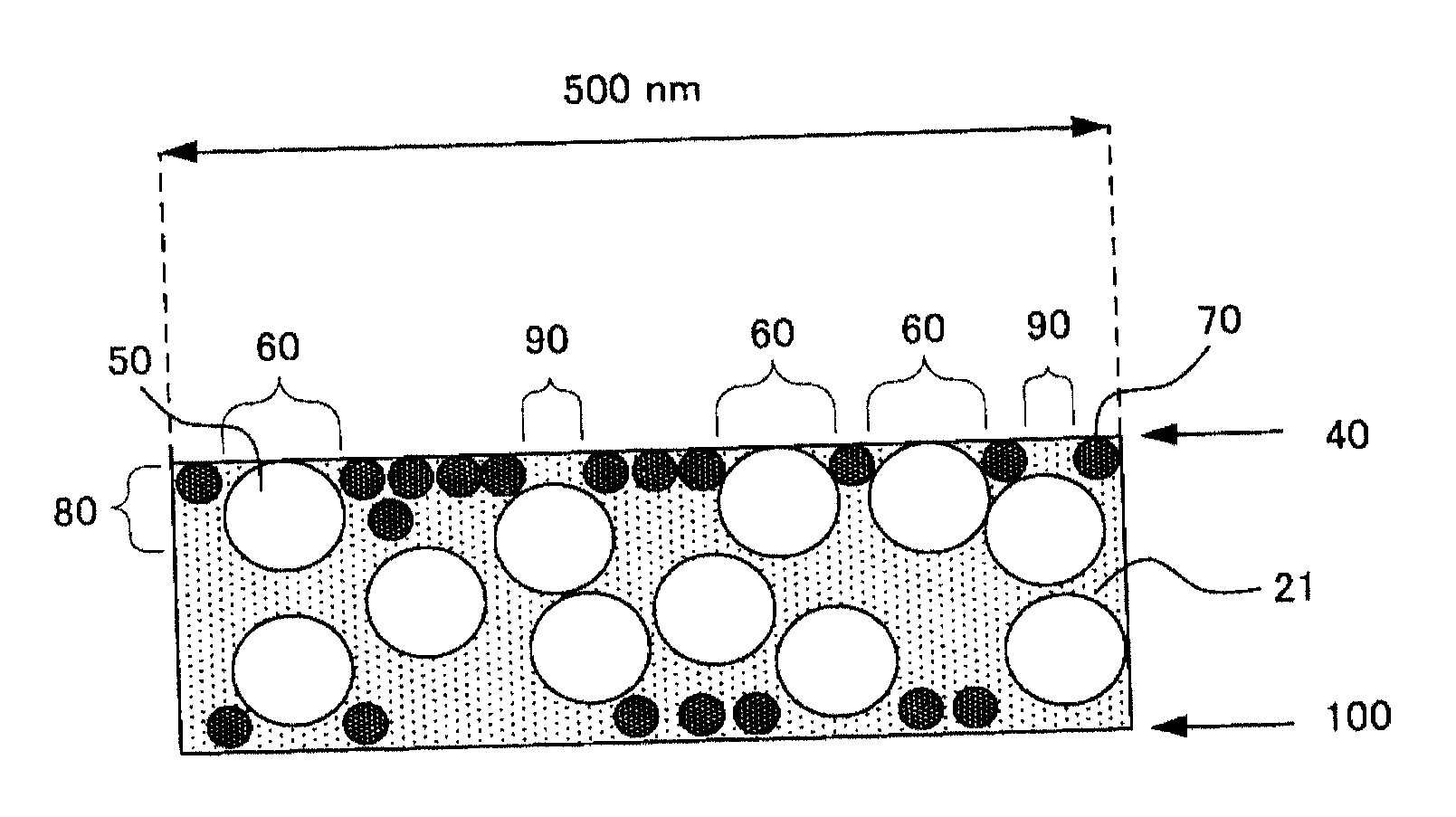

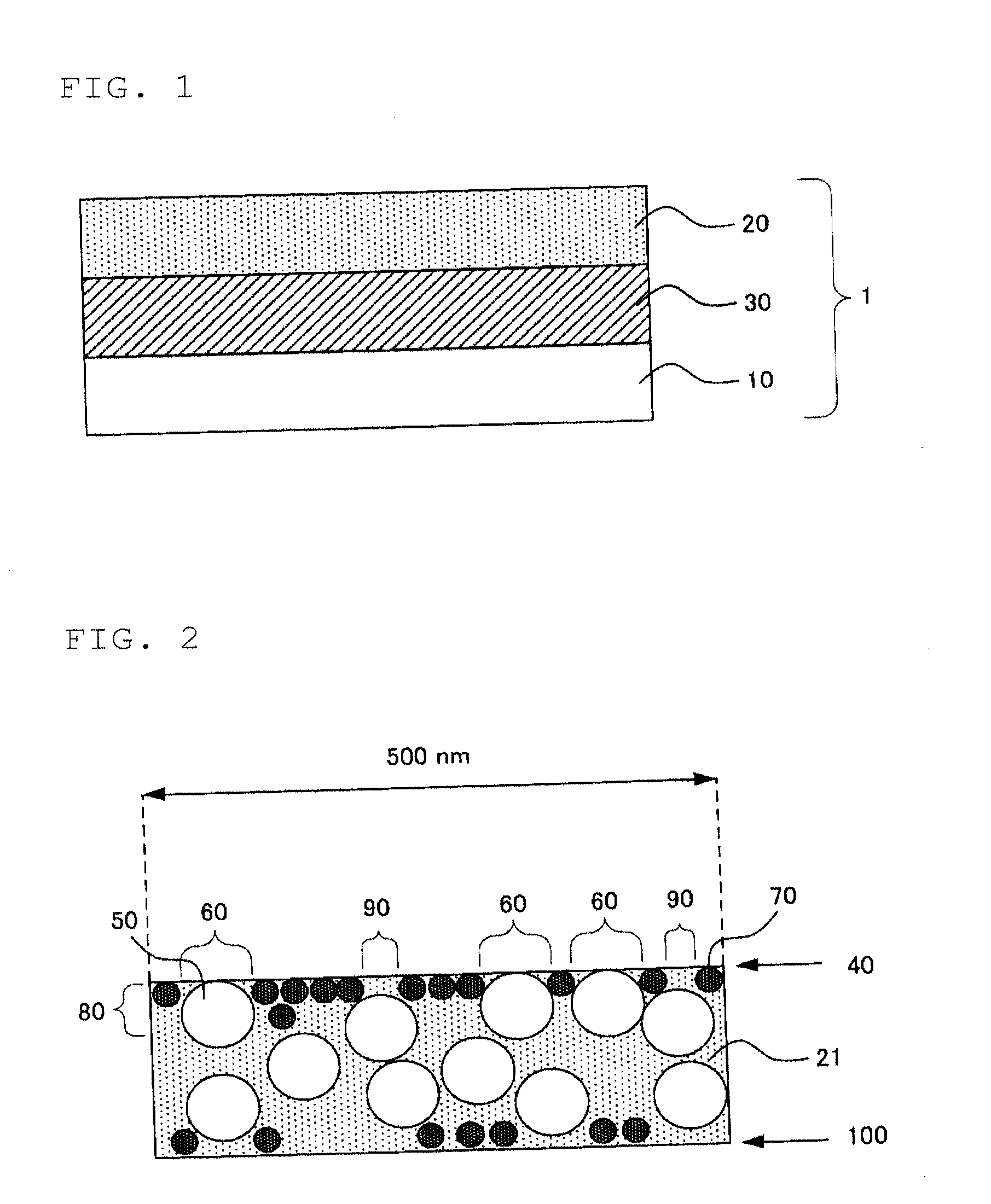

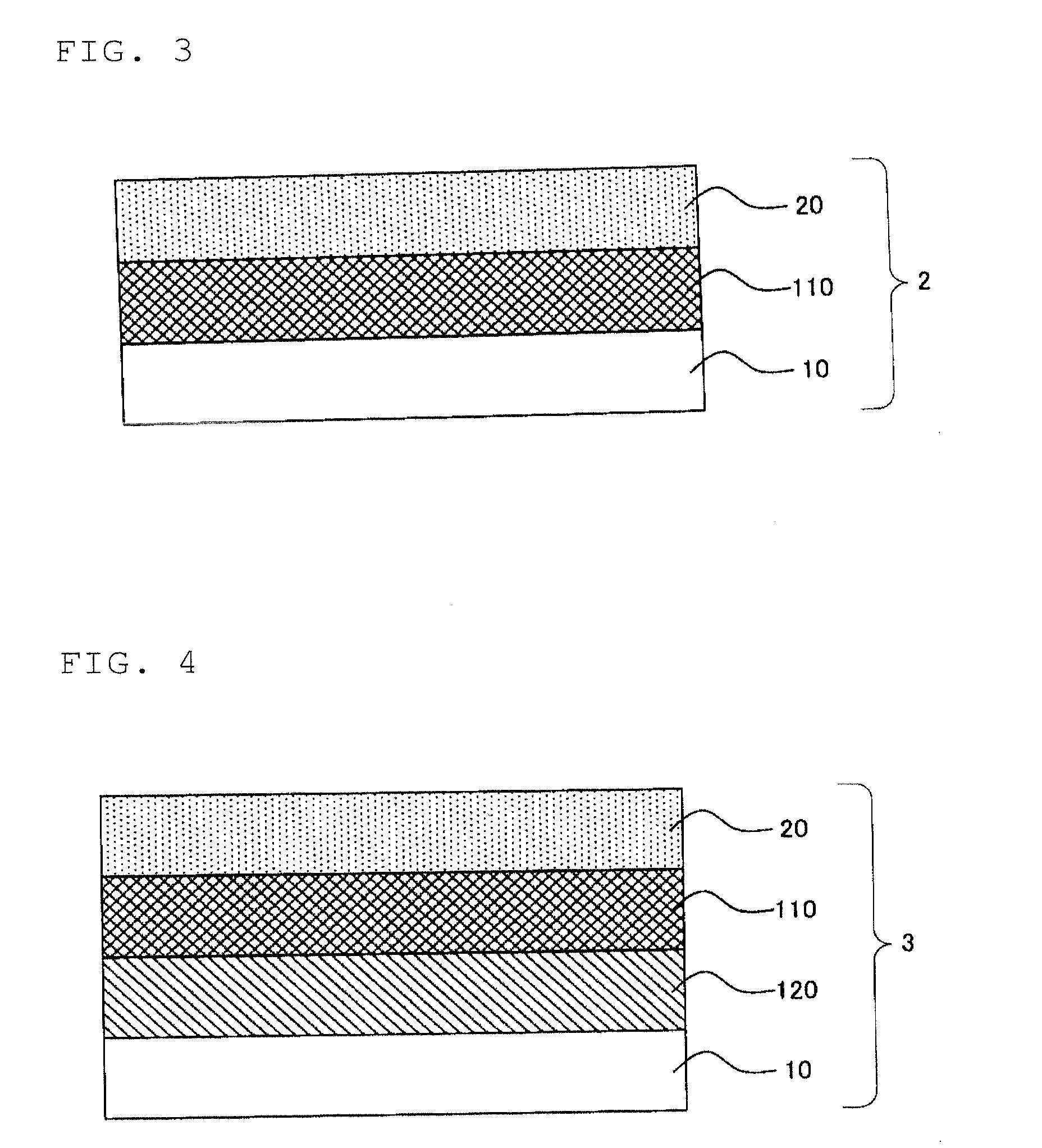

An image sensor device (100) is described comprising a semiconductor substrate (1), a MOS-based pixel structure and a planarization layer (30) on top. The planarization layer (30) is provided to avoid lensing due to the roughness of the pixel structure surface. The planarization layer (30) may be further optimized by adapting its thickness and refractive index to obtain anti-reflective coating properties for some regions in the image sensor device. This allows increasing the quantum efficiency and the spectral response of the image sensor device significantly.

Owner:CYPRESS SEMICONDUCTOR CORP (BELGIUM) BVBA

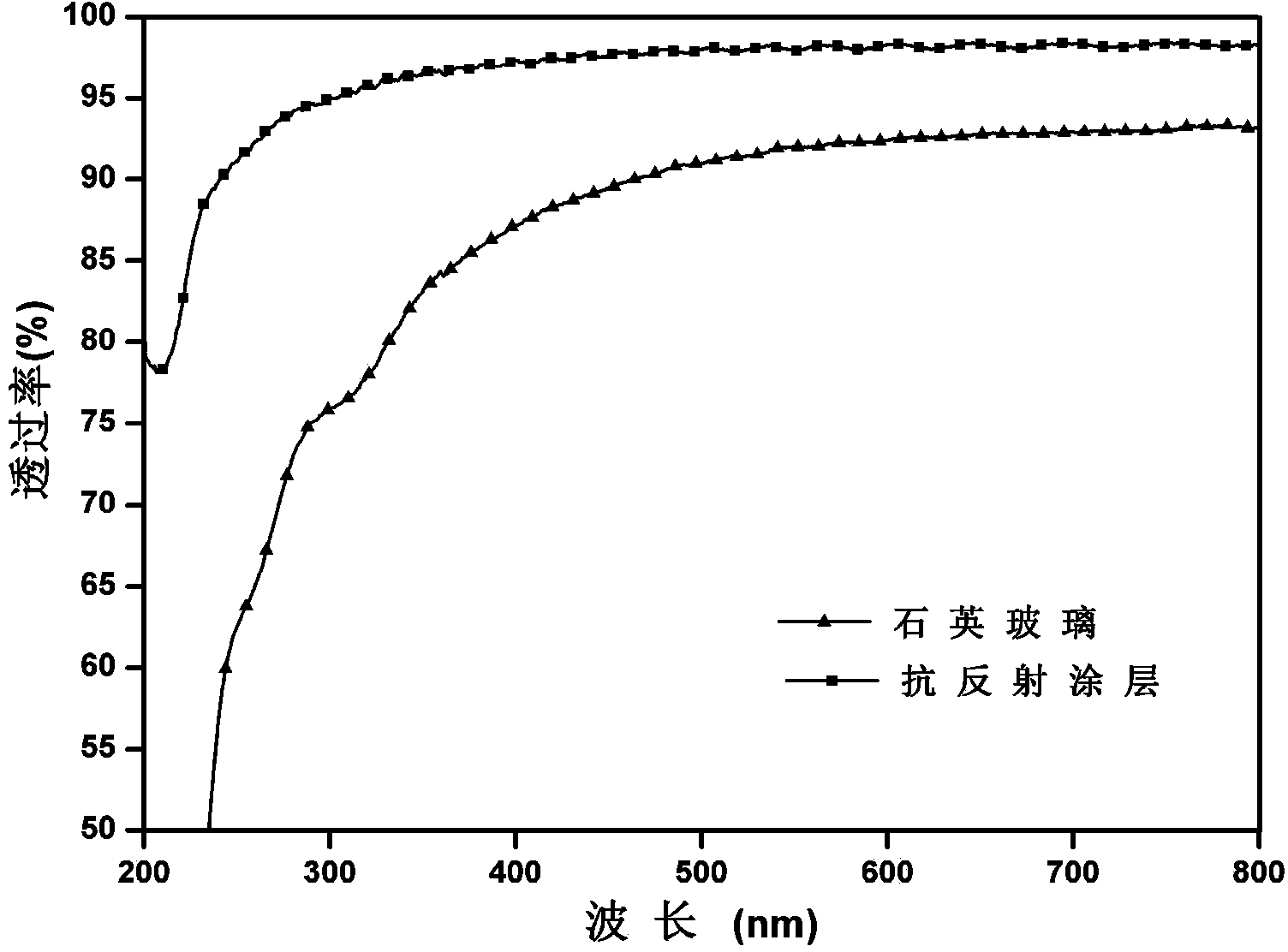

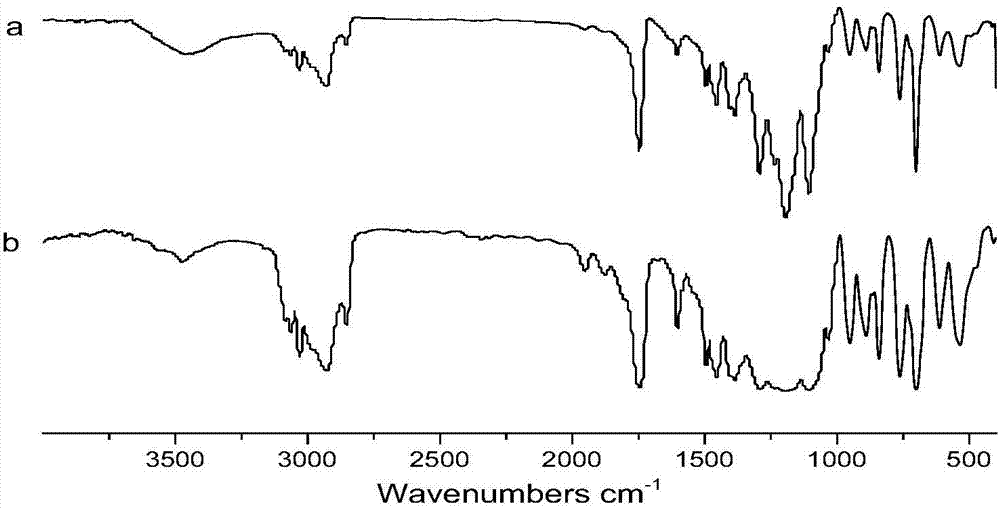

Novel antireflective coatings with graded refractive index

InactiveUS20140009834A1Improve anti-reflection abilityImprove propertiesCoatingsOptical elementsPorosityChemical treatment

One or more coated layers having a variation in index of refraction can provide improvements in antireflection property. For example, different sol gel formulations can be employed in a multiple coating step approach to achieve a desired gradation of index of refraction using individual or combinations of particles containing sol formulations. Different organic porosity forming agents, surfactants and binders can be used to provide further control in forming the gradual index of refraction. In addition, different heat and chemical treatment conditions could also provide control over the gradation of index of refraction.

Owner:GUARDIAN GLASS LLC +1

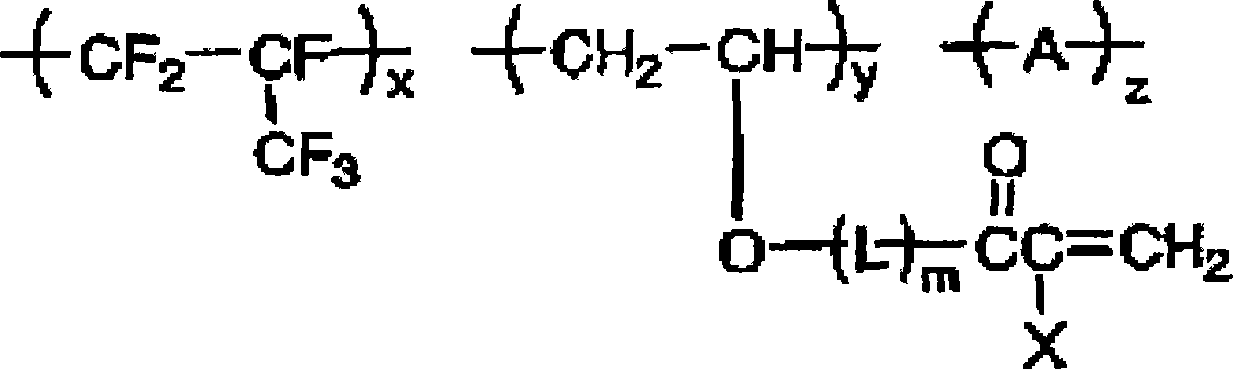

Curable composition, cured film, antireflection film, polarizing plate and liquid crystal display

InactiveUS20070116970A1Improve anti-reflection abilityIncreased durabilityLiquid crystal compositionsDiffusing elementsLiquid-crystal displayHydrolysate

A curable composition is provided and contains (A) at least either a hydrolyzed product of organosilane or a condensation reaction product of the hydrolyzed product having a mass average molecular weight of from 500 to 10,000 in terms of ethylene glycol, (B) a fluorine-containing resin having a mass average molecular weight of 5,000 or more in terms of polystyrene, and a fluoroalkyl structure and a polysiloxane structure, and (C) a silane coupling agent represented by a prescribed formula or at least either a hydrolyzed product of the silane coupling agent or a condensation reaction product of the hydrolyzed product.

Owner:FUJIFILM CORP

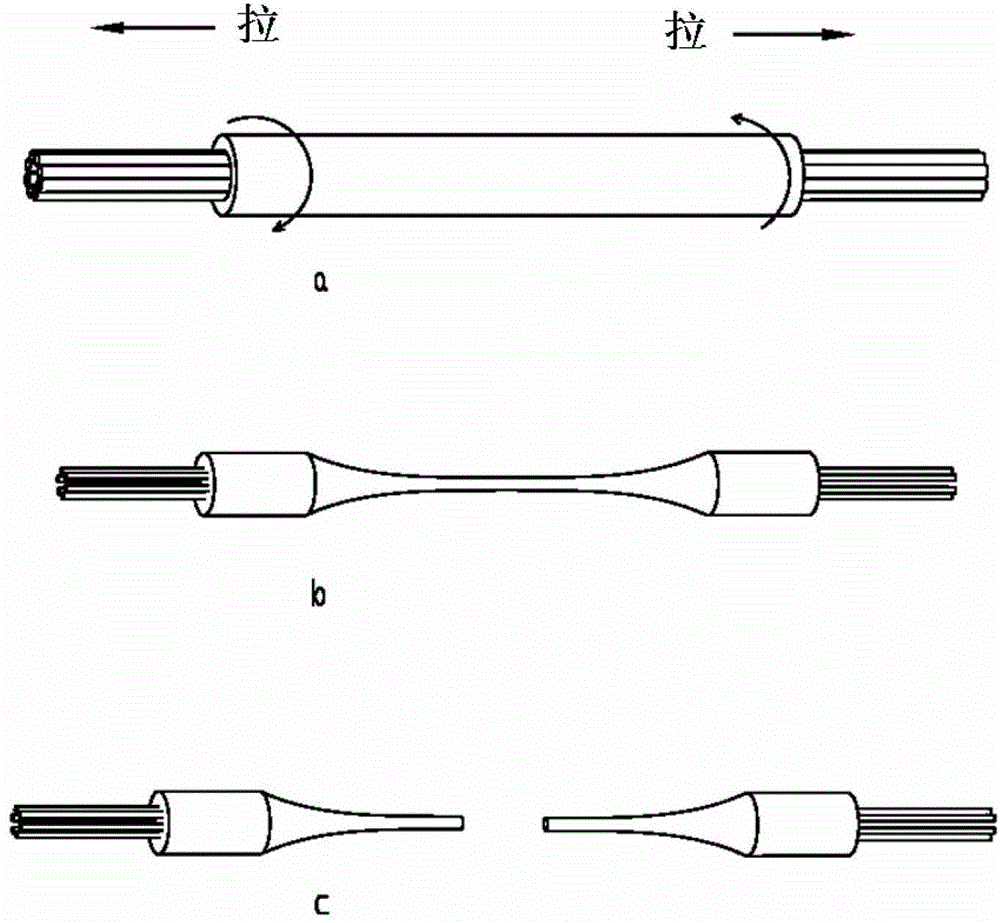

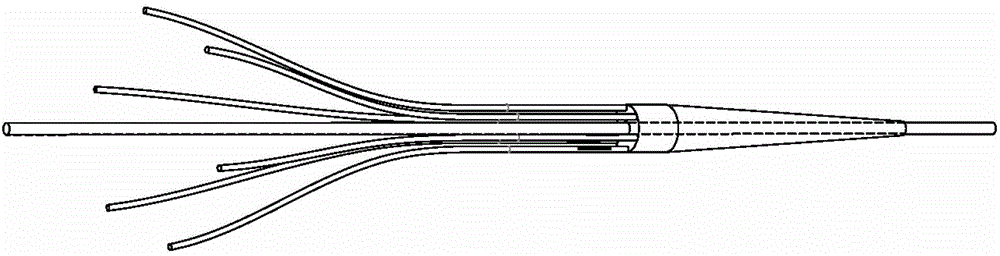

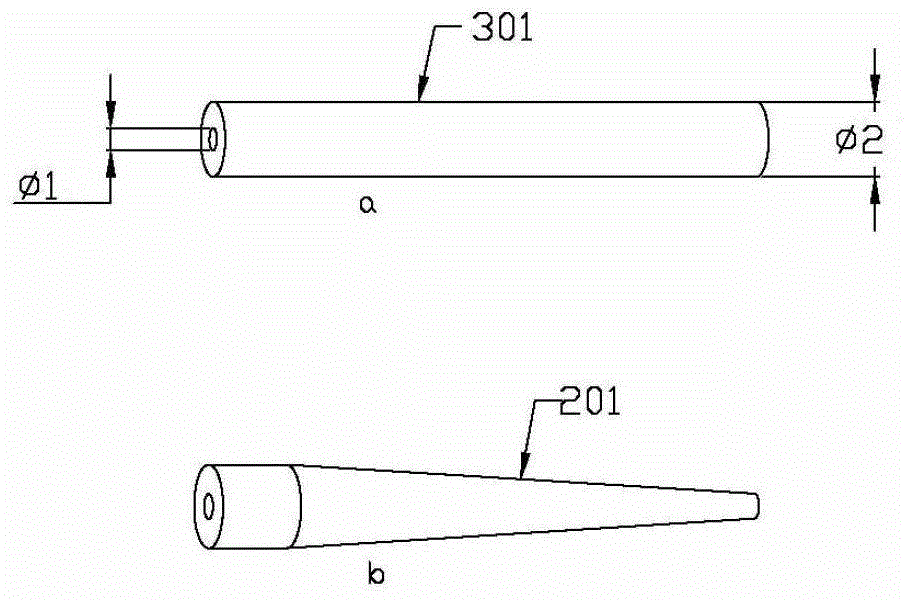

Pump fiber combiner manufacturing method for large power fiber laser

ActiveCN103336333AImprove efficiencyImprove anti-reflection abilityCoupling light guidesLaser fiberEngineering

The invention relates to a pump fiber combiner manufacturing method for a large power fiber laser. The pump fiber combiner manufacturing method comprises steps of: 1), selecting a quartz capillary; 2), processing the quartz capillary; 3), tabulating; 4), welding; and 5), packaging. The pump fiber combiner manufacturing method realizes omission of a fusion tapering process, generates no fiber deformation, greatly reduces insertion loss and improves pump efficiency.

Owner:DANYANG JUCHEN OPTOELECTRONICS TECH

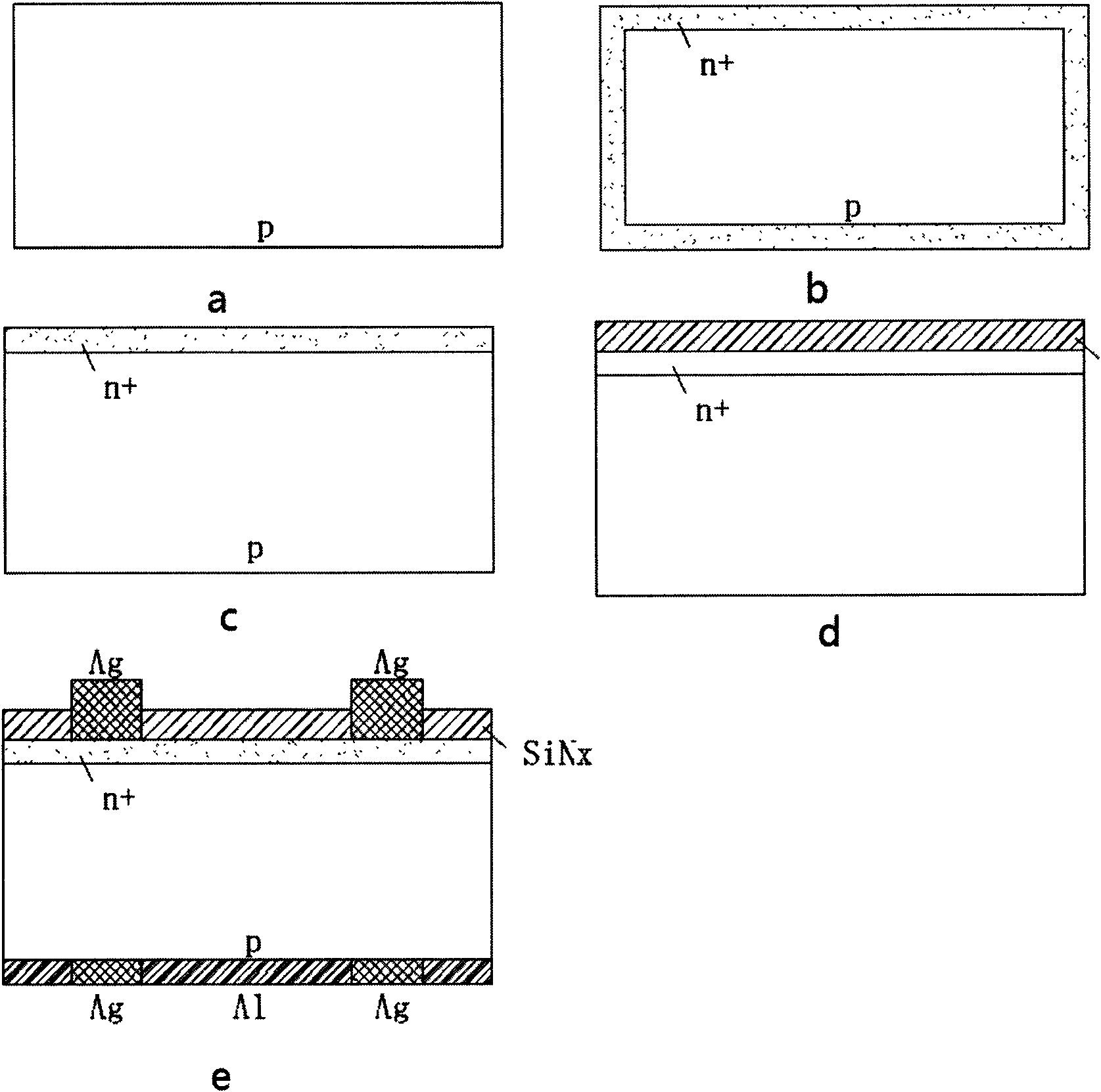

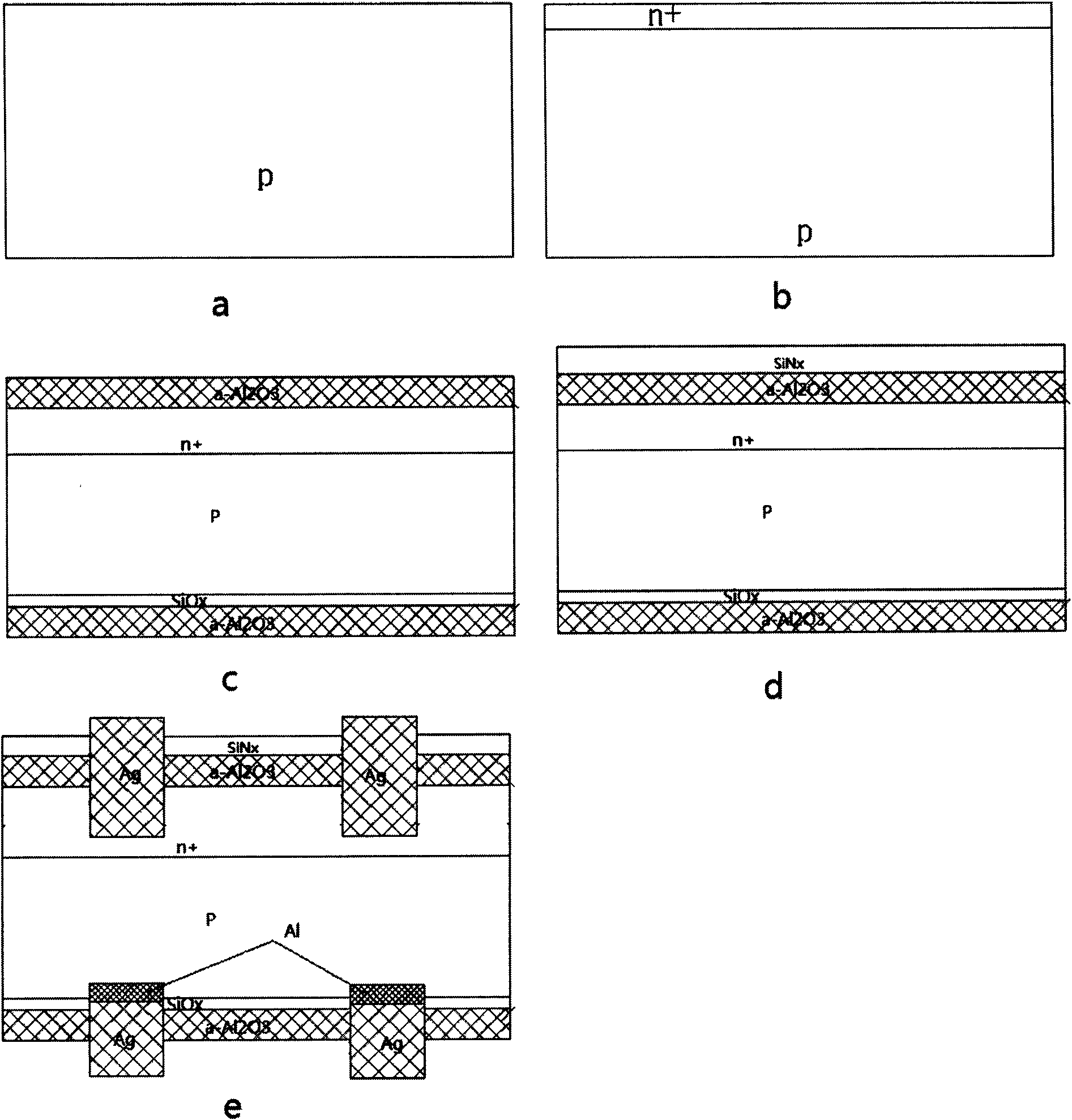

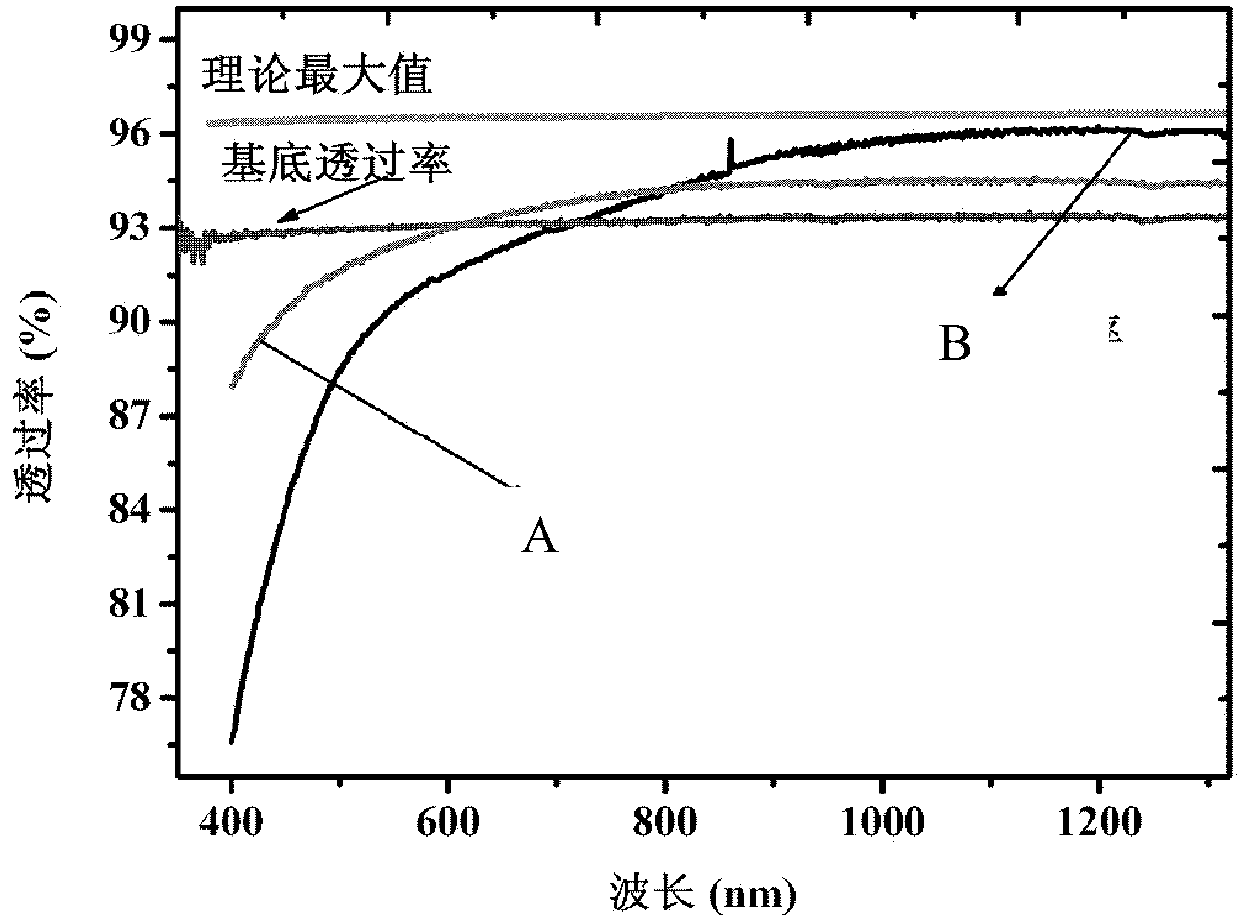

Crystalline silicon solar cell and preparation method thereof

ActiveCN102122674APromote passivationImprove anti-reflection abilityFinal product manufacturePhotovoltaic energy generationSilver electrodeSilicon oxide

The invention discloses a crystalline silicon solar cell and a preparation method thereof, and the crystalline silicon solar cell comprises a pn plus junction silicon substrate, wherein a first amorphous alumina layer and an amorphous silicon nitride layer are arranged on the surface of an n plus emitter, a silver electrode penetrates the amorphous silicon nitride layer and the first amorphous alumina layer and is connected with the n plus emitter, a composite passivation medium layer is arranged on the surface of a p type substrate, the p type substrate comprises a silicon oxide layer and a second amorphous alumina layer, and a p type substrate is in contact with a back electrode. The preparation method comprises the special preparation of the composite passivation medium layer, nitric acid and hydrogen peroxide solution are adopted for processing the surface of the p type substrate, the sol-gel process is adopted for preparing the second amorphous alumina layer, and the composite passivation medium layer (4) is formed after annealing. The crystalline silicon solar cell has the advantages of simple process, low equipment investment, good passivation and anti-reflection performances of the front surface, excellent passivation effect of the composite passivation medium layer on the back surface, capability of improving the utilization efficiency of long waves, and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Optical transparent member and optical system using the same

InactiveCN1834693AImprove anti-reflection effectLong-term corrosion resistanceLayered productsRecord information storageMaterials scienceCrystal

It is an object to provide an optical transparent member capable of maintaining a high-performance antireflection effect for a base over a long period of time, and an optical system using the same, specifically an optical transparent member including on a base, a layer containing SiO 2 as a main component, a layer containing Al 2 O 3 as a main component, and a plate crystal layer formed from plate crystals containing Al 2 O 3 as a main component, wherein the surface of the plate crystal layer has a shape of irregularities, and an optical system using the same.

Owner:CANON KK +1

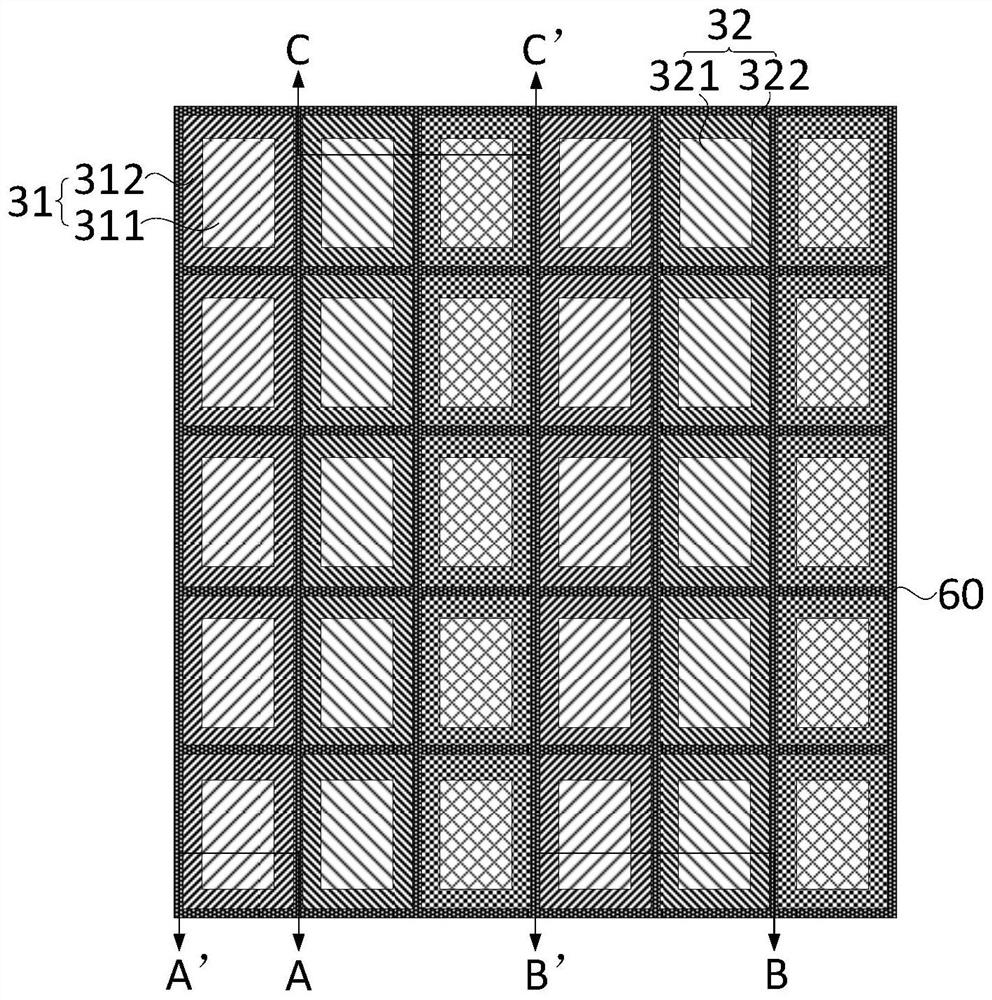

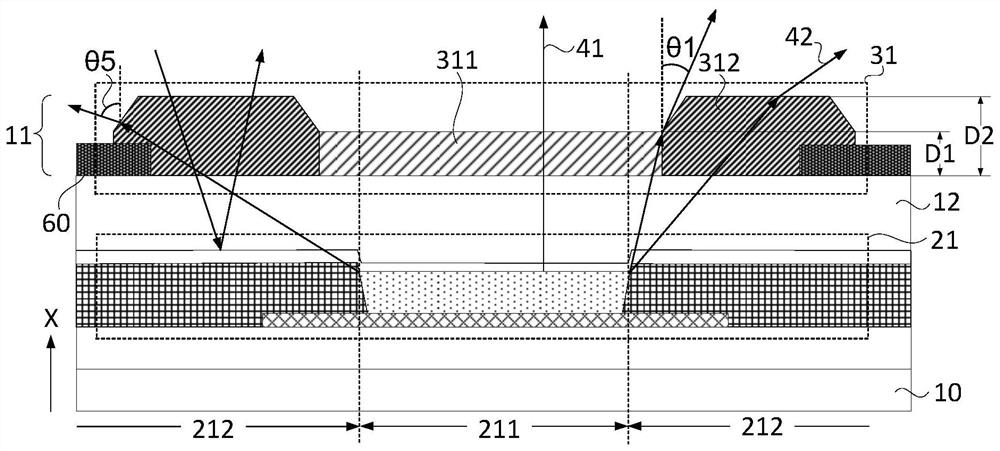

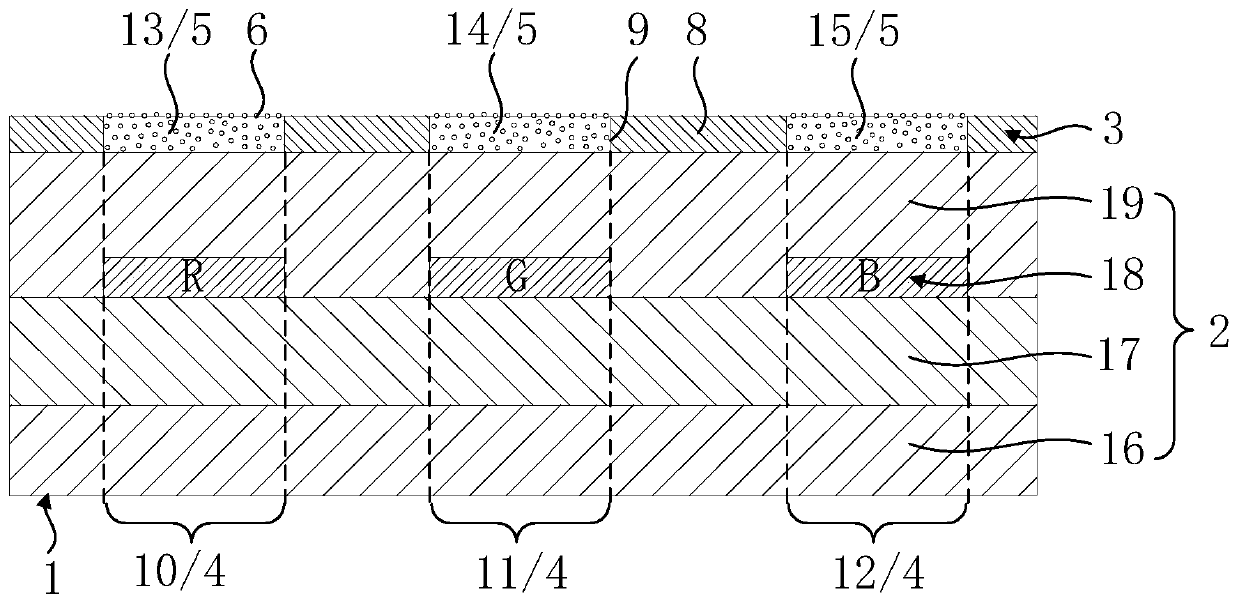

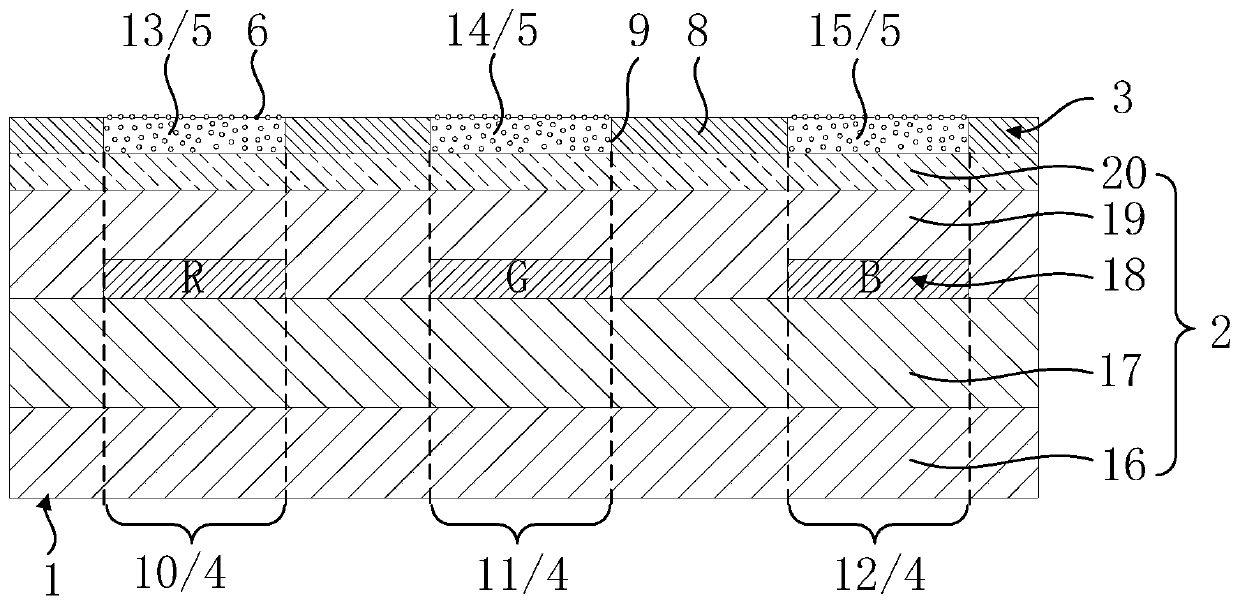

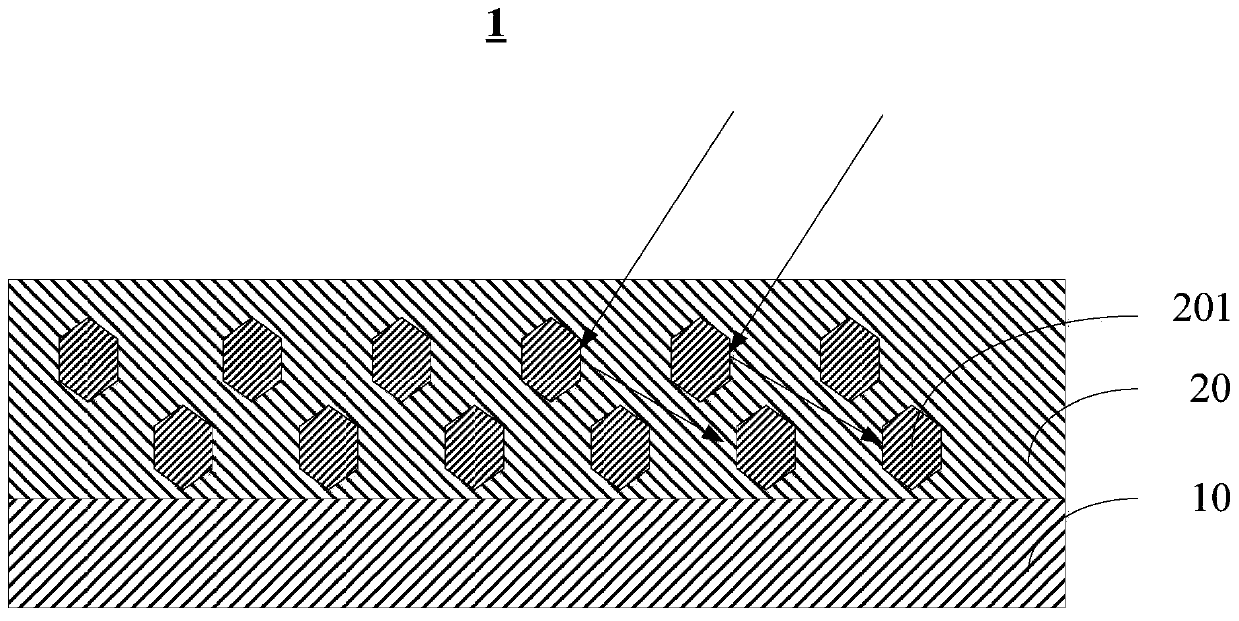

Display panel and display device

ActiveCN111969032AImprove transmittanceReduce transmittanceSolid-state devicesSemiconductor devicesColor filmMaterials science

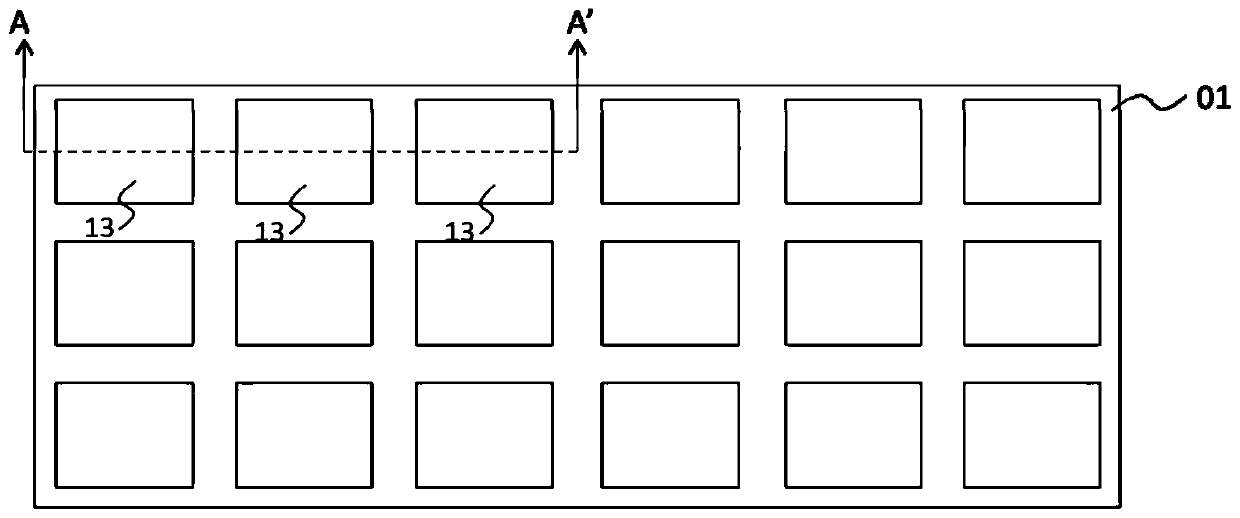

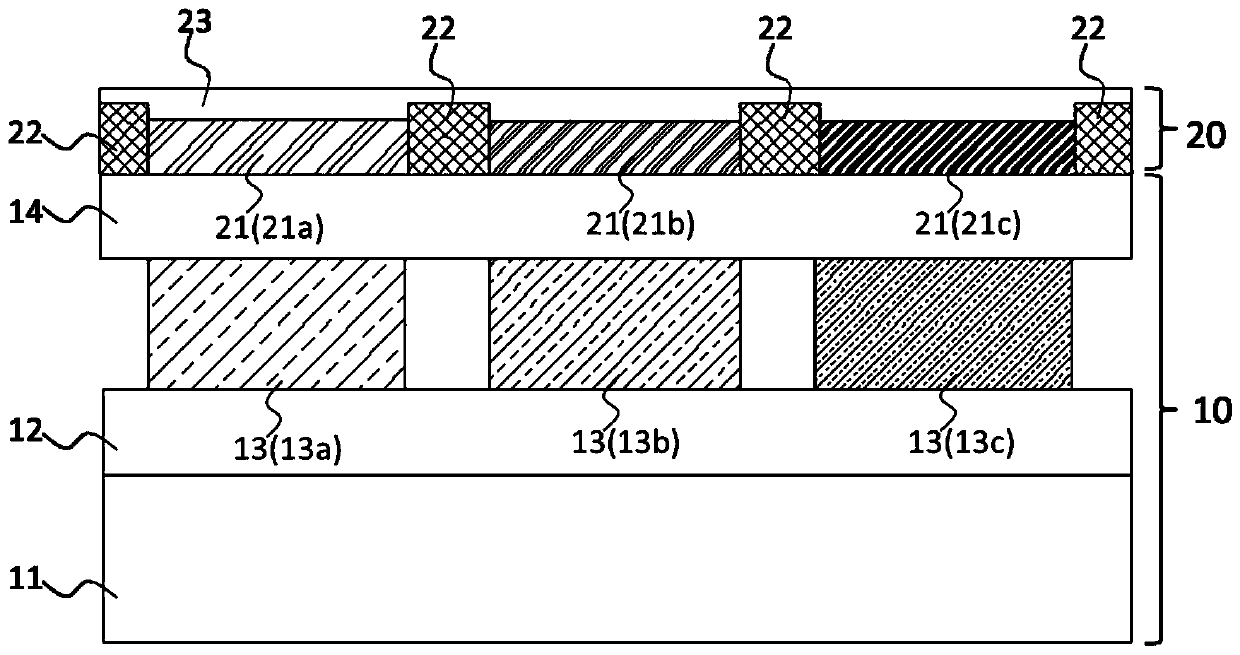

The invention discloses a display panel and a display device. The display panel comprises a substrate, a plurality of sub-pixels and a color film layer, each sub-pixel comprises an opening area and anon-opening area. The color film layer comprises a plurality of color resistance blocks; the sub-pixels comprise first sub-pixels; the color resistance blocks comprise a first color resistance block;the first color resistance block corresponds to the first sub-pixel; the first color resistance block comprises a first light-transmitting part and a second light-transmitting part; the projection ofthe first light-transmitting part on the plane where the substrate is located is at least partially overlapped with the projection of the opening area of the first sub-pixel on the substrate; the projection of the second light-transmitting part on the plane where the substrate is located is at least partially overlapped with the projection of the non-opening area of the first sub-pixel on the substrate, and the transmittance of the first light-transmitting part to the light of the first color is larger than that of the second light-transmitting part to the light of the first color. According to the display panel and the display device provided by the invention, the reflection of external ambient light is reduced, and the light extraction rate of the display panel is increased.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

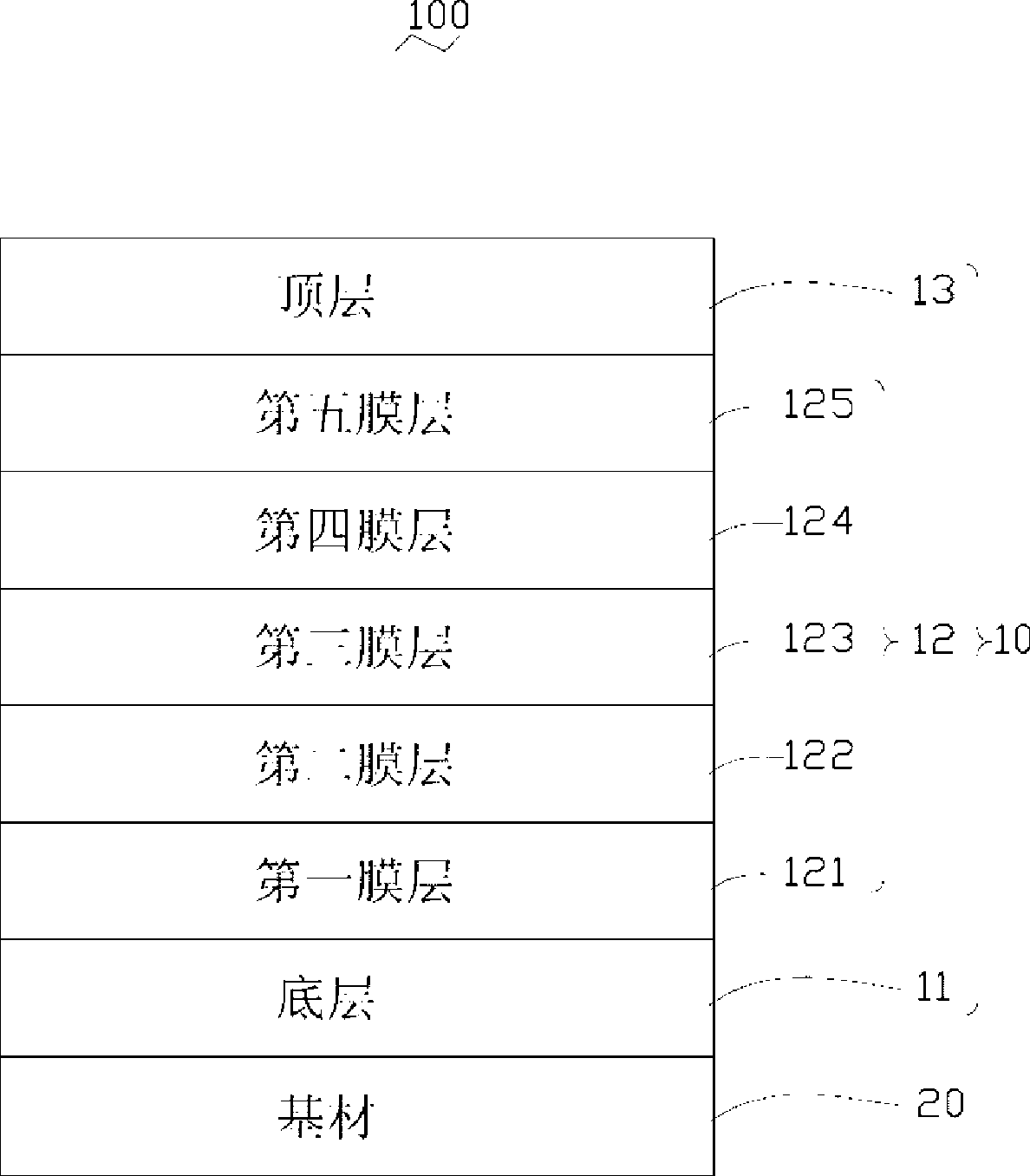

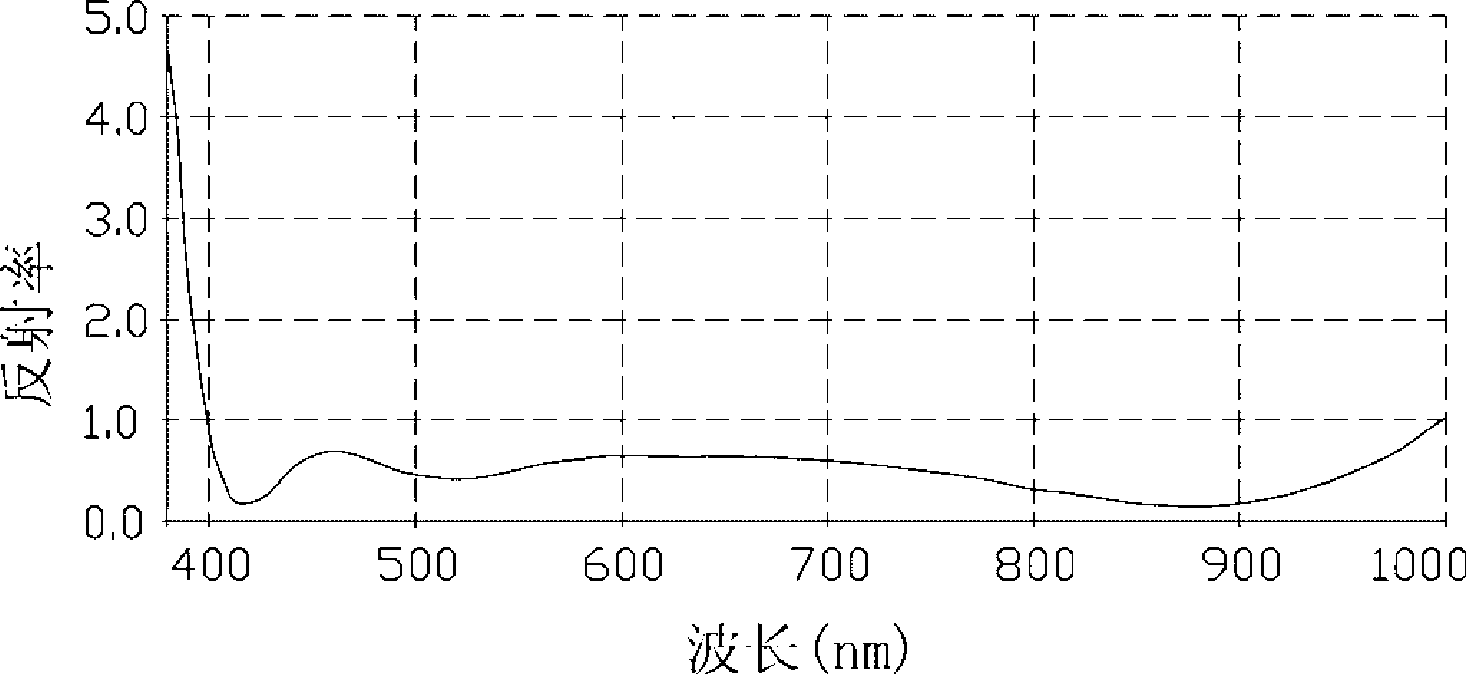

Wide-band antireflective film and optical element with the wide-band antireflective film

InactiveCN101393276AReduce reflectivityImprove anti-reflection effectCoatingsOptical elementsRefractive indexBroadband

The invention relates to a broadband anti-reflection film, which comprises a bottom layer, a widened layer and a top layer which are formed on the surface of an optical element in turn, wherein the bottom layer is an intermediate refractive index material layer the film thickness of which is between 0.95 and 1.05 d; the top layer is a low refractive index material layer the film thickness of which is between 0.95 and 1.05 d; the widened layer comprises a first film, a second film, a third film, a fourth film and a fifth film which are formed along the direction from the bottom layer to the top layer in turn; the first film is a high refractive index material layer the film thickness of which is between 0.311 and 0.343 d; the second film is a low refractive index material layer the film thickness of which is between 0.147 and 0.163 d; the third film is a high refractive index material layer the film thickness of which is between 1.561 and 1.725 d; the fourth film is a low refractive index material layer the film thickness of which is between 0.210 and 0.232 d; and the fifth film is a high refractive index material layer the film thickness of which is between 0.321 and 0.355 d, wherein d is equal to lambda / (4n), wherein lambda refers to the wavelength of incident light and n refers to the refractive index of a corresponding film.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

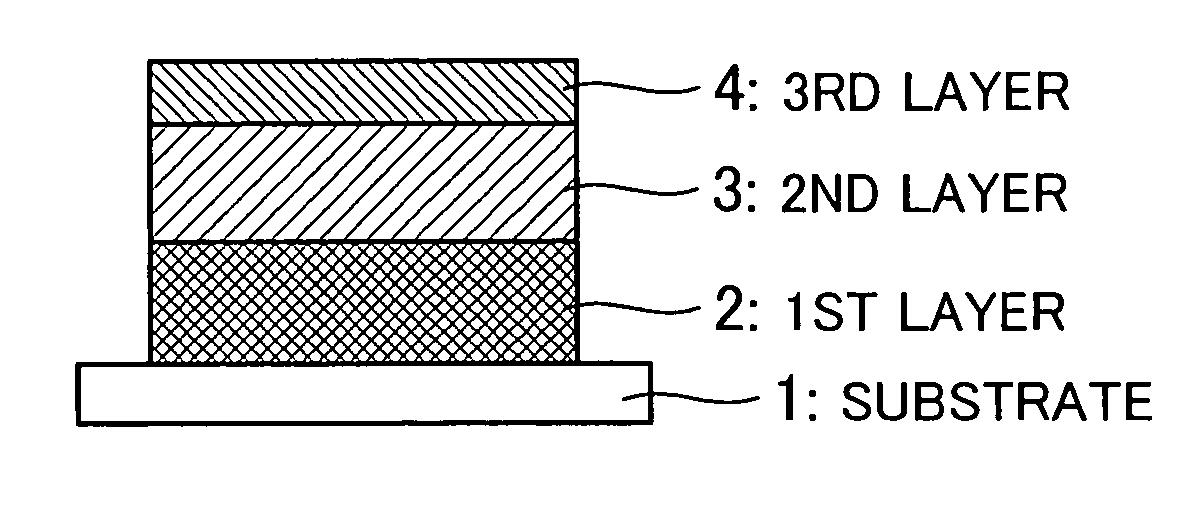

Anti-reflection Coating and Optical Member Comprising Same

ActiveUS20150055222A1High anti reflection performanceStorage stability be excellentCoatingsOptical elementsSecondary layerWavelength range

An anti-reflection coating having an three-layer structure comprising first to third layers formed in this order on a substrate, the substrate having a refractive index of 1.6-1.9, the first layer having a refractive index of 1.37-1.57, the second layer having a refractive index of 1.75-2.5, and the third layer having a refractive index of 1.18-1.32, to light in a wavelength range of 550 nm; the third layer being formed by silica aerogel; and the first and second layers containing no Al2O3.

Owner:RICOH IMAGING COMPANY

Organic light-emitting diode display panel and display device

InactiveCN110600514ARealize thin and light designImprove anti-reflection abilitySolid-state devicesIdentification meansHysteresisPhase function

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Optical element, and optical system and optical apparatus using same

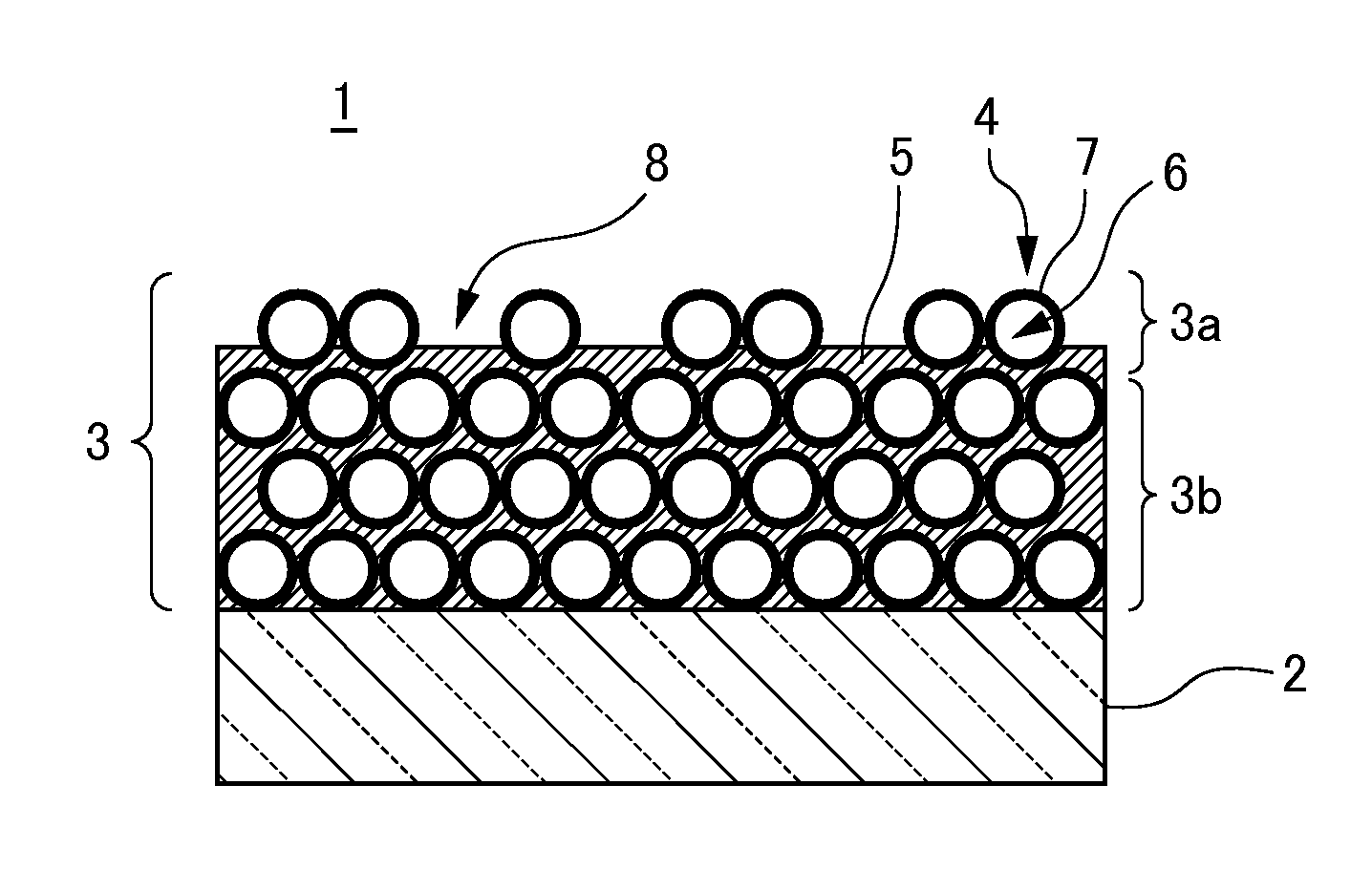

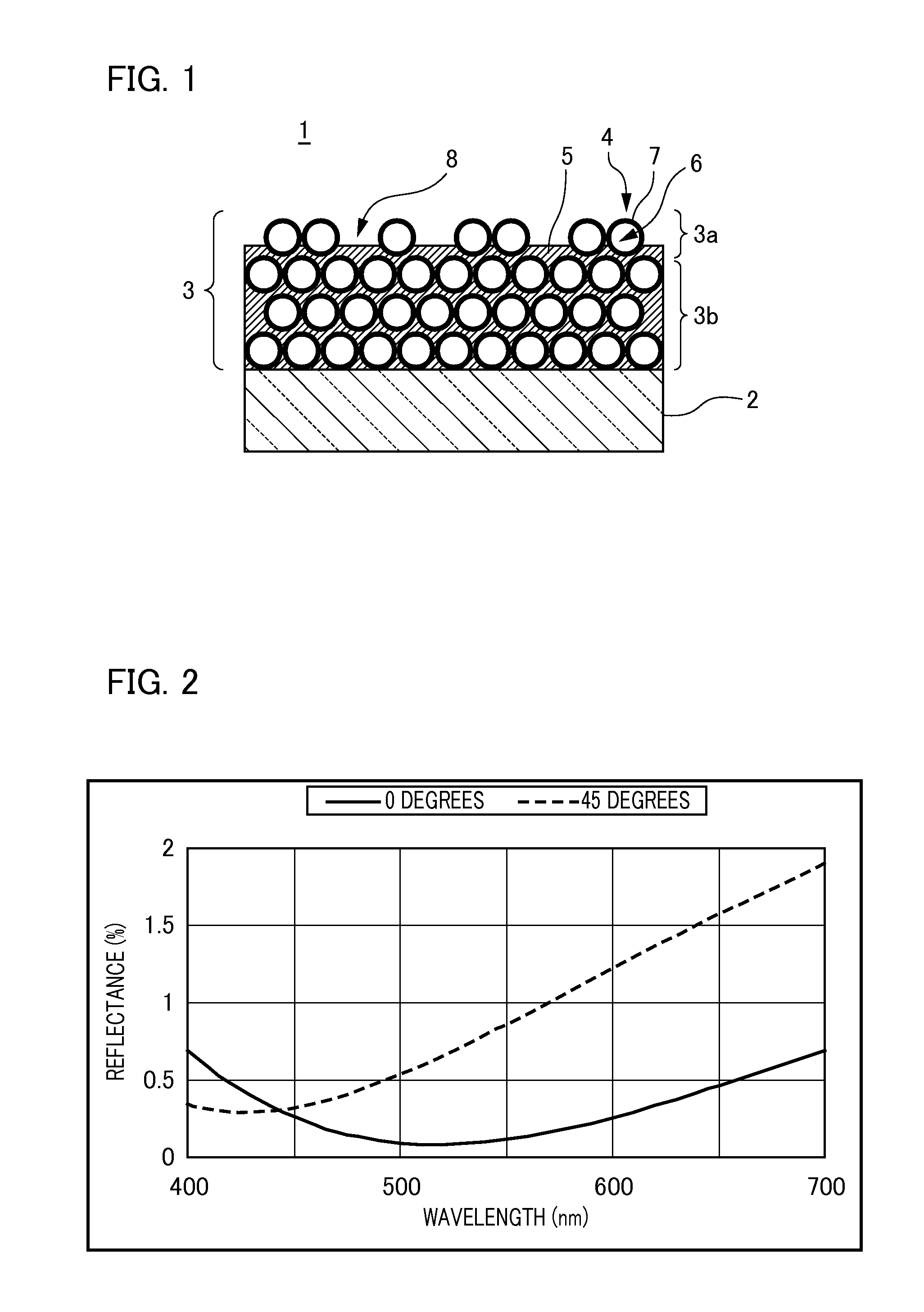

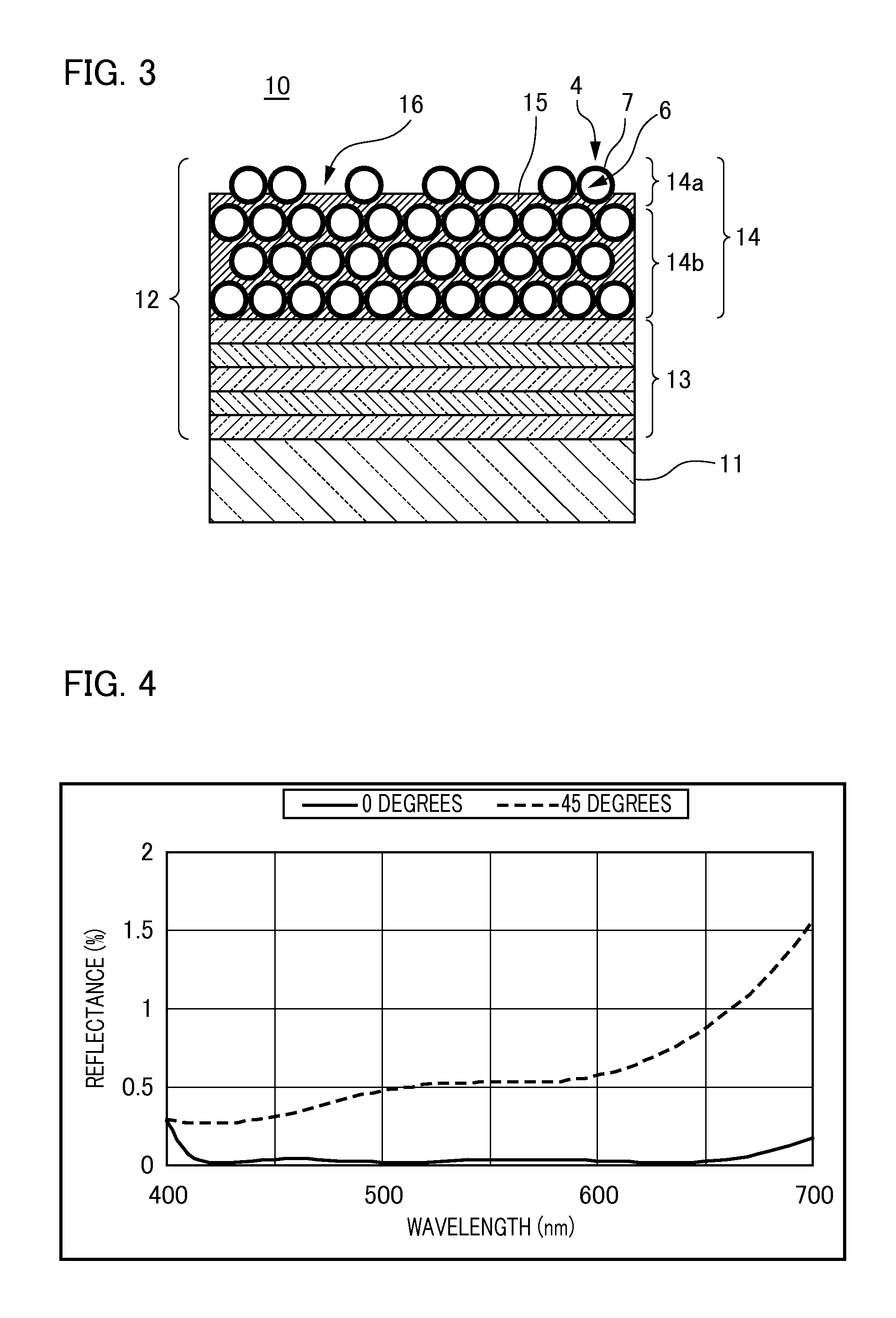

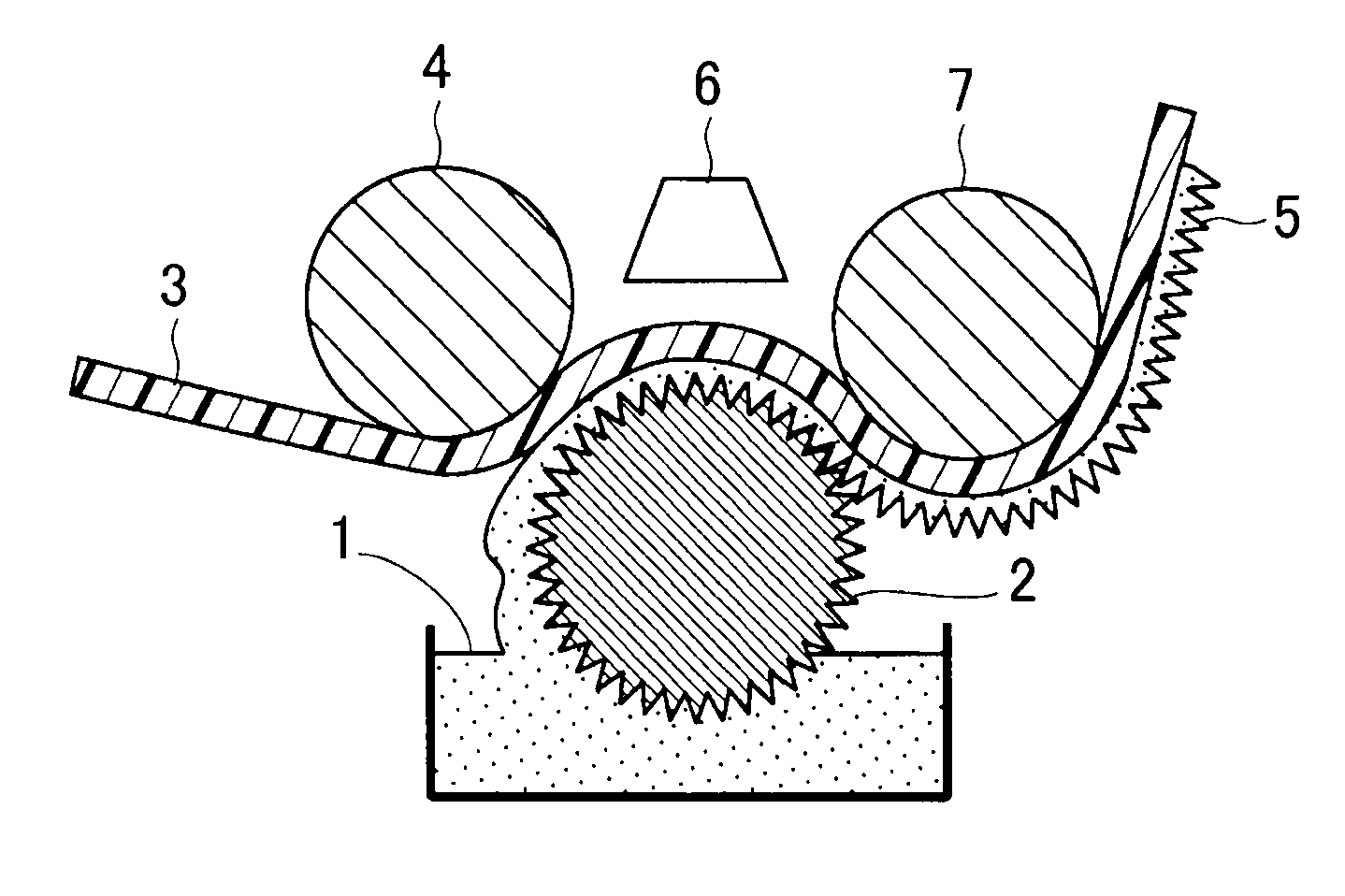

ActiveUS20130034711A1Improve scratch resistanceImprove anti-reflection abilityLayered productsCoatingsRefractive indexComputational physics

The optical element of the present invention has an anti-reflection film formed on a substrate. The anti-reflection film comprises a low refractive index layer that is formed by mutually binding hollow fine particles, each of which has a vacancy therein, using a binder, and the low refractive index layer consists of a first layer serving as an outermost layer and a second layer which is adjacent to the first layer and is located on the substrate side. Here, the filling ratio of the binder to the first layer is lower than the filling ratio of the binder to the second layer, the refractive index of the first layer is 1.1 or more but not more than 1.25 and the refractive index of the second layer is 1.26 or more but not more than 1.35

Owner:CANON KK

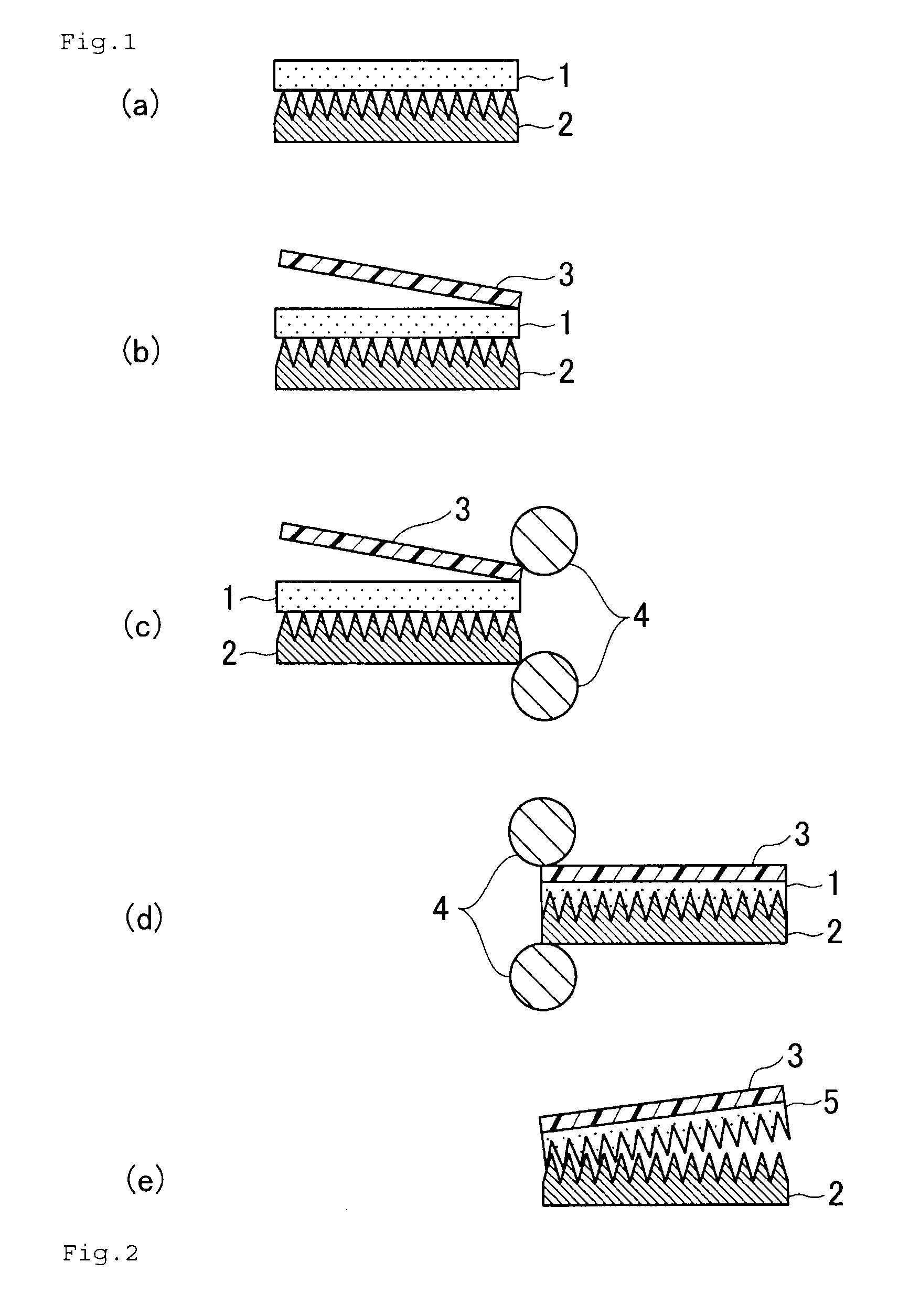

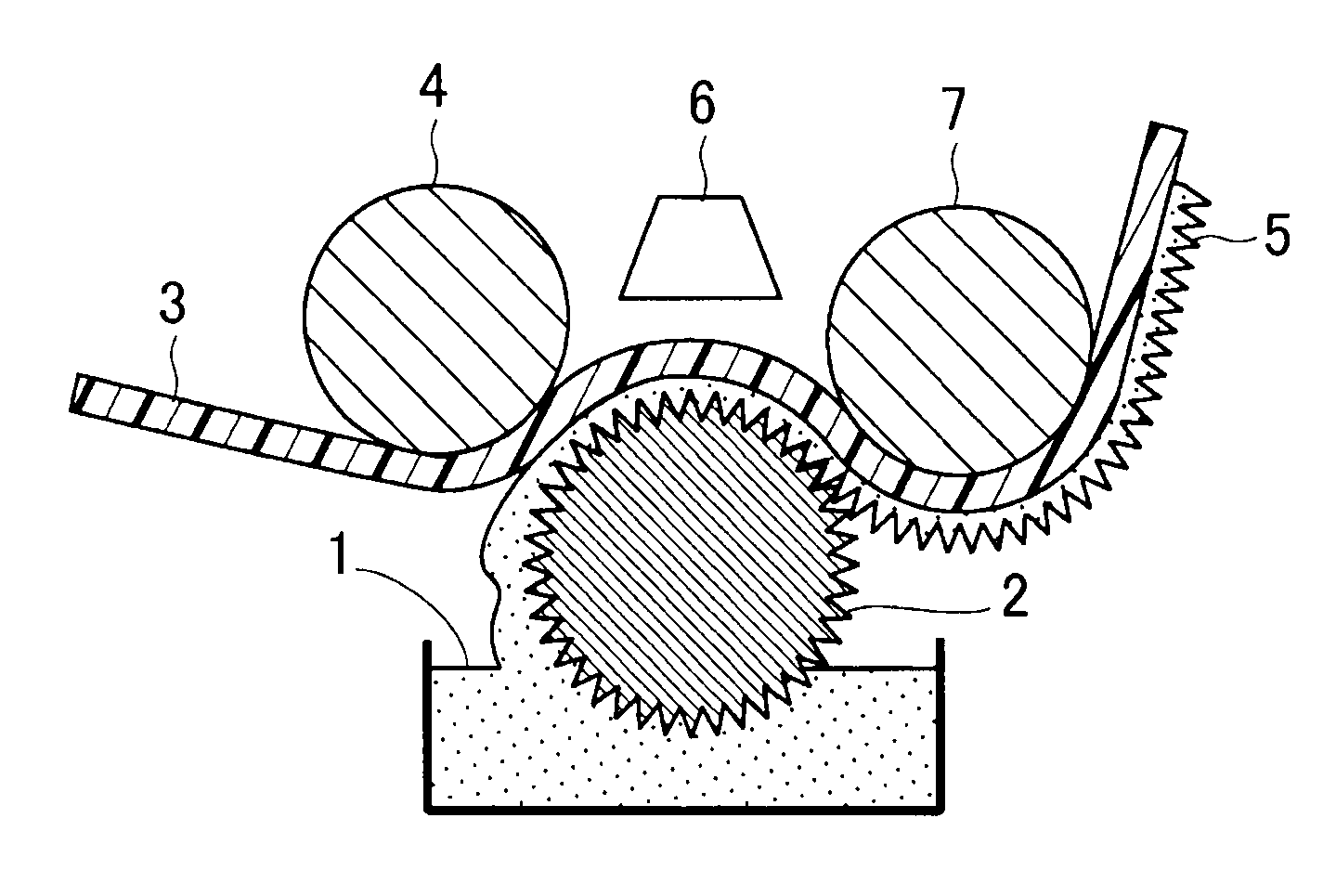

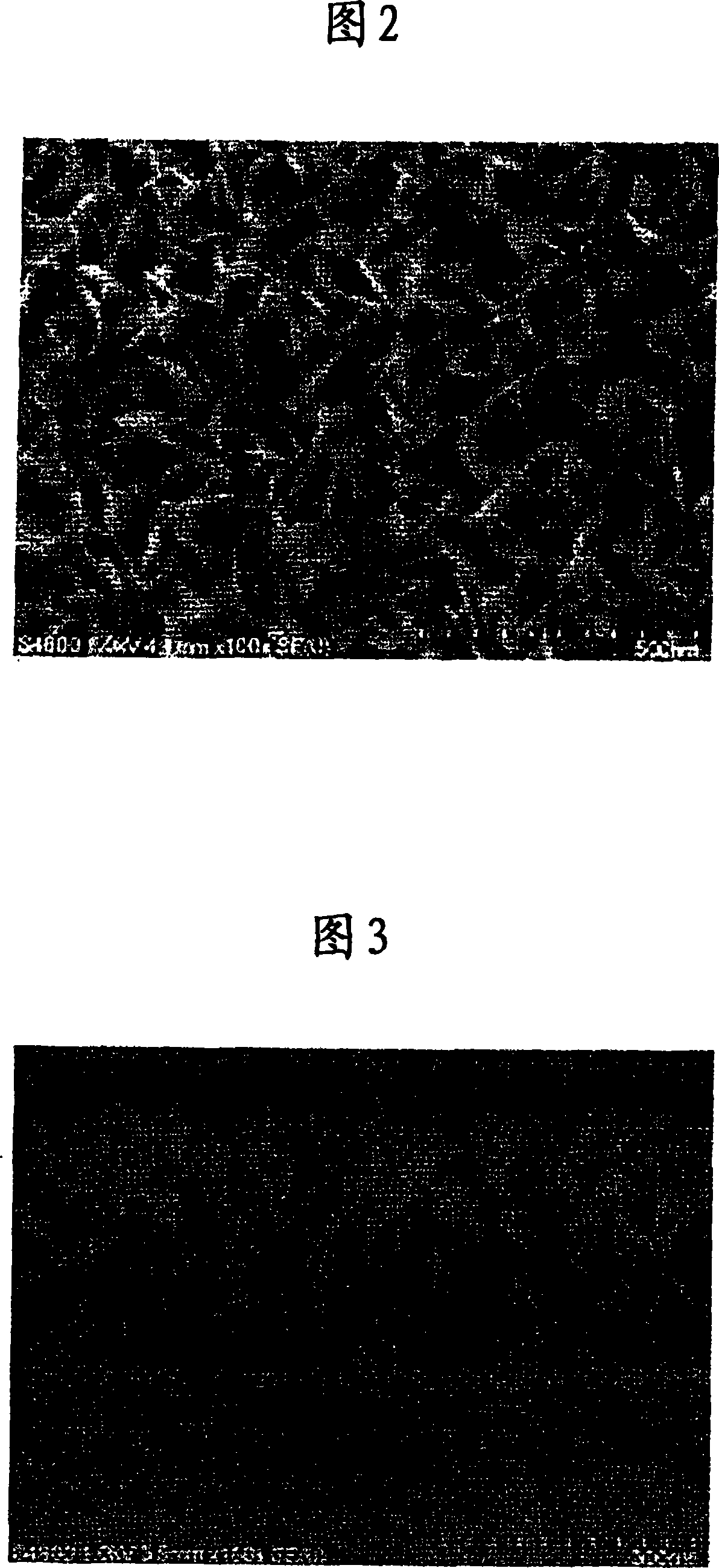

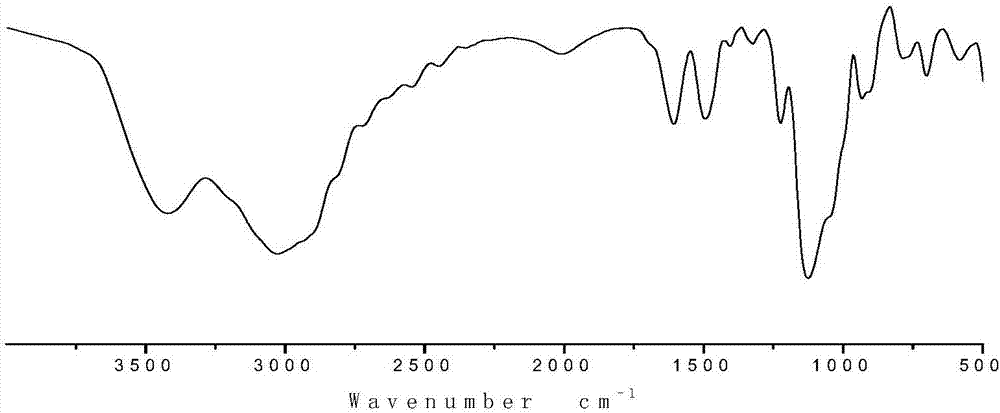

Antireflective film and production method thereof

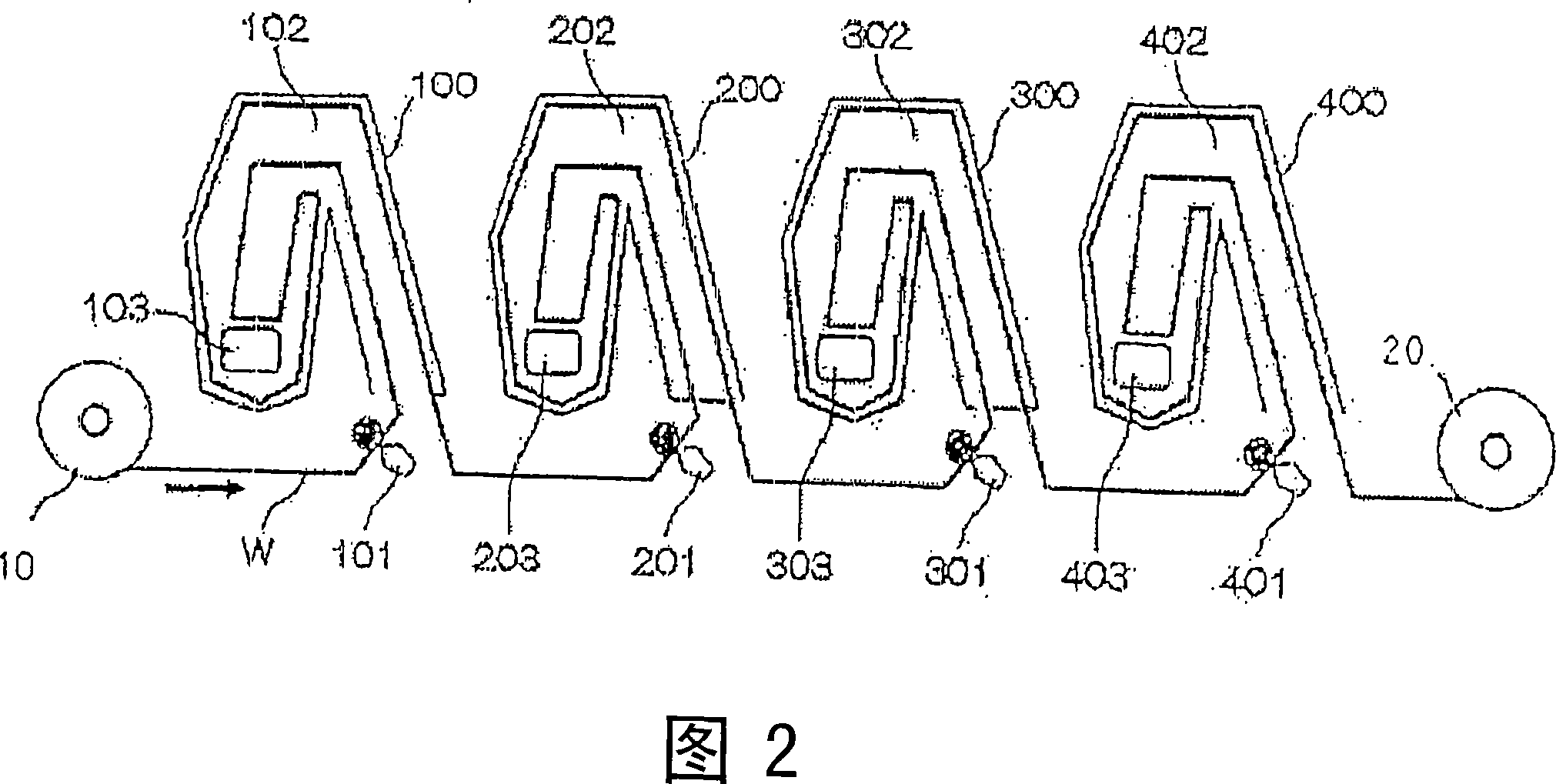

InactiveUS20110157704A1Improve anti-reflection abilityHigh light transmittanceConfectioneryOptical articlesSurface patternCompound (substance)

It is aimed at finding out a surface pattern and physical properties required for an antireflective film having an excellent antireflective property for light, a light transmissivity, and the like, and at providing an antireflective film having such a specific surface pattern and physical properties, and a production method of the antireflective film; and provided for this object, is an antireflective film, obtained by: processing a surface of an aluminum material, by mechanical polishing, chemical polishing and / or electrolytic polishing; subsequently producing a pattern of mold having taper-shaped pores on the surface of the aluminum material, by combining a formation of an anodic oxide coating based on anodic oxidation of the surface of the aluminum material, with etching of the anodic oxide coating; and transferring the pattern of mold onto an antireflective film-forming material; wherein the antireflective film has, on a surface thereof, convexities having an average height between 100 nm inclusive and 1,000 nm inclusive, or concavities having an average depth between 100 nm inclusive and 1,000 nm inclusive, and the convexities or concavities are present at an average period between 50 nm inclusive and 400 nm inclusive, at least in a certain single direction; and wherein the antireflective film has a haze of 15% or less.

Owner:DNP FINE CHEMICALS CO LTD

Anti-reflection coating constructed based on cage type silsesquioxane and preparing method and application thereof

ActiveCN104007491AImprove anti-reflection abilityIncrease temperatureCoatingsReaction layerSurface layer

The invention belongs to the technical field of nanometer hybrid composite materials and discloses an anti-reflection coating constructed based on cage type silsesquioxane and the preparing method and application thereof. The preparing method of the anti-reflection coating comprises the steps that a base reaction layer is constructed with 10-methacrylonitrile acyloxy propyl group cage type silsesquioxane and 8-aminophenyl group cage type silsesquioxane and then is precured, a surface layer is constructed with fluorinated acrylate prepolymer and 8-methacrylonitrile acyloxy propyl group cage type silsesquioxane, the two layers are co-cured under a certain condition, and stress is generated by means of the difference in reaction volume shrinkage of the two layers. The prepared anti-reflection coating is of a nanometer island structure, and the anti-reflection performance is improved remarkably. The anti-reflection coating can be widely applied to optical devices which require high anti-reflection performance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Optical transparent member and optical system using the same

It is an object to provide an optical transparent member capable of maintaining a high-performance antireflection effect for a base over a long period of time, and an optical system using the same, specifically an optical transparent member including on a base a layer containing SiO2 as a main component, a layer containing Al2O3 as a main component, and a plate crystal layer formed from plate crystals containing Al2O3 as a main component, wherein the surface of the plate crystal layer has a shape of irregularities, and an optical system using the same.

Owner:CANON KK +1

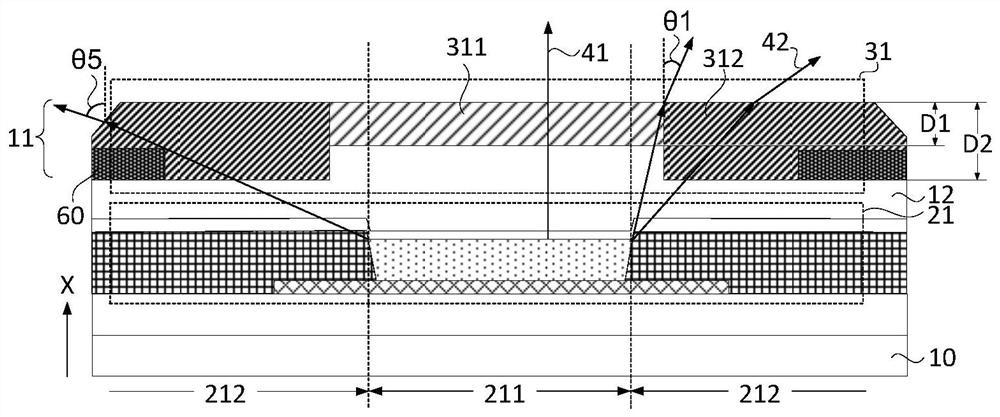

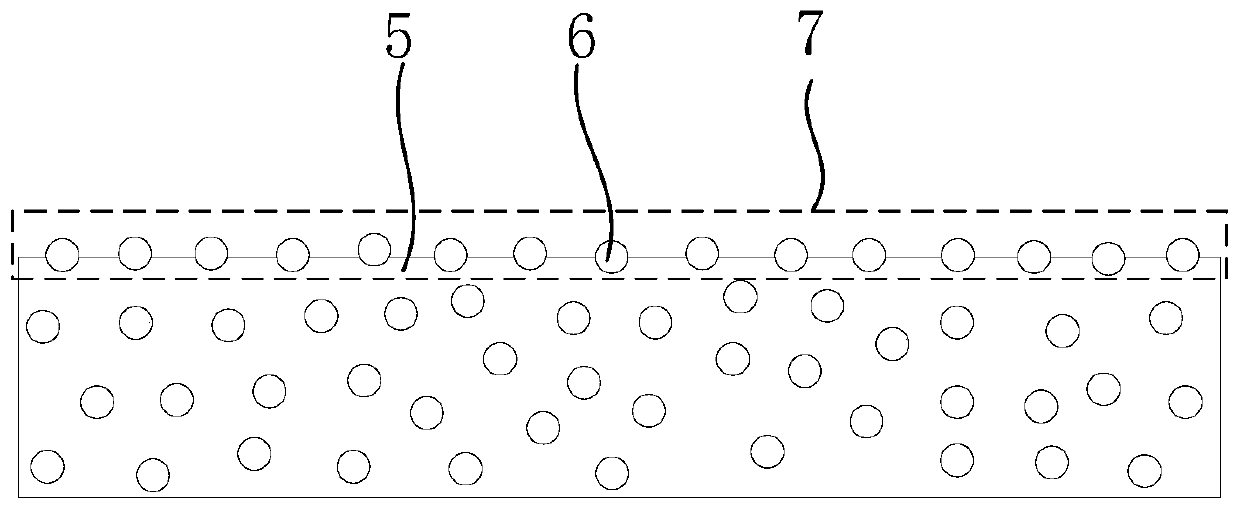

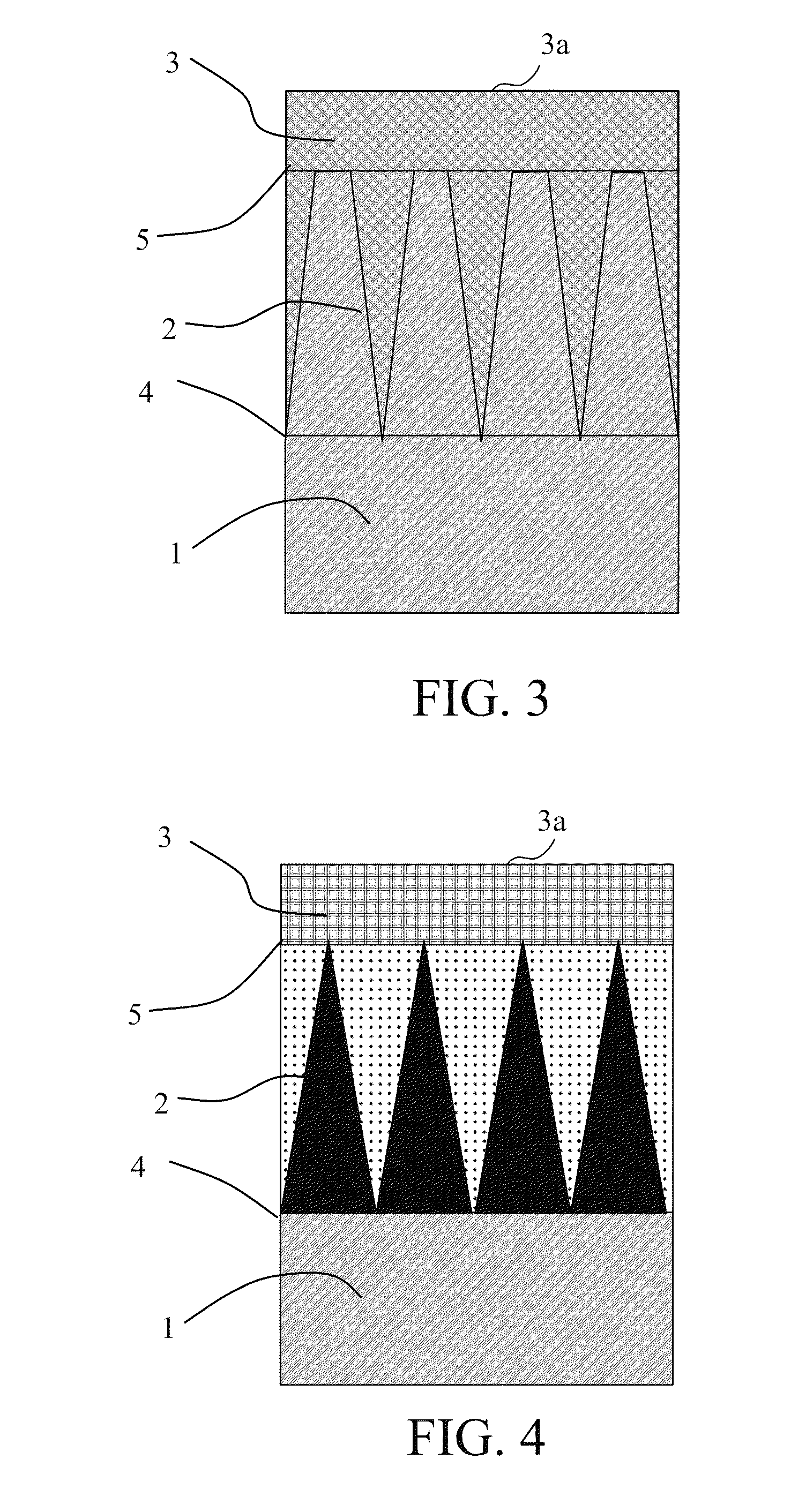

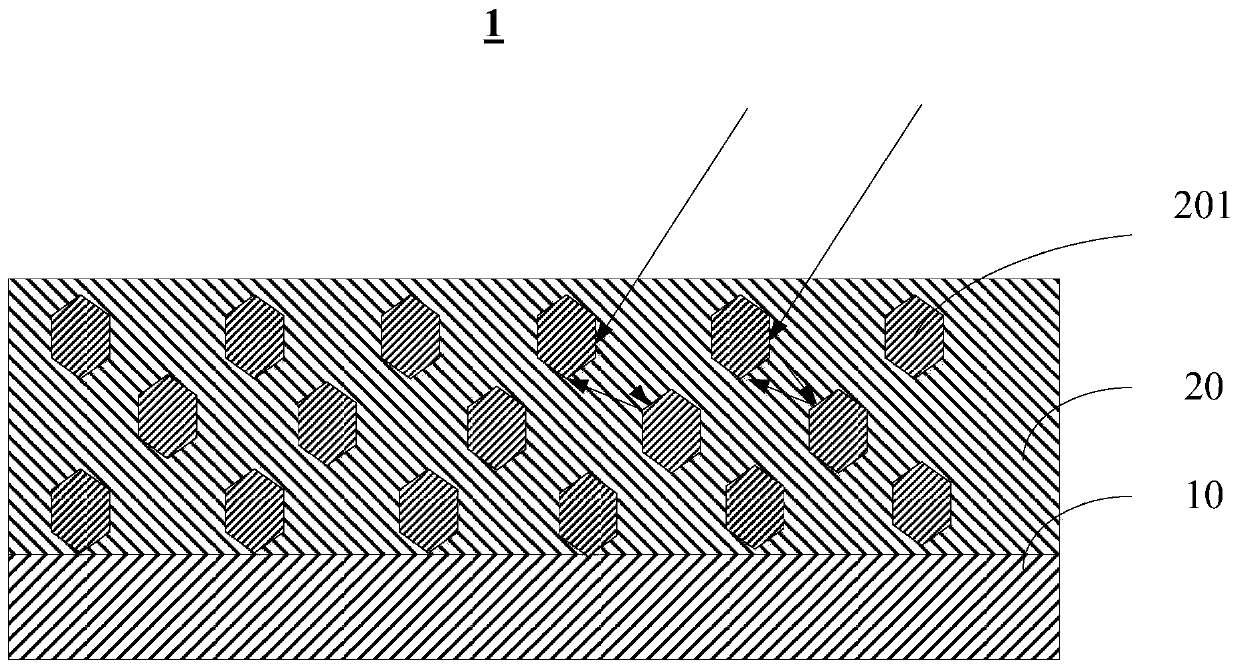

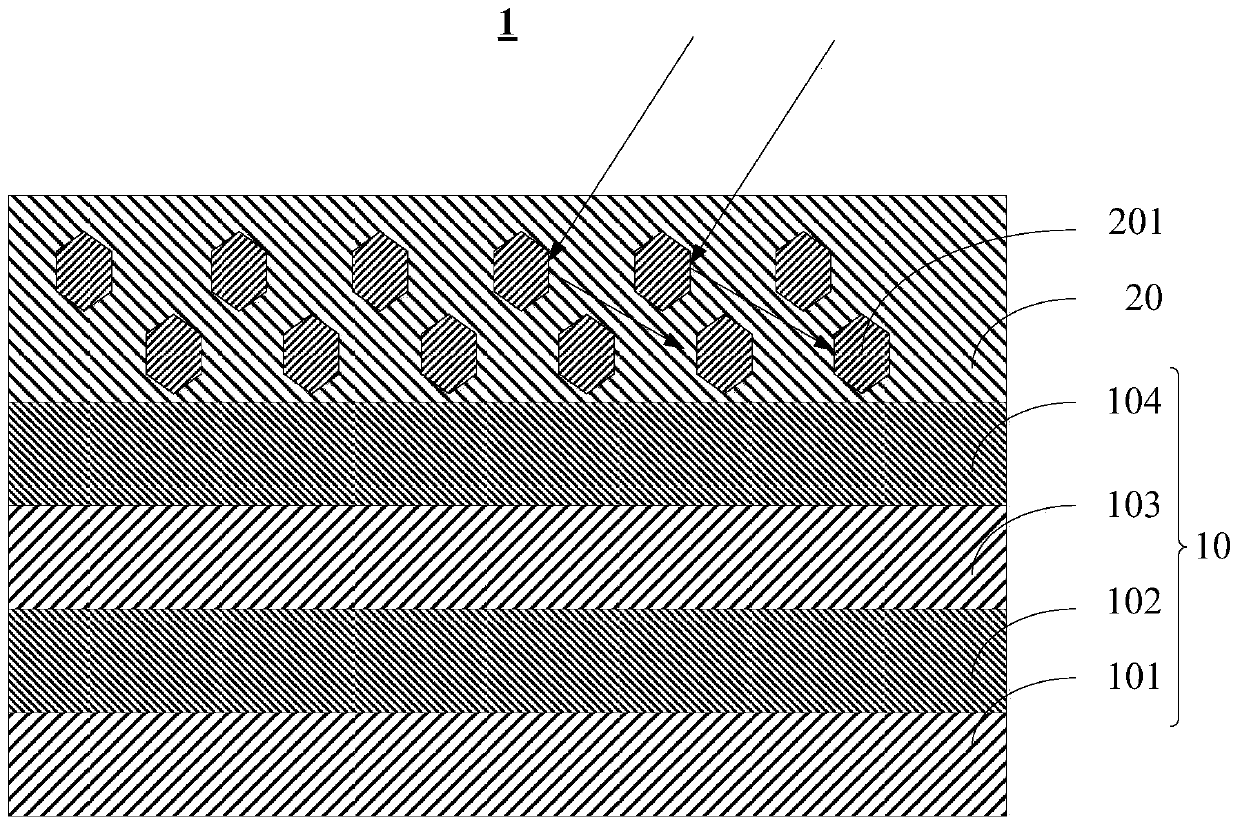

Display panel and manufacturing method thereof

PendingCN111312797AIncrease contrastImprove transmittanceMaterial nanotechnologySolid-state devicesDisplay deviceThin membrane

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises a display device and an anti-reflection layer arranged on the display device. The display devicecomprises a plurality of sub-pixel areas distributed in an array; the anti-reflection layer comprises organic light-transmitting thin films arranged corresponding to the sub-pixel areas; the organiclight-transmitting thin films are doped with inorganic nano particles, and the inorganic nano particles located on the sides, away from the display device, of the organic light-transmitting thin filmsprotrude on the surfaces of the organic light-transmitting thin films to form nano moth eye structures. According to the invention, the anti-reflection capability of the display panel can be improvedby the anti-reflection layer, and the contrast ratio of the display panel is effectively improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

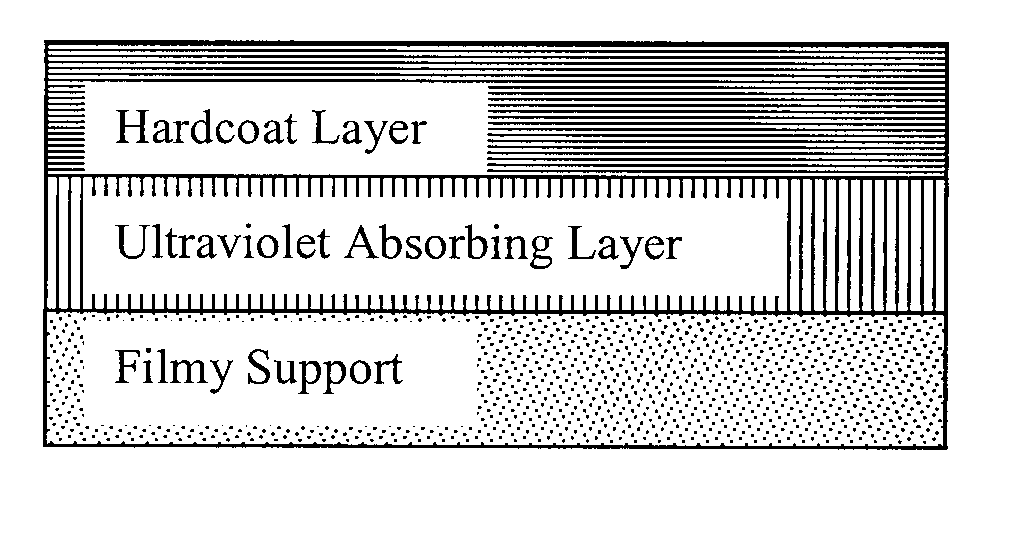

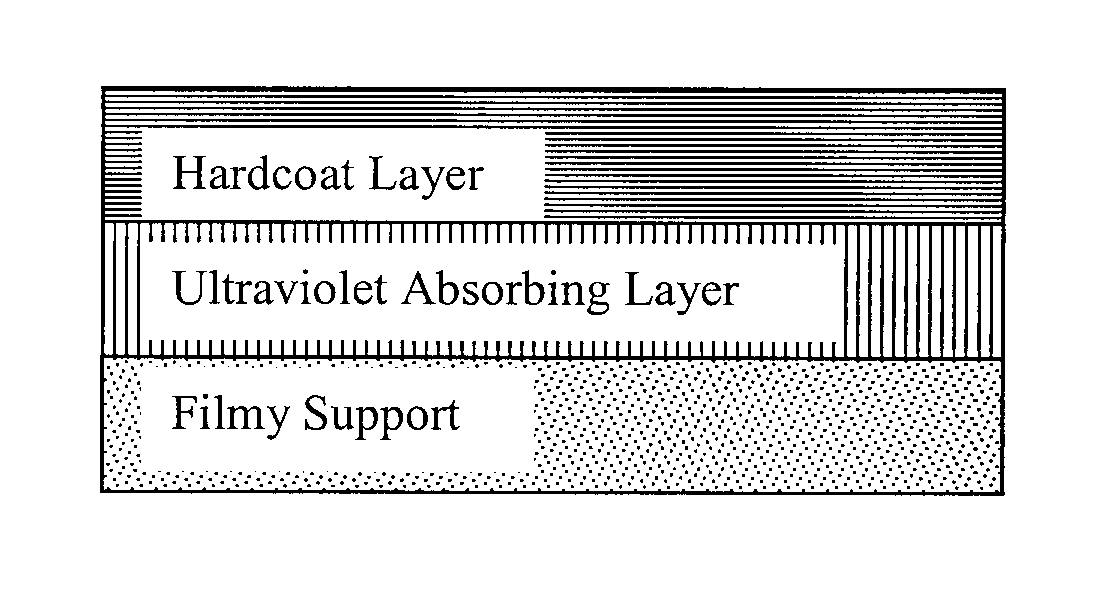

Optical film, and polarizing plate and liquid crystal display device using the optical film

ActiveUS8208197B2Reduce deteriorationEasy to solveMaterial nanotechnologyOptical filtersUltravioletOptical thin film

An optical film includes a filmy support that includes a polymer having all alicyclic structure; an ultraviolet absorbing layer; and a hardcoat layer, wherein the ultraviolet absorbing layer has a beam transmittance of 5% or less in a wavelength region of 200 to 340 nm and includes at least one ultraviolet absorbent selected from the group consisting of a metal oxide fine particle and a polymer particle.

Owner:FUJIFILM CORP

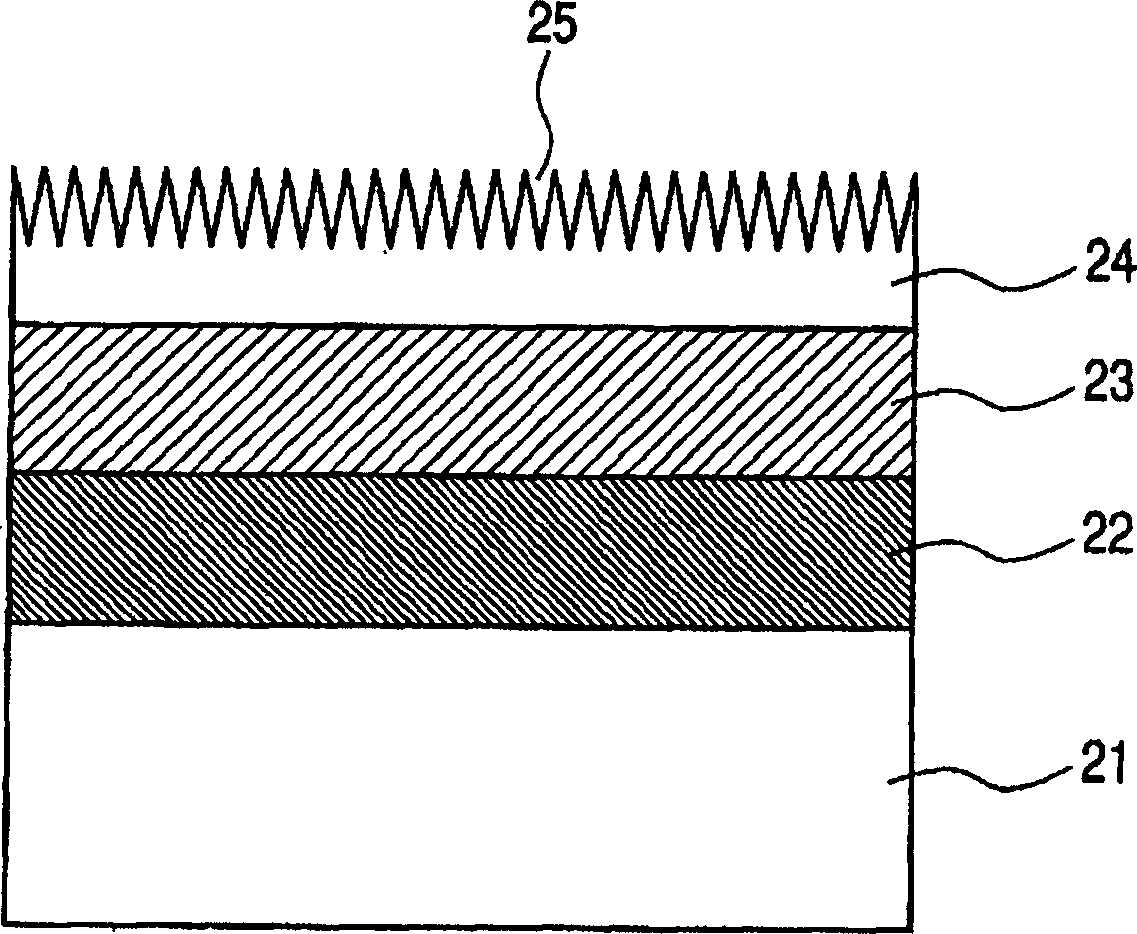

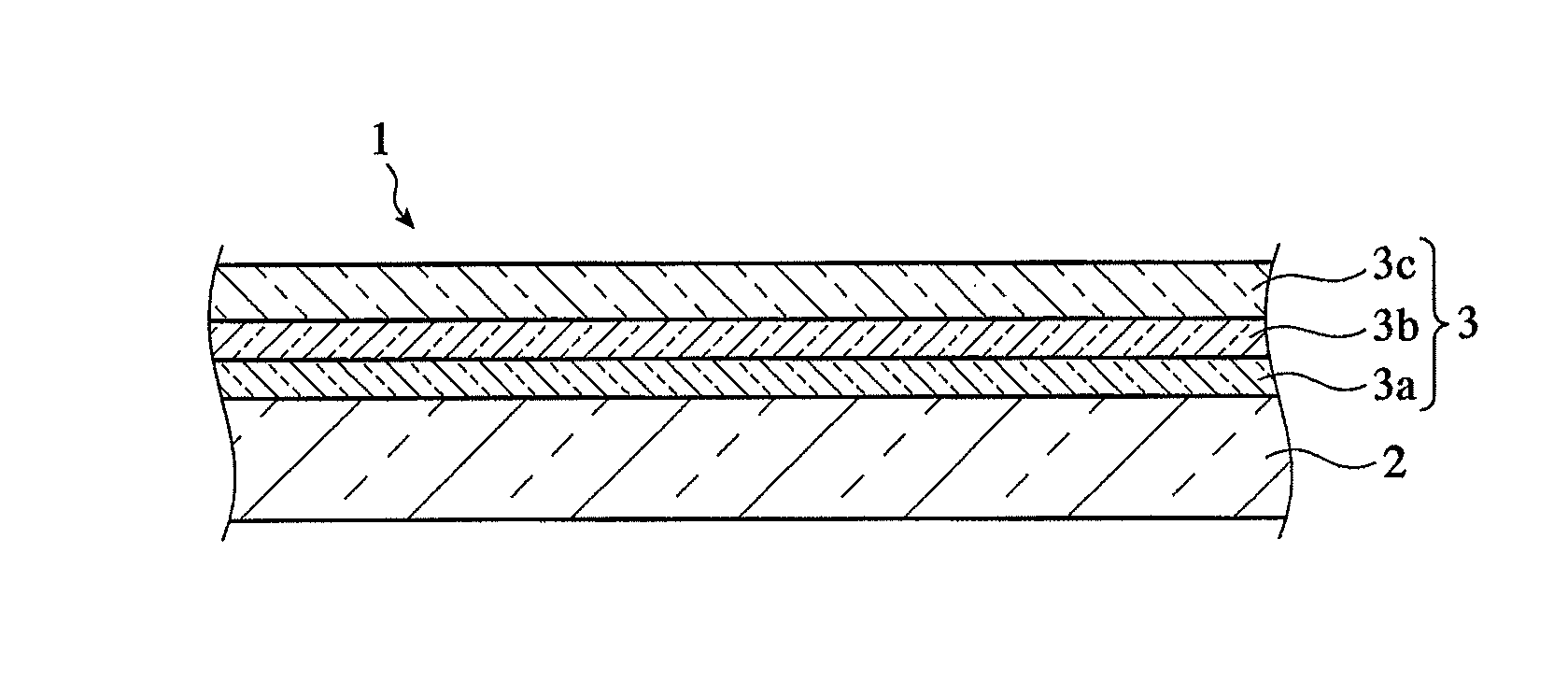

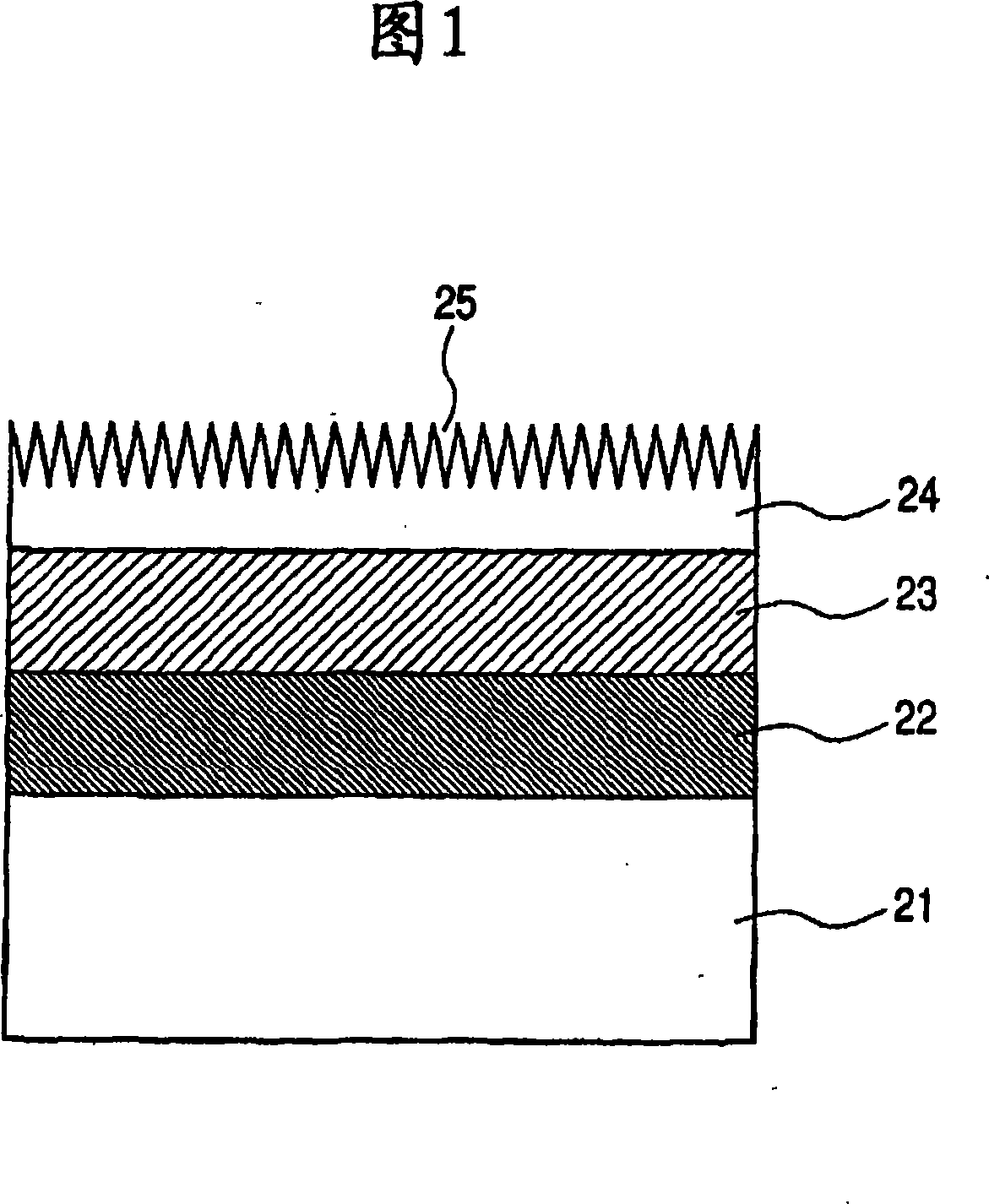

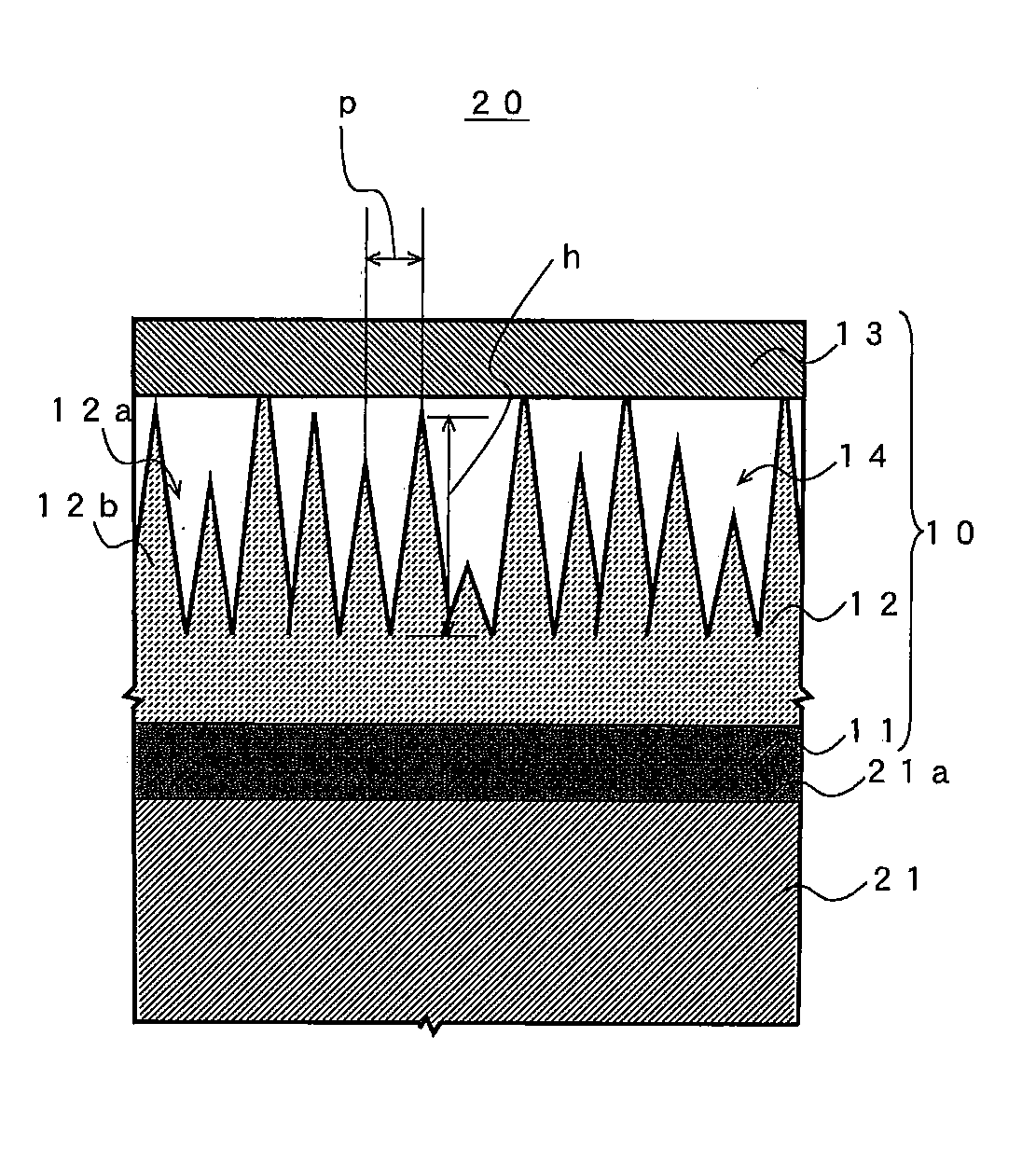

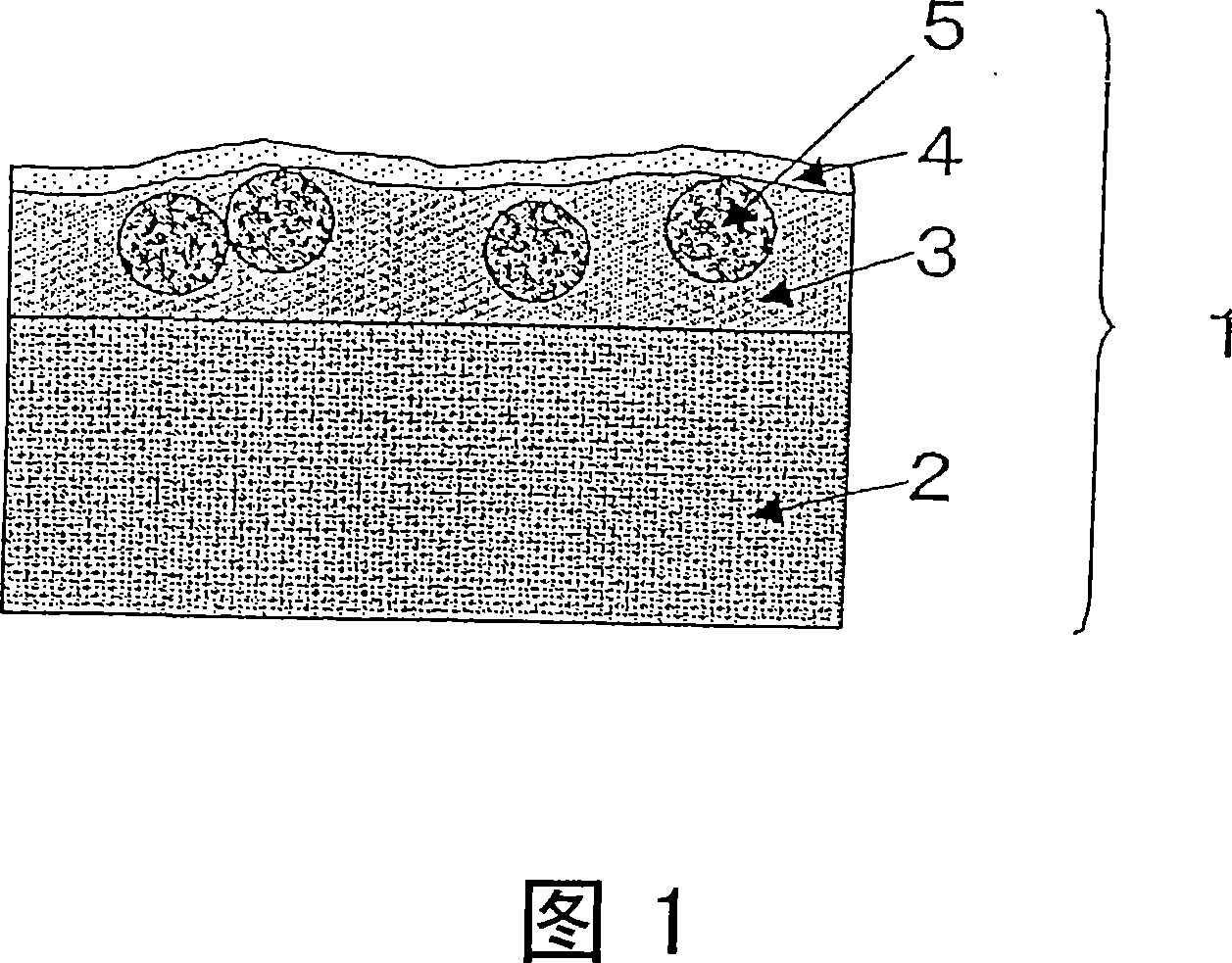

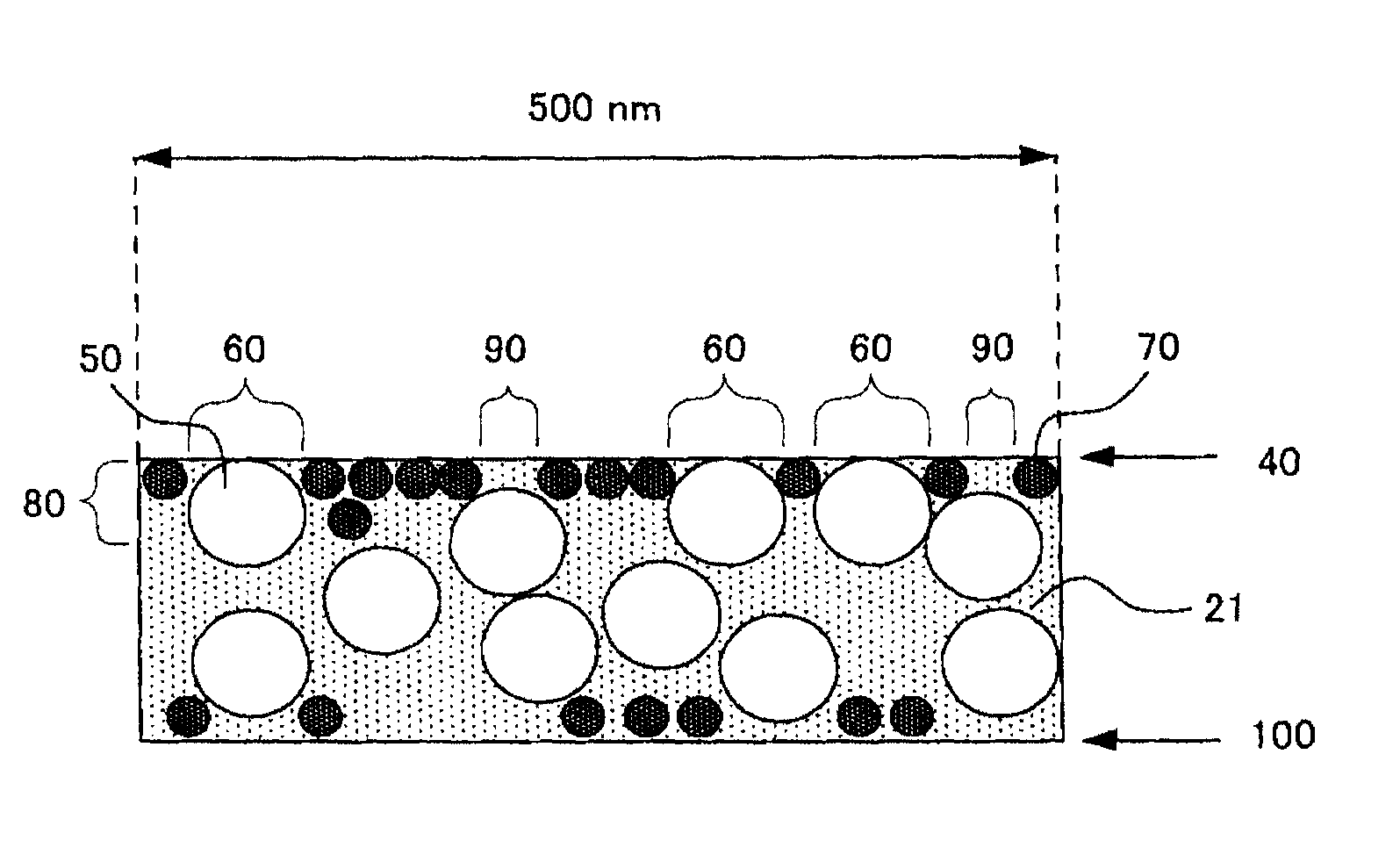

Anti-Reflection Film and Method for Manufacturing Anti-Reflection Film

ActiveUS20130271842A1Improve scratch resistanceReduce reflectionLayered productsDiffusing elementsHigh humidityOptical thin film

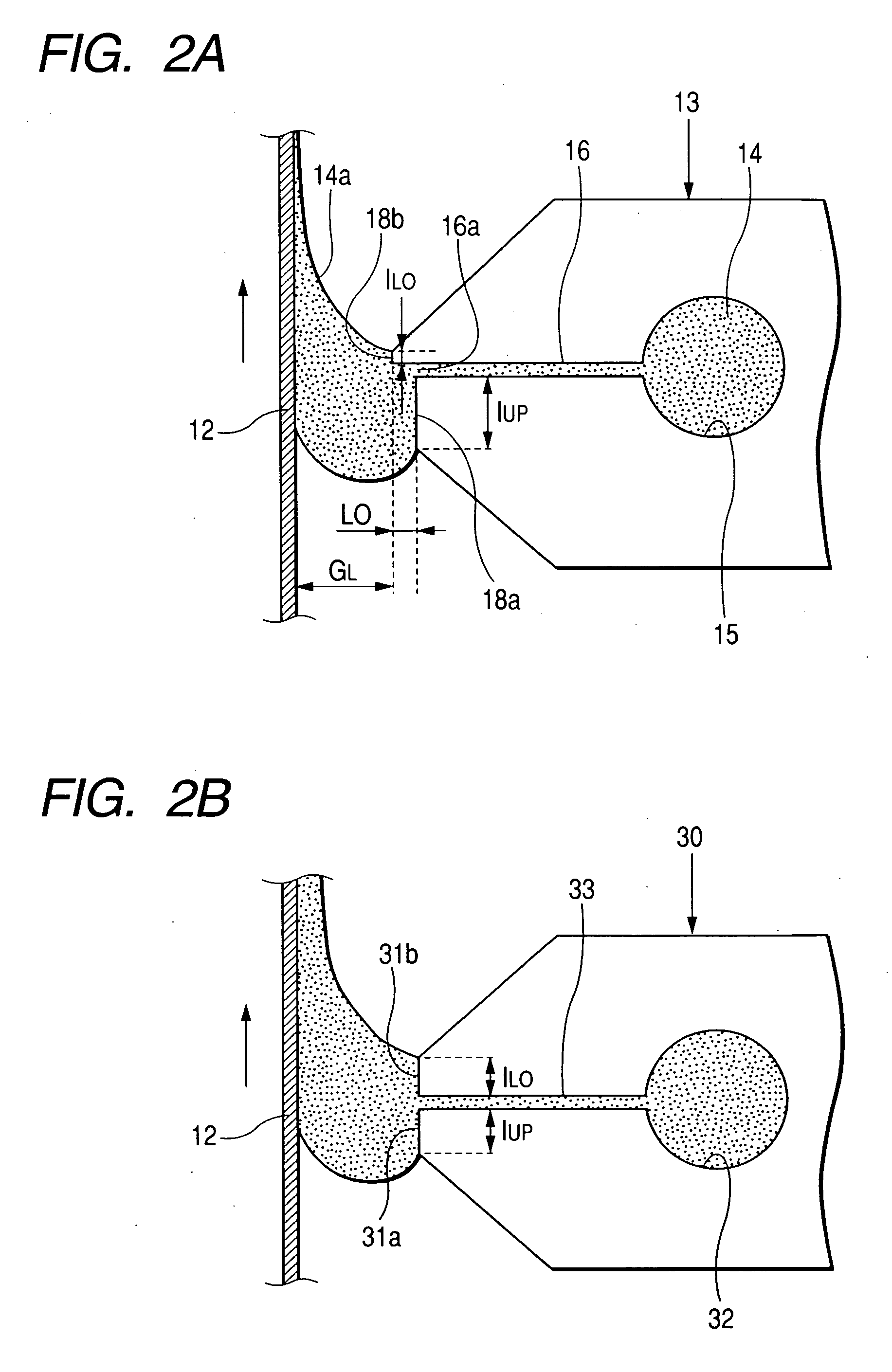

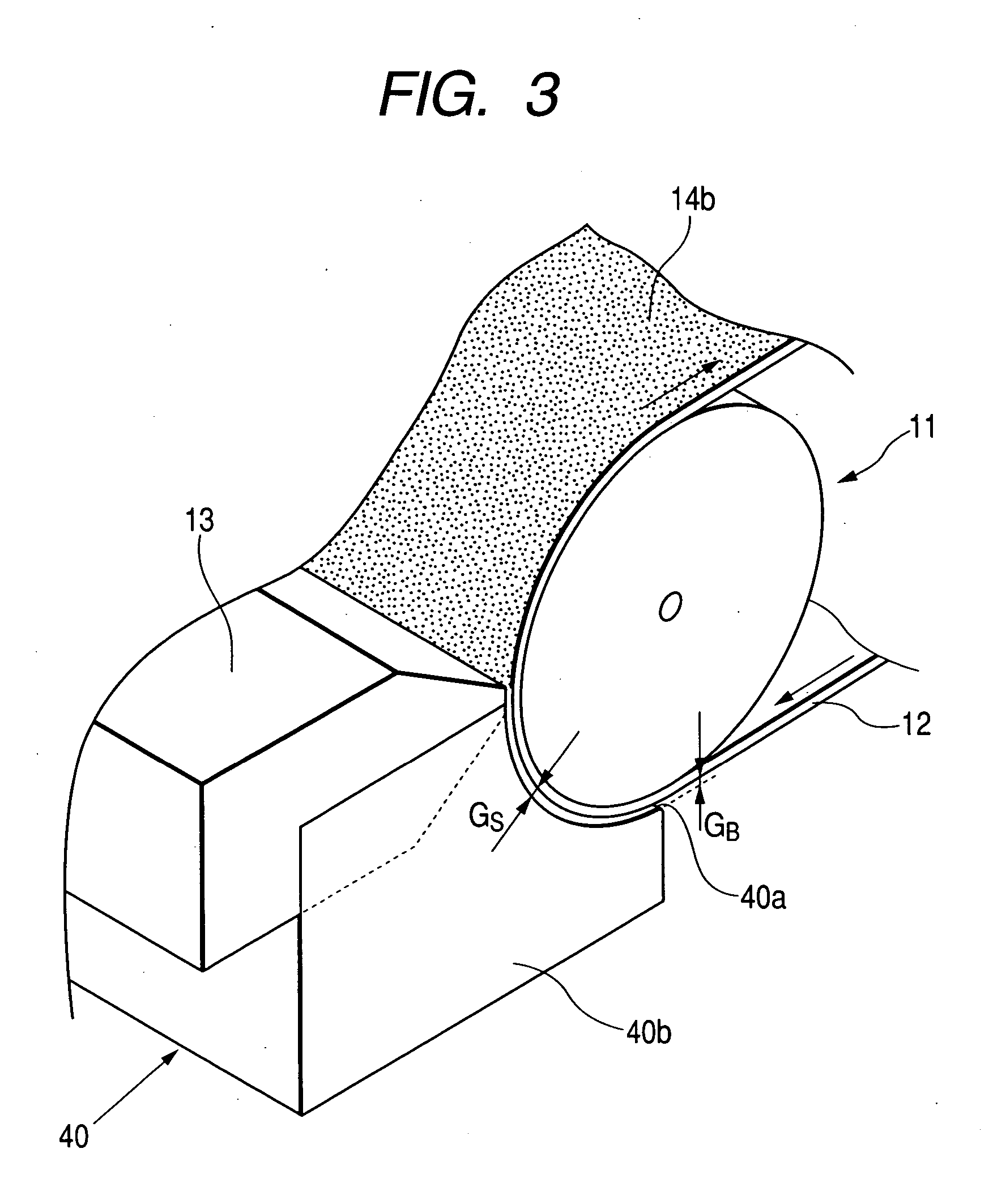

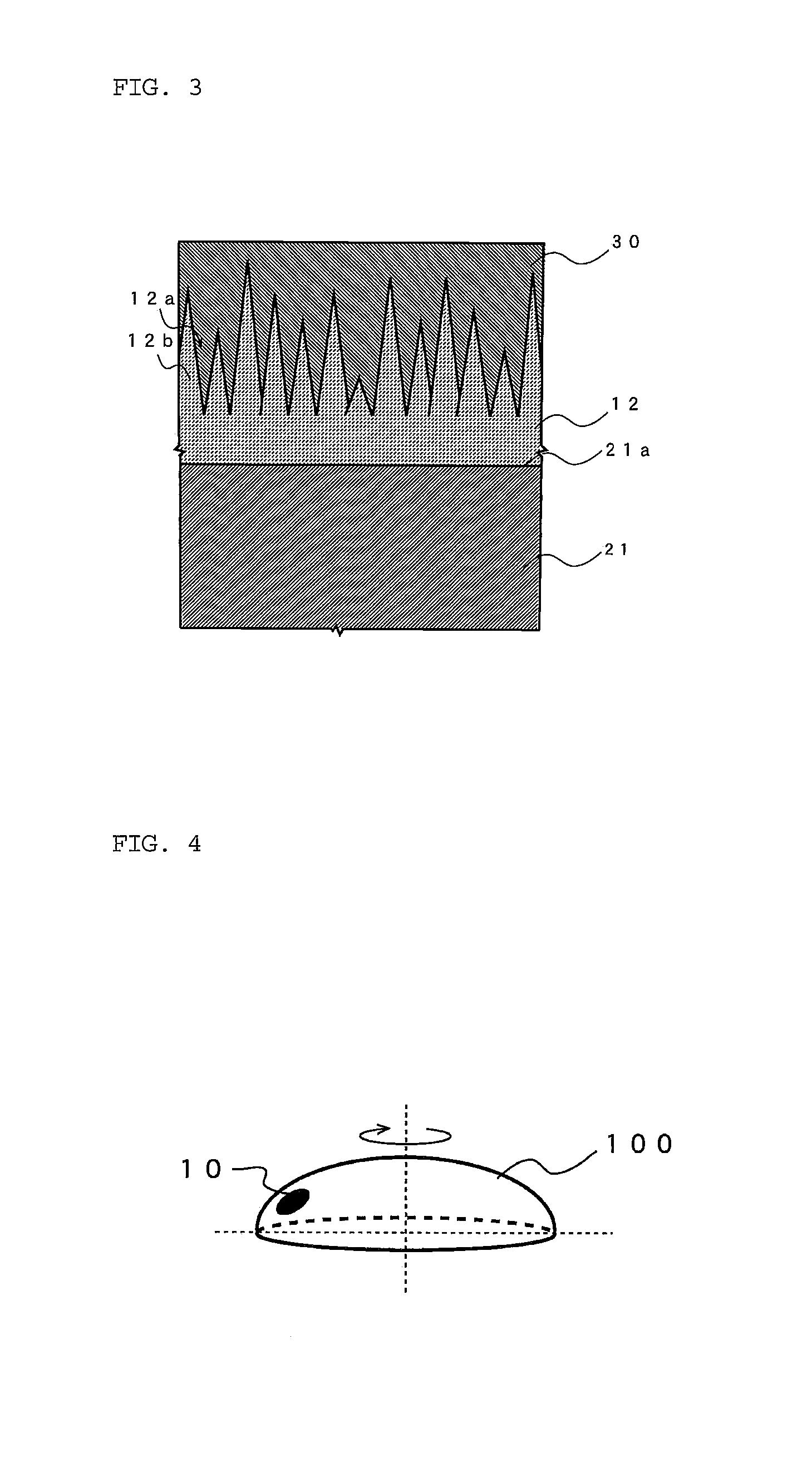

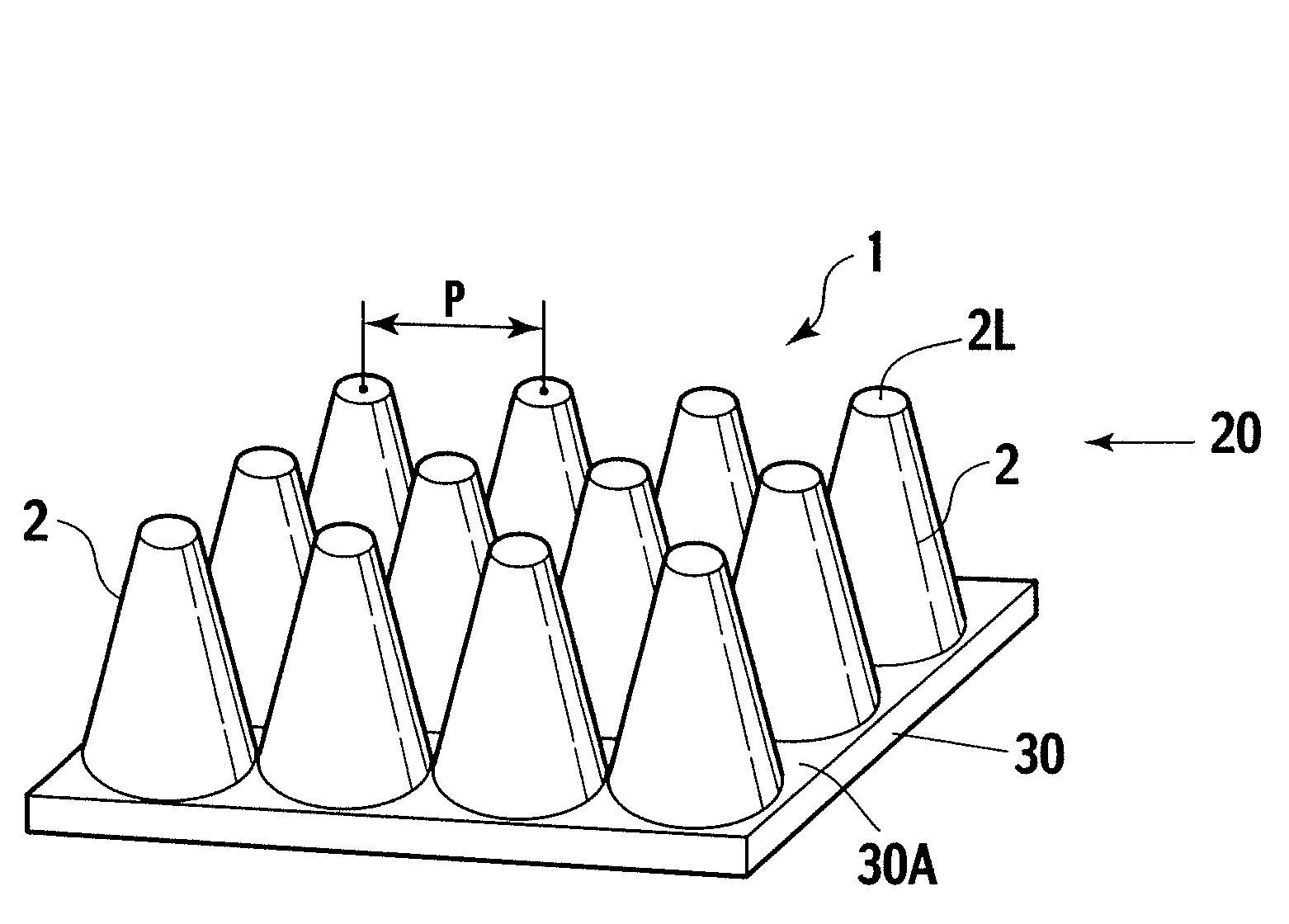

An object of the present invention is to provide an anti-reflection film excellent in high-temperature and high-humidity environment resistance and scratch resistance in addition to improved anti-reflection performance of a concave-convex nanostructure. To achieve the object, an anti-reflection film 10 comprises: a base layer 11 as a first optical thin film that is provided on an optical surface 21a of an optical element 21; a concave-convex nanostructure layer that is provided on a surface of the base layer 11 and is composed of a concave-convex nanostructure 12 formed so as to have a pitch width p between the convex parts 12b of shorter than an incident light wavelength; and a cover layer 13 as a second optical thin film that covers peaks of the convex part 12b with a void 14 being provided between the cover layer 13 and concave part 12a constituting the concave-convex nanostructure 12.

Owner:TAMRON

Antireflective structure and antireflective molded body

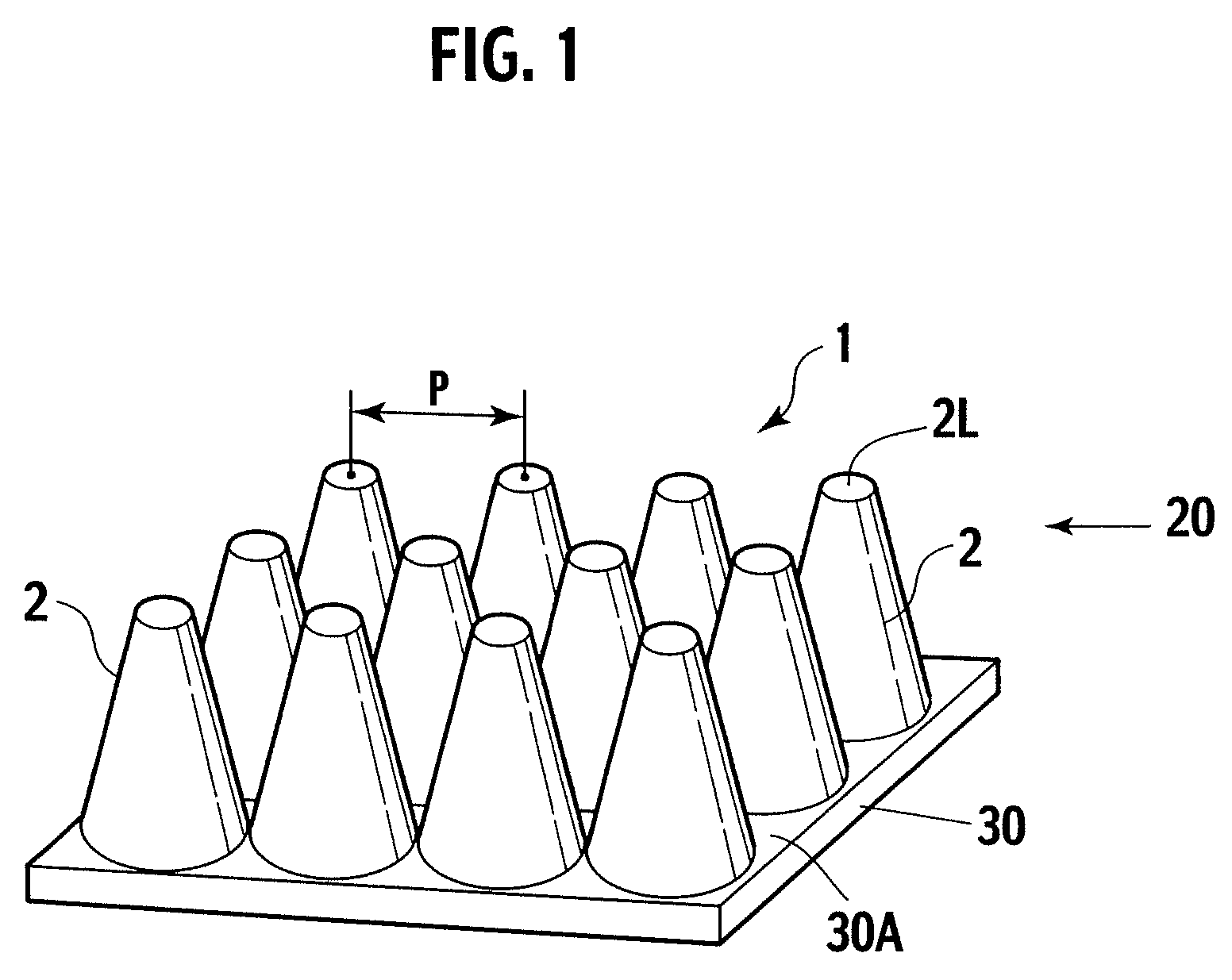

InactiveUS7940462B2Improve anti-reflection abilityAvoid damageLayered productsThin material handlingFine structureCircular cone

Owner:NISSAN MOTOR CO LTD

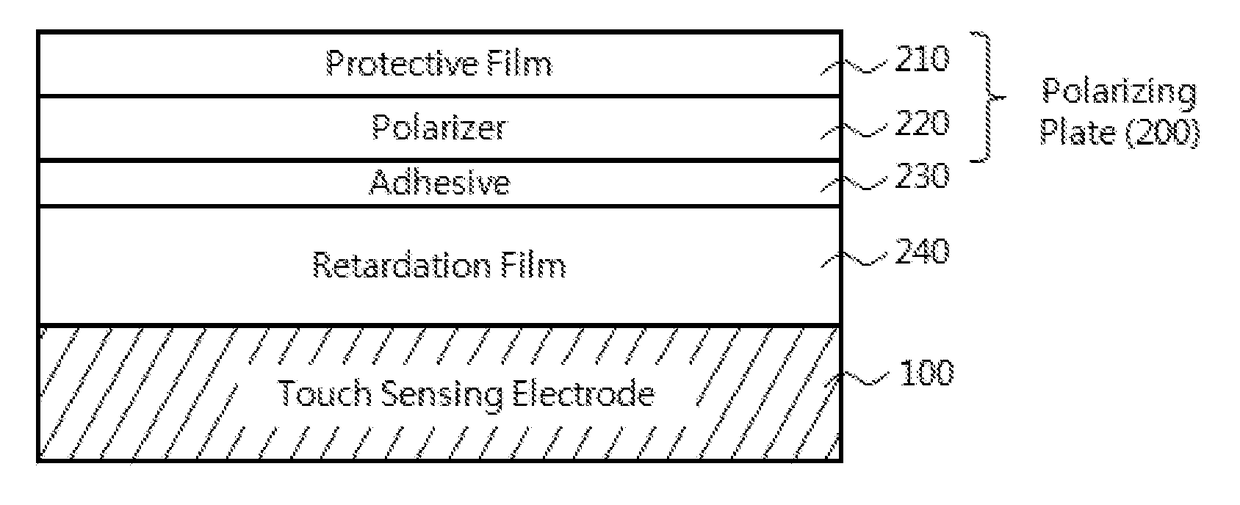

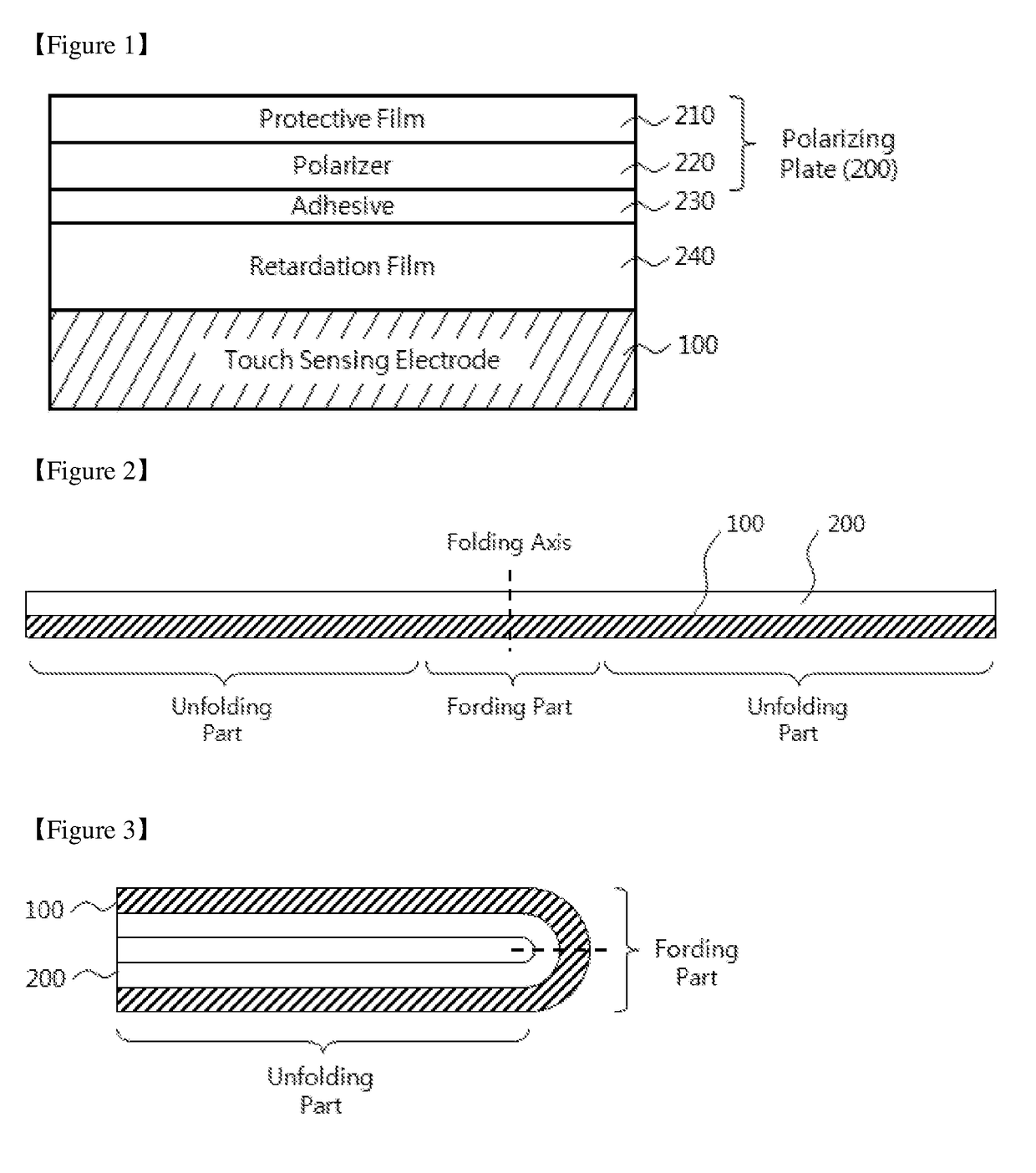

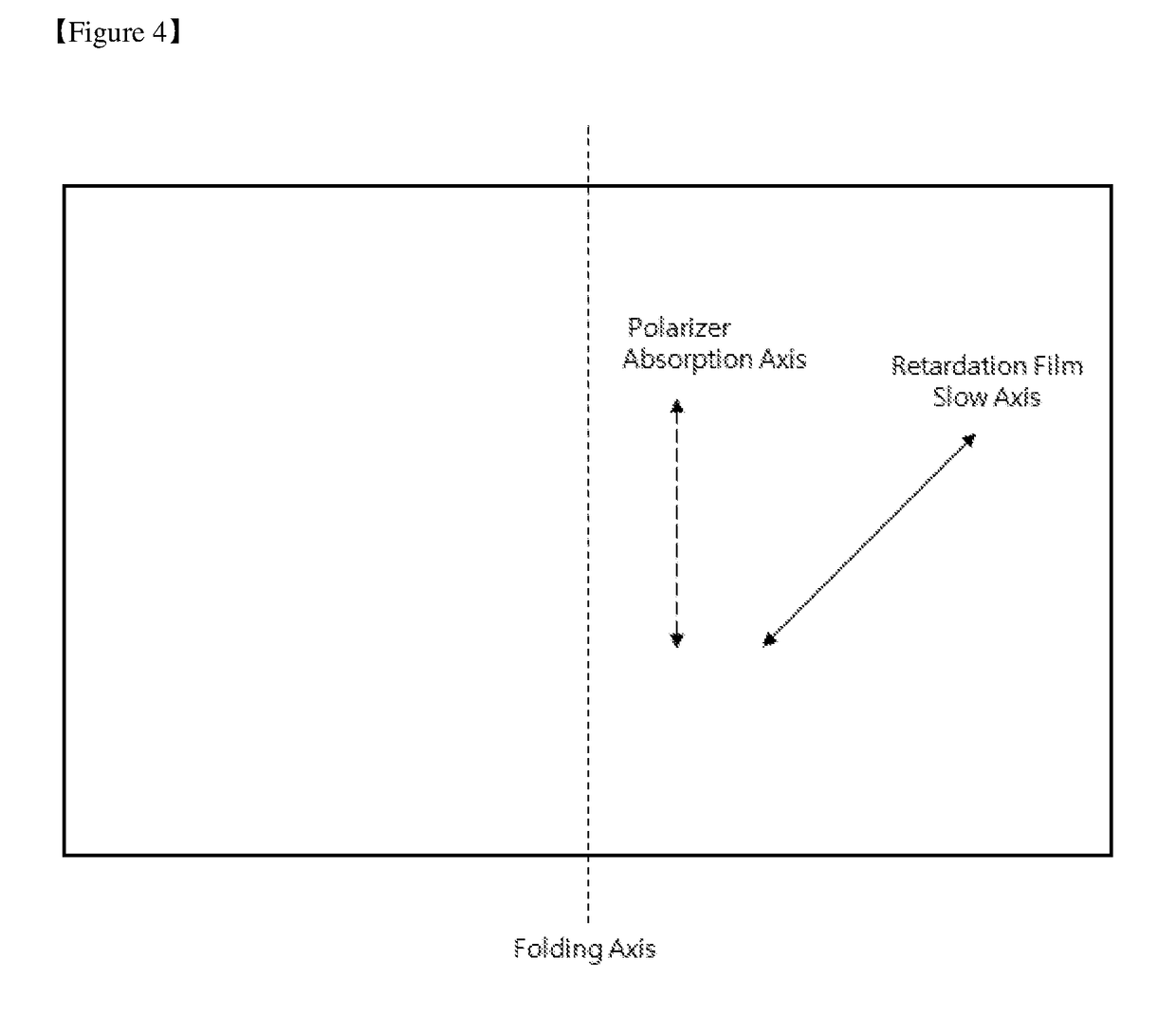

Touch sensing electrode integrally formed with polarizing plate, display device comprising same, and manufacturing method therefor

InactiveUS20170277291A1Improve visibilityEnhance display performancePolarising elementsNon-linear opticsPolarizerEngineering

The present invention relates to a touch sensing electrode with a polarizing plate, a display device comprising the same, and a method for fabricating the same.The touch sensing electrode with a polarizing plate according to the present invention comprises a touch sensing electrode capable of being folded and unfolded on its folding axis; a retardation film disposed on the touch sensing electrode and having a slow axis that forms an inclined angle with the folding axis; and a polarizing plate disposed on the retardation film.

Owner:DONGWOO FINE CHEM CO LTD

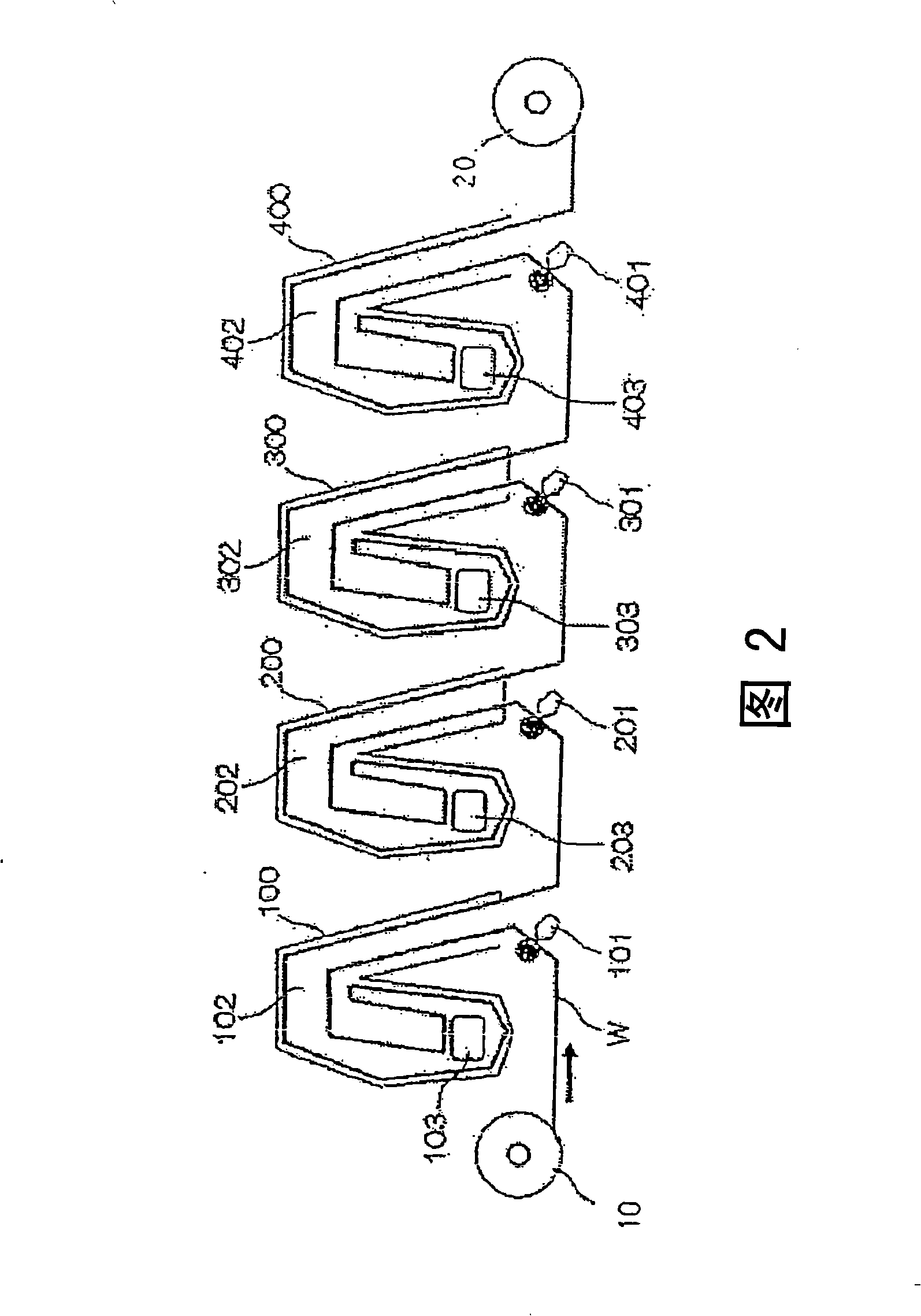

Method for manufacturing antireflection film, antireflection film, polarizing plate and image display device

InactiveCN1934464AImprove scratch resistanceImprove anti-reflection abilitySynthetic resin layered productsPolarising elementsThin membranePolarizer

Disclosed is a method for producing an antireflective film which has excellent abrasion resistance while exhibiting sufficient antireflection performance. Also disclosed is an antireflective film produced by such a method. Further disclosed are a polarizing plate and image display comprising such an antireflective film. Specifically disclosed is a method for producing an antireflective film comprising at least one antireflective layer on a transparent base which is characterized in that at least one layer on the transparent base is formed by a film-forming process including the following steps (1) and (2): (1) a step wherein a coating layer is formed on the transparent base; (2) a step wherein the coating layer is irradiated with ionizing radiation and cured in an atmosphere having a lower oxygen concentration than the air.

Owner:FUJIFILM CORP

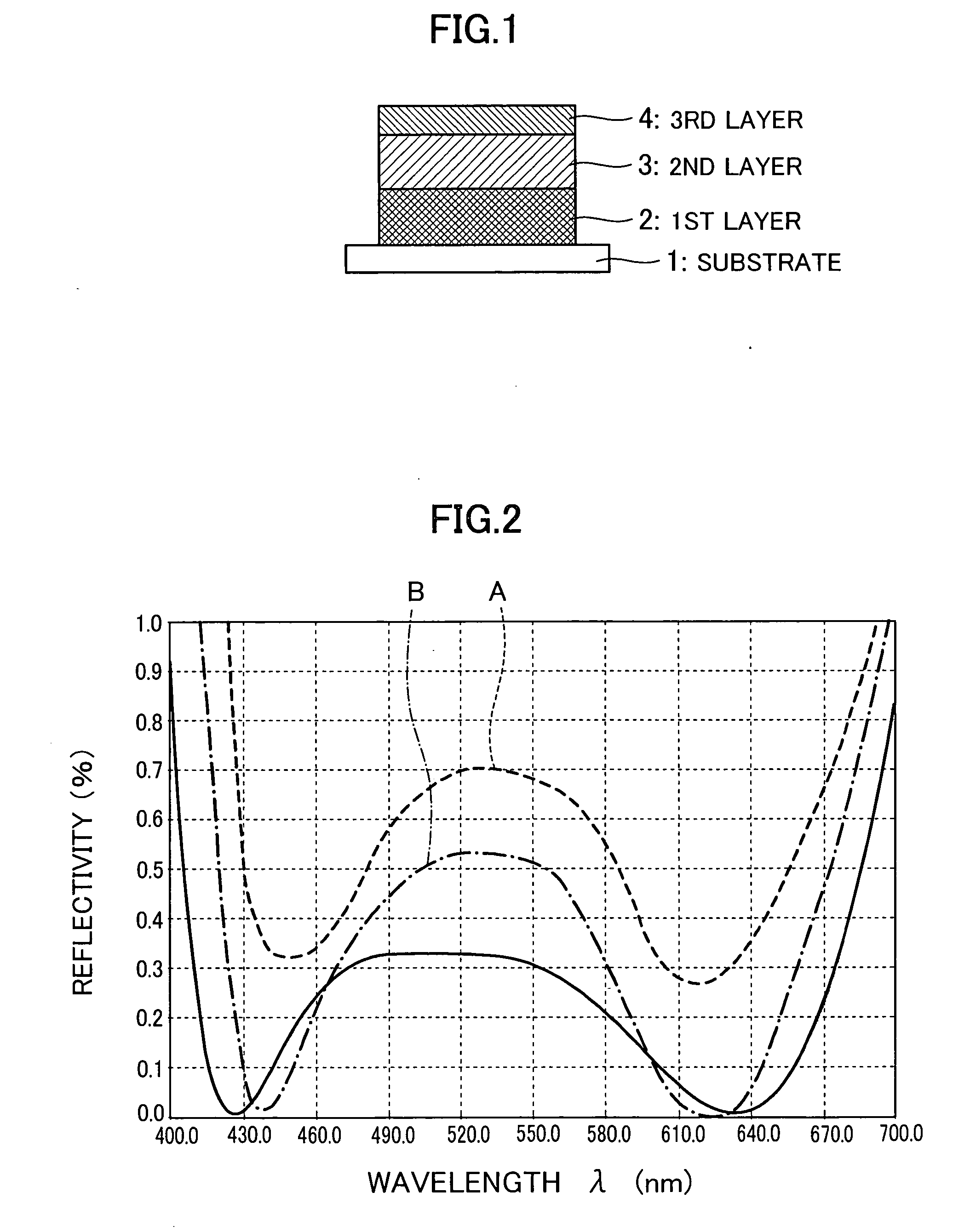

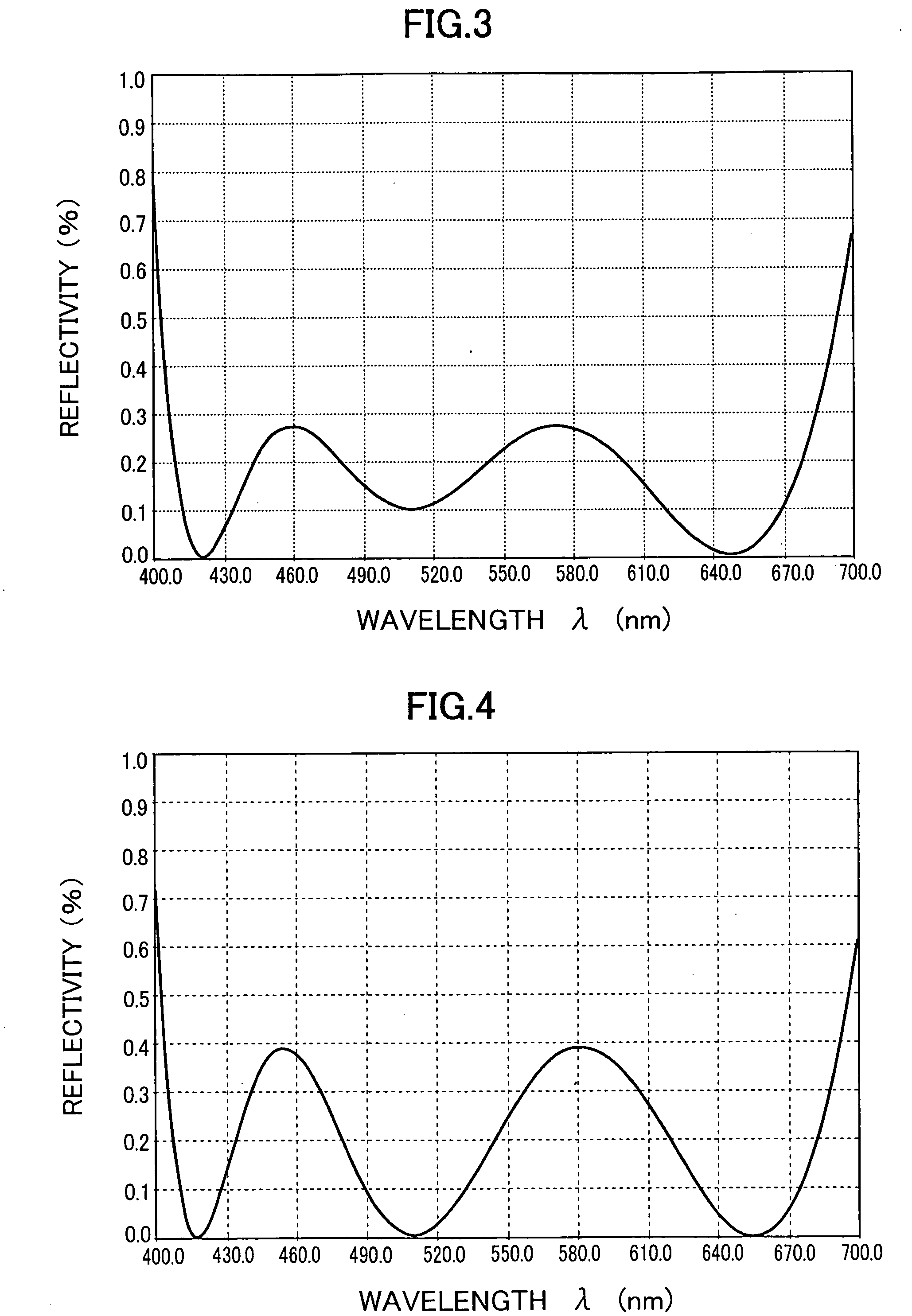

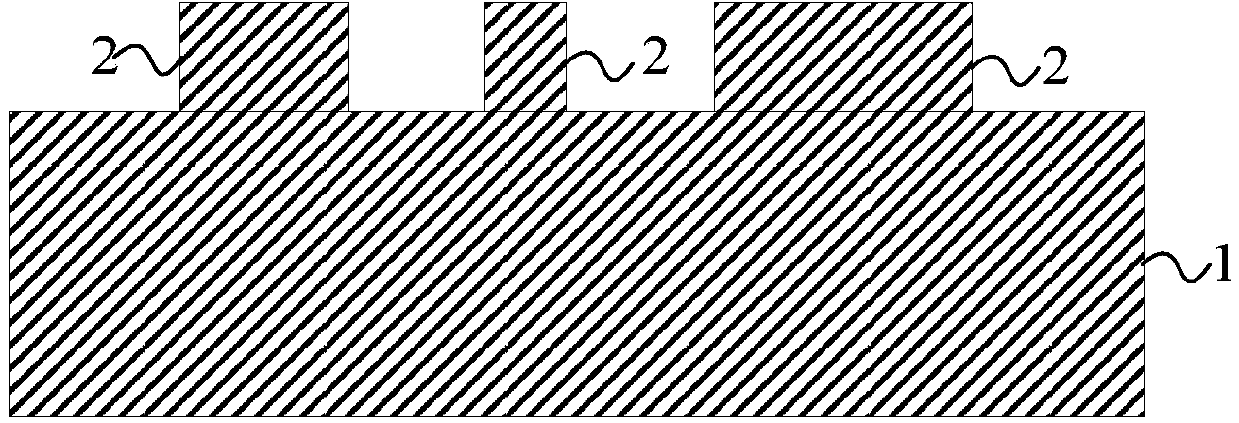

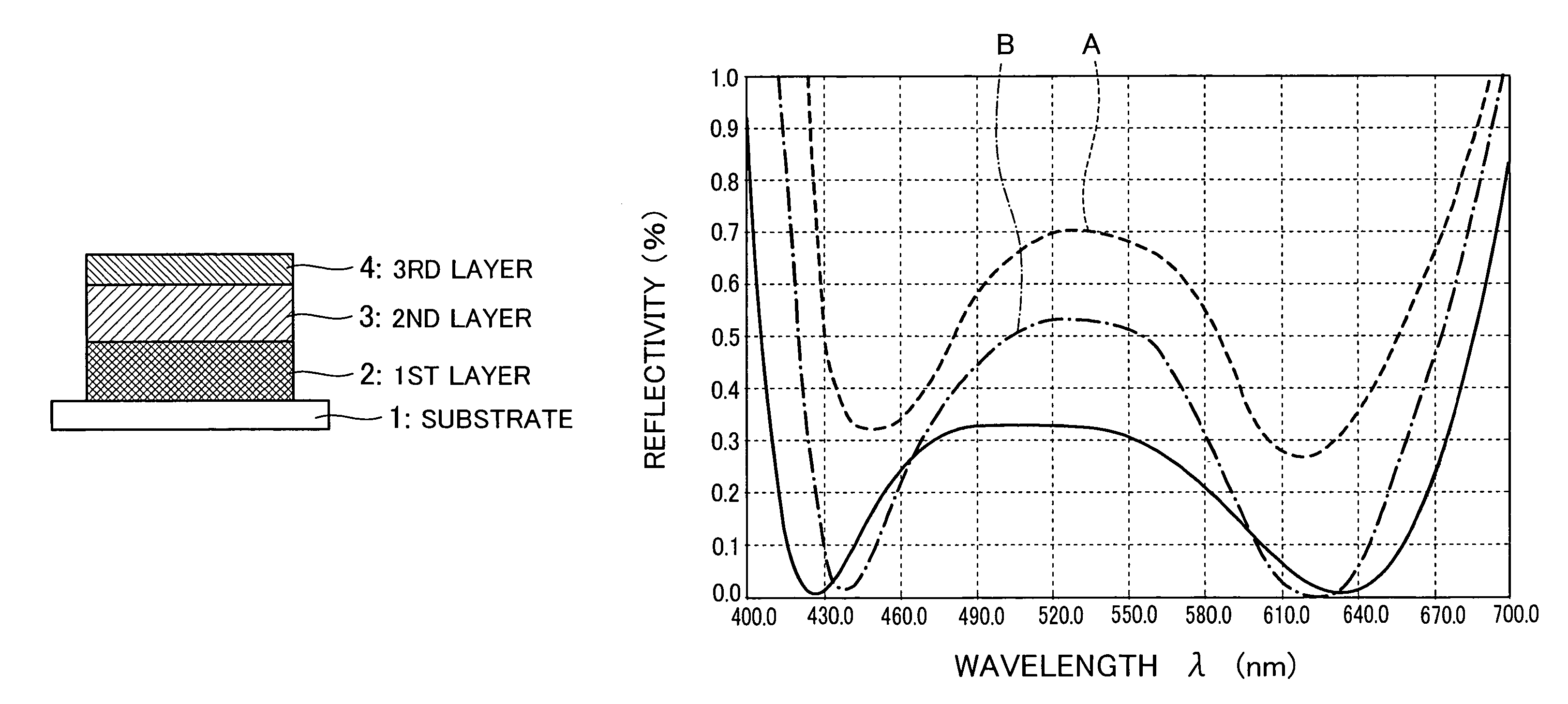

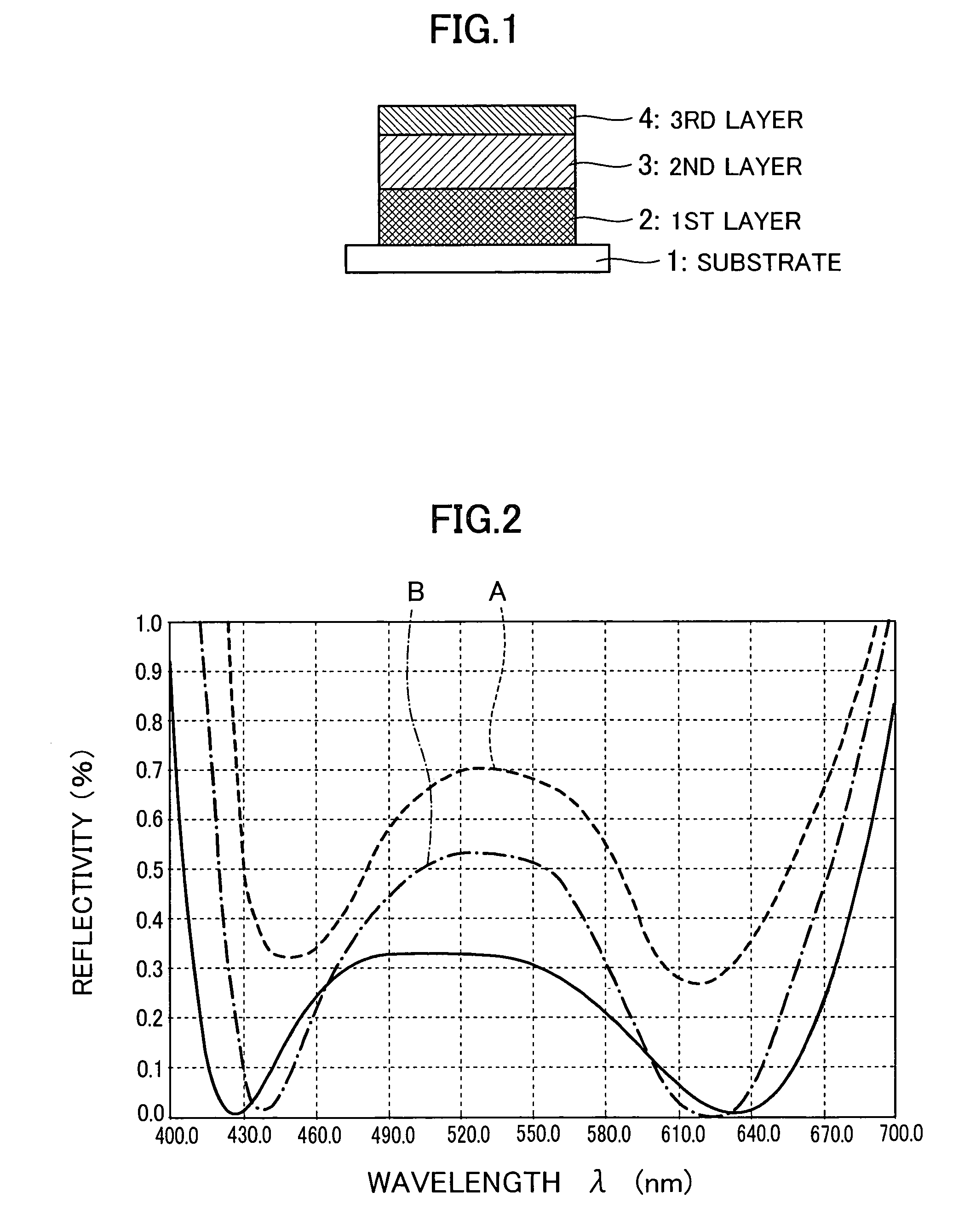

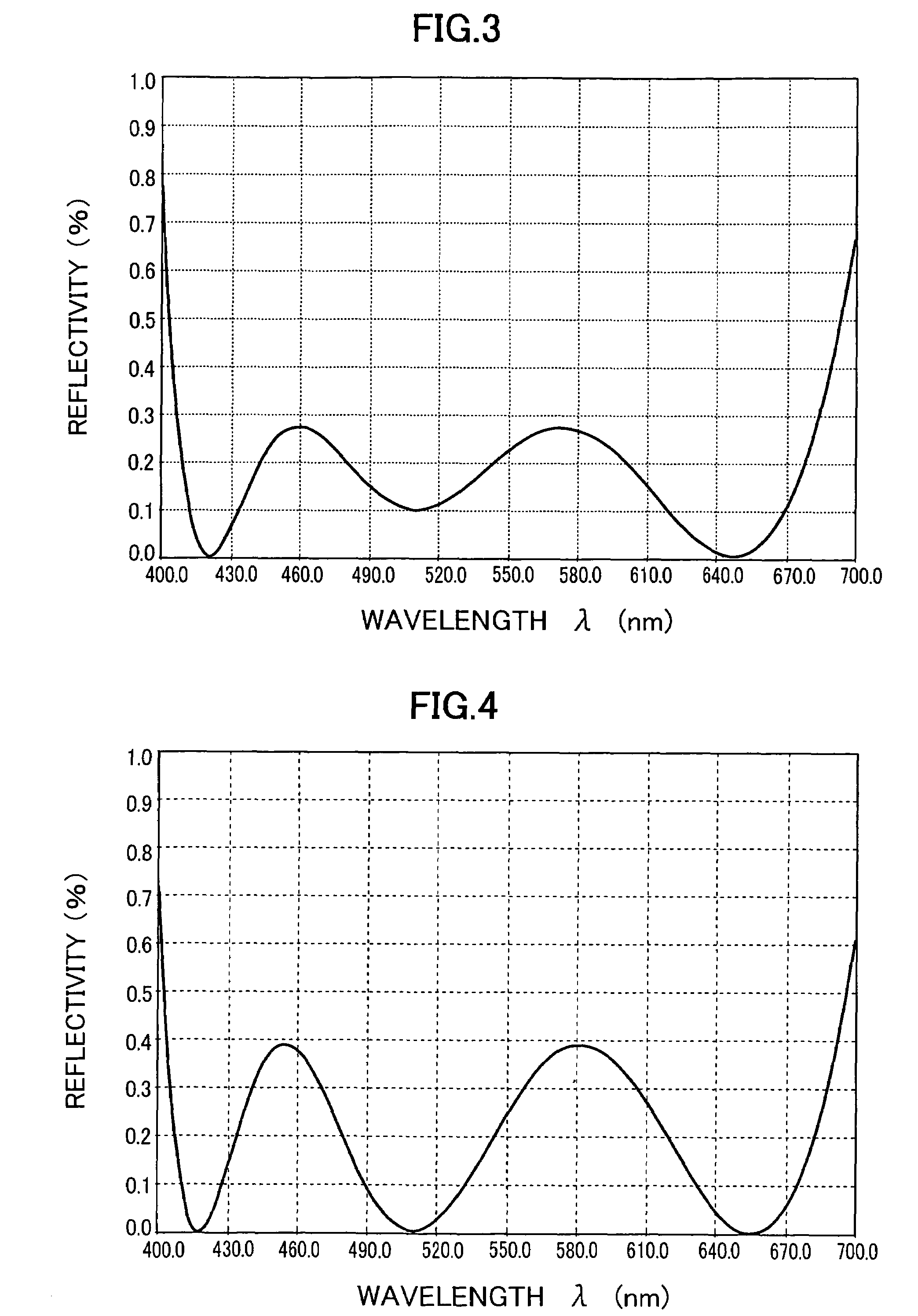

Anti-reflection film

InactiveUS20070070506A1Uniform widthReduce reflectivityCoatingsOptical elementsManufacturing cost reductionOptical property

The present invention is dedicated to a cost reduced anti-reflection film of a multi-lamination structure that is reduced in number of layers and increased in thickness of the same for the purpose of facilitating the total control of the film thickness and that can be manufactured in a simplified process so as to reduce the manufacturing cost. Three component layers are deposited one over another on a substrate ranging from 1.90≦ns≦2.10 in refractive index at an arbitrary design basis wavelength within a wavelength range in and near visible band, and these layers exhibit optical properties as in the following table: Refractive Index ‘n’Optical Film thickness ‘nd’1st Layer1.54 ≦ n1 ≦ 2.000.465 λ≦ n1d1 ≦ 0.575 λ2nd Layer1.95 ≦ n2 ≦ 2.630.490 λ≦ n2d2 ≦ 0.508 λ3rd Layer1.35 ≦ n3 ≦ 1.550.245 λ≦ n3d3 ≦ 0.255 λ

Owner:TAMRON

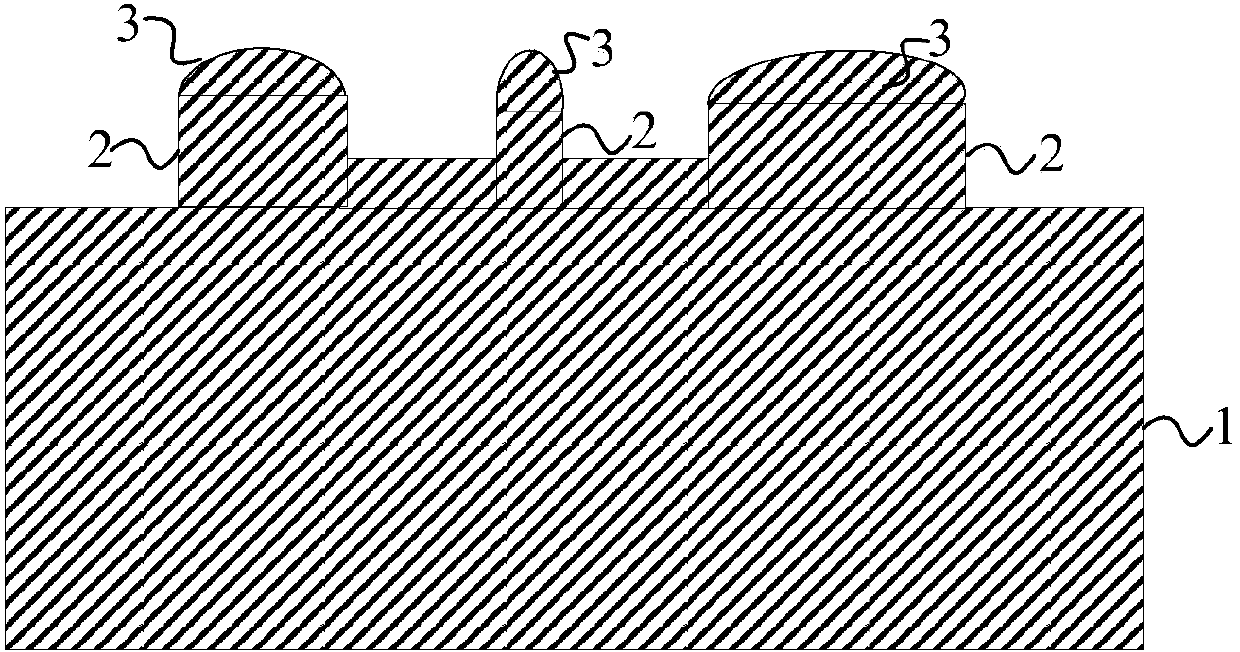

Subwavelength antireflective structure device and manufacturing method thereof

InactiveCN104049287AImprove anti-reflection abilityEasy to operateCoatingsSub wavelengthMaterials science

The invention provides a subwavelength antireflective structure device and a manufacturing method of the subwavelength antireflective structure device. The subwavelength antireflective structure device comprises a flat-top subwavelength antireflective structure, and the flat-top subwavelength antireflective structure comprises a substrate and a flat-top surface microstructure etched on the substrate; the subwavelength antireflective structure device further comprises a non-flat-top structure, obtained in an oblique incidence depositional mode, above the flat-top surface microstructure; the non-flat-top structure and the substrate are made of the same material. Compared with the prior art, the subwavelength antireflective structure device can enhance the antireflective effect of a flat-top subwavelength antireflective structure in the prior art.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Production method of antireflection film, antireflection film, polarizing plate and image display device

InactiveCN101320100AImprove scratch resistanceImprove anti-reflection abilitySynthetic resin layered productsPolarising elementsPhysical chemistryThin membrane

To provide a production method of an antireflection film excellent in the scratch resistance while having sufficiently high antireflection performance; an antireflection film obtained by the production method; and a polarizing plate and an image display device each comprising the antireflection film. A method for producing an antireflection film comprising a transparent substrate having thereon an antireflection layer comprising at least one layer, the production method comprising forming at least one layer on the transparent support by a layer forming method comprising the following steps (1) and (2): (1) a step of applying a coating layer on a transparent substrate, and (2) a step of curing the coating layer by irradiating ionizing radiation in an atmosphere having an oxygen concentration lower than the oxygen concentration in the air.

Owner:FUJIFILM CORP

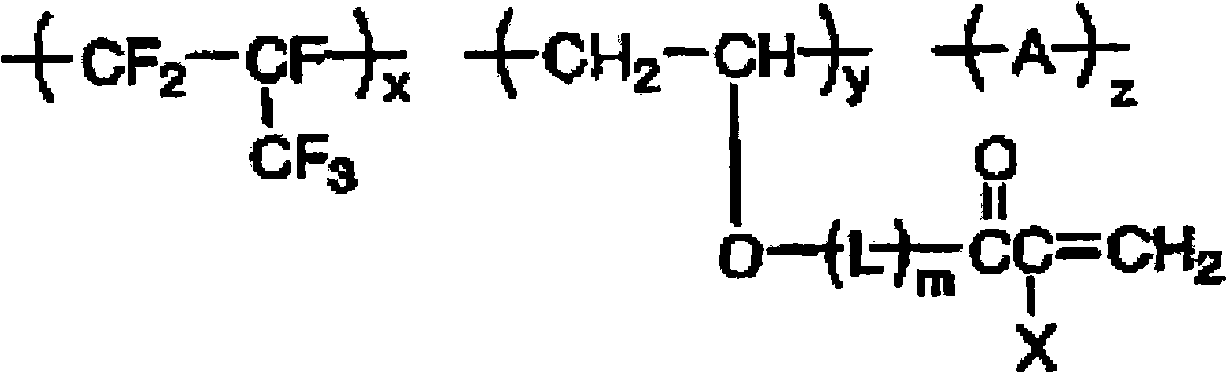

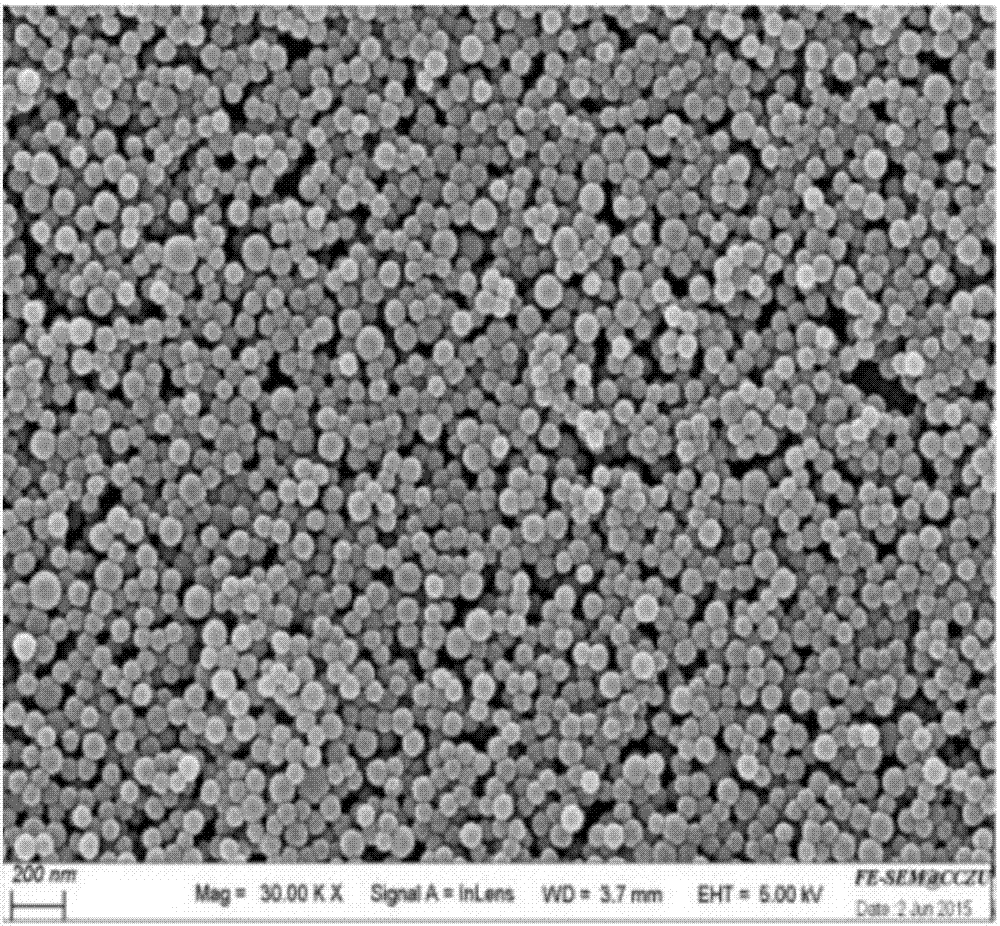

Modified high-antireflection optical thin film and preparation method thereof

The invention relates to the field of surface modification of an organic thin film material, and in particular relates to a modified high-antireflection optical thin film and a preparation method thereof. According to the modified high-antireflection optical thin film, a polyhedral oligomeric silsesquioxane structure (POSS) containing amino is introduced into a fluorine-containing emulsion polymer to synthesize a fluorine-containing emulsion copolymer with an optical antireflection function; latex particles in emulsion are uniformly distributed on the surface of a matrix, and the surface of a polyester matrix is coated with the emulsion; a lot of nano-grade pores are formed in the surface of the matrix through the effect of the polyhedral oligomeric silsesquioxane structure, so that a combined effective refractive index is relatively low, and furthermore, an optical antireflection function is realized. The preparation method provided by the invention is simple and easy to carry out and is low-cost; the light transmittance rate of the modified matrix is remarkably increased, and utilization requirements of electronic display devices and other optical elements are met.

Owner:JIANGXI KEWEI FILM NEW MATERIALS

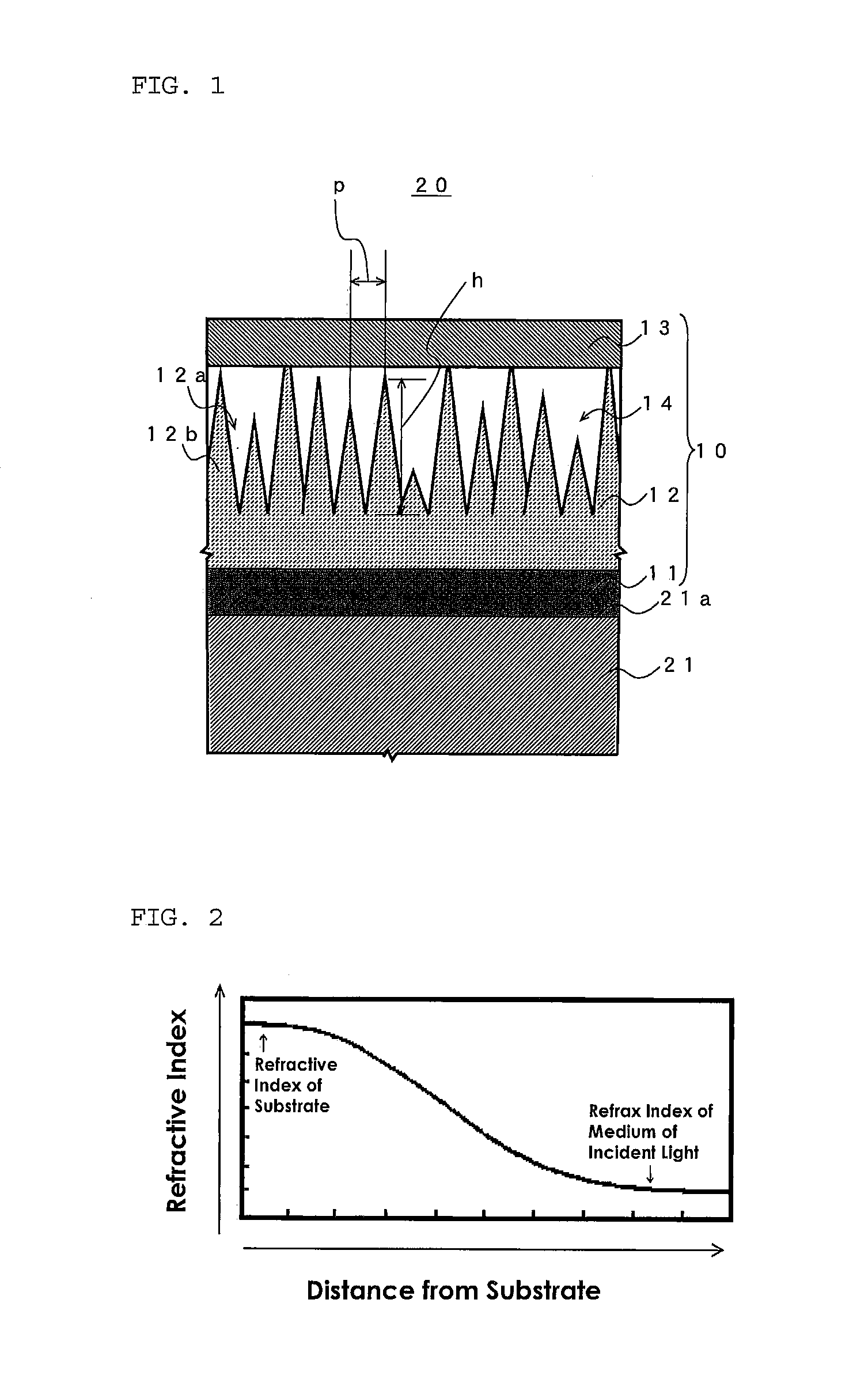

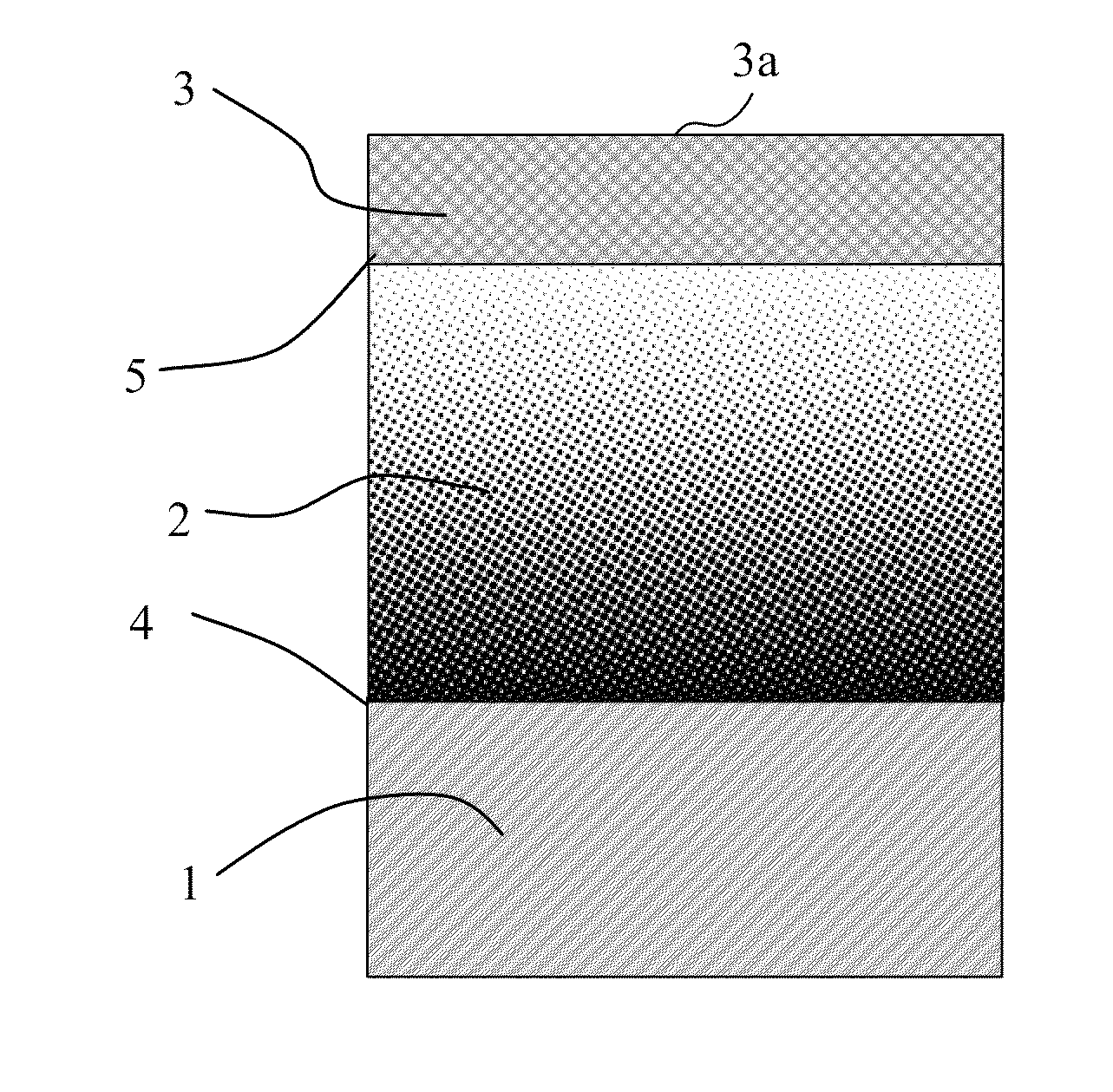

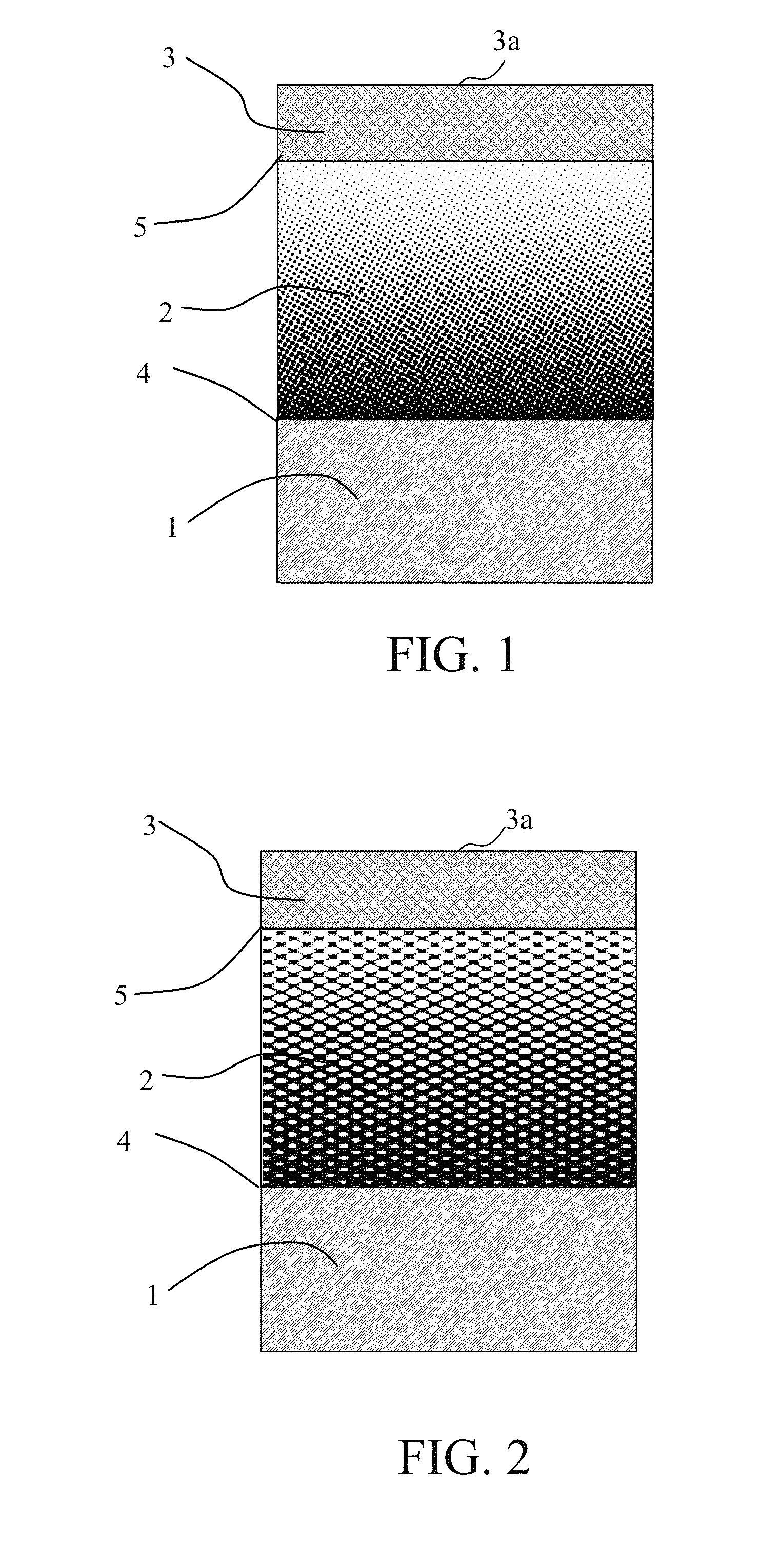

Anti-reflection structure with graded refractive index layer and optical apparatus including same

ActiveUS9291748B2High mechanical strengthImprove anti-reflection abilityOptical articlesOptical elementsEffective refractive index

The anti-reflection structure includes a graded refractive index layer that is disposed on a substrate and whose refractive index decreases as a distance from the substrate increases, and a homogeneous layer that is disposed on the graded refractive index layer and whose refractive index is homogeneous. The structure satisfies a condition of nb−na>0.10 where na represents the refractive index of the homogenous layer, and nb represents a homogenous layer side effective refractive index of the graded index refractive index layer.

Owner:CANON KK

Optical film and display panel

ActiveUS9158044B2Improve wear resistanceLow refractive indexDiffusing elementsNon-linear opticsDisplay deviceRefractive index

An optical film having an optically-transparent substrate, and a low refractive index layer having a thickness d on one side of the optically-transparent substrate, a polarizing plate and a display panel provided with the same, and a display provided with the same.

Owner:DAI NIPPON PRINTING CO LTD

Anti-reflection film

InactiveUS7379244B2Uniform widthReduce reflectivityCoatingsOptical elementsManufacturing cost reductionOptical property

The present invention is dedicated to a cost reduced anti-reflection film of a multi-lamination structure that is reduced in number of layers and increased in thickness of the same for the purpose of facilitating the total control of the film thickness and that can be manufactured in a simplified process so as to reduce the manufacturing cost. Three component layers are deposited one over another on a substrate ranging from 1.90≦ns≦2.10 in refractive index at an arbitrary design basis wavelength within a wavelength range in and near visible band, and these layers exhibit optical properties as in the following table:Refractive Index ‘n’Optical Film thickness ‘nd’1st Layer1.54 ≦ n1 ≦ 2.000.465 λ≦ n1d1 ≦ 0.575 λ2nd Layer1.95 ≦ n2 ≦ 2.630.490 λ≦ n2d2 ≦ 0.508 λ3rd Layer1.35 ≦ n3 ≦ 1.550.245 λ≦ n3d3 ≦ 0.255 λ.

Owner:TAMRON

Preparation method of optical film, optical film and display panel

InactiveCN110221363AImprove anti-reflection abilityIncrease contrastPretreated surfacesSpecial surfacesEngineeringSurface plate

The application provides a preparation method of an optical film, the optical film, and a display panel. The preparation method of the optical film comprises the following steps of placing a pluralityof graphene sheets prepared in advance in a mixed solution to form an anti-reflection mixed solution; coating the anti-reflective mixed solution on a substrate; orienting the anti-reflective mixed solution by a magnetic field to deflect the plurality of graphene sheets in the anti-reflective mixed solution to a predetermined angle; and curing the anti-reflective mixed solution to form an anti-reflective layer on the substrate. In the application, by forming an anti-reflective layer having graphene sheets on the substrate, the graphene sheets can reduce reflection of the ambient light when external ambient light is irradiated onto the optical film, thereby improving the anti-reflective capability of the display panel and further improving the contrast of the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com