Anti-reflection coating constructed based on cage type silsesquioxane and preparing method and application thereof

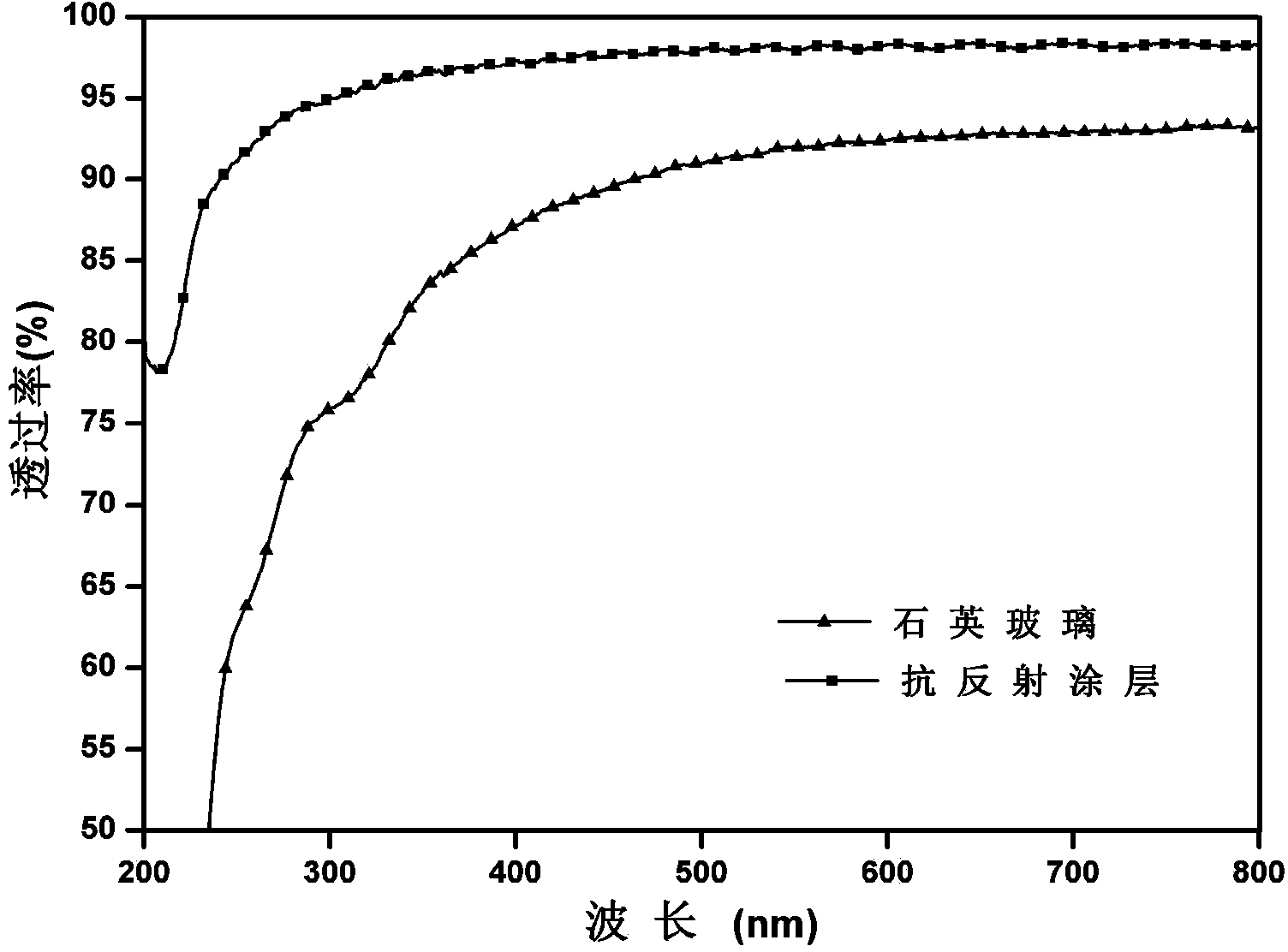

A technology of silsesquioxane and anti-reflection coating, which is applied in the field of nano-hybrid composite materials, can solve problems such as the influence of anti-reflection performance on the coating surface, and achieve improved anti-reflection performance, convenient operation, and improved corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 0.2g of decamethacryloxypropyl cage silsesquioxane (CMSQ-T 10 ) and 0.01g octaaminophenyl cage silsesquioxane (OAPS-T 8 ) mixed to obtain the bottom spin coating, adding 21g of methanol-acetone mixed solvent with a mass ratio of 1:1 and 100ppm cerium ammonium nitrate and mixing uniformly to obtain the bottom spin coating solution; 15 μL of the above bottom spin coating solution was placed in 10% HCl solution After ultrasonic cleaning with acetone for 30 minutes, the center of the quartz glass sheet substrate was spin-coated at 200r / min for 10s and 3000r / min for 10s with a spin coater (WS-400B, Laurell Technologies Corporation) to obtain a uniform transparent primer with a thickness of 80-90nm. layer film; place the quartz glass substrate coated with the bottom coating film in a vacuum drying oven, and pre-cure at 80°C for 15 minutes to obtain the bottom coating;

[0043] (2) Preparation of surface coating film: Add 10g of hexafluorobutyl acrylate monomer (HFBA) and...

Embodiment 2

[0047] (1) 0.2g of decamethacryloxypropyl cage silsesquioxane (CMSQ-T 10 ) and 0.02g octaaminophenyl cage silsesquioxane (OAPS-T 8 ) mixed to obtain the bottom spin coating material, adding 22g of methanol-acetone mixed solvent with a mass ratio of 1:1 and 100ppm cerium ammonium nitrate and mixing uniformly to obtain the bottom spin coating solution; 15 μL of the above bottom spin coating solution was placed in 10% HCl solution respectively After ultrasonic cleaning with acetone for 30 minutes, the center of the quartz glass sheet substrate was spin-coated at 200r / min for 10s and 3000r / min for 10s with a spin coater (WS-400B, Laurell Technologies Corporation) to obtain a uniform transparent primer with a thickness of 80-90nm. layer film; place the quartz glass substrate coated with the bottom coating film in a vacuum drying oven, and pre-cure at 80°C for 30 minutes to obtain the bottom coating;

[0048] (2) Preparation of surface coating film: Add 10g of hexafluorobutyl acryl...

Embodiment 3

[0052] (1) 0.2g of decamethacryloxypropyl cage silsesquioxane (CMSQ-T 10 ) and 0.04g octaaminophenyl cage silsesquioxane (OAPS-T 8 ) mixed to obtain the bottom spin coating material, add 24g of methanol-acetone mixed solvent with a mass ratio of 1:1 and 100ppm cerium ammonium nitrate and mix uniformly to obtain the bottom spin coating liquid; take the above bottom spin coating liquid 15 μ L and put it in 10% HCl solution respectively After ultrasonic cleaning with acetone for 30 minutes, the center of the quartz glass sheet substrate was spin-coated at 200r / min for 10s and 3000r / min for 10s with a spin coater (WS-400B, Laurell Technologies Corporation) to obtain a uniform transparent primer with a thickness of 80-90nm. layer film; place the quartz glass substrate coated with the bottom coating film in a vacuum drying oven, and pre-cure at 80°C for 15 minutes to obtain the bottom coating;

[0053] (2) Preparation of surface coating film: Add 10g of hexafluorobutyl acrylate mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com