Modified high-antireflection optical thin film and preparation method thereof

An optical film and modification technology, applied in the direction of coating, etc., can solve the problem that the light transmittance of polyester film cannot be achieved, and achieve the effect of improving optical anti-reflection effect, stable performance, and enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

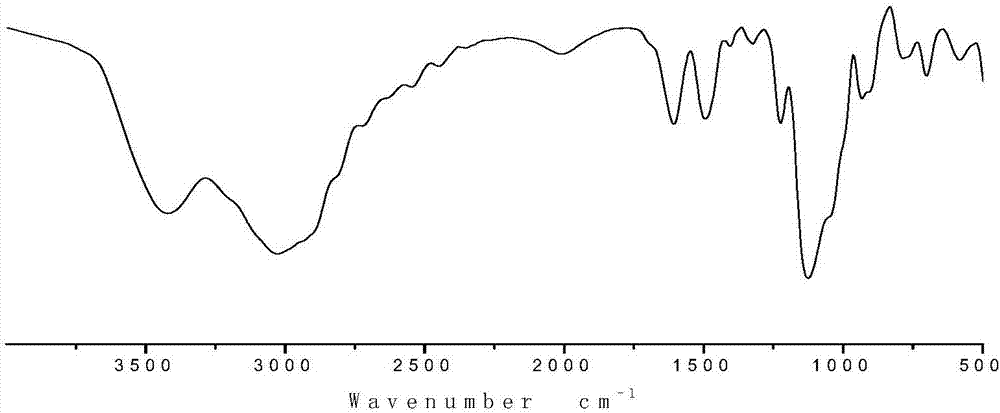

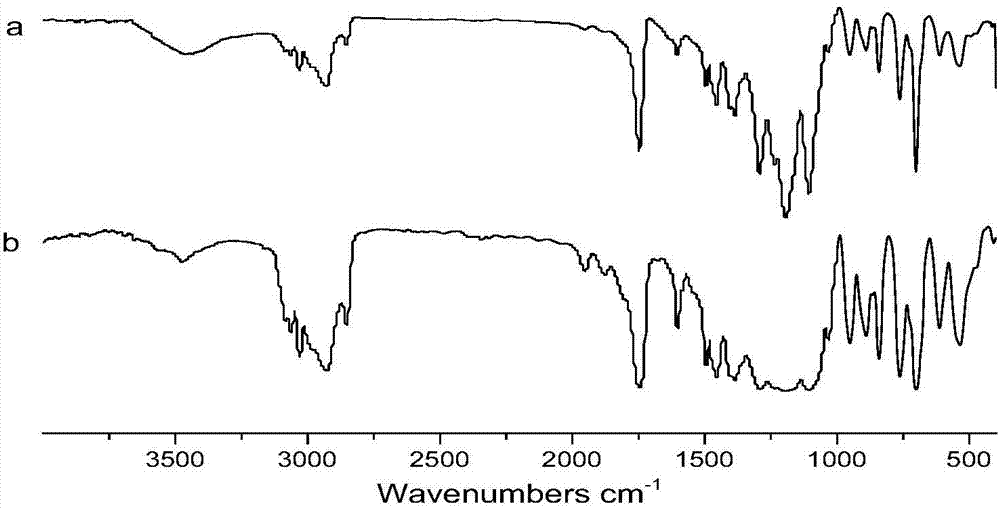

[0024] (1) Preparation of unmodified fluorine-containing acrylate emulsion copolymer: Add 0.8 g of sodium dodecylsulfonate emulsifier, distill 60 mL, and 0.2 g of potassium persulfate initiator into a three-necked flask, and place it in an oil bath at 45°C Stir evenly, and add 2.5mL of St (styrene) and 5mL of HFMA mixture dropwise into the three-necked flask through a constant pressure funnel. When the solution turns blue, add 0.2g of potassium persulfate initiator, slowly add the remaining 2.5mL of St (styrene) and 5mL of HFMA (hexafluorobutyl methacrylate) monomer through a constant pressure funnel at a temperature of 60°C, After the dropwise addition, react at 65°C for 5 hours to obtain an unmodified fluorine-containing acrylate emulsion copolymer, which is dried at room temperature to obtain a dried unmodified fluorine-containing acrylate emulsion copolymer;

[0025](2) Preparation of amino POSS modified fluorine-containing acrylate emulsion copolymer: Take 15mL of γ-amino...

Embodiment 2

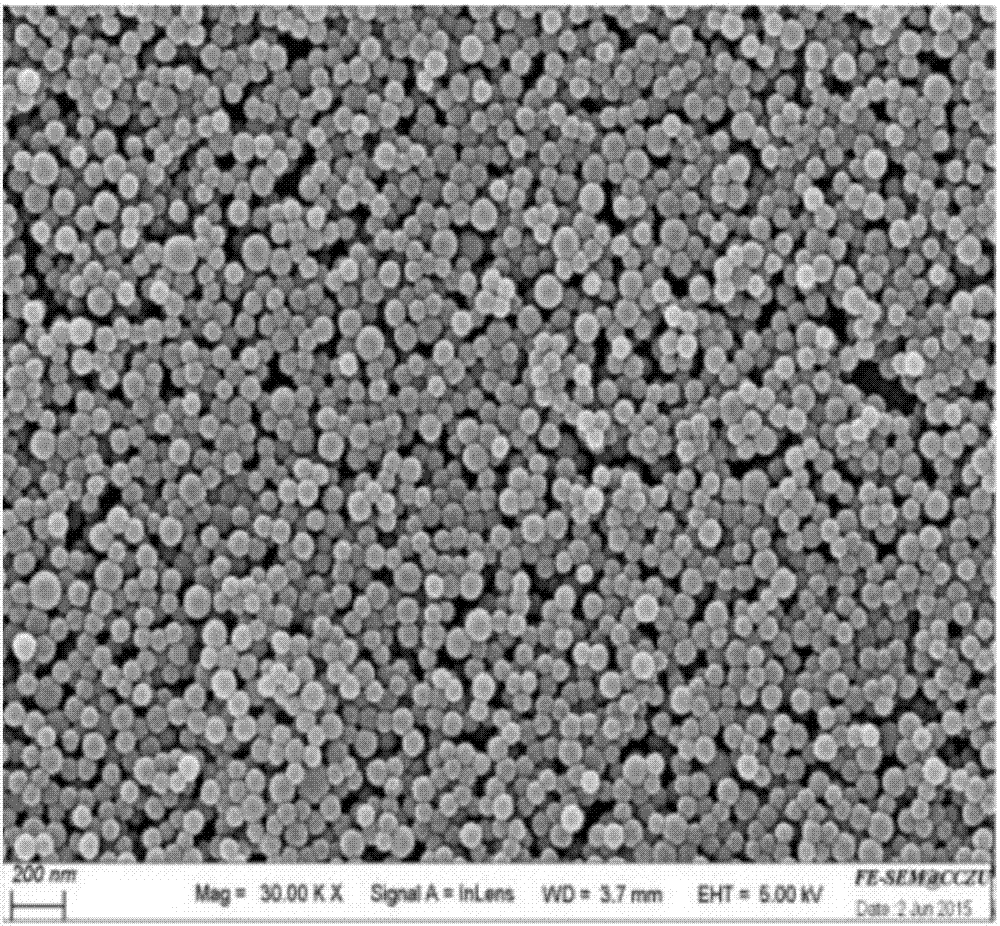

[0029] (1) Take 15mL of γ-aminopropyltriethoxysilane (KH-550) and 5-8mL of concentrated hydrochloric acid with a mass concentration of 30% and add it dropwise to 200mL of methanol solution and stir. After the reaction is complete, add 500mL of acetone solution , high-speed centrifugation, standing, and drying to obtain solid amino POSS; 0.8 g of sodium dodecylsulfonate emulsifier, 60 mL of distillation, 0.2 g of potassium persulfate initiator and 0.15 g of amino POSS were added to the three-necked flask, Put it in an oil bath at 45°C and stir evenly, and add 2.5mL of St (styrene) and 5mL of HFMA mixture into the three-necked flask dropwise through a constant pressure funnel. When the solution turns blue, add 0.2g of potassium persulfate initiator, slowly add the remaining 2.5mL of St (styrene) and 5mL of HFMA (hexafluorobutyl methacrylate) monomer through a constant pressure funnel at a temperature of 60°C, After the dropwise addition, react at 65°C for 5 hours to obtain an am...

Embodiment 3

[0033] (1) Take 15mL of γ-aminopropyltriethoxysilane (KH-550) and 5-8mL of concentrated hydrochloric acid with a mass concentration of 30% and add it dropwise to 200mL of methanol solution and stir. After the reaction is complete, add 500mL of acetone solution , high-speed centrifugation, standing, and drying to obtain solid amino POSS; 0.8 g of sodium dodecyl sulfonate emulsifier, 60 mL of distillation, 0.2 g of potassium persulfate initiator and 0.2 g of amino POSS were added to the three-necked flask, Put it in an oil bath at 45°C and stir evenly, and add 2.5mL of St (styrene) and 5mL of HFMA mixture into the three-necked flask dropwise through a constant pressure funnel. When the solution turns blue, add 0.2g of potassium persulfate initiator, slowly add the remaining 2.5mL of St (styrene) and 5mL of HFMA (hexafluorobutyl methacrylate) monomer through a constant pressure funnel at a temperature of 60°C, After the dropwise addition, react at 65°C for 5 hours to obtain an am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com