Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Guaranteed vertical accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

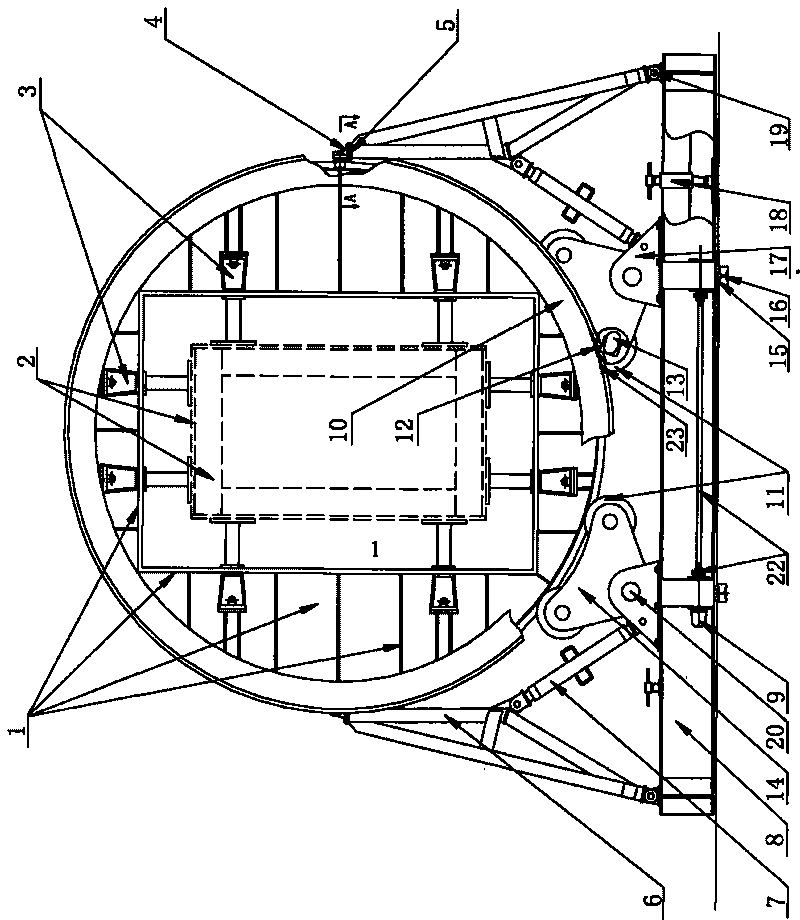

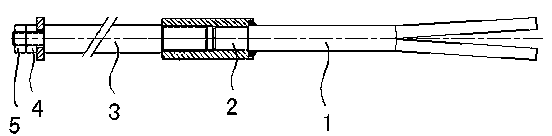

Rotator for welding box-shaped structural member

ActiveCN101700609AEasy to operate and labor-savingGuarantee the quality after weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld bead

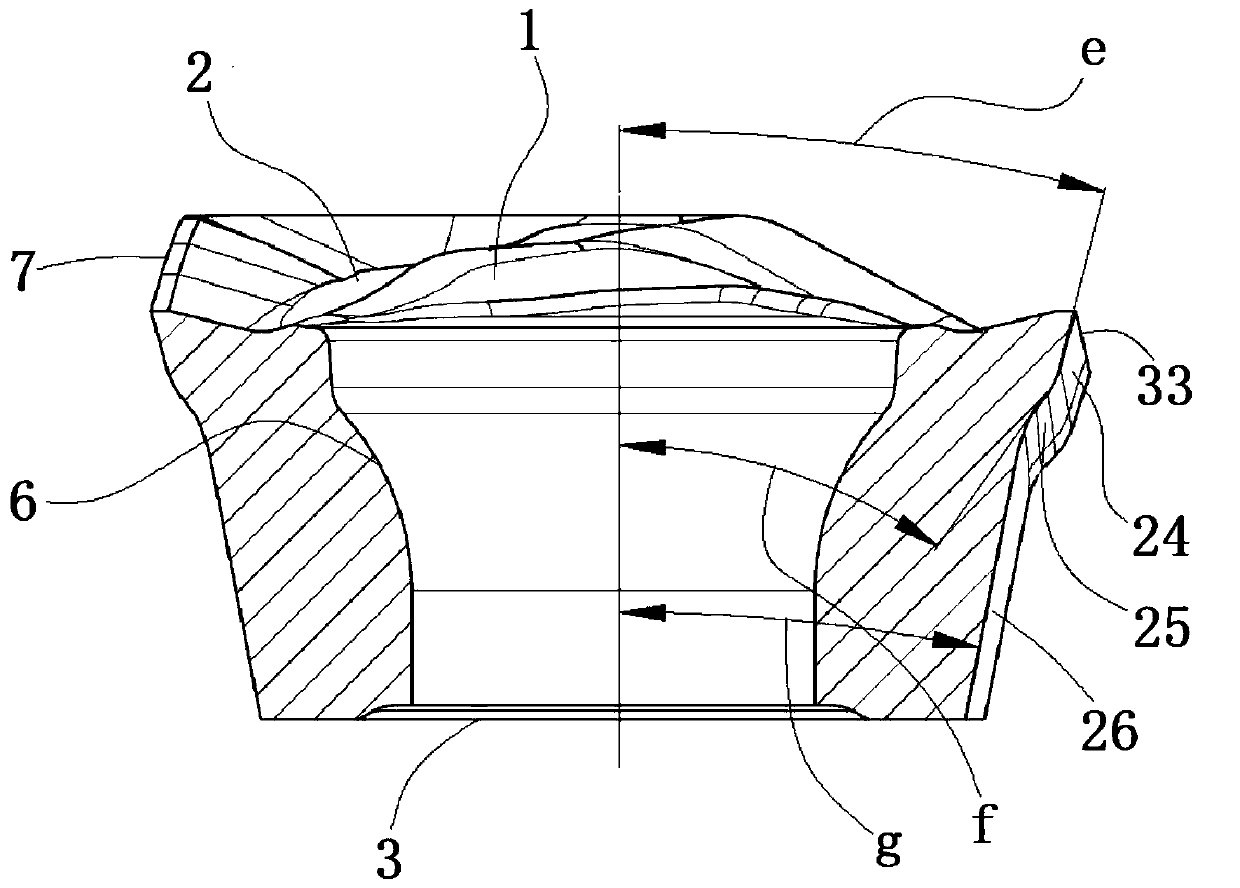

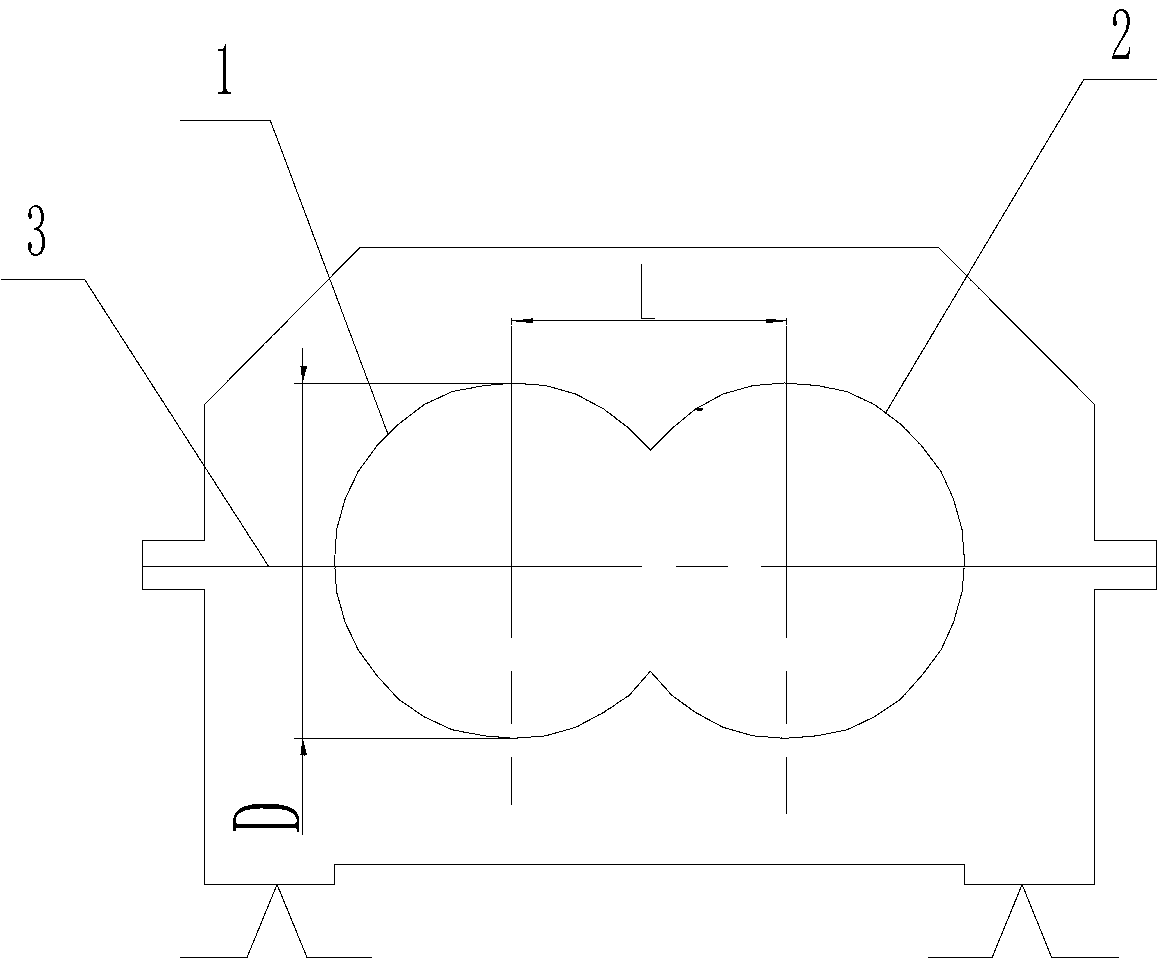

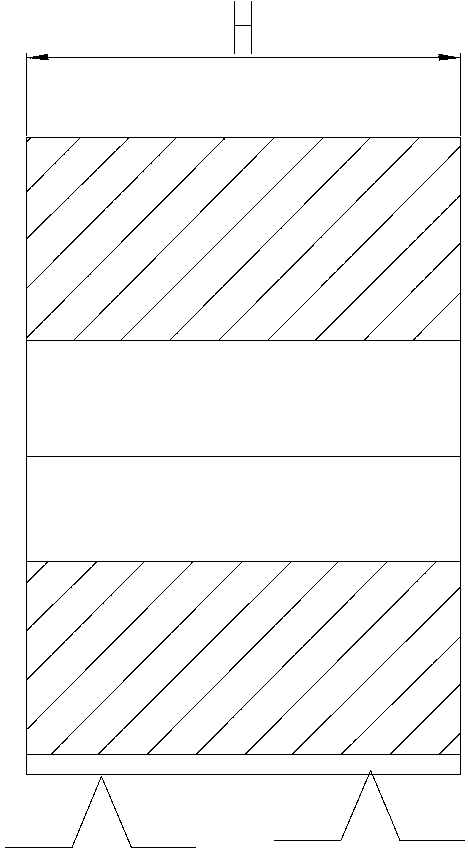

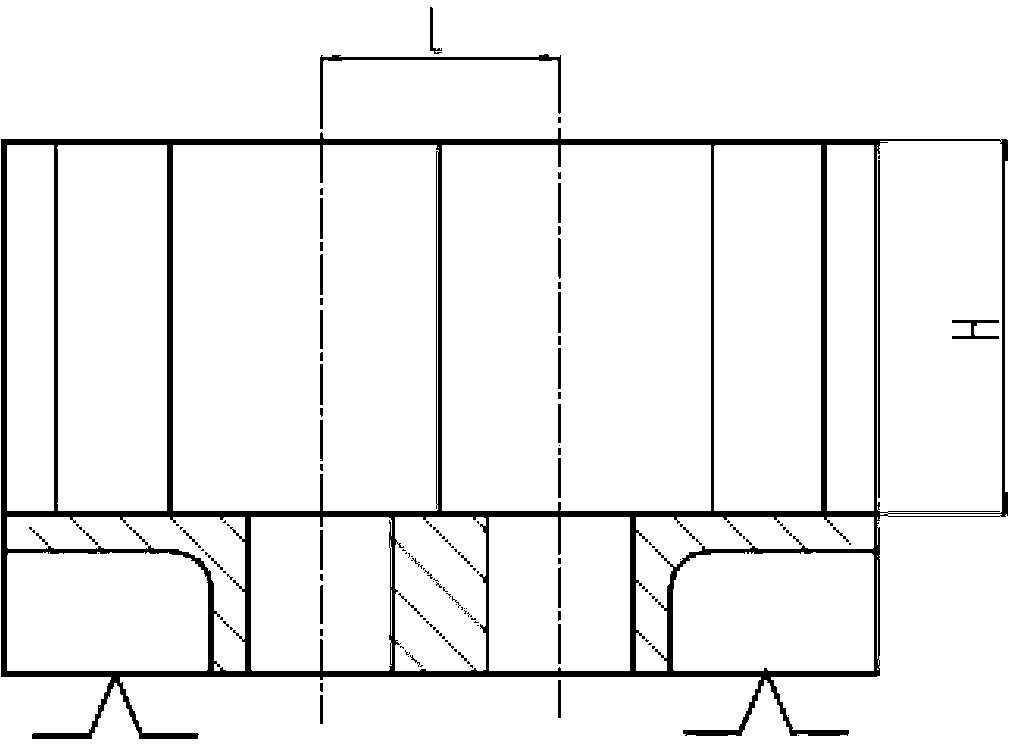

The invention discloses a rotator for welding a box-shaped structural member, which comprises two rotating track supporting mechanisms formed by annular groove-shaped tracks and intra-annular rectangular frames, wherein pin wheels are welded on axial end surfaces of the rotating track supporting mechanisms, and two sets of symmetrical supporting roller systems are arranged at the lower ends of the rotating track supporting mechanisms; each set of the supporting roller system comprises a supporting roller seat which is fixed on a base and is articulated with a supporting roller frame, and supporting rollers are symmetrically arranged at two sides at the upper part of the supporting roller frame and are embedded into the annular groove-shaped tracks; gears which are meshed with the pin wheels are concentrically installed on the supporting rollers at different axes; each supporting roller seat is connected with two side supporting frames through a tension adjuster, the lower ends of the supporting frames are articulated with the base, and the upper ends of the supporting frames are fixedly connected with a guide roller mechanism through supporting frame seat boards; and traveling steel wheels which are embedded into a traveling track are arranged on the bottom surface of the base, and fixing devices are arranged at two sides of the base. The rotator of the invention can freely turn the welded box-shaped structural member at any time in the welding process, thereby turning a welding bead to the optimal angle for welding.

Owner:苏州盛泽科技创业园发展有限公司

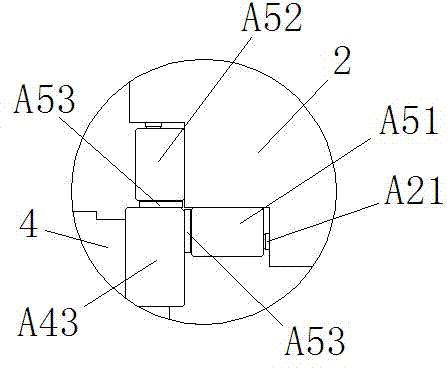

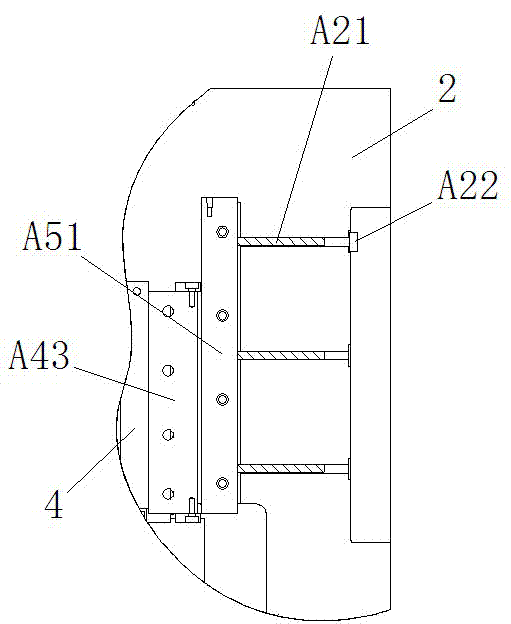

Continuous wall milling machine

InactiveCN102155035AExtended service lifeReduce maintenance costsSoil-shifting machines/dredgersBulkheads/pilesMilling cutterEngineering

The invention discloses a continuous wall milling machine, which comprises a host machine base plate, an upright post, a gantry frame, a guide frame, a milling box, a milling and stirring chain, a steel wire rope, an inclined strut and a correcting mechanism, wherein a milling frame adopts a box structure and can be extended to a set length; the milling and stirring chain comprises a chain, and multiple groups of crossed milling cutter bodies and multiple groups of stirring bodies which are fixedly arranged on the chain at certain intervals; after the chain is arranged on a driving chain wheel and a driven chain wheel, a chain transmission mechanism is formed; a transmission case is positioned on the upper part of the milling box; a driving head is fixedly arranged at an installation position above the transmission case; the driving chain wheel is arranged on an output shaft at the lower end of the transmission case; the output shaft is arranged on a supporting platform; one end of a tension oil cylinder is hinged with the lower part of the supporting platform, and the other end of the tension oil cylinder is connected with a lower rod piece; the correcting mechanism is used for obliquely correcting the front, back, left and right of the milling frame; multiple groups of grout pipes are arranged inside the milling frame along the length direction of the milling frame; and the end parts of the grout pipes are provided with spray heads. The continuous wall milling machine is suitable for underground facilities of large buildings, deep foundation excavation and cut-off wall construction of water conservancy dams.

Owner:上海工程机械厂有限公司

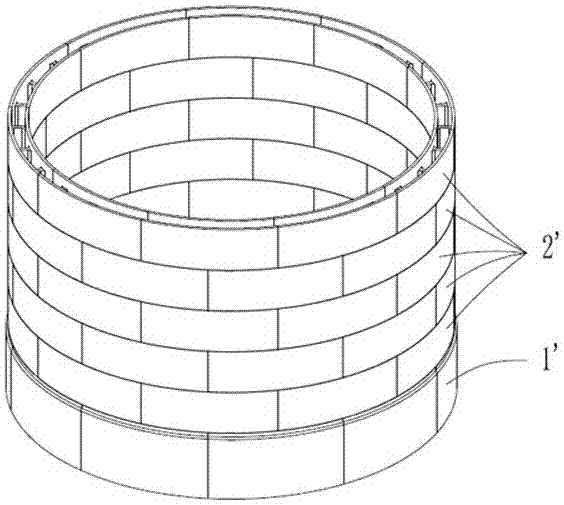

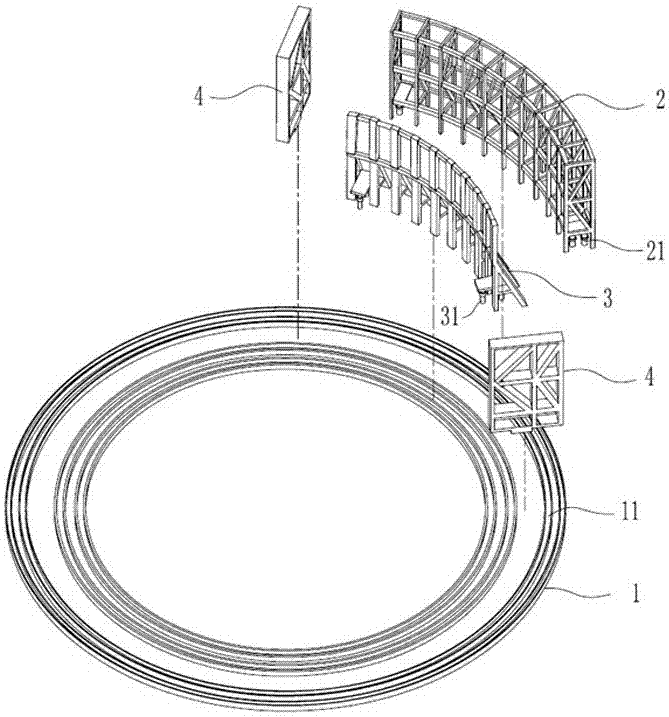

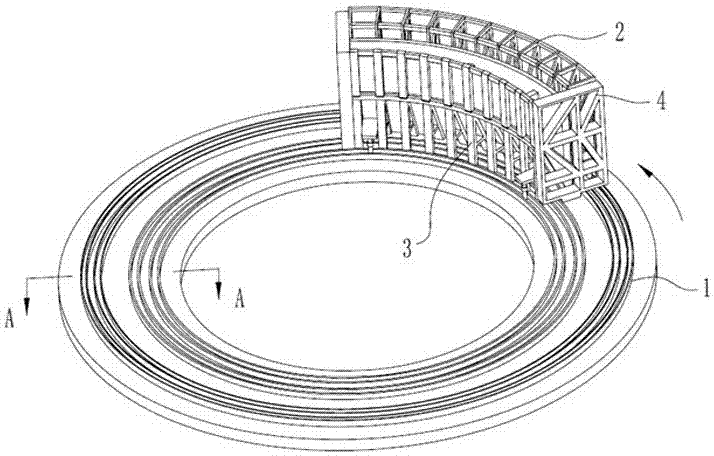

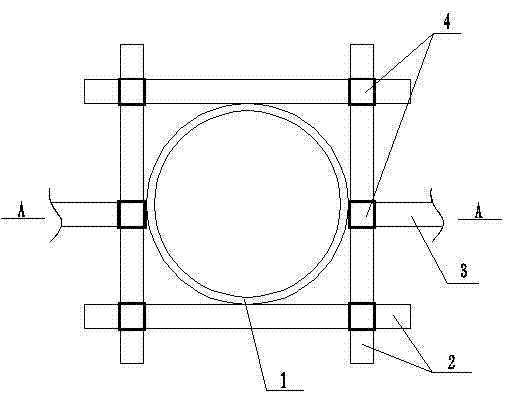

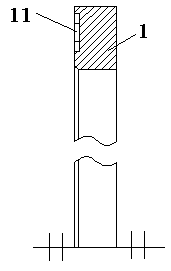

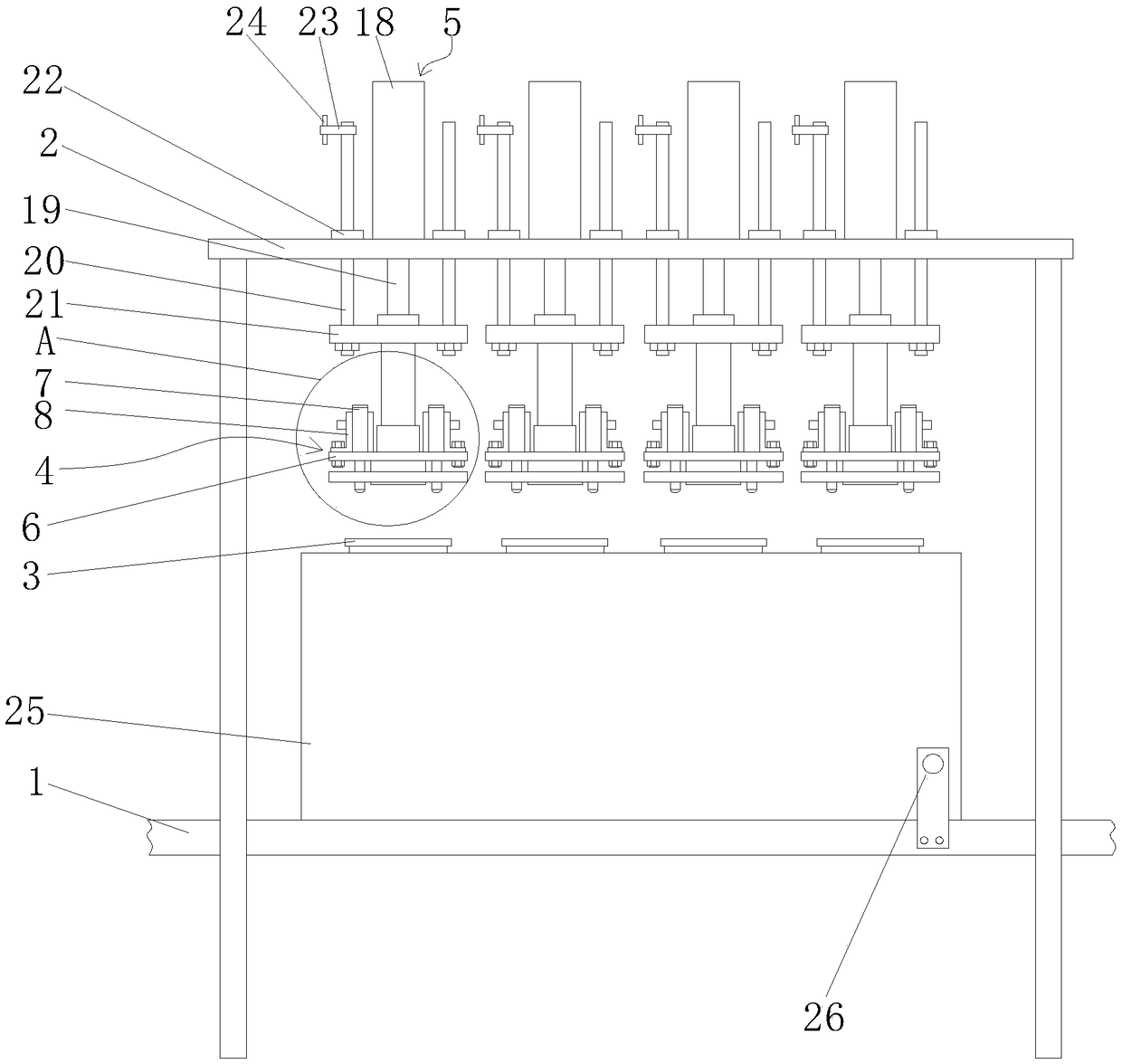

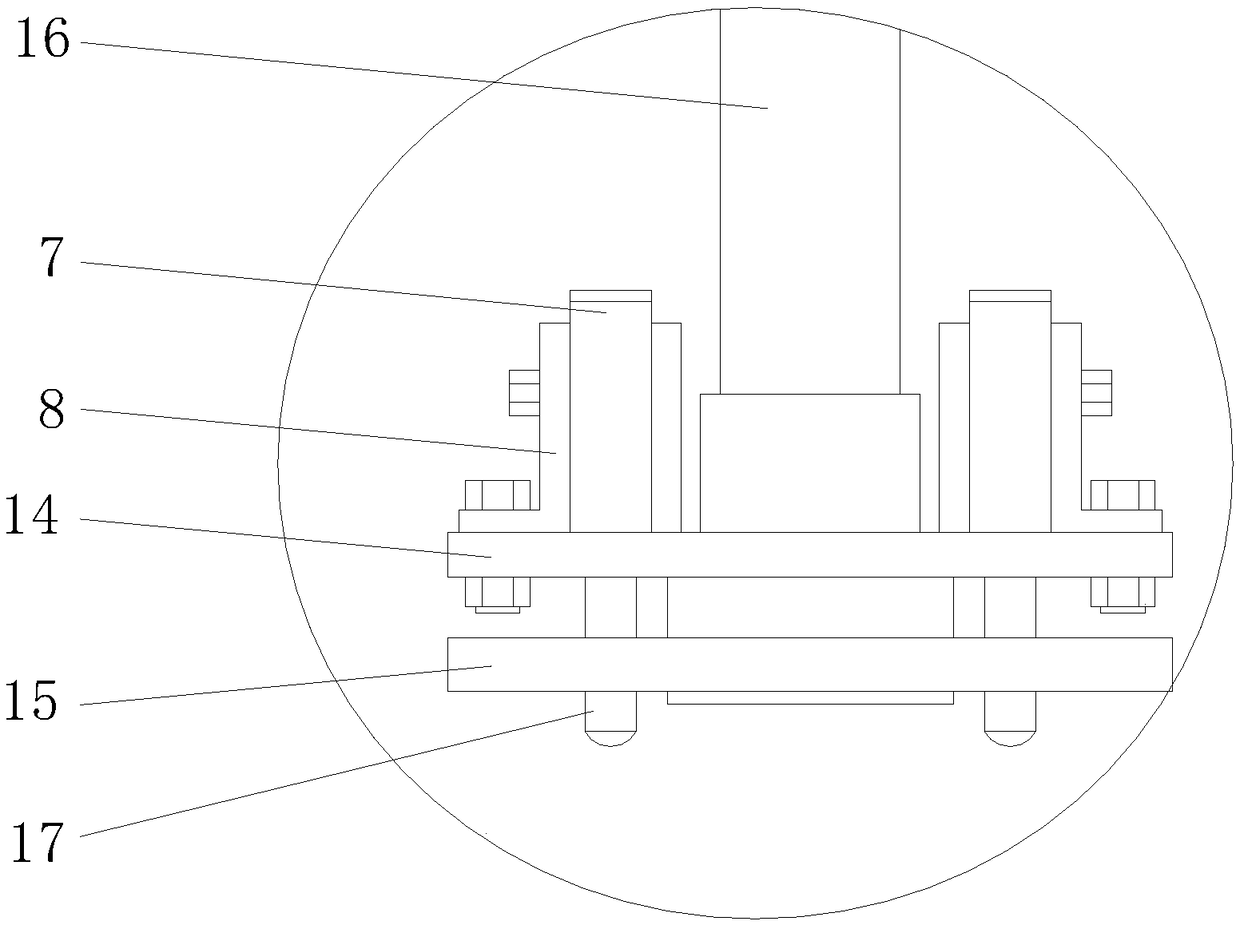

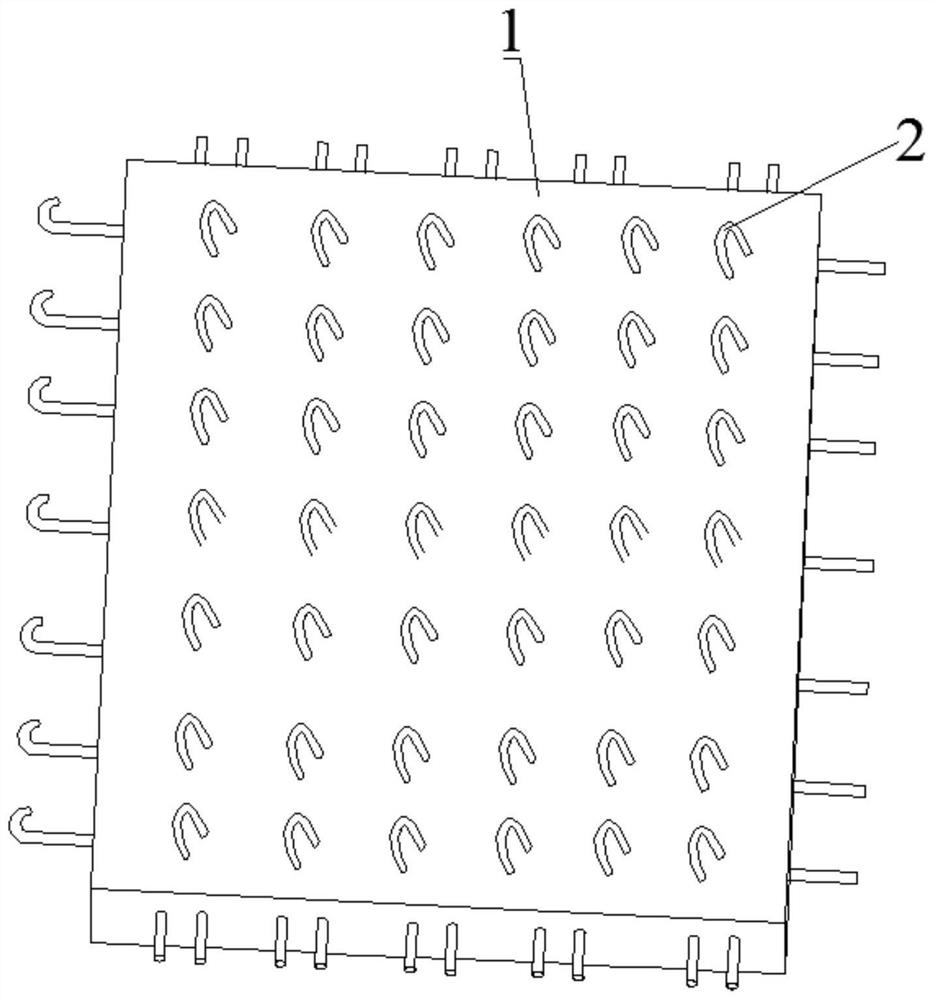

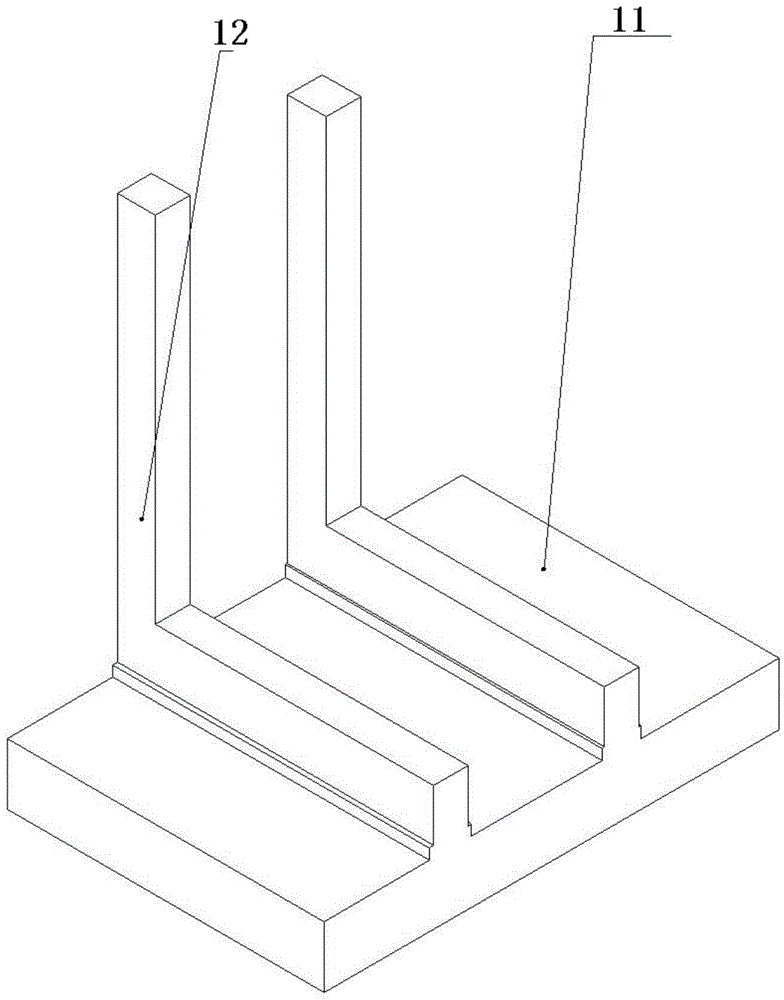

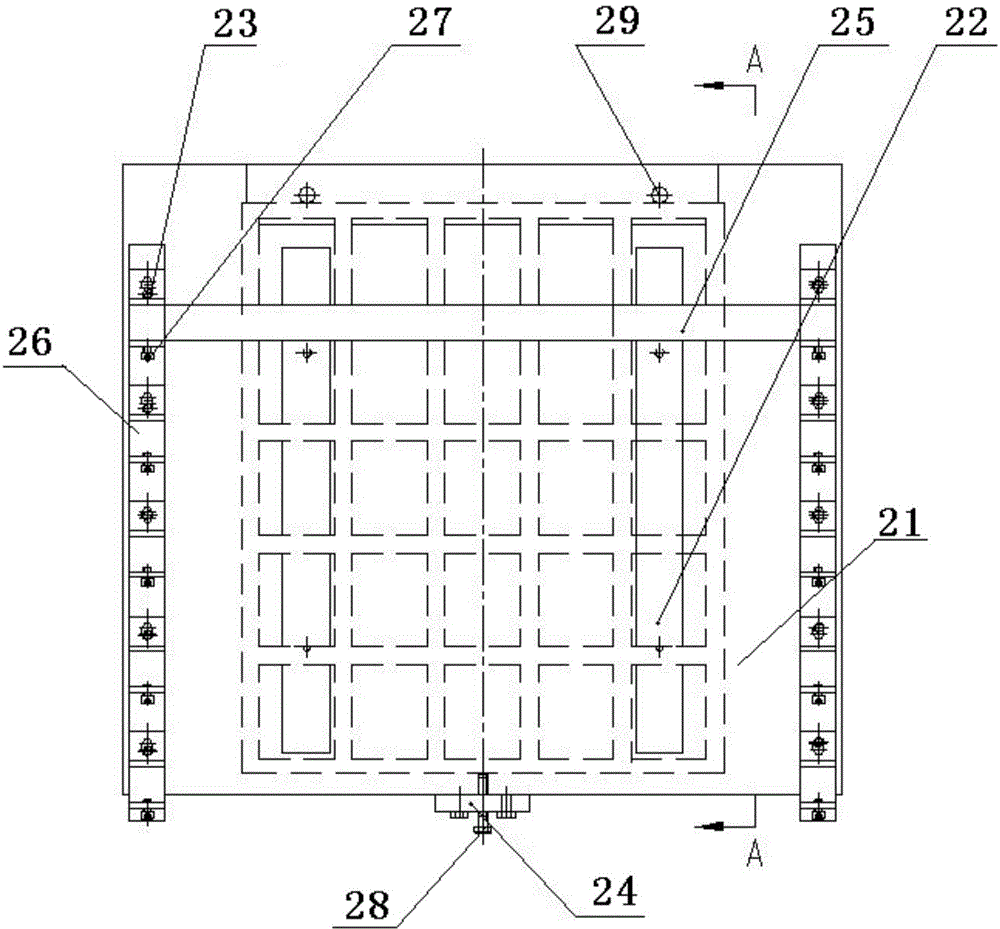

Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

PendingCN107575023AGuaranteed vertical accuracyGuaranteed assembly qualityForms/shuttering/falseworksCaissonsSteel barBuilding construction

The invention discloses a sliding formwork component. The sliding formwork component comprises a sliding way, an outer template, an inner template, two side templates and a plurality of connecting fixing pieces. The sliding way is provided with a plurality of sliding grooves for installation of the outer template and the inner template. A plurality of outer stand bars are arranged at the bottom ofthe outer template. The outer stand bars are arranged on the outer side of the sliding way and can be installed and move along the sliding grooves. A plurality of inner stand bars are arranged at thebottom of the inner template. The inner stand bars are arranged on the inner side of the sliding way and can be installed and move along the sliding grooves. The side templates are arranged on the two side edges of the inner template and the two side edges of the outer template and are connected with the inner template and the outer template through the connecting fixing pieces. The invention further discloses an open caisson blade foot layer sliding formwork construction method. The method comprises the steps of field leveling, sliding way installing, steel bar bundling, template installing,concrete pouring, side template dismounting, template sliding and the like. According to the sliding formwork component and the method, the linear vertical perpendicularity after blade foot construction is finished can be ensured, and accordingly the assembling quality of upper-layer open caisson standard segments is guaranteed.

Owner:中铁科建有限公司

Prestressed pipe pile construction method under boulder group geological conditions

InactiveCN103290840AHigh selectivityPrevent buried drilling phenomenonBulkheads/pilesPre stressArchitectural engineering

The invention relates to a pipe pile construction method, in particular to a prestressed pipe pile construction method under boulder group geological conditions. According to the method, a down-the-hole hammer drilling process is adopted for guide hole construction; during pile sinking construction, first cement mortar is poured in a pile hole, and then a static pile driver is utilized to press a pipe pile into the pile hole; during pile head fixing construction, a #-shaped fixing frame formed by connecting fasteners is utilized to fix a pile head through a steel pipe at the position of an orifice of the pile hole, a splayed steel pipe is adopted to support two ends of the #-shaped fixing frame, the lower end of the steel pipe is embedded in a soil layer; and after the cement mortar is hardened and is integrated with surrounding rock stratums and the pipe pile, prestressed pipe pile construction is finished. According to the prestressed pipe pile construction method, a hole forming speed is quick, a construction period is short, and construction cost can be reduced by over 10%; by adopting a mode of pouring the cement mortar in the guide hole, pipe pile side pressure, end bearing capacity and the position of the pile side can be guaranteed, and side-direction stress safety of the pipe pile can be guaranteed; a pile head fixing head is simple, construction is convenient, verticality of the pipe pile is guaranteed, and bearing capacity of the prestressed pipe pile is also effectively improved.

Owner:二十二冶集团天津建设有限公司

Method for compensating laser flatness measurement error

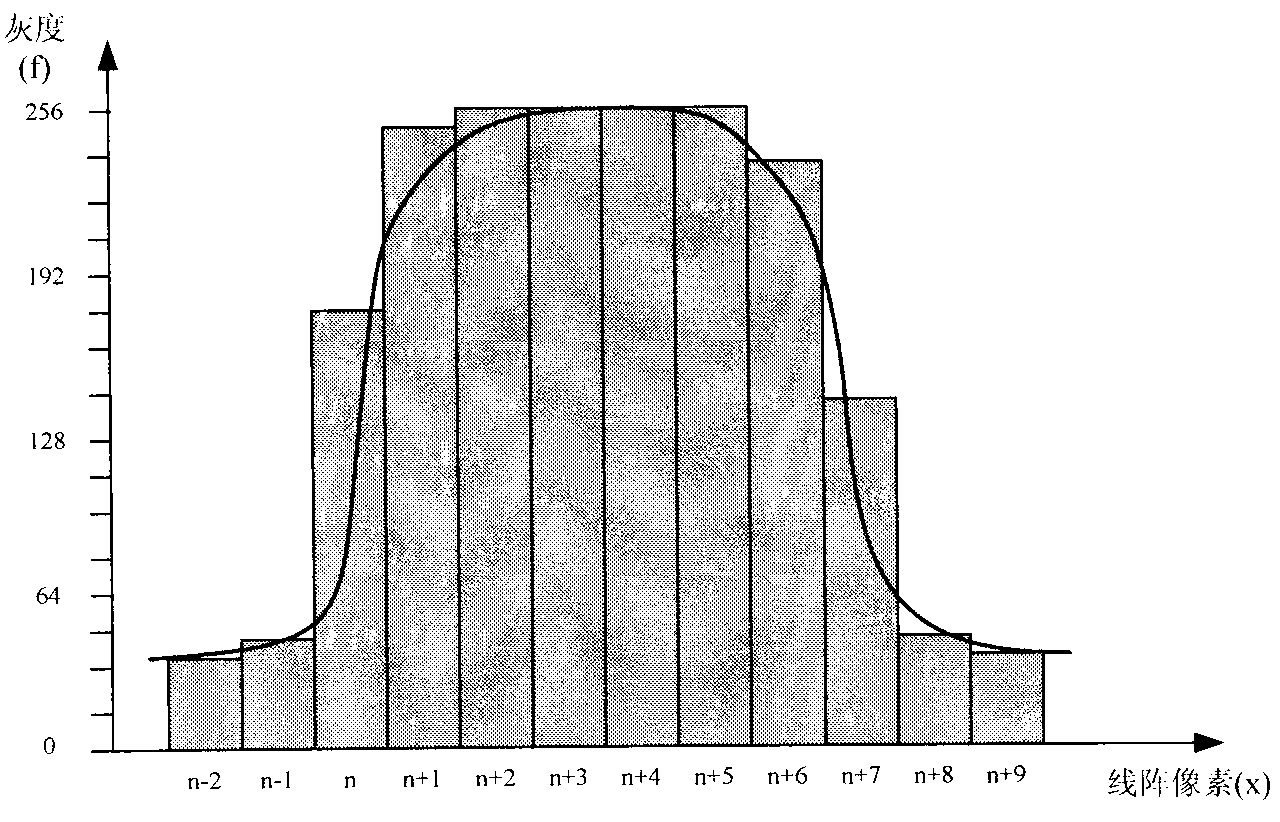

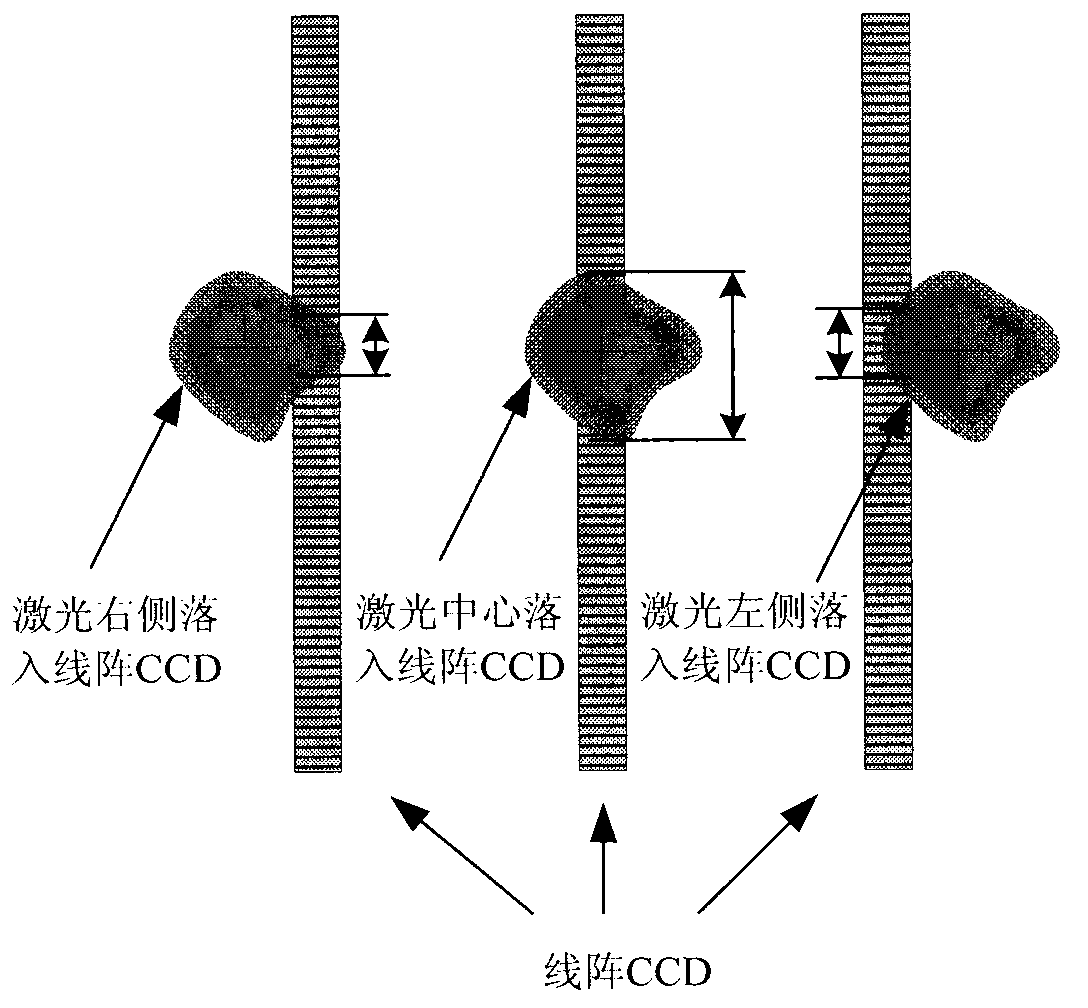

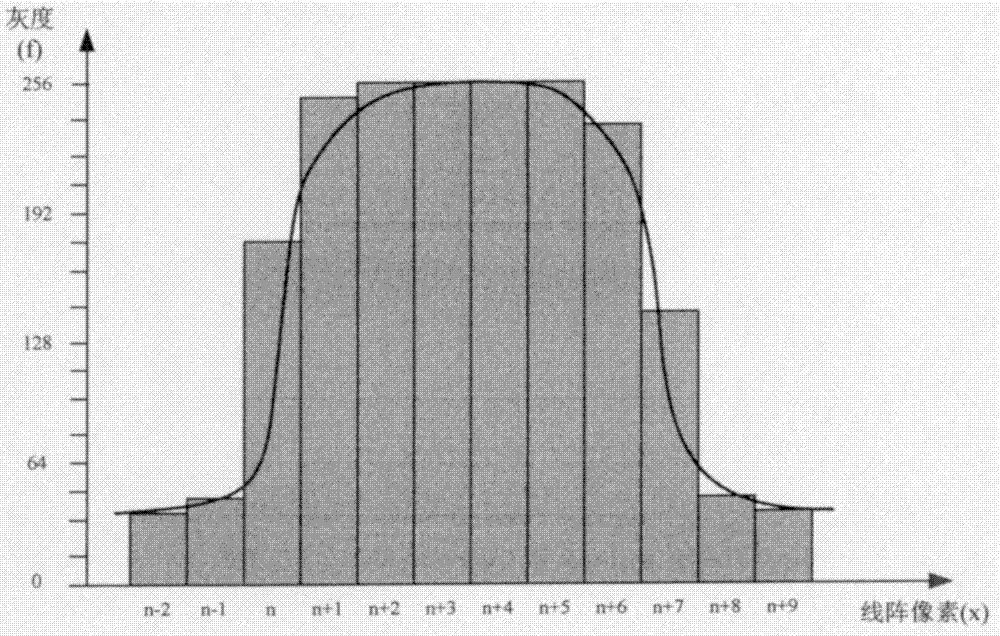

InactiveCN103245309ASolving Scattering ProblemsGuaranteed vertical accuracyUsing optical meansLaser targetLaser beams

The invention discloses a method for compensating a laser flatness measurement error. The method is characterized by consisting of sub-pixel image scattering compensation, benchmark dip angle compensation and spot abnormal change alignment compensation, so that the measurement accuracy of a laser flatness measuring system is effectively increased. In the sub-pixel image scattering compensation, the problem of scattering caused by long-distance transmission of laser beams is solved by using a pixel edge identifying method, and the vertical accuracy of planar measurement can be ensured. In the benchmark dip angle compensation, the problem of benchmark deviation of laser target placement is solved by using a dip angle height changing method, and the height benchmark of a laser target can be ensured; and in the spot abnormal change alignment compensation, the problem of abnormal change of spot size along with the change of a target distance is solved by using a reciprocating inching method, and the projection accuracy of a laser point is increased.

Owner:杭州鼎热科技有限公司

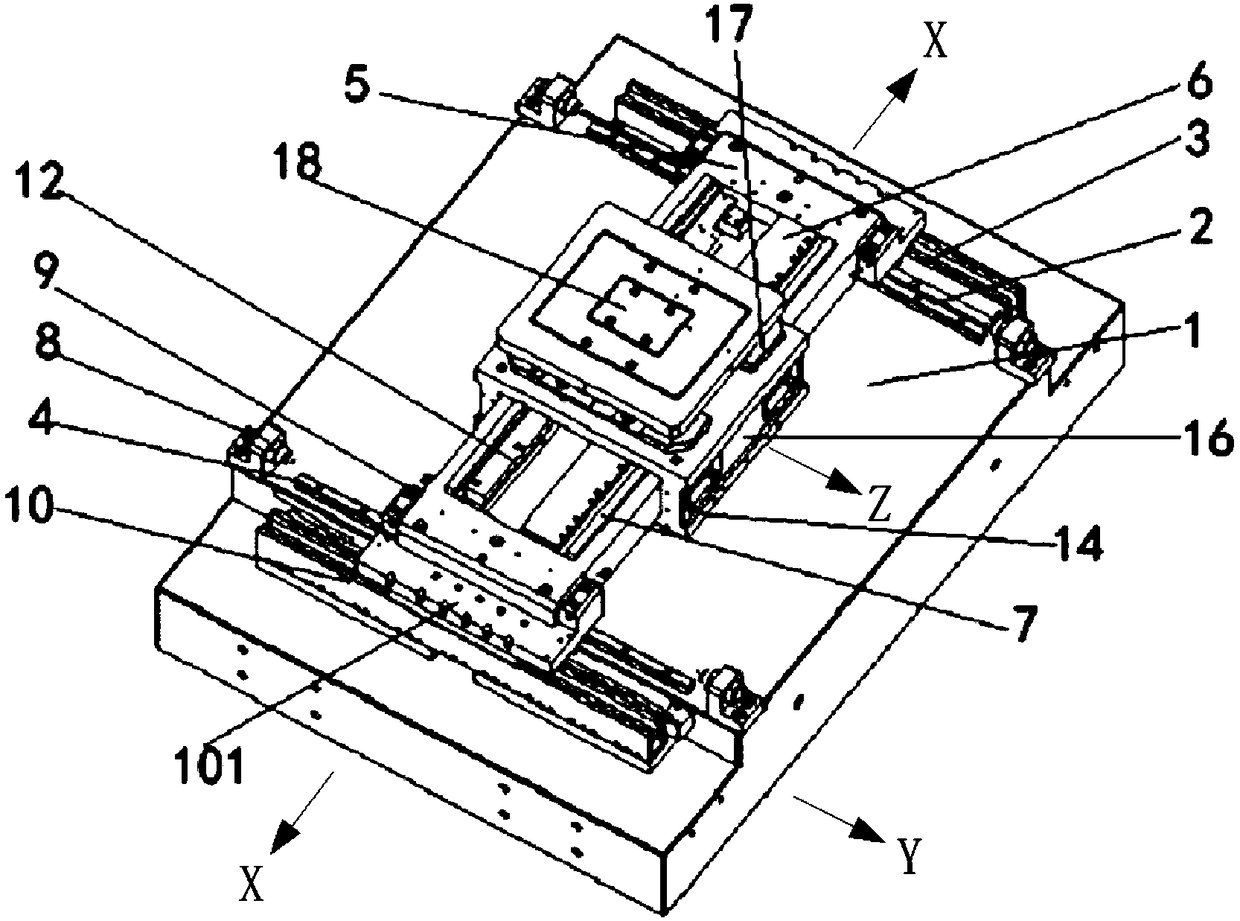

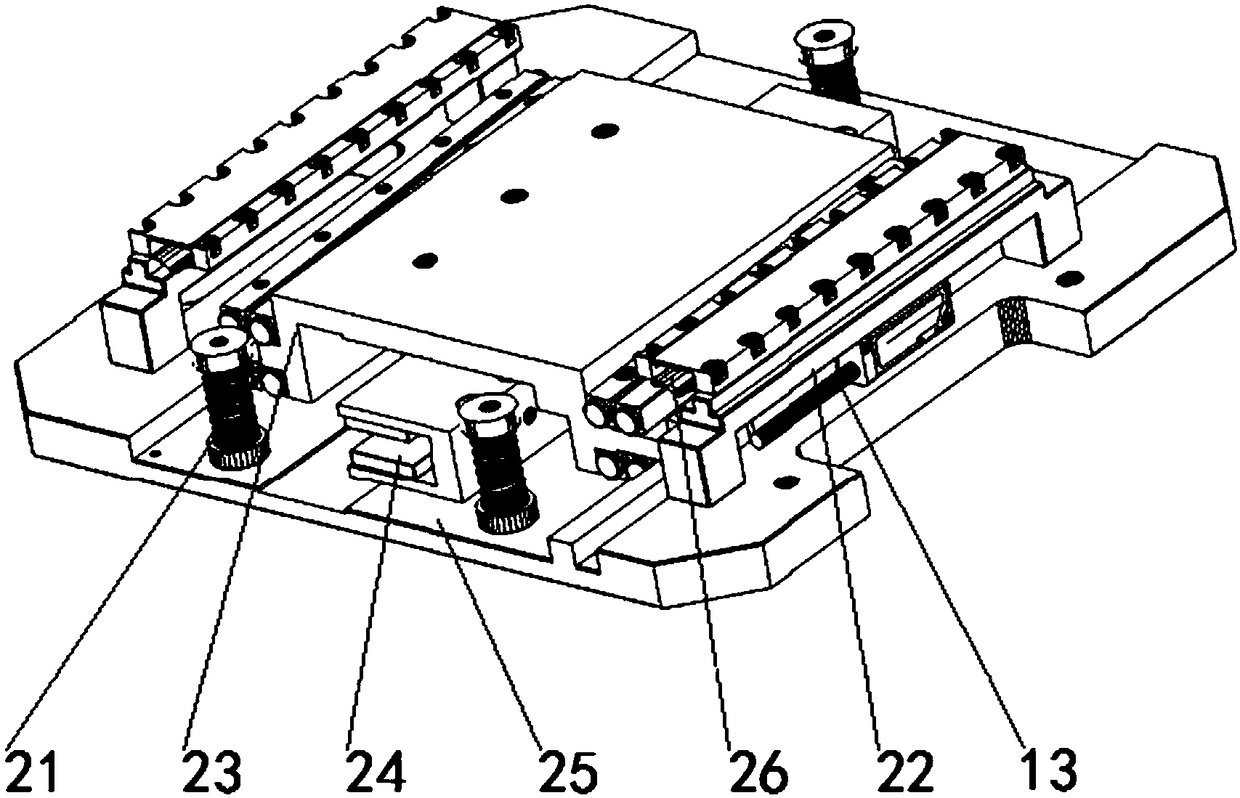

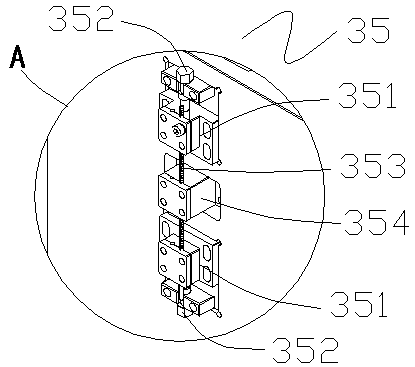

Moving platform for OLED detecting equipment

PendingCN108214423AGuaranteed vertical accuracySmall flatness errorWork benchesPermanent magnet linear motorBalance spring

The invention relates to the technical field of moving platforms, in particular to a moving platform for OLED detecting equipment. The platform sequentially comprises a vacuum chuck, a Z-direction fine adjustment table, an XY-direction moving table and a marble pedestal from top to bottom. One side of a Y1 permanent magnet linear motor and one side of a Y2 permanent magnet linear motor are each provided with a Y-direction mechanical buffer. One side of an X permanent magnet linear motor is provided with an X-direction mechanical buffer. The Z-direction fine adjustment table comprises a Z-direction permanent magnet linear motor, a Z-direction mechanism, a Z-direction balance spring and a Z-direction carrying table. A wedge-shaped block is arranged on one side of the Z-direction carrying table, the Z-direction fine adjustment table is provided with a flexible elastic sheet, vertical-direction mechanism design is simplified, and straightness errors in the Z-axis moving process are reduced. The moving platform can guarantee the vertical accuracy of a carrying table top in the XY overall moving process, the flatness error of the carrying table in the detecting journey range needs to besmaller than 1 micron, and the moving platform has the characteristics of compactness, precision and high response.

Owner:无锡星微科技有限公司

Integral fixed installation method of embedded steel pipe on roof of coal furnace foundation

InactiveCN101892672AReduce labor intensityLow costOven foundationsFoundation engineeringCouplingUltimate tensile strength

The invention discloses an integral fixed installation method of embedded steel pipe on the roof of coal furnace foundation, which is characterized in that channel steel is used as a horizontal cross beam fixed rack and a horizontal longitudinal beam fixed rack, which are welded onto a channel steel post fixed on an embedded iron part, the lower end of the embedded pipe is positioned through a square iron sheet fixed on a multilayered plate, the upper end of the embedded pipe is positioned and elevated by the horizontal cross beam fixed rack and the horizontal longitudinal beam fixed rack via an adjustment pipe coupling, thereby guaranteeing the verticality of the embedded pipe. According to the method, the fixed installation of a plurality of embedded pipes can be completed by means of one-step alignment and adjustment, thus the method is convenient and fast and reduces labor intensity to a great extent, enhances working efficiency, achieves less manpower and lowers expenditure, in addition, the embedded pipes are so fixed and firm that the positioning thereof cannot be impacted by the implementation of other procedures, so the elevation and vertical precision of the embedded pipes are guaranteed.

Owner:TIANJIN 20 CONSTR

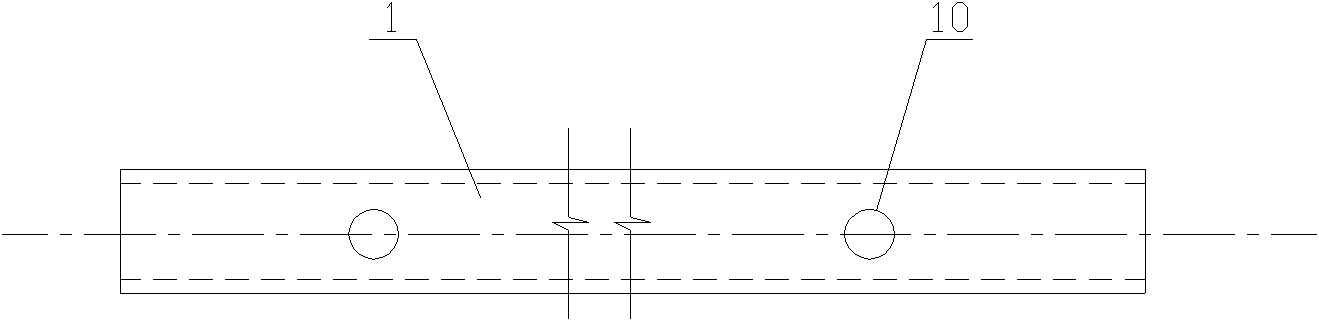

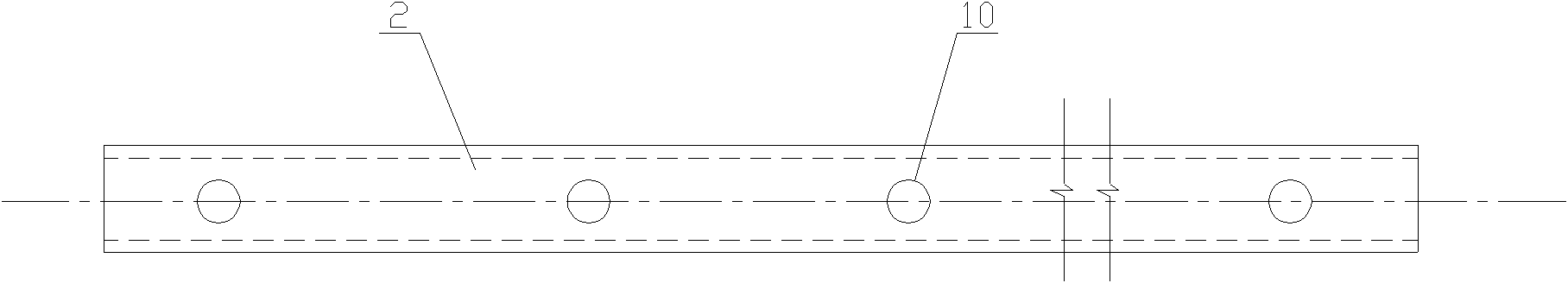

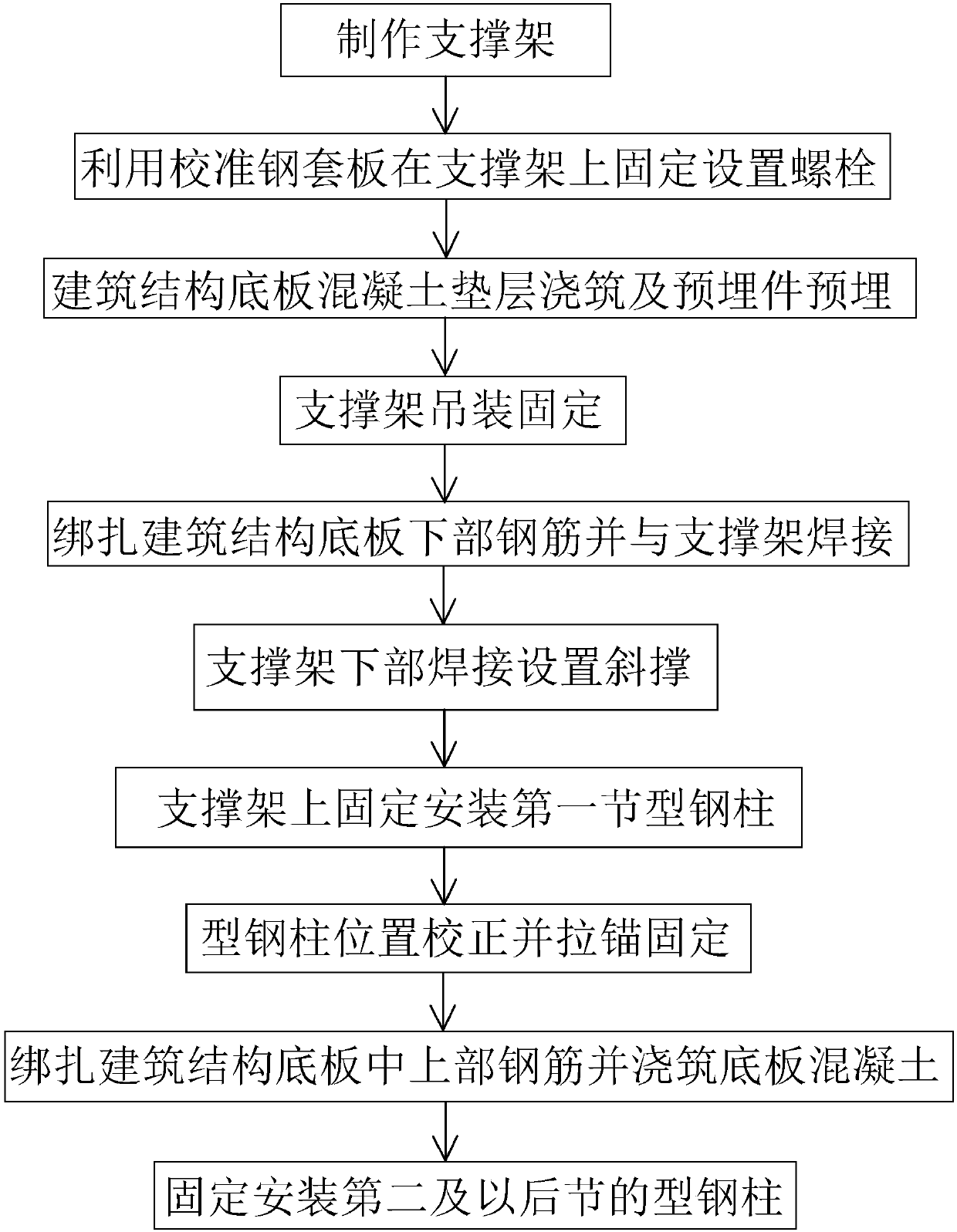

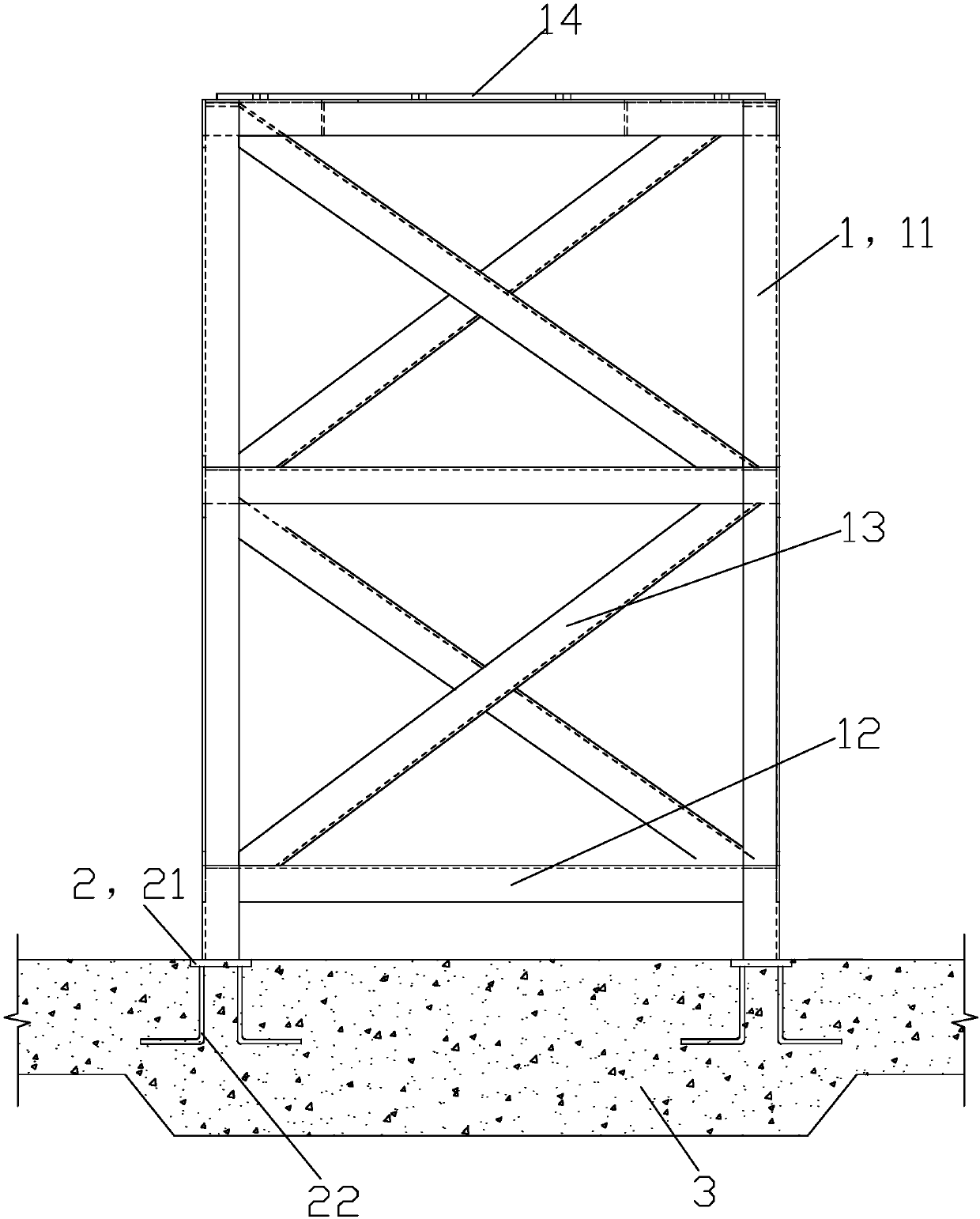

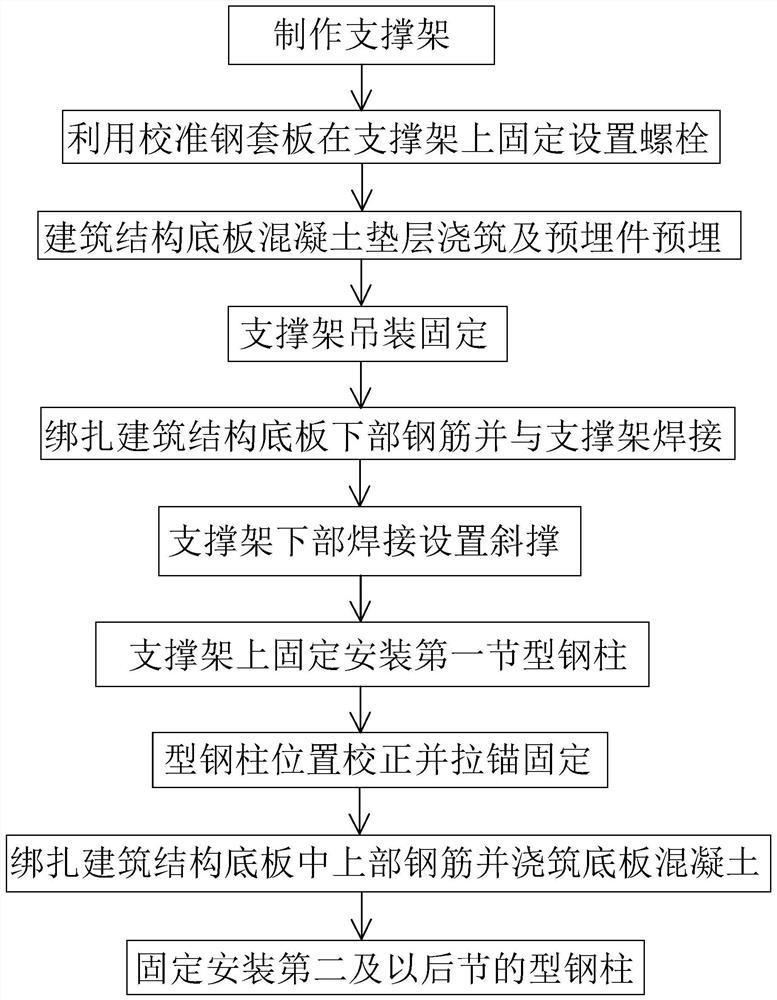

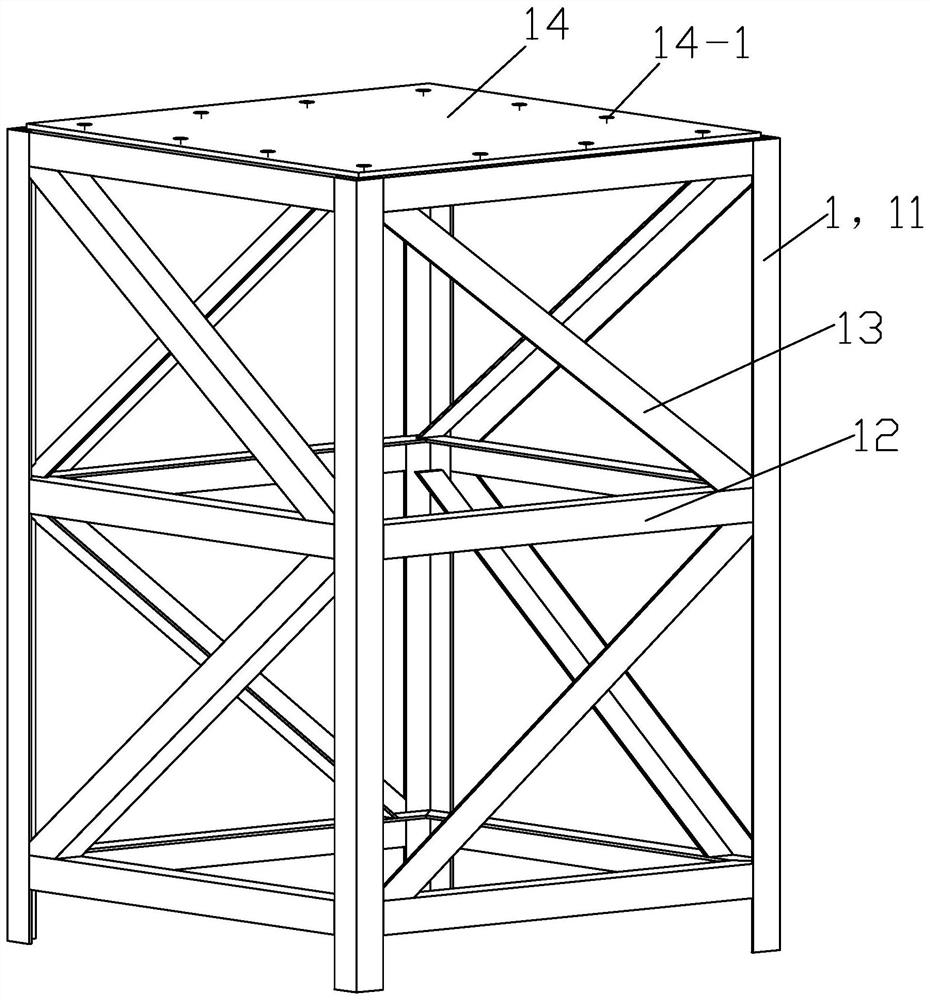

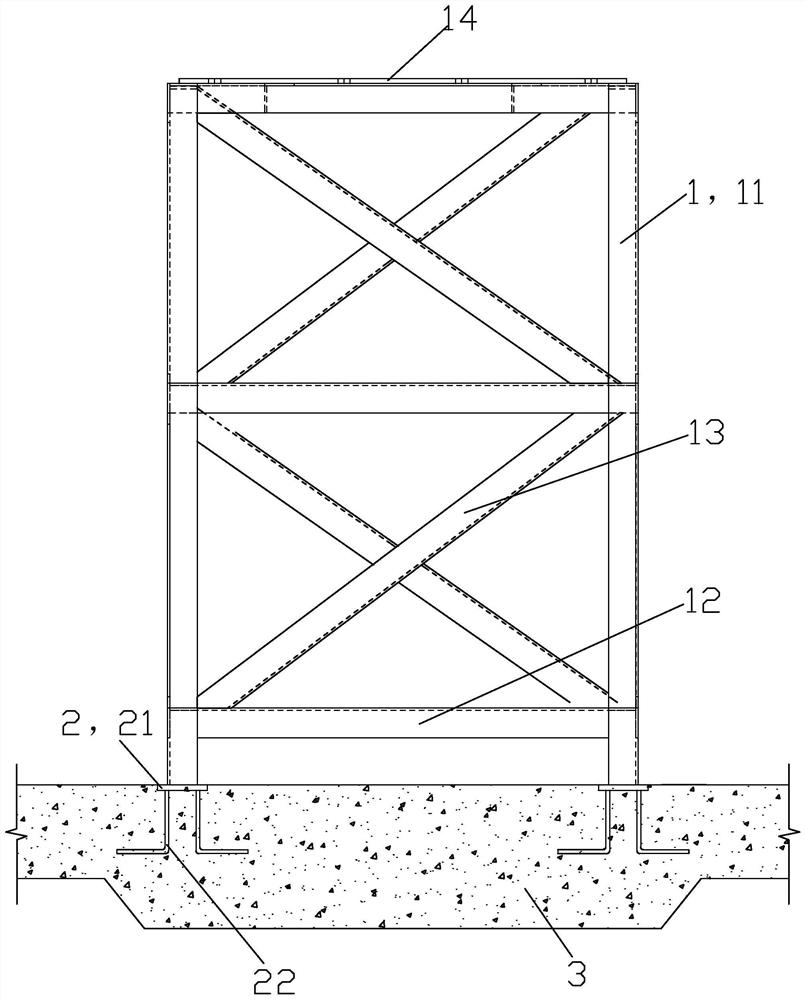

Section-steel-column support frame construction method for super-high-rise-building frame column

ActiveCN108035554AHighly stableGuaranteed vertical accuracyBuilding material handlingSteel barSteel columns

The invention provides a section-steel-column support frame construction method for a super-high-rise-building frame column. The method includes the steps that 1, a support frame is made; 2, bolts arefixedly arranged on the support frame through a calibration steel sleeve plate; 3, a concrete cushion of a building structure bottom plate is poured, and embedded parts are embedded; 4, the support frame is lifted and fixed; 5, lower reinforcing steel bars of the building structure bottom plate are bound and welded to the support frame; 6, slant supports are welded to the lower portion of the support frame; 7, a first steel column is fixedly installed on the support frame; 8, positions of section steel columns are corrected, and the section steel columns are anchored and fixed; 9, upper reinforcing steel bars of the building structure bottom plate are bound, and bottom plate concrete is poured; 10, a second steel column and rear steel columns are fixedly installed. According to the section-steel-column support frame construction method for the super-high-rise-building frame column, construction is easy, convenient, safe and reliable, the construction quality is easy to control, the embedded quality of the section steel columns in a foundation bottom plate or a ground beam can be guaranteed, and three problems that in a construction method for section steel columns of a traditionalbuilding structure frame column, the anchor bolt accuracy is poor, the stability of the support structure is poor, and as key construction procedures are occupied, the construction period is influenced are effectively solved.

Owner:CHANGZHOU NO 1 CONSTR GRP

Continuous hole type knife template and machining method thereof

ActiveCN107745410AEasy to processGood effectMetal working apparatusBoring/drilling componentsStructural engineeringKnife blades

The invention belongs to the technical field of knife templates, and particularly relates to a continuous hole type knife template and a machining method of the continuous hole type knife template. The continuous hole type knife template comprises a first face and a second face, and is provided with an installation knife gap applicable to installation of a knife template blade. The installation knife gap is extended in the mode of a straight line or a broken line or a curve line. The installation knife gap comprises multiple continuously-arranged penetrating holes formed in the first face at least, a spacing wall portion is formed between every two adjacent penetrating holes, and the middle positions in the width direction of the installation knife gap of the spacing wall portions are provided with broken portions or thinning portions. In addition, the invention further provides a machining method of the continuous hole type knife template. The machining method has the advantages thata die cutter blade fixing effect of the knife template is good, the installation knife gap is easy to machine, the manufacturing difficulty is small, and the machining efficiency is high.

Owner:DONGGUAN YISONG CNC TECH

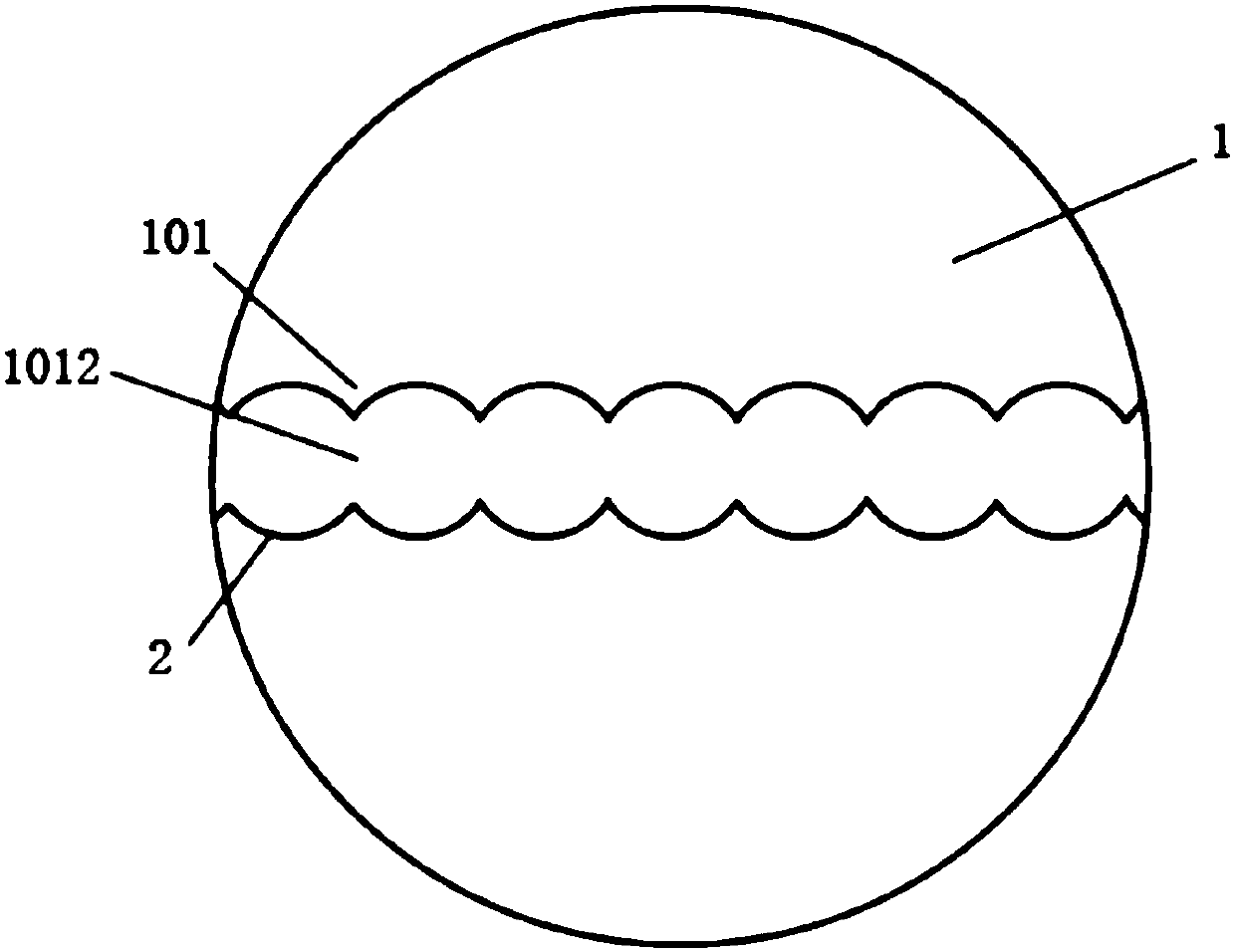

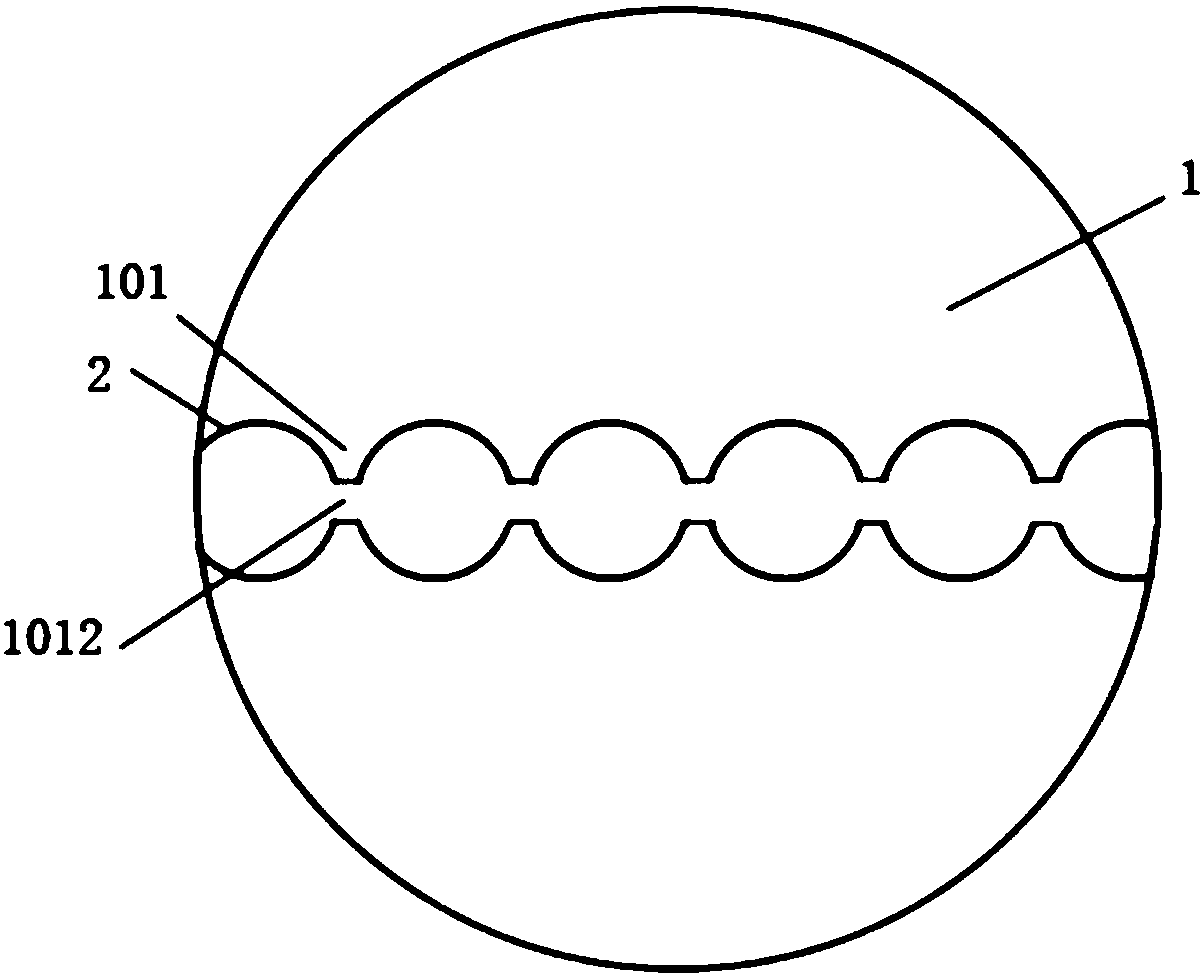

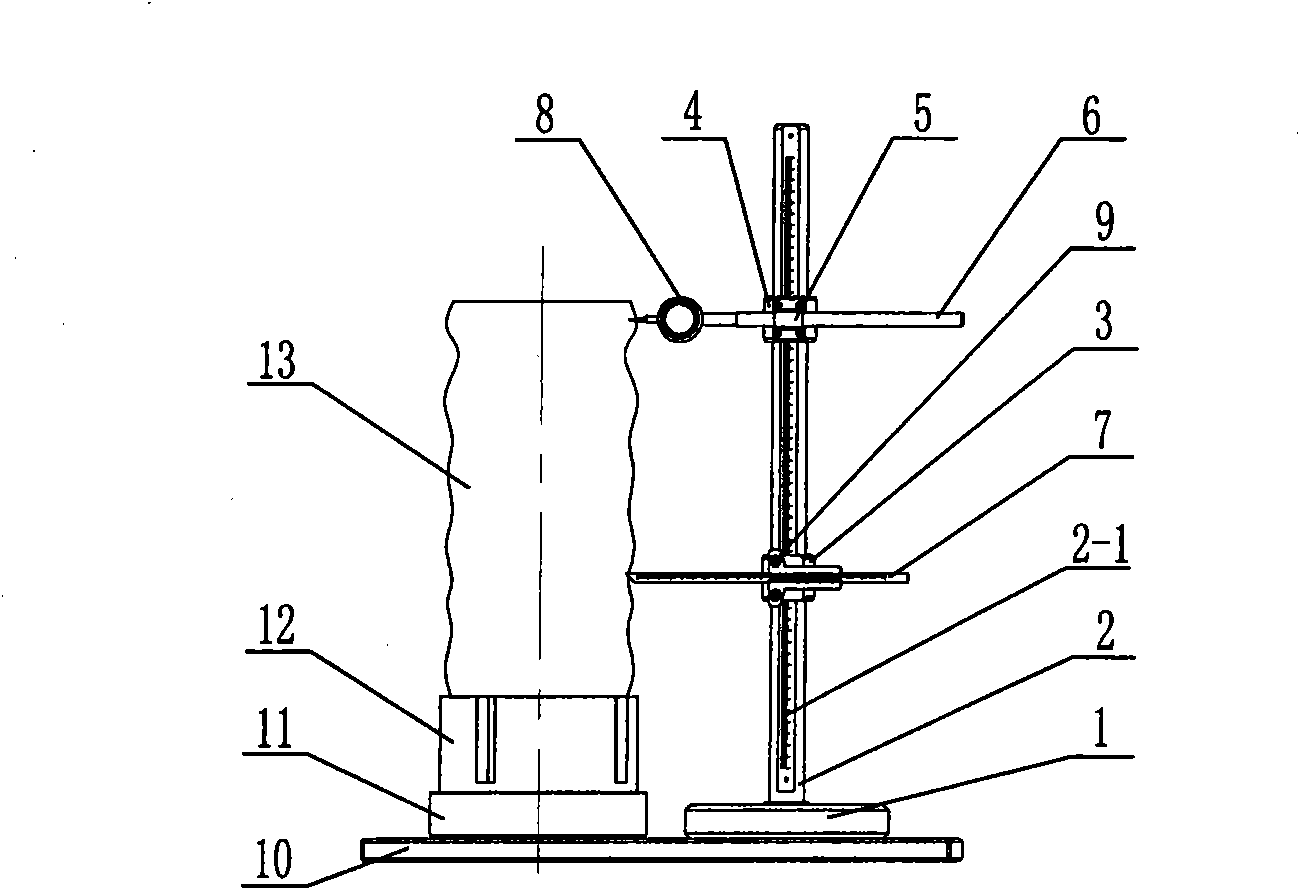

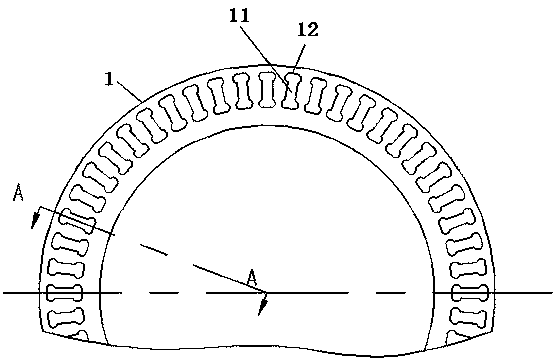

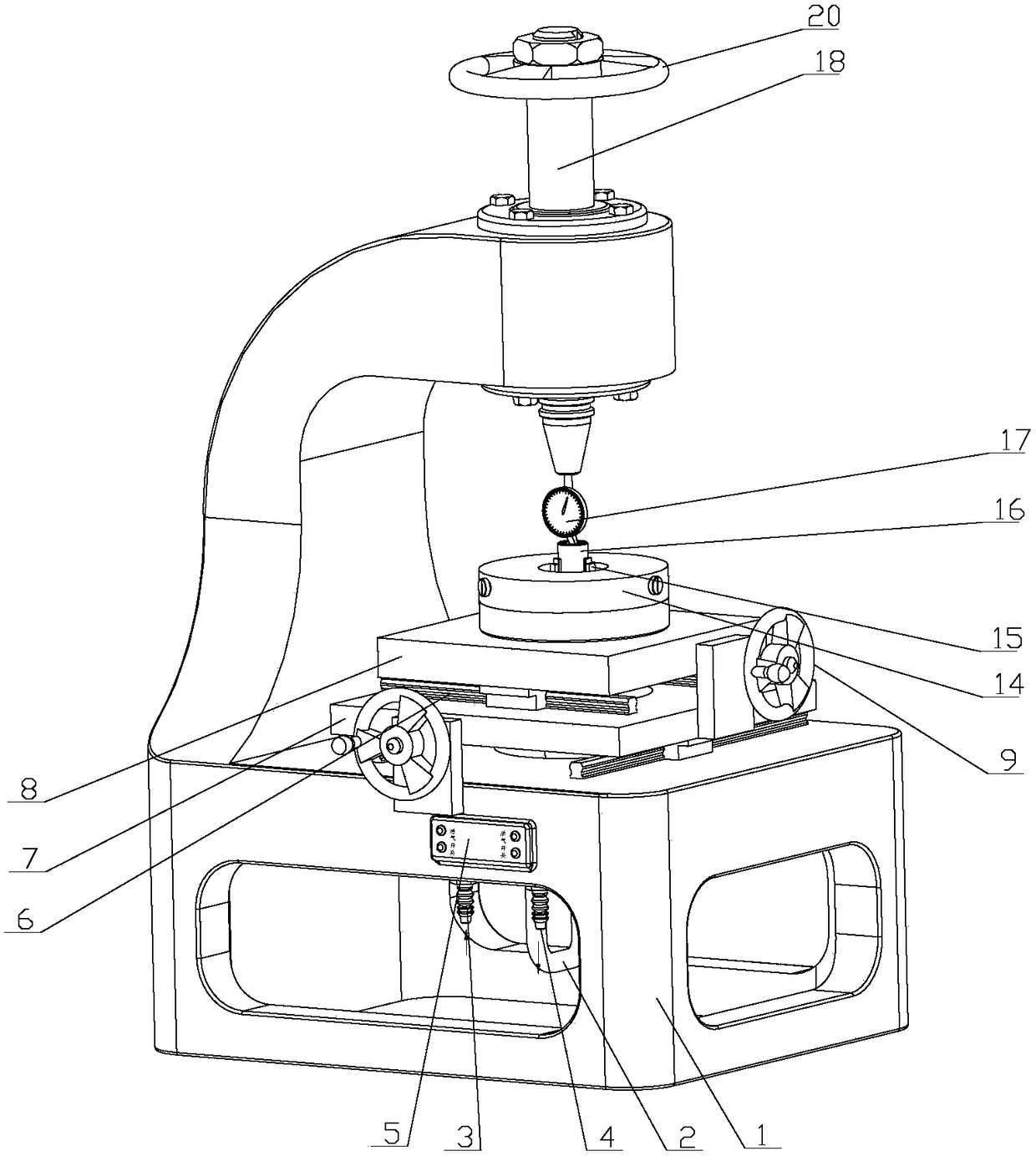

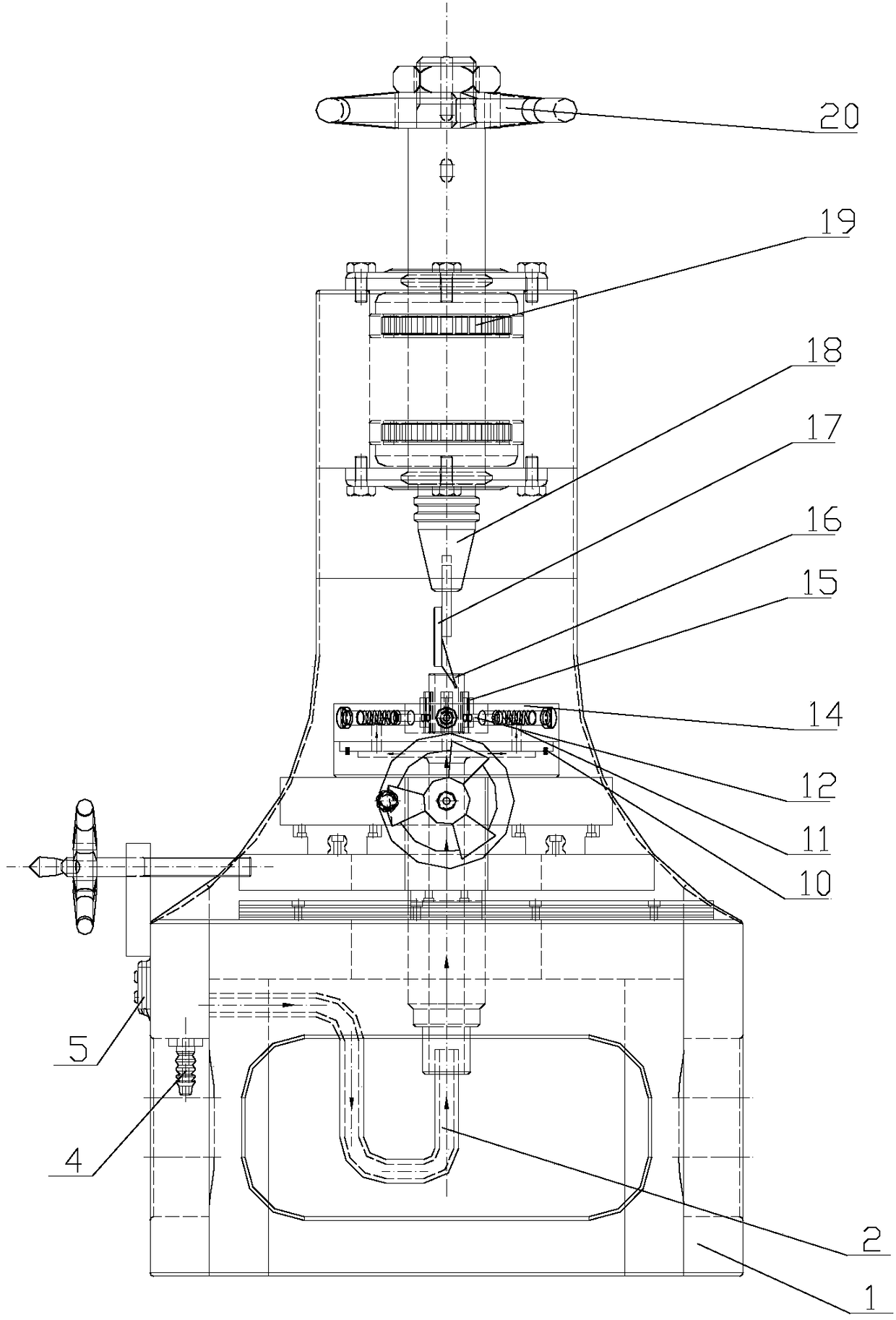

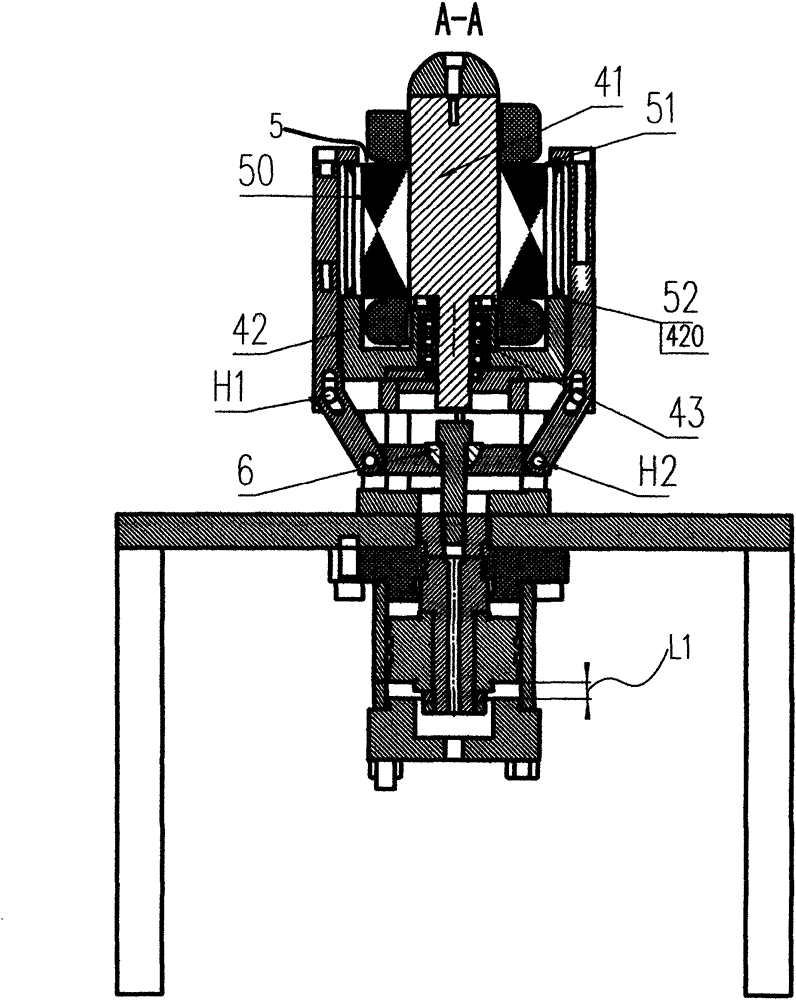

Radial verticality detection platform

InactiveCN102032857AGuaranteed vertical accuracyGuaranteed medium precisionMechanical measuring arrangementsEngineeringSingle crystal

The invention relates to a radial verticality detection platform for detecting the radial verticality of a single-wafer rod in photovoltaic industry. The radial verticality detection platform comprises a bottom plate, (10), a dial (11), a pillar (2) with a calibrated scale (2-1), a depth measuring scale (7) and an indexing table (8), wherein the lower end of the pillar (2) is provided with a base (1); the base (1) is fixed on the bottom plate (10); the dial (11) is rotatably supported on the bottom plate (10); the depth measuring scale (7) and the indexing table (8) are movably arranged on the pillar (2); and the depth measuring scale (7) is arranged below the indexing table (8). The invention not only ensures the vertical precision of the single-wafer rod but also ensures the accuracy of alignment of the single-wafer rod and does not need to detect circular runout for the second time.

Owner:江苏有则创投集团有限公司

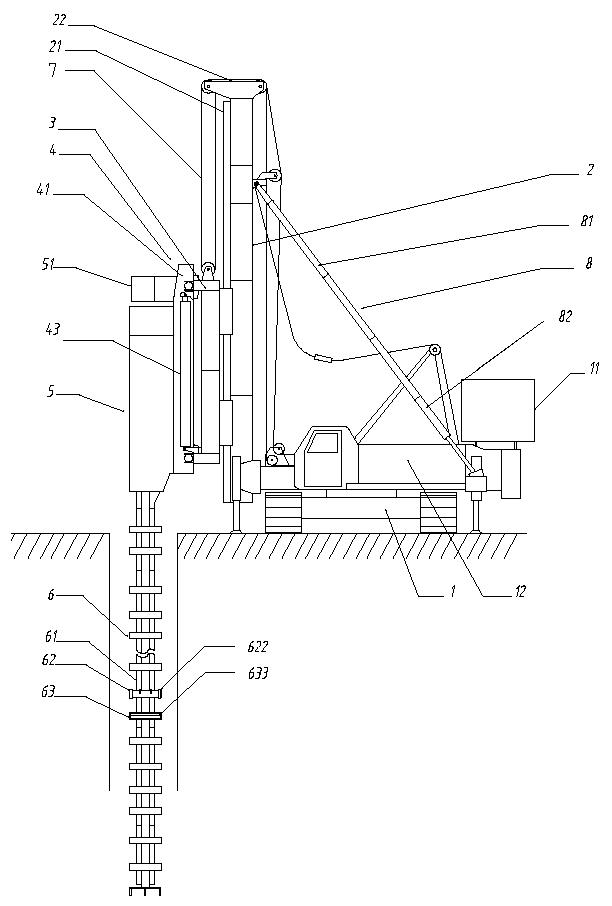

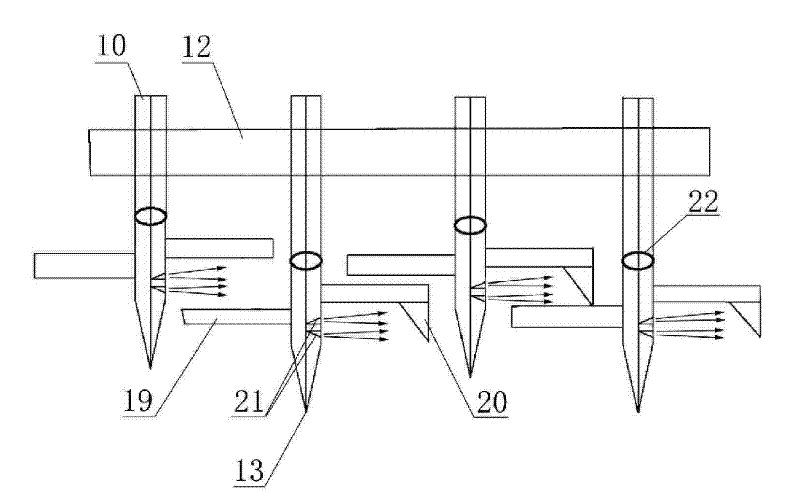

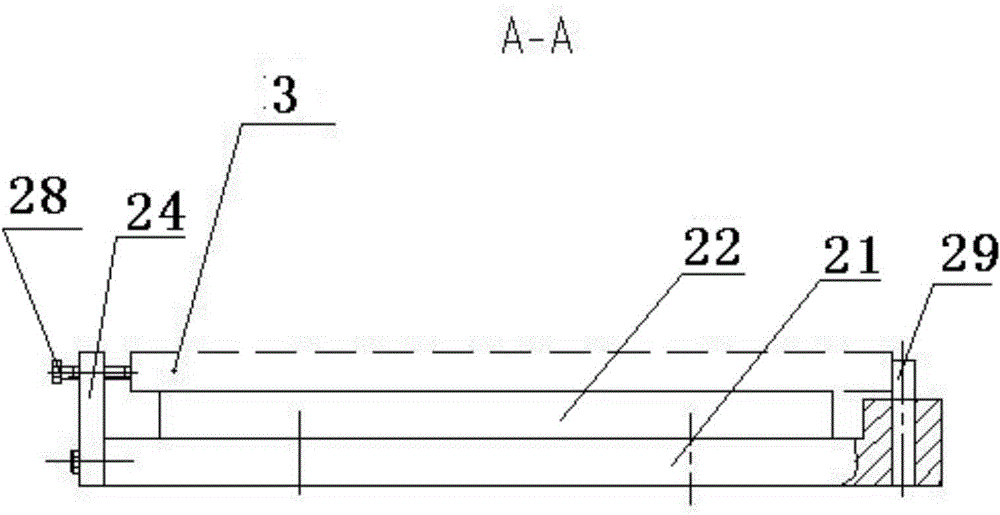

Two-wheel-driven bidirectional heavy-pipe deep stirring ground wall connecting machine

InactiveCN103074888AGuaranteed verticalityStir wellDrilling rodsDrilling casingsSlurry wallCement grout

The invention relates to a two-wheel-driven bidirectional heavy-pipe deep stirring ground wall connecting machine for building an anti-seepage underground continuous wall in the field of engineering drillers. The two-wheel-driven bidirectional heavy-pipe deep stirring ground wall connecting machine comprises drill rods, wherein an elevating table is arranged on the tops of the drill rods; the drill rods include hollow inner drill rods and hollow outer drill rods which are arranged concentrically and can rotate towards each other; the inner drill rods and the outer drill rods are rotationally connected below the elevating table; the elevating table is provided with a top driving mechanism for driving the inner drill rods to rotate; the elevating table is suspended on a supporting machine through a steel wire rope; the middle parts of the outer drill rods are provided with a middle driving mechanism for driving the outer drill rods to rotate; the inner drill rods extend out of the lower ends of the outer drill rods; the peripheries of the extension ends of the inner drill rods are provided with lower stirring blades; and the lower ends of the outer drill rods are provided with upper stirring blades rotating opposite to the lower stirring blades. According to the two-wheel-driven bidirectional heavy-pipe deep stirring ground wall connecting machine, stirring uniformity, a good anti-seepage effect and high production efficiency are realized, and cement grout is effectively prevented from spilling over along the drill rods.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

Rotatable milling blade for sidewall machining

ActiveCN110315118AImprove fitting accuracyImprove overall cutting performanceMilling cuttersMilling cutting insertsEngineeringSurface smoothness

The invention provides a rotatable milling blade for sidewall machining. The milling blade comprises an upper top surface, a lower bottom surface, two end surfaces connected with the upper top surfaceand the lower bottom surface, and an approximately cuboid blade main body defined by two side surfaces; the upper top surface and the two side surfaces extent at respective curvatures and intersect,and a first main cutting edge and a second main cutting edge are formed; the first main cutting edge is fitted on a first cutting rotating cylindrical surface with the diameter being D and orderly extends on the first cutting rotating cylindrical surface; and the second main cutting edge is fitted on a second cutting rotating cylindrical surface with the diameter being d and extends orderly on thesecond cutting rotating cylindrical surface. The vertical precision and the surface smoothness of a machined side surface at different cutting depths can be met, the cutting quality of the side surface is improved, and the cutting efficiency is improved.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

Method for processing large-diameter figure-eight-shaped hole series

InactiveCN102794472AHigh dimensional accuracyImprove shape and position accuracyEngineeringPerpendicular direction

The invention discloses a method for processing a large-diameter figure-eight-shaped hole series. The hole series comprises a first hole and a second hole which are crossed in parallel to form a figure-eight shape and are cut by a boring tool in a vertical boring way, and the range of a cutting edge angle Alpha of the boring tool is not less than 72 DEG and not more than 90 DEG; and the method comprises the steps as follows: 1), placing workpieces onto a vertical boring worktable and enabling the front end surfaces of the workpieces to face up, and enabling the shaft lines of the first hole and the second hole to be in the perpendicular direction and parallel to a vertical boring spindle; 2), aligning the shaft center of the first hole by a dial indicator and enabling the front end surfaces of the workpieces to be perpendicular to the vertical boring spindle, clamping and fixing the workpieces; 3), carrying out pre-boring, semi-fine boring and fine boring on the first hole in sequence, and blowing away cuttings by compressed air; 4), aligning the shaft center of the second hole on the basis of the shaft center of the first hole; 5), carrying out pre-boring, semi-fine boring and fine boring on the second hole in sequence, and blowing away the cuttings by the compressed air; and 6), deburring, chamfering, and finishing the workpieces. According to the method, the processing precision and the working efficiency are improved; and the method is suitable for cutting the large-diameter figure-eight-shaped hole series in large rotary screw rods or other large workpieces.

Owner:CSSC MES DIESEL

High-speed precise punch press

The invention relates to a high-speed precise punch press, which is provided with an eight-face positioning mechanism, a dual-nut slider structure and a dual-elbow joint transmission structure. The high-speed precise punch press is reasonable in structural design, very simple in operation and high in work efficiency, the adjusting and die adjusting are more convenient, operation personnel can operate the punch press without the need of professional skills of professional punch press maintaining staff, the parallelism of vertical motion and precision of perpendicularity of a slider can be ensured, the precision of the punch press is improved, meanwhile, the anti-fatigue performance of the machine is improved, the work stability is improved, the machine can be normally operated at higher speed, the production time of products is shortened and the cost is saved.

Owner:浙江帅锋精密机械制造有限公司

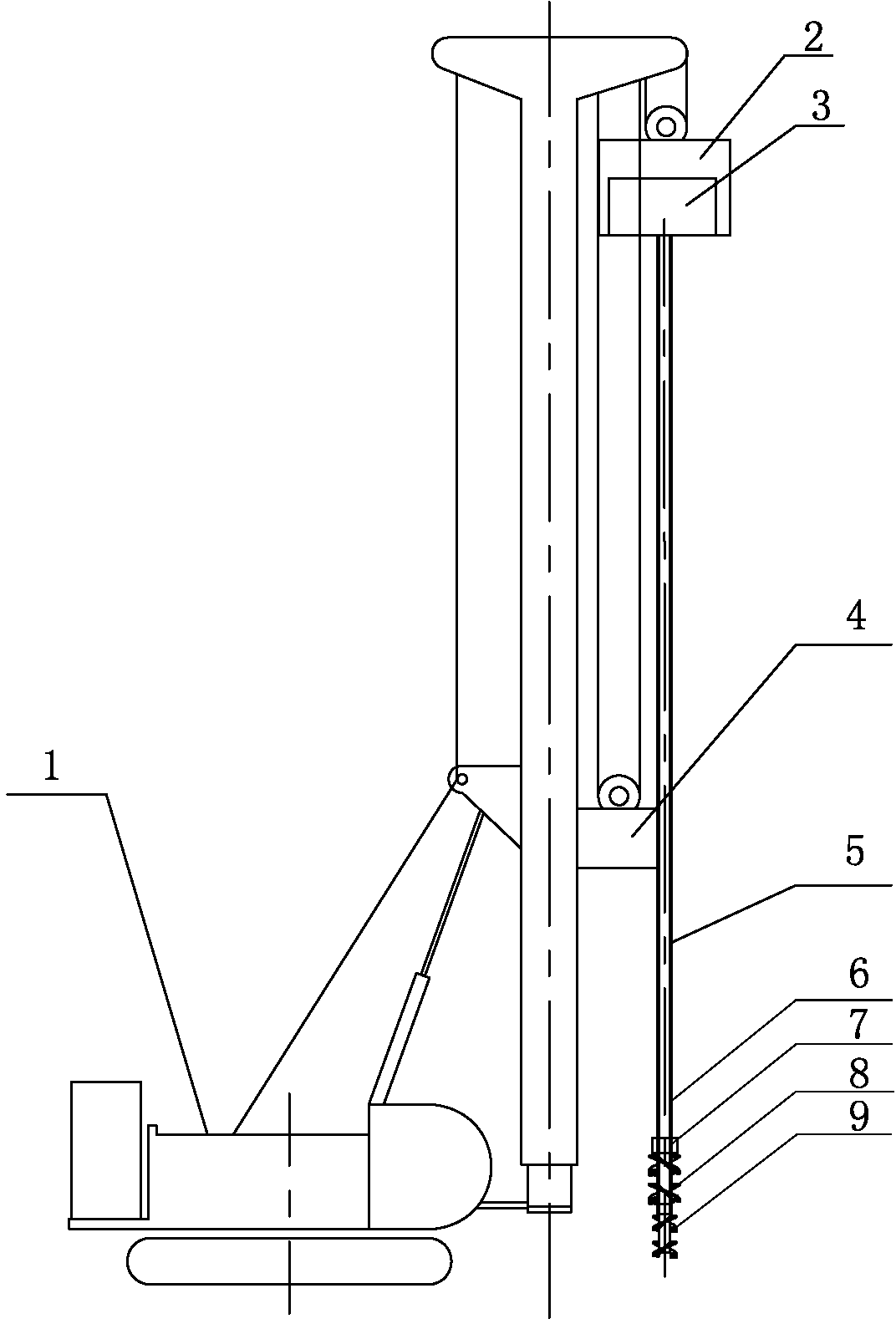

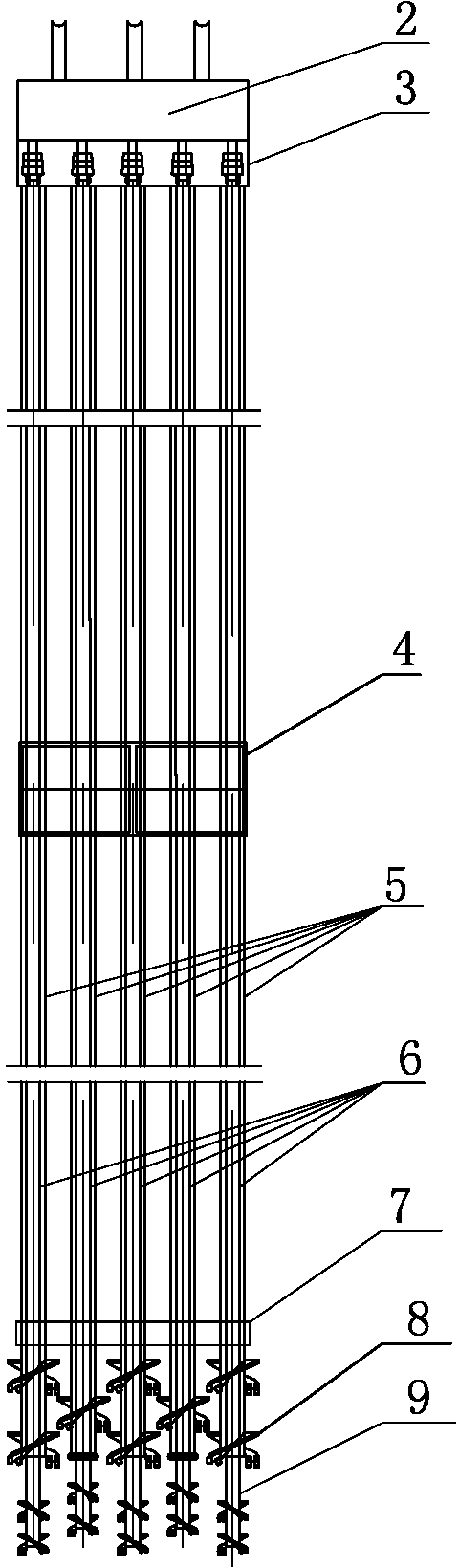

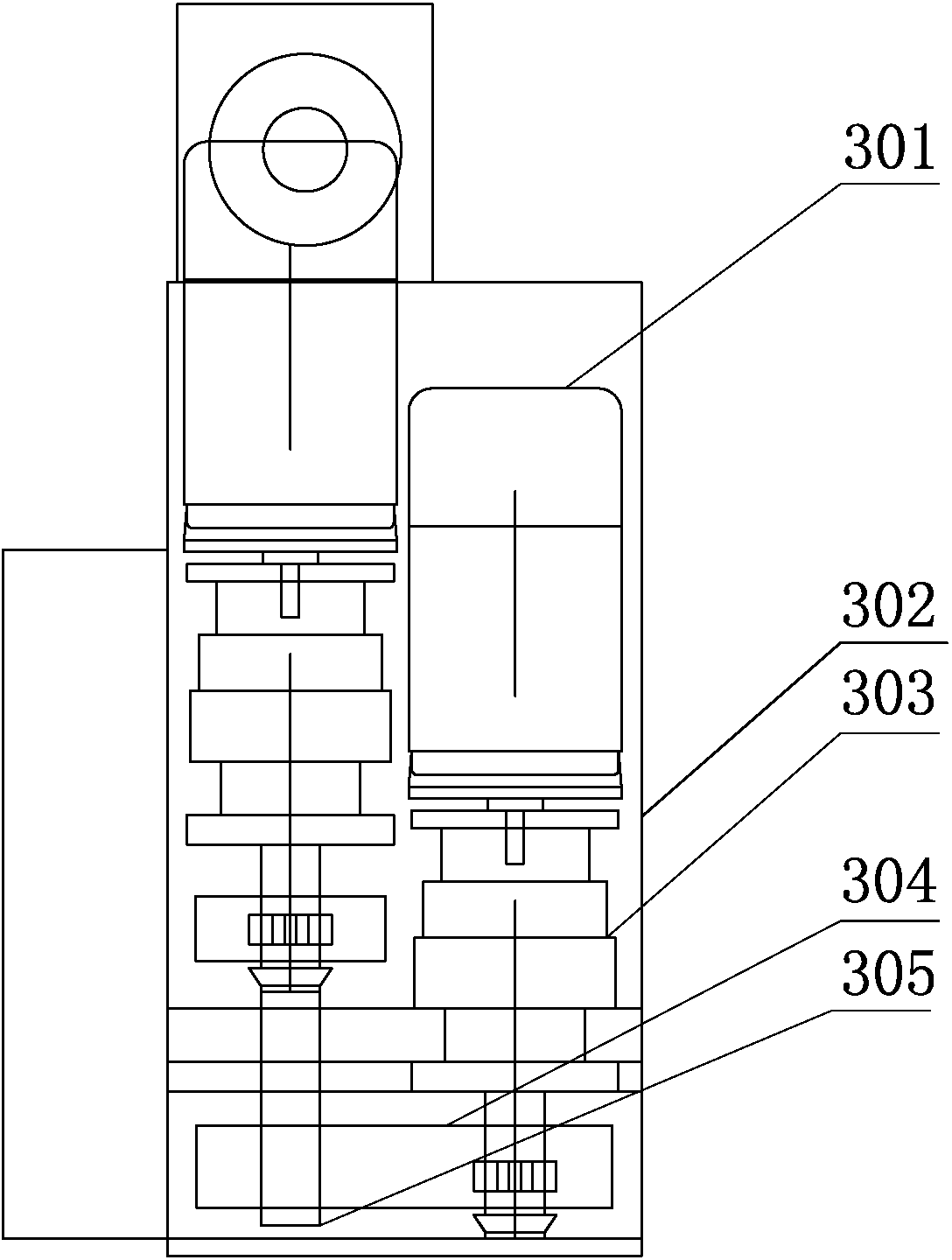

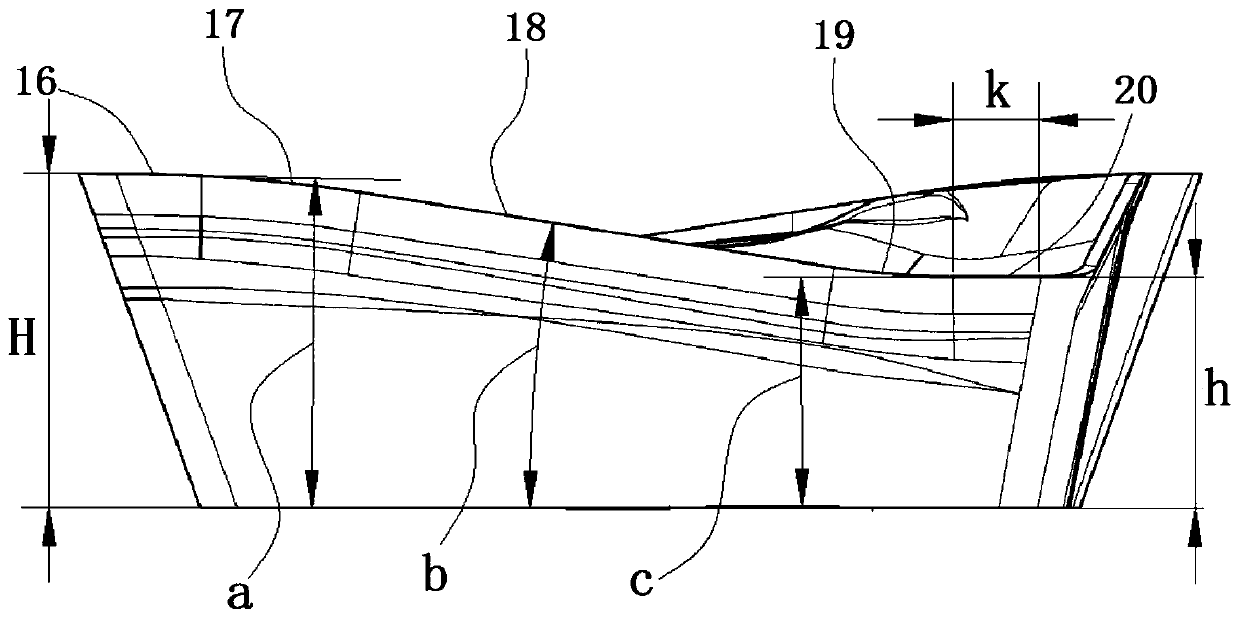

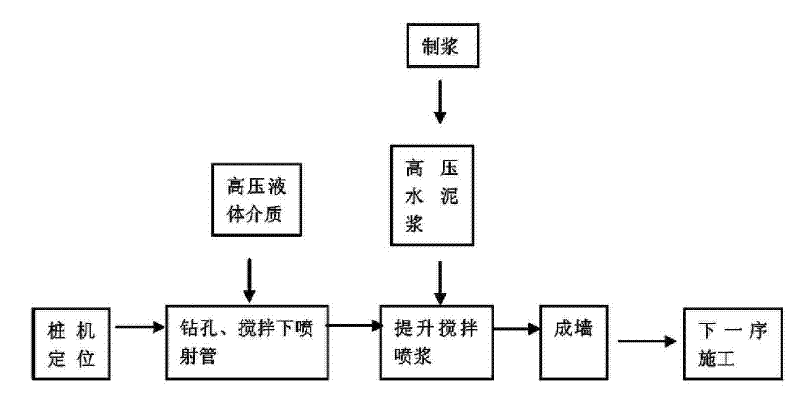

Construction method of multi-drill high-pressure jet agitation based anti-seepage reinforcing equipment

InactiveCN101660309BHigh anti-seepage coefficientImprove verticalityBulkheads/pilesDrilling machines and methodsPulp and paper industryHigh pressure

Owner:赵延龙

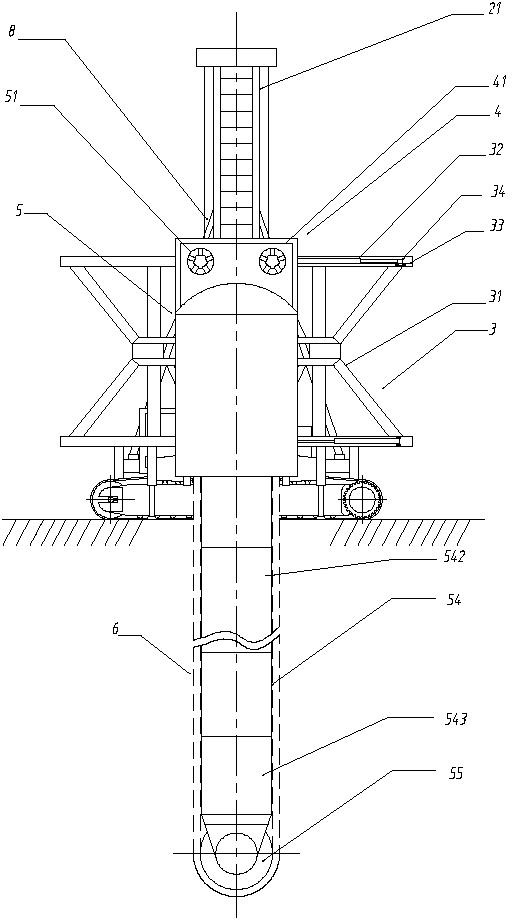

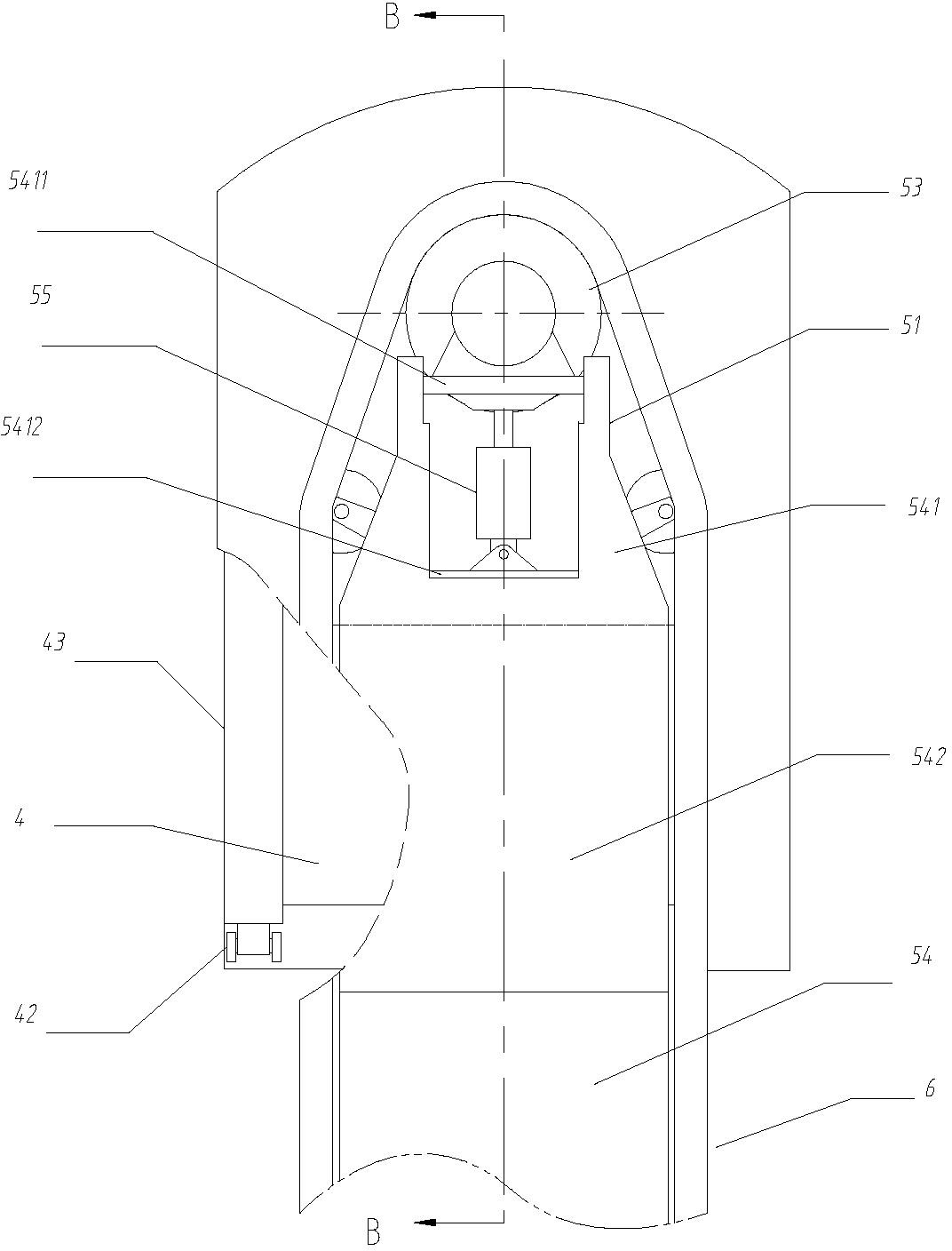

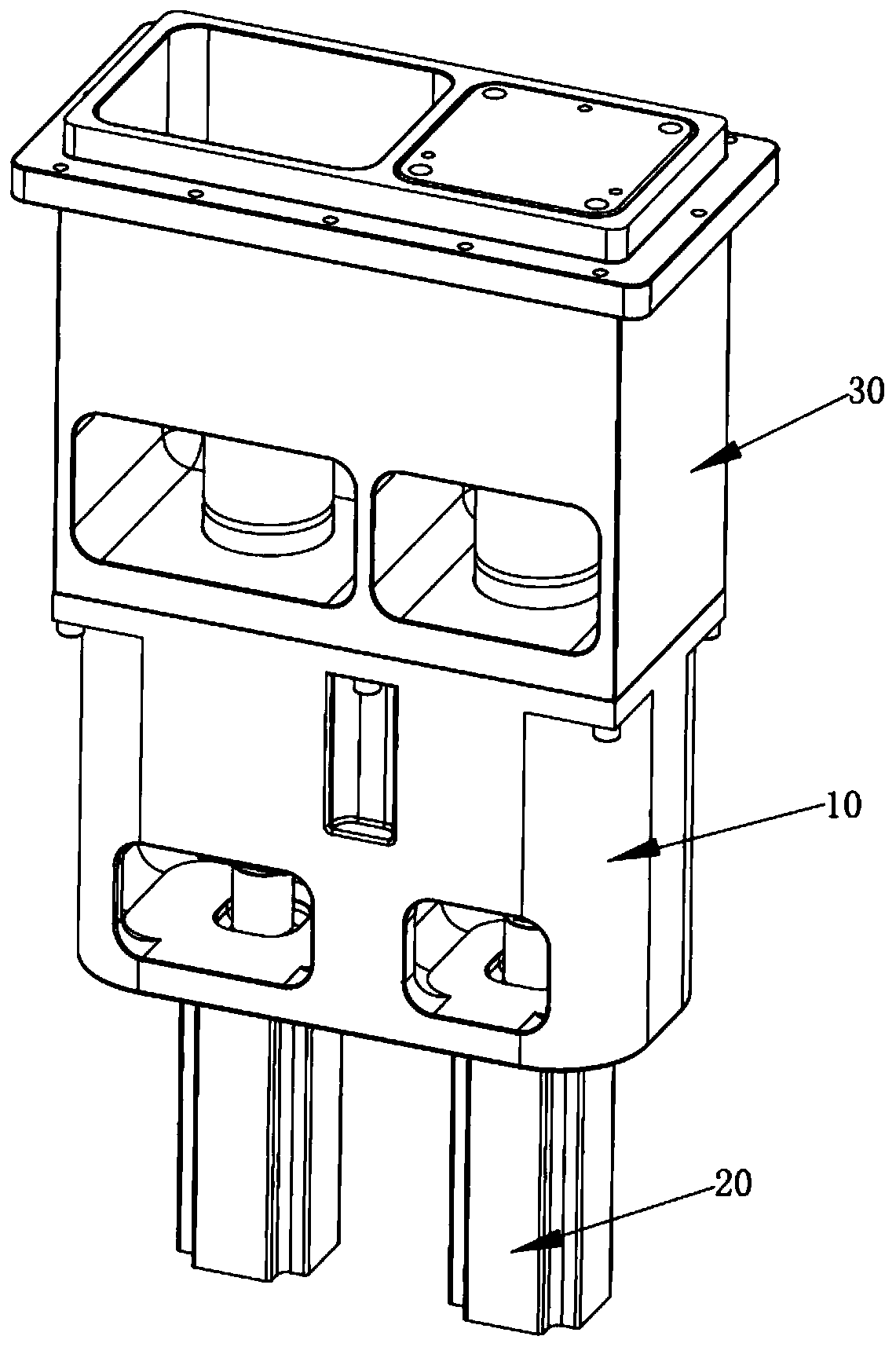

Hydraulic vertical insertion machine and method for connecting foundation pile and steel pipe column

InactiveCN101886398AControl floatGuaranteed verticalityFoundation engineeringBuilding material handlingEngineeringEnergy conservation

The invention relates to a hydraulic vertical insertion machine. The hydraulic vertical insertion machine comprises a seat body and a first hydraulic vertical insertion device arranged on the seat body, and is characterized in that the seat body is provided with a platform on which a second hydraulic vertical insertion device is arranged; the first hydraulic vertical insertion device and the second hydraulic vertical insertion device are sequentially arranged along the axial direction of the seat body; the first hydraulic vertical insertion device is arranged below the second hydraulic vertical insertion device; and the first hydraulic vertical insertion device and the second hydraulic vertical insertion device can independently or synchronously rotate 360 degrees to regulate the verticality of a steel pipe column. The hydraulic vertical insertion machine can effectively control the up-floating of the steel pipe column and ensure the vertical precision of inserting the steel pipe column. Compared with the conventional reversed construction method, the invention has the advantages of short construction period, saved energy resources and saved cost investment. The invention discloses the hydraulic vertical insertion machine and a method for connecting a foundation pile and a steel pipe column.

Owner:王薇

Installation method of special anchor rod for pre-installing temporary wall-hanging air and water pipeline during shaft construction

ActiveCN103953374ASaving Horizontal AccuracySave vertical accuracyAnchoring boltsEarth surfaceRock bolt

The invention discloses an installation method of a special anchor rod for pre-installing a temporary wall-hanging air and water pipeline during shaft construction. The installation method comprises the following steps: (1) welding a combined anchor rod seat on the ground and screwing an anchor rod seat fixing sleeve in the combined anchor rod seat; (2) aligning and positioning a shaft metal template vertical mould; (3) trepanning a metal template; (4) putting the combined anchor rod seat through the holes formed in the metal template; (5) casting concrete on the metal template; (6) screwing out the anchor rod seat fixing sleeve from the combined anchor rod seat after cast shaft concrete is solidified; (7) demolding the metal template; (8) screwing an anchor rod seat suspension beam in the combined anchor rod seat.

Owner:TONGLING ZHONGDU MINING CONSTR

Welding method and structure for motor end ring and conducting bars

InactiveCN109352111AReduce dosageGuaranteed vertical accuracyMagnetic circuit rotating partsSoldering apparatusSolderingFiller metal

The invention discloses a welding method and structure for a motor end ring and conducting bars. The welding structure comprises the end ring and the conducting bars. The welding structure is characterized in that grooves which are in one-to-one correspondence to the conducting bars are processed in the end surface of the end ring according to the dimensions of the end parts of the conducting bars, wherein the conducting bars and the grooves are correspondingly welded on the end ring. The welding structure reduces area of grooves in the end ring, and welding flux is limited in a single grooveduring welding, so that melting and curing of the welding flux in a welding process are guaranteed to be always limited in single groove, dosage of sliver brazing filler metal and soldering flux can be effectively reduced, welding cost is reduced, the conducting bars are guaranteed to be uniformly spaced and distributed in the peripheral direction of the end ring, the welding positions of the conducting bars are positioned simply and clearly, distance regulating does not need to be manually performed, welding operation difficulty is effectively reduced, and welding efficiency and welding quality for the end ring and the conducting bars is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

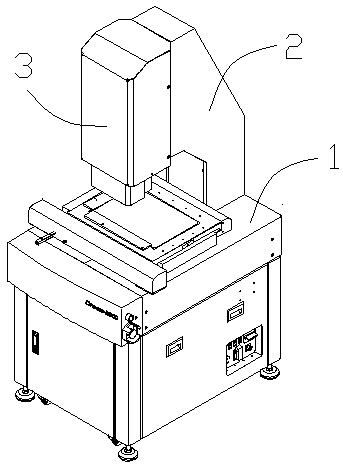

High precision imager

PendingCN108318004AMake sure it's nearly verticalGuaranteed vertical accuracyPhotogrammetry/videogrammetryCopper wireSlide plate

The invention relates to a high precision imager, comprising a machine head; the machine head comprises a fixed plate, a screw rod frame and a Z-axis sliding plate, wherein the two ends of the screw rod frame are fixed on the fixed plate; the screw rod frame drives the Z-axis sliding plate to make vertical movement by means of a soft connecting mechanism. The high precision imager has the beneficial effects that the soft connecting mechanism comprises a fixed block, a steel wire rope and a connecting block; the connecting block is in non-contact with the Z-axis sliding plate; when the screw rod frame is deformed, the copper wire rope can absorb the deformation so as to prevent the deformation from being transmitted to the Z-axis sliding plate, so that the Z-axis sliding plate is enabled tobe closer to vertical, and the vertical accuracy of the Z-axis sliding plate is guaranteed. Due to the arrangement of three sliding blocks, only one connection surface is enabled to exist between theZ-axis sliding plate and the fixed plate, and the vertical precision of the Z-axis sliding plate is better guaranteed.

Owner:东莞市骏智机电科技有限公司

Pneumatic device for detecting coaxiality of inner hole

The invention discloses a pneumatic device for detecting coaxiality of an inner hole and is aimed at providing a pneumatic clamp detection device with easy operation, rapid clamping, small detection error and flexible adjustment. The invention is realized through the following technical scheme: a clamping plate clamping up a to-be-measured workpiece communicates with trisected radial vents of an air inlet channel, and the front segment rectangular rod body of a pneumatic spring push rod is fixedly connected to an equant arc clamping jaw through a shaft end of a radial hole of the same segmentin each radial vent; air flow passes through trisected circumferential holes at the bottom of the clamping plate to communicate with the radial vents, the air flow pushes the pneumatic spring push rodto move toward the axis of a clamping hole, and the equant arc clamping jaw fixedly connected to the shaft end of the pneumatic spring push rod is pushed to center to press the to-be-measured workpiece; and a scale rod measuring head of a numeric scale falls into an inner hole of the to-be-measured workpiece, contacts with a containment area of the hole wall of the inner hole of the to-be-measured workpiece within a detected length, measures each part needing the coaxiality of the to-be-measured workpiece, determines a maximum runout and a minimum runout, and obtains the coaxiality of the to-be-measured workpiece.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Tool for locking and fixing steel plate sticking self-adsorption bracket in limiting condition

PendingCN108868188AAvoid the failure of bonding steelPrevent slippageBuilding repairsElectricityElectric machine

The invention discloses a tool for locking and fixing a steel plate sticking self-adsorption bracket in a limiting condition. The tool comprises a permanent magnet substrate, a rectangular strip column and a pressing plate. The interior of the permanent magnet substrate is provided with a long groove. The inner side of the rectangular strip column is provided with a sliding rail. The interior of the sliding rail is provided with a slider. The left side of a baffle is provided with a steel plate. The upper surface of the baffle is fixedly provided with a first rotating shaft. The upper surfaceof the rectangular strip column is fixedly provided with a limiting column. The right side of a permanent magnet pressing rod is provided with a permanent magnet pressing block. The tool for locking and fixing the steel plate sticking self-adsorption bracket in the limiting condition is capable of performing off-site installation. The tool can be used on site without using electricity and an electric machine, without welding and working with naked fire, without using an expansion bolt for anchoring and the like, can be used in special industries, and capable of guaranteeing construction quality of steel sticking and reinforcing on a steel structure and stability of steel sticking glue within a curing period. Secondly, the device is convenient in use, simple in operation and can be repeatedly used.

Owner:天津核海源科技发展有限公司

Engine cylinder sleeve press-fitting detection device

InactiveCN109443300AImprove detection efficiencyReduce labor intensityUsing optical meansLinear motionEngineering

The invention discloses an engine cylinder sleeve press-fitting detection device. The engine cylinder sleeve press-fitting detection device comprises a bracket mounted above a conveyer belt, at leastone detection head used for detecting the flatness of an engine cylinder sleeve is arranged between the bracket and the conveyer belt, the bracket is provided with a linear motion mechanism used for driving each detection head to move up and down, each detection head comprises a base and at least three displacement sensors, the displacement sensors are uniformly arranged on the periphery of the base around the axis of the base, and connecting tools connecting the displacement sensors and the base are arranged between the displacement sensors and the base; the engine cylinder sleeve press-fitting detection device further comprises a controller electrically connected with the linear motion mechanism and the displacement sensors. The engine cylinder sleeve press-fitting detection device has the advantages that the detection efficiency is high, and the labor intensity is low.

Owner:GUANGXI YUCHAI MASCH CO LTD

Prefabricated laminated slab suitable for laying floor heating pipeline and preparation process

PendingCN112095876AImprove production and processing efficiencyReduce manufacturing costFloorsCeramic shaping apparatusConstruction engineeringRebar

The invention discloses a prefabricated laminated slab suitable for laying a floor heating pipeline and a preparation process. According to the prefabricated laminated slab, stirrup reinforcing steelbars are adopted to replace pins, the stirrup reinforcing steel bars and reinforcing steel bars in the prefabricated laminated slab are laid, bound and fixed at the same time, and truss bars in the prefabricated laminated slab are canceled, so that the steel bar laying and binding time in the prefabricated laminated slab is effectively shortened, and the production and machining efficiency of theprefabricated laminated slab is remarkably improved compared with a plug pin manner; the truss ribs are cancelled, so that the production cost of the prefabricated laminated slab is reduced; the stirrup reinforcing steel bars are higher in strength, so that the stirrup reinforcing steel bars are prevented from being broken during on-site assembly construction; the stirrup reinforcing steel bars are simple and reasonable in structural design and can be conveniently bound and fixed to the reinforcing steel bars in the prefabricated laminated slab, and the vertical precision of the upper end of an n-shaped rod is guaranteed; the prefabricated laminated slab is simple and reasonable in structural design, high in preparation implementation feasibility and high in economic practicability, and has potential application and popularization prospects; and the preparation process of the prefabricated laminated slab is simple to operate, and the production and processing efficiency of the prefabricated laminated slab is ensured.

Owner:常州杰通装配式建筑有限公司

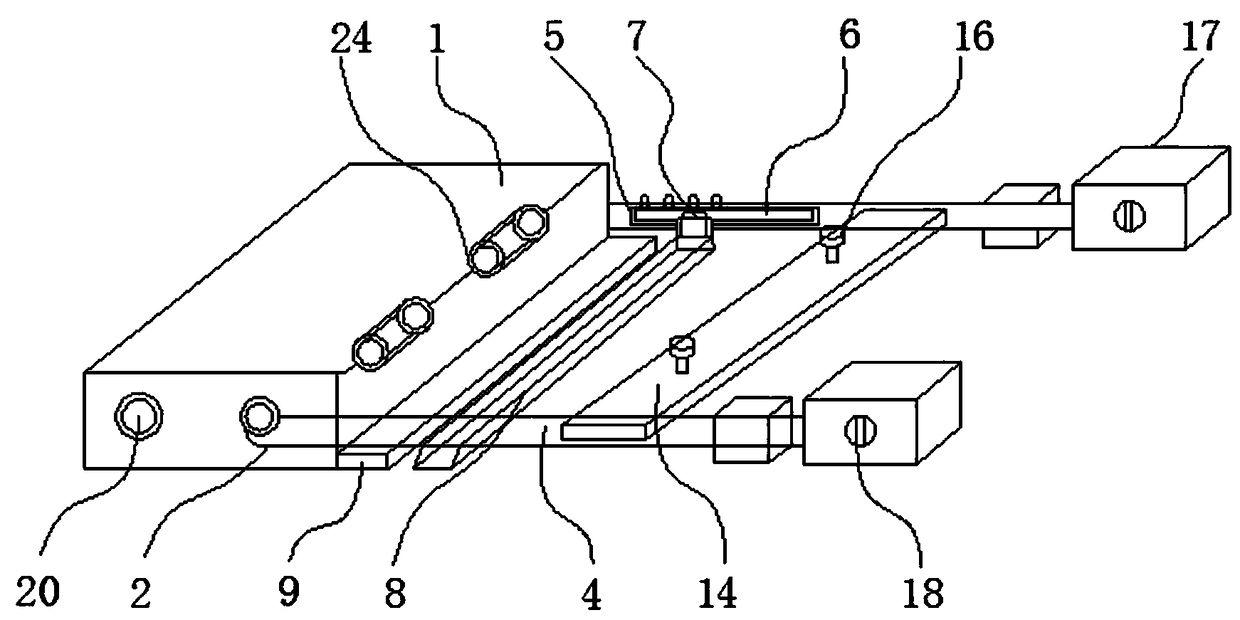

Material adhering tool assembly for machining bulk NdFeB (neodymium iron boron)

ActiveCN104100618AImprove machining accuracyGuaranteed vertical accuracyFastening meansKnurlingEngineering

The invention discloses a material adhering tool assembly for machining bulk NdFeB (neodymium iron boron). The material adhering tool assembly comprises a material adhering tool and a positioning tool, wherein the material adhering tool comprises a support plate and knife edge angle rulers distributed at the top surface of the support plate; the positioning tool comprises a support bottom plate, regulating seats, a compressing plate and a positioning strip; two slender regulating seats are arranged and are distributed at the left and right sides of the top surface of the support bottom plate in parallel; positioning strip mounting slots are correspondingly formed at the two top ends of the two regulating seats at intervals; a locking bolt is arranged at the side surface of each positioning strip mounting slot in a penetrating mode; a material plate support strip is distributed at the top surface of the support bottom plate between the two regulating seats; the lower part of the compressing plate is fixed at the lower side of the support bottom plate; knurling bolts are arranged at the upper part of the compressing plate in a penetrating mode. Positioning pins are transversely distributed at the upper side, corresponding to the knurling bolts, of the support bottom plate. According to the material adhering tool assembly for machining the bulk NdFeB, the machining precision and machining efficiency of a multi-wire sawing machine are improved.

Owner:SINO MAGNETICS TECH

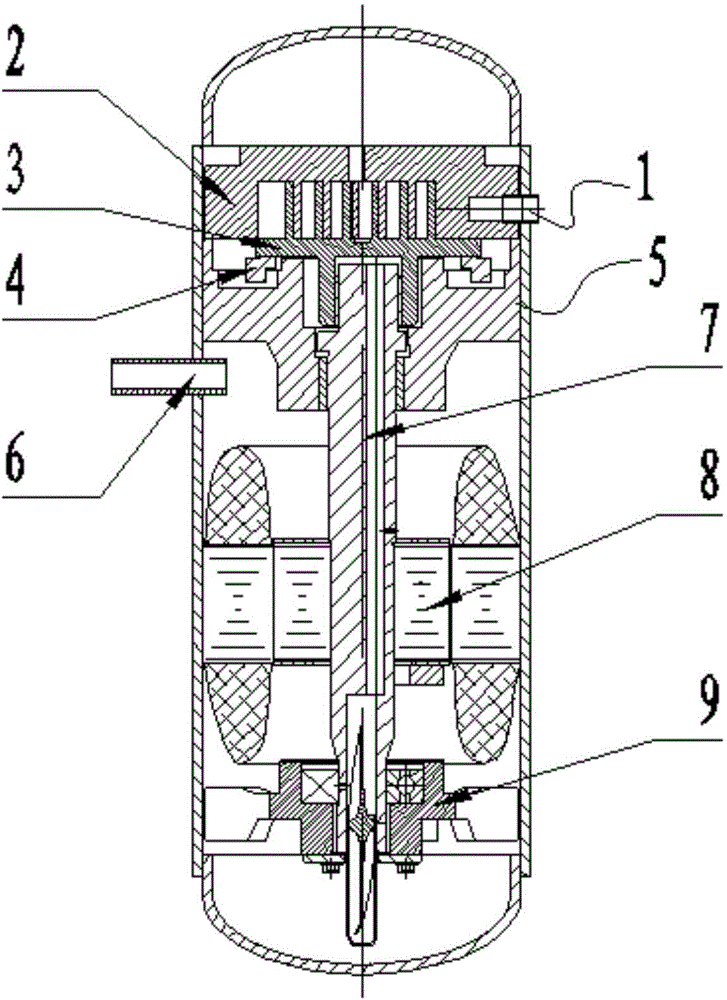

Dynamic simulation test method for small power compressor motor stator iron core verticality

ActiveCN105180882AImprove ergonomicsGuaranteed vertical accuracyMeasurement devicesEngineeringMechanical engineering

The invention discloses a dynamic simulation test method for small power compressor motor stator iron core verticality. The method comprises steps: a) a forming stator is locked on a mounting plane of a cylinder seat at 15 to 22N.m before the test, the central aperture of the stator iron core is set to be Dmm, and the rotor diameter is 0.8 to 1.0mm smaller than the aperture; b) the test is carried out on a special simulation tester, four clamping claws are opened, a to-be-tested stator is sleeved on a simulation rotor, the bottom end surface of the stator iron core touches the horizontal top surface of a mold seat, the central aperture of the stator iron core is also Dmm, and the diameter of the simulation rotor is 0.3 to 0.4mm smaller than the aperture; c) the clamping claws are closed, and the stator iron core top end surface is touched; d) a hydraulic adjustable tension mechanism is opened, a piston, a tension connection rod and a pulling plate are pushed to move downwardly until the clamping claws uniformly apply a 15 to 22N.m pre-tightening force on the stator iron core when the piston moves for 15 to 23mm; and e) the simulation rotor is rotated to test the dynamic air gap between the to-be-tested stator and the simulation rotor. The method of the invention realizes the test is carried out when the stator is pre-tightened and the simulation rotor tries to rotate, and the work efficiency is high.

Owner:浙江迪贝电气股份有限公司

Radial verticality detection platform

InactiveCN102032857BGuaranteed vertical accuracyGuaranteed Alignment AccuracyMechanical measuring arrangementsPhotovoltaic industrySingle crystal

The invention relates to a radial verticality detection platform of single crystal pole for detecting the radial verticality of a single-wafer rod in photovoltaic industry. The radial verticality detection platform comprises a bottom plate, (10), a dial (11), a pillar (2) with a calibrated scale (2-1), a depth measuring scale (7) and an indexing table (8), wherein the lower end of the pillar (2) is provided with a base(1); the base (1) is fixed on the bottom plate (10); the dial (11) is rotatably supported on the bottom plate (10); the depth measuring scale (7) and the indexing table (8) are movably arranged on the pillar (2); and the depth measuring scale (7) is arranged below the indexing table (8). The invention not only ensures the vertical precision of the single-wafer rod but also ensures the accuracy of alignment of the single-wafer rod and does not need to detect circular run out for the second time.

Owner:江苏有则创投集团有限公司

A Compensation Method for Laser Flatness Measurement Error

InactiveCN103245309BSolving Scattering ProblemsGuaranteed vertical accuracyUsing optical meansObservational errorSize change

A laser flatness measurement error compensation method is characterized in that it consists of three parts: sub-pixel image scattering compensation, reference inclination angle compensation, and light spot variation centering compensation, which can effectively improve the measurement accuracy of a laser flatness measurement system. The sub-pixel image scattering compensation uses the pixel edge recognition method to solve the scattering problem of the laser beam due to long-distance transmission, which can ensure the vertical accuracy of the plane measurement. The reference inclination compensation uses the method of inclination transformation height to solve the problem of the reference deviation of laser target placement, which can ensure the height reference of the laser target. The spot variation centering compensation uses the reciprocating micro-movement method to solve the problem that the size of the laser spot varies with the change of the target distance, and improves the projection accuracy of the laser spot.

Owner:杭州鼎热科技有限公司

Construction method of section steel column support frame for frame column of super high-rise building

ActiveCN108035554BHighly stableGuaranteed vertical accuracyBuilding material handlingArchitectural engineeringSteel columns

The invention provides a section-steel-column support frame construction method for a super-high-rise-building frame column. The method includes the steps that 1, a support frame is made; 2, bolts arefixedly arranged on the support frame through a calibration steel sleeve plate; 3, a concrete cushion of a building structure bottom plate is poured, and embedded parts are embedded; 4, the support frame is lifted and fixed; 5, lower reinforcing steel bars of the building structure bottom plate are bound and welded to the support frame; 6, slant supports are welded to the lower portion of the support frame; 7, a first steel column is fixedly installed on the support frame; 8, positions of section steel columns are corrected, and the section steel columns are anchored and fixed; 9, upper reinforcing steel bars of the building structure bottom plate are bound, and bottom plate concrete is poured; 10, a second steel column and rear steel columns are fixedly installed. According to the section-steel-column support frame construction method for the super-high-rise-building frame column, construction is easy, convenient, safe and reliable, the construction quality is easy to control, the embedded quality of the section steel columns in a foundation bottom plate or a ground beam can be guaranteed, and three problems that in a construction method for section steel columns of a traditionalbuilding structure frame column, the anchor bolt accuracy is poor, the stability of the support structure is poor, and as key construction procedures are occupied, the construction period is influenced are effectively solved.

Owner:CHANGZHOU NO 1 CONSTR GRP

A precise and compact 3D printer powder supply mechanism and transmission method

ActiveCN106623920BHigh linear motion precisionMeet transmission precision requirementsAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingElectric machinery

A precision compact 3D printer powder supply mechanism and transmission method, including a lower cylinder body, a spline assembly, a screw and a motor, a support is provided above the lower cylinder body; the spline assembly includes a spline shaft and Spline sleeve, the spline sleeve is fixed on the bottom surface of the support member, the spline shaft can be inserted into the spline sleeve for axial movement, and one end of the spline shaft protrudes from the lower cylinder body The screw rod includes a screw rod and a screw nut, the screw nut is arranged in the lower cylinder body, the screw nut is fixed on the bottom end of the spline shaft, the screw rod and the screw rod The nut is threaded, the screw rod extends into the spline shaft, and the screw rod is connected with the servo motor. The invention uses the connection between the screw rod and the spline assembly, and the transmission between the two. The powder supply mechanism has high linear motion accuracy, which meets the transmission accuracy requirements of the 3D printer. In addition, extending the screw rod into the spline assembly has the advantage that the arrangement space of the transmission structure is small.

Owner:XIAMEN UNIV OF TECH +1

Cross slip ring, scroll compressor with cross slip ring, air conditioner and heat pump water heater

InactiveCN104595193AMiniaturizationLightweightRotary piston pumpsRotary piston liquid enginesCross SlipMechanical engineering

The invention provides a cross slip ring, a scroll compressor with the cross slip ring, an air conditioner with the scroll compressor, and a heat pump water heater with the scroll compressor. The cross slip ring comprises a first annular pedestal and a second annular pedestal, the first annular pedestal is detachably combined with the second annular pedestal, the first annular pedestal is provided with a first key and a second key opposite to the first key, and the second annular pedestal is provided with a third key and a fourth key opposite to the third key. The cross slip ring is divided into a plurality of detachable portions in order to simplify processing, so the vertical precision of two pairs of keys of the cross slip ring is guaranteed, and the miniaturization and the lightening of the cross slip ring are realized.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com