Dynamic simulation test method for small power compressor motor stator iron core verticality

A dynamic simulation, motor stator technology, applied in the direction of measuring devices, instruments, etc., can solve the problems affecting the performance of the motor, the working performance of the stator, the deviation of the concentricity of the center hole of the stator, etc., and achieve the effect of easy operation and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

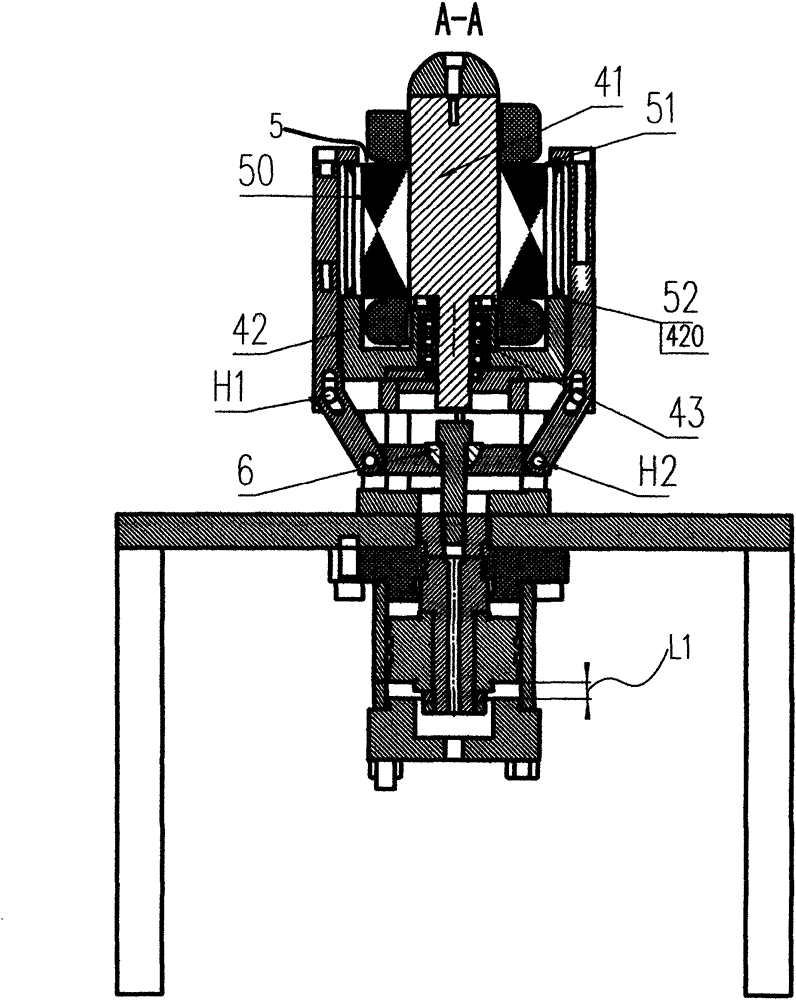

[0029] see figure 1 , 2 , Shown in 3 is a preferred embodiment of the present invention.

[0030] A dynamic simulation test method for the verticality of the stator core of a small-power compressor motor, the method includes the following steps in sequence:

[0031] a) Before implementing the dynamic simulation test, the formed stator (not shown) is locked to the installation plane of the compressor cylinder block (not shown), and the torque during locking is measured as 15~ 22N.m, wherein, the central hole diameter of the stator core of the formed stator is Dmm, and the diameter of the rotor (not shown) matched with the formed stator is [D-(0.8~1.0)]mm.

[0032] The stack height of the stator core of the formed stator ranges from 60mm to 108mm.

[0033] In the formed stator in this embodiment, the central aperture of the stator core is 79.3 mm, the stack height of the stator core is 108 mm, the diameter of the matching rotor is 78.4 mm, and the torque when fastened with bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com